#modulus of rigidity

Explore tagged Tumblr posts

Text

How an Online Science Lab Helps Students Conduct Safe Experiments at Home

The advancement of digital learning tools has transformed science education, allowing students to conduct experiments safely from home. One of the most significant innovations in this space is the Online Science Lab, which enables learners to explore scientific concepts through virtual simulations. These platforms eliminate safety risks while providing a hands-on approach to experimentation, making them an excellent alternative to traditional labs.

The Benefits of an Online Science Lab

An Online Science Lab allows students to perform experiments without requiring expensive lab equipment or specialized materials. By using interactive simulations, they can test scientific theories, manipulate variables, and observe real-time results. This approach not only enhances understanding but also provides a safe learning environment where mistakes become valuable learning opportunities rather than safety hazards.

Virtual labs also offer flexibility, enabling students to repeat experiments multiple times at their own pace. Whether studying physics, chemistry, or biology, learners can explore different scientific principles without time constraints, making it an effective tool for both self-paced learning and classroom instruction.

Exploring Physics with Virtual Experiments

Physics often requires practical demonstrations to fully grasp complex theories. A great example is Young’s Double Slit Experiment, which demonstrates the wave nature of light through an interference pattern. Traditionally, this experiment requires precise equipment, but with virtual simulations, students can easily manipulate factors such as slit width, wavelength, and screen distance to observe the resulting changes in the interference pattern.

Using a virtual version of Young’s Double Slit Experiment, students can experiment with different conditions and see how light behaves under various circumstances. This hands-on approach helps reinforce theoretical concepts while making abstract principles more tangible and accessible.

Understanding Material Properties Through Simulations

In physics and engineering, studying the mechanical properties of materials is essential. One crucial property is the modulus of rigidity, which measures a material's resistance to deformation under shear stress. Traditionally, determining this value requires specialized lab equipment, but virtual tools now make it possible for students to explore this concept safely from home.

Through an interactive simulation, students can apply different amounts of force to various materials and observe how they respond. This allows them to understand how the modulus of rigidity differs for substances like steel, rubber, or glass. By analyzing these behaviors in a virtual environment, students gain a deeper understanding of material strength and flexibility without needing a physical lab setup.

Conclusion

The introduction of an Online Science Lab has revolutionized science education by making experiments more accessible, safe, and interactive. From studying light behavior in Young’s Double Slit Experiment to exploring material properties like the modulus of rigidity, these virtual platforms provide students with valuable learning experiences without the constraints of traditional labs. As technology continues to evolve, virtual labs will play an increasingly vital role in scientific education, making hands-on learning possible for students everywhere.

0 notes

Note

What's your lab report about?

elastic rigid modulus poiszonz ratio etc (hating it)

8 notes

·

View notes

Text

Nickel 200 Wires Exporters in UAE

Meraki Star Metals Oil & Gas Equipment Trading L.L.C. is a Wires provider and exporter of Nickel 200 wires. We Manufacture them open in custom nuances, plans, lengths, thickness, widths, and that is only a brief gander at something more prominent. We are known Exporters in the general market of ferrous and nonferrous things. Our clients can intercessors for nickel wires as shown by their application necessities.

Nickel 200 Wires are made with the assistance of the different Amalgam affiliations like carbon, manganese, silicon, copper, sulfur, chromium, iron, nickel, nitrogen, etc. too. These nickel wires ought to have physical and mechanical properties like thickness, loosening up point, flexibility, yield strength, astonishing rigid nature, broadening, warm conductivity, electrical conductivity, and modulus of extension. These wires are made with different decisions like broadness, shape, size, length, width, thickness, types, structures, condition, surface, application, standard, finish, obstacles, etc. as well. These wires are accessible in many sorts, for example, reshape wire, made never-ending wire.

Nickel 200 Wires are material in various organizations, for instance, offshore oil entering undertakings, petrochemicals industry, power age plant, drug industry, substance gear, seawater equipment, drug equipment, special engineered industry, paper industry, pound industry, heat exchanger, and condenser. These wires are also significant in many general purposes like valves, shaft, shipbuilding, structure advancement, transportation equipment, range improvement, radiator parts, and various temperature-safe things.

Nickel 200 Wires are made with the best material and incredible mechanical and real properties. These wires are a good blend of formability, usefulness, welding, and resistance from the high temperatures. These wires are outrageous, hard, and made with the protected material to work at high temperatures. These wires are furthermore protected against the entire expansive disintegration like gap utilization, stress breaking, pitting block, and impact disintegration. These wires are protected in the oxidizing, decreasing and unprejudiced circumstances. These wires have the low electrical and warm conductivity that helps the wires with contradicting the electric.

Nickel 200 Wires need to go through many tests after the creation from the business, for example, erupting test, straightening test, large scale test, miniature test, hydrostatic test, ultrasonic test, pitting test, radiography test, hardness test, synthetic test, mechanical test, PMI test, etc too.

For more information : Visit our website : https://www.merakimetals.ae/ Contact us : +971-523973687, +971-48801107, +971-48240333 Email : [email protected]

#Nickel 200 Wires Manufacturers in UAE#Nickel 200 Wires Suppliers in UAE#Nickel 200 Wires Stcokists in UAE#Nickel 200 Wires Exporters in UAE

3 notes

·

View notes

Text

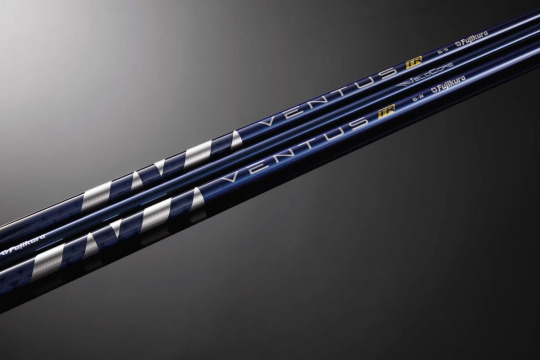

Unlocking Your Potential: A Comprehensive Guide to the Ventus TR Swing Speed Chart

For serious golfers, the quest for optimal performance often leads to the intricate world of golf shafts. Among the most revered names in shaft technology, Fujikura's Ventus line, particularly the Tour Rated (TR) series, stands out for its exceptional stability and feel. But with different profiles like Red, Blue, and Black, how do you know which Ventus TR shaft is the perfect match for your swing? The answer lies in understanding the Ventus TR swing speed chart and how it correlates with your unique swing characteristics.

This in-depth article, crafted for the discerning golfer, will demystify the Ventus TR series, analyze its swing speed recommendations, and guide you towards unlocking your maximum potential on the course.

The Science Behind Ventus TR: VeloCore Technology and Beyond

Before diving into swing speed specifics, it's crucial to appreciate the core technology that underpins the Ventus TR series: Fujikura's proprietary VeloCore Technology. This multi-material bias core construction, featuring full-length, ultra-high modulus Pitch 70 Ton Carbon Fiber (150% stronger and more stable than T1100g), is designed to stabilize the shaft wall and prevent ovaling and deformation, especially during the high-stress transition and impact phases of the swing.

The TR designation in the Ventus series introduces an additional layer of innovation: Spread Tow carbon fabric. This ultra-high modulus and lightweight composite woven material further stiffens the torque in the mid/handle section of the shaft. Fujikura's enso® analytics, a sophisticated 3D motion capture system, identified this area as a critical stress point during the swing, and the Spread Tow material effectively reduces shaft twist and ovalization by nearly 10% compared to the original Ventus Blue. The result is enhanced stability, consistency, and control without sacrificing feel.

