#paper structures to micro folds

Explore tagged Tumblr posts

Text

Geometric Paper Sculptures from Matthew Shlian

#geometric works that are composed of tight-knit tessellations#paper structures to micro folds#TELEMETRY#paper engineering as a metaphor for scientific principals#composed of tight-knit tessellations#artistic inspiration

1 note

·

View note

Text

I saw some days prior how a LEGO-like independent brick company had a set of the former WTC (the one in New York City) but the cheaper small even called "micro" version still was like 40 U.S. dollars.

But then I remembered those 3-D structures one can build out of papercraft sheets you cut out and then fold and glue as indicated. Back when I was a wee lad, I bought many of those from a local stationery's as they had them exhibed on the ceiling and shelves; so as I printed out one for the WTC and put it together I got reminded of those times.

And lo and behold, now I have my own personal little paper model of the complex.

2 notes

·

View notes

Note

I'm on my knees BEGGING for an Austin Powers cosplay from you holy shit you would make it insane!!! Side question: My biggest issue I have with sewing is deciding which fabric I should use for specific projects/pieces. Trying to find an answer on that online is not easy as usually tutorials just say like "With your fabric, do X" without saying which fabric to look for 😭How do you personally choose your fabric when doing your cosplays? Do you have a cheat-sheet of like what to look for?

I'm about to have a micro-lull in projects so who knows! maybe now is the time for Austin Powers.

To tell true, my strategy for choosing fabrics is kind of a goofy one. if you look at everything i've made, you'll notice that I tend to use a lot of the same fabrics repeatedly. Microsuede, mystique spandex, pleather, stretch twill/sateen, stretch denim, and matte satins. I dont have a lot of access to fabric stores anymore where I can go in person choose it based on inspection, so instead I take what I know and work with it! So I tend to either choose projects based on a fabric that I'm familiar with, or I take the design and make it compatible with one I like. for example on Thistle, i'm sure using something like taffeta, dupioni, or velvet wouldve worked for his design, but I chose microsuede because I like it and I leaned into properties it has like a textured appearance and stiffness.

But that being said, even if you help yourself by working with a more limited scope of fabrics, how do you choose between fabric A and fabric B for an application? Typically what influences how a fabric behaves is its weight (ie is this a super light fabric that blows in the breeze, or something heavy like what you might find on a couch), its drape (will this fabric hang straight down or be stiff and fold more like paper), and its finish (is this something shiny and reflective, or matte? does it have a texture, or a totally smooth surface?).

in general if you want something fitted and structured like a crisp jacket, bodice, or a skirt that holds its shape, you tend to want heavier, stiffer fabrics. if you want something to look soft and flowy, then lighter, more draping fabrics are best. (thers also the mechanical issue that if you're working on something big like say a ballgown, if you chose a heavy fabric, you will need to account for the scaling weight. making a short skirt vs a long skirt out of a heavy fabric will have very different outcomes.) it's hard to give specific advice about fabrics in general, since each project has its own specific needs and each project can be made with any variety of fabrics, but will result in different appearances in the overall garment.

BUT i do have a mini word of wisdom, which is if you have a fabric in mind but you're not sure it will work, you can always try looking up like....."matte satin dresses", or "suede jackets" and see if you can find any examples of the fabric you're thinking of being used in the garment you want to make (or in general) to check if it gives the look you want. you can even go backwards and look up like...."prince costume" and try to identify common fabrics that usually come up for that garment style.

12 notes

·

View notes

Text

Fendi’s Finest: The Must-Have Bags of 2025

Fashion may be fleeting, but Fendi’s bags are forever. The Italian powerhouse continues to redefine luxury with designs that blend timeless craftsmanship and contemporary flair. Whether you’re a collector of iconic classics or a devotee of modern reinvention, Fendi’s 2025 lineup (https://bagcodex.com/fendi/) offers something irresistibly chic. Here are the standout models worth investing in this year.

1. The Peekaboo Evolution – A Legacy Reimagined

A bag that needs no introduction, the Peekaboo remains an undisputed icon. In 2025, Fendi takes this beloved silhouette to new heights with architectural updates—sculptural hardware, contrast lining, and ultra-supple leathers that feel like a second skin. The latest iteration also includes customizable panels, allowing wearers to express their personality with interchangeable textures and hues. Think of it as a sartorial mood ring—one bag, infinite possibilities.

2. The Baguette XXL – Oversized and Over-the-Top

The legendary Baguette is no stranger to reinvention, and this season, it gets a dramatic, supersized makeover. With enough room to carry your essentials (and then some), the Baguette XXL makes a bold statement, whether slung effortlessly over the shoulder or tucked under the arm with casual defiance. The 2025 version comes in cloud-soft nappa leather and futuristic metallics—because if you’re going big, you might as well shine.

3. The Origami Tote – Sculptural Sophistication

A newcomer to the Fendi family, the Origami Tote is the definition of understated elegance. Inspired by the intricate folds of Japanese paper art, this bag transforms effortlessly from a structured work tote into a relaxed carryall with a flick of the wrist. It’s where tradition meets innovation—a piece designed for women who move between boardrooms and boutiques with equal finesse.

4. The Nano Fendigraphy – Micro Magic

If 2025 has a fashion mantra, it’s that smaller is better. Enter the Nano Fendigraphy, a tiny wonder that delivers maximum impact. With the iconic curved shape of its full-sized predecessor, this micro bag dangles delicately from wrists, belt loops, or larger bags—because in a world obsessed with details, sometimes the smallest things make the biggest impression.

5. The FF Chain Pouch – Sleek, Chic, and Ready for Anything

Minimalism meets decadence in this streamlined pouch adorned with the unmistakable FF logo. Designed for those who prefer a fuss-free yet striking statement, the FF Chain Pouch works as an evening clutch or a crossbody companion for daytime elegance. The color palette is pure indulgence: deep Bordeaux, icy platinum, and a signature Fendi yellow that radiates effortless confidence.

Final Thoughts

Fendi’s 2025 collection proves once again that the house understands the modern woman’s desires—bags that are both practical and poetic, classic yet cutting-edge. Whether you opt for an oversized icon or a miniature masterpiece, each piece is an invitation to indulge in luxury, one perfectly stitched seam at a time.

