#electroniccomponents

Explore tagged Tumblr posts

Text

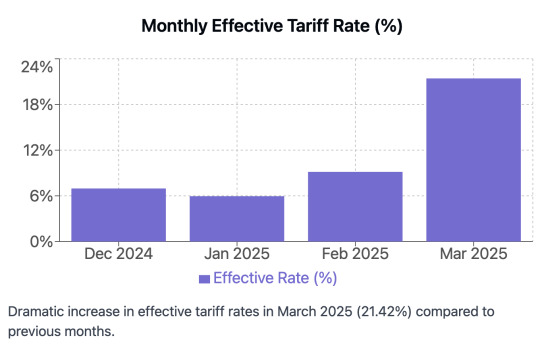

TARIFF TALK! WITH LADYADA 🌍🚢 - Join Ladyada as she breaks down how recent tariff shifts impact electronic component availability and pricing, reshoring trends, and what may happen to engineering/BOM and DIY project costs. Get the inside scoop on navigating supply chain challenges while keeping your builds affordable and excellent! All this week on ASK AN ENGINEER WEDS 8PM ET on all the socials.

#tariffs#electronics#supplychain#ladyada#askanengineer#diyprojects#reshoring#componentprices#engineeringlife#bomcosts#hardwarehacks#techupdate#electroniccomponents#makersmovement#buildsmart#makerlife#electronicsengineering#technews#engineeringtalk#affordablebuilds#openhardware#makerspace#engineering#programming#linux#python#java#software engineering#coding#hardwaredesign

17 notes

·

View notes

Text

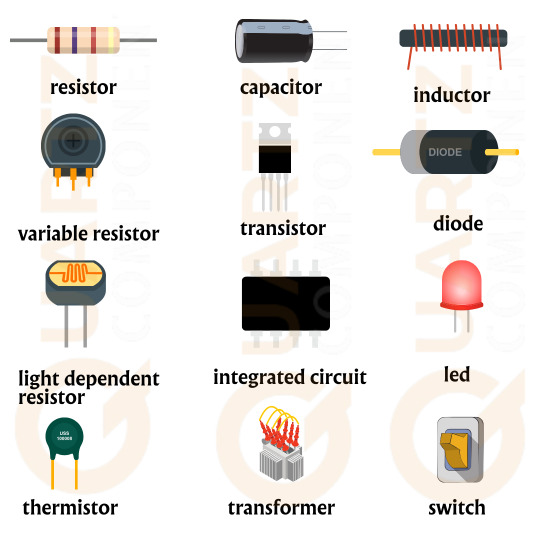

Electronics Components #components #electronics #engineering #electrical #arduino #electronic #innovation #design #robotics #electroniccomponents #raspberry #technology #manufacturing #industrial #gaming #school #learningbydoing #solar #bahrain #pc #pcb #budaiya #muhharaq #manama #engineeringforkids #saar #riffa #makersgonnamake #isatown #summerprogram

#Electronics Components#components#electronics#engineering#electrical#arduino#electronic#innovation#design#robotics#electroniccomponents#raspberry#technology#manufacturing#industrial#gaming#school#learningbydoing#solar#bahrain#pc#pcb#budaiya#muhharaq#manama#engineeringforkids#saar#riffa#makersgonnamake#isatown

13 notes

·

View notes

Text

🌟Buy Components from Element14 on Semikart! 🌟

Element14 Electronics, a premier high-service distributor of technology products, for electronic system design, maintenance, and repair, is now available on Semikart.com

Explore a vast array of Element14 Electronics’s high-quality products on Semikart.com. Elevate your projects with Element14 Electronics's unparalleled support and vast offerings.

#Semikart#element14#TechInnovation#Electronics#indiastartups#semiconductors#components#electroniccomponents#electronicsengineering#electronicsprojects

2 notes

·

View notes

Text

Essential Electronic Items for IoT and Electronics Enthusiasts

Are you diving into the world of Internet of Things (IoT) and electronics? Whether you are a seasoned engineer or simply beginning out, having a stable list of essential components is key to bringing your initiatives to existence. Here’s a curated list of electronic objects that each maker and tech enthusiast ought to have of their toolkit:

1. Microcontrollers

Arduino Uno: Great for novices and versatile for diverse projects.

