#iot bms

Explore tagged Tumblr posts

Text

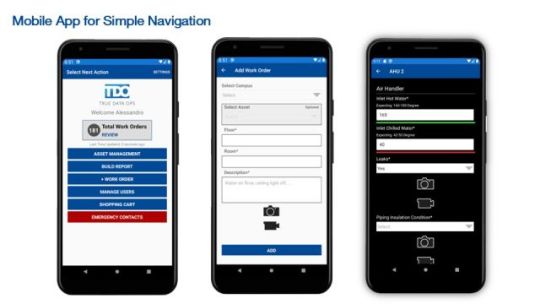

True Data Ops (TDO) is a federally certified Service-Disabled Veteran-Owned Small Business (SVOSB) specializing in comprehensive solutions for Work Order Management, Asset Management, and Energy Efficiency. Our cutting-edge technologies integrate IoT sensors, Building Automation Systems (BAS), and Building Management Systems (BMS) to deliver real-time insights and optimize operational performance. With advanced tools for Inventory Management and Predictive Maintenance, TDO empowers organizations to achieve seamless operations while reducing costs and energy consumption.

0 notes

Text

Yapay Zeka İklimlendirme Sistemlerinde Nasıl Kullanılıyor? Dünyada yaşanan iklim değişikliği ve çevresel faktörler nedeniyle ısınan dünyamızı daha iyi yönetmek için iklimlendirme çözümleri önem kazanıyor. Dünyada ve Tü...

0 notes

Text

Low Voltage Switchgear for Commercial Buildings: Key Requirements, Standards, and Best Practices

In the construction and modernization of commercial buildings, low voltage switchgear plays a critical role in ensuring safe, reliable, and efficient power distribution. From office complexes and retail malls to hospitals and data centers, these buildings rely on robust electrical infrastructure — and low voltage switchgear is the backbone of that system.

Whether you’re an electrical panel manufacturer, a building contractor, or a facility manager, understanding the key requirements for selecting and integrating LV switchgear in commercial buildings is essential.

What Is Low Voltage Switchgear?

Low voltage switchgear is an assembly of electrical devices designed to control, protect, and isolate electrical circuits under 1,000V AC. It typically includes:

· Air Circuit Breakers (ACBs)

· Molded Case Circuit Breakers (MCCBs)

· Miniature Circuit Breakers (MCBs)

· Contactors and Relays

· Busbars

· Metering and Protection Devices

Why LV Switchgear Is Critical in Commercial Buildings

Commercial buildings demand:

· Continuous power availability

· High energy efficiency

· Electrical safety for occupants

· Scalability for future expansion

Low voltage switchgear delivers:

· Protection against overloads and short circuits

· Isolation for maintenance and fault conditions

· Load management for energy optimization

· Monitoring via smart metering and IoT integration

Key Requirements for LV Switchgear in Commercial Applications

Safety & Protection Standards

Must comply with IEC 61439 or UL 891 depending on the region

Must include overcurrent, short-circuit, and earth fault protection

Arc flash safety features (like arc fault containment) are crucial in populated buildings

2. Compact Footprint and Modular Design

Space is often limited in commercial utility rooms. LV switchgear should be:

Compact to fit tight electrical rooms

Modular for easy expansion as building loads increase

3. Smart Metering and Monitoring

Today’s commercial buildings demand energy-efficient and intelligent systems. Choose LV switchgear with:

Integrated smart meters

IoT-based energy monitoring

Remote control via BMS (Building Management Systems)

4. High Service Continuity (Form Segregation)

To ensure maintenance without full shutdowns, opt for:

Form 3b or Form 4b segregation

Withdrawable ACBs or MCCBs

Dual incomer and bus coupler arrangements for redundancy

5. Scalability and Flexibility

Commercial facilities evolve. Your switchgear must too:

Allow for load expansion

Be compatible with renewable sources (like solar panels)

Support future retrofits and upgrades

Standards to Follow

Ensure LV switchgear in commercial buildings is compliant with:

IEC 61439–1/2 — General and Power Switchgear Assemblies

UL 891 — US Standard for Dead-Front Switchboards

NEC (National Electrical Code) or local building codes

Also factor in:

Ingress Protection (IP Ratings) — IP54/IP65 for dusty or humid environments

Short Circuit Withstand Ratings — Ensure it matches building fault levels

Best Practices for Installation in Commercial Building

Centralize the switchgear for easy maintenance and reduced cable runs

Provide ample ventilation or forced cooling

Use color-coded wiring for clear identification

Ensure emergency shutdown mechanisms are accessible

Document the system with single-line diagrams and load calculations

Applications in Commercial Buildings

Office Buildings: Smart load shedding and energy metering

Hospitals: Redundant systems for life safety

Data Centers: N+1 configurations and continuous monitoring

Malls & Retail: Segmented load distribution for different zones

Hotels: Backup and emergency panel integration

Choosing the Right LV Switchgear Partner

Look for a supplier who provides

Customized switchgear assemblies

Fast lead times and local support

Engineering assistance for layout and specs

Pre-tested or type-tested assemblies

Future Trends in Commercial LV Switchgear

Digitization & predictive maintenance

Energy-efficient, low-loss designs

AI-assisted load forecasting

SF6-free eco-friendly designs

Need Help Choosing LV Switchgear for Your Next Commercial Project?

At Daleel Trading, we supply certified, compact, and smart low voltage switchgear solutions tailored for commercial buildings. Whether it’s a small retail site or a multi-floor office tower, we deliver performance, compliance, and reliability — on time.

👉 Contact us today for a quote, a technical consultation, or a custom panel solution.

8 notes

·

View notes

Text

Innovations in Electrical Switchgear: What’s New in 2025?

The electrical switchgear industry is undergoing a dynamic transformation in 2025, fueled by the rapid integration of smart technologies, sustainability goals, and the growing demand for reliable power distribution systems. As a key player in modern infrastructure — whether in industrial plants, commercial facilities, or utilities — switchgear systems are becoming more intelligent, efficient, and future-ready.

At Almond Enterprise, we stay ahead of the curve by adapting to the latest industry innovations. In this blog, we’ll explore the most exciting developments in electrical switchgear in 2025 and what they mean for businesses, contractors, and project engineers.

Rise of Smart Switchgear

Smart switchgear is no longer a futuristic concept — it’s a necessity in 2025. These systems come equipped with:

IoT-based sensors

Real-time data monitoring

Remote diagnostics and control

Predictive maintenance alerts

This technology allows for remote management, helping facility managers reduce downtime, minimize energy losses, and detect issues before they become critical. At Almond Enterprise, we supply and support the integration of smart switchgear systems that align with Industry 4.0 standards.

2. Focus on Eco-Friendly and SF6-Free Alternatives

Traditional switchgear often relies on SF₆ gas for insulation, which is a potent greenhouse gas. In 2025, there’s a significant shift toward sustainable switchgear, including:

Vacuum Interrupter technology

Air-insulated switchgear (AIS)

Eco-efficient gas alternatives like g³ (Green Gas for Grid)

These options help organizations meet green building codes and corporate sustainability goals without compromising on performance.

3. Wireless Monitoring & Cloud Integration

Cloud-based platforms are transforming how switchgear systems are managed. The latest innovation includes:

Wireless communication protocols like LoRaWAN and Zigbee

Cloud dashboards for real-time visualization

Integration with Building Management Systems (BMS)

This connectivity enhances control, ensures quicker fault detection, and enables comprehensive energy analytics for large installations

4. AI and Machine Learning for Predictive Maintenance

Artificial Intelligence is revolutionizing maintenance practices. Switchgear in 2025 uses AI algorithms to:

Predict component failure

Optimize load distribution

Suggest optimal switchgear settings

This reduces unplanned outages, increases safety, and extends equipment life — particularly critical for mission-critical facilities like hospitals and data centers.

