#precision servomotor

Explore tagged Tumblr posts

Text

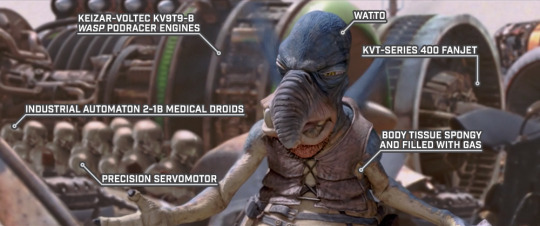

Republic Credits are No Good Out Here

STAR WARS EPISODE I: The Phantom Menace 00:34:01

#Star Wars#Episode I#The Phantom Menace#Tatooine#Xelric Draw#Mos Espa#Watto's Junkshop#Watto's Junkyard#Watto#Keizar-Voltec#KV9T9-B Wasp#podracer engine#Industrial Automaton#2-1B#medical droid#precision servomotor#KVT-series 400 fanjet#Toydarian

0 notes

Text

The starship's hallways trembled under the incessant hammering of railgun shells. Lights flashed and automated alarms wailed repetitive warnings and commands, all of them readily ignored by the panicking crew. Much louder than the bombardment were the gunshots inside, piercing through walls and exploding in flaming blossoms of incendiary shells. They ran through the wide corridors until reaching the breached sector, barreling the path in a brave attempt at slowing the invader's advance.

For minutes, all they could hear was explosions and screaming with occasional plasma detonations. The servomotors of the door shrieked against multiple impacts, holding it together for a moment more. Silence ensued for half a second, only to be cut by massive plume of blue flame shattering everything around it, piercing a hole clean to the hallway.

The soldiers held their fire, shaking, hesitant, their rifles ready to let loose cyan energy beams. Barrels peeked from the covering walls and makeshift barricades, transparent helmets illuminating the dusty hallway as the floodlights went off. A half-screamed order was cut short by a precise red ray, popping off the target's head as a bloody balloon of biomass and fluid.

A barrage of lasers filled the hallway, being answered with a reciprocate burst of gunfire. Explosive shells tore everything they hit to shreds as a soldier clad in black skeletal armor barreled through the stream of turquoise doom. They ignored every single hit and kept firing back, eventually ripping all of their foes' bodies to a blurred pile of steaming liquids and melting metal.

[-----]

"Initial defense force neutralized. Over, echo?"

"Echo. Proceed and feel free to use extensive lethal force. Over."

The human took a few more steps inside the hallway before their squad could join them, halting when they saw an alien still crawling to grab their weapon. A single bullet silenced them. Rather be sure and act like a fool than be a fool and act like you're sure, they justified to themselves, as they marched forward inside the starship.

#my writing#writing#science fiction#dark fiction#creative writing#humans are terrifying#humans are deathworlders#my work#my stuff#tw blood#tw gun#tw death#fuck them aliens

6 notes

·

View notes

Text

The Moog W-2-P8-040-17-17-16 Brushless Servomotor is a high-performance motor designed for precision motion control in industrial automation systems. Known for its powerful torque, high accuracy, and reliable performance, this servo motor is ideal for demanding applications in robotics, CNC machinery, and automated production lines. Its compact and rugged build ensures long-lasting operation even in harsh environments. Easy to integrate and energy-efficient, it helps improve productivity and reduce downtime. Trust Auto2mation for quality industrial automation products like the Moog W-2-P8-040-17-17-16 servomotor — your go-to solution for smooth and controlled motion.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#Moog#brushless servomotor#motor

0 notes

Text

Designing the Future: How Robotics and Engineering Design Are Revolutionizing Our World

Robots have emerged from the pages of science fiction to become an integral part of modern life, from factories and hospitals to our very homes. But behind every successful robot lies exceptional engineering design—a meticulous process that combines mechanics, electronics, software, and human factors into one cohesive system. The synergy of robotics and engineering design isn’t just shaping individual machines; it’s redefining what’s possible in technology, industry, and society. Here’s a deep dive into how these fields intersect, the principles driving innovative robotic design, and where they’re leading us next.

The Heart of Robotics: What Is Engineering Design?

Engineering design is the backbone of robotics. It’s a structured, iterative process that involves defining a problem, brainstorming solutions, prototyping, testing, and refining until the best possible product emerges. In robotics, this means integrating diverse engineering disciplines—mechanical design for movement, electrical engineering for power and sensors, computer engineering for control, and industrial design for human interaction.