0 notes

Text

Micro Flute Paper Market Size, Share, and Industry Analysis

Rising Demand for Lightweight and Sustainable Packaging Solutions Drives Growth in the Micro Flute Paper Market.

The Micro Flute Paper Marketsize was USD 74.91 billion in 2023 and is expected to Reach USD 120.99 billion by 2032 and grow at a CAGR of 5.47% over the forecast period of 2024-2032.

The global micro flute paper market is driven by the increasing demand for lightweight, durable, and eco-friendly packaging solutions. Micro flute paper, known for its high strength-to-weight ratio and excellent cushioning properties, is widely used in consumer goods, food & beverage, electronics, and e-commerce packaging. The rise of sustainable packaging solutions, regulatory restrictions on plastic packaging, and the booming online retail sector are key factors fueling market expansion. Additionally, improvements in printing technology have made micro flute paper a preferred choice for attractive and brand-enhancing packaging designs.

Key Players in the Micro Flute Paper Market

Novolex Holdings (Sustainable packaging solutions, paper-based packaging products)

Smurfit Kappa (Corrugated packaging, lightweight micro flute boards)

Van Genechten Packaging (Folding cartons, micro flute packaging for food and beverages)

DS Smith Plc (Recyclable packaging solutions, micro flute corrugated boxes)

Mondi Group (Eco-friendly corrugated packaging, specialty kraft paper)

Olmuksan International Paper (Corrugated boxes, micro flute packaging materials)

International Paper (Industrial packaging, lightweight corrugated boards)

Stora Enso (Renewable packaging materials, corrugated micro flute boards)

Netpak (Custom packaging, micro flute paperboard solutions)

WestRock Paper LLC (High-performance corrugated packaging, micro flute containers)

Future Scope and Emerging Trends

The micro flute paper market is evolving rapidly with a strong focus on sustainability, recyclability, and enhanced printability. As brands and consumers seek eco-friendly alternatives to plastic packaging, micro flute paper is gaining prominence due to its biodegradability and lightweight structure. Innovations in coating technologies and digital printing are further improving the market appeal, allowing for customized branding and high-quality graphics. The expansion of e-commerce and direct-to-consumer businesses has also led to an increased demand for protective, compact, and visually appealing packaging solutions. Additionally, the use of recycled fiber in micro flute paper production is a growing trend, reducing the carbon footprint and aligning with corporate sustainability goals.

Key Points

Rising Demand for Sustainable Packaging: Micro flute paper serves as an alternative to plastic-based packaging.

Expansion of E-Commerce and Retail Packaging: Lightweight and strong packaging solutions for online shipments.

Advancements in Printing and Coating Technologies: Improved branding and custom packaging options.

Growing Use of Recycled Fiber: Enhancing eco-friendliness and reducing environmental impact.

Regulatory Push for Green Packaging: Governments and organizations promoting sustainable materials.

Conclusion

The micro flute paper market is poised for strong growth, driven by rising consumer awareness, sustainability trends, and increasing adoption across multiple industries. Companies investing in eco-friendly materials, advanced printing techniques, and recyclable packaging solutions will gain a competitive advantage. As global industries transition toward sustainable and lightweight packaging, micro flute paper will play a key role in shaping the future of environmentally responsible packaging solutions.

Read Full Report: https://www.snsinsider.com/reports/micro-flute-paper-market-3676

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Micro Flute Paper Market#Micro Flute Paper Market Size#Micro Flute Paper Market Share#Micro Flute Paper Market Report#Micro Flute Paper Market Forecast

0 notes

Text

GPS Watch Tracker Market Size, Share, Volume, Trends, Demand, Growth and Forecast Report 2024-2032

GPS Watch Tracker Market provides in-depth analysis of the market state of GPS Watch Tracker manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of GPS Watch Tracker in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of GPS Watch Tracker Market Report:

The report offers a comprehensive and broad perspective on the global GPS Watch Tracker Market.

The market statistics represented in different GPS Watch Tracker segments offers complete industry picture.

Market growth drivers, challenges affecting the development of GPS Watch Tracker are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of GPS Watch Tracker.

Major stakeholders, key companies GPS Watch Tracker, investment feasibility and new market entrants study is offered.

Development scope of GPS Watch Tracker in each market segment is covered in this report. The macro and micro-economic factors affecting the GPS Watch Tracker Market

Advancement is elaborated in this report. The upstream and downstream components of GPS Watch Tracker and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/gps-watch-tracker-market-100560

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Medical or Healthcare Scales MarketMarket