5. Enhanced Safety Features and Arc Flash Protection

With increasing focus on workplace safety, modern switchgear includes:

Advanced arc flash mitigation systems

Thermal imaging sensors

Remote racking and switching capabilities

These improvements ensure safer maintenance and operation, protecting personnel from high-voltage hazards.

6. Modular & Scalable Designs

Gone are the days of bulky, rigid designs. In 2025, switchgear units are:

Compact and modular

Easier to install and expand

Customizable based on load requirements

Almond Enterprise supplies modular switchgear tailored to your site’s unique needs, making it ideal for fast-paced infrastructure developments and industrial expansions.

7. Global Standardization and Compliance

As global standards evolve, modern switchgear must meet new IEC and IEEE guidelines. Innovations include:

Improved fault current limiting technologies

Higher voltage and current ratings with compact dimensions

Compliance with ISO 14001 for environmental management

Our team ensures all equipment adheres to the latest international regulations, providing peace of mind for consultants and project managers.

Final Thoughts: The Future is Electric

The switchgear industry in 2025 is smarter, safer, and more sustainable than ever. For companies looking to upgrade or design new power distribution systems, these innovations offer unmatched value.

At Almond Enterprise, we don’t just supply electrical switchgear — we provide expert solutions tailored to tomorrow’s energy challenges. Contact us today to learn how our cutting-edge switchgear offerings can power your future projects.

6 notes

·

View notes

Text

The Benefits of Using Modular Switchgear Systems

Why Modern Industries Are Choosing Modular Solutions for Electrical Infrastructure

In today’s fast-paced industrial and commercial environments, electrical safety, efficiency, and scalability are more important than ever. That’s where modular switchgear systems come into play. Designed to meet the evolving needs of various sectors — such as manufacturing, commercial buildings, power utilities, and data centers — modular switchgear offers flexibility, safety, and long-term value.

In this article, we’ll explore the key benefits of using modular switchgear systems, and why they are becoming the preferred choice over traditional switchgear configurations.

What Is a Modular Switchgear System?

A modular switchgear system is a type of switchgear that is built from interchangeable modules or sections. Each module contains electrical components such as circuit breakers, busbars, relays, isolators, and fuses. These modules are pre-engineered and can be easily configured, added, or replaced based on the specific requirements of a facility.

Modular switchgear is used for the protection, control, and isolation of electrical equipment. It is typically found in low voltage (LV) and medium voltage (MV) power distribution systems.

Top Benefits of Modular Switchgear Systems

1. Flexibility and Scalability

One of the most significant advantages of modular switchgear is its flexible design. Whether you’re expanding an existing facility or starting from scratch, modular systems allow you to add or remove units without interrupting the entire system.

· Ideal for facilities expecting future expansion

· Easy to customize layout based on project demands

· Supports phased development in infrastructure projects

2. Enhanced Safety and Reliability

Modern modular switchgear systems are designed with advanced safety features. Segregated compartments, arc fault containment, and reliable insulation materials ensure operator safety and system reliability.

· Reduces risk of electrical faults and arc flashes

· Complies with IEC and ANSI safety standards

· Minimizes downtime during maintenance or upgrades

3. Ease of Installation and Maintenance

Thanks to its pre-fabricated modules, modular switchgear is faster and easier to install compared to conventional systems. It also simplifies troubleshooting and routine maintenance.

· Less on-site wiring and civil work required

· Individual modules can be isolated for servicing

· Reduces maintenance costs and system downtime

4. Compact and Space-Saving Design

With limited space in modern industrial setups, compactness is crucial. Modular switchgear systems are designed for space optimization, making them perfect for high-density environments.

· Vertical and horizontal expansion possible

· Reduced footprint compared to traditional gear

· Neat and organized layout improves cable management

5. Future-Proof and Upgrade-Friendly

Industries evolve, and so should your electrical infrastructure. Modular switchgear supports easy integration of new technologies, such as remote monitoring, IoT-enabled control systems, and energy management solutions.

· Supports integration with SCADA and BMS systems

· Accommodates evolving energy needs

· Long lifecycle with upgrade options

6. Cost-Effective Over the Long Term

Though the initial investment may be higher than conventional switchgear, the long-term benefits of modular systems — including reduced downtime, lower maintenance costs, and scalability — make them a cost-effective solution.

· Lower total cost of ownership (TCO)

· Reduced operational expenses

· Optimized energy efficiency

Applications of Modular Switchgear Systems

Modular switchgear is suitable for a wide range of applications, including:

🏢 Commercial buildings

🏭 Industrial plants

⚡ Power generation and distribution

🖥 Data centers

🏥 Hospitals

🏗 Infrastructure projects and smart cities

Conclusion

If you’re looking for a smart, scalable, and reliable solution for your electrical distribution system, modular switchgear systems are a worthy investment. With benefits ranging from safety and efficiency to cost savings and future readiness, they offer a significant upgrade over traditional switchgear models.

3 notes

·

View notes

Text

Smart Switchgear in 2025: What Electrical Engineers Need to Know

In the fast-evolving world of electrical infrastructure, smart switchgear is no longer a futuristic concept — it’s the new standard. As we move through 2025, the integration of intelligent systems into traditional switchgear is redefining how engineers design, monitor, and maintain power distribution networks.

This shift is particularly crucial for electrical engineers, who are at the heart of innovation in sectors like manufacturing, utilities, data centers, commercial construction, and renewable energy.

In this article, we’ll break down what smart switchgear means in 2025, the technologies behind it, its benefits, and what every electrical engineer should keep in mind.

What is Smart Switchgear?

Smart switchgear refers to traditional switchgear (devices used for controlling, protecting, and isolating electrical equipment) enhanced with digital technologies, sensors, and communication modules that allow:

Real-time monitoring

Predictive maintenance

Remote operation and control

Data-driven diagnostics and performance analytics

This transformation is powered by IoT (Internet of Things), AI, cloud computing, and edge devices, which work together to improve reliability, safety, and efficiency in electrical networks.

Key Innovations in Smart Switchgear (2025 Edition)

1. IoT Integration

Smart switchgear is equipped with intelligent sensors that collect data on temperature, current, voltage, humidity, and insulation. These sensors communicate wirelessly with central systems to provide real-time status and alerts.

2. AI-Based Predictive Maintenance

Instead of traditional scheduled inspections, AI algorithms can now predict component failure based on usage trends and environmental data. This helps avoid downtime and reduces maintenance costs.

3. Cloud Connectivity

Cloud platforms allow engineers to remotely access switchgear data from any location. With user-friendly dashboards, they can visualize key metrics, monitor health conditions, and set thresholds for automated alerts.

4. Cybersecurity Enhancements

As devices get connected to networks, cybersecurity becomes crucial. In 2025, smart switchgear is embedded with secure communication protocols, access control layers, and encrypted data streams to prevent unauthorized access.

5. Digital Twin Technology

Some manufacturers now offer a digital twin of the switchgear — a virtual replica that updates in real-time. Engineers can simulate fault conditions, test load responses, and plan future expansions without touching the physical system.

Benefits for Electrical Engineers

1. Operational Efficiency

Smart switchgear reduces manual inspections and allows remote diagnostics, leading to faster response times and reduced human error.

2. Enhanced Safety

Early detection of overload, arc flash risks, or abnormal temperatures enhances on-site safety, especially in high-voltage environments.

