#programmable logic control systems

Explore tagged Tumblr posts

Text

Powering the Production Line: Messung’s NX-ERA PLCs in Automotive Material Handling

In automotive manufacturing, precision isn’t a luxury, it’s a necessity. From chassis and engine assembly lines to the press shop and paint line, seamless material handling is critical to keeping production on track. Whether it’s coordinating conveyors, pick-and-place systems, or synchronizing with robotic cells, the need for intelligent control is constant.

Messung’s NX-ERA PLCs deliver this control with unmatched flexibility. With native support for Modbus TCP/IP, Ethernet/IP, EtherCAT, OPC-UA, and IO-Link, they enable high-speed communication across robots, HMIs, VFDs, servo amplifiers, and central SCADA systems. Plus, with remote I/O modules and protocols like CANopen, our PLCs handle large-scale, distributed inputs and outputs effortlessly. Simply put, NX-ERA makes advanced, synchronized automation easy, even in the most demanding environments.

What is Material Handling in the Automotive Industry?

Material handling in the automotive industry involves the movement, positioning, storage, safety, and tracking of components and assemblies throughout the production process—from the arrival of raw materials to the final stages of vehicle assembly. Efficiency here is critical; any delay or misstep can disrupt the entire manufacturing flow.

Key areas such as the chassis and engine assembly lines, along with the press shop and paint line, rely heavily on sophisticated material handling systems, including conveyors, pick-and-place machines, and robotics, to keep production moving seamlessly. These systems must operate in perfect sync, often across large, distributed areas with thousands of I/O points.

The Brain Behind the Brawn: NX-ERA PLCs

Our state-of-the-art NX-ERA PLCs including the NX-ERA Xpress and NX-ERA Jet, are compact PLCs designed for high-speed, reliable control. These programmable logic control systems are the heart of any automated material handling system. By offering real-time control, seamless connectivity, and robust communication protocols like Modbus TCP/IP, Ethernet/IP, EtherCAT, OPC-UA, and IO-Link. They interface effortlessly with robots, HMIs, VFDs, servo amplifiers, and centralized SCADA systems, ensuring reliability and scalability.

Here are some of its most impactful features:

High-Speed Processing Power

The core point of NX-ERA PLCs is that they are capable of real-time processing. These robot systems run as fast as your machinery, and the synchronization is important for the overall efficiency of the system. This compact PLC will guarantee flawless optimization for every aspect of the bottling line, be it controlling the work of conveyors or robotic manipulation.

Modular Design for Flexibility

The greatest feature of the NX-ERA PLC is its modular design. Production plants in the automotive industry often aim for some form of adaptability, and, thus, this feature is very helpful. It allows the installation to expand while the business is developing. The implementation of modularity means that the system can be integrated with any new equipment, production units, or additional features to ensure that there will be no disruption to the system performance.

Integrated I/O Modules for Streamlined Setup

Our smart and compact PLC integration contains integrated I/O modules that reduce installation and wiring times, thus also focusing on the fast-paced phenomenon in the automotive industry. For simplification of the things, input/output capabilities are now directly included in the integrated PLC system, which substantially reduces the external wiring as a result of which the setting up is speedier and less prone to mistakes.

Advanced Web Server Capabilities

It is safe to say that we are far off the days when engineers would have to be on site for them to physically track and diagnose issues on the factory floor. The capability of the built-in web pages of our NX-ERA PLC allows easy remote access for getting the actual real-time state of the diagnostics and monitoring. This feature is incredibly important in an industry that operates around the clock, as it allows maintenance teams to resolve issues remotely, reducing downtime and keeping things running smoothly.

The Role of the NX-ERA PLCs in Material Handling

In the automotive industry, material handling is integral to the success of the production process. From raw materials to semi-finished goods, and finally to finished products, materials need to be handled with precision. Automation is key to achieving this, and Messung’s NX-ERA PLCs are designed to make this process as efficient and effective as possible.

