#plc programming training

Explore tagged Tumblr posts

Text

The Basics of PLC Programming: A Comprehensive Guide

If you're interested in the field of industrial automation or looking to enhance your skills in the industry, PLC programming is a crucial skill to possess. Programmable Logic Controllers (PLCs) are widely used in manufacturing and process control systems, and understanding how to program them is essential for ensuring efficient and reliable operation.

In this comprehensive guide, we will explore the basics of PLC programming, covering key concepts and providing valuable insights for beginners in the field.

1. What is PLC Programming?

PLC programming involves creating a set of instructions that control the behavior of a programmable logic controller. PLCs are used to monitor inputs from various sensors, process that data, and execute specific actions based on pre-defined logic. By programming a PLC, you can automate complex industrial processes, making them more efficient and reliable.

2. Why Learn PLC Programming?

PLC programming offers numerous benefits in the industrial automation realm. By acquiring this skill, you can:

Improve productivity: PLCs enable automation, reducing manual labor and increasing overall productivity.

Enhance efficiency: Automation minimizes human error and optimizes processes, resulting in higher efficiency levels.

Facilitate troubleshooting: Understanding PLC programming allows you to diagnose and fix issues efficiently, minimizing downtime.

Expand career opportunities: PLC programming expertise is in high demand, with many industries seeking professionals with these skills.

3. PLC Programming Training Courses:

To learn PLC programming effectively, it's essential to enroll in specialized training courses. These courses provide a structured curriculum, hands-on exercises, and expert guidance. Here are a few key aspects to consider when choosing a PLC programming training institute or center:

Comprehensive curriculum: Look for a training program that covers both theoretical concepts and practical implementation.

Experienced instructors: Ensure that the training institute has qualified instructors with industry experience to guide you effectively.

Hands-on practice: Practical exercises and projects are crucial for gaining proficiency in PLC programming.

Industry relevance: Verify that the training course aligns with current industry standards and practices.

Certification: Opt for courses that offer certifications upon completion, as they enhance your credibility in the job market.

4. Key Concepts in PLC Programming:

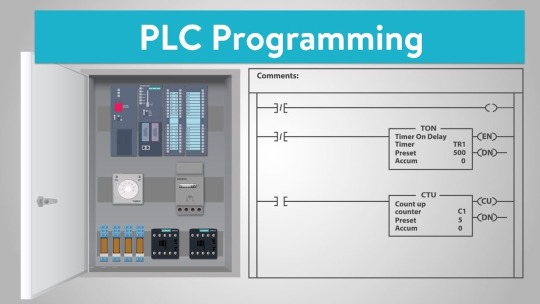

Ladder Logic: Ladder Logic is the most commonly used programming language for PLCs. It employs graphical symbols to represent logic functions and control sequences, making it easy to understand and implement.

Inputs and Outputs: PLCs interact with the physical world through inputs (sensors) and outputs (actuators). Understanding how to read inputs and control outputs is fundamental in PLC programming.

Programming Instructions: PLCs execute a set of instructions to perform desired operations. These instructions can include timers, counters, mathematical operations, logic gates, and more.

Program Execution: PLC programs are executed in a cyclical manner. The PLC scans inputs, processes logic, updates outputs, and repeats the cycle continuously.

5. Programming Tools and Software:

PLC programming software provides an interface to create, edit, and debug programs. Familiarize yourself with popular software tools such as Siemens TIA Portal, Allen-Bradley RSLogix, or Schneider Electric Unity Pro, as they are widely used in the industry.

Conclusion:

PLC programming is an essential skill for individuals aspiring to succeed in the field of industrial automation. By learning the basics of PLC programming, you open up a world of opportunities to streamline processes, enhance productivity, and contribute to the advancement of various industries. Enroll in a reputable PLC programming training institute or center, explore the key concepts, and start your journey towards becoming a proficient PLC programmer.

#plc-programming#learn plc programming#plc programming training#plc programming courses#plc training course in india

3 notes

·

View notes

Text

Which language is best for PLC?

In the realm of industrial automation, Programmable Logic Controllers (PLCs) serve as the backbone of countless manufacturing processes. These versatile devices are the driving force behind the automation of various tasks, from simple machinery control to complex manufacturing processes. However, when it comes to choosing the best programming language for PLCs, beginners often find themselves at a crossroads. In this article, we'll delve into the key factors to consider when selecting a programming language for PLC and explore some popular options to help you make an informed decision.

Importance of PLC Training and Courses: Before delving into the PLC programming languages, it's crucial to emphasize the significance of PLC training and courses. As the demand for skilled automation professionals continues to rise, enrolling in a reputable corporate training institute that offers comprehensive PLC training becomes a stepping stone towards a successful career. PLC courses, especially those tailored for beginners, provide a solid foundation in PLC programming, troubleshooting, and design, enabling individuals to tackle real-world automation challenges.

Selecting the Ideal Programming Language: The choice of programming language for PLC largely depends on the specific application, hardware compatibility, and personal preferences. Let's take a look at some commonly used programming languages in the PLC landscape:

Ladder Logic (LD): As one of the oldest and most widely used languages in PLC programming, Ladder Logic offers a graphical representation of control circuits. Its resemblance to electrical relay diagrams makes it an excellent choice for individuals with a background in electrical engineering. PLC programming courses for beginners often start with Ladder Logic due to its user-friendly nature.

Structured Text (ST): For those with a programming background, Structured Text provides a text-based language resembling traditional programming languages. It offers more advanced control and data manipulation capabilities, making it suitable for complex applications. ST is commonly used in PLC programming courses for those who want to dive deeper into automation.

