#learn plc programming

Explore tagged Tumblr posts

Text

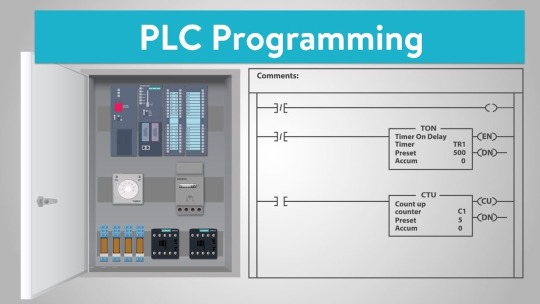

The Basics of PLC Programming: A Comprehensive Guide

If you're interested in the field of industrial automation or looking to enhance your skills in the industry, PLC programming is a crucial skill to possess. Programmable Logic Controllers (PLCs) are widely used in manufacturing and process control systems, and understanding how to program them is essential for ensuring efficient and reliable operation.

In this comprehensive guide, we will explore the basics of PLC programming, covering key concepts and providing valuable insights for beginners in the field.

1. What is PLC Programming?

PLC programming involves creating a set of instructions that control the behavior of a programmable logic controller. PLCs are used to monitor inputs from various sensors, process that data, and execute specific actions based on pre-defined logic. By programming a PLC, you can automate complex industrial processes, making them more efficient and reliable.

2. Why Learn PLC Programming?

PLC programming offers numerous benefits in the industrial automation realm. By acquiring this skill, you can:

Improve productivity: PLCs enable automation, reducing manual labor and increasing overall productivity.

Enhance efficiency: Automation minimizes human error and optimizes processes, resulting in higher efficiency levels.

Facilitate troubleshooting: Understanding PLC programming allows you to diagnose and fix issues efficiently, minimizing downtime.

Expand career opportunities: PLC programming expertise is in high demand, with many industries seeking professionals with these skills.

3. PLC Programming Training Courses:

To learn PLC programming effectively, it's essential to enroll in specialized training courses. These courses provide a structured curriculum, hands-on exercises, and expert guidance. Here are a few key aspects to consider when choosing a PLC programming training institute or center:

Comprehensive curriculum: Look for a training program that covers both theoretical concepts and practical implementation.

Experienced instructors: Ensure that the training institute has qualified instructors with industry experience to guide you effectively.

Hands-on practice: Practical exercises and projects are crucial for gaining proficiency in PLC programming.

Industry relevance: Verify that the training course aligns with current industry standards and practices.

Certification: Opt for courses that offer certifications upon completion, as they enhance your credibility in the job market.

4. Key Concepts in PLC Programming:

Ladder Logic: Ladder Logic is the most commonly used programming language for PLCs. It employs graphical symbols to represent logic functions and control sequences, making it easy to understand and implement.

Inputs and Outputs: PLCs interact with the physical world through inputs (sensors) and outputs (actuators). Understanding how to read inputs and control outputs is fundamental in PLC programming.

Programming Instructions: PLCs execute a set of instructions to perform desired operations. These instructions can include timers, counters, mathematical operations, logic gates, and more.

Program Execution: PLC programs are executed in a cyclical manner. The PLC scans inputs, processes logic, updates outputs, and repeats the cycle continuously.

5. Programming Tools and Software:

PLC programming software provides an interface to create, edit, and debug programs. Familiarize yourself with popular software tools such as Siemens TIA Portal, Allen-Bradley RSLogix, or Schneider Electric Unity Pro, as they are widely used in the industry.

Conclusion:

PLC programming is an essential skill for individuals aspiring to succeed in the field of industrial automation. By learning the basics of PLC programming, you open up a world of opportunities to streamline processes, enhance productivity, and contribute to the advancement of various industries. Enroll in a reputable PLC programming training institute or center, explore the key concepts, and start your journey towards becoming a proficient PLC programmer.

#plc-programming#learn plc programming#plc programming training#plc programming courses#plc training course in india

3 notes

·

View notes

Text

@huntunderironskies

YEAH!!!!! YES LITERALLY YOU GET ME!!!!!!!! I am so constantly astounded by how much stuff brains do and how it's like. we're so used to doing all of those things that it's like whatever it's not impressive who cares. but me. i do i care!!! we are breathing living animal creatures and we've got this organ. this big mass of cells and material and whatnot that has to interface with all our other cells and meat and material and it DOES. even the most basic stuff like breathing or ambulating. LOOKING at things and processing visual information, or hearing/audio information etc etc. and whether you need those things more or not, whatever processes you've got running they're all going concurrently, intersecting and interacting. it's so much WORK.

And like you said it's all completely unique to each individual!!!!! everything that goes into growing and forming it, the events that happen and stick there, that are navigated thru.. ephemeral feeling things like preferences and style and aesthetics..thoughts n feelings n personality.... graaghhh its all so...!!!! [my telekenesis throws everything around the room]

human brains are so cool . every day i thank my brain for takiing care of so many ridiculously complex tasks for me that would make me explode if i had to manually think and put effort into each and every single step. they make those autonomic processes look so easy. i love you brains

#SHAKING HANDS EMOJI MY FRIEND!!!!!!#its like. whenever i have an anxiety moment/loop which is often or im feeling down on myself#i try to think abt like. im trying to learn a bunch of new n different things right now#PLCs and computer programming and piano. and all of thats different stuff#arbitrary stuff. THAT WE MADE.#and theres SOOOOO FUCKING MUCH that goes into even Basic Understanding of those things#everything that needs to be focused on and taken in ON TOP OF all the sensory stuff + emotional regulation#+ body regulation + whatever other stuff im forgetting#that when i feel frustration being a beginner and things not Clicking right away i stop n go. yknow in the context of#being an animal. an alive living organism. this is kind of fucking off the charts absurd what im doing and what most ppl do#EVERYDAY JUST AS A REGULAR THING

12 notes

·

View notes

Text

I'm very good at "professionalism" I was trained from a young age. If I get an interview, I'm getting the job. I sit upright in my chair and wear a collared shirt and my employer thinks, "wow! She has a lot of passion for this role!" Buddy, you don't know the start of it. You don't even know my gender.