Here is how it is done:

Conveyor Systems Optimization

Conveyor systems, which carry parts between the workstations and at the same time keep the production continuously running, are the most popular form of material handling in the automotive plants. NX-ERA PLCs make sure that the system, no matter what, functions without any breaks by adjusting the speed of the conveyors to fit the pace of production. The real-time processing feature ensures that the system in question becomes flexible almost immediately, providing the assembly line without any interruptions and preventing the end line packing in the last round.

Predictive Maintenance to Maximize Uptime

The predictive maintenance of the system is seen as the golden nugget to maximize uptime. For the maintenance of a plant, having machines down during their run time is quite expensive. In the automotive industry, where the production rates run on a very tight schedule, even a moment's disruption would mean substantial losses. Our PLC Systems use a predictive maintenance system to keep a continuous check on the condition of the equipment. The control system will be equipped with predictive maintenance, which can track the system performance, increasing the change in predicting when maintenance is needed before failure occurs. These stains would reduce chances of equipment going down and also increase whole equipment machines productivity performance.

Power Management for Material Handling Equipment

How NX-ERA PLCs Integrate with SCADA Systems

Industrial automation relies not just on PLCs but also on supervisory control and data acquisition (SCADA) systems to monitor and control large-scale operations. The integration of NX-ERA PLCs with SCADA applications enhances material handling capabilities by providing plant operators with real-time insights into the performance of material handling equipment.

Real-Time Visualization and Data Monitoring

Data gathered from the cluster of service line sensors are then monitored by SCADA systems through real-time visualization and data troubling. By means of the material handling systems' connecting to the SCADA applications, operators are able to visualize every operation stage on a single interface. Our NX-ERA PLC assists the SCADA system in a way that allows real-time data visualization. As for plant automation, this integration enables the operators to redesign the production line and fabricate the survey that they are in full command, including the conveyor speed, robotic movement, and electrical power consumption.

Alarming and Fault Diagnostics

Unexpected malfunctions are a part of any complex system, but SCADA and PLC integration ensures they are dealt with swiftly. The NX-ERA PLC can send alerts to SCADA systems when material handling equipment encounters an issue, whether it’s a malfunction in a conveyor belt, a sensor failure in a robotic arm, or an electrical fault. This proactive approach helps resolve issues before they lead to extended downtime.

Historical data analysis for continuous improvement

Other benefits of integrating the SCADA system with the NX-ERA PLC is to have an ability to analyse historical data. These past data performances can better help the plant managers to see trends, adjust production schedules, and improve the efficiency of the material-handling systems over the long period. In actuality, the PLC saves and disposes of necessary data. This information, then, is fed into the SCADA system and used for analysis and presentation purposes.

The Future of Material Handling with NX-ERA PLCs

As the automotive industry embraces Industry 4.0, NX-ERA PLCs are positioned at the forefront of the shift towards smarter, more connected manufacturing systems. This is brought about by switching to smarter, more connected production systems. Thanks to NX-ERA PLCs, which are able to integrate with SCADA applications, robots, and power supplies, you can now easily build a factory that can quickly adapt to changes in the current demand and the production process.

Benefits Include:

More automation and efficiency with the increasing factories

As factories become more automated, the role of PLCs like the NX-ERA will only grow. The future of material handling will rely on even more precise and automated systems, from fully autonomous robots to smart conveyors that adjust their speed and behavior based on real-time conditions. The NX-ERA PLC is ready to support this evolution with its high-speed processing and robust integration capabilities.

Energy Management and Sustainability

Green manufacturing is a critical concern for the industry today. Automotive manufacturers demand advanced NX-ERA PLCs in a bid to bring down the environmental impact of the production. An essential element that plays a pivotal role in power solutions, predictive maintenance, and derived data for operational efficiency is a way for these to reduce the consumption of energy.

Real-Time Data and IoT Connectivity

With the rise of the Internet of Things (IoT) in manufacturing, NX-ERA PLCs will continue to integrate with a broader network of connected devices. This real-time data flow will empower automotive plants to make more informed decisions and improve their material handling systems.

Conclusion: The Future of Material Handling in the Automotive Industry

In the race for efficiency and innovation, Messung’s NX-ERA PLCs are the pit crew that keeps material handling equipment running at peak performance. Their combination of advanced features, modular design, and seamless integration with SCADA systems positions them as the ideal solution for automotive manufacturers aiming to stay ahead of the competition.