Function Block Diagram (FBD): FBD is another graphical language that allows users to create complex functions by combining various function blocks. It's ideal for modular design and is often used in conjunction with other languages.

Sequential Function Chart (SFC): SFC focuses on the sequential control of processes, making it suitable for applications where the order of operations is critical. It's commonly used in industries where processes follow a specific sequence, such as batch processing.

Instruction List (IL): IL is a low-level language resembling assembly language. While it may not be the first choice for beginners, it offers precise control over the PLC's operations and is often used for optimizing code.

PLC SCADA Training Institute and Beyond: As you embark on your journey to master PLC programming, consider enrolling in a reputable PLC SCADA training institute. Such institutes offer specialized courses that cover not only PLC programming but also SCADA (Supervisory Control and Data Acquisition) systems, HMI (Human-Machine Interface) design, and industrial communication protocols. This comprehensive training equips you with the skills needed to design, implement, and maintain sophisticated industrial automation systems.

Conclusion: In the dynamic world of industrial automation, choosing the right programming language for PLC is a decision that shouldn't be taken lightly. Factors such as application requirements, hardware compatibility, and personal familiarity play a crucial role. Whether you opt for the user-friendly Ladder Logic or the more versatile Structured Text, embarking on a PLC programming course for beginners is the first step towards a rewarding career in automation. DIAC in noida, is one of the best industrial automation institutes in Delhi NCR, your right step makes a huge change in your journey of automation. Remember, the journey doesn't end with PLC – exploring additional aspects like SCADA and HMI through specialized training institutes can further enhance your skill set and open doors to exciting opportunities in the world of industrial automation.

#plc training#plc scada training#plc scada training in noida#plc networking#plc scada#scada training#plc scada training in delhi#plc programming training#plc programming courses#PLC SCADA TRAINING#PLC courses#plc programming courses for beginners

0 notes

Text

What is HMI SCADA Software

#automation#trending#tumblr trends#viral#bestdeals#trendingnow#viralpost#rockwell automation#allen bradley#plc#SCADA#software programing#scadatraining#plc scada training#scada software

1 note

·

View note

Link

0 notes

Text

Engineering Training In Pune

Welcome to Perfecto Robotics Institute, your perfect destination for Engineering Training In Pune. Our organization prides itself on offering advanced courses designed to equip you with essential technical skills.

At Perfecto Robotics Institute, we are dedicated to providing exceptional training programs for individuals of all skill levels. Whether you are a beginner looking to build a solid foundation to grow your career. We provide step-by-step guides in robotics as well as automation fields. In the Institute we take practical exercises for students to better understand as well as for incrementing their knowledge.

Lesson Highlights:

Moreover, Our educational program is carefully designed to cover a wide range of engineering disciplines. Students benefit from hands-on training using state-of-the-art equipment, ensuring the application of practical knowledge in real-world situations.

Why should you choose us?:

Additionally,

our expert professors are industry-experienced.

We provide outstanding practical experience to the students.

Individual guidance.

We support you foster collaboration.

Rich learning environment.

From basic principles to advanced techniques.

Career Opportunities:

With Perfecto Robotics Institute we provide successful completion of our training programs. our courses are designed to meet your specific needs. We provide career opportunities in automotive, robotics, etc.

Offered Courses:

Basic Industrial Automation

Advanced Industrial Automation

Basic Industrial Robotics

Advanced Industrial Robotics

In conclusion, Perfecto Robotics Institute stands out as an indication of excellence in Engineering Training in Pune. Whether you aspire to enhance your skills or embark on a new career path in engineering, we are committed to helping you achieve your professional training experience.

Ready to take the next step toward a successful career in engineering? Contact Perfecto Robotics Institute today to learn Engineering Training In Pune for more about our courses, enrollment procedures, and how we can support your educational journey.

0 notes

Text

UEE40420 Certificate IV in Electrical Instrumentation – Improve your Skills as a Certified Electrician

Looking beyond the basics, the Electrical Instrumentation course delves into advanced concepts crucial for thriving in today's dynamic industrial landscape. Participants explore cutting-edge technologies, such as advanced PLC programming techniques and the integration of smart sensors for enhanced process control and optimization.

Moreover, the course emphasizes industry best practices in safety protocols and regulatory compliance, ensuring that graduates are well-equipped to navigate complex work environments with confidence and proficiency.

Why choose the Instrumentation course?

What sets PMV's training apart is its commitment to providing a truly immersive learning experience. The state-of-the-art training centers in Perth, Karratha, and Adelaide boast fully equipped instrumentation and control skids that replicate real-world industrial settings. This hands-on approach allows students to gain practical experience in a safe and controlled environment, preparing them to tackle the challenges of the field head-on.

In addition to technical skills, the course also emphasizes soft skills development, such as communication, teamwork, and problem-solving. These skills are invaluable for success in the field, where collaboration and adaptability are often as critical as technical expertise. Contact PMV for Instrumentation and Control Courses

Furthermore, PMV's industry-aligned curriculum ensures that graduates are not only technically proficient but also familiar with the latest industry standards and practices. This alignment with industry requirements enhances the employability of graduates, making them highly sought after by employers across various sectors.

Whether you're a seasoned professional looking to upskill or a newcomer to the field seeking to kickstart your career, the UEE40420 Certificate IV in Electrical Instrumentation at PMV offers a comprehensive and practical learning experience that sets you up for success in the exciting and rewarding field of instrumentation and control.

Read More:

1. What are the key components of nationally accredited training in hazardous area classification and design?2. What specific qualifications are necessary for someone to be considered competent in high voltage switching?3. What are the top 10 common mistakes that individuals should avoid when setting up solar grid-connected systems?4. What are some common types of hazardous area equipment, and how are they typically utilized in industrial settings?5. What are the key requirements and procedures for conducting an EEHA audit and ensuring compliance with AS/NZS 3000:2018 standards?