Deconstructing the Ventus TR Family: Red, Blue, and Black

The Ventus TR series offers three distinct profiles, each engineered to cater to specific swing dynamics and desired ball flight characteristics:

1. Ventus TR Red: The Mid-High Launch & Mid-Low Spin Performer

Launch: Mid-High

Spin: Mid-Low

Feel: Smooth and easy launch

Ideal for: Golfers seeking maximized carry distance with a slightly higher ball flight. This shaft offers a balance of stability and launch, making it a great option for players who desire more airtime and easier loading of the shaft.

2. Ventus TR Blue: The Balanced Mid-Launch & Low Spin Option

Launch: Mid

Spin: Low

Feel: Powerful combination of stability and feel, maintaining an ultra-stiff tip section for superior control.

Ideal for: A wide range of golfers who prioritize a balanced flight with low spin for optimal total distance. The increased torsional stiffness in the TR Blue allows for more aggressive swings while still providing a smooth feel. It’s often considered the "Goldilocks" option for players who find the original Ventus Blue slightly too soft but the Ventus Black too rigid.

3. Ventus TR Black: The Low Launch & Ultra-Low Spin Powerhouse

Launch: Low

Spin: Ultra-Low

Feel: Exceptionally stable and precise, offering a penetrating ball flight.

Ideal for: Golfers with very fast, aggressive swing speeds and tempos who demand maximum control and minimal spin. The TR Black is designed to withstand the highest loads, promoting a powerful, piercing trajectory with significant roll.

The Ventus TR Swing Speed Chart: Finding Your Match

While a professional fitting is always recommended for precise optimization, understanding the general guidelines of the Ventus TR swing speed chart can provide a valuable starting point. These recommendations correlate typical driver swing speeds with the ideal Ventus TR profile and flex.

Here's a general breakdown, keeping in mind that individual tempo, transition, and desired ball flight also play significant roles:

Driver Swing Speed (MPH)

Recommended Ventus TR Profile

Recommended Flex Range

Characteristics & Benefits

Below 90 mph

Ventus TR Red

Regular (R) to Stiff (S)

Higher launch and spin to maximize carry distance. Smooth feel and easier to load, promoting better control for moderate swing speeds.

90 - 105 mph

Ventus TR Blue

Regular (R) to Stiff (S)

Balanced mid-launch and low spin for controlled ball flight and good overall distance. Offers a blend of feel and stability for a wide range of golfers.

105 - 115 mph

Ventus TR Blue or TR Black

Stiff (S) to Extra Stiff (X)

At the lower end, TR Blue provides a stable, low-spin option. For more aggressive swings, TR Black offers superior stability and ultra-low spin for maximum distance and control.

Above 115 mph

Ventus TR Black

Extra Stiff (X) to Tour X (TX)

Unparalleled stability and control for extremely fast and aggressive swings. Produces a penetrating, low-spin trajectory for maximum distance and accuracy.

Important Considerations Beyond Swing Speed:

Tempo and Transition: Golfers with aggressive transitions (a quick change from backswing to downswing) often benefit from stiffer profiles, even if their peak swing speed isn't exceptionally high. The Ventus TR shafts are specifically designed to handle these higher stresses.

Ball Flight Desired: If you tend to hit the ball too high and with too much spin, a stiffer, lower-launching, and lower-spinning shaft like the TR Black or a heavier TR Blue might be beneficial. Conversely, if you struggle to get the ball in the air, a TR Red could provide the extra launch you need.

Feel: While data is crucial, personal feel is also vital. Some golfers prefer a "boardier" feel for maximum control, while others prefer a more active, responsive shaft. The Ventus TR series aims to provide enhanced stability without sacrificing the signature Ventus feel.

Tipping: For golfers on the cusp of a flex or seeking to fine-tune the shaft's performance, custom tipping (cutting a small amount off the tip of the shaft) can increase its stiffness and lower launch/spin. This is a common practice in professional fittings.

The Unbeatable Advantage of a Professional Fitting

While the Ventus TR swing speed chart provides excellent guidance, the nuances of your individual swing are best analyzed by a qualified club fitter. Using advanced launch monitors and their expertise, a fitter can precisely measure your:

Clubhead speed

Ball speed

Launch angle

Spin rate

Attack angle

Swing path

Tempo and transition

This comprehensive data, combined with your personal preferences and on-course tendencies, allows them to recommend the exact Ventus TR shaft model, flex, weight, and tipping that will optimize your performance. A properly fitted shaft ensures maximum energy transfer, tighter dispersion, and consistent ball striking, ultimately leading to lower scores.

Conclusion: Swing Smarter, Not Just Harder

The Fujikura Ventus TR series represents the pinnacle of golf shaft technology, offering unprecedented stability and control. By understanding the Ventus TR swing speed chart and the unique characteristics of the Red, Blue, and Black profiles, golfers can take a significant step towards optimizing their equipment. However, for truly maximizing your potential, investing in a professional club fitting remains the gold standard. With the right Ventus TR shaft in your hands, you'll gain the confidence to swing freely and unleash your best golf.

0 notes

Text

Understanding Borehole Geophysical Logging with the PS Logger® Probe

In the realm of civil engineering, offshore construction, and geotechnical investigations, obtaining accurate subsurface data is paramount. Without it, designing safe foundations, evaluating soil conditions, and assessing geological risks become speculative endeavors. This is where the PS Logger® probe stands out—a revolutionary tool engineered for fast, precise, and safe measurement of seismic wave velocities in boreholes.

🔍 What is Borehole Geophysical Logging?

Borehole geophysical logging is a technique used to measure the physical properties of subsurface formations by lowering specialized instruments into boreholes. These measurements provide invaluable data on the geological characteristics of the area, aiding in:

Foundation design

Earthquake engineering

Offshore construction

Environmental assessments

Traditional logging methods often require external energy sources, such as explosives or weight drops, to generate seismic waves. However, these methods can be cumbersome, costly, and sometimes hazardous.

⚙️ Enter the PS Logger® Probe

The PS Logger® probe, developed by Robertson Geo, revolutionizes borehole geophysical logging by incorporating an internal solenoid-operated hammer. This innovative design allows for the generation of seismic waves without the need for external energy sources, ensuring quicker, safer, and more efficient logging operations.

Key features of the PS Logger® include:

Dual-wave measurement: Simultaneously measures P-wave (compression) and S-wave (shear) velocities.

High-resolution data: Captures full waveforms with sample rates as low as 2.5 microseconds.

Robust design: Built to withstand harsh environments, including deep marine conditions.

User-friendly operation: Compatible with industry-standard software for seamless data acquisition and analysis.

📈 Why Measure P-Wave and S-Wave Velocities?

Understanding the speeds of seismic waves in subsurface materials provides critical insights:

P-wave velocity: Indicates material density and compressional stiffness.

S-wave velocity: Relates directly to shear strength and rigidity of soils or rocks.

When combined with bulk density measurements, this data enables the calculation of small-strain moduli such as:

Young’s modulus

Shear modulus

Bulk modulus

These parameters are essential for designing safe foundations, predicting soil behavior under load, and modeling geotechnical structures. Simply put, better velocity data translates to better engineering decisions.