The process begins with a clear understanding of what the robot must do. Is it assembling microchips on a factory floor, delivering medications in a hospital, or exploring the ocean depths? Each application demands a unique set of design considerations, from material selection to navigation algorithms.

Bio-Inspired Designs: Learning from Nature

One of the most exciting trends in robotic engineering design is bio-inspiration—emulating the solutions perfected by millions of years of evolution. Nature offers brilliant models of locomotion, sensing, and adaptability.

Consider Boston Dynamics’ Spot robot, whose design is inspired by canine locomotion, enabling it to climb stairs, traverse rough terrain, and recover balance after slips. Or robotic fish designed to mimic the fluid, energy-efficient swimming of real fish, ideal for underwater inspections.

These bio-inspired robots utilize flexible joints, compliant materials, and advanced control systems to navigate complex, unstructured environments, surpassing the capabilities of traditional rigid robots.

Mechanical Design: Creating the Perfect Motion

At the core of every robot lies its mechanical design, which comprises the arrangement of actuators, gears, joints, and frames that determine how it moves and interacts with the world.

Robots designed for precision—like those assembling electronics—feature high-stiffness, low-backlash joints for micron-level accuracy. Those intended for heavy lifting, such as industrial robotic arms in automotive plants, use powerful servomotors and reinforced structures.

New mechanical designs include flexible and soft robotics, which replace rigid metal with silicone and elastic polymers. These robots can bend and stretch, making them ideal for gripping delicate objects, such as fruit, or performing surgery without damaging tissues.

Control Systems: The Brain Behind the Body

While mechanical design provides the body, control systems form the brain of any robot. Engineers design these systems to process data from sensors, plan motions, and execute tasks in real time.

Early robots followed fixed, repetitive motions with minimal adaptability. Modern control systems, however, integrate artificial intelligence, machine learning, and computer vision, allowing robots to recognize objects, adapt to new environments, and even learn from mistakes.

For example, advanced control algorithms let warehouse robots autonomously navigate crowded spaces, avoid obstacles, and reroute when paths are blocked—all essential for today’s fast-paced logistics.

Human-Centered Design: Robots Made for People

Engineering design in robotics must also prioritize how humans will use, control, and coexist with these machines. This is the essence of human-centered design: ensuring robots are intuitive, safe, and effective partners.

Collaborative robots, also known as cobots, embody this principle. Designed with rounded edges, force sensors, and easy-to-program interfaces, they can safely work alongside humans on assembly lines or in laboratories.

Good engineering design also considers visual and auditory feedback—robots that communicate status through lights, sounds, or screens improve usability and trust. These elements are essential for robots deployed in healthcare, hospitality, and customer service, where clear human-robot interaction can significantly impact success.

Modular and Reconfigurable Designs: Building Flexibility

One of the breakthroughs in modern robotic engineering is the modular design, which creates robots built from interchangeable parts. Modular robots can be quickly repaired, upgraded, or adapted for new tasks by swapping components.

In manufacturing, modular robotic arms can change end-effectors—from welding torches to suction cups—within seconds, enabling a single robot to handle a diverse range of tasks. In research and space exploration, modular robots can reconfigure themselves into new shapes, assembling structures or adapting to changing terrain.

This flexibility maximizes investment in robotics, extends the lifespan, and allows industries to pivot more quickly in response to new demands.

Simulation and Digital Twins: Designing Before Building

Engineering design today increasingly relies on simulation and digital twins—virtual models of physical robots that allow engineers to test designs in digital environments before committing to costly prototypes.

Simulation tools enable designers to evaluate kinematics, stress loads, thermal effects, and control algorithms in various scenarios, thereby identifying weaknesses and optimizing performance early in the development process.

Digital twins take it a step further by creating real-time, data-driven virtual copies of deployed robots. They allow engineers to monitor performance, predict failures, and plan maintenance, enhancing reliability and reducing downtime.

Sustainability in Robotic Design: The Green Imperative

As industries and consumers demand more sustainable solutions, engineering design must prioritize energy efficiency and environmentally friendly materials.

Designing lightweight structures reduces power consumption, extending battery life in mobile robots. Engineers are exploring recyclable polymers, biodegradable components, and low-energy actuators to minimize the environmental impact of robotics.

Sustainable design is critical as robotics becomes more pervasive in fields like agriculture, logistics, and consumer goods—areas where millions of robots could one day operate.

The Future of Robotics & Engineering Design: Smarter, Smaller, and More Personal

Looking ahead, the convergence of robotics and engineering design will bring unprecedented possibilities:

Miniaturized robots will navigate inside the human body, delivering therapies or performing microsurgeries.