Raspberry Pi: Ideal for more complex duties and going for walks complete operating structures.

ESP8266/ESP32: Perfect for wireless communication and IoT projects.

2. Sensors

DHT22: For temperature and humidity readings.

PIR Sensor: Useful for movement detection.

Ultrasonic Distance Sensor: Measures distances with high accuracy.

3. Actuators

Servo Motors: For unique manage in robotics and mechanical structures.

Stepper Motors: Ideal for applications requiring particular movement.

Solenoids: Good for growing mechanical actions and locks.

4. Displays

LCD Display: Useful for showing records and debugging.

OLED Display: Compact and clean for exact photographs and texts.

5. Connectivity Modules

Bluetooth Module (HC-05/HC-06): For short-range wi-fi communication.

Wi-Fi Module (ESP8266): Connects gadgets to the internet.

GSM Module: Enables verbal exchange over mobile networks.

6. Power Supplies

Battery Packs: Various types for transportable electricity.

Voltage Regulators: Ensure solid voltage ranges in your circuits.

Power Banks: Handy for charging and powering devices on the move.

7. Prototyping Tools

Breadboards: Essential for prototyping with out soldering.

Jumper Wires: For making connections on breadboards.

Soldering Kit: For everlasting connections and circuit meeting.

eight. Additional Components

Resistors, Capacitors, and Diodes: Fundamental for circuit design and stability.

Transistors: Key for switching and amplification tasks.

Connectors and Switches: For interfacing and controlling circuits.

By preserving these objects handy, you'll be nicely-prepared to address a huge range of IoT and electronics projects. Whether you're constructing smart domestic devices, wearable tech, or computerized structures, having the right additives can make all the difference.

#IoT#Electronics#Arduino#RaspberryPi#ESP32#Sensors#Actuators#Displays#ConnectivityModules#PowerSupplies#Prototyping#Tech#DIY#Makers#Engineering#ElectronicComponents#TechProjects

2 notes

·

View notes

Text

Why Are Abrasive Discs the Backbone of Industrial Surface Treatment?

Abrasive discs might appear simple, but they are behind some of the most critical operations in manufacturing, metalworking, construction, and automotive industries. These compact yet powerful tools are designed to strip, grind, cut, and smooth surfaces with ease and efficiency. Their applications go far beyond everyday sanding—they’re the hidden engine of productivity across workshops worldwide.

Understanding what makes abrasive discs essential, how they differ, and where they excel helps professionals and DIYers alike make informed choices and achieve top-quality results.

The Functionality of Abrasive Discs in Everyday Operations

In industrial terms, abrasive discs are rotating tools fitted to power equipment, used to wear down, smoothen, or cut materials through controlled friction. Their abrasive-coated surfaces act like miniature cutting tools, making them indispensable for jobs that require surface precision or material shaping.

From smoothing out rough metal welds to prepping wooden surfaces for painting, abrasive discs offer unmatched flexibility in use.

Key Reasons Professionals Rely on Abrasive Discs

They save time and labor by performing tasks faster than manual alternatives.

They allow precision, essential in industries that demand strict tolerances.

They offer a wide range of textures and finishes, from coarse grinding to ultra-fine polishing.

They are compatible with various materials—metal, wood, composites, stone, and plastics.

Exploring the Different Variants of Abrasive Discs

There isn’t a one-size-fits-all disc. Each type has been developed to meet specific finishing or cutting requirements. Knowing the differences can transform project outcomes.

Flap Discs

Made of overlapping flaps of abrasive material, they provide a soft and consistent finish while offering both grinding and finishing capabilities in one go.

Fiber Discs

Ideal for aggressive material removal, especially in metal applications. Their rigid construction and heat resistance make them perfect for paint stripping and surface blending.