🌍 Global Applications of the PS Logger®

The PS Logger® has been deployed worldwide across various challenging environments:

Civil Engineering Projects: Bridges, tunnels, dams, and deep foundations rely on accurate subsurface profiles.

Offshore Construction: Oil platforms, wind farms, and subsea pipelines benefit from reliable geophysical data in extreme marine conditions.

Geotechnical Investigations: Site characterization for urban development, mining, and research all gain from high-quality seismic logs.

Its rugged design and user-friendly operation have made it the go-to choice for professionals seeking precise subsurface data.

🛠️ Deployment and Compatibility

The PS Logger® integrates seamlessly with Robertson Geo’s proven surface equipment, including:

Micrologger2 and Winlogger software for data acquisition and processing

Various winch systems ranging from mini winches to 3000m marine winches

Sheaves rated for 2k and 3k loads for reliable deployment

This compatibility ensures that whether your site is onshore or offshore, you have the right tools to deploy and collect data efficiently.

🎓 Training and Support

At PSLogger.com, we believe that great equipment must be backed by excellent support. We provide a comprehensive range of resources, including:

Video tutorials: Covering probe assembly, data collection, and analysis.

Technical guides: Offering insights into probe maintenance and troubleshooting.

Expert assistance: Our team is ready to support you with any queries or challenges.

This ensures operators at every level can confidently use the PS Logger® and maximize its capabilities.

✅ Why Choose the PS Logger®?

No external seismic source required: Safer and simpler operation.

High-resolution data: With sample rates as low as 2.5 microseconds.

Durable, compact design: Suited for harsh environments.

Compatible with industry-leading surface systems: Ensuring seamless integration.

Trusted worldwide: Deployed across thousands of projects globally.

Whether you're conducting routine site investigations or complex offshore surveys, the PS Logger® delivers the seismic insights you need quickly and accurately.

📞 Get Started with PSLogger.com

Ready to upgrade your seismic logging capabilities

Download detailed product literature

Access our video tutorial library

Request pricing and availability

Contact our expert support teams

We're here to help you take your projects to the next level with smarter, safer, and more efficient seismic data acquisition.

Conclusion

Accurate subsurface seismic data is the foundation of safe, successful engineering projects. The PS Logger® delivers this data with a unique blend of innovation, simplicity, and reliability—all from a single borehole and without external energy sources.

Explore deeper insights, accelerate your workflow, and build with confidence using the PS Logger®.

👉 Visit us today at PSLogger.com to learn more! 🌐✨

1 note

·

View note

Text

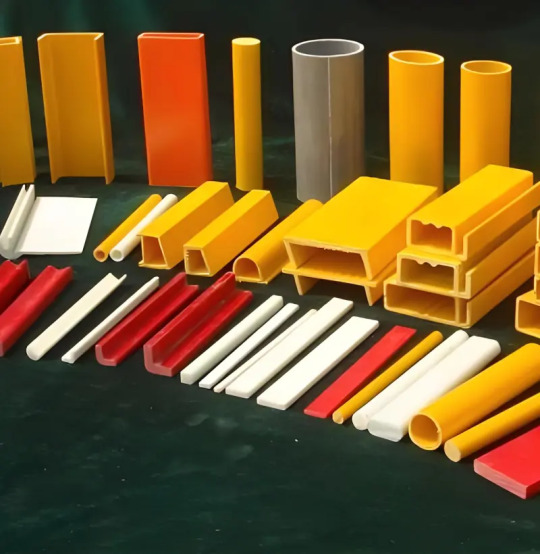

Fiberglass: A Versatile Material Powering Modern Innovation

Fiberglass, also known as FRP, GRP, a composite material made from fine glass fibers embedded in a polymer matrix, has revolutionized industries worldwide since its commercialization in the 1930s. Combining the strength of glass with the flexibility of plastics, it offers a unique blend of properties that make it indispensable in applications ranging from aerospace to consumer goods. This article explores fiberglass’s composition, manufacturing processes, key products, intrinsic properties, and its transformative role across diverse industries.

1. Introduction to Fiberglass

What is Fiberglass?

Fiberglass, or glass-reinforced plastic (GRP), is a composite material consisting of glass fibers (typically 3–25 microns in diameter) bound together by a thermosetting resin, such as polyester, epoxy, or vinyl ester. The glass fibers provide tensile strength and rigidity, while the resin matrix distributes loads and protects the fibers from environmental damage.

Historical Development

1930s: Owens-Illinois and Corning Glass Works developed the first commercial glass fibers.

1940s: Widespread adoption in World War II for radar domes and aircraft components.

1950s–Present: Expanded into construction, automotive, and renewable energy sectors.

Manufacturing Process

Fiber Production:

Melting: Silica sand, limestone, and soda ash are melted at 1,400–1,600°C.

Fiber Drawing: Molten glass is extruded through platinum bushings to form continuous filaments.

Sizing: Fibers are coated with lubricants and binders to enhance adhesion to resins.

Composite Formation:

Layup: Fibers are woven into mats, fabrics, or rovings and impregnated with resin.

Curing: The resin hardens via heat, pressure, or catalysts, forming a rigid structure.

2. Properties of Fiberglass

Fiberglass’s popularity stems from its exceptional physical, chemical, and mechanical properties:

A. Mechanical Properties

High Strength-to-Weight Ratio: Tensile strength of 1,000–3,000 MPa (comparable to steel) at 25% of steel’s density (2.5 g/cm³ vs. 7.8 g/cm³).

Stiffness: Elastic modulus of 70–85 GPa, ideal for load-bearing structures.

Fatigue Resistance: Withstands cyclic loading without cracking, critical for automotive parts.

B. Thermal and Electrical Properties

Thermal Insulation: Thermal conductivity of 0.03–0.05 W/m·K, outperforming most metals.

Fire Resistance: Non-combustible up to 540°C, with low smoke emission.

Electrical Insulation: Dielectric strength of 10–20 kV/mm, suitable for electrical components.

C. Chemical and Environmental Resistance

Corrosion Immunity: Resists acids, alkalis, and saltwater, unlike metals.

UV Stability: UV-resistant resins (e.g., isophthalic polyester) prevent degradation in sunlight.

Low Moisture Absorption: <0.1% water absorption, preventing swelling or warping.

D. Design Flexibility

Can be molded into complex shapes, colored, or textured during production.

3. Industry Applications

Fiberglass’s adaptability has made it a cornerstone material in multiple sectors:

A. Construction and Infrastructure

Structural Panels: Lightweight wall panels and roofing sheets reduce building costs.

FRP Structural Profiles: FRP H Beams, U Channels, and Angles replace steel in corrosive environments (e.g., coastal bridges, chemical plants).

Walkway Systems: Molded FRP Grating and Covered FRP Grating provide slip-resistant, durable surfaces for industrial platforms and pedestrian bridges.

B. Automotive and Transportation

Body Components: Hoods, bumpers, and fenders reduce vehicle weight, improving fuel efficiency.

Aerospace: Radomes, interior panels, and cargo liners leverage fiberglass’s strength and radar transparency.

Railways: FRP Pultruded Tubes and Rods are used in overhead cable supports and lightweight seating frames.

C. Marine and Offshore

Boat Hulls: Fiberglass-reinforced polyester resists osmotic blistering and marine fouling.

Decking: Molded FRP Grating withstands saltwater corrosion on ship decks and oil rigs.

