#power socket

Explore tagged Tumblr posts

Text

Structural Innovation and Easy Installation Technologies in Power Socket Design

As smart homes, office automation, and industrial digitalization rapidly advance, the demand for user-friendly, efficient, and safe power sockets continues to grow. Traditional socket designs are no longer sufficient for fast-paced environments that require high reliability, ease of installation, and space optimization. This has driven innovation in both internal structure and external mounting mechanisms of modern power sockets.

This article explores key advancements in structural design and installation technologies of power sockets, focusing on terminal innovations, mounting bracket designs, and strategies to increase module density without increasing volume. We will also discuss real-world examples and applicable technologies for B2B manufacturers and system integrators.

1. Integrated vs. Modular Terminal Design: Which is More Efficient?

The terminal structure of a power socket directly determines wiring efficiency and stability. The two mainstream types are:

A. Integrated Terminal Block (One-Piece)

All terminals are integrated into a single housing.

Benefits: Shorter installation time. Reduced loose contacts. Lower resistance due to shorter conductive paths.

Limitations: Less flexible for modular replacement. May increase overall production complexity.

B. Modular Terminal Block (Multi-Part)

Each terminal is separately assembled or replaceable.

Benefits: Ideal for custom configurations. Easier to repair and replace.

Limitations: Longer assembly time. Risk of performance inconsistency.

2. Push-in Spring Connection Technology: Fast, Safe, Tool-Free Wiring

Compared to screw terminals, push-in spring terminals provide:

Quick installation: Simply push the stripped wire into the terminal.

Strong contact: Stainless steel or beryllium copper springs maintain pressure for years.

No need for torque tools: Reduces operator training and tool investment.

🔧 Case Example: A European power socket brand uses a push-in spring design that allows a full 5-gang module to be wired in under 30 seconds — 60% faster than screw terminals.

3. Quick-Mount Bracket Designs: Screw-Free, Time-Saving, and Reliable

In large-scale installations (e.g., hotels, office buildings), fast mounting systems dramatically reduce labor costs and error rates.

Key Innovations:

A. Snap-In Mounting Frame

Socket modules are inserted directly into wall plates with audible clicks.

Uses elastic clips or sliding locks for firm placement.

Ideal for drywall and modular building systems.

B. Screwless Embedded Mounting

Eliminates screw holes by using slide-in rail structures.

Allows easy front-facing maintenance or upgrades.

Common in premium wall systems and panel furniture.

C. Magnetic or Cam-Lock Fastening

Applies in high-end modular offices.

Enables tool-free repositioning.

🔧 Case Example: A Chinese manufacturer developed a double-locking quick-install bracket that passed 500N pull force tests, suitable for vibration-prone environments like rail stations.

4. Increasing Module Density Without Expanding Volume

Modern installations demand multi-functionality in limited space. Techniques include:

A. Vertical Layering of Internal PCB

Using 3D layout: control, relay, and detection circuits are stacked.

Reduces horizontal footprint while maintaining thermal separation.

B. Multi-Function Integration

Combining USB chargers, smart sensors, and energy monitors in one unit.

Example: A 55x55mm wall socket includes 2 USB-A ports, 1 USB-C PD port, and Wi-Fi controller.

C. High-Density Terminal Design

Dual-row spring contacts with insulation barriers allow up to 10 terminals in standard footprint.

Ensures safety spacing while maintaining compact size.

5. Material Innovation: Making Structural Compactness Possible

A. High-Performance Plastics:

Use of PA66, PC+ABS, and flame-retardant PBT with thin-wall molding tech.

Improves space efficiency without sacrificing insulation performance.

B. Conductive Material Optimization:

Use of laminated copper busbars.

Electroplated or stamped silver contact surfaces to reduce thickness.

6. Installation Aids and Engineering Enhancements

A. Color-coded Wiring Guides:

Reduces wiring errors during bulk installations.

Accelerates compliance with local electrical codes.

B. Pre-assembled Harnesses:

For standard socket layouts, pre-assembled wire bundles reduce on-site labor.

C. Tool-Assisted Plug-In Systems:

Modular rail sockets with plug-in interfaces (e.g., DIN-rail smart outlets) improve interchangeability.

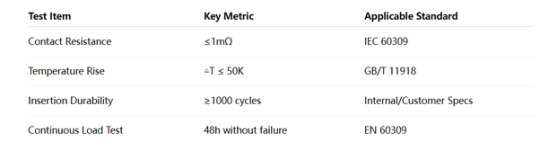

7. Structural Testing and Validation

8. Conclusion: Towards Smarter, Faster, and Denser Power Socket Design

Power socket structure and installation are no longer just mechanical tasks—they are core parts of user experience, energy efficiency, and engineering cost control. Through structural innovation like push-in terminals, quick-install brackets, and functional integration in compact modules, manufacturers can deliver plug-and-play, space-saving, and intelligent power socket solutions.