Resin Fiber Discs

Typically used in metal and masonry, these discs combine flexibility with strength for both coarse and fine sanding.

Diamond Cutting Discs

A top choice when cutting through hard surfaces like granite, tile, or reinforced concrete. Their synthetic diamond coating ensures longevity and clean cuts.

Sanding Discs

Versatile and often used in woodworking or prepping surfaces for painting. They come in many grit sizes to tailor the finish quality.

Surface Conditioning Discs

Built for deburring, blending, and finishing tasks, especially on stainless steel or aluminum. They’re favored in high-precision jobs.

What Abrasive Grains Are Found in Discs?

The grain or mineral used defines the disc’s performance. Each has its strengths based on application, cost, and lifespan.

Aluminum Oxide: Best for general-purpose use on wood and metal.

Zirconia Alumina: Self-sharpening and durable, perfect for heavy-duty grinding.

Ceramic Alumina: For high-pressure grinding of tough metals.

Silicon Carbide: Preferred for softer metals, plastics, or stone.

Diamond: Reserved for cutting extremely hard surfaces like glass and concrete.

The Role of Grit Sizes in Application Quality

Grit size directly impacts the finish you achieve. Lower grit means coarser material, removing stock rapidly. Higher grits deliver smoother, refined surfaces.

Coarse Grit (24–60): Excellent for rapid removal and shaping.

Medium Grit (80–120): Balances material removal with finish control.

Fine Grit (150–400+): Ideal for surface prep and final finishing.

Choosing the wrong grit can damage surfaces or make the process unnecessarily long, so matching it to the task is vital.

Applications That Make Abrasive Discs Indispensable

Abrasive discs are found in nearly every industry where shaping, cleaning, or refining material is needed.

Cutting and trimming metal pipes or bars

Sanding wooden surfaces for cabinetry or flooring

Cleaning welds and prepping steel for painting

Polishing vehicle body panels

Grinding concrete floors or stone slabs

Sharpening blades or tools

From fine finishing to aggressive removal, their adaptability is unmatched.

Tips to Select the Most Suitable Abrasive Disc

With the variety available, knowing what to look for ensures you get optimal performance.

Match the disc to your power tool’s size and speed rating.

Choose the disc type based on your desired finish or application.

Consider material compatibility to avoid premature wear or surface damage.

Prioritize quality and durability, especially for professional-grade use.

Evaluate heat resistance for prolonged tasks or high-pressure grinding.

Safety Isn’t Optional—It’s Essential

Even the best abrasive disc is dangerous without proper handling. High-speed rotation and friction require strict safety adherence.

Always wear eye protection, gloves, and respiratory gear.

Ensure discs are free from cracks or defects before use.

Use proper mounting hardware to avoid imbalance.

Let the disc reach full speed before contacting the workpiece.

Avoid applying excess pressure, which can lead to premature wear or accidents.

Storage and Maintenance of Abrasive Discs

To maintain performance and longevity, proper storage is key.

Keep discs in a dry, dust-free area.

Store flat to prevent warping.

Protect from direct sunlight and moisture.

Dispose of worn or damaged discs responsibly.

How Abrasive Discs Support Sustainable Manufacturing

Many industries are shifting to eco-conscious practices, and abrasive discs contribute by improving efficiency, reducing waste, and enabling material reuse. High-quality discs reduce the need for replacements, while precision finishing limits the margin for error, minimizing scrap.

Final Thoughts

Abrasive discs may not receive as much attention as large-scale machinery, but their impact on project outcomes is undeniable. Their flexibility, reliability, and range of applications make them a must-have in workshops, job sites, and manufacturing floors around the world. Investing in the right disc not only improves surface quality but also enhances efficiency, safety, and long-term savings. For anyone serious about surface treatment or material preparation, abrasive discs remain an essential ally.

0 notes

Text

High-quality Electronic Components for efficient performance.