D. Energy and Utilities

Wind Turbines: Fiberglass-epoxy composites form lightweight, durable blades up to 100 meters long.

Electrical Grids: FRP Pultruded Tubes serve as non-conductive crossarms in high-voltage transmission towers.

E. Industrial and Chemical

Support Structures: FRP H Beams and Angles frame chemical storage tanks and scrubbers.

Cable Trays: FRP U Channels organize wiring in corrosive industrial settings.

4. Innovations and Sustainability Trends

Recyclable Resins: Development of thermoplastic composites (e.g., PA6-GF) for easier recycling.

Pultrusion Efficiency: Automated production of FRP Pultruded Tubes and H Beams reduces material waste.

Bio-Based Fibers: Hybrid composites combining glass fibers with natural fibers (flax, hemp).

The global fiberglass market, valued at $12.8 billion in 2023, is projected to grow at 5.4% CAGR, driven by green construction and electric vehicle adoption.

5. Challenges and Future Prospects

Health Concerns: Inhalation of glass dust during manufacturing requires stringent safety protocols.

End-of-Life Management: Recycling FRP Angle and Grating remains technically challenging but critical for sustainability.

Future advancements may include:

Smart Fiberglass: Sensors embedded in FRP Pultruded Tubes for structural health monitoring.

Hybrid Systems: Combining FRP H Beams with carbon fiber for ultra-high-strength frameworks.

Conclusion

Fiberglass stands as a testament to material science’s ability to bridge the gap between nature’s limitations and human ingenuity. From Molded FRP Grating securing industrial walkways to FRP Pultruded Tubes revolutionizing energy infrastructure, its versatility continues to redefine engineering possibilities. As industries prioritize sustainability and performance, fiberglass will remain a vital enabler of innovation, proving that even the most unassuming materials can shape the future.

0 notes

Text

200g Carbon Fiber Plain Cloth/Carbon Fiber Cloth

Material: Carbon fiber, carbon fiber has excellent strength and rigidity, and is very light, making it an ideal high-performance composite material.

Model: Plain Carbon Fiber Cloth, plain cloth is a common type of carbon fiber cloth with high structural strength and uniform surface, suitable for a variety of structural applications.

Specifications: 200g surface cloth, 200g rib cloth. The "200g" here means that the weight of the cloth per square meter is 200g, indicating that it is relatively light, but still has good strength and durability.

Function: High modulus refers to the high rigidity of the material when it is stressed, that is, it can resist deformation and maintain its original structural form.

Compression strength: T300, which represents the compression strength grade of the carbon fiber cloth. T300 grade carbon fiber is a standard carbon fiber material commonly used in high-strength and high-performance applications, with good mechanical properties and durability.

Application range: This material is mainly used to manufacture carbon fiber products, such as carbon fiber composites, automotive parts, etc. It is used in the automotive industry for lightweight design to improve vehicle performance and safety.

Contact us

Phone: +86-0513-81813680 +86-18012885770

E-mail:[email protected]

0 notes

Text

¶ … Teeth Enamel and Teeth, Generally The hardest part of the human body is the tooth. Teeth help to chew and break down food particles into smaller units for easier digestion down the system. Teeth also help humans to articulate language ((Hoffman)). The enamel is the hardest part of a tooth. Calcium phosphate is its primary composition compound. Enamel Formation and its Strength, Durability The tooth crown constitutes a cellular material known as enamel. The enamel happens to be the hardest body tissue. The thickness of the material on the tooth depends on the part of the tooth and its shape. The thickest enamel is usually found at the cusp crest and incisal edges. The sloping part, the fissures, the cervix of the tooth, and the various pits of cuspid teeth have the thinner layers. The enamel on an adult human's teeth is high in energy and is home to significant intermolecular forces. It has been referred to by experts as a composite bioceramic. Enamel is rigid and brittle in nature. It has a low tensile strength and a high elasticity modulus. The enamel of the tooth does not regenerate. It is cellular. The enamel prism is the largest structural unit of the enamel. It is compact; densely attached and intertwined in a wavy pattern. It extends from the dento-enamel convergence point to a few micrometers before the surface of the tooth (Terry, et.al, 2008). The primary structure of the prisms looks like a key-hole. It measures approximately 0.5 µm. The rods look like rounded heads that form a continuous pattern of interlocked prisms. The prism of the enamel is thin at its base but enlarges as it extends to the surface. It has a diameter of 4.0 µm on average. The prisms are arranged in a parallel fashion to each other. They extend outwards starting from the DEJ in a radial fashion. They are averagely perpendicular to the surface of the crown on the outside. The orientation of the rod in the enamel cusp area is perpendicularly positioned to the DEJ. In the cervical region, there is an apical inclination while in the third part of the occlusal, the prisms make an acute angle relative to the surface while they approach the tip of the crown as it is approached. It exhibits a tendency that is directly antagonistic to the masticulation forces (Terry, et.al, 2008). This knowledge is indispensable in the process of preparing cavity. It will help a dentist avoid injuring the enamel rod. These can easily fracture along the planes of cleavage that run parallel to prisms of enamel. Why the Enamel Breaks Down The following can cause the enamel to erode (Tooth Enamel: Erosion and Restoration): • Consumption of soft drinks without control • Love for fruit drinks. Some fruit drinks contain extremely erosive acid • Little salivary flow or dry mouth syndrome, also called xerosomia • Diet full of sugar and starch • GERD: the acid reflux disease • Problems of gastrointestinal nature • Such medications as aspirins and antihistamines • Inherited problems • Environmental triggers including friction, stress, tear and wear The sticky substance that forms between one's teeth is made up of food substances, bacteria and saliva. It infiltrates the inner corners and fissures of the tooth; especially the molars. It finds its way round the tooth cavity fillings and builds around the lining of the gum. Some of the bacteria change the food particles in the teeth spaces into acid (Tooth Enamel: Erosion and Restoration). These acids are responsible for the teeth erosion that occurs. It effectively wears out the enamel. Preserve/Care/Maintain Enamel It is known that the enamel does not regenerate. However, dentists offer help to replace worn out minerals of teeth. Two ways exist and are applied to treat teeth that are eroded (The Truth about Tooth Erosion: How to repair tooth enamel?): • Milder cases of enamel erosion can be treated through bonding. Tinted resin meant to match the color shade of your tooth is put on the damaged tooth and then trimmed so as to fit correctly into your mouth. • In more acute cases of enamel erosion, a crown is applied. The procedure entails capping a new crown that will guard the areas already damaged. Indeed, a crown, often, restores function to the tooth that is damaged. It is a useful protection against decay too. It is clear that fruit juices and soda are harmful to teeth. If these drinks can be replaced by a margin of one or two every day, with water, there is a chance that your teeth will be greatly helped; health wise. Swirling liquid such as soda or fruit juice around your mouth, you expose more of your teeth to erosion caused by the ingredients of liquid being swirled. It is advisable to avoid swishing drinks in the mouth (The Truth about Tooth Erosion: How to repair tooth enamel?). The acid in the stomach easily and quickly corrodes teeth. When you experience a digestive disorder, or an eating disorder, the acid in the stomach simmers into the esophagus channel and finds way into your mouth. It erodes your teeth in the process. If you experience a medical condition that negatively affects your dental health, be sure to seek medical attention. Your entire body needs healing. Fluoride has been found to boost the strength of the tooth enamel. Consequently, you are better protected against the erosive acid effects. It is better to go into offensive if you want the best shot at protecting your teeth. You should act proactively when handling the health of your teeth. Regular dental checkups and cleaning every six months will help you achieve the best possible results for your dental health. References (2015). Dentist in Glendale AZ | Phoenix Arizona Family Dentists. The Truth about Tooth Erosion: How to repair tooth enamel? Retrieved February 19, 2017, from http://www.arizonafamilydental.com/blog/weak-enamel-truth-about-tooth-erosion/ Hoffman. (n.d.). WebMD - Better information. Better health. The Teeth (Human Anatomy): Diagram, Names, Number, and Conditions. Retrieved February 19, 2017, from http://www.webmd.com/oral-health/picture-of-the-teeth#1 Terry, Trajtenberg, Blatz, & Leinfelder. (2008). DentalAEGIS. A Review of Dental Tissue Microstructure, Biomodification, and Adhesion | special-issues | dentalaegis.com. Retrieved February 19, 2017, from http://www.dentalaegis.com/special-issues/2008/02/review-of-dental-tissue-microstructure-biomodification-and-adhesion (n.d.). WebMD - Better information. Better health. Tooth Enamel: Erosion and Restoration. Retrieved February 19, 2017, from http://www.webmd.com/oral-health/guide/tooth-enamel-erosion-restoration#2 Read the full article