3. Data-Driven Decisions

Real-time analytics help engineers understand load patterns and optimize distribution for efficiency and cost savings.

4. Seamless Scalability

Modular smart systems allow for quick expansion of power infrastructure, particularly useful in growing industrial or smart city projects.

Applications Across Industries

Manufacturing Plants — Monitor energy use per production line

Data Centers — Ensure uninterrupted uptime and cooling load balance

Commercial Buildings — Integrate with BMS (Building Management Systems)

Renewable Energy Projects — Balance grid load from solar or wind sources

Oil & Gas Facilities — Improve safety and compliance through monitoring

What Engineers Need to Know Moving Forward

1. Stay Updated with IEC & IEEE Standards

Smart switchgear must comply with global standards. Engineers need to be familiar with updates related to IEC 62271, IEC 61850, and IEEE C37 series.

2. Learn Communication Protocols

Proficiency in Modbus, DNP3, IEC 61850, and OPC UA is essential to integrating and troubleshooting intelligent systems.

3. Understand Lifecycle Costing

Smart switchgear might have a higher upfront cost but offers significant savings in maintenance, energy efficiency, and downtime over its lifespan.

4. Collaborate with IT Teams

The line between electrical and IT is blurring. Engineers should work closely with cybersecurity and cloud teams for seamless, secure integration.

Conclusion

Smart switchgear is reshaping the way electrical systems are built and managed in 2025. For electrical engineers, embracing this innovation isn’t just an option — it’s a career necessity.

At Blitz Bahrain, we specialize in providing cutting-edge switchgear solutions built for the smart, digital future. Whether you’re an engineer designing the next big project or a facility manager looking to upgrade existing systems, we’re here to power your progress.

#switchgear#panel#manufacturer#bahrain25#electrical supplies#electrical equipment#electrical engineers#electrical

6 notes

·

View notes

Text

BC847 Transistor: The Tiny Star-Keeper of Our Tech Planets

A Meeting in the Circuit Desert

The desert stretched endlessly, its sands glowing like gold under the sun. I was tracing the dunes, heading toward a distant oasis, when I spotted a glint in the sand—a small, silver shape, no bigger than a ladybug.

“You’re… very small,” I said, kneeling. “And you’re a child who talks to transistors,” it replied, voice steady as the wind. “But some keepers of light are smallest when they’re strongest. Ask the fox.”

It was a BC847—an NPN bipolar junction transistor, but to me, it felt like a secret. Let me tell you its story.

1. What Is a BC847? (Not Just Metal—A Keeper of Light)

This was no ordinary silicon. It was a BC847, a tiny hero in a SOT-23-3 suit—smaller than a ladybug, but tough as a baobab’s roots. Here’s its secret:

Voltage: 45V collector-emitter (VCEO), 5V base-emitter (VBE). It’s like a windbreak for circuits—sturdy against storms of static.

Current: 100mA collector current (IC), 5mA base current (IB). Sips power like a hummingbird, not a thirsty camel.

Speed: 100MHz transition frequency (fT). Faster than the fox darting across the dunes.

Real-World Magic: Powers LED drivers in Philips Hue bulbs (keeping your roses lit) and Tesla’s battery sensors (guiding spaceships on Earth).

“Why so quiet?” I asked. “Keepers don’t shout,” it said. “They just keep.”

2. BC847 & Its Neighbors: Brothers, Not Twins

In the desert of transistors, BC847 has cousins—some taller, some faster, but none quite like it:

BC846: A stronger brother. Handles 65V (vs. BC847’s 45V) but same current. Like a cactus that grows taller, not wider.

BC547: An old friend. Cheaper, but bulkier (TO-92 vs. SOT-23). Like a postman with a big bag—reliable, but takes up space.

2N3904: A flashy neighbor. Faster, but panics at voltage spikes. Like a sprinter who trips at the finish line.

Roast Alert: 2N3904 (boasting): “I’m cheaper!” BC847 (calm, like the fox): “I’m in Tesla’s BMS. You’re in a kid’s science kit. Bye.”

3. Why BC847 Shines Brighter Than Most

BC847 isn’t just a transistor—it’s a star in the circuit sky. Here’s why:

Tiny, But Tenacious: SOT-23-3 fits wearables and IoT sensors, like a key in a tiny lock. Even the fox couldn’t squeeze into spaces this small.

Speed of Light: 100MHz fT processes signals faster than your Wi-Fi rage-quits. The fox? He’s impressed.

Cheap, But Charming: $0.02/unit—cheaper than your morning espresso. Even the rose, who’s picky, approves.

“Why not be bigger?” I asked. “Big things break,” it said. “Tiny things fit. In smartwatches. In Mars rovers. In insulin pumps.”

4. BC847: Keeper of a Thousand Stars

From your wrist to the cosmos, BC847 guards:

Medical (The Healer’s Planet): Powers portable ECG monitors, amplifying weak heart signals (no “404 Error: Heartbeat”). Keeps insulin pumps precise—because roses (and diabetics) need gentle care.

Automotive & Aerospace (The Cosmic Planets): Monitors Tesla’s battery cells (no TikTok fire memes��phew!). Survives cosmic radiation in satellites (Earth drama is overrated, anyway).

Consumer Tech (Your Daily Planet): Powers smartwatch sensors, outlasting your gym motivation. Keeps wireless earbuds jamming—because even foxes need their Hotline Bling.

“Do you get lonely?” I asked. “No,” it said. “I’m everywhere. In your watch, in your car, in the stars. Loneliness is for roses that forget they’re loved.”

5. Brand Battle: The Guardians of the Desert

Not all keepers are made equal. Let’s meet the ones worth trusting:

Nexperia: The geographer of transistors. Makes high-speed BC847W variants—pricier ($0.05/unit), but worth it for precision.

ON Semiconductor: The cactus of the bunch. Works from -40°C (Arctic) to +150°C (Sahara). Bulk orders only, but tough as nails.

Guangzhou Guangxin: The friendly merchant. Budget-friendly ($0.02/unit), but skip if you need fancy datasheets.

Pro Tip: For Mars rovers, stick to ON Semi’s BC847HR (-55°C rated). Even the stars trust it.

6. How to Find Your BC847 (Avoid the Baobabs of Fakes)

In 2025, shop like a wanderer—no baobab-sized fakes:

Retailers: Digi-Key, Ersaelectronic. Search “BC847 SOT-23”—they’ll guide you like the desert’s wind.

Bulk Orders: Alibaba, with verified suppliers like Guangzhou Guangxin. Bargain like a merchant, but check for laser-etched logos (stickers = baobabs).

Price Range: $0.02–$0.10/unit retail; $0.015/unit for 1k+ (AliExpress).

The Secret of the Tiny Keeper

BC847 isn’t flashy. It doesn’t need a name in lights or a viral meme. It’s the kind of friend you remember when your smartwatch works, your Tesla doesn’t catch fire, or a Mars rover sends back photos.

“What makes you special?” I asked, as I left. It didn’t answer. It just sat there, quiet as the desert, as the stars, as time itself.

And I realized—some keepers don’t need to be big. They just need to shine.

Written by a wanderer who once mistook a BC847 for a ladybug. (Spoiler: It didn’t fly, but it powered a toy robot. Close enough.)

🌵 You become responsible, forever, for the stars you once overlooked.