CONTACT US:

Website: https://www.pmv.net.au/

Email: [email protected]

Perth

10/22 Shields Crescent, Booragoon, WA, 6154 Contact no.: (08) 9317 2146

Adelaide

1042 Port Road, Albert Park, SA, 5014 Contact no.: (08) 9317 2147

Karratha

Unit 48, 5-15 Sharpe Ave, Karratha WA, 6714 Contact no.: (08) 9317 2147

Also, follow us:

Youtube: https://www.youtube.com/@PmvNetAu/

Facebook: https://www.facebook.com/pmvaustralia/

Instagram: https://www.instagram.com/pmv.australia/

#pmv training#pmv#Electrical Instrumentation#uee40420#advanced PLC programming#instrumentation courses perth#electrical instrumentation course#certificate iv in instrumentation

0 notes

Text

I'm very good at "professionalism" I was trained from a young age. If I get an interview, I'm getting the job. I sit upright in my chair and wear a collared shirt and my employer thinks, "wow! She has a lot of passion for this role!" Buddy, you don't know the start of it. You don't even know my gender.

I'm OSHA certified. I got my 24-hour GD&T training. They can see this. What they don't see is me waxing poetical about surface finish or some shit on this website. When I was in 6th grade, I was exposed to Autodesk Inventor and it changed me fundamentally as a person. Whenever I look at any consumer good (of which there are a lot) I have to consider how it was made. And where the materials came from and how it got here and really the whole ass process. It's fascinating to me in a way that can be described as "intense". I love looking at large machines and thinking about them and taking pictures of them. There are so many steps and machines and people involved to create anything around you. I think if any person truly understood everything that happened in a single factory they would go insane with the knowledge. But by god am I trying. My uncle works specifically on the printers that print dates onto food. There are hundreds or even thousands of hyperspecific jobs like that everywhere. My employer looks away and I'm creating an unholy abomination of R and HTML, and I'm downloading more libraries so I can change the default CSS colors. I don't know anything about programming but with the power of stack overflow and sheer determination I'm making it happen. Is it very useful? No. But I'm learning a lot and more importantly I don't give a fuck. I'm learning about PLCs. I'm learing about CNC machines. I'm fucking with my laptop. I'm deleting SQL databases. I'm finding electromechanical pinball machines on facebook marketplace. I'm writing G-code by hand. I'm a freight train with no brakes. I'm moving and I'm moving fast. And buddy, you better hope I'm moving in the right direction. I must be, because all of my former employers give me stellar reviews when used as a reference. I'm winning at "career" and also in life.

14 notes

·

View notes

Text

Living the life like an adult

One thing I have learned on my journey “you cannot have it all”

Indeed.

I remember once I was so scared to live my life not as what I want to be. Question, what I wanna be?

I dreamed to be a scientist. Working in Laboratories with some living organisms, writing scientific journals, and finding some new discoveries. I also remember about the conversation with the stranger in the bar (i am totally sober it was weekday and no no to alcohol). I was still studying and how I explained what I wanna be after studies. He simply talked about that he was studying some life sciences study and he becomes working in some finance of medical tools company (?). Naively, I was surprised, like how you are not working on your field…. I told him that I am scared being you, being not to work on my field.

AND WHAT I AM NOW ?

That it is true „you attract what you fear”

I am working in the automation company. I still romanticize about my background in BIOTECHNOLOGY and end up in automation.

Long story short, I got my new training for programming the PLC (that’s my labs picture with controllers). I was extremely excited with that new journey. I live with my fear now. I deal with it, I embrace it. Now, I enjoy how I do. Do I STILL WANNA BE A SCIENTIST??? of course even if it is only exist in my wildest dreams.

I am trying to be a proper adult here, working so I can pay my bills. I still can dream when I sleep but now we face the bitter truth, reality. Am I okay? I try not to think that much. But one thing I know, I am the explorer! New path here I am.

2 notes

·

View notes

Text

Website: https://www.createstechcontent.com/

Address: 2102 Wood Acres Rd SW, Oakwood, GA 30566, United States

Creates Tech Content offers engineering consulting services, electrical engineering consulting, PLC programming services, and technical documentation consulting for manufacturers and OEMs. Their automation engineering consultants specialize in enclosure-less systems, control system design, and industrial automation consulting. Known for delivering technical training for engineers and engineering documentation services, they provide online engineering consulting tailored to complex projects. With expertise in automation consulting services, electrical CAD, and system integration, Creates Tech Content supports industries including automotive, aerospace, and food processing. Based in Georgia, they serve clients nationwide with scalable, efficient engineering solutions.

LinkedIn: https://www.linkedin.com/in/david-fischhaber-86086a280/

Keywords: Engineering consulting services Automation engineering consultant Electrical engineering consulting electrical engineering consultant electrical engineering consultants Industrial automation consultant industrial automation consulting Engineering mentor Technical training for engineers online engineering consulting technical documentation technical documentation consulting technical training for engineers PLC programming services PLC programming consultant developing a training manual technical training services engineering documentation services automation consulting services engineering content writer engineering consultant automation engineering consulting

#Engineering consulting services#Automation engineering consultant#Electrical engineering consulting#electrical engineering consultant#electrical engineering consultants#Industrial automation consultant#industrial automation consulting#Engineering mentor#Technical training for engineers#online engineering consulting#technical documentation#technical documentation consulting

1 note

·

View note

Text

Automation and Control Market Size Enabling Industry 4.0 with Precision and Intelligence

The Automation and Control Market Size is at the forefront of industrial innovation, integrating programmable logic controllers (PLCs), distributed control systems (DCS), human-machine interfaces (HMIs), sensors, and industrial software to modernize manufacturing, infrastructure, and utility operations. Technologies such as advanced robotics, AI-driven decision-making, and real-time monitoring are transforming traditional processes into agile, highly efficient systems.