Swarm robotics will enable fleets of small robots to collaborate in various fields, from agriculture to disaster response.

Intelligent, adaptive design will allow robots to learn, evolve, and customize themselves to individual user needs.

These advances will depend on ever-more sophisticated design tools, integrating real-world testing with AI-driven optimization to create robots that are faster to develop and better suited to their tasks.

Designing a Robotic World

Robotics and engineering design are more intertwined than ever before—each driving the other to new heights. The thoughtful integration of form, function, and human factors is transforming robots into indispensable partners across various industries, including manufacturing, medicine, and even the home and city.

As engineers continue to innovate, they’ll create robots that are not just tools, but collaborators, companions, and catalysts for a safer, more efficient, and more connected world.

0 notes

Text

Genuine Weishaupt Burner Parts for Optimal Efficiency and Long-Term Reliability

Weishaupt burner parts are essential components designed to maintain the high-performance standards of Weishaupt’s world-class burners. Whether you're conducting routine maintenance or addressing a specific issue, using genuine Weishaupt parts ensures your burner system continues to operate safely, efficiently, and in line with original engineering specifications.

Weishaupt offers a comprehensive range of spare parts for their oil, gas, and dual-fuel burners. Commonly replaced components include ignition transformers, electrodes, solenoid valves, control boxes, flame sensors, servomotors, nozzles, and air dampers. Each part is built with precision and tested to meet the strict durability and performance standards Weishaupt is known for.

Genuine Weishaupt burner parts help prevent system failures, reduce downtime, and ensure consistent fuel combustion. These OEM parts are specifically designed to integrate seamlessly with Weishaupt burner models like WL, WN, WM, and WG series, maintaining their energy efficiency and low-emission performance.

By using authentic parts, you also extend the lifespan of your burner and avoid the risks associated with low-quality aftermarket alternatives. For critical industrial operations—whether in heating plants, manufacturing, or processing facilities—reliability is key, and genuine Weishaupt spares provide peace of mind.

To ensure the right fit and expert guidance, always source your Weishaupt burner parts from authorized distributors or certified service providers. With the right parts and regular maintenance, your Weishaupt burner will continue to deliver clean, efficient heat for years to come.

#industrialburnerspares#burnerspareparts#weishauptburnerspareparts#oilburnerparts#gasburnerspares#industrialgasburnerparts#sparepartburner#weishauptburnerspares

0 notes

Text

Latest Technologies in Wire Drawing and Bending Machines: Revolutionizing Precision Manufacturing

The wire processing industry is undergoing a transformative shift, driven by advancements in automation, energy efficiency, and material science. From high-speed CNC wire bending machines to eco-friendly wire drawing systems, manufacturers are leveraging cutting-edge technologies to enhance precision, reduce waste, and meet the demands of industries like automotive, aerospace, and electronics.

Wire Machinery Manufacturers

This blog explores the latest innovations in wire drawing and bending machines, highlighting key trends, emerging technologies, and their impact on modern manufacturing.

1. Automation and Industry 4.0 Integration

Smart Wire Drawing Machines

Modern wire drawing machines now incorporate real-time monitoring, predictive maintenance, and AI-driven optimization to improve efficiency and reduce downtime. Key advancements include:

CNC-controlled drawing units that eliminate manual adjustments, ensuring consistent wire diameter and tensile strength.

Electric servomotors replacing hydraulic systems, reducing fluid leaks and maintenance while improving precision.

Digital twins that simulate production processes, minimizing trial runs and material waste.

AI-Powered Wire Bending Machines

3D wire bending machines now feature:

Multi-axis CNC controls for complex geometries in automotive and aerospace applications.

Automated tool changers that switch bending dies without manual intervention, reducing setup time.

Integrated sensors that monitor wire stress and adjust bending parameters in real time.

Wire Machinery Manufacturers

2. Energy Efficiency and Sustainable Practices

Eco-Friendly Wire Drawing

Regenerative braking systems recover energy during wire drawing, cutting power consumption by 15–20%.

Heat recovery systems repurpose waste heat from drawing processes, improving energy efficiency.

Biodegradable lubricants replace petroleum-based oils, reducing environmental impact.

Sustainable Bending Solutions

Direct-drive motors eliminate gearbox energy losses, improving efficiency in CNC bending machines.

Material optimization algorithms minimize scrap by calculating the most efficient wire usage.

3. Advanced Materials and Coatings

High-Performance Wire Materials

High-strength alloys (e.g., titanium-coated wires) enhance durability for aerospace and medical applications.

Nano-coated wires offer superior corrosion resistance, extending product lifespans.