1 note

·

View note

Text

Advanced HVAC Design Services for Modern Architectural Needs

In the rapidly evolving landscape of modern architecture, HVAC (Heating, Ventilation, and Air Conditioning) systems are no longer just about maintaining comfort—they are integral to sustainable design, energy efficiency, and indoor air quality. As buildings become smarter, eco-friendly, and more complex, the demand for advanced HVAC design services has surged. Verde Solutions LLC explores the latest innovations, techniques, and considerations in HVAC design tailored for modern architectural projects.

1. The Evolution of HVAC in Modern Architecture

1 From Traditional Systems to Integrated Solutions

Traditional HVAC systems primarily focused on temperature control. Today, they are part of a holistic approach that includes energy efficiency, environmental impact, and occupant health.

2 The Rise of Green Building Standards

Standards like LEED, BREEAM, and WELL emphasize sustainable and healthy indoor environments, prompting designers to incorporate advanced HVAC solutions.

3 Embracing Smart Technologies

The integration of IoT devices, automation, and real-time monitoring has transformed HVAC systems into intelligent networks.

2. Key Drivers for Advanced HVAC Design

1 Sustainability and Energy Efficiency

Reducing carbon footprints and operational costs through innovative design.

2 Indoor Air Quality (IAQ)

Enhancing occupant health and productivity with superior ventilation and filtration.

3 Architectural Flexibility

Designing systems that adapt seamlessly to innovative and complex architectural forms.

4 Regulatory Compliance

Meeting evolving codes and standards for safety and environmental impact.

3. Core Principles of Advanced HVAC Design

1 Zoning and Personalized Climate Control

Creating distinct zones within buildings for tailored comfort.

2 Use of Renewable Energy Sources

Incorporating solar, geothermal, and other renewable options.

3 Integration with Building Management Systems (BMS)

Ensuring seamless operation and optimization.

4 Emphasizing Flexibility and Scalability

Designing for future upgrades and modifications.

4. Cutting-Edge Technologies in HVAC Design

1 Variable Refrigerant Flow (VRF) Systems

Highly efficient, adaptable, and space-saving solutions.

2 Underfloor and Displacement Ventilation

Innovative air distribution methods enhancing IAQ and comfort.

3 Demand-Control Ventilation (DCV)

Adjusting ventilation based on occupancy and air quality data.

4 Advanced Filtration and Purification

HEPA filters, UV sterilization, and air purification technologies.

5 Smart Sensors and IoT Integration

Real-time data collection for proactive maintenance and optimization.

5. Design Considerations for Modern Architectural Projects

1 Aesthetic Integration

Ensuring HVAC components complement architectural aesthetics.

2 Space Optimization

Maximizing usable space while maintaining system efficiency.

3 Noise Control

Implementing sound attenuation strategies for quiet operation.

4 Energy Modeling and Simulation

Using software to predict performance and optimize HVAC design services.

5 Resilience and Redundancy

Preparing for power outages, system failures, and climate challenges.

6. Case Studies

1 Green Office Complex with Integrated HVAC

Highlighting sustainable design and energy savings.

2 High-Rise with Smart HVAC Automation

Demonstrating IoT-enabled climate control.

3 Museum with Custom Ventilation Solutions

Ensuring preservation conditions while maintaining aesthetic integrity.

7. Collaborating with Architects and Engineers

1 Early Design Integration

Involving HVAC specialists from the concept stage.

2 Interdisciplinary Coordination

Aligning structural, electrical, and HVAC plans.

3 Use of BIM Technology

Facilitating accurate modeling and clash detection.

8. Future Trends in HVAC Design

1 AI-Driven Optimization

Harnessing artificial intelligence for system management.

2 Carbon-Neutral HVAC Systems

Developing systems that produce zero emissions.

3 Adaptive and Responsive Systems

Systems that adjust dynamically to occupant needs and environmental conditions.

Conclusion

Verde Solutions LLC The landscape of HVAC design is transforming with technological advances and a greater emphasis on sustainability and occupant well-being. Modern architectural projects require HVAC services that are intelligent, adaptable, and environmentally conscious. Embracing these advanced HVAC design services ensures buildings are not only comfortable and healthy but also aligned with the future of sustainable architecture.

Let's Connected

Name: Verde Solutions LLC Address: 2211 N Elston Ave Suite 208, Chicago, IL 60614, United States Phone: +18005411137 Map: https://maps.app.goo.gl/TXH5fiC4VQqhyiRB7

0 notes

Text

Building Management System by Zenatix

A Building Management System (BMS) by Zenatix is an advanced, IoT-driven solution designed to streamline and optimize the operation of commercial and industrial facilities. Zenatix's BMS empowers users with real-time control and monitoring capabilities, offering a holistic view of a building's essential systems, including HVAC, lighting, security, and energy consumption. This innovative system leverages data analytics and automation to enhance energy efficiency, reduce operational costs, and improve occupant comfort. With its user-friendly interface and intelligent algorithms, Zenatix's BMS is a smart choice for modern facility managers seeking to maximize productivity and sustainability while ensuring a seamless, data-driven approach to building management.

#energy analytics#building automation system#energy management system#building management system#energy savings#energy management#iot companies in india#remote asset management#energy management solutions#iot bms

0 notes

Text

Why Electro‑Mechanical Contractors in UAE Are Critical for Smart Buildings

As urban growth accelerates across the UAE, the demand for intelligent, efficient buildings is skyrocketing. That’s why Electro‑Mechanical Contractors in UAE, especially Electro‑Mechanical Companies in UAE, are becoming indispensable.

1. Integrated MEP Expertise for Dubai’s Smart Infrastructure

Smart buildings rely on seamless electro‑mechanical contracting in Dubai to unify HVAC, lighting, power, plumbing, and fire protection under one intelligent, automated umbrella. Leading MEP Contractors in Dubai coordinate these systems with precision, ensuring comfort, safety, and energy savings from day one.

2. Efficiency, Safety & Compliance in One Package

Top-tier contractors like LAPPSCO focus on delivering clean, reliable, and compliant installations. Whether it’s high-voltage cabling, earthing systems, or fire-fighting integration, their streamlined approach minimizes onsite disruption and ensures every connection is safe and future-ready.

3. Full-Spectrum MEP Package: Design to Maintenance

From initial design and system planning to commissioning and ongoing upkeep, complete MEP solution in UAE providers offer a truly end-to-end service. These supercharged MEP Contractors in Dubai guarantee durability and performance—maintaining your building long after handover.

4. Smarter Buildings Using Advanced Tech

The rise of smart building trends has made electro‑mechanical contracting in Dubai a tech-intensive practice. With BIM, IoT sensors, and Building Management Systems (BMS), these contractors enable real-time monitoring and predictive maintenance—driving up performance and reducing energy bills.

5. Sustainability Aligned with UAE’s Vision

Integrating green MEP systems—like energy-efficient HVAC, LED lighting, low-flow plumbing, and solar-ready infrastructure—is non-negotiable in today’s UAE developments. Electro-Mechanical Contractors in UAE support sustainability goals such as LEED, Estidama, and Dubai Green Building regulations.

The Bottom Line

For developers, facilities managers, and owners in Dubai, relying on specialized Electro‑Mechanical Companies in UAE and forward-looking MEP Contractors in Dubai means unlocking smart, safe, and sustainable buildings. These full-lifecycle partners deliver integrated systems, harness cutting-edge technology, and maintain regulatory compliance—making them the go-to experts for complete MEP solutions in UAE.