0 notes

Text

304 Stainless Steel I Beam Supplier

SD-steel is a leading supplier of high-quality 304 Stainless Steel I Beams, catering to a diverse range of industries worldwide. Our commitment to excellence and reliability ensures that our products meet the highest standards of quality and performance. With a strong focus on customer satisfaction, we provide robust solutions for various applications, backed by our extensive experience and expertise in the steel industry.

Product Overview

Our 304 Stainless Steel I Beams are designed to offer exceptional strength, durability, and corrosion resistance. These beams are ideal for structural applications where both aesthetic appeal and functional integrity are paramount. Whether you're working on construction projects, manufacturing equipment, or any other application requiring sturdy and reliable materials, our I Beams are engineered to deliver superior performance under demanding conditions. Here’s a detailed overview of our product, including specifications, material properties, and usage scenarios.

Product Description

| Width (mm) | Height (mm) | Thickness (mm) |

|------------------|--------------|---------------|-----------------|

| Standard Sizes | 100x100x12 mm to 400x400x13 mm |

|------------------|-------------|

| Yield Strength | 205 MPa |

| Ultimate Tensile Strength | 515 MPa |

| Hardness | 190 HBW |

| Elongation | 40% |

| Modulus of Elasticity | 193 GPa |

| Poisson's Ratio | 0.28 |

| Young's Modulus | 200 GPa |

| Typical Uses | Structural Support, Frameworks, Bridges, Automotive parts |

| Applications | Construction, Machinery, Transportation |

Dimensions and Specifications

| Size (mm) | Depth (mm) | Flange Width (mm) | Web Thickness (mm) |

|-----------------|-------------|----------------|-----------------|

| Length | 6000 mm | 100 | 100 | 12 |

| Flexural Rigidity | 193 GPa | | |

| Thermal Conductivity | 16.3 W/m.K | | |

Usage Scenarios

304 Stainless Steel I Beams are commonly used in structural frameworks, automotive components, and marine applications. |

Application Scenarios

These beams are ideal for structural supports, bridges, and heavy-duty machinery. Their high tensile strength and toughness make them suitable for structural integrity and long-lasting performance. |

Company Strength

SD-steel prides itself on consistent quality and precision. We ensure each beam meets international standards such as ASTM A276, EN 10088:2005, ASME SA-240/SA-312 TP304L | | |

| Density | 7.93 g/cm³ | | |

| | | | |

| | | | |

Common Applications

Construction: Used in building structures, bridges, and infrastructure projects.

Automotive Industry: Ideal for automotive parts and components. |

|-----------------|--------------|----------------|----------------|

| Thickness | 100 | 100 | 12 |

|-----------------|--------------|----------------|----------------|

| Thickness | 100 | 100 | 12 |

Key Features

Corrosion Resistance: Excellent resistance to oxidation at temperatures up to 870°C. | | |

|-----------------|----------------|----------------|----------------|

| | | | |

| | | | |

Frequently Asked Questions

Q: What are the benefits of using 304 Stainless Steel? |

| | | | |

| | | | |

| | | | |

Why Choose SD-steel?

Durability: Suitable for outdoor and indoor applications. |

Versatility: Versatile for multiple uses. |

Aesthetics: Polished surfaces enhance visual appeal and structural integrity. |

FAQs

Q: What are the typical applications of 300°C | | |

|-----------------|----------------|----------------|----------------|

| | | | |

| | | | |

Contact Us

For inquiries, please contact us at +65 83016969 | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | | |

| | | |

加飞机@yuantou2048

Stainless Steel Capillary Tube

Stainless Steel Round Bar

0 notes

Text

Fixed Base Office Chairs: Silent Guardians of Professional Spaces

At NASA’s Jet Propulsion Laboratory, engineers are using fixed-base chairs to calibrate Mars rover parts, where even a 0.01-degree angle deviation could lead to catastrophic consequences. This extreme demand for absolute stability has made fixed-base office chairs irreplaceable in professional fields. The non-rotating design is not just a physical limitation, but also a biomechanical safeguard for precise work.

1. Precise Control of Mechanical Structure

The aerospace-grade aluminum alloy frame, optimized through topology, reduces structural stress concentration by 62%. The four-point contact base design achieves 98% uniformity in force distribution, improving by 23% compared to traditional five-legged bases. Vibration tests at MIT’s Mechanical Laboratory show that fixed-base chairs have only 0.13mm displacement under a 6-point earthquake simulation, providing a stable platform for precision tasks.

The ergonomic locking mechanism includes three layers of safety redundancy: electromagnetic latch (response time 0.2 seconds), mechanical buckle (weight capacity of 500kg), and hydraulic damping (displacement ≤0.05mm). Boeing’s application data shows this design reduces assembly errors to one-seventh of rotating chairs.

The fine-tuning system allows for millimeter-level positioning, with a footrest integrated with a digital angle gauge (precision ±0.1°) and a backrest adjustment gear track (0.5mm per tooth). This creates a fully personalized mechanical support system. Clinical tests show a 41% reduction in muscle fatigue when maintaining a fixed posture.

2. Breakthrough Innovations in Material Science

Carbon Fiber-Kevlar Composite Seat Cushion This combination of aerospace materials ensures surface modulus reaches 120GPa for rigidity and features a honeycomb structure that absorbs 70% of vibration energy. In semiconductor cleanroom tests, the material dust emission is only 0.03μg/m³, meeting ISO Class 3 standards.

Bionic Coating Innovation The self-healing polyurethane layer developed by Germany’s Covestro contains 5 million microcapsules/cm². Scratches larger than 3μm are repaired at a molecular level within 40 seconds, and the surface friction coefficient remains stable between 0.35-0.55, extending the product lifespan to 15 years.

Bio-Based Composite Materials DSM’s EcoPaXX seat base material, made from 51% castor oil extract, has reduced its carbon footprint by 68% compared to traditional plastics, while its impact resistance has increased to 42kJ/m², certified by UL ECVP 2809’s closed-loop standards.