Wire Machinery Manufacturers

Innovative Bending Techniques

Laser-assisted bending ensures precision in ultra-thin wires for electronics 11.

Additive manufacturing integration allows custom wire forms with minimal material waste.

4. Precision and Flexibility in Wire Bending

3D Wire Bending Machines

Multi-axis CNC systems enable complex shapes (e.g., automotive seat frames, medical implants) with ±0.1mm tolerance.

Automated straightening systems ensure wire uniformity before bending, reducing defects.

Modular Bending Solutions

WAFIOS multi-head machines allow simultaneous bending operations, boosting productivity by 30%

Quick-change tooling systems adapt to different wire diameters and materials in seconds

5. Future Trends: What’s Next?

AI-Driven Predictive Maintenance – Machines will self-diagnose wear and schedule repairs autonomously

Hybrid Wire Processing – Combining additive manufacturing with traditional drawing/bending for custom parts

Fully Autonomous Factories – Siemens’ Xcelerator platform integrates IoT for end-to-end smart production.

Conclusion: Embracing the Next Industrial Revolution

The wire processing industry is at the forefront of smart manufacturing, with innovations in automation, sustainability, and precision redefining production standards. Companies investing in these technologies will gain a competitive edge through higher efficiency, lower costs, and greener operations.

Wire Machinery Manufacturers

For manufacturers, the message is clear: Adopt these advancements now or risk falling behind.

0 notes

Text

Servomotor Drivers

Servomotor drivers are essential components in the world of automation, robotics, and precision control systems. They play a critical role in ensuring that servomotors operate efficiently and accurately. In this post, we’ll explore what a servomotor driver is, how it works, its importance, and the different types available. What is a Servomotor Driver? A servomotor driver is an electronic…

0 notes

Text

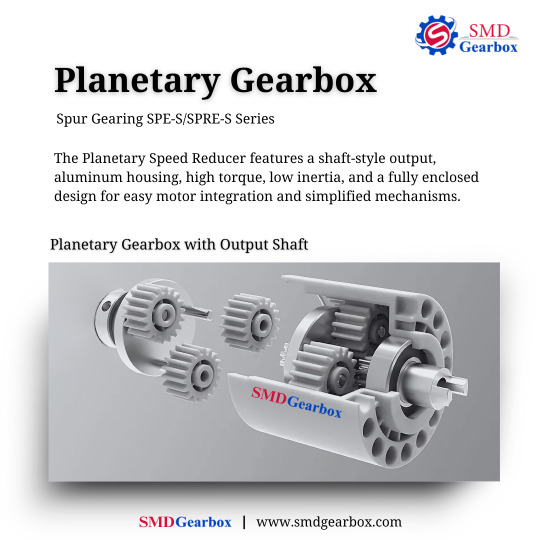

Planetary Speed Reducer: Torque, Precision, and Versatility

The Planetary Speed Reducer offers a torque range of 18Nm to 550Nm, with backlash as low as 10-12 arc-min and reduction ratios from 1:3 to 1:100. Its aluminum shaft-style output and sealed, self-lubricated design ensure high torque capacity, low inertia, and compatibility with various servomotors. Easy to install, it's ideal for rack drives and simplified mechanisms.

#smdgearbox#gearboxmanufacturer#supplier#gearbox#automation#manufacturingindustry#planetaryspeedreducer#planetarygearbox#planetarygearboxes#precisionautomation#precisionengineering

0 notes

Text

Atomic force microscope LAFM-A11

Labtron Atomic Force Microscope features an integrated scan head and sample stage for superior anti-vibration performance. Equipped with a servomotor for CCD auto-focusing, it ensures precise scanning area positioning with manual or automatic sample approach. Its precision laser detection and probe alignment simplify laser beam adjustments, delivering highly accurate results.

0 notes

Text

Servo Drives: Key Technologies for Motion Control

Servo drives are at the heart of modern motion control systems, playing a crucial role in industries where precision, speed, and control are essential. From robotics to CNC machinery, and automated manufacturing systems, servo drives have become key enablers of advanced motion control, enhancing the performance and efficiency of various applications.

So, what exactly are servo drives? In simple terms, a servo drive is a specialized electronic amplifier used to control electric servomotors. It works by receiving commands from a control system, processing the feedback signals, and making adjustments to ensure the motor behaves exactly as intended. This precise control is what makes servo drives indispensable in high-performance systems.

One of the standout advantages of servo drives is their ability to offer highly accurate position, velocity, and torque control. By continuously adjusting the motor’s speed and position, they ensure optimal performance, even in dynamic environments where loads and forces may change rapidly. This makes servo drives ideal for industries such as aerospace, automotive, and robotics, where even the slightest error can be costly.

