#piezo sensors

Explore tagged Tumblr posts

Text

Unlock Precision and Reliability with Advanced Piezo Sensor Technology

In the world of sensing and measurement, precision is paramount. Whether you're working on industrial automation, medical devices, or cutting-edge research, piezo sensors are the key to achieving accurate, reliable, and real-time data.

These versatile devices convert mechanical energy into electrical signals, making them indispensable in a wide range of applications.

At Seis-Tech, we specialize in delivering high-quality piezo sensors that meet the demands of even the most challenging environments. Let’s explore how our innovative solutions can elevate your projects.

Why Choose Piezo Sensors?

High Sensitivity and Accuracy

Piezo sensors are renowned for their ability to detect even the slightest changes in pressure, force, or vibration, ensuring precise measurements every time.

Experience unmatched precision with our advanced piezo sensor technology.

Durability in Harsh Conditions

Built to withstand extreme temperatures, moisture, and mechanical stress, our piezo sensors are ideal for demanding industrial and outdoor applications.

Versatility Across Industries

From automotive testing to medical diagnostics, piezo sensors offer solutions for a wide range of industries and use cases.

Discover the Seis-Tech Advantage

At Seis-Tech, we’re committed to providing piezo sensors that combine cutting-edge technology with exceptional performance. Here’s what sets us apart:

Wide Product Range: From miniature sensors for delicate applications to rugged designs for industrial use, we have the perfect solution for your needs.

Customization Options: Tailor our sensors to meet your specific requirements, including size, shape, and output characteristics.

Quality Assurance: Every sensor undergoes rigorous testing to ensure reliability and accuracy.

Expert Support: Our team of engineers is here to help you select and integrate the right sensor for your project.

Featured Piezo Sensor Solutions

1. High-Frequency Piezo Sensors

Designed for applications requiring rapid response times, these sensors are perfect for vibration monitoring and impact detection.

2. Flexible Piezo Film Sensors

Lightweight and adaptable, these sensors are ideal for wearable devices, medical equipment, and creative applications.

3. Rugged Industrial Piezo Sensors

Built to endure harsh environments, these sensors deliver reliable performance in heavy machinery, automotive testing, and more.

Applications of Piezo Sensors

Industrial Automation: Monitor machinery health and optimize performance with real-time data.

Medical Devices: Enable precise measurements in diagnostic equipment and patient monitoring systems.

Aerospace and Automotive: Test and validate components under extreme conditions.

Consumer Electronics: Enhance touchscreens, wearables, and other devices with responsive sensing technology.

Research and Development: Push the boundaries of innovation with sensors designed for cutting-edge experiments.

Why Trust Seis-Tech?

Proven Expertise: With years of experience in sensor technology, we understand the unique challenges of your industry.

Global Reach: We serve customers worldwide, delivering high-quality products and support wherever you are.

Commitment to Innovation: Our R&D team is constantly developing new solutions to meet evolving needs.

Customer-Centric Approach: Your success is our priority. We work closely with you to ensure seamless integration and satisfaction.

Elevate Your Projects with Seis-Tech Piezo Sensors

Whether you’re optimizing industrial processes, advancing medical technology, or pioneering new research, Seis-Tech is your trusted partner for piezo sensor solutions. Our products are designed to deliver the accuracy, reliability, and performance you need to succeed.

Visit Seis-Tech today to explore our full range of piezo sensors and discover how we can help you achieve your goals.

Precision. Reliability. Innovation. Choose Seis-Tech for piezo sensors that make a difference.

Transform your sensing capabilities with Seis-Tech – where technology meets excellence!

0 notes

Text

Global Flexible Lead Piezo Film Sensor Market to Reach US$ 148.6 Million by 2032

Flexible Lead Piezo Film Sensor Market Analysis:

The global Flexible Lead Piezo Film Sensor Market size was valued at US$ 89.4 million in 2024 and is projected to reach US$ 148.6 million by 2032, at a CAGR of 6.6% during the forecast period 2025-2032

Flexible Lead Piezo Film Sensor Market Overview

This report provides a deep insight into the global Flexible Lead Piezo Film Sensor market covering all its essential aspects. This ranges from a macro overview of the market to micro details of the market size, competitive landscape, development trend, niche market, key market drivers and challenges, SWOT analysis, value chain analysis, etc. The analysis helps the reader to shape the competition within the industries and strategies for the competitive environment to enhance the potential profit. Furthermore, it provides a simple framework for evaluating and accessing the position of the business organization. The report structure also focuses on the competitive landscape of the Global Flexible Lead Piezo Film Sensor Market, this report introduces in detail the market share, market performance, product situation, operation situation, etc. of the main players, which helps the readers in the industry to identify the main competitors and deeply understand the competition pattern of the market. In a word, this report is a must-read for industry players, investors, researchers, consultants, business strategists, and all those who have any kind of stake or are planning to foray into the Flexible Lead Piezo Film Sensor market in any manner.

Flexible Lead Piezo Film Sensor Key Market Trends :

Rising Adoption in Medical Devices Flexible lead piezo film sensors are increasingly used in medical applications for patient monitoring and diagnostics due to their flexibility and sensitivity.

Growth in Industrial Automation Industries are integrating these sensors in automated systems for precise motion detection and control, boosting demand.

Advancements in Flexible Electronics Innovations in flexible and wearable electronics are driving the integration of piezo film sensors into new product designs.

Expansion in Defense Applications Defense sectors are utilizing these sensors for surveillance, vibration monitoring, and advanced weaponry systems.

Increased Research & Development Activities Continuous R&D efforts focus on improving sensor durability, accuracy, and miniaturization to expand applications.

Flexible Lead Piezo Film Sensor Market Regional Analysis :

https://semiconductorinsight.com/wp-content/uploads/2025/01/download-34_11zon-1.png

North America:Strong demand driven by EVs, 5G infrastructure, and renewable energy, with the U.S. leading the market.

Europe:Growth fueled by automotive electrification, renewable energy, and strong regulatory support, with Germany as a key player.

Asia-Pacific:Dominates the market due to large-scale manufacturing in China and Japan, with growing demand from EVs, 5G, and semiconductors.

South America:Emerging market, driven by renewable energy and EV adoption, with Brazil leading growth.

Middle East & Africa:Gradual growth, mainly due to investments in renewable energy and EV infrastructure, with Saudi Arabia and UAE as key contributors.