0 notes

Text

Unlock Precision & Power with Premium IGBTs, Switches & Circuit Breakers from Top Brands – Only at Adatronix

Contact us: +91-96115-17500 / +91-99022-80773 Email us: [email protected] Shop Now: https://adatronix.com/product-category/power-devices/

#adatronix#ElectronicComponents#PowerDevices#circuitbreaker#converter#diodes#thyristors#IGBTs#magnetbrakes#PowerSupply#switches#transistors

0 notes

Text

#automotive#ElectronicComponents#SlidingSwitches#IndustrialElectronics#AutomotiveSolutions#ComponentInnovation#SwitchTechnology#ReliabilityEngineering#ProductLaunch#TimestechUpdates#SmartManufacturing#NextGenDevices#electronicsnews#technologynews

0 notes

Text

Looking to Upgrade Your Products with Electroplating Services in the UAE?

Boost durability, performance, and visual appeal with Noble Metal Coating LLC expert electroplating in Sharjah, Dubai, Abu Dhabi, and beyond.

Our Specialties include: Tin, Silver, Gold, Antique, Brass, Bronze, Copper & Nickel Electroplating services.

📍 Serving: Sharjah, Dubai, Abu Dhabi, Ras Al Khaimah, Umm Al Quwain

📞 Upgrade your products today — Contact Noble Metal Coating Now!

#Electroplating#TinPlating#GoldPlating#SilverPlating#ConductivityBoost#ElectronicComponents#MetalFinishing#TechInnovation#NobleMetalCoating#BetterPerformance#IndustrialCoating#PrecisionFinishing#IndustrialCoatings#SharjahServices

0 notes

Text

TPS65131 split boost converter revision ✅🔧

We designed this split +12/-12 power supply board based on the TPS65131 (https://www.digikey.com/en/products/detail/texas-instruments/TPS65131RGER/1672464) a few months ago, but it languished while we worked on some other projects. We had an issue where the negative power rail was unstable. Thankfully, we found a thread that suggested slowing down the VNEG feedback loop (https://e2e.ti.com/support/power-management-group/power-management/f/power-management-forum/628380/tps65131-q1-abnormal-operation-of-tps65131-q1-s-vneg) with a 51k resistor. We hand-soldered that in, and it worked nicely. Then, the other fix was to flip around the trimmers so the turn direction matched the expected behavior. This should be good to book a second prototype, and then it can go into the shop.

#tps65131#powersupply#electronicsengineering#pcbdesign#circuitdesign#electronicsproject#embeddedhardware#hardwareengineering#powersolutions#analogdesign#electroniccircuits#electricalengineering#techfix#engineeringlife#electronicslab#hardwarefix#electronicsrepair#pcbprototype#voltageregulator#negativevoltage#boostconverter#dcconverter#electroniccomponents#custompcb#powercircuit#ti#texasinstruments#prototypeboard#makersgonnamake

14 notes

·

View notes

Text

Looking for the perfect speaker pair to enhance your LED/LCD TV experience? Look no further! 🔊📺 Explore our wide selection of high-quality speakers on quartzcomponents.com and elevate your audio game today. Don't miss out – shop now for immersive sound that complements your TV viewing like never before! 🛒🔊

#TVAudio#HomeEntertainment#SpeakerUpgrade#ImmersiveAudio#TechGadgets#HomeTheater#AudioExperience#electronics#Tech#circuitry#gadgets#diyelectronics#electronicprojects#arduino#RaspberryPi#pcbdesign#microcontrollers#robotics#iot#electroniccomponents#soldering#wirelesstechnology#electricalengineering#circuitdesign#embeddedsystems#powerelectronics#electronicsrepair#sensortechnology

2 notes

·

View notes

Text

#semikart#electroniccomponents#buy online electronics components#electronic parts distributor#electronic components distributor#components