Industrial Labels MarketMarket Share

Albendazole MarketMarket Growth Rate

Semiconductor Vacuum Pump After MarketMarket Forecast

Global Metal Expansion Joints MarketMarket Size

Customer Experience Management Software MarketMarket Growth

Control Cable MarketMarket Analysis

Dental Ultrasonic Scaler MarketMarket Size

Global Organic Pet Food MarketMarket Share

Global Next Generation Sequencing (NGS) Data Analysis MarketMarket Growth

Transcatheter Heart Valve Replacement and Repair MarketMarket

Cyber Warfare MarketMarket Share

Computational Lithography Software MarketMarket Growth Rate

Refurbished Medical Devices MarketMarket Forecast

Global Biaxially Oriented Polypropylene (BOPP) Films MarketMarket Size

Stereolithography 3D Printing MarketMarket Growth

BAW Filters MarketMarket Analysis

Ferulic Acid MarketMarket Size

Global Switches MarketMarket Share

Global Clear Aligners MarketMarket Growth

Carbon Credits MarketMarket

L-Carnosine MarketMarket Share

Ketamine Treatment MarketMarket Growth Rate

Unattended Ground Sensor MarketMarket Forecast

Global Objectives and Key Results (OKR) Software MarketMarket Size

Metal Seals MarketMarket Growth

Soybean MarketMarket Analysis

Post-consumer Recycled Plastics In Consumer Electronics MarketMarket Size

Global Military Body-Worn Cameras MarketMarket Share

Global Dental Silica And Paper Mass Silica MarketMarket Growth

In-store Music Service MarketMarket

Duty Free Travel Retail MarketMarket Share

Pork Processing MarketMarket Growth Rate

Olfactory Technology Product MarketMarket Forecast

Global Antimicrobial Coated Urinary Tube MarketMarket Size

Baby Astringent Powder MarketMarket Growth

Folding Walkers MarketMarket Analysis

Multi-Dose Eye Dropper System MarketMarket Size

Global IoT Automatically Sorts Garbage Bin MarketMarket Share

0 notes

Text

Sustainable Packaging Solutions in the Polyacrylamide Market

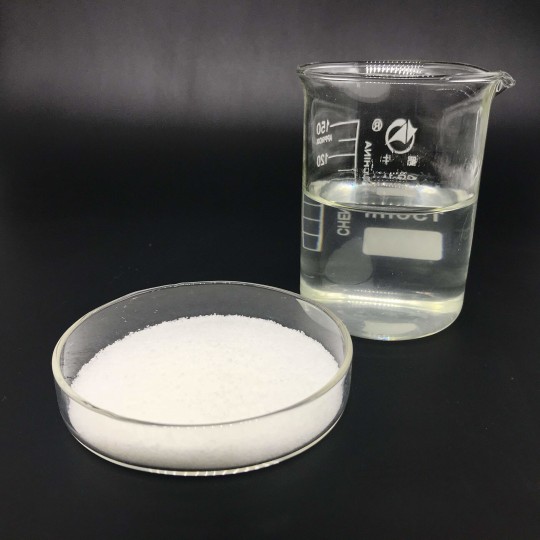

Polyacrylamide: A Versatile Synthetic Polymer Used in Various Industries and Applications What is PAMs?

PAMs is a water-soluble non-ionic polymer made from acrylamide subunits through free-radical polymerization. It comes as a white water-soluble powder and has a chemical formula of (C3H5NO)n. Simply put, PAMs is a long-chain synthetic molecule made up by the polymerization of acrylamide monomers. PAMs is a highly water-absorbent substance and can retain up to 200-600 times its mass in water. Uses of Polyacrylamide in Flocculation

One of the main uses of PAMs is in waste water treatment and mining via a process called flocculation. In flocculation, PAMs polymers are added to suspensions containing small suspended particles like sediments, algae, heavy metals etc. The long molecular chains of PAMs bind to the particles and form larger, easily settleable clumps called flocs. This allows for faster and more efficient solid-liquid separation processes like sedimentation and filtration. PAMs flocculants are commonly used in water treatment plants and mining operations to purify water and recover valuable minerals. Applications in Paper Manufacturing

PAMs finds applications in paper manufacturing processes as well. It is added to pulp and paper mill wastewater streams during treatment to remove suspended fibers and fillers. This improves the drainage rate by coagulating fine particles and increasing the consolidation rate when dewatering paper sludge. PAMs is also used as a binder and strength agent in the wet end of paper making to increase physical properties like tensile strength, burst strength and fold endurance of paper products. Uses in Enhanced Oil Recovery

Due to its ability to increase viscosity, PAMs is used extensively in enhanced oil recovery (EOR) techniques. In EOR processes like polymer flooding, a dilute solution of PAMs is injected into oil reservoirs after conventional methods to increase the mobility of the displacing fluid. The high molecular weight PAMs solutions form a polymer bank that sweeps through the reservoir and tends to drive more oil toward the production well by improving microscopic displacement efficiency. This technique can extract 10-15% additional oil from mature oilfields. Applications in Agriculture

PAMs also has beneficial uses in agriculture. It is used as a soil conditioner to help retain moisture and nutrients in soil. When applied to soil, PAMs absorbs water and prevents runoff, thereby conserving water. It also seals micro cracks in soil to reduce loss of moisture and small fertilizer particles. This leads to better water efficiency and increased crop yields. In hydroponics systems and greenhouse soils, PAMs acts as a water retaining agent that allows for controlled release of water to plant roots. Role in ConstructionDue to its moisture absorbing property, polyacrylamide plays a key role in construction. It is added to concrete mixtures as a superplasticizer or water reducing admixture to improve workability. PAMs allows concrete to be mixed at lower water-cement ratios without compromising on slump or flow properties. This leads to stronger, more durable concrete structures. It is also used to manufacture grouts and floor leveling compounds with self-leveling and self-curing properties. PAMs based compounds fill cracks, level floors and bond building surfaces. Uses as a Thickening Agent

Because of its high molecular weight and hydrophilic nature, PAMs has superb thickening properties. It is widely used as a thickening agent in various industrial and consumer products like paints, coatings, adhesives, cosmetics, pharmaceuticals and foods. PAMs helps increase viscosity without significantly affecting other product properties. It provides stable viscosity even under low shear/high stress conditions. Some common applications as a thickener include its use in low-fat foods, shampoos, lotions, syrups, soups and metalworking fluids. Applications in Biotechnology

Due to biocompatibility, PAMs also finds applications in biotechnology and biochemical engineering processes. It is often used to prepare gels and beads for electrophoresis, isoelectric focusing and chromatography techniques in laboratories. PAMs gels serve as excellent media for separation, isolation and purification of biomolecules like proteins, nucleic acids and enzymes. In medicine, hydrogels made of PAMs are being researched for use in tissue engineering, artificial skin, soft contact lenses and drug delivery. In summary, polyacrylamide is a versatile synthetic polymer with wide applications across industries owing to its water solubility and moisture absorption properties. It acts as an efficient flocculant, thickening agent, soil conditioner, plasticizer, strengthening additive and supports various biochemical separation processes. With continued innovation, new uses of PAMs will likely be discovered, cementing its important role in science, engineering and technology.

0 notes

Text

Research allows for 3D printing of 'organic electronics'

An example of 3D laser printing. Credit: University of Houston

When looking at the future of production of micro-scale organic electronics, Mohammad Reza Abidian—associate professor of Biomedical Engineering at the University of Houston Cullen College of Engineering—sees their potential for use in flexible electronics and bioelectronics, via multiphoton 3D printers.

The newest paper from his research group examines the possibility of that technology. “Multiphoton Lithography of Organic Semiconductor Devices for 3D Printing of Flexible Electronic Circuits, Biosensors, and Bioelectronics” was published online in Advanced Materials.