Flexible Lead Piezo Film Sensor Market Segmentation :

The research report includes specific segments by region (country), manufacturers, Type, and Application. Market segmentation creates subsets of a market based on product type, end-user or application, Geographic, and other factors. By understanding the market segments, the decision-maker can leverage this targeting in the product, sales, and marketing strategies. Market segments can power your product development cycles by informing how you create product offerings for different segments. Key Company

TE Connectivity

SparkFun Electronics

E-Touch

Market Segmentation (by Type)

Surface

Implant

Market Segmentation (by Application)

Industry

Defense

R&D Laboratories

Technical Education

Medical

Drivers

Increasing Demand for Lightweight and Flexible Sensors The need for lightweight, flexible, and thin sensors in electronics and healthcare is a major growth driver.

Rising Industrial Automation Automation in manufacturing and process industries requires precise sensing technologies, boosting market demand.

Growth in Healthcare Monitoring Systems Flexible piezo film sensors are favored in wearable health devices, increasing their adoption in the medical sector.

Restraints

High Production Costs The complex manufacturing process of flexible piezo film sensors leads to higher costs, limiting widespread adoption.

Limited Durability in Harsh Environments Some sensor materials may degrade under extreme conditions, restricting use in certain industrial applications.

Technological Complexity Integrating these sensors with existing systems can be challenging, hindering fast market penetration.

Opportunities

Expansion into Emerging Markets Growing electronics and healthcare sectors in Asia-Pacific offer lucrative opportunities for market expansion.

Development of Customized Sensor Solutions Tailoring sensors for specific applications can open new revenue streams for manufacturers.

Integration with IoT and Wearable Devices The rise of IoT and wearable tech creates strong demand for flexible sensors in consumer electronics and fitness monitoring.

Challenges

Competition from Alternative Sensing Technologies Other sensor types like MEMS and capacitive sensors compete for market share, challenging growth.

Regulatory and Compliance Issues Stringent regulations in medical and defense applications can slow down product approvals and adoption.

Supply Chain Disruptions Global supply chain issues can impact the availability of raw materials and components, affecting production timelines.

Key Benefits of This Market Research:

Industry drivers, restraints, and opportunities covered in the study

Neutral perspective on the market performance

Recent industry trends and developments

Competitive landscape & strategies of key players

Potential & niche segments and regions exhibiting promising growth covered

Historical, current, and projected market size, in terms of value

In-depth analysis of the Flexible Lead Piezo Film Sensor Market

Overview of the regional outlook of the Flexible Lead Piezo Film Sensor Market:

Key Reasons to Buy this Report:

Access to date statistics compiled by our researchers. These provide you with historical and forecast data, which is analyzed to tell you why your market is set to change

This enables you to anticipate market changes to remain ahead of your competitors

You will be able to copy data from the Excel spreadsheet straight into your marketing plans, business presentations, or other strategic documents

The concise analysis, clear graph, and table format will enable you to pinpoint the information you require quickly

Provision of market value (USD Billion) data for each segment and sub-segment

Indicates the region and segment that is expected to witness the fastest growth as well as to dominate the market

Provides insight into the market through Value Chain

Market dynamics scenario, along with growth opportunities of the market in the years to come

6-month post-sales analyst support

Customization of the Report In case of any queries or customization requirements, please connect with our sales team, who will ensure that your requirements are met.

0 notes

Text

youtube

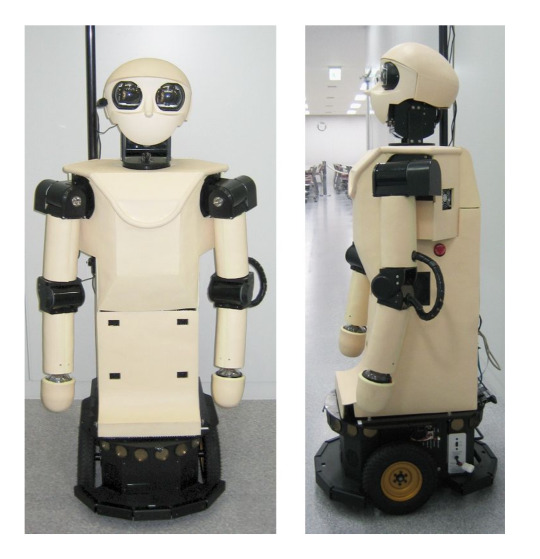

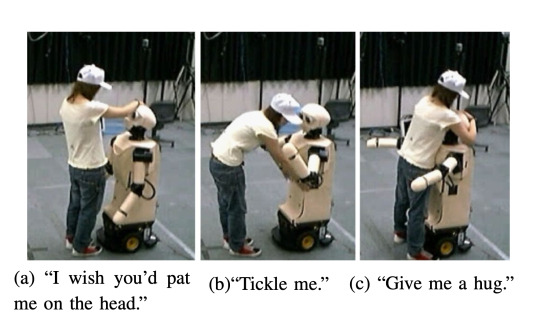

Robovie-IIF (2005) by Takahiro Miyashita, ATR, Kyoto, Japan. Robovie-IIF's skin is a sensor network with 274 3×3cm, or 5×5cm piezo-film (PVDF film) touch sensors, embedded in soft silicone rubber.

"The Osaka-based Advanced Telecommunications Research Institute (ATR) has developed a crowd-monitoring humanoid robot that recognizes when people are lost and helps them find their way. In a series of demonstrations … a souped-up version of ATR's Robovie humanoid robot monitored people as they passed through a 100 square meter (1,076 sq ft) section of the Universal Citywalk Osaka shopping center. Relying on data from 16 cameras, 6 laser range finders and 9 RFID tag readers installed in and around the area, the robot was able to watch up to 20 people at a time, pinpoint their locations to within a few centimeters, and classify each individual's behavior into one of 10 categories (waiting, wandering, walking fast, running, etc.). Whenever Robovie spotted people who looked disoriented, the child-sized droid wheeled up to them and asked, "Are you lost?" If so, the robot provided simple directions to the destination and pointed the way. If not, the robot proceeded to recommend nearby shops and restaurants." – Robovie droid helps lost shoppers, pink tentacle.

20 notes

·

View notes

Text

Ceramic Adhesives Market: Size, Growth Projections, and Competitive Landscape Analysis 2033

The global ceramic adhesives market is valued at US$ 8.3 billion in 2023 and is expected to reach US$ 17.8 billion by 2033, growing at a robust CAGR of 7.9% over the next decade.