I'm OSHA certified. I got my 24-hour GD&T training. They can see this. What they don't see is me waxing poetical about surface finish or some shit on this website. When I was in 6th grade, I was exposed to Autodesk Inventor and it changed me fundamentally as a person. Whenever I look at any consumer good (of which there are a lot) I have to consider how it was made. And where the materials came from and how it got here and really the whole ass process. It's fascinating to me in a way that can be described as "intense". I love looking at large machines and thinking about them and taking pictures of them. There are so many steps and machines and people involved to create anything around you. I think if any person truly understood everything that happened in a single factory they would go insane with the knowledge. But by god am I trying. My uncle works specifically on the printers that print dates onto food. There are hundreds or even thousands of hyperspecific jobs like that everywhere. My employer looks away and I'm creating an unholy abomination of R and HTML, and I'm downloading more libraries so I can change the default CSS colors. I don't know anything about programming but with the power of stack overflow and sheer determination I'm making it happen. Is it very useful? No. But I'm learning a lot and more importantly I don't give a fuck. I'm learning about PLCs. I'm learing about CNC machines. I'm fucking with my laptop. I'm deleting SQL databases. I'm finding electromechanical pinball machines on facebook marketplace. I'm writing G-code by hand. I'm a freight train with no brakes. I'm moving and I'm moving fast. And buddy, you better hope I'm moving in the right direction. I must be, because all of my former employers give me stellar reviews when used as a reference. I'm winning at "career" and also in life.

14 notes

·

View notes

Text

Getting Started with Industrial Robotics Programming

Industrial robotics is a field where software engineering meets automation to drive manufacturing, assembly, and inspection processes. With the rise of Industry 4.0, the demand for skilled robotics programmers is rapidly increasing. This post introduces you to the fundamentals of industrial robotics programming and how you can get started in this exciting tech space.

What is Industrial Robotics Programming?

Industrial robotics programming involves creating software instructions for robots to perform tasks such as welding, picking and placing objects, painting, or quality inspection. These robots are typically used in factories and warehouses, and are often programmed using proprietary or standard languages tailored for automation tasks.

Popular Robotics Programming Languages

RAPID – Used for ABB robots.

KRL (KUKA Robot Language) – For KUKA industrial robots.

URScript – Used by Universal Robots.

Fanuc KAREL / Teach Pendant Programming

ROS (Robot Operating System) – Widely used open-source middleware for robotics.

Python and C++ – Common languages for simulation and integration with sensors and AI.

Key Components in Robotics Programming

Motion Control: Programming the path, speed, and precision of robot arms.

Sensor Integration: Use of cameras, force sensors, and proximity detectors for adaptive control.

PLC Communication: Integrating robots with Programmable Logic Controllers for factory automation.

Safety Protocols: Programming emergency stops, limit switches, and safe zones.

Human-Machine Interface (HMI): Designing interfaces for operators to control and monitor robots.

Sample URScript Code (Universal Robots)

# Move to position movej([1.0, -1.57, 1.57, -1.57, -1.57, 0.0], a=1.4, v=1.05) # Gripper control (example function call) set_digital_out(8, True) # Close gripper sleep(1) set_digital_out(8, False) # Open gripper

Software Tools You Can Use

RoboDK – Offline programming and simulation.

ROS + Gazebo – Open-source tools for simulation and robotic control.

ABB RobotStudio

Fanuc ROBOGUIDE

Siemens TIA Portal – For integration with industrial control systems.

Steps to Start Your Journey

Learn the basics of industrial robotics and automation.

Familiarize yourself with at least one brand of industrial robot (ABB, KUKA, UR, Fanuc).

Get comfortable with control systems and communication protocols (EtherCAT, PROFINET).

Practice with simulations before handling real robots.

Study safety standards (ISO 10218, ANSI/RIA R15.06).

Real-World Applications

Automated welding in car manufacturing.

High-speed pick and place in packaging.

Precision assembly of electronics.

Material handling and palletizing in warehouses.

Conclusion

Industrial robotics programming is a specialized yet rewarding field that bridges software with real-world mechanics. Whether you’re interested in working with physical robots or developing smart systems for factories, gaining skills in robotics programming can open up incredible career paths in manufacturing, automation, and AI-driven industries.

2 notes

·

View notes

Text

Living the life like an adult

One thing I have learned on my journey “you cannot have it all”

Indeed.

I remember once I was so scared to live my life not as what I want to be. Question, what I wanna be?

I dreamed to be a scientist. Working in Laboratories with some living organisms, writing scientific journals, and finding some new discoveries. I also remember about the conversation with the stranger in the bar (i am totally sober it was weekday and no no to alcohol). I was still studying and how I explained what I wanna be after studies. He simply talked about that he was studying some life sciences study and he becomes working in some finance of medical tools company (?). Naively, I was surprised, like how you are not working on your field…. I told him that I am scared being you, being not to work on my field.

AND WHAT I AM NOW ?

That it is true „you attract what you fear”

I am working in the automation company. I still romanticize about my background in BIOTECHNOLOGY and end up in automation.

Long story short, I got my new training for programming the PLC (that’s my labs picture with controllers). I was extremely excited with that new journey. I live with my fear now. I deal with it, I embrace it. Now, I enjoy how I do. Do I STILL WANNA BE A SCIENTIST??? of course even if it is only exist in my wildest dreams.

I am trying to be a proper adult here, working so I can pay my bills. I still can dream when I sleep but now we face the bitter truth, reality. Am I okay? I try not to think that much. But one thing I know, I am the explorer! New path here I am.

2 notes

·

View notes

Text

Waste Oil to Diesel: How to Convert Old Oil Waste into Clean Fuel

Every day, tons of waste oil are discarded from vehicles, factories, and workshops. This old oil waste, if not properly managed, becomes a dangerous environmental hazard. But what if we told you there’s a way to convert oil to diesel, giving waste a second life—and helping the planet too?

In this blog, we’ll explore how to convert old oil waste into diesel, why this process matters, and how you can be part of this sustainable revolution.

🛢️ What is Waste Oil?