According to Market Size Research Future, the market is projected to achieve USD 175 billion by 2030, growing at a CAGR of 8.2% from 2023 to 2030. This expansion is fueled by the push towards Market Size 4.0, smart factory adoption, sustainability goals, and increasing demand for automated solutions with low operational costs and minimal human intervention.

Market Size Overview

Automation and control systems enable precise management of industrial processes by monitoring variables like temperature, flow, pressure, and motion. These systems improve production accuracy, safety, quality control, and energy usage in sectors such as automotive, oil & gas, power generation, pharmaceuticals, and food and beverage.

Recent innovations include cloud-connected SCADA platforms, edge analytics, digital twins, and predictive maintenance tools—empowering operators to optimize processes remotely, reduce unplanned downtime, and adapt rapidly to shifts in demand.

Key Drivers

1. Market Size 4.0 and Digital Transformation

Companies are adopting automation to gain competitive advantage through data-driven operations, traceability, and rapid adaptability.

2. Labor Shortages and Workforce Shifts

Automation addresses challenges like an aging workforce and high turnover, ensuring continuity and quality in critical processes.

3. Regulatory Pressures and Quality Standards

Regulations like ISO 50001 (energy management) and FDA requirements for process validation drive adoption of robust automation systems.

4. Energy Optimization and Sustainability

Integrated control systems help industries monitor energy usage, reduce waste, and achieve targets for carbon neutrality.

Market Size Segmentation

By Component:

Hardware: PLCs, DCS, HMIs, Sensors, Actuators

Software: Manufacturing Execution Systems (MES), HMI/SCADA, Analytics Platforms

Services: Maintenance, Integration, Training, Consulting

By End-User Market Size:

Automotive

Oil & Gas

Power & Utilities

Chemicals & Petrochemicals

Food & Beverages

Pharmaceuticals

Water & Wastewater

Mining & Metals

Infrastructure

Regional Insights

North America

Continues to lead thanks to mature industrial automation, strong R&D investment, and cross-border deployment of smart systems.

Europe

Germany’s Industrie 4.0 programs, the UK’s digital manufacturing platforms, and Scandinavia's clean-tech initiatives drive widespread system modernization.

Asia-Pacific

Growth in manufacturing hubs like China, India, South Korea, and Southeast Asia is accelerating adoption, supported by government-driven smart city and high-tech corridor initiatives.

Competitive Landscape

Leading solution providers are enhancing hardware interoperability, offering pre-configured software stacks, and deploying predictive analytics and AI:

Siemens AG

ABB Ltd.

Schneider Electric

Rockwell Automation

Emerson Electric Co.

Mitsubishi Electric

Honeywell International

Yokogawa Electric

General Electric

Fanuc Corporation

These firms offer digital twins, unified control platforms, and secure OT/IT convergence—ushering in smarter, more resilient industrial ecosystems.

Trends to Watch

Edge and Cloud Integration: Distributed control and analytics at the edge enable real-time decision-making with reduced latency.

Robotics and Cobots: Collaborative robots assist in assembly, packaging, and inspection tasks.

Digital Twin Adoption: Virtual replicas of systems support real-time testing and process improvements.

Cybersecurity Emphasis: OT/IT security convergence is critical, with AI-driven intrusion detection and secure remote access.

Sustainable Automation: Green manufacturing practices with energy-efficient components and closed-loop control systems.

Challenges

High Upfront Investment: Capex for full automation systems can be substantial—especially for SMEs.

Integration Complexity: Legacy systems integration requires skilled engineers and interoperability expertise.

Cyber Risk: Connected OT systems create vulnerabilities that demand robust cybersecurity strategies.

Skilled Labor Gap: Technical proficiency in control systems, cybersecurity, and data analytics remains scarce.

Future Outlook

The Automation and Control Market Size is well-positioned for growth as industries embrace smart manufacturing, remote operations, and sustainability. Future milestones include widespread digital twin adoption, self-healing systems, autonomous operations supported by AI, and standardized platforms enabling plug‑and‑play scalability. Continued emphasis on resilience, flexibility, and low-carbon operations will also guide the market.

Trending Report Highlights

Explore related technology areas that complement and accelerate automation initiatives:

RF Isolator Market Size

RF Transistor Market Size

RFID Sensor Market Size

Sound Level Meter Market Size

Embedded Display Market Size

Embedded Subscriber Identity Module Market Size

Enterprise Manufacturing Intelligence Market Size

Ethernet Adapter Market Size

Robotic Refueling System Market Size

Roll To Roll Printing Market Size

Rugged IC Market Size

Single Mode Optical Fiber Market Size

Smart Motor Market Size

0 notes

Text

Why is PLC programming used?

Have you ever thought about how enormous industries, industrial facilities, or even amusement park attractions operate so smoothly? PLCs (Programmable Logic Controllers) are a fascinating technology that holds the solution.

What is PLC programming?

PLC programming is the process of developing instructions for a specific digital computer known as a PLC. These controllers function as the brains behind the scenes, automating a variety of operations and jobs in companies, buildings, and even home appliances.

Why is PLC Programming Used?

Automation Simplified: By automating repetitive operations, PLC programming revolutionizes businesses. PLCs can conduct pre-defined sequences of activities instead of depending on human operators, making industrial processes quicker and more dependable.

Accuracy and precision: PLCs provide accurate control over machines and processes. They can accurately measure and respond to factors like temperature, pressure, and speed, assuring consistency in production and decreasing mistakes.