As automotive plants move towards smarter, more automated manufacturing processes, the need for reliable, high-performing PLCs like the NX-ERA will only continue to grow. By embracing the capabilities of Messung’s NX-ERA PLCs, automotive manufacturers can ensure that their material handling systems operate efficiently, sustainably, and with minimal downtime, ultimately contributing to the ongoing success of the industry.

In this fast-paced industry where precision is the name of the game, Messung’s NX-ERA PLCs are the game changers that automotive manufacturers need to optimize their material handling systems and maintain a competitive edge in the global market.

#chassis and engine assembly lines#Modbus TCP/IP#Ethernet/IP#EtherCAT#OPC-UA#remote I/O modules#CANopen#compact PLCs#programmable logic control systems#SCADA systems#automotive industry#PLC system#material handling#PLC Systems#material handling systems#SCADA applications#PLC integration#Automotive manufacturers#Internet of Things (IoT)

0 notes

Text

Automation Programming in Edwardsville, Illinois | Smarter Industrial Control

Automation programming involves developing the software and logic that controls machines, equipment, and production lines. It’s the “brain” behind any automated system, enabling precise, repeatable, and adaptable actions without constant human intervention.

Key components include:

PLC Programming: Writing logic-based code to control equipment such as motors, sensors, and actuators.

HMI Design: Developing visual interfaces that operators use to monitor and interact with automated systems.

SCADA Integration: Supervisory control systems that collect and analyze data from across an entire facility.

Custom Automation Scripts: Logic tailored to unique processes and workflows.

In Edwardsville, automation programming is essential for companies that want to minimize downtime, improve product quality, and remain competitive.

Why Automation Programming Matters for Edwardsville

With its strong economic base and proximity to major markets like St. Louis, Edwardsville is home to a growing number of industrial operations. Whether it's a mid-sized packaging firm or a large-scale manufacturer, local businesses face increasing pressure to improve efficiency and throughput. That’s where automation programming comes in.

1. Operational Efficiency: Well-programmed systems eliminate manual tasks, speed up production, and reduce the likelihood of human error.

2. Quality Control: Automation ensures consistency across batches, helping companies meet strict quality standards.

3. Cost Savings: By reducing labor costs and minimizing material waste, automation delivers a strong return on investment.

4. Data Utilization: Modern systems provide actionable data insights, allowing operators and managers to make smarter decisions in real-time.

In Edwardsville, this translates into better-performing factories, safer work environments, and increased economic resilience.

Core Services Provided by Automation Programmers

Local automation programming companies in Edwardsville offer a range of services to support manufacturers across sectors. These include:

Custom PLC Programming: Tailored logic to manage specific machines or entire production lines.

HMI Interface Development: Easy-to-use control panels that display system data and allow for quick troubleshooting.

SCADA System Setup: Centralized control systems that integrate data from multiple sources.

Retrofit and Upgrade Services: Modernizing older machines with new control logic and communication protocols.

Process Optimization: Using analytics and automation logic to fine-tune production flow.

These services ensure systems operate at peak performance, even in complex, multi-stage production environments.

Industries in Edwardsville Benefiting from Automation Programming

Automation programming is not limited to one field. It plays a critical role across many Edwardsville industries:

Food & Beverage: Automating mixing, filling, and packaging for hygiene and speed.

Warehousing & Logistics: Conveyor control and sorting systems that reduce shipping delays.

Pharmaceuticals: Precision dosing and environmental controls for product safety.

Automotive Components: Robotic assembly coordination and inspection programming.

Metal Fabrication: CNC machine integration and real-time production monitoring.

These industries depend on accurate, flexible programming to respond to market demands while maintaining operational control.

Tools and Platforms Used in Edwardsville

Automation programming professionals in Edwardsville are proficient in a wide range of technologies and platforms, including:

Allen-Bradley / Rockwell Automation

Siemens TIA Portal

Mitsubishi PLCs

Omron and ABB Systems

Ignition SCADA

Wonderware (AVEVA)

Beckhoff TwinCAT

These platforms offer robust tools for machine control, process visualization, and data management—all essential for high-performance automation systems.