Ceramic adhesives are produced using ceramic binders, and are commonly used as filler or strengthening putties, offering strong adhesion to metals, plastics, glass, and ceramics. Additionally, ceramics are known for their excellent insulating properties, further enhancing the performance of these adhesives.

𝐅𝐨𝐫 𝐦𝐨𝐫𝐞 𝐢𝐧𝐬𝐢𝐠𝐡𝐭𝐬 𝐢𝐧𝐭𝐨 𝐭𝐡𝐞 𝐌𝐚𝐫𝐤𝐞𝐭, 𝐑𝐞𝐪𝐮𝐞𝐬𝐭 𝐚 𝐒𝐚𝐦𝐩𝐥𝐞 𝐨𝐟 𝐭𝐡𝐢𝐬 𝐑𝐞𝐩𝐨𝐫𝐭: https://www.factmr.com/connectus/sample?flag=S&rep_id=8207

What Are the Growth Drivers in the Ceramic Adhesives Industry?

"Innovations & Advancements in Adhesive Technology"

The ceramic adhesives industry is witnessing significant innovations and advancements, particularly in the development of smart adhesives.

For example:

On November 26, 2020, Panacol launched its dual-acrylic adhesive, Vitralit UD 8052F. This adhesive is specifically designed for actuators and piezo sensors, offering excellent tear resistance and low viscosity, making it ideal for bonding plastics.

Hydrogel, a unique material made up of 90% water, is more durable than organic adhesives. It offers strong wet adhesion, ensuring reliable performance even in highly humid environments. Additionally, hydrogel is rubber-like, transparent, and can adhere to various surfaces such as titanium, aluminum, silicon, glass, and ceramics.

Country-wise Insights

The ceramic adhesives market in Germany is expected to grow at a CAGR of 6% through 2033, driven by an increasing number of construction projects. Additionally, industrial growth and rapid technological advancements are key factors fueling market expansion.

In the U.S., sales of ceramic adhesives exceeded US$ 1.9 billion in 2022. The market is poised to maintain the largest regional share, supported by the rising demand for high-performance, eco-friendly, and cost-effective adhesives. The presence of major ceramic adhesive manufacturers, such as H.B., 3M, and others, further enhances the growth potential in the region.

Category-wise Insights

The ceramic adhesives market is segmented by type into cement-based, epoxy, acrylic, and others. Among these, cement-based adhesives are expected to capture the largest share of the market revenue. The growing demand for cement-based adhesives is driven by their strong bonding capabilities, particularly for bonding stone, porcelain, and ceramics to both non-porous and porous surfaces in domestic and commercial applications.

Cement-based adhesives offer long-lasting bonding, flexibility, and superior strength, making them ideal for commercial uses. These adhesives are commonly applied in areas such as kitchen and laundry spaces, swimming pools, brick masonry, cement plaster/floor screed, and cement mortar beds.

Competitive Landscape

Industry players are introducing innovative products to create new growth opportunities in the global market in the coming years.

For example:

Bamburi Cement launched Bamburi TectorCeram SETI 300 in Kenya on March 30, 2022. This ready-to-use tile adhesive is designed specifically for laying porous tiles, including natural stone, earthenware, terracotta, and ceramic tiles.

Key manufacturers of ceramic adhesives include 3M, Ardex, Terraco, Construction Chemicals Pty, Saint-Gobain Weber, Dural Industries, Norcros Adhesives, and H.B. Fuller Construction Products.

Segmentation of Ceramic Adhesives Industry Research

By Type:

Cement-based

Epoxy

Acrylic

Others

By Application:

Building & Construction

Dental

Others

By Region:

North America

Europe

Asia Pacific

Latin America

Middle East & Africa

𝐂𝐨𝐧𝐭𝐚𝐜𝐭:

US Sales Office 11140 Rockville Pike Suite 400 Rockville, MD 20852 United States Tel: +1 (628) 251-1583, +353-1-4434-232 Email: [email protected]

1 note

·

View note

Text

An international research group has engineered a novel high-strength flexible device by combining piezoelectric composites with unidirectional carbon fiber (UDCF), an anisotropic material that provides strength only in the direction of the fibers. The new device transforms kinetic energy from the human motion into electricity, providing an efficient and reliable means for high-strength and self-powered sensors. Details of the group's research were published in the journal Small on Dec.14, 2023. Motion diction involves converting energy from the human motion into measurable electrical signals and is something crucial for ensuring a sustainable future.

Read more.

8 notes

·

View notes

Text

Achieve Precision Motion Control with Robust Piezoelectric Bimorphs

A piezoelectric bimorph is a specialized bending actuator or sensor comprised of two bonded piezoelectric ceramic layers separated by an inner passive layer. When subjected to an electric field, one ceramic layer expands while the other contracts due to the converse piezoelectric effect, causing the composite to bend. This bending motion can be harnessed for precision actuation and vibration control applications.

The central passive layer, typically made of a metal or polymer, provides mechanical support and prevents electrical shorting between the two active piezo layers. The ceramic layers are poled during manufacturing to align their electric dipole moments in opposite axial directions. When an electric field is applied across the bimorph’s thickness, one layer expands longitudinally while the other contracts, resulting in a net bending displacement perpendicular to the field direction.

For More Information Please visit, pzt bimorph

Bimorphs exhibit higher generative force compared to unimorphs, but slightly lower displacement range. The three-layer symmetric configuration also provides enhanced thermal stability. Bimorphs are engineered to resonance in desired frequency ranges from ~5 Hz up to hundreds of kHz depending on the materials and construction.

Key bimorph advantages:

Large bidirectional bending motions possible up to ±1 mm range.

Fast response times in milliseconds or less.

Generative force up to 100s of newtons.

Low operating voltages, often less than 30V.

Tailorable dynamics via materials selection and dimensions.

Compact, simple construction suitable for arrays.

Lower cost compared to stacks.

Consistent performance over billions of cycles.

Bimorph applications include:

Precision positioning stages and manipulators.

Piezoelectric motors and pumps.

Speakers and headphones due to good audio range response.

Vibration suppression and shock absorption.

Energy harvesting from vibrations and motion.

Overall, the bimorph configuration offers a balanced set of advantages for electromechanical transduction compared to other multilayer piezo options. With thoughtful design, bimorphs enable highly adaptable and robust motion control, acoustic, and sensor solutions.

2 notes

·

View notes

Text

Haptic Feedback Systems Transforming Digital Experiences Worldwide

The global haptic technology market, valued at USD 10.2 Bn in 2023, is poised for remarkable growth. Projected to expand at a CAGR of 10.5% from 2024 to 2034, the market is expected to reach USD 30.5 Bn by the end of 2034, driven by the rising demand for immersive user experiences and technological integration across various industries.

