#plastic testing

Explore tagged Tumblr posts

Text

How Flammability Testing of Plastics Helps Improve Product Safety?

In today’s product-driven world, plastics are found everywhere—from home appliances and automobiles to electronics and construction materials. While these materials offer durability, lightness, and cost-efficiency, they also raise safety concerns—especially related to fire. That’s why flammability testing of plastics is a crucial service provided by every top-tier Plastic Testing Lab.

In this blog, we will explore what flammability testing entails, why it's essential for ensuring product safety, and how plastic testing labs help manufacturers meet global fire safety standards.

What is Flammability Testing?

Flammability testing determines how easily a plastic material ignites, how fast it burns, and whether it continues to burn or extinguishes on its own after ignition. The results of these tests help manufacturers assess the fire risk of their plastic components and determine their suitability for specific applications.

A Plastic Testing Lab performs these tests under controlled conditions using international testing standards such as:

UL 94 – Tests horizontal and vertical burning characteristics

ASTM D635 – Measures the rate of burning

ASTM E84 – Surface burning characteristics of building materials

ISO 9772/9773 – Flammability testing for cellular plastics

Why Flammability Testing Matters

1. Protects Human Life

The primary purpose of flammability testing is to protect end users. In the event of a fire, materials with poor flame resistance can ignite quickly, contributing to the spread of fire, smoke, and toxic gases. Testing helps prevent such scenarios by ensuring only fire-resistant materials are used in critical applications.

2. Enhances Product Safety

From televisions and laptops to dashboards and wiring insulation, many plastic components are integral to everyday products. Flammability testing confirms that these components do not pose a fire hazard during regular or malfunctioning conditions.

3. Meets Regulatory Compliance

Many industries are bound by strict fire safety regulations. Products that do not meet these standards cannot enter the market. A Plastic Testing Lab helps manufacturers verify that their materials comply with regulations like:

UL standards in the US

European EN fire safety standards

NFPA (National Fire Protection Association) guidelines

Building and transportation safety codes

4. Improves Consumer Confidence

Products that pass flammability tests are safer, and consumers trust brands that prioritize safety. Flammability ratings are often used in marketing and labeling to demonstrate compliance and quality assurance.

Industries That Rely on Flammability Testing

● Electronics and Electrical

Plastic is widely used in casings, cable insulation, switches, and circuit boards. Flammability testing ensures these components do not catch fire under overload or fault conditions.

● Automotive and Aerospace

Vehicles and aircraft use lightweight plastic materials to improve fuel efficiency. These plastics must meet rigorous flame retardancy standards to reduce fire hazards in case of electrical failure or accidents.

● Construction

Plastics used in insulation, wall panels, flooring, and ceiling materials are tested for flame spread and smoke development. Building codes worldwide require verified flame-retardant materials.

● Appliances

Kitchen appliances, heaters, and air conditioners contain plastic components that must withstand high heat without catching fire.

● Consumer Products

Toys, furniture, and other household goods made from plastics must pass flammability tests to protect users—especially children.

Types of Flammability Testing in Plastic Testing Labs

A specialized Plastic Testing Lab uses multiple methods to evaluate how plastics behave under fire exposure:

1. Vertical and Horizontal Burn Tests (UL 94)

Horizontal Burning Test (HB): Measures how fast the flame travels along a horizontally mounted plastic sample.

Vertical Burning Test (V-0, V-1, V-2): Assesses how quickly a vertically mounted sample extinguishes after being exposed to flame. V-0 is the most flame-resistant rating.

2. Oxygen Index Testing (ASTM D2863)

Determines the minimum concentration of oxygen needed to support combustion. Higher oxygen index values indicate better flame resistance.

3. Limiting Oxygen Index (LOI)

Indicates the percentage of oxygen needed in the atmosphere for the plastic to burn. Materials with LOI above 26% are considered flame-retardant.

4. Cone Calorimeter Testing

Simulates real-world fire scenarios by measuring heat release rate, time to ignition, smoke production, and mass loss. Commonly used in aerospace and construction industries.

5. Glow Wire Testing (IEC 60695)

Used for electrical components to assess fire risk from heated or glowing elements such as resistors or malfunctioning circuits.

How a Plastic Testing Lab Supports Product Development

A Plastic Testing Lab is not just a service provider—it’s a safety partner that helps manufacturers:

Evaluate different plastic grades for flame resistance

Select flame-retardant additives or coatings

Develop compliant and fire-safe products

Generate documentation for certification and market entry

Troubleshoot material performance in case of field failures

Lab experts provide insights that help improve both product design and safety from the early stages of development.

Flame-Retardant vs. Non-Flame-Retardant Plastics

Not all plastics are naturally flame-resistant. Here’s how they compare:

Plastic Type

Flame Resistance

PVC (Polyvinyl Chloride)

High (self-extinguishing)

PTFE (Teflon)

High

Polypropylene (PP)

Low

Polyethylene (PE)

Low

Nylon

Moderate

Polycarbonate (PC)

High (with additives)

Plastics with low flame resistance can be treated with additives or coatings to enhance safety.

Benefits of Flammability Testing

✅ Reduces risk of fire-related accidents

✅ Improves safety of electrical and mechanical systems

✅ Ensures adherence to national and international standards

✅ Supports product recalls and liability defense

✅ Enhances brand value through proven safety

Future Trends in Plastic Flammability Testing

As sustainability and environmental impact become top priorities, manufacturers are moving away from halogen-based flame retardants to eco-friendly alternatives. This shift necessitates more advanced flammability testing, especially to balance fire safety with environmental compliance (e.g., RoHS, REACH).