PLC programming provides engineers with the ability to simply alter and update control logic. This adaptability allows for fast alterations to match changes in production requirements or process enhancements.

Enhanced Safety: In industrial environments, safety is of the utmost importance. PLCs are configured to apply safety features like emergency stops and interlocks, which safeguard personnel and equipment from possible risks.

PLCs can monitor and diagnose operations in real time, providing vital data on performance and efficiency. This information assists engineers in analyzing patterns, identifying problems, and optimizing manufacturing operations.

PLCs may interface with other devices such as sensors, motors, and Human-Machine Interfaces (HMIs), resulting in a comprehensive and linked control system.

Cost-Effectiveness: PLCs are less expensive than custom-built control systems. They provide a dependable and standardized solution that lowers total implementation costs.

PLCs contribute to energy management by optimizing power use in processes, allowing organizations to save money on energy and lower their carbon impact.

Conclusion

PLC programming has transformed how industries and organizations work by automating and streamlining operations. These smart controllers provide accuracy, flexibility, and real-time monitoring, resulting in safer, more efficient, and cost-effective manufacturing. We may expect a smarter and more connected world as PLC programming drives the future of automation. PLCs' potential uses will only grow as technology advances, altering industries and enhancing our daily lives.

PLC training is required for working professionals to comprehend this. Training is required for a deeper understanding, and institutes such as DIAC in Noida are helping professionals maximize their utility for many years to come. PLC programming is at the heart of industrial automation, allowing for the efficient management and monitoring of a wide range of operations in manufacturing, energy, infrastructure, and beyond.

#plc training#plc scada training#plc scada training in noida#plc networking#plc scada#scada training#plc scada training in delhi#plc programming training#plc programming courses#PLC SCADA TRAINING#PLC courses

0 notes

Text

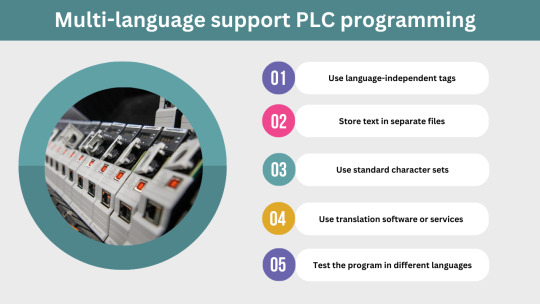

Multi-language support PLC Programming

Multiple languages in PLC (Programmable Logic Controller) programming can be crucial for various reasons, including internationalization, ease of collaboration across multinational teams, and compliance with local regulations.

IEC 61131-3 Languages

Language Selection

Internationalization and Localization

Comments and Documentation

Training and Support Materials

Standardization Across Projects

Testing and Validation

Collaboration Tools

Compliance with Regulations

Flexibility and Adaptability

🌐Website :- https://asteamtechno.com

👉Contact us :- +91 95372 40404

📧Email :- [email protected]

#trending#automation#tumblr trends#viral#viralpost#trendingnow#bestdeals#allen bradley#rockwell automation#plc#today on tumblr#artists on tumblr#poets on tumblr#plcprogramming#technology

3 notes

·

View notes

Text

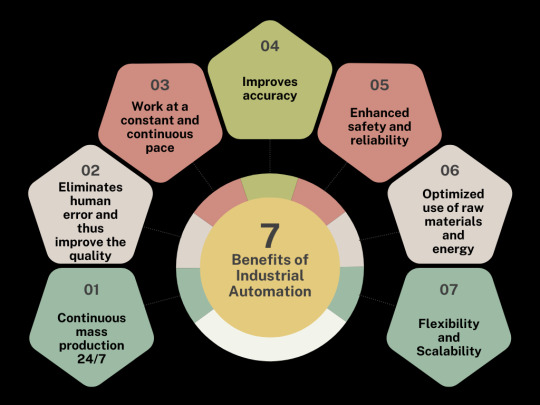

Industrial automation transforms industries by optimizing processes, improving productivity, and reducing operational costs. It replaces repetitive tasks with advanced technology, ensuring consistent quality and enhanced safety. With systems like PLCs (Programmable Logic Controllers), businesses achieve greater precision and control in manufacturing and other operations. PLC programming courses equip individuals with the expertise needed to harness these technologies and thrive in the evolving automation landscape.

0 notes

Text

Revolutionizing the Global Pharmaceutical Manufacturing Industry with Turn-Key Pharmaceutical Machinery Solutions

In the pharmaceutical era of today, efficiency, precision, and conformance are not ideals—but necessities. Pharmaceutical companies look for faster ways to streamline their business, provide quality, and cater to the mounting demands. Pharmateq aids pharmaceutical companies with innovative Turn-Key Pharmaceutical Machinery Solutions and ultra-high-performance Pharmaceutical Powder Granulators that are promised to revolutionize each production stage.

What Are Turn-Key Pharmaceutical Machinery Solutions

Turn-Key Pharmaceutical Machinery Solutions are turn-key, end-to-end equipment packages that are shipped complete and ready for instant deployment. Turn-key solutions encapsulate all steps in pharmaceutical production, from granulation and blending to drying, milling, coating, and packaging.

Our Turn-Key Pharmaceutical Machinery Solutions at Pharmateq are constructed and designed to international GMP standards, particularly. We specialize in systems for instant deployment, low downtime, and ease.

Key Advantages of Turn-Key Pharmaceutical Machinery Solutions

Seamless Integration: Networked equipment without junction integration.

Rapid Installation: Plug-and-play equipment makes installation and integration history.

Compliance Ready: Factory pre-programmed for FDA, WHO, and cGMP compliance.