Over the past few years, 3D printing of electronics have become a promising technology due to their potential applications in emerging fields such as nanoelectronics and nanophotonics. Among 3D microfabrication technologies, multiphoton lithography (MPL) is considered the state-of-the-art amongst the microfabrication methods with true 3D fabrication capability, excellent level of spatial and temporal control, and the versatility of photosensitive materials mostly composed of acrylate-based polymers/monomers or epoxy-based photoresists.

“In this paper we introduced a new photosensitive resin doped with an organic semiconductor material (OS) to fabricate highly conductive 3D microstructures with high-quality structural features via MPL process,” Abidian said.

They showed that the fabrication process could be performed on glass and flexible substrate poly(dimethylsilosane). They demonstrated that loading as low as 0.5 wt% OS into the resin remarkably increased electrical conductivity of printed organic semiconductor composite polymer over 10 orders of magnitude.

“The excellent electrical conductivity can be attributed to presence of OS in the cross-linked polymer chains, providing both ionic and electronic conduction pathways along the polymer chains,” Abidian said.

To demonstrate the potential electronic applications based on the OS composite resin, his team fabricated various microelectronic devices, including micro-printed circuit board, which comprises various electrical elements, and an array of microcapacitors.

Three dimensional bioprinting of organic semiconductor microdevices based on MPL has potential in biomedical applications including tissue engineering, bioelectronics and biosensors. Abidian’s team successfully incorporated bioactive molecules such as laminin and glucose oxidase into the OS composite microstructures (OSCMs). To confirm that the bioactivity of laminin was retained throughout the entire MPL process, primary mouse endothelial cells were cultured on OS composite microstructures. Cells seeded on laminin incorporated OSCMs displayed evidence of adherence to substrate, proliferation, and enhanced survival.

“We also assessed the biocompatibility of the OS composite structures by culturing lymphocytes, namely splenic T-cells and B-cells, on the fabricated surfaces and compared them with control surfaces. After seven days of culture, OS composite polymers did not induce cell mortality with approximately 94 percent cell viability compared to the control surfaces,” Abidian said. “In addition, the potential effect of OS composite polymers on cell activation was also studied. After seven days of culture, there was no significant difference in the expression of activation markers on the lymphocytes between OS composite structures and control surfaces.”

Finally, Abidian proposed a maskless method based on MPL for fabrication of bioelectronics and biosensors. They fabricated a glucose biosensor similar to Michigan style neural electrodes. Glucose oxidase, an enzyme for the specific recognition of glucose, was encapsulated within the solidified OS composite microelectrodes via the MPL process. The biosensor offered a highly sensitive glucose sensing platform with nearly 10-fold higher sensitivity compared to previous glucose biosensors. In addition, this biosensor exhibited excellent specificity and high reproducibility.

“We anticipate that the presented MPL-compatible OS composite resins will pave the path towards production of soft, bioactive, and conductive microstructures for various applications in the emerging fields of flexible bioelectronics, biosensors, nanoelectronics, organ-on-chips, and immune cell therapies.” Abidian said.

Researchers use organic semiconductor nanotubes to create new electrochemical actuator

More information: Omid Dadras‐Toussi et al, Multiphoton Lithography of Organic Semiconductor Devices for 3D Printing of Flexible Electronic Circuits, Biosensors, and Bioelectronics, Advanced Materials (2022). DOI: 10.1002/adma.202200512

Provided by University of Houston

Citation: Research allows for 3D printing of ‘organic electronics’ (2022, June 24) retrieved 26 June 2022 from https://techxplore.com/news/2022-06-3d-electronics.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without the written permission. The content is provided for information purposes only.

New post published on: https://livescience.tech/2022/06/26/research-allows-for-3d-printing-of-organic-electronics/

2 notes

·

View notes

Text

Still thinking about Richard and his origami

Richard doing Origami is like my favorite thing ever. He does it for fun and also when he's nervous.

He does not struggle with advance models and folds. He can even fold perfect paper structures behind his back with alarming speed.

An extremely anxious Nines can leave a trail of flowers in his path.

When he does not have proper paper, sticky notes can work. Infact he quite enjoys micro origami. Little screaming foxes the size of your pinky nail.

He loves learning new folds. And especially when he's frustrated he partakes in incredibly difficult and complex structures.

He leaves his origami around the precinct and unfortunately most officers throw them away, not knowing who made them. Richard had hoped it may bring even just a little smile to their faces.

He had once made over 1000 throwing stars and he and Connor had a rather scary war with them as Hank would describe it.

And of course he had won Gavin over with his vast array of cat models. The tinier the kitten the cutier Gavin claimed it to be. And so Nines made the cat smaller and smaller with each morning coffee he brought him. To at one point the cat had to be folded with a needle under a magnifying glass and could fully fit on the eraser of a pencil.

When it rains he likes to make boats to send down the streams of water.

254 notes

·

View notes

Photo

3-D printing technique accelerates nanoscale fabrication 1000-fold

Using a new time-based method to control light from an ultrafast laser, researchers have developed a nanoscale 3-D printing technique that can fabricate tiny structures 1000 times faster than conventional two-photon lithography (TPL) techniques, without sacrificing resolution.

Despite the high throughput, the new parallelized technique—known as femtosecond projection TPL (FP-TPL)—produces depth resolution of 175 nanometers, which is better than established methods and can fabricate structures with 90-degree overhangs that can't currently be made. The technique could lead to manufacturing-scale production of bioscaffolds, flexible electronics, electrochemical interfaces, micro-optics, mechanical and optical metamaterials, and other functional micro- and nanostructures.

The work, reported Oct. 3 in the journal Science, was done by researchers from Lawrence Livermore National Laboratory (LLNL) and The Chinese University of Hong Kong. Sourabh Saha, the paper's lead and corresponding author, is now an assistant professor in the George W. Woodruff School of Mechanical Engineering at the Georgia Institute of Technology.

Read more.

96 notes

·

View notes

Text

One of my favorite things about the classic style of internet forums is the way that nerds who obsess over particular subject end up recreating academic structures.