Plastic Testing Labs are adopting new methods and technologies to support this trend, ensuring safer and greener materials enter the market.

Conclusion

Flammability testing is an essential part of the product development process for any application involving plastics. It’s not just about passing a test—it’s about protecting lives, property, and brand reputation.

By partnering with a certified Plastic Testing Lab, manufacturers can:

Identify fire hazards early

Select appropriate materials

Ensure compliance with stringent regulations

Boost product performance and safety

In a world where safety is non-negotiable, flammability testing is the frontline defense in creating plastic products that are both high-performing and fire-safe.

0 notes

Text

#Mechanical testing laboratory in thane#material analysis#tensile testing#hardness testing#fatigue testing#quality assurance#plastic testing#composite testing#micro testing laboratory solutions#MTLSPL

1 note

·

View note

Text

Plastic Testing Lab | +971 554747210

0 notes

Text

How Ajman’s Plastic Testing Labs Support Innovation in the Plastic Manufacturing Sector? | +971 554747210

Innovation is a key driver of success in the plastic manufacturing industry. As manufacturers seek to develop new materials and processes to meet the evolving demands of industries such as automotive, packaging, medical devices, and consumer products, ensuring that these innovations are reliable, safe, and efficient is crucial. This is where plastic testing lab in Ajman play a vital role.

Ajman’s plastic testing labs not only provide essential testing services to ensure compliance with industry standards but also support innovation in material development, new product design, and sustainability efforts. In this blog, we will explore how these testing labs contribute to the advancement of the plastic manufacturing sector and help businesses stay ahead in a highly competitive global market.

1. The Role of Plastic Testing Labs in Supporting Innovation

The global plastic industry is undergoing rapid transformation, driven by consumer demands for more sustainable products, improved material performance, and cutting-edge technological advancements. With these changes comes the need for testing and validation to ensure that new plastic products, materials, and processes meet the required safety, environmental, and performance standards.

Plastic testing labs in Ajman help manufacturers:

Test and validate new plastic materials for specific applications.

Refine manufacturing processes to improve efficiency and reduce costs.

Ensure compliance with regulatory standards to access global markets.

Accelerate product development cycles, reducing time-to-market.

By offering comprehensive testing services, these labs support innovative breakthroughs in plastic manufacturing and help businesses navigate the challenges associated with developing new plastic products.

2. How Plastic Testing Labs Facilitate Material Innovation

Innovation in the plastic industry often begins with the development of new materials. Researchers and manufacturers are constantly exploring new polymer blends, additives, and processes to improve the properties of plastics. Whether for enhancing durability, flexibility, strength, or sustainability, these innovations need rigorous testing to ensure that the final product will perform as expected in real-world conditions.

Plastic testing labs in Ajman are equipped with state-of-the-art technology to conduct a wide range of tests, which include:

2.1 Mechanical Testing

For plastic materials to be viable in innovative applications, they must exhibit the appropriate mechanical properties, such as tensile strength, impact resistance, and elongation at break. Testing labs in Ajman assess the ability of new plastic materials to withstand mechanical stress without cracking, deforming, or breaking.

These tests are especially important in the development of high-performance plastics used in industries like automotive, aerospace, and electronics, where failure is not an option. By conducting mechanical testing, manufacturers can ensure that their newly developed materials meet the required standards for strength and reliability.

2.2 Thermal Testing

Innovative plastic materials may be designed to operate in extreme temperature conditions, whether exposed to high heat in automotive engines or freezing temperatures in refrigeration. Plastic testing labs conduct thermal stability testing to determine the performance of materials under various temperature conditions, ensuring that the materials retain their properties over time.

Tests such as heat deflection temperature, thermal conductivity, and melt flow index are essential for ensuring that new plastic products can perform reliably in challenging environments.

2.3 Chemical Resistance Testing

As plastic materials evolve, they may need to withstand exposure to chemicals such as oils, solvents, and cleaning agents. Chemical resistance testing helps determine how well a material resists degradation when exposed to various chemicals, which is crucial for developing plastics used in packaging, automotive, medical, and industrial applications.

Ajman’s plastic testing labs provide comprehensive chemical testing to validate that newly developed materials will maintain their integrity in real-world environments, ultimately enhancing their applicability and reliability.

3. Accelerating Innovation through Sustainability Testing

Sustainability is at the forefront of the plastic industry’s innovation agenda. As pressure mounts on manufacturers to reduce plastic waste and develop more environmentally friendly materials, the role of sustainability testing becomes even more critical.

Plastic testing labs in Ajman play an instrumental role in supporting the development of sustainable plastic products by offering the following services:

3.1 Recyclability and Biodegradability Testing

One of the biggest challenges for plastic manufacturers is creating materials that are recyclable or biodegradable, reducing the environmental impact of plastic products. In Ajman, testing labs help manufacturers evaluate the recyclability and biodegradability of plastic materials. These tests assess how easily plastics can be processed and reused, as well as how quickly they decompose under natural conditions.

By conducting these tests, plastic testing labs help companies develop eco-friendly products that align with global sustainability goals and help reduce plastic pollution.

3.2 Life Cycle Assessment (LCA)

Life Cycle Assessment is an analytical tool used to evaluate the environmental impact of a product throughout its entire lifecycle, from production to disposal. Plastic testing labs in Ajman help manufacturers perform LCAs to understand the total environmental footprint of their products, identify opportunities for reducing waste, and optimize manufacturing processes to minimize energy consumption and raw material usage.