Additionally, modern servo drives come equipped with advanced features like programmable motion profiles, safety functions, and communication interfaces that allow seamless integration into complex automation systems. As technology evolves, the capabilities of servo drives continue to expand, offering even greater precision and control.

In conclusion, servo drives are a fundamental technology for motion control, enabling machines and systems to achieve high accuracy, speed, and reliability. Their impact spans across multiple industries, making them an essential component in the future of industrial automation and robotics.

0 notes

Text

Power Up Your Peace of Mind: A Guide to Voltage Stabilizers

In today's tech-driven world, our homes rely on a steady flow of electricity to power everything from refrigerators to laptops. But voltage fluctuations – dips or spikes in power – can wreak havoc on our precious electronics. Enter the voltage stabilizer, a silent guardian protecting your appliances from these harmful fluctuations. This blog will shed light on voltage stabilizers, their purpose, and how to choose the right one to keep your devices safe and sound.

Why Do We Need Voltage Stabilizers?

Electricity isn't always a perfect current. Several factors can cause voltage fluctuations:

Overloaded power grids: During peak usage times, the power grid might struggle to meet demand, leading to voltage dips.

Lightning strikes: These can cause sudden voltage spikes that can damage appliances.

Faulty wiring: Internal electrical issues within a building can also lead to voltage fluctuations.

How Do Voltage Stabilizers Work?

Voltage stabilizers act as a buffer between your appliances and the incoming power supply. They work in two main ways, depending on the technology:

Relay-based stabilizers: These quickly switch between multiple taps within the stabilizer to maintain the desired output voltage.

Servo-based stabilizers: These use a servomotor to continuously adjust a transformer, ensuring a smooth and precise output voltage.

The Benefits of Using a Voltage Stabilizer:

Protects Appliances: By regulating voltage, stabilizers prevent damage to your electronics caused by power fluctuations.

Extends Appliance Lifespan: A stable power supply reduces wear and tear on your appliances, potentially extending their lifespan.

Improves Performance: Consistent voltage ensures optimal performance from your electronics.

Peace of Mind: Knowing your devices are protected from voltage fluctuations provides peace of mind.

Choosing the Right Stabilizer for Your Needs:

With various voltage stabilizers available, here are some factors to consider when making your choice:

Appliance Wattage: Choose a stabilizer with a capacity that exceeds the total wattage of the appliances you want to protect.

Type of Stabilizer: Relay-based stabilizers are generally more affordable, while servo-based models offer more precise voltage regulation.

Features: Consider features like overload protection, LED indicators, or automatic shut-off for added safety and convenience.

Brand Reputation: Opt for a reputable brand known for quality and reliable voltage stabilizers.

Investing in Stability for Your Electronics

Voltage stabilizers are a worthy investment for anyone who wants to safeguard their electronic devices from the damaging effects of voltage fluctuations. By understanding their purpose, benefits, and how to choose the right one, you can ensure a stable power supply for your home and enjoy peace of mind knowing your appliances are protected. So, don't let voltage fluctuations disrupt your day – find the perfect voltage stabilizer and power up your peace of mind!

#Stabilizers#Voltage stabilizers#Voltage stabilizers price#stabilizer#ac stabilizer#fridge stabilizer#tv stabilizer

0 notes

Text

Moog w-2-p8-040-17-17-16 brushless servomotor | Auto2mation

The Moog W-2-P8-040-17-17-16 brushless servomotor is a high-performance motor designed for precision control in automation systems. Ideal for demanding applications, it offers smooth and efficient motion with high torque and low maintenance. This servomotor is known for its reliability and durability, making it suitable for a wide range of industries, including robotics, aerospace, and manufacturing. With its advanced brushless design, it reduces wear and tear, ensuring long-lasting performance. Enhance your automation setup with the Moog W-2-P8-040-17-17-16 servomotor, designed to provide superior control and efficiency for complex systems.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#servo motor#industrial servo motor#motor#moog#brushless servomotor

0 notes

Text

The PFM Pearl Horizontal Flow Wrapper: Revolutionizing Packaging for Australian Businesses

In today's competitive Australian market, presentation is key. Consumers are drawn to products that not only look appealing but are also securely packaged. This is where Emrich, a leading supplier of packaging machinery, steps in with the PFM Pearl Horizontal Flow Wrapper – a game-changer for businesses seeking efficient and versatile packaging solutions.