Let me back up and explain what I mean. Thomas Kuhn argues that the process of academic science is built around the acceptance of a few central beliefs, what he calls a “paradigm”. Anyone not adhering to these beliefs is working outside the mainstream of the field. For instance, if you were doing physics between 1700 and 1900 and didn’t accept Newton’s laws, you were an outsider. Moreover, the paradigm also contains beliefs about what is and isn’t a valid target for inquiry. The central questions tend to focus on resolving observations with the beliefs of the paradigm. Hyper-focused forums blend this with the slightly more personality-focused flavor of academic philosophy.

For instance, D&D optimization boards. These groups tend to hyperfocus on a couple problems that are largely tangential to the way most people play the game, but the problems they choose and the way they approach those problems have this structure to them. There’s a single paper/post that serves the role of a paradigm. It’s a very persuasive little article on how to conceptualize power in a tabletop RPG (Namely, in terms of versatility instead of damage). Generally, everybody accepts this premise, and looks for builds that are optimal *under this specific metric*. There are distinct posters who were active over a decade ago who wrote guides that were influential enough that people still reference them, use their terminology (eg “batman wizard”), and default to their notational conventions.

Another really good example is Smogon, a site for competetive online Pokemon, where people have, I shit you not, re-implemented the entire pokemon battle system from scratch, complete with all the moves, animations, etc. But most interestingly, they have a unique ladder ranking system that the site admins argue is superior to other ladder systems. This is, by the way, an active area of research in real academia. Somebody devised a new ladder system, which could totally be publishable, and named it after their forum handle. It’s just absolutely wild to me that statistics researchers might write in a paper a reference to [”GXE (GLIXARE)” -- forum user X-Act, 2009]. That work done under our online personas could make its way into academia, and so be cemented into references to be cited for decades to come.

The “sequences” on LessWrong also seem to sort of fit into this mold, albiet in a much more intentional way.

The bottom line is that it makes me wonder if academic discourse is a sort natural endpoint of intensely pursued curiosity. If people passionately pursuing a subject, whatever it may be, always fold their discussions into the same shapes. If given the chance, we always settle on the same long-form style of expressing, discussing, and refuting ideas. It seems like this is much less common on modern social media platforms that don’t really allow this kind of extended discussion, with the possible exception of Reddit. But it’s interesting to think that in another world where forums stayed relevant, thousands of micro-fields might have chugged on daily, doing their work unravelling incredibly niche subjects, even if only for the enjoyment of a few.

3 notes

·

View notes

Text

Packaging with cardboard and corrugated cardboard

Packaging with cardboard and corrugated cardboard

The most commonly used packaging materials, derived from paper, are corrugated cardboard and plain cardboard. There are significant differences in their characteristics and it is important that they are well known in order to make the best choice of packaging for a particular application.Get more news about Packaging Boxes 1 Layer,you can vist our website!

Cardboard is a thick material with excellent properties that allow folding and modeling at a much better hardness than paper. It can be easily cut and shaped, and its lightness, strength and recyclability make it ideal for many packaging applications. It is most often used for making small boxes, packages, etc. It can be used to make transport packaging, but it does not provide sufficient protection and it is good to additionally secure the contents with an inner packaging of protective material.

It is made from cellulose, which is often recycled, and various binders, fillers and other ingredients are added to it, depending on the purpose. According to the DIN standards, any paper with a density of more than 150 g / m2 can be classified as cardboard. The most important characteristics that are monitored when managing the quality of the produced cardboard are weight per 1 m2, thickness and humidity. The production of cardboard is very similar to that of paper. The raw material goes through a process of grinding, casting, pressing and drying. A significant difference is that coarser and harder fibrillated celluloses are usually used for cardboard.

Corrugated cardboard or so-called goffered cardboard consists of several layers of material with an intermediate folded layer. The types of corrugated cardboard differ according to the number of layers and the thickness of the wave. The difference in the structure of the corrugated cardboard also leads to the different strength of the material. The more layers and the better quality paper is used, the stronger the packaging material. Important advantages are the combination of lightness, plasticity and impact resistance. Although corrugated cardboard provides a higher level of security than plain cardboard, the load that has to be packed must be consistent with the material limitations.

Corrugated cardboard is an effective means of transporting products of various natures due to its durability. Leading companies in the field of supply conduct engineering testing of strains and deformations and the effect of vibration load on shipments in moving trucks. This allows them to optimize the weight of corrugated packaging and reduce the total weight of packaging by about 9 percent. This in turn reduces the corrugated cardboard waste that goes into recycling. This is just one of the examples of the flexibility and rapid modification of the material – qualities sought by every company focused on resource optimization.

Double-layer corrugated cardboard is a flexible material, a combination of a flat layer of paper and a pleated layer, and can have the sealing and strengthening application of an inner packaging. The three-layer corrugated cardboard consists of two flat layers with one pleated intermediate layer. The most common corrugated cardboard is with profile C, B, E. Three-layer corrugated cardboard with wave profile E (micro corrugated cardboard) has a thickness of up to 1.3 mm. It is used in the production of small or laminated packaging with light and medium weight. It is extremely suitable for punching and can produce an unlimited variety of constructions and designs. Three-layer corrugated cardboard with wave profile B – 3 mm thick is used for medium-sized packages and cardboard boxes with a product weight of up to 10 – 15 kg. It has very good resistance to pressure.

Three-layer corrugated cardboard with wave profile C – 4 mm thick, can withstand loads weighing 20 kg. It is very durable and can be used to make large cardboard boxes, laminated and punched products. The four-layer corrugated cardboard consists of one outer, one inner straight layer and two folded intermediate ones and is used for lamination. The five-layer corrugated cardboard consists of three straight and two intermediate pleated layers of paper. The five-layer corrugated cardboard, which combines C and E profile waves, is 5 mm thick and is the preferred material due to its high strength and high print quality, which gives it a very attractive commercial appearance.