This allows manufacturers to design products that not only meet performance standards but also adhere to the growing demand for sustainable materials and processes.

3.3 Energy Efficiency Testing

Innovation is not just about new materials but also about improving the efficiency of manufacturing processes. Testing labs in Ajman support energy-efficient practices by evaluating the energy consumption of plastic production methods. By identifying areas of improvement, manufacturers can reduce operational costs while reducing the environmental impact of their production processes.

4. Ensuring Compliance with Global Standards for Market Access

In a globalized world, manufacturers must meet the standards and regulations set by various international organizations to access and sell products in different markets. Ajman’s plastic testing labs help manufacturers ensure their products meet the stringent requirements set by organizations such as ISO (International Organization for Standardization), REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), and RoHS (Restriction of Hazardous Substances).

By testing new materials and products to meet these global standards, plastic testing labs in Ajman help manufacturers:

Ensure regulatory compliance in both local and international markets.

Gain certifications that demonstrate the safety and reliability of their products.

Streamline the approval process, reducing time-to-market for innovative products.

By working with testing labs, manufacturers can confidently introduce new plastic innovations into the global marketplace, knowing their products meet all regulatory requirements.

5. Testing for Safety and Reliability in New Plastic Products

Safety and reliability are paramount when it comes to plastic products used in critical applications such as medical devices, automotive components, and food packaging. Ajman’s plastic testing labs provide essential services to ensure that new products meet safety standards, reducing the risk of product failure and enhancing consumer confidence.

5.1 Flammability Testing

Many plastic materials used in industries like automotive and consumer goods must meet strict flammability standards to prevent fire hazards. Testing labs in Ajman assess the ability of plastic materials to resist ignition, slow down the spread of fire, or self-extinguish when exposed to flame.

5.2 Toxicity Testing

Certain plastic additives or chemicals can pose health risks if they leach into the environment or come into contact with consumers. Toxicity testing helps identify any harmful substances in new plastic materials, ensuring that products used in sensitive applications like toys, medical devices, and food packaging are safe for use.

6. Conclusion

Ajman’s plastic testing labs play a crucial role in supporting innovation within the plastic manufacturing sector. By providing comprehensive testing services for mechanical properties, sustainability, safety, and regulatory compliance, these labs help manufacturers refine their materials, accelerate product development, and meet the growing demand for high-performance and eco-friendly plastics.

As the plastic industry continues to evolve, Ajman’s plastic testing labs will remain a key partner for businesses looking to innovate and stay ahead in a competitive global market. Whether it's developing new materials, ensuring product safety, or meeting sustainability goals, these testing labs are essential to the success of the modern plastic manufacturing industry.

0 notes

Text

Explore reliable plastic testing services in Chennai at our accredited lab. From material analysis to quality assurance, our expert team ensures compliance with industry standards for all your plastic testing needs.

#Plastic Testing#Lab Services#Plastic Properties#plastic manufacturing#maeon laboratory#chennai#composite testing laboratory

1 note

·

View note

Text

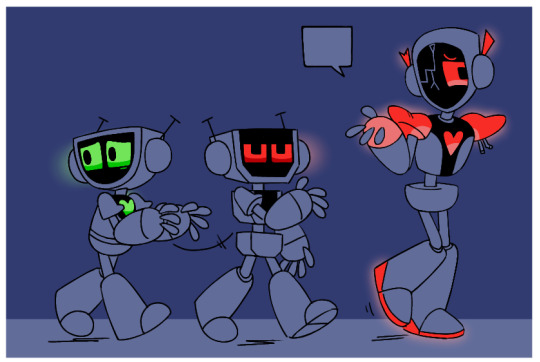

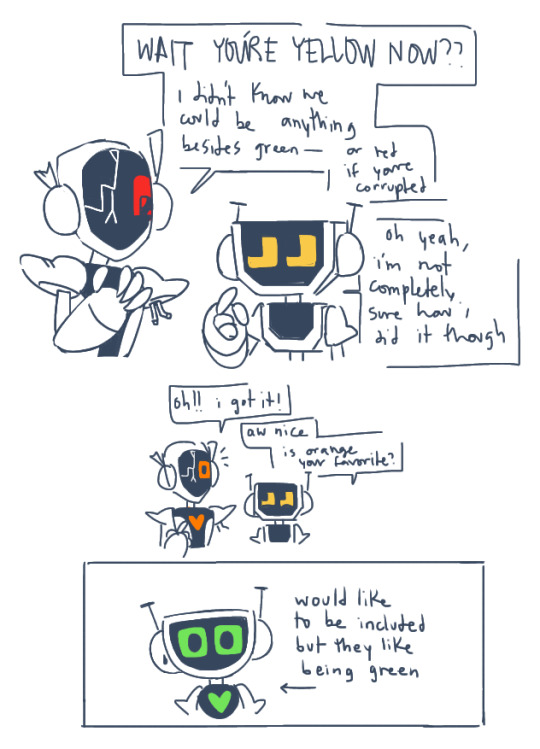

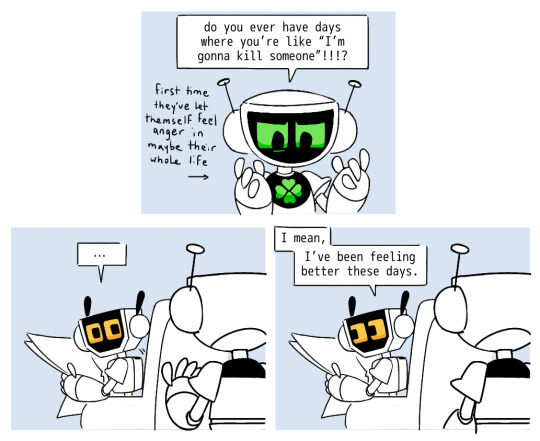

this was intended to be all void-centric but well. last two are based on conversations between my sibling and i :] the last one was Originally about me just being ambivalent about cream soda(my sibling doesn’t really like soda(carbonation) but xe is a ride or die for cream soda apparently)