Custom Designs: Where feasible, custom-designed specifically to your facility's specific space, process, and capacity needs.

Single-Point Responsibility: Single, reliable partner for design, installation, training, and after-sales support.

With Pharmateq Turn-Key Pharmaceutical Machinery Solutions, you're not buying the machines—you're investing in a total solution to achieve your production objectives.

Uses of Pharmaceutical Powder Granulators in Contemporary Manufacturing

Pharmaceutical Powder Granulators are involved in the process of solid dosage manufacture. They granulate pharmaceutical powder to improve flowability, minimize dusting, and provide tablet compression uniformity and capsule filling uniformity.

Pharmateq's Pharmaceutical Powder Granulators are grained precisely without compromising the potency of active pharmaceutical ingredients. Dry granulation or wet granulation, your requirement is, we have models with which you can work on various scales of production as well as various types of formulas.

Advantages of Pharmateq's Pharmaceutical Powder Granulators:

High Shear Capability: Immediate and consistent formation of granules.

Ease of Simple Cleaning: GMP-grade construction with tool-less assembly ensures rapid changeovers.

Scalable Technology: R&R at development scale to commercial scale production, our technology scales with you.

Advanced Controls: PLC and HMI integration for precise process control.

Rugged Build: Constructed from corrosion-resistant stainless steel to endure.

Sequencing the ideal Pharmaceutical Powder Granulators is the key to achieving consistency in each batch. With Pharmateq, you enjoy state-of-the-art equipment shared among industry leaders in global pharma.

Why Pharmateq is a Leader in Turn-Key Pharmaceutical Machinery Solutions

Pharmateq is the industry's leading market vendor of Turn-Key Pharmaceutical Machinery Solutions because we never cut corners on innovation, customization, or quality. We don't sell equipment—your line is customized by us.

Why our Turn-Key Pharmaceutical Machinery Solutions excel:

End-to-End Project Management: From consultation and design layout to delivery and validation.

On-Site Installation & Training: Our engineers guide your staff through every process.

Ongoing Support: Total maintenance packages and remote trouble shooting.

Energy-Saving Systems: Optimized and eco-friendly design with green sustainability in mind.

Customizable Features: Design your own formulation and output profile.

Partner with Pharmateq, your Turn-Key Pharmaceutical Equipment Solution source, and you're selecting reliability, compliance, and unmatched industry experience.

Applications of Pharmaceutical Powder Granulators

Pharmaceutical Powder Granulators are central components in a vast array of applications, including

Tablet Production: Granules enable enhanced compaction and mechanical strength.

Capsule Filling: Volumetric uniformity is improved with granulated powders.

Nutraceuticals: Herbal and dietary supplement granule uniformity.

Veterinary Products: Veterinary health product stable granulation.

OTC Medicines: High-performance, fast production of over-the-counter medications.

We at Pharmateq ensure our Pharmaceutical Powder Granulators act in all industries, backed by performance support, safety, and GMP certification.

Turn-Key Solutions merging with Granulation Technology

Having Pharmaceutical Powder Granulators as part of a Total Turn-Key Pharmaceutical Machinery Solution unlocks new levels of manufacturing potential. Our Pharmateq design engineers are proficient in designing total integrated systems with granulation and upstream and downstream processes such as mixing, drying, and pressing tablets.

Our clients benefit from having a Turn-Key Pharmaceutical Machinery Solution with in-line Pharmaceutical Powder Granulators to utilize:

Less Manual Handling: Maintains hygiene and eliminates human error.

Greater Throughput: Synchronization minimizes batch cycle time.

Standardized Batching: Automation provides consistent, repeatable results.

Space Conservation: Compact, space-efficient designs conserve precious floor space.

Our machines are future-proofed, expandable, and scalable to meet your increased operations.

Pharmateq Global Success Stories

Turn-Key Pharmaceutical Equipment Solutions with in-built Pharmaceutical Powder Granulators have been successfully installed by us for Asian, European, and Middle Eastern customers. Our projects are:

One Malaysian tablet manufacturing plant, where we commissioned an entire wet granulation line.

One Saudi Arabian contract manufacturing plant with modular Pharmaceutical Powder Granulators with high capacity.

One Indian R&D laboratory, with small-sized granulators for rapid prototyping and formulation development.

All these are the testimonials that reflect how solutions from Pharmateq can guarantee consistent quality anywhere in the world.

FAQs: Turn-Key Pharmaceutical Machinery Solutions & Powder Granulators

Q: How quickly can a Turn-Key Pharmaceutical Machinery Solution be shipped?

A: 10–16 weeks, scale and custom dependent, for shipping and installation.

Q: Do you supply what type of granulators?

A: High shear granulators, oscillating granulators, and fluid bed granulators—all pharmaceutical powder processing.

Q: Are your Pharmaceutical Powder Granulators GMP compliant?

A: Yes. All Pharmateq equipment complies with international GMP and FDA standards.

Q: Can I incorporate existing equipment in a Turn-Key Solution?

A: Certainly, our engineers shall visit your current infrastructure and create a system that integrates quite well with new and current equipment.

Let Pharmateq Power Your Production

In a business where accuracy and compliance with regulations are the sine qua non, the appropriate technology partner can be the difference between success and failure. Pharmateq Turn-Key Pharmaceutical Machinery Solutions and Pharmaceutical Powder Granulators are made to propel your business through higher production, exposure to new markets, or retrofitting your plant.

Idea to start-up, we're with you every step of the way, delivering innovative solutions, technical knowledge, and full support.

Call us today to talk about your production requirements and how our Turn-Key Pharmaceutical Machinery Solutions and Pharmaceutical Powder Granulators can revolutionize your business.