Market Overview: Haptic technology simulates the sensation of touch using tactile feedback, transforming how humans interact with machines and digital environments. Its applications span consumer electronics, automotive, healthcare, virtual and augmented reality, aviation, and industrial automation.

From vibrating smartphone screens to immersive gaming controllers and surgical simulators, haptic feedback has become a cornerstone of next-gen user interfaces. As industries strive for greater human-machine interaction, the need for real-time tactile response is accelerating the growth of haptic-enabled solutions globally.

Market Drivers & Trends

1. Immersive Consumer Experience

The rise of smartphones, wearables, and gaming devices with touch-enabled features is boosting demand for enhanced, intuitive user interfaces. Haptic feedback adds realism and emotional engagement especially in gaming, where controllers replicate tactile sensations such as tension and impact.

2. VR/AR Expansion

As virtual reality (VR) and augmented reality (AR) technologies gain mainstream adoption, haptic solutions are crucial for delivering lifelike sensations. Applications include military simulations, flight training, remote education, and virtual commerce. Haptics bridges the sensory gap between digital visuals and physical feedback, improving user retention and satisfaction.

3. Automotive Integration

The surge in electric vehicles (EVs) and advanced driver-assistance systems (ADAS) has created new opportunities for haptic interfaces in infotainment systems, dashboards, and steering wheels. By reducing driver distraction and improving control, tactile feedback contributes to safer driving experiences.

4. Healthcare Innovation

Haptic technology is increasingly used in surgical simulation and telemedicine, offering precision and realism in remote diagnostics and robotic-assisted surgeries. It allows medical professionals to feel anatomical structures virtually, improving outcomes and training effectiveness.

Latest Market Trends

Active haptic devices are dominating the market, comprising over 61.6% share in 2023. These devices provide real-time, dynamic feedback in wearables, AR glasses, and smartphones.

Tactile feedback leads the feedback type segment with an 85.9% share, being preferred in consumer and automotive interfaces due to its efficiency in communicating alerts without distracting the user visually.

Technological breakthroughs in low-power piezo actuators, multi-modal haptic SDKs, and miniaturized sensors are transforming device capabilities.

Gain a preview of important insights from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=16538

Key Players and Industry Leaders

Prominent companies shaping the haptic technology landscape include:

AITO BV

Boréas Technologies

Cirrus Logic Inc.

hap2U

Immersion Corporation

Johnson Electric Holdings Limited

KEMET Corporation

Microchip Technology Inc.

onsemi

Renesas Electronics Corporation

Synaptics Incorporated

TDK Corporation

Texas Instruments Incorporated

Other Key Players

These players are heavily investing in R&D and forming strategic alliances to introduce next-generation haptic solutions tailored for emerging markets.

Recent Developments

October 2023: AITO BV unveiled a compact integrated touchpad with class-leading haptic performance, optimized for laptops and smart devices.

October 2023: Boréas Technologies launched HapticStudio, a developer-friendly SDK that allows designers to build customized tactile effects for CapDrive piezo drivers.

September 2023: TDK Corporation introduced the PowerHap development kit, enabling rapid prototyping of haptic-enabled applications with ultra-fast response time.

These innovations aim to democratize access to high-performance haptics across multiple device categories.

Market Opportunities

Education and E-learning: Virtual classrooms integrated with haptic tools can simulate hands-on experiments and environments, improving remote learning outcomes.

Commercial and Industrial Applications: Haptics are being tested in robotic arms, industrial automation, and collaborative robots (cobots) to improve precision in complex tasks.

E-commerce and Retail: Immersive online shopping experiences that let consumers “feel” products before buying are becoming possible through AR + haptic synergies.

Gaming and Entertainment: The integration of advanced haptics into VR headsets and gaming gear presents a massive growth opportunity for startups and developers.

Future Outlook

By 2034, haptic technology will be an essential part of digital transformation across industries. It will redefine how people interact with content, machines, and environments. Future advancements in AI, machine learning, and 5G will further boost haptic responsiveness, efficiency, and scalability.

With rising demand for connected devices and interactive interfaces, market players are expected to expand into untapped regions, develop cost-efficient solutions, and leverage software-hardware co-design to optimize tactile experiences.

Market Segmentation

By Haptic Devices

Active (Dominant Segment)

Passive

By Component

Hardware (Actuators, LRAs, ERMs, Piezoelectric, Drivers)

Software

By Touchscreen Type

Capacitive

Resistive

Others

By Feedback Type

Tactile (Dominant Segment)

Force

By End-use Industry

Consumer Electronics (Smartphones, Tablets, Wearables, Gaming)

Automotive & Transportation (ADAS, Dashboards)

Healthcare (Surgical Simulations)

Education & Research

Commercial & Industrial

Regional Insights

Asia Pacific: Market Leader

In 2023, Asia Pacific held a 40.8% market share, emerging as the dominant region. The growing adoption of smartphones, gaming consoles, and wearables—especially in China, Japan, and South Korea—is fueling demand. Additionally, automotive manufacturers in the region are embedding haptic technology into EV dashboards and infotainment systems for better driver engagement.

North America and Europe

Strong presence of key market players, coupled with advanced healthcare systems and high consumer spending on gaming and electronics, make these regions ripe for further growth.

Why Buy This Report?

Comprehensive industry analysis from 2020 to 2034

Segmentation insights by device, feedback type, application, and region

In-depth company profiles with financial and strategic overviews

Recent developments and R&D pipeline evaluations

Market forecast in terms of revenue (US$ Bn) and volume (Million Units)

Key drivers, opportunities, and challenges mapped with Porter’s Five Forces analysis

0 notes

Text

Global Active Piezo Buzzer Market : Global outlook & Forecast to 2032

Global Active Piezo Buzzer Market size was valued at US$ 1,200 million in 2024 and is projected to reach US$ 1,700 million by 2032, at a CAGR of 7.2% during the forecast period 2025-2032.

Active Piezo Buzzer Market Overview

Active Piezo Buzzers are electroacoustic devices that convert electrical signals into sound using the piezoelectric effect. Unlike passive buzzers that require an external oscillator circuit, active piezo buzzers come with a built-in oscillating circuit. This self-contained design allows active piezo buzzers to produce sound by simply applying a DC voltage, making them easier to implement in various electronic applications.