#the art gallery#friendship test#friendship test spoilers#first one is just bc i don’t think I acknowledge well enough that voids colors are like. A Light and not like colored plastic#i just don’t typically color the rest bc it doesn’t look visually balanced next to other characters when i just color their eyes/heart

182 notes

·

View notes

Text

Alpine Marbon CRV, 1966, by OSI. The Cycolac Research Vehicle was commissioned by US company Marbon-Chemical to showcase their ABS plastic material Cycolac for automotive applications. The car toured Europe's car makers and found a taker at Citroën who used Marbon's ABS for their Mehari

#Alpine#Alpine Marbon CRV#OSI#Cycolac Research Vehicle#research vehicle#test vehicle#prototype#Marbon-Chemical#ABS Plastic#1966#coachbuilt#rear engine#1960

392 notes

·

View notes

Text

★ 096 // “SBR"

#jjba#jojo's bizarre adventure#steel ball run#sbr#johnny joestar#offerings#tools used:#wooden letters I bought at Michael's#acrylic paint#mod podge#tiny plastic star rhinestones#krazy glue#glow in the dark puffy paint#This came out cooler than I thought. I decided to add the glow in the dark after I saw the bottle laying around and WOWIE!!#Starting to make objects for the summoning circle; this is one of them! Figured we needed the letters of what we want!!#I HAD A CRAZY BREAKTHROUGH FOR THE CIRCLE. I KNOW HOW I'M GONNA THE CIRCLE ITSELF. Y'ALL ARE GONNA FREAK!!#You can pretty much expect every entry from now until 101 to be related to the circle. HOWEVER THERE IS A RUSSIAN ROULETTE ELEMENT!!--#-- Because one of the offerings will be the Discord server I've been teasing! It's literally 95% done. I finally had someone test the roles#I just need to gloss over it one last time and make the proper promo images for it hehe!#I CAN'T WAIT TO HANG OUT IN IT YIPPEE!!!#WHAT IF WE HAD A SLEEPOVER WHERE WE DON'T SLEEP LEADING INTO JOJO DAY? :D

67 notes

·

View notes

Text

Chernobyl has been performing a lot of science experiments lately. She's managed to create this weird one-eyed one-horned skull, and I suspect she's trying to bring back the long extinct purple-people eater

This is a problem because if she succeeds it'll be catastrophic for our ecosystem. Though, I get the feeling that's exactly what Chernobyl wants :/

#stole this test tube from a restaurant#it was for adding a shot of alcohol to your drink lol#and no it's not uranium glass#just plastic#furby#custom furby#razzle dazzle#chernobyl

61 notes

·

View notes

Text

Last Call for Lowest Rice Purity Test Score Tournament!

Tomorrow is the last day to submit characters for the Lowest Rice Purity Test Score poll tournament! There are currently 14 characters submitted:

John Constantine (3 nominations!)

Hal Jordan (4 nominations!)

Sir Justin Arthur

Greg Saunders (2 nominations!)

Roy Harper (2 nominations!)

Lois Lane (2 nominations!)

Oliver Queen (2 nominations!)

Lobo (no propaganda)

Plastic Man

Deadpool (our first guest nominee!)

Bruce Wayne (2 nominations!)

Jonathan Crane

Skinner Sweet

Jason Todd

Stephanie Brown

Booster Gold

Well, 16 characters have been nominated thus far, but Lois and Stephanie both competed in the previous tournament and are thus barred from this one.

With that in mind, the Batfandom is sitting right at the three character limit, with Batman, Scarecrow, and Red Hood. Though frankly the propaganda submitted for them was rather lackluster compared to some of the other nominees.

Similar story with the Arrow fandom. Y'all gave Roy one word of propaganda and it was just "drugs". I swear, it's almost like you don't actually want your blorbos to win /hj

On a happier note, we finally have our first guest from a non-DC fandom. Rather fittingly, it's the Merc with the Mouth

#lowest rice purity test score#silly dc polls#dc comics#dc polls#pre-tournament update#john constantine#hellblazer#hal jordan#green lantern#sir justin#shining knight#greg saunders#roy harper#arsenal#red arrow#oliver queen#green arrow#lobo#eel o'brian#plastic man#wade wilson#deadpool#bruce wayne#batman#jonathan crane#scarecrow#skinner sweet#jason todd#red hood#michael carter

26 notes

·

View notes

Text

What to Look for When Choosing a Plastic Testing Lab for Your Product?

In today’s highly competitive and regulated marketplace, ensuring the quality, safety, and compliance of plastic products is non-negotiable. Whether you're manufacturing consumer goods, automotive parts, packaging, electronics, or medical devices, choosing the right plastic testing lab can directly impact your product’s market acceptance and long-term success.

With numerous labs available, how do you identify the one that aligns with your technical, regulatory, and operational needs? This guide outlines what to look for when choosing a plastic testing lab for your product—from certifications and capabilities to turnaround time and industry expertise.