2 notes

·

View notes

Text

𝐖𝐡𝐲 𝐎𝐏𝐌? - 𝘋𝘦𝘥𝘪𝘤𝘢𝘵𝘪𝘰𝘯 𝘵𝘰 𝘩𝘪𝘨𝘩 𝘲𝘶𝘢𝘭𝘪𝘵𝘺 𝘴𝘵𝘢𝘯𝘥𝘢𝘳𝘥𝘴 𝘢𝘯𝘥 𝘤𝘰𝘯𝘵𝘪𝘯𝘶𝘰𝘶𝘴 𝘪𝘮𝘱𝘳𝘰𝘷𝘦𝘮𝘦𝘯𝘵 - 𝘊𝘰𝘮𝘮𝘪𝘵𝘮𝘦𝘯𝘵 𝘵𝘰 𝘴𝘢𝘧𝘦𝘵𝘺 𝘪𝘯 𝘢𝘭𝘭 𝘰𝘱𝘦𝘳𝘢𝘵𝘪𝘰𝘯𝘴 - 𝘐𝘯𝘷𝘦𝘴𝘵𝘮𝘦𝘯𝘵𝘴 𝘪𝘯 𝘯𝘦𝘸 𝘦𝘲𝘶𝘪𝘱𝘮𝘦𝘯𝘵 𝘢𝘯𝘥 𝘵𝘦𝘤𝘩𝘯𝘰𝘭𝘰𝘨𝘺 - 𝘊𝘰𝘮𝘱𝘦𝘵𝘪𝘵𝘪𝘷𝘦 𝘱𝘳𝘪𝘤𝘪𝘯𝘨 𝘢𝘯𝘥 𝘰𝘯-𝘵𝘪𝘮𝘦 𝘥𝘦𝘭𝘪𝘷𝘦𝘳𝘺

Plastic injection molding for electronics is an extremely efficient and versatile production technology that has transformed the electronics industry. With the growing demand for high-quality, high-volume electronic parts, injection molding services have become indispensable for producing a diverse range of products, from simple components to sophisticated assemblies.

Request an injection molding quote today. Email:[email protected] Contact No:+91-9900299893

#electronicsinjectionmolding#manufacturingprocess#injectionmoldingdesign#injectionmold#electroniccomponents#plasticinjectionmoldingelectronics#moldingdesigncompanies#injectionmoldingmanufacturing

0 notes

Text

Omron G2RL-1A-E DC12 Power Relay – 12V DC 16A SPST-NO (1 Form A) Sealed PCB Mount Relay

The Omron G2RL-1A-E DC12 is a high-performance general-purpose power relay featuring a 12V DC coil and SPST-NO (1 Form A) contact capable of handling up to 16A. Designed for through-hole PCB mounting, this sealed relay offers flux protection, Class F coil insulation, and high switching capacity—ideal for HVAC, home appliances, industrial automation, and control panels.

Key Features:

Coil Voltage: 12V DC Contact Form: SPST-NO (1 Form A) Current Rating: 16A Switching Voltage: 440VAC / 300VDC Sealed Type: Flux Protected Mounting Style: Through Hole (PC Pin) Operate/Release Time: 15 ms / 5 ms Temperature Range: -40°C to +85°C Contact Material: Silver Alloy (Cadmium Free)

📦 Bulk orders available – DM us or call to get the best price!

📞 Contact Today : +919810987429

📥 Enquire Now : [email protected]

#OmronRelay#G2RLRelay#12VRelay#PowerRelay#SPSTRelay#PCBMountRelay#FluxProtectedRelay#HighCurrentRelay#IndustrialRelay#HomeApplianceRelay#AutomationRelay#ThroughHoleRelay#ElectronicComponents#RelayIndiaMart#GeneralPurposeRelay

0 notes

Text

How Do Infrared Temperature Sensors Revolutionise Non-Contact Measurement?

Infrared temperature sensors have rapidly become indispensable tools across modern industries, offering a reliable, contactless solution to temperature monitoring. By detecting the infrared radiation emitted from surfaces, these sensors provide rapid and accurate temperature readings without touching the object. This article explores their significance, underlying principles, diverse applications, and why they’re increasingly preferred in precision-driven environments.