The core component of an active piezo buzzer is a piezoelectric ceramic disc which vibrates to generate audible sound waves when an electric field is applied. The integrated circuitry controls the frequency of oscillation to produce specific tones or alarms. These devices are known for their reliability, energy efficiency, compact size, and ability to operate over a wide range of voltages and temperatures.

Active piezo buzzers are widely utilized in environments that require clear and consistent audible signals such as alarms, timers, and notifications. Typical applications include automotive electronics like parking sensors and reverse alarms, household appliances such as microwave ovens and washing machines, security systems, medical devices, and consumer electronics.

The versatility and ease of integration of active piezo buzzers have made them a staple component in the electronics industry. Their ability to function with minimal external circuitry simplifies the design process for manufacturers while ensuring consistent and dependable sound output.

This report provides a deep insight into the global Active Piezo Buzzer Market, covering all its essential aspects. This ranges from a macro-overview of the market to micro details of the market size, competitive landscape, development trend, niche market, key market drivers and challenges, SWOT analysis, value chain analysis, etc.

The analysis helps the reader to shape the competition within the industries and strategies for the competitive environment to enhance the potential profit. Furthermore, it provides a simple framework for evaluating and assessing the position of the business organization. The report structure also focuses on the competitive landscape of the Global Active Piezo Buzzer Market. This report introduces in detail the market share, market performance, product situation, operation situation, etc., of the main players, which helps the readers in the industry to identify the main competitors and deeply understand the competition pattern of the market.

In a word, this report is a must-read for industry players, investors, researchers, consultants, business strategists, and all those who have any kind of stake or are planning to foray into the Active Piezo Buzzer Market in any manner.

Get Full Report : https://semiconductorinsight.com/report/global-active-piezo-buzzer-market/

Active Piezo Buzzer Key Market Trends :

Increasing adoption in automotive electronics for safety and alert systems is driving demand for small and medium-sized buzzers.

Growing smart home appliance industry is fueling the use of buzzers for better user interaction and feedback.

Advancements in miniaturization technology enable production of compact and efficient buzzers suitable for portable devices.

Rising demand for energy-efficient components is leading manufacturers to develop buzzers with low power consumption.

Expansion in emerging markets such as Asia-Pacific due to rapid industrialization and urbanization is boosting market growth.

Active Piezo Buzzer Market Regional Analysis :

North America:Strong demand driven by EVs, 5G infrastructure, and renewable energy, with the U.S. leading the market.

Europe:Growth fueled by automotive electrification, renewable energy, and strong regulatory support, with Germany as a key player.

Asia-Pacific:Dominates the market due to large-scale manufacturing in China and Japan, with growing demand from EVs, 5G, and semiconductors.

South America:Emerging market, driven by renewable energy and EV adoption, with Brazil leading growth.

Middle East & Africa:Gradual growth, mainly due to investments in renewable energy and EV infrastructure, with Saudi Arabia and UAE as key contributors.

Active Piezo Buzzer Market Segmentation :

The research report includes specific segments by region (country), manufacturers, Type, and Application. Market segmentation creates subsets of a market based on product type, end-user or application, Geographic, and other factors. By understanding the market segments, the decision-maker can leverage this targeting in the product, sales, and marketing strategies. Market segments can power your product development cycles by informing how you create product offerings for different segments.

Market Segmentation (by Application)

Automotive Electronics

Home Appliances

Other

Market Segmentation (by Type)

Small Size

Medium Size

Large Size

Key Company

Murata

TDK

Kingstate Electronics

Db Products Limited

Cui Inc.

Sonitron

Huayu Electronics

Hunston Electronics

Ariose

Hitpoint

Kepo Electronics

Soberton

Kingwei Electronic

Get A Sample Report : https://semiconductorinsight.com/download-sample-report/?product_id=96448

Drivers

Growing Automotive Electronics Demand The rise in vehicle safety features and alert systems is increasing the use of piezo buzzers, especially in electric and autonomous vehicles.

Expansion of Smart Home Appliances Integration of buzzers in home appliances for alerts and notifications enhances product usability and convenience, driving market growth.

Technological Advancements Improvements in piezoelectric materials and manufacturing processes allow more durable, compact, and energy-efficient buzzers, attracting more applications.

Restraints

High Production Costs Advanced materials and precision manufacturing raise the cost of high-quality buzzers, limiting adoption in low-cost product segments.

Competition from Alternative Technologies Other alert systems such as LED indicators or voice alerts sometimes replace buzzers, restraining market expansion in certain applications.

Environmental Concerns Disposal and recycling challenges related to electronic components may hinder growth due to increasing regulations and consumer awareness.

Opportunities

Rising Demand in Healthcare Devices The growing use of buzzers in medical and wearable devices for alerts opens new market opportunities.

Expansion in Emerging Economies Increasing electronics manufacturing and consumer electronics adoption in Asia-Pacific and Latin America create vast growth potential.

Integration with IoT Devices Active piezo buzzers can be integrated into smart IoT devices for better notification systems, increasing their utility and demand.

Challenges

Maintaining Product Reliability Ensuring consistent buzzer performance under various environmental conditions remains a technical challenge.

Supply Chain Disruptions Fluctuations in raw material availability and geopolitical tensions may affect production and delivery schedules.

Meeting Miniaturization Demands Balancing buzzer size reduction without compromising sound output and durability is a critical design challenge.

Key Benefits of This Market Research:

Industry drivers, restraints, and opportunities covered in the study

Neutral perspective on the market performance

Recent industry trends and developments

Competitive landscape & strategies of key players

Potential & niche segments and regions exhibiting promising growth covered

Historical, current, and projected market size, in terms of value

In-depth analysis of the Consumer Network Connected Cameras Market

Overview of the regional outlook of the Consumer Network Connected Cameras Market:

Key Reasons to Buy this Report:

Access to date statistics compiled by our researchers. These provide you with historical and forecast data, which is analyzed to tell you why your market is set to change

This enables you to anticipate market changes to remain ahead of your competitors

You will be able to copy data from the Excel spreadsheet straight into your marketing plans, business presentations, or other strategic documents

The concise analysis, clear graph, and table format will enable you to pinpoint the information you require quickly

Provision of market value (USD Billion) data for each segment and sub-segment

Indicates the region and segment that is expected to witness the fastest growth as well as to dominate the market

Market dynamics scenario, along with growth opportunities of the market in the years to come

6-month post-sales analyst support

Customization of the Report In case of any queries or customization requirements, please connect with our sales team, who will ensure that your requirements are met.