Waste oil is used oil that has been contaminated with dirt, water, chemicals, or metal particles. It's usually produced from:

Engine oil changes

Industrial lubricants

Gearbox and transmission oils

Hydraulic fluids

Traditionally, this old oil waste is either burned (causing pollution) or dumped illegally, harming ecosystems. But advanced technology now allows us to convert oil to diesel through safe and efficient methods.

🔥 The Process: How to Convert Oil to Diesel

Wondering how we take dirty oil and turn it into clean-burning fuel? The process of converting old oil waste into diesel involves several steps:

1. Pre-treatment

Before processing, the waste oil goes through filtering and dehydration to remove water, dust, and sludge.

2. Distillation

The pre-treated waste oil is heated in a distillation reactor at high temperatures (300–450°C). This separates different oil components based on boiling points.

3. Condensation

The vapors created during distillation are condensed into liquid diesel fuel.

4. Purification

The diesel is then purified using chemical or clay filtration systems to remove odors, sulfur, and any remaining impurities.

And just like that, you’ve successfully converted oil to diesel!

⚡ Why Convert Old Oil Waste into Diesel?

Here’s why this method is gaining global attention:

✅ Environmental Safety – Prevents waste oil from contaminating soil and water.

✅ Energy Recovery – Transforms useless waste into valuable diesel fuel.

✅ Economic Value – High returns for workshops, factories, and fuel stations.

✅ Sustainability – Reduces dependency on fossil fuels and promotes circular energy use.

When you convert old oil waste into diesel, you’re not just saving money—you’re saving the Earth.

🏭 Equipment Needed to Convert Oil to Diesel

Many companies now offer machines and plants specifically designed for waste oil to diesel conversion. These include:

Waste Oil Distillation Plants

Used Oil to Diesel Recycling Machines

Black Oil Refining Equipment

PLC-Controlled Oil Conversion Systems

These machines are built to handle hundreds of liters of waste oil, converting it efficiently into usable diesel with 85–90% recovery rate.

💼 Who Benefits from Oil to Diesel Conversion?

Vehicle service centers

Municipal recycling programs

Energy startups

Logistics and transport firms

Small oil refineries

Anyone who deals with waste oil or needs a low-cost, alternative fuel source can benefit from learning how to convert oil to diesel.

📈 Business Potential: Waste Oil into Diesel Industry

With fuel prices rising and environmental regulations tightening, the industry for waste oil conversion is booming. Countries across Asia, Africa, and South America are adopting this model to:

Lower fuel imports

Create local energy jobs

Reduce pollution

Starting a plant to convert oil to diesel has become both an eco-friendly and profitable business idea.

🌿 Final Thoughts

Turning waste oil and old oil waste into diesel isn’t just a technological innovation—it’s a vital step toward a cleaner, more energy-resilient future.

When you convert oil to diesel, you turn waste into wealth, pollution into power, and problems into profits.

So next time you change your engine oil or see a barrel of black waste oil, think twice. It’s not garbage—it’s potential.

0 notes

Text

Simulink System Modeling Overview

Simulink system modeling, developed by MathWorks, is a powerful graphical programming environment for modeling, simulating, and analyzing dynamic systems. Widely used across industries such as automotive, aerospace, robotics, and control systems, Simulink enables engineers to design and test complex systems through block-diagram-based modeling.

Core Features of Simulink

Simulink provides a versatile platform for system modeling with features tailored to dynamic and multidomain systems:

Block-Diagram Interface: Simulink’s drag-and-drop interface allows users to build models using pre-built blocks representing mathematical operations, signal processing, and physical components. These blocks can be connected to represent system dynamics visually, simplifying the design process.

Multidomain Simulation: Simulink supports modeling of continuous, discrete, and hybrid systems, enabling engineers to simulate mechanical, electrical, hydraulic, and thermal systems within a single environment. Toolboxes like Simscape extend capabilities to physical modeling.

Real-Time Simulation and Testing: Simulink supports Hardware-in-the-Loop (HIL) testing and real-time simulation, allowing models to interact with physical hardware. This is critical for validating control algorithms in automotive and aerospace applications.

Code Generation: Simulink’s Embedded Coder and Simulink Coder generate optimized C, C++, or HDL code from models, enabling deployment on embedded systems, microcontrollers, and FPGAs. This streamlines the transition from simulation to production.

Integration with MATLAB: Simulink seamlessly integrates with MATLAB, allowing users to leverage MATLAB’s scripting capabilities for data analysis, parameter optimization, and custom block creation, enhancing model flexibility.

Extensive Toolboxes: Simulink offers specialized toolboxes for control systems, signal processing, computer vision, and machine learning. These toolboxes provide domain-specific blocks and functions, reducing development time for complex applications.

Applications of Simulink System Modeling

Simulink’s versatility makes it a cornerstone in various engineering domains:

Automotive Systems: Simulink is used to model and simulate vehicle dynamics, powertrains, and advanced driver-assistance systems (ADAS). For example, engineers design and test engine control units (ECUs) and autonomous driving algorithms using Simulink models.

Aerospace and Defense: Simulink models flight control systems, avionics, and satellite dynamics. It supports the design of robust controllers for aircraft and spacecraft, ensuring compliance with safety standards like DO-178C.

Robotics: Engineers use Simulink to develop control algorithms for robotic manipulators, drones, and autonomous vehicles. The Robotics System Toolbox facilitates motion planning and sensor integration.

Industrial Automation: Simulink models programmable logic controllers (PLCs) and supervisory control systems, optimizing manufacturing processes and energy management in smart factories.

Renewable Energy: Simulink simulates wind turbines, solar panels, and battery management systems, enabling the design of efficient power electronics and grid integration strategies.

Medical Devices: Simulink supports the development of control systems for devices like insulin pumps and ventilators, ensuring precision and reliability in critical applications.

Benefits of Simulink System Modeling

Simulink offers significant advantages for engineers and organizations:

Rapid Prototyping: Simulink’s visual interface enables quick model development and iteration, reducing design time. Engineers can test multiple scenarios without building physical prototypes.