Why Plastic Testing is Crucial

Plastics are integral to modern product development, but their performance varies based on composition, additives, and environmental exposure. Testing helps verify:

Material identity and consistency

Mechanical strength and durability

Thermal resistance and flammability

Chemical composition

Regulatory compliance (e.g., REACH, RoHS, FDA, ISO)

A reliable plastic testing lab ensures your product meets industry standards and consumer safety expectations.

1. Accreditation and Certifications

The most important factor when choosing a plastic testing lab is third-party accreditation, which validates the lab’s technical competence and reliability.

✅ ISO/IEC 17025 Accreditation

An ISO/IEC 17025-accredited lab meets global standards for laboratory testing. It proves the lab has the technical capability and quality management systems in place for accurate and repeatable test results.

✅ Industry-Specific Certifications

FDA compliance testing for food-contact plastics

RoHS and REACH compliance for electronics and packaging

ASTM and ISO standards for product quality

Always ask the lab to provide proof of accreditation relevant to your industry.

2. Scope of Testing Services

Not all labs offer the same services. A top-tier plastic testing lab should provide a comprehensive range of tests, including:

🔍 Physical and Mechanical Testing

Tensile strength

Flexural and impact resistance

Hardness (Shore A/D, Rockwell)

🔥 Thermal Testing

Heat deflection temperature (HDT)

Vicat softening point

Flammability (UL 94)

🧪 Chemical Analysis

Fourier Transform Infrared Spectroscopy (FTIR)

Gas Chromatography-Mass Spectrometry (GC-MS)

Heavy metal detection (XRF, ICP-MS)

🧬 Environmental and Aging Tests

UV exposure

Humidity and temperature cycling

Oxidative Induction Time (OIT)

Make sure the lab can customize testing protocols based on your product's unique requirements.

3. Regulatory Compliance Expertise

Your product may need to comply with regional and international regulations. Choose a plastic testing lab that has deep knowledge of:

REACH (EU) – for substances of very high concern (SVHCs)

RoHS (EU) – for restricted hazardous substances

FDA (USA) – for food-grade and medical plastic

ISO/ASTM Standards – for performance and quality benchmarks

A lab experienced with these regulations can provide not just testing, but also guidance on staying compliant and avoiding costly recalls or delays.

4. Industry Specialization

Plastic is used across a wide range of industries. A lab that understands your sector will deliver better insights and more relevant testing. Consider labs with experience in:

Automotive – for temperature, vibration, and chemical resistance

Electronics – for insulation resistance, fire safety, and RoHS

Medical – for biocompatibility, sterilization, and extractables

Packaging – for barrier properties, migration, and seal strength

Construction – for weathering, load bearing, and chemical exposure

Ask for case studies or references from clients in your industry to verify expertise.

5. Modern Equipment and Technology

Advanced testing equipment ensures greater accuracy, sensitivity, and speed. A reputable plastic testing lab should be equipped with:

Spectrometers (FTIR, UV-Vis, ICP-MS)

Chromatographs (GC, HPLC)

Thermal analyzers (TGA, DSC)

Mechanical test machines (Universal Testing Machine)

Environmental chambers (for UV, humidity, temperature)

Well-maintained and calibrated instruments are crucial for reliable testing results. Don’t hesitate to ask about the lab’s equipment list and maintenance protocols.

6. Turnaround Time and Capacity

In fast-paced industries, time-to-market is key. Ask the lab about:

Turnaround time for standard and custom tests

Capacity for batch or high-volume testing

Ability to meet urgent or project-specific deadlines

Labs that offer expedited services or 24/7 operations can be strategic partners for tight production schedules or urgent certifications.

7. Transparent Reporting and Documentation

The results from a plastic testing lab are only as valuable as the way they're reported. Choose a lab that provides:

Clear, easy-to-read test reports

Certificates of compliance (e.g., REACH, RoHS, FDA)

Digital access to results

Support for data interpretation

The best labs not only deliver results but also help you understand them in the context of regulatory and functional requirements.

8. Customer Support and Communication

Responsive communication is key, especially if you’re new to testing or your project is complex. Look for a lab that:

Offers pre-testing consultations

Has expert support to interpret results

Keeps you informed on progress and timelines

Provides guidance on remedial action in case of non-compliance

Good customer service is an indicator of a lab’s professionalism and commitment to partnership.

9. Location and Logistics

While some tests can be conducted remotely or with shipped samples, location still matters. A nearby lab can:

Reduce shipping costs and delays

Allow in-person visits and audits

Provide faster response times

If the lab is overseas, check their experience with international clients and shipping protocols to avoid customs issues or delays.

10. Cost and Value

Price is important, but it shouldn’t be the only factor. A low-cost lab that delivers inaccurate or incomplete results can cost you much more in the long run.

Instead, evaluate value based on:

Scope and quality of services

Regulatory expertise

Turnaround speed

Quality of support and documentation

Obtain detailed quotes and ensure there are no hidden fees.

Conclusion

Choosing the right plastic testing lab can mean the difference between product success and failure. From ensuring compliance with global regulations to verifying product durability and quality, the right lab serves as your quality assurance partner.

Look for a lab that is accredited, experienced in your industry, equipped with modern technology, and transparent in its operations. The right partnership will not only protect your brand and consumers but also open doors to global markets with confidence.