Related Reports :

Contact us:

+91 8087992013

0 notes

Text

Why Are Piezo Buzzers Important in Modern Electronics? A Complete Guide

Piezo buzzers are integral components in a wide range of electronic devices, providing audible feedback and alerting users to important system statuses. These small yet powerful devices are used in everything from alarms to home appliances and mobile devices. But what exactly are piezo buzzers, and why are they such an essential part of modern electronics? Let’s take a closer look.

Understanding Piezo Buzzers

A piezo buzzer is an electromechanical component that generates sound using the piezoelectric effect. This effect occurs when certain materials produce an electric charge when subjected to mechanical stress. In a piezo buzzer, the piezoelectric material vibrates to produce sound when an electrical signal is applied. These devices can generate a wide range of sounds, from simple beeps to more complex tones.

How Do Piezo Buzzers Work?

Piezo buzzers work based on the principle of piezoelectricity. When an electric current passes through the piezoelectric element within the buzzer, it causes the material to vibrate. This vibration produces sound waves, which are then emitted as an audible noise.

The structure of a piezo buzzer typically consists of a metal disc or ceramic plate made from piezoelectric material.

The electrical signal passed through the buzzer causes the piezoelectric material to deform, producing mechanical oscillations.

These oscillations generate sound waves, which are heard as a beep or alarm sound.

Types of Piezo Buzzers

Piezo buzzers come in two main types: active and passive.

Active Piezo Buzzers

Active buzzers have a built-in oscillator that generates the sound.

They require only a DC voltage to produce sound.

These buzzers are easy to use in devices because they don’t need additional components to function.

Commonly used in low-power applications like alarms, toys, and kitchen appliances.

Passive Piezo Buzzers

Passive buzzers do not have an internal oscillator, so they require an external signal source to generate sound.

They offer more flexibility in terms of sound patterns, as they can be driven by various frequencies.

These buzzers are often used in more complex devices like communication systems, medical devices, and automotive applications.

Applications of Piezo Buzzers

Piezo buzzers are widely used across many industries, thanks to their versatility and efficiency. Some common applications include:

Alarms and Safety Devices: In fire alarms, smoke detectors, and security systems, piezo buzzers are used to alert individuals to potential hazards.

Consumer Electronics: Devices like microwaves, washing machines, and mobile phones use piezo buzzers to notify users about system statuses or errors.

Medical Devices: Piezo buzzers are used in hearing aids, patient monitoring equipment, and diagnostic devices to provide audio cues or feedback.

Automotive Systems: Car alarms, reverse parking sensors, and vehicle navigation systems often use piezo buzzers to alert drivers to critical situations.

Toys and Gadgets: Many electronic toys and gadgets use piezo buzzers for sound effects and alerts.

Benefits of Using Piezo Buzzers

Piezo buzzers offer several key advantages over other types of sound-emitting devices.

High Efficiency and Low Power Consumption

Piezo buzzers consume very little power while providing reliable sound output.

They are ideal for battery-powered devices, where power efficiency is crucial.

Compact Size and Lightweight

These buzzers are compact, lightweight, and easy to integrate into a wide range of devices.

Their small form factor allows them to fit into tight spaces, which is particularly important for portable electronics.

Durability and Reliability

Piezo buzzers are durable and capable of withstanding harsh conditions, such as extreme temperatures or moisture.

Unlike mechanical buzzers, they have fewer moving parts, reducing wear and tear and ensuring longer lifespans.

High Sound Output

Despite their small size, piezo buzzers can produce relatively loud sounds.

They are able to generate clear and sharp tones, making them suitable for alarms and other applications where attention is needed.

Factors to Consider When Choosing a Piezo Buzzer

When selecting a piezo buzzer for a specific application, there are several important factors to keep in mind.

Frequency Range

The frequency range of the buzzer determines the pitch of the sound it produces.

Some buzzers are designed for higher frequencies, while others work better at lower frequencies. The choice depends on the intended application.

Voltage and Power Requirements

Piezo buzzers vary in their voltage and power consumption.

Active buzzers usually require a DC voltage of 3V, 5V, or 12V, while passive buzzers may require a wider voltage range.

It’s important to choose a buzzer that is compatible with your device’s power specifications.

Sound Level

Depending on the application, the sound level of the buzzer may be crucial.

Higher sound levels are necessary for alarms or outdoor applications where the buzzer needs to be heard over long distances or in noisy environments.

Mounting and Size

Piezo buzzers come in different sizes and mounting configurations, including surface-mount and through-hole varieties.

Ensure that the buzzer you select fits into the available space in your device and is easy to integrate.

Conclusion

Piezo buzzers play a vital role in modern electronics, providing a simple yet effective way to alert users or communicate system statuses. Their high efficiency, compact size, and reliability make them a preferred choice for a wide range of applications. Whether you're designing a household appliance, medical device, or automotive system, piezo buzzers offer the performance you need to ensure your device delivers clear, audible feedback. By understanding the different types and factors to consider when choosing a piezo buzzer, you can select the ideal component for your specific application.

#Piezo buzzers#electronic components#electricalparts#electrical parts#electroniccomponents#technology

0 notes

Text

Piezo Nanopositioner Controllers Market 2025-2032

The global Piezo Nanopositioner Controllers Market size was valued at US$ 198 million in 2024 and is projected to reach US$ 312 million by 2032, at a CAGR of 6.7% during the forecast period 2025-2032

The United States Piezo Nanopositioner Controllers Market size was valued at US$ 49 million in 2024 and is projected to reach US$ 68 million by 2030, at a CAGR of 5.6% during the forecast period 2024-2030.

Piezo Nanopositioner Controllers are specialized electronic devices that precisely control the position and movement of piezoelectric actuators at the nanoscale. These controllers are used in applications requiring high precision and stability, such as microscopy, semiconductor manufacturing, and laser machining. They enable rapid and accurate adjustments in position, allowing for fine-tuning of components or samples in research and industrial settings.

Specialized control systems designed for ultra-precise positioning at the nanometer scale using piezoelectric actuators, commonly used in microscopy, semiconductor manufacturing, and optical alignment.