Understanding the Science Behind Infrared Sensors

Infrared temperature sensors work based on the principle of blackbody radiation. Every object above absolute zero emits infrared radiation, which increases with temperature. These sensors detect radiation and translate it into temperature data using built-in algorithms.

Advantages of Using Infrared Temperature Sensors

Infrared sensors are not only about technology—they’re about improving performance, safety, and convenience in various scenarios.

Offer real-time monitoring without physical contact

Minimise contamination risk in clean environments

Reduce wear and tear compared to contact-based probes

Enable temperature readings in hard-to-reach or hazardous zones

Support fast-moving industrial processes with instantaneous results

Core Applications in Diverse Industries

From factories to food storage, the versatility of infrared temperature sensors extends across sectors.

Manufacturing and Automation

Used to measure temperatures of metal surfaces, plastic moulds, and rotating machinery parts. They help avoid equipment failures by spotting abnormal heat levels early.

Electrical and Electronics

Crucial for monitoring circuit boards, batteries, and components under stress. They detect overheating risks before permanent damage occurs.

Food and Beverage Industry

Infrared sensors ensure food is stored, processed, and cooked at safe temperatures. They’re ideal for measuring surface temperatures of cooked items or refrigerated goods.

Medical and Healthcare Settings

Used in thermography, fever screening, and patient monitoring. Their non-invasive nature makes them ideal for hygienic and quick diagnostics.

Energy Auditing and Building Inspection

Identify heat losses in homes and commercial buildings. Used for HVAC evaluations and insulation performance analysis.

Automotive Systems

Essential in brake diagnostics, engine temperature checks, and tyre surface assessments. They improve overall vehicle safety and performance insights.

How to Select the Right Infrared Temperature Sensor

Not every sensor fits every need. Choosing the right one depends on several performance metrics.

Temperature Range: Must align with expected minimum and maximum surface temperatures

Accuracy and Repeatability: Important for high-precision applications

Distance-to-Spot Ratio: Affects how far the sensor can measure a target of a given size

Emissivity Setting: Allows adjustment to match various surface materials

Environmental Resistance: Sensors should be rugged if used in dusty, wet, or corrosive surroundings

Integration in Smart and IoT-Based Systems

Modern infrared temperature sensors are often designed with connectivity in mind. This makes them suitable for smart systems where data logging, real-time alerts, and analytics are crucial.

Embedded with Bluetooth, Zigbee, or Wi-Fi modules

Paired with cloud dashboards for remote monitoring

Integrated into industrial control systems for automation

Utilised in predictive maintenance frameworks via AI

Practical Tips for Optimal Use

Even the best infrared sensor can produce unreliable results if used incorrectly. To ensure precision and longevity:

Always keep the lens clean from dust and debris

Aim perpendicularly at the target for accurate readings

Use sensors with adjustable emissivity for varying surface types

Avoid steam, smoke, or reflective backgrounds when possible

Calibrate periodically for environments with strict accuracy requirements

Emerging Innovations in Infrared Technology

As industries demand more intelligent and adaptive tools, infrared sensor technology is evolving.

Compact thermal imaging modules for drones and wearables

Dual-spectrum sensors combining visual and IR data

AI-enhanced thermal diagnostics for predictive fault detection

Edge computing integration to reduce cloud dependency

Flexible IR sensors for curved surfaces and embedded devices

Final Thoughts on Infrared Temperature Sensors

Infrared temperature sensors bridge the gap between safety, speed, and accuracy in thermal monitoring. They are indispensable tools for engineers, technicians, healthcare professionals, and energy consultants who rely on instant data without compromise. With expanding use in automation and smart technologies, infrared sensors are not just tools—they are strategic assets in building responsive, safe, and efficient systems. Whether monitoring machines, patients, or processes, their non-contact advantage keeps them ahead in the evolving landscape of sensor technology.

#Infrared temperature sensors#Enrgtech#Electroniccomponents#electronic components#electrical parts#technology#Electronics

0 notes

Text

Reliable Electronic Components for your vehicle’s needs.

0 notes