0 notes

Text

Robot Training In Pune

What is Robot Training?

Robotics is a field of engineering that focuses on the design, construction, and use of autonomous machines designed for robotic or human effort. At its core, robots combine computer science with engineering and electricity to perform tasks.

What do you teach in Robotics?

How to build the robotics body from components

How to program the robot’s brain through coding.

Learn to code

Types of Robots:

Autonomous Mobile Robots(AMRs)

Automated Guided Vehicles(AGVs)

Articulated Robots

Humanoids

Robots

Hybrids

Moreover, our institute has state-of-the-art laboratories with the latest robotics technology, software, and hardware. This allows students to simulate technical issues and gain practical experience in robot design.

Furthermore, students benefit from our strong industry, we provide practical training.

In conclusion, Perfecto Robotics Institute stands out as the best choice for Robot Training In Pune with its practical approach, advanced facilities as well as industry-focused courses. Contact us and leave a successful career in robotics.

Explore our courses today and take the first steps to becoming a professional roboticist.

0 notes

Text

Weight Loss and Obesity Management Market Size, Share, Trends, Demand, Future Growth, Challenges and Competitive Analysis

"Executive Summary Weight Loss and Obesity Management Market : Data Bridge Market Research analyses that the global weight loss and obesity management market which was USD 20,386.78 million in 2022, would rocket up to USD 43,094.03 million by 2030, and is expected to undergo a CAGR of 9.8% during the forecast period 2023-2030

The market study of Weight Loss and Obesity Management Market report helps minimize the risks of uncertainties and helps in taking sound decisions. This market report is also helpful in assessing the effectiveness of advertising programme and knows the causes of consumer resistance. It reveals the nature of demand for the firm’s product to know if the demand for the product is constant or seasonal. The report ascertains status of the firm and its products. The report aids to know how patents, licensing agreements and other legal restrictions affect the manufacture and sale of the firm’s products. The market analysis and competitor analysis helps the firm in determining the range in terms of sizes, colours, designs, and prices, etc within which its products are to be offered to the consumers.

This industry report is helpful in knowing the general conditions prevailing in the mark, the marketing and pricing strategy of competitors. Weight Loss and Obesity Management Market research report is a vital document in planning business objectives or goals. It is an organized method to bring together and document information about the industry, market, or potential customers. The info covered helps businesses know how patents, licensing agreements and other legal restrictions affect the manufacture and sale of the firm’s products. It is helpful in determining the discount rates, the actual prices and the price ranges, price elasticity for its products.

Discover the latest trends, growth opportunities, and strategic insights in our comprehensive Weight Loss and Obesity Management Market report. Download Full Report: https://www.databridgemarketresearch.com/reports/global-weight-loss-and-obesity-management-market

Weight Loss and Obesity Management Market Overview

**Segments**

- **By Diet** - Meals - Beverages - Supplements

- **By Fitness Equipment** - Cardiovascular Training Equipment - Strength Training Equipment - Others

- **By Surgical Equipment** - Minimally Invasive Surgical Equipment - Non-Invasive Surgical Equipment

- **By Services** - Fitness Centers - Slimming Centers - Consulting Services - Online Weight Loss Programs

The global weight loss and obesity management market is segmented based on diet, fitness equipment, surgical equipment, and services. In terms of diet, the market is further divided into meals, beverages, and supplements. The fitness equipment segment includes cardiovascular training equipment, strength training equipment, and other related equipment. Surgical equipment is categorized into minimally invasive and non-invasive surgical equipment. Furthermore, services provided in this market consist of fitness centers, slimming centers, consulting services, and online weight loss programs.

**Market Players**

- **Apollo Endosurgery, Inc.** - **Brunswick Corporation** - **Covidien plc (Medtronic)** - **Ethicon, Inc. (Subsidiary of Johnson & Johnson)** - **Herbalife Ltd.** - **Nutrisystem, Inc.** - **Weight Watchers International, Inc.** - **Jenny Craig** - **Technogym** - **Gold's Gym** - **Johnson Health Tech Co., Ltd.** - **Cybex International** - **Amer Sports** - **VLCC Healthcare Ltd.**

Several key players operate in the global weight loss and obesity management market. These include Apollo Endosurgery, Inc., Brunswick Corporation, Covidien plc (Medtronic), Ethicon, Inc. (Subsidiary of Johnson & Johnson), Herbalife Ltd., Nutrisystem, Inc., Weight Watchers International, Inc., Jenny Craig, Technogym, Gold's Gym, Johnson Health Tech Co., Ltd., Cybex International, Amer Sports, and VLCC Healthcare Ltd. These market players are actively involved in product development, strategic partnerships, mergers and acquisitions, and geographical expansions to gain a competitive edge in the market and cater to the growing demand for weight loss and obesity management solutions.

The global weight loss and obesity management market is witnessing significant growth driven by the rising prevalence of obesity and lifestyle-related diseases across the world. With changing dietary patterns, sedentary lifestyles, and increasing awareness about the health risks associated with obesity, there is a growing need for effective weight management solutions. The market is characterized by a diverse range of products and services catering to different segments such as diet, fitness equipment, surgical procedures, and specialized services.

One of the key trends shaping the market is the increasing adoption of personalized weight loss programs and solutions. Consumers are looking for tailored approaches that take into consideration their individual dietary preferences, fitness levels, and health conditions. This has led to the development of customized meal plans, personalized fitness regimens, and specialized consulting services that provide targeted support to individuals on their weight loss journey. Market players are investing in technology and data analytics to offer personalized recommendations and monitoring tools to enhance the effectiveness of weight loss programs.