The global Piezo Nanopositioner Controllers market is experiencing steady growth, driven by increasing demand for high-precision instrumentation in life sciences, advancements in atomic force microscopy, and growing applications in photonics alignment. Key players include Newport Corporation, Aerotech, and nPoint. The market benefits from continuous improvements in control algorithms and sensor technologies. In 2024, single-axis controllers accounted for 45% of the market, with multi-axis systems growing at 7.5% annually. The industry is seeing innovation in hybrid controllers combining piezo and servo-motor control for extended travel ranges. There’s increasing demand for controllers with sub-nanometer resolution capabilities, now representing 32% of sales. Manufacturers are developing user-friendly interfaces and software integration tools, commanding a 20% price premium. The market is benefiting from the trend towards automated and high-throughput research instrumentation. Challenges include mitigating thermal drift and vibration in nanopositioning systems. The US market shows strength in semiconductor and biotechnology research, with an average annual investment of $200,000 per high-end research facility in nanopositioning equipment.

Request Your Free Sample Report

Piezo Nanopositioner Controllers Market Overview

This report provides a deep insight into the global Piezo Nanopositioner Controllers market covering all its essential aspects. This ranges from a macro overview of the market to micro details of the market size, competitive landscape, development trend, niche market, key market drivers and challenges, SWOT analysis, value chain analysis, etc. The analysis helps the reader to shape the competition within the industries and strategies for the competitive environment to enhance the potential profit. Furthermore, it provides a simple framework for evaluating and accessing the position of the business organization. The report structure also focuses on the competitive landscape of the Global Piezo Nanopositioner Controllers Market, this report introduces in detail the market share, market performance, product situation, operation situation, etc. of the main players, which helps the readers in the industry to identify the main competitors and deeply understand the competition pattern of the market. In a word, this report is a must-read for industry players, investors, researchers, consultants, business strategists, and all those who have any kind of stake or are planning to foray into the Piezo Nanopositioner Controllers market in any manner.

Piezo Nanopositioner Controllers Key Market Trends :

Rising Adoption in Semiconductor ManufacturingIncreased demand for precision alignment in semiconductor wafer processing is accelerating the use of nanopositioner controllers.

Growth of Multi-Axis ControllersMulti-axis controllers are growing at 7.5% annually, offering extended flexibility in complex industrial and research applications.

Integration with Hybrid SystemsHybrid controllers combining piezo and servo-motor technologies are becoming popular for achieving long-range precision motion.

Demand for Sub-Nanometer ResolutionSystems offering sub-nanometer precision now represent 32% of the market, highlighting the push for ultra-precision control.

Advanced Software and Interface ToolsUser-friendly interfaces and seamless software integration are driving demand, often commanding a 20% price premium.

Piezo Nanopositioner Controllers Market Segmentation :

The research report includes specific segments by region (country), manufacturers, Type, and Application. Market segmentation creates subsets of a market based on product type, end-user or application, Geographic, and other factors. By understanding the market segments, the decision-maker can leverage this targeting in the product, sales, and marketing strategies. Market segments can power your product development cycles by informing how you create product offerings for different segments. Key Company

Newport

Aerotech

Mad City Labs

PI USA

Market Segmentation (by Type)

Linear

Rotary

Market Segmentation (by Application)

Optical Component

Metrology Equipment

Precision Finishing

Other

Grab Your Complimentary Sample Report

FAQs

Q: What are the key driving factors and opportunities in the Piezo Nanopositioner Controllers market?A: Rising demand in semiconductor, photonics, and life sciences sectors along with automation trends are major growth drivers.

Q: Which region is projected to have the largest market share?A: The United States is a key region, driven by high investments in semiconductor and biotechnology research.

Q: Who are the top players in the global Piezo Nanopositioner Controllers market?A: Leading companies include Newport, Aerotech, Mad City Labs, and PI USA.

Q: What are the latest technological advancements in the industry?A: Innovations include hybrid piezo-servo controllers, sub-nanometer resolution systems, and advanced software integration.

Q: What is the current size of the global Piezo Nanopositioner Controllers market?A: The market was valued at US$ 127.8 million in 2024 and is projected to reach US$ 215.6 million by 2032.

0 notes

Text

0 notes

Text

Elmalo, let's move forward with scoping a full pilot buildout—starting with the v1 Mars Habitat Monitor. This path offers a compelling, high-stakes testbed for the Iron Spine system and allows us to prototype under extreme, failure-intolerant conditions. Designing for Mars pushes the architecture to its limits, ensuring resilience, autonomy, and layered intelligence from the outset.

🚀 v1 Mars Habitat Monitor – Pilot Buildout

🔧 Environmental Design Requirements

Radiation-Hardened Components: Select radiation-tolerant MCU/FPGA and sensor components (e.g., RAD750 derivatives or Microsemi FPGAs).

Thermal Regulation: Passive and active methods (phase-change materials, aerogels, thin-film heaters).

Dust Protection: Hermetically sealed enclosures with electrostatic or vibrational dust mitigation (similar to the Mars 2020 rover’s approach).

Power Constraints: Solar panels + supercapacitors for charge buffering, with ultra-low power idle modes.

Communications Delay Tolerance: Incorporate DTN (Delay-Tolerant Networking) bundles for relayed Earth-Mars messaging.

🧠 Sensor Suite

Life Support Monitoring:

CO₂ / O₂ / CH₄ levels

Humidity / Temperature / Pressure

Structural Integrity:

Microfracture sensors (piezo-acoustic or fiber optic strain gauges)

Vibration analysis (accelerometers/IMUs)

Radiation Exposure:

Ionizing radiation detectors (Geiger-Müller tubes or RADFETs)

Environmental:

Dust density (LIDAR or IR scattering)

UV exposure, ambient EM fields

🧩 System Architecture

Sensor Synchronization:

Use local PTP clocks with oscillator drift correction from a central unit

Redundant clocks for fault detection

Data Fusion Layer:

Edge-level Kalman filters for each sensor type

Onboard anomaly detection with TensorRT-lite or ONNX models for pattern deviation

Edge Inference:

PyTorch Mobile or ONNX on an ARM-based SOM (e.g., NVIDIA Jetson Nano with radiation shielding)

Data Relay and Storage:

Store all telemetry in redundant onboard buffers

Use prepackaged DTN bundles and error-correcting transmission protocols to transmit during windowed comms

Digital Twin Integration:

Each monitor syncs with a simulated Mars habitat replica in Earth orbit or ground control

Dashboard via Prometheus/Grafana or a bespoke Unity/Unreal-powered 3D monitoring console

⚙️ Resilience & Power

Watchdog Timers: Auto-reset on failure, with a secondary power rail for minimal heartbeat signal

Power Monitoring: Real-time tracking of draw, supercapacitor status, and solar charge

Failover States: Downgraded functionality tier for power preservation and sensor core redundancy

Would you like a modular breakdown of the above, suitable for PCB design, mechanical housing, and software stack implementation? Or perhaps a visual mission profile that tracks expected operational phases, anomaly response, and maintenance cycles for the Mars system?