0 notes

Text

How Plastic Testing Labs in Abu Dhabi Support Sustainability and Environmental Standards? | +971 554747210

In the modern era, sustainability and environmental responsibility have become crucial considerations for manufacturers across the globe. This is especially true for industries that rely heavily on plastic materials, such as automotive, packaging, electronics, and consumer goods. With the increasing concerns surrounding plastic waste and its environmental impact, plastic products must be carefully tested to ensure they meet both safety standards and environmental regulations. This is where plastic testing labs in Abu Dhabi play a vital role in supporting sustainability and ensuring that manufacturers comply with the evolving environmental standards.

This blog will explore how plastic testing lab in Abu Dhabi help manufacturers navigate the complex landscape of environmental regulations and contribute to sustainability efforts. We will discuss the key tests performed by these labs, how they align with global sustainability goals, and how they enable businesses to meet the demand for eco-friendly products.

1. The Growing Demand for Sustainable Plastics

Plastic, once hailed for its versatility and durability, has become one of the most widely used materials in the world. However, its environmental impact, particularly in terms of plastic waste, has sparked a global movement toward sustainability. Governments, industries, and consumers are increasingly demanding environmentally friendly products, pushing manufacturers to explore alternatives to traditional plastic.

Sustainable plastic products are those that are designed with the environment in mind, focusing on aspects like recyclability, biodegradability, reduced carbon footprint, and the use of renewable resources. The growing emphasis on reducing plastic waste and ensuring the responsible use of plastics has led to the development of various regulations and standards at both the national and international levels.

As a key player in the Middle East, Abu Dhabi's plastic testing labs are helping manufacturers meet these demands by ensuring their products comply with these strict environmental standards.

2. Key Tests Performed by Plastic Testing Labs in Abu Dhabi

Plastic testing labs in Abu Dhabi use advanced technologies and methodologies to assess the environmental impact of plastic products. These tests are designed to determine whether plastic materials meet the necessary environmental regulations, sustainability guidelines, and performance standards.

2.1 Recyclability Testing

Recyclability is one of the most important aspects of sustainable plastic products. Many countries have introduced extended producer responsibility (EPR) regulations, which require manufacturers to ensure that their products are recyclable or reusable. In regions like the European Union, plastic recycling rates are closely monitored, and non-recyclable products may face heavy fines or restrictions.

Plastic testing labs in Abu Dhabi assess the recyclability of plastic products by analyzing their composition and the processes involved in breaking them down for reuse. This includes testing for polymer compatibility, ease of separation, and recycling potential. Labs also examine whether the products can be efficiently processed in local recycling facilities and whether they contribute to the circular economy, where materials are reused rather than discarded.

Through recyclability testing, manufacturers can ensure that their products comply with the global push for circularity and help reduce the environmental burden of plastic waste.

2.2 Biodegradability Testing

Biodegradable plastics are designed to break down more quickly than conventional plastics, reducing the long-term environmental impact. With the increasing focus on reducing landfill waste and plastic pollution, biodegradable plastics have gained popularity, particularly in packaging and single-use items.

Plastic testing labs in Abu Dhabi conduct biodegradability tests to assess how quickly and efficiently plastic products decompose in natural environments. This includes aerobic biodegradation (involving the presence of oxygen) and anaerobic biodegradation (without oxygen) tests. Labs use standardized methods, such as ISO 14855 and ASTM D5511, to simulate the breakdown process under various environmental conditions, such as soil, water, or landfill environments.

By ensuring that plastic products meet biodegradability standards, testing labs help manufacturers contribute to global efforts to reduce plastic pollution and waste.

2.3 Chemical Leaching Testing

Plastics can sometimes release harmful chemicals into the environment, particularly when exposed to heat or UV radiation. These chemicals can contaminate soil, water, and ecosystems, posing risks to both human health and wildlife. As part of sustainability efforts, manufacturers are increasingly required to ensure that their products do not leach toxic substances.

Plastic testing labs in Abu Dhabi perform chemical leaching tests to assess the potential for harmful substances to leach from plastic products into the environment. These tests evaluate the migration of chemicals, such as phthalates, bisphenol A (BPA), and other additives commonly found in plastics, under various environmental conditions.

By conducting chemical leaching tests, manufacturers can ensure their plastic products are safe for the environment and comply with regulations such as REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) in the European Union or California Proposition 65 in the United States.

2.4 UV Resistance Testing

Plastics exposed to sunlight over time can degrade due to the effects of ultraviolet (UV) radiation. This can lead to discoloration, brittleness, and the release of harmful chemicals into the environment. For many products, especially those used outdoors or in direct sunlight, ensuring UV resistance is essential for both product longevity and environmental safety.

Plastic testing labs in Abu Dhabi assess the UV resistance of plastic materials by simulating prolonged exposure to sunlight using UV chambers and measuring changes in physical properties. This ensures that plastic products can withstand the effects of UV radiation without breaking down into harmful microplastics.

2.5 Tensile and Impact Strength Testing

Durability is another critical aspect of sustainable plastic products. Plastics that break easily or wear out quickly contribute to waste and environmental degradation. By testing the tensile strength (resistance to stretching) and impact strength (resistance to cracking or breaking), testing labs ensure that plastic products are not only durable but also designed for longevity.

In the context of sustainability, durable plastic products are more likely to be reused, recycled, or repurposed, thus contributing to a circular economy. Plastic testing labs in Abu Dhabi help manufacturers create stronger, more resilient products that minimize waste and reduce the need for frequent replacements.