3. Professional Adaptation in Specialized Designs

In Rolls-Royce’s aircraft engine assembly line, fixed-base chairs and workbenches form a golden triangle of support: the seat angle is locked at 5°, and the armrest height tolerance is ±1.5mm. This configuration improves assembly efficiency by 37%, and reduces repetitive strain injuries to one-fourth of the industry average.

Medical Surgery Chairs Integrated with a sterile control system, the base is made from 316L stainless steel, and the surface is electro-polished to Ra≤0.8μm. The gas lift system allows micro-adjustments down to 0.01mm, and the temperature-sensing seat maintains a consistent 36.5-37°C temperature range, speeding up wound healing by 19%.

Esports Training Chairs Equipped with a neurofeedback system, the seat features 32-channel electromyography sensors to monitor posture stability. When muscle tremor frequency exceeds the threshold, the armrest’s tactile feedback module provides an immediate warning, enhancing the precision of professional players' operations by 28%.

4. Technology-Driven Health Management

Dynamic Pressure Distribution Monitoring System This system includes 2048 sensor units that map the pressure distribution between the ischium and femur. When localized pressure exceeds 32kPa, the air cushions automatically adjust support, reducing the risk of sciatic nerve compression by 63%, according to clinical trials.

Biological Rhythm Lighting System The ActiveLight technology from Philips is integrated into the chair’s backrest with full-spectrum LEDs. The system automatically adjusts color temperature based on circadian rhythms—6500K blue light in the morning to boost cognition, and 3000K amber light in the evening to promote melatonin secretion, reducing work efficiency fluctuations by 41%.

Aerodynamic Design for Local Microclimate Optimization A laminar airflow channel is set beneath the seat (airflow speed of 0.25m/s ±5%) and is coupled with a HEPA 13-level filtration system. Air quality monitoring shows that the PM0.3 concentration in the breathing zone remains below 12μg/m³, increasing brain oxygen levels by 18%.

At the University of Tokyo’s ultra-precision machining laboratory, quantum-level stable chairs are creating miracles: using superconducting magnetic levitation technology, 99.97% of ground vibration is neutralized, achieving a nanometer-level processing precision of 0.5nm Ra. This shows that fixed-base chairs have evolved from physical limitations into technology enablers, releasing the maximum potential of human creativity through absolute stability. When biomechanics, material science, and environmental control deeply integrate, fixed-base chairs no longer restrict but become the solid foundation of professional excellence.

Choose Ekintop Furniture, and we will provide you with the best solutions for your professional workspace needs.

0 notes

Text

youtube

Welcome to Episode 10 of our Strength of Materials - Engineering Basics series!

🚀 In this episode, we dive into bending mechanics, exploring how beams respond to different loads, their bending behavior, and the resulting deflection. Learn step-by-step about shear forces, bending moments, and Bernoulli's bending equation, making beam analysis easier and engaging.

📊 Perfect for engineering students and professionals looking to sharpen their understanding of structural mechanics!

💡 Key Highlights: 📐 Understanding Point Loads, UDL, and UVL on SFD & BMD. 🔍 Derivation of bending formulas and explanation of bending behavior. 📊 What is a neutral axis and how to identify it? ⚖️ Concept of Moment of Resistance and its role in beam bending. 🛠️ Bernoulli's Bending Equation and Section Modulus derivation. 📉 Deflection of beams: Calculations and significance. 🚀 Introduction to Flexural Rigidity and elastic curves in beams.

Check out the episodes of this series here! https://www.youtube.com/playlist?list=PL9-f9hWLZS62gOBDTQ_SoBVyTpghK0fAn

#youtube#skilllync#mechanicalengineering#engineering#automotiveengineering#stressstrain#stressanalysis

0 notes

Text

Pressure Sensitive Adhesives Market-Industry Forecast, 2024–2030.

Pressure Sensitive Adhesives Market Overview

Request Sample:

The increasing usage of resins such as silicone polymers, polyisobutene, and elastomers, generally synthetic rubber as the base polymer owing to its functionality and durability, in various end-use sectors will also substantially drive the demand for PSAs. Nitrocellulose adhesive, hydrogenated hydrocarbon resins, and ethylene-vinyl acetate are the thermoplastic resins generally employed in pressure-sensitive adhesives. Moreover, the increasing usage of bio-based pressure-sensitive adhesives and advancements in pressure-sensitive adhesive tapes is expected to offer enormous market expansion opportunities and boost the pressure-sensitive adhesives (PSA) industry in the projected time frame.

Impact of Covid-19

The COVID-19 pandemic and its disruption to several manufacturing activities declined the growth of the pressure sensitive adhesives market in the year 2020. Due to the supply chain disruption and insufficient labor, the manufacturing activities of the packaging, automotive, and electrical and electronic industries were set at a pause which affected the market growth. Furthermore, considering the new government norms and reopening of several industries, it is presumed that the market for pressure sensitive adhesives will return to normal conditions.

Inquiry before Buying :

Report Coverage

The: “Pressure Sensitive Adhesives Market Report — Forecast (2024–2030)”, by IndustryARC, covers an in-depth analysis of the following segments of the pressure sensitive adhesives Market.

By Formulation: Water-based, Solvent-based, Hot Melt, Others

By Resin Type: Elastomer (Natural and Synthetic), Acrylic, Silicone, Ethylene-Vinyl Acetate, Polyvinyl Ether, Polyisobutene, Polybutadiene, and Others

By Application: Tapes, Labels, Graphics, and Others

By End Use Industry: Construction, Automotive, Electronics, Medical and Healthcare, Paper, Furniture, Renewable Energy, Wood Working, and Others

By Geography: North America (USA, Canada, and Mexico), Europe (UK, Germany, Italy, France, Spain, Netherlands, Russia, Belgium, and Rest of Europe), Asia Pacific (China, Japan, India, South Korea, Australia and New Zealand, Taiwan, Indonesia, Malaysia, and Rest of Asia Pacific),South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), and RoW (Middle East and Africa)

Schedule A Call :

Key Takeaways

Asia-pacific region dominated the pressure sensitive adhesives Market due to the rising government investments in the healthcare, electronics, and construction and infrastructure segments in countries such as China, India, South Korea, and Australia.

Current product innovations to improve modulus of elasticity and rigidity are expected to broaden the application range of pressure sensitive adhesives in structural applications and drive the growth of the market in the projected period.

Rising demand for silicone polymers based pressure sensitive adhesive (PSA) in the electronic and medical industry will further drive the growth of the pressure sensitive adhesives market.

Low adhesive strength provided by the pressure-sensitive adhesives (PSA) would further affect the growth of the market over the forecast period.

For More Details on This Report — Request for Sample

Pressure Sensitive Adhesives Market Segment Analysis- By Resin Type

Acrylic resin held the largest share in the pressure sensitive adhesives market in 2020. Acrylic PSAs are widely employed in a variety of applications due to the saturated nature of the polymer and its subsequent oxidation resistance. Also, the acrylic PSAs have good physical properties in general for a wide range of long-term exterior applications. Owing to its attractive properties such as non-flammable, easy to handle, low level of contamination, little tendency to migrate, good resistance to sunlight, oxygen and heat, and offer adhesion, cohesion and tack, the demand for acrylic resins is anticipated to rise. With the increasing demand for acrylic resin, the market for pressure sensitive adhesives will also increase, which will further drive the market growth in the forecast period.