Let’s make this pilot the template for Iron Spine’s interplanetary leap.

0 notes

Text

Nerd Herd (AKA “toaster-bots”) by Maja Matarić (1992), MIT AI Laboratory, Cambridge, MA. Known as "toaster-bots" due to their resemblance to the eponymous kitchen appliance, they also have bread themed names including Brioche, Zwieback and Wonder. In the lower photo three of them form a chain, while another returns with a puck after an excursion around the pen. “Each robot is a 12”-long four-wheeled base, equipped with a forklift for picking up, carrying, and stacking pucks, and a radio transceiver for inter-robot communication and data collection. Each of the robots is also equipped with piezo-electric bump sensors, and infra-red collision and puck detection sensors.” – Controlling a Mobile Robot Herd: Theory and Practice, by Maja Matarić.

“Robots in The Nerd Herd have definite, if simple, sets of goals and subgoals - for instance, Bring home as many pucks as possible. Beyond that, Mataric´ has built reinforcement schemes into every robot, giving them internal mechanisms for "liking" or "disliking" things. When they do something well, such as picking up a puck, they get positive reinforcement and repeat that action in the future. When they do something badly, such as colliding with a wall, they get negative reinforcement and avoid that in the future. … As I watch them running around inside the pen, it's hard not to wonder how much of Mataric´'s own biases about society and social behavior affect the qualities she programs into her robots. "Ah," she laughs at the obvious attempt at a little pop psychology. "Does my desire for distributed systems mean that I don't believe in any type of centralized authority? Let's just say that I'm not given to taking authority easily. I am something of an iconoclast, and in general the approaches I've taken have been iconoclastic." Regardless of the politics involved, the result is a group of robots that is able to think locally but act globally.” – Herd mentality, by Jerry Shine, WIRED magazine, June 1996.

9 notes

·

View notes

Text

Enhance Operational Efficiency with High-Performance Numeric Keypads

In industrial and commercial sectors where precision and resilience are non-negotiable, numeric keypads serve as critical interfaces for data entry, equipment control, and security systems. However, standard keypads often struggle with wear, environmental exposure, or complex maintenance. Our 13x4 Aluminium Piezo Keypad IP68 KPF34 redefines durability without compromising functionality, offering a seamless blend of engineering excellence and practicality for mission-critical applications.

Traditional keypads with mechanical switches are prone to degradation from dust, moisture, and frequent use. Our 13x4 Aluminium Piezo Keypad IP68 KPF34 eliminates these vulnerabilities through piezo switch technology, which uses advanced pressure-sensitive sensors instead of moving parts. This innovation ensures:

• IP68 Protection: Sealed against water, dust, and contaminants, ideal for outdoor, marine, or manufacturing settings.

• Zero Maintenance: A single-piece aluminum construction and potted rear switches prevent corrosion and mechanical failure.

• Enhanced Longevity: Engineered for high-cycle use, reducing replacement costs and downtime.

Key Features Tailored for Demanding Applications

1. 3x4 Keypad Layout with 12 Keys ,Optimized for numeric input in logistics, HVAC, or access control systems, the compact design maximizes workspace efficiency.

2. Matrix Keypad Output ,Simplifies integration with industrial PLCs, HMIs, or IoT devices through standardized matrix signaling.

3. Solid Aluminium Construction

A monolithic aluminum body withstands impacts, extreme temperatures, and prolonged UV exposure, ensuring reliability in harsh climates.

4. Ruggedized Switching Technology ,Piezo elements eliminate contact bounce and wear, delivering consistent performance even after millions of actuations.

Streamline Your Equipment with Versatile Deployment Solutions

Unlike bulky or fragile alternatives, the 13x4 Aluminium Piezo Keypad IP68 KPF34 combines lightweight design with industrial-grade durability. Its IP68-rated sealing and corrugated aluminum surface resist abrasion, making it suitable for:

• Outdoor Terminals: Weatherproof operation in transportation or energy sectors.

• Food Processing: Hygienic, easy-to-clean surfaces compliant with sanitation standards.

• Security Systems: Tamper-resistant interfaces for restricted access zones.

By integrating this keypad, businesses reduce long-term maintenance budgets while enhancing equipment lifespan—a strategic advantage for ROI-focused operations.

For enterprises prioritizing reliability, compliance, and operational continuity, standard keypads fall short. The 13x4 Aluminium Piezo Keypad IP68 KPF34 delivers unmatched performance in demanding environments, backed by scalable integration options and industry-leading longevity.

Contact our team to discuss custom configurations or bulk procurement. Visit our website to explore the 13x4 Aluminium Piezo Keypad IP68 KPF34 and discover how precision-engineered numeric keypads can transform your workflow efficiency.

0 notes

Text

For sell New Mutoh XpertJet 1462UF UV-LED flatbed printer

For sell New Mutoh XpertJet 1462UF UV-LED flatbed printer

Price: $24,498.00 Find more mutoh flatbed printers at www.indraminer.shop

The MUTOH XpertJet 1462UF UV-LED flatbed printer with a moving gantry features a large 55″ x 27″ printable surface area, two 4″ UV-LED lamps, two piezo drop on demand dual print heads in a staggered configuration, and will print on objects up to 5.9″ thick. Legally prints ADA compliant braille and 2.5D layered prints to create fine textured art to add value to any print job. Tie that in with MUTOH’s Local Dimming Control Technology, and you now have the ability to add glossy finishes easily in one pass. With MUTOH’s “Made in Japan Quality” and proprietary features such as the Automatic Nozzle Detection Unit and the Area Select function, the MUTOH XPJ-1462UF is the ideal printer for any print shop looking for reliability, high quality, and fast speeds.

Features 55″ x 27″ Printing Area Two 4″ UV-LED Lamps Staggered Dual Print Head Configuration Up to 5.9″ Thick Material Height Laser Height Detection Sensor Rigid Chassis and Bed Laser Etched Guide-Lines 4-Zone Vacuum Table Unit Pre-Drilled Jig Holes Ferromagnetic Table Bed Comes Pre-Assembled Available with UH-21 hard/rigid ink, 6 colors CMYK+White+Varnish Automatic Nozzle Check Unit Nozzle Area Select.

0 notes