Beyond Aesthetics: Unveiling the Power of the PFM Pearl

The PFM Pearl isn't just about creating visually pleasing pillow-pack styles. It's a powerhouse of functionality designed to streamline your packaging process and elevate your product presentation. Here's what sets this horizontal flow wrapper apart:

Versatility Meets Efficiency: The PFM Pearl utilizes a flat reel of film, allowing you to package a wide range of products, from food items like biscuits and confectionery to non-food items like stationery and pharmaceuticals.

Dual Sealing Power: This innovative machine offers both heat sealing and cold sealing capabilities. This flexibility ensures you can choose the most appropriate sealing method for your specific product, maximizing its shelf life and integrity.

Food-Safe Packaging: The PFM Pearl prioritizes food safety. All parts that come in contact with your products are made from high-quality, food-grade plastic or stainless steel, ensuring your food items remain untouched by harmful contaminants.

Export-Ready Packaging: The PFM Pearl creates robust and secure packages, ideal for protecting your products during transportation, even for export purposes. This allows you to confidently expand your market reach without compromising on product quality.

Designed for Smooth Operation and Efficiency

Emrich understands that efficiency is paramount for businesses. The PFM Pearl is designed with user-friendliness and streamlined operation in mind:

Compact Design: This space-saving machine is perfect for businesses with limited floor space. Its compact footprint allows for optimal utilization of your production area.

Complete Automation: From feeding the film to sealing the package, the PFM Pearl automates the entire flow wrapping process. This minimizes manual intervention, increases production speed, and reduces labor costs.

User-Friendly Controls: The PFM Pearl features a user-friendly color touchscreen interface. This intuitive system allows for easy operation and parameter adjustments, even for new users. Operators can quickly learn to manage machine settings and optimize packaging for different products.

Advanced Technology: The PFM Pearl boasts an axis motion controller and brushless servomotors. This advanced technology translates to smooth, precise operation and minimal downtime, ensuring consistent and reliable performance.

Optimizing Your Packaging Process with Emrich

Emrich goes beyond simply providing machinery. They offer comprehensive support to ensure you get the most out of your PFM Pearl:

Expert Consultation: Their knowledgeable team can assess your specific packaging needs and recommend the ideal PFM Pearl configuration for your products.

Seamless Installation: Emrich's technicians handle the installation process meticulously, ensuring the machine is properly set up and integrated into your existing production line.

Training and Support: They provide comprehensive training for your staff on operating and maintaining the PFM Pearl effectively. Emrich's ongoing support ensures you can continue to utilize the machine to its full potential.

The PFM Pearl: A Boon for Australian Businesses

By investing in the PFM Pearl Horizontal Flow Wrapper, Australian businesses can unlock a multitude of benefits:

Enhanced Product Presentation: Create eye-catching pillow-pack styles that grab customer attention and elevate your brand image.

Increased Efficiency: Streamline your packaging process with automated operations and achieve higher production outputs.

Reduced Costs: Minimize labor costs through automation and potentially reduce material waste with optimal film utilization.

Improved Food Safety: Ensure your food products remain safe and fresh with secure packaging and food-grade materials.

Export Readiness: Confidently expand your market reach with packaging that protects your products during transportation.

Emrich: Your Partner in Packaging Innovation

Emrich's PFM Pearl Horizontal Flow Wrapper is a testament to their commitment to providing Australian businesses with advanced and versatile packaging solutions. With its efficient operation, user-friendliness, and focus on food safety, the PFM Pearl empowers you to present your products in the best light while ensuring their protection. Contact Emrich today and explore how the PFM Pearl can revolutionize your packaging process and elevate your brand in the Australian market.

Contact- Web - https://www.emrich.com.au/pfm-pearl-horizontal-flow-wrapper-machine/ Ph - 1800 801 243 / +61 3 9540 0255 Address - 1/14-18 Venture Court, Dandenong South VIC 3175, Australia.

0 notes

Text

Global Servo Press Brakes Market Size, Trends and Growth opportunity, By Type (Hydraulic Type, Electric Type), By Application (Electrical, Machine Tool, Construction, Automotive, Aerospace, Others), By Regional Outlook, Competitive Market Share & Forecast, 2023 – 2030.

Global Servo Press Brakes Market Size, Trends and Growth opportunity, By Type (Hydraulic Type, Electric Type), By Application (Electrical, Machine Tool, Construction, Automotive, Aerospace, Others), By Regional Outlook, Competitive Market Share & Forecast, 2023 – 2030.