Another notable trend is the growing popularity of online weight loss programs and digital health platforms. With the widespread availability of smartphones and internet connectivity, consumers are increasingly turning to online resources for weight management support. Virtual coaching, mobile apps for tracking diet and exercise, and online communities for sharing experiences and tips have gained traction in the market. This trend is expected to continue as digital health solutions offer convenience, accessibility, and affordability to a broader consumer base.

In terms of surgical equipment, there is a shift towards minimally invasive procedures for weight loss and obesity management. These techniques offer advantages such as reduced post-operative pain, shorter recovery times, and lower risk of complications compared to traditional surgical methods. Market players are focusing on developing advanced technologies and surgical instruments to improve the outcomes of minimally invasive procedures and expand their applications in bariatric surgery and other weight loss interventions.

Furthermore, the rising trend of holistic approaches to weight management is influencing the market dynamics. Consumers are increasingly recognizing the importance of a comprehensive lifestyle change that incorporates healthy eating, regular exercise, stress management, and behavioral modifications for sustainable weight loss. This has led to the integration of fitness and wellness services within weight loss programs, including yoga classes, mindfulness training, and mental health counseling. Market players are diversifying their service offerings to address the multifaceted needs of consumers seeking long-term weight management solutions.

Overall, the global weight loss and obesity management market is poised for continued growth with evolving consumer preferences, technological advancements, and strategic initiatives by key market players. The focus on personalized solutions, digital health innovations, minimally invasive surgical techniques, and holistic approaches to weight management are expected to drive the market forward in the coming years. The market landscape is dynamic and competitive, presenting opportunities for innovation and collaboration to meet the growing demand for effective weight loss and obesity management solutions.The global weight loss and obesity management market is experiencing notable shifts and trends that are shaping the industry landscape. Personalization has emerged as a key trend, with consumers seeking tailored weight loss solutions to address their specific needs and preferences. This trend is driving the development of customized meal plans, personalized fitness programs, and individualized consulting services to enhance the effectiveness of weight management strategies. Market players are leveraging technology and data analytics to offer personalized recommendations and monitoring tools, catering to the increasing demand for personalized weight loss programs.

Another significant trend in the market is the rise of online weight loss programs and digital health platforms. With the widespread adoption of smartphones and internet connectivity, consumers are turning towards virtual coaching, mobile apps for tracking diet and exercise, and online communities for support in their weight loss journey. The convenience, accessibility, and affordability offered by digital health solutions are attracting a broader consumer base, and this trend is expected to persist as technology continues to play a crucial role in weight management solutions.

In the realm of surgical equipment, there is a noticeable shift towards minimally invasive procedures for weight loss and obesity management. These procedures offer benefits such as reduced post-operative pain, shorter recovery times, and lower risks compared to traditional surgical methods. Market players are investing in advanced technologies and surgical instruments to enhance the outcomes of minimally invasive procedures, expanding their application in bariatric surgery and other weight loss interventions. The emphasis on minimally invasive techniques reflects the industry's commitment to improving patient outcomes and reducing the burden of traditional surgical procedures.

Moreover, holistic approaches to weight management are gaining traction in the market, emphasizing the importance of comprehensive lifestyle changes for sustainable weight loss. Consumers are increasingly acknowledging the significance of integrating healthy eating, regular exercise, stress management, and behavioral modifications into their weight management strategies. This has led to the integration of fitness and wellness services within weight loss programs, offering yoga classes, mindfulness training, and mental health counseling to address the holistic needs of individuals seeking long-term weight management solutions. Market players are diversifying their service offerings to align with consumer demands for holistic approaches to weight management, underscoring the industry's commitment to addressing multifaceted aspects of health and wellness.

In conclusion, the global weight loss and obesity management market are evolving in response to changing consumer preferences, technological advancements, and strategic innovations by key market players. The focus on personalization, digital health solutions, minimally invasive surgical techniques, and holistic weight management approaches is driving the market towards continued growth and innovation. As the industry continues to adapt to emerging trends and consumer needs, opportunities for collaboration, innovation, and differentiation will shape the future of weight loss and obesity management solutions.

The Weight Loss and Obesity Management Market is highly fragmented, featuring intense competition among both global and regional players striving for market share. To explore how global trends are shaping the future of the top 10 companies in the keyword market.

Learn More Now: https://www.databridgemarketresearch.com/reports/global-weight-loss-and-obesity-management-market/companies

DBMR Nucleus: Powering Insights, Strategy & Growth

DBMR Nucleus is a dynamic, AI-powered business intelligence platform designed to revolutionize the way organizations access and interpret market data. Developed by Data Bridge Market Research, Nucleus integrates cutting-edge analytics with intuitive dashboards to deliver real-time insights across industries. From tracking market trends and competitive landscapes to uncovering growth opportunities, the platform enables strategic decision-making backed by data-driven evidence. Whether you're a startup or an enterprise, DBMR Nucleus equips you with the tools to stay ahead of the curve and fuel long-term success.

The report provides insights on the following pointers:

Market Penetration: Comprehensive information on the product portfolios of the top players in the Weight Loss and Obesity Management Market.

Product Development/Innovation: Detailed insights on the upcoming technologies, R&D activities, and product launches in the market.

Competitive Assessment:In-depth assessment of the market strategies, geographic and business segments of the leading players in the market.

Market Development:Comprehensive information about emerging markets. This report analyzes the market for various segments across geographies.

Market Diversification:Exhaustive information about new products, untapped geographies, recent developments, and investments in the Weight Loss and Obesity Management Market.

Browse More Reports:

XYZ

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us: Data Bridge Market Research US: +1 614 591 3140 UK: +44 845 154 9652 APAC : +653 1251 975 Email:- [email protected]

Tag

"

0 notes