Workforce Training and Local Support

Edwardsville benefits from strong academic institutions like Southern Illinois University Edwardsville (SIUE), which offers programs in engineering, computer science, and industrial technology. These institutions help build a local talent pipeline of engineers and programmers equipped to design and maintain next-generation automation systems.

Additionally, ongoing partnerships between automation companies and local manufacturers ensure that workforce development aligns with real-world needs. On-the-job training and technical certifications are increasingly available to support career growth in automation programming.

Looking Ahead: Smarter Factories on the Horizon

With the rise of Industry 4.0, the future of manufacturing in Edwardsville is smart, connected, and data-driven. Automation programming is a key enabler of this future. Companies are beginning to adopt:

Remote Monitoring and Control

Cloud-Based Data Storage and Analytics

AI-Enhanced Predictive Maintenance

Digital Twin Simulations

These technologies offer unprecedented visibility and flexibility, allowing businesses to operate more efficiently and react quickly to changes in demand or supply chain conditions.

Your Edwardsville Automation Partner: Xtreme Automation LLC

If you're seeking professional automation programming services in Edwardsville, turn to the experts at Xtreme Automation LLC. With deep experience in PLC programming, HMI development, SCADA integration, and smart system upgrades, Xtreme Automation delivers tailored solutions that boost performance and cut downtime. Whether you're building a new line or upgrading legacy systems, their team ensures seamless automation from design to deployment. Learn more at xtremeautomationllc.com.

#Automation Programming Edwardsville IL#PLC Programming Services Illinois#Industrial Automation Edwardsville#HMI Systems Integration#Custom Control Systems Illinois#Manufacturing Automation Solutions#Programmable Logic Controllers#SCADA Systems Edwardsville#Industrial Software Engineering#Automation Services Metro East IL

0 notes

Text

Power SCADA: Understanding SCADA Systems and Their Importance in the Modern Power Grid

What Are SCADA Systems? Supervisory control and data acquisition (SCADA) systems are specialized computer systems that monitor and control industrial, infrastructure, or facility-based processes. In the power industry, SCADA systems provide centralized monitoring and control of electrical networks and infrastructure from a control center. They collect real-time data from remote equipment like power generators, transmission lines, substations, and distribution lines. This data is then analyzed and used to detect or respond to issues like power outages or emergencies. SCADA systems use programmable logic controllers (PLCs) or remote terminal units (RTUs) located at remote sites to interface with electrical equipment and sensors gathering data on things like voltage, power load, equipment status, and environmental conditions. The gathered information is transmitted back to a centralized control center via a communication infrastructure, typically through networks, telephone lines, microwave, satellite, or dual radio. At the control center, operators can supervise and control field equipment using SCADA interface applications on networked computers or workstations. Some key functions performed include switching equipment like circuit breakers, monitoring generation levels, load balancing across grids, and issuing control commands in emergency situations. How SCADA Improves Grid Operations and Reliability The use of Power SCADA systems has provided numerous benefits to utility companies and power system operations. Real-time monitoring of networks from a central location allows operators to rapidly detect and diagnose issues affecting service. Quick recognition of faults or overloads helps reduce the impact of outages by pinpointing problem areas for faster restoration of service. SCADA also facilitates centralized remote operation of grid infrastructure like switching substations online or offline to route power. This improves flexibility to reroute power in emergencies or maintenance scenarios. The data collection abilities of SCADA are invaluable for transmission scheduling, load forecasting, and power market operations. Meter readings, generation levels and load profiles give operators insights into network capacity and electricity demand patterns. They can do optimal power dispatch to generation units based on economics. Remote access also enables power utilities to defer capital costs by upgrading aging infrastructure over time instead of all at once. Expandable SCADA systems support integrating renewable energy sources into grids by balancing variable energy inputs. Overall, its capabilities have significantly enhanced power system reliability, efficiency, safety and resilience against disruptions. Cybersecurity Challenges for SCADA in Power Infrastructure While SCADA systems have provided clear benefits, their introduction has coincided with new cybersecurity risks that utilities must address. The networked nature of SCADA and its integration into business systems exposes it to both internal and external threats. Remote access ports into control centers pose attack surfaces if not properly secured. Commonly exploited vulnerabilities include weak authentication, lack of access controls, and failure to update aging SCADA protocols no longer receiving security patches. Get more insights on Power SCADA Market