Improved Accuracy: By simulating systems under various conditions, Simulink identifies design flaws early, ensuring robust performance. This is particularly valuable in safety-critical applications.

Cost and Time Savings: Virtual testing in Simulink reduces the need for expensive hardware prototypes and field tests. Code generation further accelerates deployment, minimizing development cycles.

Cross-Disciplinary Collaboration: Simulink’s intuitive interface bridges gaps between mechanical, electrical, and software engineers, fostering collaboration on complex systems.

Scalability: Simulink handles systems of varying complexity, from simple control loops to large-scale multidomain models, making it suitable for diverse projects.

Verification and Validation: Simulink’s simulation capabilities support model-based testing, ensuring systems meet requirements before implementation. Tools like Simulink Verification and Validation automate testing processes.

Challenges in Simulink System Modeling

Despite its strengths, Simulink modeling presents challenges:

Learning Curve: Simulink’s extensive features require training, particularly for beginners or engineers transitioning from text-based programming. Mastering toolboxes and best practices takes time.

Computational Resources: Large or complex models demand significant computational power, especially for real-time simulations. This can strain hardware resources and increase simulation times.

Model Management: As models grow in complexity, maintaining readability and organization becomes difficult. Poorly structured models can lead to errors or inefficiencies.

Licensing Costs: Simulink and its toolboxes require paid licenses, which may be a barrier for small organizations or academic institutions with limited budgets.

Integration Challenges: While Simulink integrates well with MATLAB, incorporating third-party tools or legacy systems can be complex, requiring custom interfaces or additional software.

Future Prospects

The future of Simulink system modeling is shaped by emerging technologies and industry trends:

Artificial Intelligence and Machine Learning: Simulink is integrating AI capabilities through toolboxes like Deep Learning Toolbox, enabling engineers to incorporate neural networks into control systems for applications like autonomous vehicles.

Digital Twins: Simulink supports digital twin development, allowing real-time monitoring and optimization of physical systems. This is gaining traction in manufacturing and aerospace.

Cloud and Distributed Computing: MathWorks is enhancing Simulink’s cloud integration, enabling collaborative modeling and high-performance simulations on distributed systems.

Cyber-Physical Systems: As IoT and smart systems proliferate, Simulink’s role in modeling cyber-physical interactions will expand, supporting applications in smart cities and healthcare.

Sustainability Focus: Simulink will play a key role in designing energy-efficient systems, such as electric vehicles and renewable energy grids, aligning with global sustainability goals.

Conclusion

Simulink system modeling by servotechinc is a cornerstone of modern engineering, offering a robust platform for designing, simulating, and deploying dynamic systems. Its visual interface, multidomain capabilities, and integration with MATLAB make it indispensable across industries. While challenges like cost and complexity exist, Simulink’s benefits—rapid prototyping, cost savings, and improved accuracy—outweigh these hurdles. As technologies like AI, digital twins, and cloud computing evolve, Simulink will continue to empower engineers to innovate, driving advancements in safety, efficiency, and sustainability.

0 notes

Text

How does AI-powered hyper-personalization influence retail growth by 2035

The Retail Analytics Market was valued at USD 8.0 Billion in 2023 and is expected to reach USD 45.4 Billion by 2032, growing at a CAGR of 21.31% from 2024-2032.

Retail Analytics Market is transforming the global retail industry by equipping businesses with data-driven insights to optimize inventory, personalize customer experience, and streamline operations. With the increasing reliance on omnichannel strategies and e-commerce platforms, retail analytics has become an essential tool for competitive growth across major markets.

U.S. Leads Retail Analytics Adoption With Strong Digital Maturity

Retail Analytics Market is experiencing accelerated adoption, particularly among retailers in the U.S. and Europe. Companies are leveraging analytics solutions for real-time decision-making, demand forecasting, and customer behavior tracking—delivering measurable improvements in revenue, customer loyalty, and operational agility.

Get Sample Copy of This Report: https://www.snsinsider.com/sample-request/2913

Market Keyplayers:

SAP SE - SAP Customer Activity Repository

Oracle Corporation - Oracle Retail Analytics

IBM Corporation - IBM Watson Retail Analytics

SAS Institute Inc. - SAS Retail Analytics

Microsoft Corporation - Microsoft Power BI

Qlik Technologies Inc. - Qlik Sense

Teradata Corporation - Teradata Vantage

Nielsen Holdings PLC - NielsenIQ

Tableau Software - Tableau Analytics Platform

Google LLC - Google Cloud Retail Analytics

Infor - Infor CloudSuite Retail

Manthan Systems - Manthan Retail Analytics Suite

TIBCO Software Inc. - TIBCO Spotfire for Retail Analytics

Market Analysis

The Retail Analytics Market is driven by a surge in digital transformation initiatives and heightened consumer expectations for personalized and seamless shopping experiences. Retailers are investing in data platforms, AI, and machine learning to gain visibility across supply chains, optimize pricing, and predict customer trends more accurately. As retailers expand their digital footprints, analytics is becoming the backbone of strategic planning and customer engagement.

The United States remains the leading region for retail analytics deployment, with tech-savvy retailers and advanced infrastructure pushing innovation forward. Europe follows with a focus on compliance, sustainability insights, and customer-centric business models.

Market Trends

Rising adoption of AI and ML for real-time recommendation engines

Use of predictive analytics to manage dynamic pricing and demand planning

Integration of analytics in customer loyalty and retention programs

Growing importance of in-store behavior analytics using smart sensors

Increased reliance on cloud-based analytics platforms

Expansion of data visualization tools for actionable reporting

Emphasis on sustainability tracking and ethical sourcing insights

Market Scope

The scope of the Retail Analytics Market is broadening as retailers across all segments seek to convert raw data into actionable intelligence. Whether in-store or online, analytics platforms are now central to performance measurement and customer strategy execution.