0 notes

Text

The Life and Death of the Original Micro-Apartments

Earlier this month, demolition began on the Nakagin Capsule Tower, an iconic building designed by Kisho Kurokawa. Still, in many ways, Kurokawa's dynamic vision is woven into the fabric of our architectural present. From a report: The building at the time was in a conspicuous state of disrepair. Its concrete surface was pockmarked; many of the circular windows were papered over. Last year, after more than a decade of back-and-forth over the building's fate, the owners' association agreed to sell the towers to a consortium of real-estate firms, and earlier this month news came that demolition of the structure had finally begun. Recent photos posted by a preservationist initiative on Facebook show that its base now half gone; the hundred and forty-four capsules float above the construction, bereft and doomed. The future that Kurokawa and the Metabolism movement imagined didn't come to pass, yet in many ways their dynamic vision is woven into the fabric of our architectural present. Metabolism officially launched with a manifesto, in 1960, as Japanese cities were being reconceptualized after the destruction of the Second World War. Part of a new postwar generation of architects, Metabolism's founders -- among them Kurokawa, Kiyonori Kikutake, and Fumihiko Maki -- were driven, as Kurokawa wrote in his 1977 book, "Metabolism in Architecture," by "traumatic images of events that took place when we were in our formative childhood years." Born in 1934, in Aichi Prefecture, Kurokawa was the son of an architect whose style he described as "ultra-nationalistic." In his own studies, he was drawn first to Kyoto University, for its sociological approach to architecture, then to Tokyo University, where he studied under the modernist architect Kenzo Tange, who worked after the war on the Hiroshima Peace Memorial Museum. But Kurokawa was more interested in looking forward. "I felt that it was important to let the destroyed be and to create a new Japan," he wrote. [...] The Nakagin capsules suggest a kind of utopian urban life style. Their paucity of space and equipment meant that activities typically done at home, like eating and socializing, would instead be conducted out on the street. The Nakagin capsules were not full-time residences but pieds-a-terre for suburban businessmen or miniature studios for artists and designers. The individual capsules were pre-assembled, then transported to the site and plugged in to the towers' central cores. Each unit -- two and a half metres by four metres by two and a half metres, dimensions that, Kurokawa noted, are the same as those of a traditional teahouse -- contained a corner bathroom fit for an airplane, a fold-down desk, integrated lamps, and a bed stretching from wall to wall. Televisions, stereos, and tape decks could also be included at the buyer's discretion. [...] In some ways, Kurokawa's vision of a domestic architecture that prioritized mobility and flexibility proved prophetic. The capsules were the original micro-apartments, an ancestor to today's capsule hotels, and a forebear of the shared, temporary spaces of Airbnb.

Read more of this story at Slashdot.

from Slashdot https://ift.tt/jnFp6vR

0 notes

Text

Global Waterbased Inks Market

Water-based Inks Market was valued US$ XX Bn in 2018 and is expected to reach US$ XX Bn by 2027, at CAGR of 7.2 % during forecast period of 2019 to 2027.

To know about the Research Methodology:-Request Free Sample Report

The Water-based Inks Market has witnessed considerable growth in latterly because of growth in flexible packaging, increasing demand for printing inks, and rise in environment and safety issues are main factors that drive the growth for water-based inks market. Water-based ink formulations consist of surfactant, wax, and deformer additives were prepared and printed on polyethylene film substrates.

The report study has analyzed revenue impact of covid-19 pandemic on the sales revenue of market leaders, market followers and disrupters in the report and same is reflected in our analysis. Water-based Inks Market Drivers and Restrains

The Global Water-based Inks Market has become more competitive and price-sensitive owing to the high potential and steady growth of the Water-based Inks Market. Use of water-based inks decreases amount of hazardous waste. The water-based inks market is expected to register substantial growth because of increase in demand for environment friendly inks in emerging economies such as Asia Pacific and North America. Slow drying and printing speed is the main drawback of Water-based Inks. The use of water-based inks is limited around highly alkaline environments as these inks are soluble in alkaline solutions, such inks cannot wet and print smoothly on difficult substrates owing to high surface energy of water molecules. The above mentioned factors hamper the growth of the water-based inks market.

However, continuous innovation in water-based inks such as development of pH stable inks and improvement in resins utilized in ink formulation offer potential growth opportunities for market expansion. The UV-cured printing inks are a superior alternative to traditional inks, they are used in various printing processes such as inkjet, gravure, and flexography, as they offer several benefits over the Water-based Inks. UV-cured inks do not contain Volatile Organic Compounds (VOC), since drying process is faster. The above mentioned factors are restrain the water-based inks market during the forecast period.

Water-based Inks Market Segmentation Analysis Among all the segments of resin type, Acrylic was highly demanding segment according to analysis of the global water-based inks market in 2018 and this trend is likely to continue during the forecast period because of rise in mandate for acrylic resin-based inks from the global packaging industry. Acrylic resins offer soft-film ink polymers, dry quickly, with excellent resistance to ice water crinkles, high adhesion and pH stability.

In terms of technology, the flexography printing technology is one of the broadly used in printing processes such as paper, plastic, and paperboard. Market share of the flexography technology segment is projected to increase during the forecast period thanks to its ability to print of a wide variety of substrates and usage of eco-friendly printing inks for example water-based printing inks. Growth of flexible tags & labels and packaging printing industries is drive the segment during the forecast period.

Among all the segments of Application, the packaging segment is expected to grow at the highest XX% CAGR during the forecast period, thanks to increasing demand for flexible packaging in the food and beverages sector due to its esthetic appeal and less weight, is expected to fuel the demand for packaging in the next few years. The packaging segment comprises flexible packages, tags, corrugated containers, labels, metal cans, and folding cartons. Water-based Inks Market Regional Analysis

Among all the regions, the Asia Pacific had the largest market share in 2018 and is projected to lead the market during the forecast period, Because of development of packaging and newspaper industries and presence of major industrialists of water-based inks, mandate for water-based inks in these regions is expected to rise in recent few coming years. Expansion of the market is attributed to the growth in the packaging industry. North America is the second largest market in the Water-based Inks Market and accounted for XX% shares in 2018, nearly follow Asia Pacific in terms of profits.

The objective of the report is to present comprehensive analysis of Water-based Inks Market including all the stakeholders of the industry. The past and current status of the industry with forecasted market size and trends are presented in the report with the analysis of complicated data in simple language. The report covers all the aspects of industry with dedicated study of key players that includes market leaders, followers and new entrants by region. PORTER, SVOR, PESTEL analysis with the potential impact of micro-economic factors by region on the market have been presented in the report. External as well as internal factors that are supposed to affect the business positively or negatively have been analyzed, which will give clear futuristic view of the industry to the decision makers. The report also helps in understanding Water-based Inks Market dynamics, structure by analyzing the market segments, and project the Water-based Inks Market size. Clear representation of competitive analysis of key players by Water-based Inks Type, price, financial position, product portfolio, growth strategies, and regional presence i n the Water-based Inks Market make the report investor’s guide.