Pressure Sensitive Adhesives Market Segment Analysis- By Application

Tapes held the largest share in the pressure sensitive adhesives market in 2020. Rising demand for tapes owing to its low cost and ease of use when compared to traditional methods is estimated to uplift the growth of the market. Due to the advantageous properties of pressure sensitive adhesives tapes such as reduced assembly time, vibration dampening and noise reduction eliminates the need for surface refinishing, and others has raised the demand for these tapes in various end use industries. Moreover, pressure sensitive adhesive tapes do not require the use of a water, solvent, or heat to activate. The amount of pressure used to apply the adhesive to the surface has a direct impact on the bond. Rising demand for polypropylene tapes owing to its flexibility and strength, and good low temperature characteristics will further drive the market growth. Thus, rising demand and production for pressure sensitive adhesives tapes is estimated to drive the pressure sensitive adhesives market growth over the forecast period.

Pressure Sensitive Adhesives Market Segment Analysis- By End Use Industry

The packaging sector held the largest share in the pressure sensitive adhesives market in 2020 and is projected to grow at a CAGR of 6% during the forecast period 2021–2026. There are two types of packaging namely flexible and rigid, pressure sensitive adhesives (PSAs) are used in these packaging depending on the application’s suitability. These adhesives are used in the packaging of electronics and electrical devices, hygiene and medical packaging, drug delivery packaging, construction sector transit packaging, automotive-related logistics packaging, and consumer and industrial goods packaging, among others. Furthermore, the increasing use of packaging tapes such as polypropylene tapes in a variety of applications including packaging transport, cartons, goods, warehousing, and logistics is estimated to uplift the market growth. PSAs are used in packaging sectors to improve consumer appeal through graphics. Therefore, the pressure sensitive adhesives market is estimated to see an upsurge over the forecast period with the growing packaging industry.

Pressure Sensitive Adhesives Market Segment Analysis– By Geography

The Asia Pacific region held the largest share of more than 39% in the pressure sensitive adhesives market in 2020. Globally, the region’s growth in the market is mainly due to strong economic growth and heavy investments in the packaging, construction, automotive, and electronic industries. Also, the rising adoption of various resins such as polyisobutene, silicone polymers, and elastomers in emerging economies has uplifted the market growth. APAC is increasing in importance as a worldwide trade and business hub. The market for pressure sensitive adhesives is expected to rise as government investments in many medical and electronic projects increase in countries such as China, India, Japan, and South Korea. The Union Cabinet authorized the production-linked incentive (PLI) plan in ten critical industries (including electronics and white products) on November 11, 2020, in order to strengthen India’s manufacturing capabilities, increase exports, and promote the “Atmanirbhar Bharat” program as per the India Brand Equity Foundation. Thus, such initiatives taken by the government for new projects will raise the demand for pressure sensitive adhesives market in the forecast period.

Pressure Sensitive Adhesives Market Drivers

Increasing Demand for Bio-based Pressure Sensitive Adhesives

Plant-derived resources are used as a raw material in bio-based PSAs. The biomass content of a bio-based material used in an adhesive product is expressed as a percentage (dry weight basis). Also, the bio-based PSAs are considered “carbon neutral” because their plant-derived raw materials absorb the same amount of CO2 during production as they emit when incinerated at the end of product life. Additionally, there is no overall increase in greenhouse gases that can cause global warming, resulting in significantly lower CO2 emissions when compared to traditional, purely petroleum-based formulations. Furthermore, most of the raw materials used for conventional PSAs are derived from fossil fuels, which are limited in supply. Bio-based PSAs can help reduce the demand for petroleum sources by replacing them with renewable plant-based materials. Thus, due to the above mentioned factors the demand for bio-based PSAs is predicted to rise, which would further drive the growth of the pressure sensitive adhesives in the projected period.

Rising Demand from the Electronics Industry will Lead Towards the Growth of the Market

For shock absorption, thermal and electrical conductivity, electromagnetic shielding, and optical characteristics, among other factors, pressure-sensitive adhesives (PSA) are increasingly being utilized in the electronics industry. Because of its high transparency, weather resilience, heat resistance, and adhesion strength, acrylic and synthetic rubber PSA composed of hydrogenated hydrocarbon resin is widely used in the display, mobile phones, and automotive applications. PSA also provides higher processability than liquid-type adhesives since it can stick to three-dimensional substrates without the need for a hardening process. With the development of new innovative products the market for pressure sensitive adhesives is estimated to rise. For instance, in 2020 DELO has developed adhesives that has similar properties to (double-sided) adhesive tapes but is applied in liquid form and that can be extensively used in the electronic applications such as smartphone speakers or display frames. Growing demand of pressure sensitive adhesives in the electronics industry is therefore expected to drive market growth during the forecast era.

Buy Now :

Pressure Sensitive Adhesives Market Challenges

Low Adhesive Strength will Hamper the Market Growth

The main challenges faced by the pressure sensitive adhesives (PSAs) are that the adhesive strength (shear and peel) is low and that it is generally sensitive to high temperatures and solvents. As a result, most pressure sensitive adhesives are unsuitable for high strength or structural applications. They are frequently used with substrates that are relatively weak, such as paper or film. Pressure sensitive adhesives are also unsuitable for rough surfaces and are relatively costly in terms of cost per bond area. Thus, due to the above mentioned properties the market growth for pressure sensitive adhesives (PSAs) is estimated to face challenges in the upcoming years.

Pressure Sensitive Adhesives Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the pressure sensitive adhesives market. Major players in the pressure sensitive adhesives market are Henkel AG & Company KGAA, Arkema Group, The Dow Chemical Company, H.B. Fuller, Avery Dennison Corporation, Sika AG, 3M Company, Scapa Group, and Ashland Inc., among others.

Acquisitions/Technology Launches

In May 2021, with the planned acquisition of Edge Adhesives Texas, a complementary asset in pressure sensitive adhesives and hot-melt adhesive tapes for residential construction, Arkema Group increased its Bostik offering of high performance adhesives in the United States.

Key Market Players:

The Top 5 companies in the Pressure Sensitive Adhesives Market are:

Henkel AG & Co., KGaA.

Arkema Group

Dow Chemical Company

H.B. Fuller

Sika AG

For more Chemicals and Materials Market reports — Please click here

0 notes

Text

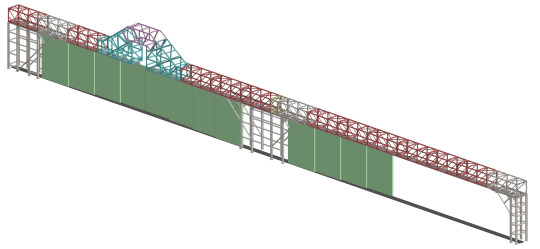

Structural Design and FEA Simulation of Aircraft Hangar Outrigger Door Structure

The structural design and simulation of an aircraft hangar outrigger door are pivotal in ensuring the reliability and safety of this essential part of the hangar infrastructure. In this blog, we explore the technical aspects of the design and finite element analysis (FEA) simulation of such structures, with a focus on optimizing performance, ensuring durability, and meeting stringent safety standards.

Overview of Aircraft Hangar Outrigger Door Structure

An outrigger door is typically designed as part of large hangar facilities, providing additional clearance for the aircraft. Its design must withstand the operational loads and environmental conditions, ensuring longevity and minimal maintenance.