#Electro-Mechanical Contractors in UAE#Electro-Mechanical Companies In Uae#Electro-Mechanical contracting in Dubai#MEP Contractors in Dubai#complete mep solution in uae

0 notes

Text

Industrial Chillers Market Analysis by Type, End-Use & Region

United States of America – The Insight Partners is delighted to present its newest market research report, "Industrial Chillers Market: A Comprehensive Analysis of Global Trends, Growth Drivers, and Future Outlook". The in-depth research report provides a 360-degree overview of the Industrial Chillers market, outlining the present market scenario, chief drivers, changing challenges, and strategic opportunities anticipated.

Overview

The INDUSTRIAL CHILLERS market is facing dynamic changes due to technological innovation, evolving environmental regulations, and changing industrial needs. These systems play a pivotal role in sustaining regulated temperatures for production processes across industries like chemicals, food & beverage, pharmaceuticals, and plastics.

The report provides insights into the main drivers of market trends from energy-saving innovations and green regulations to shifting consumer expectations and intelligent integration with Industry 4.0 solutions.

Key Findings and Insights

Market Size and Growth

Historical Data & Forecast: Industrial chillers market was valued at US$ 2.77 billion in 2024 and is anticipated to reach US$ 4.30 billion by 2031; it is estimated to register a CAGR of 6.6% during the forecast period.

Key Drivers for Growth:

Growing industrial automation and process efficiency demand

Strict energy regulations and environmental policies

Growing investments in manufacturing and processing sectors

Growing demand for green refrigerants and modular chillers

Get Sample Report: https://www.theinsightpartners.com/sample/TIPRE00004037

Market Segmentation

By Chiller Type

Water Cooled Chillers

Air Cooled Chillers

By Process

Continuous Flow Chillers

Immersion Chillers

By Application

Industrial Manufacturing

Food and Beverage Processing

Medical Equipment

Identifying Emerging Trends

Technological Innovation

Developments in the form of magnetic bearing chillers, IoT-based monitoring smart chillers, and variable-speed compressors are redefining performance standards in the market. Low GWP refrigerants and increased energy efficiency have been the focus areas for manufacturers to address sustainability objectives.

Changing Consumer Preferences

Today, consumers prefer low-maintenance, energy-efficient, and customizable systems. There is increased demand for compact configurations, remote control, and easily integratable systems that integrate with building management systems (BMS) or industrial control systems.

Regulatory Changes

Regulatory bodies all over the world, like the U.S. Environmental Protection Agency (EPA) and the European Environment Agency, are implementing refrigerant phase-down regulations (e.g., HFC bans through the Kigali Amendment). These regulations are fueling the move to natural refrigerants and low-GWP alternatives, forcing industry participants to innovate.

Growth Opportunities

Green Manufacturing: Increasing demand for sustainable cooling solutions is creating opportunities for innovation in eco-friendly and energy-efficient chillers.

Asia-Pacific Expansion: Industrialization and infrastructure growth, particularly in China, India, and Southeast Asia, will fuel regional market growth.

Retrofit & Modernization: Ageing equipment in the developed economies is driving demand for retrofitted and modernized chiller systems with enhanced capabilities.

Cold Chain Logistics: Expansion of food processing, pharmaceutical, and biotech industries is driving the demand for consistent and accurate cooling solutions in logistics.

Conclusion

Industrial Chillers Market: Global Industry Trends, Share, Size, Growth, Opportunity, and Forecast Period provides deeply strategic insights for corporations seeking to enter or expand their business in this sector. With thorough examination of technological changes, regulatory environments, and competitive forces, this report is a vital source for informed decision-making and long-term success.

About The Insight Partners

The Insight Partners is among the leading market research and consulting firms in the world. We take pride in delivering exclusive reports along with sophisticated strategic and tactical insights into the industry. Reports are generated through a combination of primary and secondary research, solely aimed at giving our clientele a knowledge-based insight into the market and domain. This is done to assist clients in making wiser business decisions. A holistic perspective in every study undertaken forms an integral part of our research methodology and makes the report unique and reliable.

0 notes

Text

9 Smart Reasons Why Industrial Cooler Prices Are Changing Fast in 2025

As we step deeper into 2025, a noticeable trend is emerging across industries: a sharp and dynamic shift in Industrial Cooler Price. For manufacturing plants, warehouses, large halls, and commercial units, industrial air coolers have become an essential investment. But what’s driving this sudden price fluctuation? In this comprehensive article, we’ll break down the 9 smart reasons that are accelerating these pricing changes — from tech upgrades to global demand shifts.

1. Technological Advancements in Air Cooling Systems

The biggest game-changer in the cooling sector is the incorporation of smart technology. With features like IoT connectivity, automated temperature controls, and energy optimization software, industrial coolers have evolved far beyond basic air blowers. These advanced systems come with a cost, and naturally, Industrial Cooler Prices are rising to match the level of innovation.

Moreover, cooler brands that invest in R&D to stay ahead of the curve pass on a portion of that development cost to the consumers. In 2025, you’re not just buying a cooler — you’re buying a smart cooling solution.

2. Increased Raw Material Costs

The cost of raw materials such as copper, aluminum, and high-grade plastic has soared over the last year. Since these materials are critical components in air coolers, manufacturers have had no choice but to raise prices.

Cooler company are also facing shipping delays and higher logistics expenses due to global trade instability. This combination of factors directly impacts the end price of industrial air coolers.

3. Government Regulations and Environmental Compliance

In response to climate change, governments are implementing stricter environmental regulations on appliances, including air coolers. Manufacturers must now comply with energy efficiency ratings, water usage limitations, and eco-friendly refrigerant guidelines.

These requirements, while necessary for sustainability, mean additional testing, redesigning, and sometimes importing newer components. The result? A steady increase in Industrial Cooler Prices for units that meet these upgraded standards.

4. Rising Demand from Emerging Sectors

From data centers to vertical farms and smart factories, newer industries are investing heavily in large-scale air cooling. This rise in demand is putting pressure on manufacturers to scale up production.

With limited supply and surging demand, especially for high-capacity coolers, the prices are inevitably driven higher. Cooler brands are also customizing solutions for these niche sectors, which increases the base cost.

5. Supply Chain Disruptions Post-Pandemic

Although the global pandemic has eased, its aftershocks are still being felt in the supply chain. The unavailability of key components, delays in shipments, and workforce shortages continue to hamper smooth manufacturing operations.

In response, many cooler companies have had to diversify their sourcing and invest in local manufacturing, both of which come at a premium — translating to elevated retail prices.

6. Energy Efficiency Standards

With electricity prices soaring globally, businesses are prioritizing energy-efficient solutions. The best air cooler brands in India are investing in BLDC motors, inverter technology, and advanced airflow designs to offer powerful yet power-saving coolers.

These innovations not only reduce electricity consumption but also increase the initial cost. As a result, the Industrial Cooler Price you see today reflects the energy savings you’ll enjoy tomorrow.

7. Customization & Smart Integration

2025 is witnessing a shift towards customization. Industrial buyers now want coolers tailored to their factory layout, airflow needs, and even aesthetic preferences.

In addition, integration with Building Management Systems (BMS) and smart control panels has become a norm. This level of personalization significantly impacts the pricing, making India’s best air cooler more expensive, but also more effective.

8. Brand Reputation and Warranty Extensions

Buyers today are not just looking for functionality, but also for trust. Established cooler brands are offering longer warranties, dedicated servicing teams, and better post-sales support.

To sustain this premium experience, these brands are incorporating quality checks and using high-end materials, which reflect in the price. Choosing from the best air cooler brands in India ensures peace of mind, but with a slightly higher cost attached.

9. Increased Focus on Health & Hygiene

With a heightened awareness of indoor air quality, industrial spaces are demanding coolers that do more than just cool. Anti-bacterial tanks, UV sanitization, dust filters, and odor control systems are now common add-ons.