3. How Plastic Testing Labs Align with Global Sustainability Goals

Plastic testing labs in Abu Dhabi help manufacturers comply with both local and global sustainability goals. As part of the United Nations Sustainable Development Goals (SDGs), nations around the world have committed to reducing plastic waste and improving resource efficiency. Testing labs ensure that plastic products comply with these goals by focusing on:

Reducing plastic waste: By testing for recyclability and biodegradability, labs help ensure that plastic products are designed with end-of-life disposal in mind.

Promoting sustainable production and consumption: Testing labs play a role in creating products that can be used, reused, or recycled efficiently, reducing the need for new raw materials and minimizing environmental impact.

Ensuring responsible consumption: By adhering to environmental standards, plastic testing labs help manufacturers meet consumer demands for eco-friendly products.

In addition, plastic testing labs in Abu Dhabi are aligned with various international regulations, such as the European Union's Plastics Strategy, Global Compact for Sustainable Development, and ISO 14001 (Environmental Management Systems).

4. The Benefits of Sustainable Plastics for Manufacturers

Manufacturers in Abu Dhabi and beyond can benefit greatly from adopting sustainable plastic practices and leveraging plastic testing labs to support compliance with environmental standards. Some of these benefits include:

Access to global markets: Compliance with international sustainability standards opens up new export opportunities for manufacturers, especially in regions with stringent environmental regulations.

Improved brand image: Consumers are increasingly concerned with the environmental impact of the products they purchase. By prioritizing sustainability, manufacturers can build trust and loyalty among eco-conscious consumers.

Cost savings: Sustainable practices, such as recycling and using biodegradable materials, can lead to cost savings in production and waste management.

5. Conclusion

Plastic testing labs in Abu Dhabi play a crucial role in supporting sustainability and ensuring that plastic products meet global environmental standards. Through various tests, such as recyclability, biodegradability, chemical leaching, and UV resistance, these labs help manufacturers create eco-friendly products that contribute to the global effort to reduce plastic waste and pollution.

As sustainability becomes an increasingly important factor in international trade and consumer choice, plastic testing labs in Abu Dhabi are helping businesses stay ahead of the curve, ensuring compliance with environmental regulations while supporting the transition toward a more sustainable future.

0 notes

Text

How Plastic Testing Labs in Ajman Enhance Durability and Performance of Materials | +971 554747210

The rise of plastics in modern industries has been remarkable, with these versatile materials playing a critical role in manufacturing, construction, packaging, and more. In Ajman, a thriving industrial hub, plastic materials are integral to various sectors. However, the performance and durability of these materials are paramount to ensure product quality and safety.

This is where plastic testing lab in Ajman play a pivotal role. By leveraging advanced testing methods, these labs help businesses evaluate and enhance the strength, longevity, and performance of their plastic products.

In this blog, we’ll explore the importance of plastic testing labs in Ajman and how their expertise contributes to producing durable and high-performing materials.

The Need for Durability in Plastic Materials

Durability is one of the most sought-after properties of plastic materials, as they are often exposed to harsh conditions during use. Whether in construction, packaging, automotive, or consumer goods, plastic must withstand:

Mechanical Stress: Tension, compression, and impact forces.

Environmental Factors: UV radiation, moisture, and extreme temperatures.

Chemical Exposure: Acids, alkalis, and solvents that can degrade materials.

Durable materials not only ensure longer product life but also reduce maintenance costs and environmental impact. Plastic testing labs in Ajman help manufacturers meet these durability requirements through rigorous testing and analysis.

Key Ways Plastic Testing Labs Enhance Durability and Performance

1. Mechanical Testing for Strength and Resilience

Plastic testing labs in Ajman conduct a range of mechanical tests to assess the strength and flexibility of materials:

Tensile Strength Tests: Measure how much force a material can endure before breaking.

Flexural Strength Tests: Evaluate the material’s ability to resist bending under load.

Impact Resistance Tests: Assess the material’s durability when subjected to sudden shocks or drops.

By identifying weak points, these tests enable manufacturers to improve formulations and ensure the material can withstand real-world conditions.

2. Environmental Testing for Long-Term Performance

Plastics used in outdoor or industrial applications must endure environmental factors such as:

UV Exposure: Prolonged exposure to sunlight can cause plastics to fade, crack, or weaken. UV resistance testing ensures the material retains its properties.

Thermal Resistance: Testing materials at high and low temperatures ensures they perform well in diverse climates.

Moisture Absorption: Excessive water absorption can compromise a material’s structural integrity, making this a critical factor for evaluation.

Plastic testing labs simulate these conditions in controlled environments, providing manufacturers with valuable insights to enhance material formulations.

3. Chemical Resistance Testing

Many plastics encounter harsh chemicals during their lifecycle, especially in industrial and medical applications. Labs in Ajman perform chemical resistance tests to determine how materials react to substances like:

Acids

Alkalis

Organic solvents

These tests ensure that plastics remain stable and functional, even in challenging chemical environments.

4. Thermal Analysis for Stability and Safety

Thermal properties significantly impact the performance of plastics, especially in high-heat applications such as automotive or electronics. Testing labs in Ajman conduct:

Heat Deflection Temperature (HDT): Determines the temperature at which the material starts to deform.

Melting Point Analysis: Ensures the material remains stable during processing and use.

Thermal Expansion Testing: Measures dimensional changes due to temperature variations.

These insights help manufacturers select the right plastic materials for specific applications, ensuring reliability and safety.

5. Fatigue and Creep Testing for Longevity

Plastics subjected to repeated loads over time may experience fatigue or creep (slow deformation under constant stress). Testing labs perform:

Fatigue Testing: Evaluates how materials respond to cyclic loading.