End-to-end visibility into customer journeys

Inventory and supply chain optimization

Real-time dashboards for sales and engagement metrics

Geolocation and footfall tracking for store performance

Omnichannel integration insights

Enhanced fraud detection and risk management

Scalable solutions for SMEs to global retail chains

Forecast Outlook

The Retail Analytics Market is poised for sustained momentum as businesses navigate a highly competitive and data-centric retail environment. Future growth will be powered by deeper integration of artificial intelligence, automation, and cloud infrastructure—enabling retailers to create hyper-personalized experiences and agile operations. With increasing demand for precision, agility, and customer alignment, retail analytics is expected to become a cornerstone of long-term strategy in both established and emerging retail landscapes.

Access Complete Report: https://www.snsinsider.com/reports/retail-analytics-market-2913

Conclusion

Retailers embracing data-driven transformation are redefining customer engagement and operational efficiency. The Retail Analytics Market is no longer a differentiator—it is a necessity. In a landscape shaped by rapid shifts in consumer behavior, economic variables, and technological disruption, those equipped with advanced analytics will lead the next era of intelligent retail.

About Us:

SNS Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Related Reports:

U.S.A eyes robust growth in the Trade Management Software Market as global trade complexities rise

U.S.A gears up for smarter operations as Field Service Management Market surges in adoption

U.S.A gears up for advanced transformation in the IT Operations Analytics Market

Contact Us:

Jagney Dave - Vice President of Client Engagement

Phone: +1-315 636 4242 (US) | +44- 20 3290 5010 (UK)

Mail us: [email protected]

0 notes

Text

From Classroom to Lab: Exploring SUAS’s Specialized Robotics & Automation Labs

At the heart of engineering excellence is the ability to build, test, and innovate — and that’s exactly what students at Symbiosis University of Applied Sciences, Indore (SUAS) experience every day. As a modern private university in Indore, SUAS blends academic knowledge with practical expertise, especially in its B.Tech in Automation & Robotics program. But what truly sets SUAS apart is its world-class laboratory infrastructure, designed to mirror the most advanced industry settings.

Real-World Learning Begins in the Lab

While many universities emphasize theory, Indore Symbiosis focuses on real-world application. Students spend a significant portion of their time in specialized labs, engaging with the same equipment, tools, and technologies used by industry professionals. SUAS follows a 70:30 model — 70% practical learning and 30% theoretical instruction — making it one of the top universities in Indore for hands-on engineering education.

Key Laboratories at SUAS

🔧 Automation Lab

This lab gives students access to industrial automation components like programmable logic controllers (PLCs), human-machine interfaces (HMIs), sensors, and actuators. Here, students simulate and implement automated systems just as they would in automotive, manufacturing, or packaging industries.

🤖 Robotics Lab

Equipped with robotic arms, Arduino kits, and programmable systems, this lab allows students to build and test robots from scratch. They learn everything from robotic movement and path planning to vision-guided robotics and AI integration.

⚙️ Microprocessors & Embedded Systems Lab

Students get hands-on with microcontrollers like 8051, PIC, and ARM boards, learning how to build embedded systems — the backbone of smart robots and automation devices. The lab supports courses in embedded C, IoT systems, and device-level programming.

🛠️ Lucas-Nülle Lab Setup

Through international collaboration, SUAS integrates Lucas-Nülle’s Germany-based training systems, known for bridging academic learning with practical engineering. These systems simulate real industrial environments and enhance technical training to a global standard.

Innovation Starts Here

Labs at SUAS are not just for coursework. Students regularly use them for capstone projects, hackathons, and startup prototypes — from 3D-printed robotic parts to drones and home automation systems. Supported by SUAS’s incubation center and mentorship programs, students can transform classroom ideas into real innovations.

Why It Matters

In a field like automation and robotics, real lab exposure gives students a serious edge. They not only understand theoretical models but can also wire, program, and troubleshoot physical systems — a skillset highly prized by employers in India and abroad.

Conclusion

For aspiring engineers seeking the perfect blend of academic learning and hands-on experience, Symbiosis University of Applied Sciences, Indore delivers through its specialized labs and industry-driven curriculum. It’s no wonder SUAS is widely regarded as one of the best universities in Indore for engineering in the automation era.

0 notes

Text

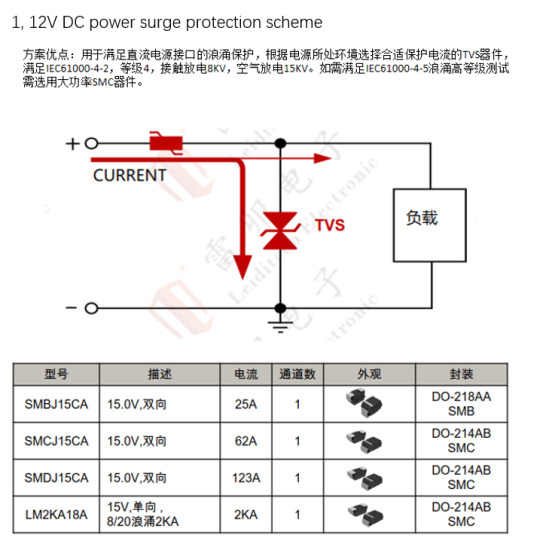

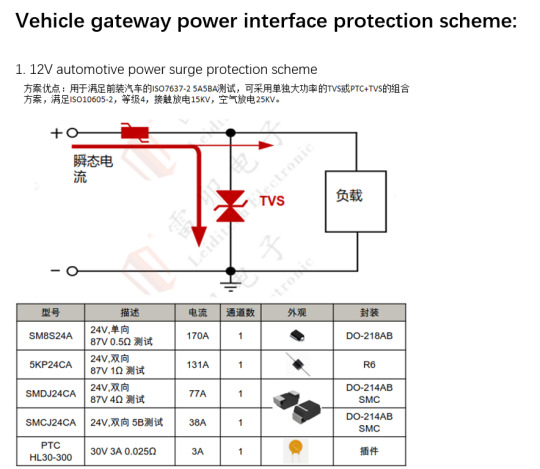

Interface protection design for edge computing gateways

With the rise of the Internet of Things and the popularity of cloud services, a new computing paradigm — edge computing — is beginning to appear in our field of vision. Edge computing advocates processing data at the edge of the network, thereby reducing system response time, protecting data privacy and security, extending battery life, and saving network bandwidth. Current applications are divided into industrial and automotive applications.