For more information visit@ https://www.maximizemarketresearch.com/market-report/global-water-based-inks-market/41006/

Scope of the Water-based Inks Market :Inquire before buying

Water-based Inks Market, by Resin Type

• Acrylic • Polyester • Maleic • Others (including Polyurethane and Phenolic) Water-based Inks Market, by Technology

• Flexography • Gravure • Digital • Others (including Screen Printing, Sheet-fed Printing, and Offset Printing) Water-based Inks Market, by Application

• Packaging • Publication • Tags & Labels • Others (including Decorative and Product) Water-based Inks Market, by Region

• Asia Pacific • North America • Europe • Latin America • Middle East Africa Water-based Inks Market, Major Players

• Sun Chemical Corporation • Flint Group • Siegwerk Druckfarben AG & Co. KGaA • Toyo Ink SC Holdings Co. • Huber Group • Wikoff Color Corporation • Doneck Euroflex S.A.Sebek Inks • Dolphin Inks • BCM Inks • Chimigraf • Group (Luxembourg) • DIC Corporation • Sakata Inx • T&K Toka (Japan), and others • Siegwerk

This report submitted by Maximize market Research Company

Customization of the report:

Maximize Market Research provides free personalized of reports as per your demand. This report can be personalized to meet your requirements. Get in touch with us and our sales team will guarantee provide you to get a report that suits your necessities.

About Maximize Market Research:

Maximize Market Research provides B2B and B2C research on 20,000 high growth emerging opportunities & technologies as well as threats to the companies across the Healthcare, Pharmaceuticals, Electronics & Communications, Internet of Things, Food and Beverages, Aerospace and Defense and other manufacturing sectors.

Contact info:

Name: Lumawant Godage

Organization Address: MAXIMIZE MARKET RESEARCH PVT. LTD.

Email: [email protected]

Address: Omkar Heights, Sinhagad Road, Manik Baug, Vadgaon Bk,Pune, Maharashtra 411051, India.

Contact: +919607195908

0 notes

Text

Nanotech scientists create world's smallest origami bird

If you want to build a fully functional nanosized robot, you need to incorporate a host of capabilities, from complicated electronic circuits and photovoltaics to sensors and antennas.

But just as importantly, if you want your robot to move, you need it to be able to bend.

Cornell researchers have created micron-sized shape memory actuators that enable atomically thin two-dimensional materials to fold themselves into 3D configurations. All they require is a quick jolt of voltage. And once the material is bent, it holds its shape -- even after the voltage is removed.

As a demonstration, the team created what is potentially the world's smallest self-folding origami bird. And it's not a lark.

The group's paper, "Micrometer-sized electrically programmable shape memory actuators for low-power microrobotics," published in Science Robotics and was featured on the cover. The paper's lead author is postdoctoral researcher Qingkun Liu.

The project is led by Itai Cohen, professor of physics, and Paul McEuen, the John A. Newman Professor of Physical Science.

McEuen and Cohen's ongoing collaboration has so far generated a throng of nanoscale machines and components, each seemingly faster, smarter and more elegant than the last.

"We want to have robots that are microscopic but have brains on board. So that means you need to have appendages that are driven by complementary metal-oxide-semiconductor (CMOS) transistors, basically a computer chip on a robot that's 100 microns on a side," Cohen said.

Imagine a million fabricated microscopic robots releasing from a wafer that fold themselves into shape, crawl free, and go about their tasks, even assembling into more complicated structures. That's the vision.

"The hard part is making the materials that respond to the CMOS circuits," Cohen said. "And this is what Qingkun and his colleagues have done with this shape memory actuator that you can drive with voltage and make it hold a bent shape."

The machines fold themselves fast, within 100 milliseconds. They can also flatten and refold themselves thousands of times. And they only need a single volt to be powered to life.

The team has already been recognized by Guinness World Records for creating the smallest walking robot. Now, they hope to capture another record with a new self-folding origami bird that is only 60 microns wide.

The team is currently working to integrate their shape memory actuators with circuits to make walking robots with foldable legs as well as sheet-like robots that move by undulating forward. These innovations may someday lead to nano-Roomba-type robots that can clean bacterial infection from human tissue, micro-factories that can transform manufacturing, and robotic surgical instruments that are ten times smaller than current devices, according to Cohen.

Support was provided by the U.S. Army Combat Capabilities Development Command's Army Research Laboratory, the National Science Foundation, the Cornell Center for Materials Research, the Air Force Office of Scientific Research, and the Kavli Institute at Cornell for Nanoscale Science. Part of the work was performed at the Cornell NanoScale Science and Technology Facility.

Video: https://www.youtube.com/watch?v=nNn4Lpd4uBM

Story Source:

Materials provided by Cornell University. Original written by David Nutt. Note: Content may be edited for style and length.

Journal Reference:

Qingkun Liu, Wei Wang, Michael F. Reynolds, Michael C. Cao, Marc Z. Miskin, Tomas A. Arias, David A. Muller, Paul L. McEuen, Itai Cohen. Micrometer-sized electrically programmable shape-memory actuators for low-power microrobotics. Science Robotics, 2021; 6 (52): eabe6663 DOI: 10.1126/scirobotics.abe6663

1 note

·

View note

Text

Global Food Storage Container Market

Global Food Storage Container Market size was valued US$ XX Mn in 2019 and the total revenue is expected to grow at 4.5% from 2020 to 2027, reaching US$ XX Mn.

Global Food Storage Container Market

The report study has analyzed the revenue impact of COVID -19 pandemic on the sales revenue of market leaders, market followers, and market disrupters in the report, and the same is reflected in our analysis.

U.S. food container industry is expected to reach US$ XX billion by the end of 2027, expanding at a predicted CAGR of 3.4% from 2019 to 2027. Product improvement by convenience food manufacturers is expected to remain a key driving force in the upcoming years.