Global Servo Press Brakes Market

The Global Servo Press Brakes Market was valued at USD 710.00 million in 2022 and is expected to reach USD 1,370.00 million by 2030 at a CAGR of 7.83% from 2023-2030. Servo press brakes, also termed as CNC press brakes, supply the pressing force via 2 synchronized servomotors used to power a belt & pulley mechanism. Servo-driven presses are extremely flexible machines due to the ability to precisely control the stroke and speed of the ram with the servomotors. An electric servo press brake is a type of electric press brake which is used in metal fabrication and bending operations. It combines the correctness and power of a hydraulic press brake with the speed and efficiency of an electric servo motor. Servo press brakes are intricate machinery that demand unique skills and knowledge to operate and maintain.

Read More Here: https://analyticalmr.com/reports-details/Global-Servo-Press-Brakes-Market

Market Drivers

A servo press brake is a specific kind of press brake in which the ram is driven down onto the workpiece by a servo motor. Precision, speed, and energy efficiency are all strong points of this kind of press brake. The rotation of a ball screw or belt drive is controlled by a servo motor in servo press brakes. Then, the ram is moved up and down using the ball screw or belt drive. The servo motor is controlled by a computer numerical control (CNC) system, which provides for very accurate control of the ram's location and speed that would fuel the market expansion. Industry 4.0 is a trend towards the automation and digitalization of manufacturing processes. Servo press brakes are well-suited for use in Industry 4.0 environments, as they can be easily integrated with other manufacturing systems. Further, metal bending and shaping procedures must be precise and accurate to meet the needs of manufacturers in all industries. Because of their high levels of accuracy, repeatability, and control, servo press brakes are crucial for sectors like automotive, aerospace, and electronics, which promotes market expansion. Automation is becoming a more common practice among manufacturers. Servo press brakes are simple to integrate into automated production lines, providing better manufacturing flexibility and efficiency that boosts market growth. Servo press brakes frequently include cutting-edge safety features like light curtains, laser guarding, and programmable safety controllers that safeguard operators and reduce workplace accidents, which promotes market expansion.

Market Restraints

Compared to conventional hydraulic or mechanical press brakes, servo press brakes are more expensive. Small and medium-sized firms may find it difficult to enter the market due to this high initial cost. In comparison to conventional press brakes, servo press brakes require more intricate operation and maintenance. Businesses that lack access to skilled labour may find this difficult. Many firms are unaware of the advantages of servo press brakes because they are a relatively new technology. This ignorance may prevent more people from using servo press brakes. Servo press brakes need routine maintenance, just like any piece of industrial machinery, to keep them performing at their best. The productivity of a corporation might be negatively impacted by maintenance expenses and downtime for repairs. In the manufacturing sector, it can be difficult to comply with safety and environmental laws. Companies must invest in making sure that their servo press brakes adhere to all pertinent safety and environmental regulations, which can increase prices and complexity and limit market expansion. Servo press brakes are made from raw materials like steel and aluminium, the prices of which are highly erratic. This may influence servo press brake producers' profitability.

Impact Of COVID-19 On Market

In response to the interruptions in manufacturing processes and the slump in the global economy, the market fell precipitously in 2020. The automotive and aerospace industries, two of the most severely affected by the epidemic, had a particularly sharp fall in demand. The supply networks of the producers of servo press brakes were also affected by the COVID-19 outbreak. This resulted from the travel bans and lockdowns that were enacted in numerous nations. Manufacturers had trouble locating raw materials and components and shipping final goods to clients due to supply chain interruptions. Manufacturers of servo press brakes saw an increase in expenses because of the COVID-19 epidemic. This resulted from rising costs for shipping and logistics as well as raw materials and component prices.

The epidemic hastened tendencies towards remote work and factory automation. Businesses who implemented or strengthened their automation capabilities may have relied more on servo press brakes with sophisticated automation features. Due to a lack of labour and the requirement to put in place social segregation and safety precautions, manufacturing facilities that make servo press brakes and related equipment had to temporarily shut down or restrict their production capacity. Post COVID-19 World Supply & Demand Condition of Global Servo Press Brakes Market The supply and demand situation for the worldwide servo press brakes market after COVID-19 is anticipated to be favourable. It is anticipated that several industries, including the automotive, aerospace, electronics, and construction, will boost their demand for servo press brakes. This is brought on by the expanding need for high-precision metal forming solutions and the manufacturing industry's increased automation. High-precision metal forming capabilities are provided by servo press brakes, which are crucial for several industries, including the automotive, aerospace, and electronics sectors. The post-COVID-19 worldwide servo press brakes market is anticipated to increase because of the rising need for high-precision metal forming solutions. After COVID19 rising markets, including China, India, and Brazil, are growing economically quickly. As a result, manufacturing investment is rising, which is fuelling the demand for servo press brakes. Due to the growing demand for high-precision metal forming solutions and the expanding automation in the manufacturing sector, the market for servo press brakes is anticipated to rise across several industries. As more manufacturers enter the market and raw materials and components become more widely available, the supply of servo press brakes is also anticipated to rise in the post-COVID-19 era.