Industrial gateways

Industrial gateway is an indispensable device of the industrial Internet of Things, it is like the nerves of the human body, the perceived various types of information to the brain for processing, the brain through the operation to determine what kind of response to do, and then transmitted by the nerves to the limbs of the whole body. The gateway can collect PLC data, do remote maintenance and download programs, and has the functions of edge computing and protocol parsing. Industrial communication gateways can perform message conversion between various network protocols, and their functions can be implemented by a chip, an embedded device or board, or a stand-alone device.

Industrial Edge Computing Gateway Features:

1. Rich interface, support Ethernet, serial port, CAN port, IO port and other equipment access and Ethernet, 2G/3G/4G full Netcom network access;

2. Embedded hundreds of industrial protocols, supporting more than 99% PLC and the vast majority of industrial equipment access;

3. 8GB local storage + SD card support, support local data cache and offline application;

4. Three-in-one serial port, support RS485/RS232/RS422 three kinds of electrical interfaces;

5. Support edge computing, realize data optimization, real-time response, agile connection, model analysis and other services in the edge node of the Internet of Things, and effectively share cloud computing resources to support simultaneous access of multiple devices;

6. Support DC9~36V wide voltage input, adapt to a variety of complex industrial sites;

Each interface protection design of the industrial gateway

D-C power supply

Features of the on-board gateway

Due to the particularity of the on-board power supply, all the product power ports taken from the car need to pass the surge load-dump test, Leiditech Electronics provides a professional protection solution for the load-dump test, compared with the industrial gateway, the on-board power supply protection needs are greater.

summary

The interface protection of electronic products needs to use overvoltage protection devices, many engineers realize that they want to use protection devices, but due to improper selection or failure to follow the ESD circuit PCB design principles, resulting in product electrostatic testing or EMC testing does not pass, product verification tests many times, waste of manpower and financial resources, causing product delays to market Things always occur, or over-design, resulting in cost pressure.

Leiditech Electronics specializes in providing customers with EMC design services for electromagnetic compatibility, providing laboratories to do thorough tests, from customers efficient, easy to complete the design, hoping that more customers can quickly pass EMC’s projects and improve product reliability. Leiditech Electronic Electromagnetic Compatibility Laboratory, which provides peripheral electrostatic surge protection reference circuits.

If you’d like to learn more or have any questions, don’t hesitate to reach out:

Visit us at [en.leiditech.com]

EdgeComputing #IndustrialIoT #EMCDesign #ESDProtection #AutomotiveGateway #SmartFactory #IoTDesign #HardwareEngineering #EmbeddedSystems #SurgeProtection #InterfaceDesign #TechBlog #EngineeringLife #ProductDevelopment #DesignTips

0 notes

Text

Catalyzing Growth: Southeast Asia Specialty Chemicals Market Outlook 2024–2034

The Southeast Asia specialty chemicals market is growing rapidly, driven by increasing demand for high-performance and sustainable chemicals in industries like textiles, construction, automotive, and electronics. In order to improve product durability, efficiency, and environmental compliance, improved formulations are needed as industry and urbanization pick up speed. The employment of environmentally friendly chemicals and green manufacturing techniques is encouraged by stringent regulations and sustainability programs. Innovation and production efficiency are being increased by technological developments including bio-based chemicals, nanotechnology, and smart manufacturing. Additionally, supply chains are strengthened and the region's growing industrial ecosystem is supported by the emergence of regional production hubs and strategic alliances between local and international businesses.

What is the current size of the Southeast Asia specialty chemicals market?

The Southeast Asia specialty chemicals market was valued at $46.86 billion in 2024 and is expected to reach $84.24 billion by 2034, witnessing a CAGR of 6.04% during the forecast period 2024-2034.

Which Southeast Asian countries are leading in specialty chemical production and consumption?

Thailand

Indonesia

Malaysia

Vietnam

What are the latest mergers and acquisitions in the Southeast Asia specialty chemicals space?

Sika acquires Elmich Pte (Singapore) Strengthens presence in ASEAN construction chemicals Deal closed in February 2025

Shell sells Singapore refinery & petrochemical assets Sold to a JV between Chandra Asri (Indonesia) and Glencore Enhances Chandra Asri’s regional petrochemicals integration (May 2024)

Indorama Ventures acquires 24.9% stake in EPL Ltd Thai firm expands in specialty packaging Deal valued at approx. USD 221 million (Early 2025)

Who are the major players operating in the Southeast Asia specialty chemicals market?

BASF

Dow

Clariant

Solvay

Evonik Industries AG

LANXESS

Croda International Plc

3M

Petroliam Nasional Berhad (PETRONAS)

Gain a comprehensive market overview from industry experts and unlock valuable insights to drive your business growth. Download our sample now!

Learn more about Advance Material and Chemical Vertical. Click Here!

Conclusion

The Southeast Asia specialty chemicals market is poised for robust growth, driven by rapid industrialization, urbanization, and rising demand for high-performance, sustainable chemical solutions across diverse industries. With industries like electronics, textiles, and construction driving consumption and a growing focus on environmentally friendly products and cutting-edge technologies, the area presents a wealth of chances for investment and innovation. For firms looking to improve their market position, strategic growth into high-value niche markets supported by robust R&D and international alliances will be essential. In the upcoming ten years, Southeast Asia is expected to develop into a vibrant center for the production and innovation of specialty chemicals as major firms continue to adjust to changing laws and consumer preferences.

#Southeast Asia Specialty Chemicals Market#Southeast Asia Specialty Chemicals Industry#Southeast Asia Specialty Chemicals Report#advance material#chemical

0 notes

Text

Simplifying Automation for Small Businesses with Eaton Easy E4

Small and mid-sized businesses are increasingly turning to automation to boost productivity, reduce errors, and stay competitive in today’s fast-paced industrial landscape. However, implementing automation doesn’t have to be complicated or expensive. The Eaton Easy E4 smart relay offers a simple, scalable solution for businesses looking to automate essential operations without the overhead of large-scale systems. When paired with other industry-leading technologies like Eaton VFD, Watlow 4FT, and Eaton DM1, the Easy E4 becomes part of a powerful, efficient automation strategy tailored to growing operations. Eaton Easy E4: Smart Automation Made Simple

The Eaton Easy E4 is designed for simplicity and flexibility. It allows users to build automation logic for tasks such as lighting control, pump management, HVAC systems, and more. With modular expansion options and intuitive programming software, even businesses with minimal engineering resources can design and deploy custom control systems.