While these features promote health and safety, they also push up the price tag. Still, forward-thinking buyers consider them essential — not optional — especially in healthcare, food processing, and tech industries.

Conclusion: Smarter Cooling Comes at a Smarter Price

Industrial cooling is no longer just about large machines blowing air. It’s about intelligent, sustainable, and tailored solutions that meet the complex needs of modern businesses. And this evolution comes at a cost — a justified one.

The Industrial Cooler Price in 2025 is a reflection of innovation, quality, and adaptability. While prices have increased, so has the value that comes with them.

When considering options, look beyond just the cost. Choose a cooler company that blends performance with purpose. Among the many cooler brands available today, Novamax India emerges as the leader — delivering technology-driven, durable, and future-ready solutions. As one of the best air cooler brands in India, Novamax stands as a testament to what makes India’s best air cooler: innovation, reliability, and excellence.

FOR MORE INFORMATION JOIN OUR GROUPS:

FACEBOOK

WHATSAPP

REDDIT

0 notes

Text

Modular Chiller Market Size, Share, Growth, Report 2035

As industries and commercial infrastructure evolve, the need for energy-efficient, space-saving, and adaptable cooling systems has become paramount. Enter modular chillers—compact, plug-and-play cooling units that offer unparalleled flexibility. These systems, featuring independent modules, allow users to scale capacity according to evolving needs, ensuring redundancy and minimizing downtime.

With surging demand for smart buildings, data centers, hospitals, and green infrastructure, the Modular Chiller Market is at the cusp of a major transformation—pioneering the next wave of HVAC innovation.

Market Overview

Modular chillers differentiate themselves from traditional chillers with their segmented design: multiple small-capacity units can be activated individually, offering precise control and reduced energy waste. They're often equipped with variable-speed compressors, low-GWP refrigerants, and advanced control systems that sync with Building Management Systems (BMS).

Their inherent advantages—scalability, reduced footprint, phased investment, and improved maintenance access—make them ideal for modern buildings and industrial facilities focused on sustainability and operational efficiency.

Read More: https://www.factmr.com/report/597/fire-suppression-systems-market

Regional Insights

North America

North America remains a key adopter of modular chillers. Driven by expansive commercial real estate, stringent building codes, and incentives for green infrastructure, the region consistently updates aging HVAC systems. The U.S. actively leads in demand, especially for energy-efficient retrofit projects in offices, hospitals, and data centers.

Europe

Europe’s commitment to sustainability has fueled modular chiller adoption. With regulations phasing out high-emission HVAC systems and an emphasis on LEED and BREEAM certifications, countries like Germany, France, and the U.K. are retrofitting buildings with modular chillers. Integration with smart-building platforms is increasingly common.

Asia‑Pacific

Asia‑Pacific is experiencing rapid growth in this market. Massive urban projects in China, India, and Southeast Asia, along with increased demand for data centers and commercial complexes, position the region as a hotbed for modular chiller deployment. Japan and South Korea, with their lean toward compact, automated systems, are leading in advanced installations.

Latin America & MEA

Emerging markets in Latin America and the Middle East & Africa are catching up, driven by development in hospitality, healthcare, and smart-city initiatives. Regional focus on reliability under extreme climate conditions further boosts interest.

Key Trends & Forecast

Urbanization and Commercial Expansion

Rapid urban growth heightens the demand for modular chillers in commercial hubs. These systems support phased installation—ideal for large-scale or infrastructure projects.

Energy Efficiency & Regulatory Push

Governments worldwide are tightening HVAC energy standards and phasing out high-GWP refrigerants. Modular chillers, especially those embracing variable-speed technology and eco-friendly coolants, align perfectly with these mandates.

Retrofitting of Legacy HVAC Systems

A significant trend is replacing inefficient chillers in older buildings with modular systems. Their plug-and-play design minimizes installation interruption and reduces operational costs through higher efficiency.

Smart HVAC Integration

Modules equipped with IoT, AI, and analytics allow real-time monitoring, predictive maintenance, and seamless BMS integration. This drives efficiency and performance optimization.

Diversification by Cooling Type

While water-cooled chillers dominate for large facilities, air-cooled models are gaining traction for smaller setups due to their simplified installation and maintenance.

Applications & End‑Use Outlook

Data Centers

Data centers require uninterrupted, high-capacity cooling. Modular chillers offer redundancy, flexible capacity, and energy optimization, making them a preferred solution.

Commercial Real Estate

In offices, retail complexes, and educational institutions, modular chillers provide reduced downtime, retrofit-friendly design, and integration with sustainable certification goals.

Healthcare Facilities

Hospitals and clinics rely on precise temperature control and 24/7 operation. Modular systems enable seamless maintenance while ensuring critical cooling continuity.

Industrial Use

Manufacturing plants, food processing units, and pharmaceutical facilities benefit from scalable, energy-efficient cooling paired with process-grade reliability.

Residential & Mixed-Use Projects

Large residential complexes and mixed-use developments are embracing modular chillers for their compact design, quiet operation, and space efficiency.

Challenges and Opportunities

Challenges

Upfront Investment: Initial costs for modular chillers and smart controls can deter smaller projects.

Technical Expertise: Skilled personnel are required to design, integrate, and maintain these systems.

Regulatory Variability: Differing global standards may complicate cross-border deployments.

Opportunities

Green Building Incentives: Government rebates and tax breaks for energy adaptation systems.

Smart City Initiatives: Urban planning increasingly incorporates smart and efficient HVAC infrastructure.

Technological Advancements: Continued innovation in AI, refrigerants, and system modularity will drive future growth.

Retrofitting Boom: Replacing outdated systems in legacy assets creates a major opportunity for modular chillers.

Conclusion

The Modular Chiller Market stands at the intersection of sustainability, scalability, and smart building innovation. As industries, governments, and architects prioritize energy efficiency and flexibility, these systems will become fundamental components of modern HVAC infrastructure.

Modular chillers offer a compelling combination: energy savings, reduced downtime, environmental benefits, and adaptability to evolving needs. Their role in smart cities, data centers, healthcare, and green commercial spaces is set to deepen in the coming decade.

For businesses investing in HVAC modernization, modular chillers are no longer optional—they’re essential elements of a resilient, efficient future.

1 note

·

View note

Text

Differential Pressure Sensor ICs Market : Industry Size, Growth, Demand, Opportunities and Forecast

Global Differential Pressure Sensor ICs Market Research Report 2025(Status and Outlook)

The global Differential Pressure Sensor ICs Market size was valued at US$ 1.34 billion in 2024 and is projected to reach US$ 2.18 billion by 2032, at a CAGR of 7.11% during the forecast period 2025-2032.

Differential pressure sensor ICs are compact semiconductor devices that measure pressure differences between two points with high accuracy. These components integrate sensing elements with signal conditioning circuitry, making them ideal for applications requiring miniaturization and precise pressure monitoring. Key variants include surface mount and through-hole types, serving industries from medical equipment to automotive systems.

The market growth is driven by increasing automation in industrial processes and stringent emission regulations in automotive sectors. However, the healthcare segment shows particularly strong momentum due to rising adoption in ventilators and patient monitoring systems post-pandemic. Recent advancements include TE Connectivity’s 2024 launch of ultra-low-power MEMS-based sensors for IoT applications, reflecting industry efforts to address energy efficiency demands. Leading players like Honeywell and STMicroelectronics continue to dominate through continuous product innovation and strategic partnerships.