Impact of Russia-Ukraine Conflict on Global Servo Press Brakes Market

Since the conflict began, the price of steel and other raw materials necessary to make servo press brakes has grown dramatically. This is brought on by a variety of circumstances, including the breakdown of supply networks, rising demand from other nations, and the devaluation of the Russian rubble. Supply chains for servo press brakes and associated parts have been hampered by the conflict. These include the shutdown of enterprises in Russia and Ukraine, the imposition of sanctions on Russia, and the difficulties of moving goods across the area. Due to the crisis, manufacturers are looking for alternatives to Russian and Ukrainian suppliers, which has increased demand for servo press brakes from other nations. This is increasing costs and making it challenging for certain enterprises to get the equipment they require. The world economy is being significantly impacted by the Russia-Ukraine conflict. This can be attributed to several things, such as the disruption of commerce, the increase in energy costs, and the drop in consumer expenditure. Businesses are postponing or cancelling investments in new equipment, which influences the market for servo press brakes. Natural gas and other energy resources frequently pass through Ukraine. Global energy prices may rise if there are any hiccups in the region's energy supply. Higher energy costs may have an impact on the running costs of manufacturers and may affect their choice to buy servo press brakes and other machinery.

Market Segmentation

The Global Servo Press Brakes Market is segmented into type and application. According to type, the Hydraulic Type segment accounted for the largest revenue share in 2022 and is predicted to maintain its position over the forecast period with a CAGR of 7.77%, as Hydraulic servo press brakes can produce extremely strong forces, which makes them perfect for a variety of tasks, including shaping thick sheets of metal.

Regional Analysis

The Global Servo Press Brakes Market is segmented into five regions such as North America, Latin America, Europe, Asia Pacific, and Middle East & Africa. Based on region, Asia-Pacific accounted for the largest share in 2022 and is anticipated to have the highest CAGR by 2030 due to the region's rapid economic growth, which is driving demand for manufactured products. The production of servo, which are essential tools in the manufacturing process, produces a wide range of products, including automobiles, electronics, and appliances. The Asia-Pacific area is likewise undergoing a considerable industrialization. As a result, there are more factories and manufacturing facilities in the region. As a result, servo press brakes are becoming more and more in demand in these plants.

Key Players

Various key players are discussed into the Global Servo Press Brakes Market Report including: Trumpf, Amada, LVD Group, Durma, ALIKO, Artizono, Prima Power, Ursviken, Jiangsu Yawei Machine Tool Co., Ltd., Prada Nargesa S.L., Jean Perrot, Cincinnati Inc, and Others.

Market Taxonomy

By Type • Hydraulic Type • Electric Type By Application • Electrical • Machine Tool • Construction • Automotive • Aerospace • Others By Region • North America o U.S. o Canada o Mexico • Latin America o Brazil o Argentina o Colombia o Peru o Chile o Venezuela o Rest of Latin America • Europe o Germany o France o UK o Russia o Italy o Spain o Rest of Europe • Asia Pacific o China o Japan o India o South Korea o Australia o New Zealand o Singapore o Malaysia o Rest of Asia Pacific • Middle East & Africa o Saudi Arabia o UAE o Egypt o Kuwait o South Africa o Rest Middle East & Africa

"

1 note

·

View note

Text

Atomic Force Microscope

Atomic Force Microscope features a scan head and sample stage for robust anti-vibration performance, servomotor for precise scanning, and precision laser detection and probe alignment device. Shop online at Labtron.us

0 notes

Text

Makishinko produces Worm Speed Reducers, Geared Motors, Screw Jacks, Bevel Gear Box, and other customized speed reducers. Precision Planetary Speed Reducers are often designed for seamless integration with servomotors, providing a complete motion control solution. These reducers are engineered to provide high efficiency in transmitting power from the input to the output. It also provides motion control solutions for robotic arms, joints, and automated systems.

Visit: https://www.seimitsu.in/Makishinko-Precise-Planetary-Gear-SA-series.html

#makishinko#bevelgearbox#gearedmotor#precisionplanetaryspeedreducer#screwjacks#wormspeedreducers#AutomatedSystem#seimitsu

0 notes