Whether it’s a small warehouse operation or a light manufacturing facility, the Easy E4 can handle automation needs without the steep learning curve or cost often associated with traditional PLCs.

Enhancing System Performance with Eaton VFD When paired with an Eaton VFD (Variable Frequency Drive), the Easy E4 can control motor-driven equipment such as fans and conveyors with remarkable energy efficiency. By dynamically adjusting motor speed to meet real-time demands, Eaton VFDs reduce power consumption and extend equipment life. Integrating the Easy E4 for simple logic control—like starting, stopping, or sequencing multiple motors—can dramatically improve energy usage without the need for complex infrastructure. Precise Thermal Management with Watlow 4FT For small-scale systems requiring temperature regulation, the Watlow 4FT is a perfect complement. It brings precision temperature control to processes such as food preparation, packaging, or small-batch chemical production. The Easy E4 can serve as the central controller for these operations, triggering heating or cooling based on input from the Watlow 4FT to maintain consistent and safe conditions. Seamless Expansion with Eaton DM1 Micro PLC As operations grow, the Eaton DM1 micro PLC can seamlessly take over more complex logic and integrate with systems already powered by the Easy E4. Together, they form a modular automation solution that grows with your business—starting simple and scaling as needed. The DM1’s communication capabilities and advanced logic processing make it ideal for expanding upon foundational systems built using the Easy E4. A Smarter Start for Small Business Automation The Easy E4 helps small businesses:

Eliminate manual errors

Streamline basic operations

Reduce energy costs with Eaton VFDs

Maintain quality with Watlow 4FT temperature control

Expand functionality through Eaton DM1 integration

This smart relay solution is a reliable entry point for companies ready to embrace automation but not yet in need of a full-scale PLC system. Ready to Simplify Your Operations? At Seagate Controls, we help businesses of all sizes implement efficient and cost-effective automation solutions. Whether you’re starting with a single Eaton Easy E4 or looking to integrate a full suite of technologies including Eaton VFD, Watlow 4FT, and Eaton DM1, our team is here to guide you.

Call us today at 1.800.472.8812 to speak with an automation expert and discover how you can simplify operations and grow smarter.

Source Url : - https://eliteveggies.com/simplifying-automation-for-small-businesses-with-eaton-easy-e4/

0 notes

Text

Programmable Logic Controller Market Set to Hit US$ 17.2 Bn with Strong Demand from Smart Industries

The global programmable logic controller (PLC) market, valued at US$ 11.6 Bn in 2022, is forecast to grow at a CAGR of 4.7% between 2023 and 2031, reaching a market value of US$ 17.2 Bn by the end of 2031, according to the latest industry insights. This growth is propelled by a surge in demand for industrial automation, smart manufacturing, and increased integration of the Industrial Internet of Things (IIoT).

Market Overview: A programmable logic controller (PLC) is a digital computer used to automate electromechanical processes, particularly in manufacturing environments. These devices are integral to the efficient operation of assembly lines, robotic devices, and any activity requiring high-reliability control and ease of programming. With increasing adoption across automotive, food & beverage, chemical, energy & utility, and construction industries, the global PLC market continues to expand in scope and application.

Market Drivers & Trends

The rising trend of smart factories and Industry 4.0 is among the most significant growth drivers. Manufacturers are increasingly adopting automation to reduce operational costs, improve productivity, and enhance precision. PLCs play a critical role in this transformation by allowing control over complex industrial processes with minimal human intervention.

Additionally, the growing need for data-driven decision-making, along with advancements in machine learning and artificial intelligence, is leading to deeper integration of PLCs in industrial settings. As automation becomes central to production and operational strategies, the demand for PLCs is expected to surge further.

Latest Market Trends

One of the most notable trends is the shift toward modular PLCs, which accounted for over 68.2% of the market share in 2022. These PLCs are gaining popularity due to their scalability and suitability for large-scale, complex automation tasks. Modular systems offer higher flexibility, can handle thousands of inputs/outputs, and support multitasking environments—making them ideal for high-volume manufacturing operations.

Another trend is the miniaturization of PLCs, which supports their deployment in compact systems and small machinery, especially in consumer electronics and smaller automated units.

Key Players and Industry Leaders

The competitive landscape is fragmented yet dominated by global industrial automation giants. Leading companies in the PLC market include:

Siemens

Rockwell Automation

Mitsubishi Electric Corporation

Schneider Electric

OMRON Corporation

ABB

Panasonic Corporation

Bosch Rexroth Corporation

Delta Electronics, Inc.

Honeywell International Inc.

These companies continue to drive innovation through strategic partnerships, R&D investments, and product expansions to enhance their market share and global footprint.

Recent Developments

Crouzet, in December 2022, launched Millennium Slim, the slimmest PLC in the world, tailored for compact industrial applications.

In July 2022, OMRON Corporation introduced the CP2E Micro PLC, designed for smaller devices and capable of data collection and machine-to-machine communication. This supports low-cost automation solutions for small- and mid-sized enterprises.

Electronics Corporation of India Limited (ECIL) released its own PLC and SCADA software in May 2022, targeting industrial control applications in Indian manufacturing ecosystems.

These product introductions underline the market’s commitment to technological advancement and responsiveness to evolving industrial demands.

Market Opportunities

The expansion of material handling systems, especially in e-commerce logistics, warehousing, and food processing industries, presents substantial growth potential for PLC integration. In material handling, PLCs streamline storage, movement, and tracking—drastically improving throughput and inventory management.

Additionally, the increasing popularity of energy-efficient manufacturing and sustainability initiatives provides ample opportunity for advanced PLC systems that help monitor and reduce energy consumption across production lines.