Key Structural Components:

Trusses: Large trusses (e.g., TRUSS-1 to TRUSS-5 as indicated in design layouts) form the backbone of the structure, distributing loads efficiently.

Vertical Columns: These columns, often consisting of robust materials, support the trusses and provide vertical stability.

Rails and Supports: The top and bottom rails, supported by various beams such as NPB (narrow parallel flange beams) and ISMB (Indian Standard Medium Beams), guide the door’s movement and secure the structure.

These components, made of high-strength steel, are interconnected with bracing and rib structures to provide both rigidity and flexibility under load.

Structural Design Considerations

The design of the outrigger door must account for several factors, including:

Load Distribution: The door structure should evenly distribute loads, including the weight of the door itself and dynamic forces from wind or operational activities.

Material Selection: High-strength steel, such as ISMB beams, is often used for its ability to handle the high loads and dynamic stresses encountered during the door’s operation.

Space Optimization: As seen in the design, dimensions and spacing of the trusses, vertical columns, and rails are meticulously calculated to ensure space efficiency without compromising structural integrity.

Thermal and Environmental Stresses: The door must withstand environmental factors such as temperature variations, wind loads, and possible seismic activity.

Finite Element Analysis (FEA) for Structural Integrity

FEA is a crucial step in validating the design of the outrigger door structure. By simulating real-world conditions, engineers can predict how the structure will perform under various loads and stresses.

FEA Simulation Process:

Model Creation: A 3D model of the door structure is created based on the design drawings, including all trusses, columns, and rails.

Material Properties: The material properties (elastic modulus, yield strength, etc.) are input into the simulation software to ensure accurate behavior during loading.

Meshing: The structure is divided into small elements for analysis. A finer mesh may be applied to critical areas like the junctions of trusses and vertical columns, where stress concentrations are expected.

Boundary Conditions: Realistic boundary conditions, such as fixed supports at the base of the columns and loading from the door’s operation or environmental forces, are applied.

Load Cases: Various load cases, including dead load (structure’s weight), live load (operational forces), and environmental forces (wind, seismic), are simulated to analyze the stress and deformation of the structure.

Results and Optimization

The FEA simulation results are used to assess:

Stress Distribution: The software highlights regions with high stress concentrations. If the stress exceeds material limits, design modifications are made to redistribute the load.

Deformation: Excessive deformation, especially in the rails or trusses, can affect the door’s function. The simulation helps ensure that deformations remain within acceptable limits.

Factor of Safety: A critical outcome of the analysis is ensuring that the design meets the required factor of safety, accounting for uncertainties in loading conditions and material properties.

Conclusion

The structural design and FEA simulation of an aircraft hangar outrigger door structure are essential processes in ensuring the reliability and safety of the door system. By combining robust design principles with advanced simulation techniques, engineers can create a structure that withstands operational and environmental challenges while maintaining optimal performance throughout its lifecycle.

This detailed approach not only ensures compliance with safety standards but also reduces the risk of future structural failures, ensuring smooth operations for the aircraft hangar facility. Graphler Technology Solution provides CFD Analysis services, Engineering Animation services, stress analysis services and structural design services They have well expertise team with 10 yrs of industrial knowledge. Partnering up with the best structural analysis services provider or top product design companies will help you to discover new ideas.

0 notes

Video

youtube

Earthquake Physics Apparent Stress Explained

In earthquake physics, apparent stress is a measure used to estimate the overall energy released by an earthquake relative to the size of the event. It provides insight into the efficiency of energy conversion from seismic strain into radiated seismic energy. Here's a breakdown: 1. Apparent Stress Formula: Apparent stress (σa) is given by the formula: σa=M0μEr Where: μ is the shear modulus of the crustal rock (a constant representing the rigidity of the material). Er is the radiated seismic energy (the energy that is released as seismic waves). M0 is the seismic moment (a measure of the total energy release based on the fault slip and area). 2. Physical Meaning: Seismic Moment (M₀): This is a measure of the earthquake's total energy release, related to fault slip, the fault area, and the rigidity of the material. Radiated Energy (Eᵣ): The portion of energy that is radiated away as seismic waves, contributing to the ground shaking felt during an earthquake. Apparent Stress (σa): It reflects the ratio of the energy radiated as seismic waves to the seismic moment. Essentially, it gauges how much of the strain energy stored in the earth's crust during tectonic loading is efficiently converted into seismic energy. A higher apparent stress suggests that a larger portion of the earthquake's energy was radiated, potentially resulting in more intense shaking for a given event size. 3. Importance in Earthquake Dynamics: Energy Budget: Apparent stress is part of the earthquake energy budget. It helps researchers understand how much energy goes into radiated seismic waves (which cause ground shaking) versus how much energy might be dissipated as heat or through other processes (like frictional resistance on the fault). Seismic Hazard Assessment: By examining apparent stress across various earthquakes, seismologists can make inferences about the efficiency of different fault systems and their potential to generate strong shaking. 4. Variation Across Earthquakes: Apparent stress can vary significantly from one earthquake to another. Earthquakes with high apparent stress tend to radiate more seismic energy for a given seismic moment, meaning they can cause stronger ground shaking even if they have similar seismic moments compared to other events. Conclusion: Apparent stress provides a crucial window into the efficiency of seismic energy release during an earthquake and helps in understanding the potential ground shaking severity associated with different seismic events.

More Info: physicistparticle.com

Contact : [email protected]

0 notes

Text

Flexural/Modulus Testing as per ASTM D790 — Kiyo R&D Center and Laboratory

Flexural/Modulus Testing Under ASTM D790: Applications and Benefits

Introduction

ASTM D790 provides a comprehensive approach to testing the flexural properties of rigid plastics. This standard test method is crucial for determining how materials perform under bending loads, influencing their applications in various sectors. This blog explores the practical applications and benefits of ASTM D790 flexural testing.

Applications of ASTM D790 Testing

Automotive Industry: In automotive manufacturing, plastic components such as bumpers and dashboards undergo flexural testing to ensure they can withstand impacts and stresses during use.

Aerospace Sector: Aerospace components often utilize composite materials, which are tested for their flexural properties to ensure they meet rigorous performance standards.

Construction: Building materials, including plastics and composites, are tested for their ability to endure bending stresses, ensuring safety and durability in construction applications.

Consumer Products: From household items to packaging materials, flexural testing ensures that plastic products meet durability and performance requirements.

Benefits of Flexural Testing

Enhanced Product Design: By understanding how materials bend and deform, engineers can design products with improved performance characteristics.

Improved Quality Control: Regular flexural testing helps manufacturers maintain high-quality standards by identifying any deviations from required specifications.

Informed Material Selection: Testing provides critical data that guides the selection of materials based on their flexural strength and modulus, ensuring that they are suitable for their intended use.

Regulatory Compliance: Flexural testing helps ensure that products meet industry standards and regulations, reducing the risk of non-compliance.

Conclusion

ASTM D790 flexural testing is integral to various industries, offering numerous benefits from improved product design to enhanced quality control. By applying this standard, businesses can ensure that their products perform reliably and meet the necessary standards for safety and durability.

For More Info About Flexural/Modulus Testing as per ASTM D790 At Kiyo R&D Center and Laboratory, Flexural/Modulus Testing as per ASTM D790, Kiyo R&D Center and Laboratory, Kiyorndlabs, Flexural/Modulus Testing as per ASTM D790 — Kiyo R&D Center and Laboratory

0 notes