Whether you're a B2B buyer, an engineering contractor, or a systems integrator, adopting these next-generation socket designs will result in lower maintenance costs, faster deployment, and greater end-user satisfaction.

en.dghongju.com

0 notes

Text

I want to insert a fork into a socket. Whether I mean a power socket or someone’s eye socket is your choice.

1 note

·

View note

Text

Have you considered that your nose kind of looks like a socket? That or an alien.

0 notes

Text

Power sockets with protective covers. Black and white photo.

#power sockets#electricity#energy#power#power socket#protective covers#covers#photography#photo#photos#picture#pictures#image#images#a photo#a picture#an image#photograph#photographs#a photograph#black and white#black and white photo#black and white photos#black and white photograph#black and white photographs#black and white picture#black and white pictures#black and white image#black and white images#blackandwhite

1 note

·

View note

Text

Nice to meet you

What can I do?

0 notes

Text

pre-encounter snack

#i hate rhulk's shitty little lamps i'm unplugging them all and putting the power sockets to proper use#acquisition more like acquire some fucking queso you weird greasy hydraulic press looking bastard and maybe youll calm down#destiny#destiny 2#damascus-12#kullen art#(deathclaugust will resume im just stuck doing other stuff rn)

547 notes

·

View notes

Text

Idk why I thought of this but its killing me

#juno didn't miss this time damn#also think this is the first time my mind redesign is posted on here#the one with the glass torso at least#also first time in awhile that i feel happy with how i drew heart#also i don't know if those things have different names#electric outlet. power outlet. electrical socket i have no idea#but you know what i mean#chonny jash#chonnys charming chaos compendium#cj mind#cj heart#-atlas art-#ive said also like 5 times in this post lol

300 notes

·

View notes

Text

When Perceptor finally sends a rebuttal to the rebuttal to the rebuttal to the rebuttal to the rebuttal of one of Brainstorm's most recent papers. Brainstorm is getting ready to write another rebuttal.

I am not a complicated person. I see @tiesthatbind-tf post a Brainstorm design here , and I am struck by the urge to draw an incredibly handsome insufferable genius.

also i didn't draw the desk that way but Brainstorm reads as the type of person to me who, if given the option, would have one of those desks that converts between being a sitting desk and a standing desk. <- The type of riveting headcanons my brain can cook up while I am trying to tie down the details.6

#tinman doodles#ttb au#i fully admit i traced that perceptor altmode microscope next to him i was NOT up for trying to freehand that right now#i was also going to try and shade this but i realized i dont really know how to shade or highlight yet#so this will be a fun piece to revisit in a bit once i improve but for now it is flats#i also have to be at work in like 5 hours so that will be fun#i also should have been packing my house more tonight but this drawing idea wouldnt leave#also if you read to the end of my tag ramble the plane on his laptop is based on a c-wing spitfire#also another fun fact the power socket on the wall is the type used in south korea#and i remembered what to put because someone just went and told me about needing an adapter

29 notes

·

View notes

Text

Improving Efficiency and Safety – Optimized Conductive Design for Industrial Power Sockets

With the rapid development of intelligent manufacturing, data centers, rail transit, and new energy infrastructure, power delivery systems are increasingly demanding higher performance from industrial power sockets. Particularly in 32A and 63A high-current applications, conductive performance has become the core indicator of product quality. Factors such as contact resistance, current-carrying capacity, and thermal control play a vital role in determining the reliability and safety of these components.

This article presents a comprehensive analysis of conductive structure optimization for industrial power sockets, focusing on structural strategies, material selection, manufacturing processes, and design implementation for typical current ratings. It aims to help B2B customers make informed decisions during product development, selection, and integration.

1. Why Is Conductive Performance So Critical for Industrial Power Sockets?

In real-world applications, conductive performance directly impacts the following aspects:

Contact resistance: Affects transmission efficiency; excessive resistance can lead to overheating and erosion.

Current stability: Ensures fault-free operation under continuous high loads.

Thermal management: Controls temperature rise, extending insulation lifespan and insertion/extraction durability.

Long-term reliability: Maintains performance in harsh environments with frequent insertion, moisture, or corrosion.

Therefore, optimizing conductive design is the first step toward enhancing socket reliability.

2. Conductive Structure Optimization for 32A and 63A Power Sockets

A. Multi-Point Contact Design: Distributing Load and Reducing Resistance

Traditional single-point spring contacts can easily generate local overheating in high-current use. Advanced designs for 32A and 63A sockets adopt multi-point contact systems, such as:

Multi-blade spring contacts: Often 6–12 fingered springs to increase contact points.

360° circumferential contact distribution: Ensures symmetric and vibration-resistant performance.

Wraparound contact blades: Like “dovetail” or “rolled” pins that form multiple ring-like contact areas.

🔧 Case Example: A high-end 63A socket uses an 8-blade spring contact that reduces resistance to below 0.5mΩ. In overload tests, temperature rise remains within 30K—well below IEC 60309 limits.