Gain a preview of important insights from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=32672

Future Outlook

The future of the programmable logic controller market lies in enhanced interoperability, cloud integration, and edge computing. With greater reliance on smart infrastructure and connected devices, PLCs are expected to evolve into more intelligent, connected controllers.

The incorporation of AI-powered PLCs is expected to revolutionize industrial automation by enabling predictive maintenance, self-diagnosis, and adaptive process control. As PLCs continue to advance, their use will extend beyond industrial sectors into smart cities, transportation systems, and building automation.

Market Segmentation

By Offering:

Hardware: CPU, I/O Modules, Power Supply, Memory System

Software

Services

By Type:

Compact PLC

Modular PLC

Nano, Micro, Small, Medium, and Large PLCs

By Application:

Material Handling

Packaging & Labeling

Process Control

Safety Monitoring

Energy Management

Home & Building Automation

Industrial Equipment Control

By End-use Industry:

Automotive

Energy & Utilities

Food & Beverage

Pharmaceuticals

Construction

Oil & Gas

Semiconductors & Electronics

Regional Insights

Asia Pacific held the largest market share of 36.3% in 2022, led by strong industrial growth in China, Japan, South Korea, and India. The increasing demand for smart manufacturing systems and compact automation solutions in the region is expected to maintain its dominance through 2031.

North America, with a market share of 26.4% in 2022, continues to grow due to early adoption of factory automation and significant investment in smart infrastructure in the U.S. and Canada.

Europe remains a hub for automation technology innovation, with countries like Germany, the U.K., and France focusing on Industry 4.0 implementation across automotive and manufacturing sectors.

Why Buy This Report?

This comprehensive report offers:

Detailed market size, forecast, and growth rate

In-depth competitive landscape and company profiling

Analysis of key market drivers, trends, and opportunities

Region-wise breakdown for strategic decision-making

Porter’s Five Forces, value chain, and trend analysis

Insights into technological developments and their impact

Market segmentation for customized investment strategies

With expert analysis and forward-looking insights, this report serves as a valuable resource for stakeholders, investors, industrial engineers, and policymakers seeking to navigate and capitalize on the fast-evolving programmable logic controller market.

Explore Latest Research Reports by Transparency Market Research: 5G Smart Antenna Market: https://www.transparencymarketresearch.com/5g-smart-antenna-market.html

Solid State Transformer Market: https://www.transparencymarketresearch.com/solid-State-transformer.html

Interactive Display Market: https://www.transparencymarketresearch.com/interactive-display-market.html

GaN Epitaxial Wafers Market: https://www.transparencymarketresearch.com/gan-epitaxial-wafers-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Why Siemens SIMATIC S7-1200 PLC is Ideal for Modern Industries

In today’s rapid-paced manufacturing environment, the roles of automation are the improvement in productivity, quality, and efficiency. At the core of many intelligent automation systems, there is the versatile and powerful PLC SIMATIC S7-1200 developed by Siemens.

Learn more about, Top 10 Features of the SIMATIC S7 1200 That Makes It a Game Changer

What is SIMATIC S7-1200?

The SIMATIC S7-1200 is a compact and modular PLC designed for small to medium automation tasks. It is scalable in nature and comes with integrated communication and user-friendly programming using the TIA Portal (Totally Integrated Automation). Be it a simple machine or a highly complex process; the Siemens SIMATIC S7-1200 strikes a perfect balance between performance and affordability.

Key Features of Siemens SIMATIC S7-1200 PLC

Packed with features, the Siemens SIMATIC S7-1200 PLC can adapt perfectly to a variety of industrial applications.

Modular Design: Easily expand your system by attaching different signal modules, communication modules, or signal boards.

Integrated Communication: Provides a built-in PROFINET interface.

High-Speed Processing: Operation with precise control and response.

Web Server: Access to the system diagnostics remotely through a web-based interface.

Security Functions: Protect with a password and access control security functions.

Energy Monitoring: Optimizes power usage in the production processes.

This makes the SIMATIC S7-1200 a perfect fit to be a controller for packaging, HVAC, conveyor systems, and other applications.

Why Choose Siemens SIMATIC S7-1200 for Automation?

Scalability:

Automation needs grow with Siemens SIMATIC S7-1200; start small and work your way up along with your processes.

Programming Flexibility:

This system supports ladder diagrams, function block diagrams, and structured text, allowing both newbie and seasoned programmers to use them.

Robust Performance:

Operating under harsh industrial conditions, the Siemens SIMATIC S7-1200 PLC looks after consistent performance even when challenged by environmental conditions.

Integrated System Diagnostics:

Diagnose and fix problems immediately without the aid of external tools to minimize system downtime and maximize operational efficiency.

Learn more, Why Siemens PLC S7-1200 is the best choice for Compact Automation System

Applications of SIMATIC S7 1200

The SIMATIC S7-1200 finds applications in several industrial fields, including:

Automotive: Automated assembly lines and robotics are controlled.

Food & Beverage: Packaging and processing lines are handled with precision.

Textile: Improves control of dyeing and printing machines.

Water treatment: Monitoring and control of pumps and filters are performed.

Material Handling: Smart conveyors and warehouse automation present a challenging application.

Because of its versatility, the Siemens SIMATIC S7-1200 PLC continues to be a very reliable solution in the industrial automation world.

Conclusion

Whether updating an existing automation system or embarking on a brand-new project, the S7-1200 affords the performance, flexibility, and reliability you need. Its intelligence and easy integration make it a wise choice in any industrial setting.

If you are considering procurement or implantation of Siemens SIMATIC S7-1200 PLC, Naksh Technology Solutions LLP is your trusted partner. With years of experience in the field of industrial automation coupled with a sturdy portfolio of Siemens products, Naksh Technology ensures the development of seamless solutions that fit your business needs.

0 notes

Text

youtube

Explore Cognidel Academy through this exclusive institute tour and discover why it’s a top choice for anyone seeking a PLC SCADA training program in Bangalore. With advanced lab facilities, hands-on learning, expert instructors, and real-time industrial projects, Cognidel equips students with the skills needed for successful careers in automation, including PLC, SCADA, DCS, VFD, and IoT technologies.

1 note

·

View note