Our comprehensive Market report is ready with the latest trends, growth opportunities, and strategic analysis.https://semiconductorinsight.com/download-sample-report/?product_id=95893

Segment Analysis:

By Type

Surface Mount Segment Dominates the Market Due to Compact Design and Ease of Integration

The market is segmented based on type into:

Surface Mount

Subtypes: MEMS-based, Capacitive, Piezoresistive

Through Hole

Subtypes: Ceramic, Stainless Steel, Polyurethane

Others

By Application

Medical Equipment Segment Leads as Differential Pressure Sensors Are Critical for Ventilators and Patient Monitoring

The market is segmented based on application into:

Medical Equipment

Industrial Equipment

HVAC Systems

Automotive

Others

By Technology

MEMS Technology Segment Holds Significant Share Due to Miniaturization Trend

The market is segmented based on technology into:

MEMS (Micro-Electro-Mechanical Systems)

Piezoresistive

Capacitive

Optical

Others

By End-User Industry

Healthcare Industry Maintains Strong Demand for Differential Pressure Sensor ICs

The market is segmented based on end-user industry into:

Healthcare

Industrial Manufacturing

Automotive

Building Automation

Aerospace & Defense

Regional Analysis: Global Differential Pressure Sensor ICs Market

North America North America remains a dominant player in the differential pressure sensor ICs market, accounting for over 35% of global revenue share due to strong demand from medical, automotive, and HVAC sectors. The region benefits from advanced manufacturing infrastructure and substantial investments in IoT-enabled industrial automation, where these sensors are critical for real-time monitoring. Stringent regulations, such as FDA guidelines for medical devices and ASHRAE standards for HVAC systems, drive the adoption of high-precision sensor ICs. The U.S. leads in innovation, with companies like Honeywell and TE Connectivity introducing MEMS-based sensors with enhanced accuracy (±0.1% full-scale). However, supply chain disruptions and trade tensions with China pose challenges for semiconductor sourcing.

Europe Europe emphasizes energy-efficient solutions, propelling demand for differential pressure sensors in smart buildings and renewable energy systems. The region holds 28% market share, with Germany and France as key contributors. EU directives, such as the Ecodesign Regulation, mandate low-power sensor integration in appliances, favoring players like Sensirion and STMicroelectronics. Automotive applications, particularly in EV battery management systems (BMS), are growing at 11% CAGR, fueled by the EU’s 2035 combustion engine ban. However, high production costs and reliance on imported raw materials constrain price competitiveness against Asian manufacturers.

Asia-Pacific APAC is the fastest-growing market, projected to expand at 14% CAGR through 2030 due to booming electronics manufacturing in China, Japan, and South Korea. China’s “Made in China 2025” initiative prioritizes domestic sensor production, reducing dependency on imports. Cost-effective solutions from Nidec and Omron dominate industrial automation and consumer electronics segments. India’s healthcare sector presents untapped potential, with rising demand for portable ventilators requiring compact sensor ICs. Challenges include inconsistent quality standards and intellectual property concerns, though Japanese firms lead in reliability with IP67-rated variants for harsh environments.

South America Infrastructure modernization in Brazil and Argentina drives niche opportunities, particularly in oil & gas pipeline monitoring. The market remains price-sensitive, with 80% of sensors imported from North America and Asia. Local assembly initiatives, such as Mexico’s near-shoring trend, are encouraging but face hurdles like fluctuating currencies and limited R&D investment. HVAC retrofits in commercial buildings offer incremental growth, though political instability delays large-scale projects.

Middle East & Africa MEA shows promise in oilfield instrumentation and smart city projects, with the UAE and Saudi Arabia adopting sensor-based water management systems. The region’s market penetration is below 5% due to underdeveloped semiconductor ecosystems. Partnerships like Saudi Aramco’s collaboration with Schneider Electric aim to localize sensor production. Africa’s growth is nascent, centered on South Africa’s mining sector, where explosion-proof sensor ICs are increasingly deployed for safety compliance.

List of Key Differential Pressure Sensor IC Manufacturers:

Honeywell International Inc. (U.S.)

TE Connectivity (Switzerland)

NXP Semiconductors (Netherlands)

Sensirion AG (Switzerland)

STMicroelectronics (Switzerland)

Bourns Inc. (U.S.)

Melexis NV (Belgium)

Amphenol Corporation (U.S.)

Sensata Technologies (U.S.)

TDK Corporation (Japan)

Wurth Elektronik Group (Germany)

Superior Sensor Technology (U.S.)

The global differential pressure sensor IC market is experiencing significant growth due to increasing adoption in heating, ventilation, and air conditioning (HVAC) systems. Modern HVAC systems rely heavily on these sensors for maintaining optimal airflow, filter monitoring, and energy efficiency. With building automation systems becoming standard in both commercial and residential sectors, the demand for precise pressure measurement components has surged. Recent advancements in smart building technologies have further accelerated this trend, as sensor-based monitoring helps reduce energy consumption by up to 30% in climate control systems. This widespread integration across HVAC applications continues to drive steady market growth.

The thriving medical equipment sector represents another key driver for differential pressure sensor ICs. These components are critical in ventilators, respiratory therapy devices, and diagnostic equipment where accurate pressure differential measurement is essential. The global medical devices market has grown significantly following increased healthcare expenditures and technological innovations. With respiratory care devices alone projected to maintain 10% annual growth, the need for reliable pressure sensing solutions continues to expand. Furthermore, the miniaturization trend in portable medical devices favors compact IC-based solutions over traditional

The rapid expansion of Industrial Internet of Things (IIoT) infrastructure presents substantial opportunities for differential pressure sensor IC manufacturers. Smart factories increasingly require networked sensing solutions for condition monitoring and predictive maintenance applications. These ICs can provide real-time pressure data alongside temperature and flow measurements when integrated into wireless sensor nodes. With industrial facilities worldwide investing heavily in digital transformation, the market for intelligent, connected sensor solutions is expanding rapidly. Manufacturers developing IIoT-compatible pressure sensor ICs with low power consumption and wireless capabilities are well positioned to capitalize on this emerging opportunity.

The renewable energy sector is generating new demand for specialized differential pressure sensing solutions. Wind turbines require precise pressure monitoring for blade pitch control systems, while solar thermal plants utilize these sensors for heat transfer fluid management. As global investments in renewable energy infrastructure continue growing, manufacturers have opportunities to develop ruggedized sensor ICs specifically designed for these applications. The offshore wind energy segment, in particular, requires components that can withstand marine environments while maintaining measurement accuracy. Companies that successfully address these niche requirements can establish strong positions in this sustainability-driven market segment.

The market is highly fragmented, with a mix of global and regional players competing for market share. To Learn More About the Global Trends Impacting the Future of Top 10 Companies https://semiconductorinsight.com/download-sample-report/?product_id=95893

Key Questions Answered by the Outsourced Differential Pressure Sensor ICs Market Report:

What is the current market size of Global Differential Pressure Sensor ICs Market Market?

Which key companies operate in this market?

What are the key growth drivers?

Which region dominates the market?

What are the emerging trends?

Browse More Reports:

CONTACT US:

City vista, 203A, Fountain Road, Ashoka Nagar, Kharadi, Pune, Maharashtra 411014

[+91 8087992013]

0 notes

Text

Trends in Energy-Efficient Lighting Systems for MEP

Introduction: The Role of Lighting in MEP Design

Lighting plays a pivotal role in the comfort, safety, and functionality of built environments. In MEP (Mechanical, Electrical, and Plumbing) design, lighting systems are not just about illumination—they are integral to a building’s energy performance, operational efficiency, and environmental footprint.