B. Copper Alloy Cold-Pressed Terminals: Balancing Conductivity and Strength

a. Material Selection

High-conductivity copper (e.g., H65, T2): Ideal for main contact pins.

Copper alloys (e.g., phosphor bronze, beryllium copper, aluminum bronze): Combine good conductivity with high elasticity and strength.

Silver/nickel plating: Enhances contact conductivity and corrosion resistance.

b. Cold Pressing Technology

Compared to welding, cold-pressed terminals offer:

Strong metal bonding with low resistance

Consistent quality with minimal process risk

Minimal thermal stress—suitable for sensitive materials

🔧 Case Example: A manufacturer uses a dual-layer structure (T2 copper + phosphor bronze) in 63A sockets, achieving <1mΩ contact resistance, with no degradation after 1000 insertions.

3. Integrating Conductive Optimization and Thermal Design

A. Thermal Decoupling Between Contacts and Housing

Use high-temperature insulation barriers between terminals and housing

Include ventilation channels to improve heat dissipation

Apply PA66-GF or PBT-GF plastics for structural insulation

B. Balancing Contact Pressure and Plugging Force

Optimize spring stiffness via FEM simulations

Adjust insertion angles for smoother engagement

Control tolerances to prevent arcing from loose fit

4. Terminal Block Design: Efficiency and Long-Term Conductivity

A. Wiring Types and Performance

Screw terminals: Stable but need regular torque checks

Cold-pressed lugs: Suitable for thick industrial wires

Push-in terminals: Quick install with stable contact

B. Design Recommendations

Use dual-clamp structures for wire stability

Apply tin/silver plating to prevent electrochemical corrosion

Align terminal and contact paths to avoid stress bending

5. Conductive Optimization in Harsh Environments

A. Corrosive Environments (Marine, Chemical Plants)

Use silver/nickel-plated copper alloys

Design sealed contact chambers

Apply IP67/IP69K enclosures with silicone sealing

B. High-Frequency Insertion (EV Charging, Port Equipment)

Use high-resilience springs for long-term force retention

Apply anti-wear coatings like gold or PTFE

Integrate arc suppression designs

6. Testing and Validation: The Final Step in Performance Assurance

Modern design also incorporates thermal simulation (FEM), infrared imaging, and arc erosion analysis.

7. Conclusion: Conductive Optimization Is the Foundation of Power Socket Performance

The shift from compliance-based design to performance-based optimization reflects the growing demand for safety, reliability, and efficiency in industrial systems.

By implementing multi-point contacts, cold-pressed copper terminals, advanced materials, and thermal design strategies, today's 32A/63A industrial power sockets are evolving into intelligent, high-performance electrical modules.

For equipment manufacturers and system integrators, choosing a well-engineered socket with optimized conductive design will significantly reduce downtime, enhance energy efficiency, and extend service life.

en.dghongju.com

0 notes

Text

0 notes

Text

#clemart#macthinker#ttcc#toontown corporate clash#im out of captions. what do i even say to this. im really embarrassed with this one#which means absolutely nothing because im embarrassed over EVERY piece but i digress.#wisdom tooth socket ache is no match for the power of macthinker withdrawl no drawing 6 days no nothing#alone in a wet cardboard box with no art .. but im free now#actually the aching isnt that bad sorry guys i lied. after the 1st day i was fine i was just tired#this was supposed to be a warmup but i got carried away#ive also done that grabbing pose like 3 times now i need to get creative

101 notes

·

View notes

Text

Being the only IT major kid means that everyone will ask you questions that could have absolutely NOTHING to do with IT and expecting you to know all the answers

I WONT HAVE THEM STOP ASKING ME THINGS I DONT KNOW ABOUT

#indyyaps#fuck technology#my parents just asked me why the computer wasn't charging#idk mom MAYBE BECAUSE THE POWER FROM THE SOCKET ISN'T WORKING??????#and then they proceed to tell me im wrong 💔#and after that they say the exact same thing i said just a minute ago#LIKE WTF#shit post

7 notes

·

View notes

Text

A black and white photo of a power socket with a protective cover.

#power socket#cover#protective cover#electronics#electricity#power#energy#photography#photo#photos#picture#pictures#image#images#a photo#a picture#an image#photograph#photographs#a photograph#black and white#black and white photo#black and white photos#black and white photograph#black and white photographs#black and white picture#black and white pictures#black and white image#black and white images#blackandwhite

2 notes

·

View notes

Text

i started playing no mans sky after. a good 5 or so years. holy shit i am in love with the new space station cores

#LET ME INTERACT WITH HER GAME. id like to bring her flowers ;w;#this game does bad things to my libido. so many starships... and the freighters too.#maybe this is why they castrated me as a baby. those doctors Knew i couldnt handle the power of having a cock#heresay testifies#or that id stick it in a wall socket#spaceship objectum

8 notes

·

View notes