The round food storage container market in the North American region is about 197.21Mn. the restaurant segment in 2016 dominated the market accounting for 6x.xx%. Lightweight Containers market is growing owing to the preference for durable and lightweight storing containers will help the market to increase with CAGR of 3.72% Flexible packaging is expected to predict revenue growth at a CAGR of XX% from 2019 to 2027. Shifting of the market from conventional glass & metal to lightweight polymers such as polyethylene (PE) and polyvinyl diene chloride (PVC) as a raw material for packaging of food items is expected to be a constructive factor.

The Latest trend in the food storage container is non-reactive and non-toxic materials for manufacturing food storage containers. Factors like improper use of different ingredients and raw materials cause food contamination and can have an unfavorable effect on the businesses. Food contamination is a major challenge for the foodservice companies in the US. Measures like Hazard analysis and critical control points (HACCP), a Protective food safety approach helps lessen the food-related hazards in any foodservice sector. In the present day, the food safety management system (FSMS) is being adopted by many food chains in the US to evaluate and establish measures to prevent potential hazards related to food.

North America, Europe, and China are the major region player of Household Food Container Market due to the bigger demand for downstream applications. In 2019, these three regions occupied about 74.00% of the world’s expenditure total volume.

• By material, Food Storage Container Market is divided into metal, plastics, glass, acrylic, ceramic, silicone, paper, and others. Plastics are dominating the food storage container market because of the high demand for unbreakable and durable material in manufacturing processes.

• By Use, Food Storage Container Market is segmented into microwave compatible, airtight container, and others. In this segment, airtight container is dominating the food storage container market due to the increasing demand for leakage proof food storage containers which protects the spoilage of the food.

• By shape, Food Storage Container Market is segmented into round, square, rectangular. Square and rectangular is dominating the Asia Pacific food storage container market because the production process is less difficult as compared to other shapes of containers.

• On the basis of storage capacity, Food Storage Container Market is segmented into less than 100 ml, 100-500 ml, 500-1000 ml, 1000-1500 ml, 1500-2000 ml, greater than 2000 ml. Greater than 2000 ml is dominating because of the enormous demand for large size containers as more quantity at one time in hotels, bakeries, and many more.

• By manufacturing technology, Food Storage Container Market is segmented into injection molding, extrusion molding, thermoforming, stretch blow molding, and others. In this segment, extrusion molding is dominating the food storage container market because this process has minimum wastage of raw material.

• By appearance, Food Storage Container Market is segmented into transparent and colored. Transparent Container segment is dominating because its process does not include the use of chemicals which is more in case of colored containers and by means of that the visibility became easier.

• By industrial function, Food Storage Container Market is segmented into storage, conveying and transport, picking, handling, and other activities. In this segment, storage is dominating the food storage container market due to the increasing demand of preserving food which can be used for a longer period.

• By application, Food storage container market is segmented into household, bakery & confectionary, chocolates, convenience food, fruits & vegetables, meat, fish & poultry, condiments & spices, dairy products, and others. Bakery & confectionary is dominating due to the growing demand for storing food in bulk in bakeriesGeographically, the Food Storage Container Market is segmented into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. North America held the prominent market share of XX% in 2019 and is expected to reach US$ Mn by the end of 2027, with a CAGR of XX%. The major growth predicted in India and China, where double-digit annual increases in food container consumption are forecasted through 2018-19. By 2022, China is predicted to become the largest global consumer of food packaging.

The objective of the report is to present a comprehensive analysis of the Global Food Storage Container Market including all the stakeholders of the industry. The past and current status of the industry with forecasted market size and trends are presented in the report with the analysis of complicated data in simple language. The report covers all the aspects of the industry with a dedicated study of key players that includes market leaders, followers, and new entrants. PORTER, SVOR, PESTEL analysis with the potential impact of micro-economic factors of the market has been presented in the report. External as well as internal factors that are supposed to affect the business positively or negatively have been analyzed, which will give a clear futuristic view of the industry to the decision-makers. The report also helps in understanding Global Food Storage Container Market dynamics, structure by analyzing the market segments and projects the Global Food Storage Container Market size. Clear representation of competitive analysis of key players by Application, price, financial position, Product portfolio, growth strategies, and regional presence in the Global Food Storage Container Market make the report investor’s guide. Scope of the Global Food Storage Container Market:

Global Food Storage Container Market, by Product Type:

• Flexible Packaging • Paperboard • Rigid Packaging • Metal • Glass Global Food Storage Container Market, by Application:

• Grain Mill Products • Dairy Goods • Fruits & Vegetables • Bakery Products • Meat Processed Products • Others Global Food Storage Container Market, by End User:

• Restaurants • Catering • Hotels • Bars Global Food Storage Container Market, by Region:

• Asia Pacific • North America • Europe • Latin America • Middle East Africa Global Food Storage Container Market, Major Players:

• Bemis Company, Inc. • Berry Plastics Corporation • Graham Packaging Company • Graphic Packaging International, LLC • Ball Corporation • Constar International UK Ltd. • Anchor Glass Container Corporation • Plastipak Holdings, Inc. • PRINTPACK • Alcan Packaging • Fold-Pak • Associated Packaging Technologies • Consolidated • Caraustar Industries Incorporated • Evergreen Packaging • Crown Holdings Incorporated • Hood Companies • Manchester Industries • Graphic • Owens-Illinois Group Incorporated • Pactiv • MeadWestvaco Corporation For More Information Visit @:https://www.maximizemarketresearch.com/

This Report Is Submitted By :Maximize Market Research Company Customization of the report: Maximize Market Research provides free personalized of reports as per your demand. This report can be personalized to meet your requirements. Get in touch with us and our sales team will guarantee provide you to get a report that suits your necessities.

About Maximize Market Research: Maximize Market Research provides B2B and B2C research on 20,000 high growth emerging opportunities & technologies as well as threats to the companies across the Healthcare, Pharmaceuticals, Electronics & Communications, Internet of Things, Food and Beverages, Aerospace and Defense and other manufacturing sectors. Contact info: Name: LumawantGodage Organization Address: MAXIMIZE MARKET RESEARCH PVT. LTD. Email: [email protected] Address:Pune, Maharashtra 411051, India. Contact: +919607195908

0 notes