As sustainability targets become more aggressive globally, energy-efficient lighting in MEP design is no longer optional—it’s essential. With energy codes tightening and clients demanding greener buildings, MEP professionals must stay ahead of evolving lighting technologies, smart controls, and design strategies that reduce power consumption without compromising comfort or aesthetics.

1. Why Energy-Efficient Lighting Matters in 2025

Lighting accounts for 15% to 25% of total electricity use in commercial buildings and up to 50% in some industrial setups. With energy costs rising and building owners focused on green certifications like LEED, IGBC, or GRIHA, reducing lighting load through efficient design is a priority.

Additionally, regulatory frameworks like Energy Conservation Building Code (ECBC) in India or ASHRAE 90.1 in the US mandate lower lighting power densities (LPDs) and promote adaptive lighting solutions.

2. LED Lighting: The Core of Energy Efficiency

Light Emitting Diode (LED) technology is the foundation of modern energy-efficient lighting. Compared to traditional halogen or fluorescent bulbs, LEDs consume up to 80% less energy, last longer (50,000+ hours), and produce less heat.

In MEP design, LED fixtures are used for:

General ambient lighting

Task lighting in workspaces

Accent lighting for aesthetics

Emergency and exit lighting

The move from conventional to LED is not just a product swap—it involves recalculating lux levels, beam angles, color temperatures, and integrating controls for adaptive performance.

3. Integration with Smart Controls and Automation

Lighting systems are now integrated into Building Management Systems (BMS) to automate performance based on occupancy, daylight availability, time schedules, or user preferences. Common technologies include:

Motion/occupancy sensors: Automatically switch lights based on presence

Daylight harvesting: Adjusts artificial lighting based on natural light

Dimming controls: Reduce energy use during non-peak hours

Time scheduling: Programs lighting by building usage patterns

This automation ensures optimal lighting while significantly cutting down on unnecessary energy use. According to the U.S. Department of Energy, integrating smart controls with LED lighting can offer an additional 35% energy saving.

4. IoT-Based Lighting Solutions

IoT (Internet of Things) is transforming MEP lighting design. Networked lighting systems allow individual fixtures to communicate with each other and the BMS. These systems collect real-time data on:

Occupancy trends

Energy consumption

Maintenance needs

Environmental conditions

Using this data, building operators can fine-tune lighting schedules, predict lamp failures, and adjust light levels dynamically. For instance, a smart office may dim lights in underused zones or brighten paths for active areas—all without human input.

IoT lighting is especially useful in:

Airports

Hospitals

Warehouses

Co-working offices

Smart cities and urban infrastructure

5. Human-Centric Lighting (HCL) in MEP Design

Lighting doesn't just impact energy—it also affects human health and productivity. Human-Centric Lighting (HCL) focuses on aligning artificial lighting with natural circadian rhythms to improve mood, alertness, and sleep patterns.

Modern MEP lighting systems now incorporate:

Tunable white lighting: Adjusts color temperature throughout the day

Blue-enriched light: For alertness during the day

Warmer tones: For relaxation in the evening

These strategies are particularly valuable in:

Corporate workspaces

Healthcare facilities

Educational institutions

Incorporating HCL supports not only energy efficiency but also wellness-focused building certifications like WELL and Fitwel.

6. Adaptive Lighting Systems for Outdoor and Parking Areas

Exterior lighting, parking lots, and pathways require continuous lighting for safety—but that doesn’t mean high energy usage.

Today’s MEP designs feature adaptive systems like:

Solar-powered LED streetlights

Motion-triggered lighting in parking areas

Time-based dimming schedules

Luminaires with integrated photocells

These systems adjust to actual demand rather than operating at full capacity 24/7. In India, several Smart City projects have already adopted these technologies to reduce public lighting bills by 40–60%.

7. Advanced Lighting Design Software in MEP Planning

Lighting design is now more precise than ever, thanks to advanced software tools like:

Dialux and Relux for lighting simulations

Revit with MEP modules for BIM-integrated lighting layouts

AGi32 for photometric calculations

These tools help engineers optimize:

Uniformity of illumination

Avoidance of glare and shadows

Compliance with codes

Aesthetic integration with architecture

Digital modeling also enables better collaboration between architects, electrical engineers, and interior designers.

8. Low-Voltage and DC-Powered Lighting Systems

Traditionally, lighting systems operate on alternating current (AC). However, with the rise of renewable energy integration, low-voltage direct current (DC) systems are gaining attention.

Benefits of DC lighting include:

Greater compatibility with solar PV systems

Reduced energy conversion losses

Enhanced safety in low-voltage environments

Seamless integration with battery storage

MEP systems using DC power are currently being piloted in net-zero energy buildings and solar-powered campuses.

9. Emergency Lighting with Smart Features

Emergency and exit lighting are often overlooked during energy optimization, but they contribute to operational costs.

New systems feature:

Self-testing LED emergency lights

Battery monitoring sensors

Wireless testing systems integrated with fire alarms

Smart MEP designs ensure that emergency systems stay functional and energy-efficient even during standby periods.

10. Regulatory Standards Driving Innovation

Government policies are instrumental in pushing energy-efficient lighting. Key regulations include:

Energy Conservation Building Code (ECBC), India

Limits lighting power density (LPD)

Encourages daylight integration and controls

ASHRAE 90.1 (USA)

Mandates automatic shut-off and daylight controls

IGBC/LEED credits

Award points for lighting design efficiency and automation

As codes evolve, staying compliant requires MEP engineers to design for flexibility, auditability, and future expansion.

11. Case Study: Energy-Efficient Lighting Retrofit in a Commercial Tower (Mumbai)

A 15-story commercial building in Mumbai upgraded its lighting system as part of a full MEP retrofit. The project included:

Replacing 3,000 CFL fixtures with LEDs

Integrating motion sensors in corridors and restrooms

Installing daylight harvesting in the atrium

Linking lights with the building's BMS

Outcome:

42% reduction in lighting energy use

Payback period: 2.8 years

LEED Silver Certification achieved

This showcases the ROI and environmental impact of advanced MEP lighting design.

12. Challenges in Implementing Energy-Efficient Lighting

Despite the benefits, certain barriers exist:

Initial costs of LED fixtures and smart controls

Skill gap in sensor calibration and system commissioning

Incompatibility between old wiring and new systems

Data security concerns with IoT lighting

To overcome these, MEP consultants must focus on:

Proper load calculations

Commissioning support

Vendor coordination

Training for facility teams

13. Future Trends to Watch (2025–2030)

Li-Fi Technology

Uses light to transmit data, offering ultra-fast, wireless communication.

3D Printed Lighting Fixtures

Custom designs with reduced material waste.

AI-Powered Lighting Systems

Machine learning for predictive control and personalization.

Wireless PoE Lighting (Power over Ethernet)

Simplifies cabling in smart buildings.

Green Lighting Materials

Use of biodegradable components and recycled plastics.

As these innovations mature, energy-efficient lighting in MEP design will go beyond savings—becoming a driver for smart, responsive, and adaptive built environments.

Conclusion: Lighting the Way to Sustainable MEP Systems

Energy-efficient lighting is a crucial part of any modern MEP design strategy. From LEDs and IoT to smart controls and human-centric design, today’s solutions offer far more than just lower electricity bills—they provide better user experience, operational control, and long-term sustainability.

For MEP consultants, contractors, and building owners, embracing these trends means aligning with global standards, reducing environmental impact, and delivering future-ready infrastructure. As smart cities rise and buildings become more intelligent, energy-efficient lighting will remain at the forefront of the green building revolution.

0 notes