Creep Testing: Assesses deformation under prolonged stress.

These tests help manufacturers predict the lifespan of plastic products and improve designs to enhance durability.

Technologies Used in Ajman’s Plastic Testing Labs

Advanced Testing Instruments

Ajman’s plastic testing labs are equipped with cutting-edge technologies, including:

Universal Testing Machines (UTM): For mechanical property testing such as tensile, compression, and bending.

Differential Scanning Calorimetry (DSC): For analyzing thermal behavior.

Fourier-Transform Infrared Spectroscopy (FTIR): For identifying material composition and contaminants.

Weathering Chambers: For simulating UV and environmental exposure.

Computer-Aided Analysis

Labs utilize software tools to analyze test data and model material performance under various conditions. This enables precise predictions of durability and performance.

Industries That Benefit from Plastic Testing in Ajman

1. Construction Industry

Plastic materials like PVC, HDPE, and composites are widely used in pipes, insulation, and roofing. Testing labs ensure these materials can withstand mechanical stress, UV exposure, and weathering.

2. Packaging Industry

Durability is essential in packaging to protect contents during transportation and storage. Labs test for strength, impact resistance, and barrier properties.

3. Automotive Sector

From interior components to fuel tanks, plastics in vehicles must be durable and resistant to heat, chemicals, and mechanical stress. Testing ensures reliability and safety.

4. Consumer Goods

Products like furniture, toys, and appliances rely on durable plastics to maintain quality and safety throughout their lifecycle.

Benefits of Collaborating with Plastic Testing Labs in Ajman

1. Improved Product Quality

Comprehensive testing ensures materials meet performance standards, reducing defects and recalls.

2. Compliance with Standards

Plastic testing labs help manufacturers comply with UAE regulations and international standards, facilitating market access.

3. Cost Savings

Identifying material weaknesses early prevents costly failures and enhances production efficiency.

4. Competitive Advantage

High-quality, durable materials enhance brand reputation and customer satisfaction.

5. Sustainable Practices

Testing for recyclability and environmental impact supports eco-friendly initiatives.

Case Study: Enhancing Material Performance

A packaging company in Ajman experienced frequent product failures due to material breakage during shipping. By collaborating with a plastic testing lab, they identified weaknesses in their material's tensile strength. The lab recommended a revised polymer formulation, which improved the durability of their packaging by 30%.

This collaboration not only reduced customer complaints but also boosted the company’s reputation in the competitive packaging market.

Future Trends in Plastic Testing

1. Sustainable Materials

As sustainability gains importance, labs are focusing on testing biodegradable and recycled plastics for performance and safety.

2. Nanotechnology

Incorporating nanomaterials into plastics enhances strength and resistance. Labs are developing tests to evaluate these advanced materials.

3. Smart Testing Methods

Automation and AI are being integrated into testing processes to deliver faster, more accurate results.

Conclusion

Plastic testing labs in Ajman are essential partners for manufacturers seeking to enhance the durability and performance of their materials. Through rigorous testing and advanced technologies, these labs ensure that plastic products meet industry standards and excel in real-world applications.

Whether you’re in construction, packaging, or any other sector, investing in plastic testing services is a strategic move to boost product quality, comply with regulations, and gain a competitive edge. For businesses in Ajman, the expertise of a reliable plastic testing lab is a key driver of success in today’s demanding markets.

0 notes

Text

Some (Late) Valentine Royais!!

#I tested some new brushes and GOD#I feel so powerful#Honestly I been thinking about getting into more textured brushes because with the one I normally use makes humans look like plastic....#and I started to try these.... and got carried away LOL#still is what they deserve this is my prettiest Riza I would also kiss her with tongue#fma#fma brotherhood#full metal alchemist#fanart#full metal alchemis brotherhood#riza hawkeye#roy mustang#royai#traditional art#fma:b#digital fanart

144 notes

·

View notes

Text

Marbon Formacar, 1969, by Borg-Warner. I posted recently about the Alpine Marbon CRV. Marbon-Chemical (a subsidiary of Borg-Warner) used the Formacar to promote their Cycolac ABS plastic to the US automotive industry. The Formacar was powered by an AMC V8 engine but failed to attract any takers for Cycolac in the US auto sector. Instead it found applications such as lawn chairs and outdoor equipment.

#Marbon#Marbon Formacar#Borg-Warner#experimental car#test vehicle#AMC V8#Cycolac#1969#ABS plastic#Marbon-Chemical

167 notes

·

View notes

Text

How is your day? I've spent part of my evening painting seagull poop, which, to be honest, I hadn't anticipated a month ago 🙃

(I'm loving every minute of it)

Slowly, slowly getting there🐢

Ok I still need to do the water and stone at the bottom as well as finish the details up top and freshen up the tentacles and varnish it....but We're. Getting. There. *Intense grin*

(edit: if you saw me post this on a Tuesday night going all in believing it was Wednesday, after having reminded myself all day that it wasn't, no you didn't🙃)

#cant wait to varnish it and remove some of the plastic gloss#i tested my varnish on one of Ed's boots and im twitchy to do it all now 😌#pennybunpirate's lighthouse#wip wednesday#wip#work in progress#art in progress#sculpture#mixed media art#ofmd#our flag means death#gentlebeard#ofmd fanart#stede bonnet#ed teach#traditional art#artists on tumblr#art#acrylic painting#crafting#fan crafts

42 notes

·

View notes