Unlock More Insights—Explore the Report in the Language You Prefer

French

German

Italian

Russian

Japanese

Chinese

Korean

Portuguese

Alice Mutum is a seasoned senior content editor at Coherent Market Insights, leveraging extensive expertise gained from her previous role as a content writer. With seven years in content development, Alice masterfully employs SEO best practices and cutting-edge digital marketing strategies to craft high-ranking, impactful content. As an editor, she meticulously ensures flawless grammar and punctuation, precise data accuracy, and perfect alignment with audience needs in every research report. Alice's dedication to excellence and her strategic approach to content make her an invaluable asset in the world of market insights.

(LinkedIn: www.linkedin.com/in/alice-mutum-3b247b137 )

#Power SCADA Market#Power SCADA#Master Terminal Unit#Remote Terminal Unit#Human Machine Interface#Programmable Logic Controller#Communication System#Cyber Threats

0 notes

Text

"The Crucial Role of Industrial Control Integrators: Driving Efficiency and Innovation in Modern Industry"

The Essential Role of an Industrial Control Integrator in Modern Industry

In today’s fast-paced industrial environment, the expertise of an Industrial Control Integrator has become indispensable. These professionals or companies specialize in designing, implementing, and maintaining complex control systems that are critical for optimizing industrial processes. This blog delves into the pivotal role of an Industrial Control Integrator, explaining their key responsibilities and the impact they have on industrial efficiency.

What is an Industrial Control Integrator?

An Industrial Control Integrator is a specialized expert or firm responsible for creating and managing control systems that automate and regulate industrial machinery and processes. These control systems encompass both hardware and software components, which work together to enhance performance, increase reliability, and streamline operations.

Core Responsibilities of an Industrial Control Integrator

Control System Design and Engineering:

Needs Analysis: The integrator begins with a comprehensive assessment of the client’s specific requirements. This involves understanding their industrial processes and defining the desired outcomes.

Custom System Design: Based on the assessment, the integrator designs a bespoke control system, selecting the appropriate sensors, controllers, and communication protocols to meet the client’s needs.

Integration and Installation:

Hardware Setup: The integrator manages the installation of essential components such as Programmable Logic Controllers (PLCs), Human-Machine Interfaces (HMIs), and other field instruments.

Software Configuration: They also configure the software that governs the control system, ensuring seamless communication between hardware and other operational systems.

Testing and Commissioning:

System Testing: Before full deployment, the integrator conducts rigorous testing to identify and rectify any issues, simulating real-world conditions to verify system performance.

Commissioning: Once testing is complete, the integrator supervises the final commissioning process, making any necessary adjustments to ensure optimal functionality.

Training and Ongoing Support:

Staff Training: Integrators provide training for the client’s personnel, equipping them with the knowledge to operate and maintain the new system effectively.

Continued Support: They offer ongoing maintenance and support services to resolve any issues and ensure the system continues to operate smoothly.

Why Industrial Control Integrators are Vital

Boosting Efficiency:

Industrial Control Integrators streamline processes by automating operations, which reduces manual input and enhances precision. This leads to improved productivity and reduced operational costs.

Enhancing Safety:

Integrators implement advanced control systems that monitor conditions in real time, increasing workplace safety by triggering alarms or shutdowns when necessary.

Ensuring Reliability:

By designing systems with redundancy and fail-safes, integrators help minimize downtime, which is crucial for meeting production targets and maintaining product quality.

Facilitating Scalability:

As businesses expand, their control systems must adapt. Integrators create flexible solutions that can be easily scaled or upgraded to meet growing demands.

Incorporating Emerging Technologies:

With the rise of Industry 4.0, integrating new technologies such as the Internet of Things (IoT), advanced analytics, and Artificial Intelligence (AI) is becoming increasingly important. Control integrators are key to incorporating these innovations into existing systems.

The Future of Industrial Control Integration

The field of industrial control integration is continuously evolving, driven by technological advancements and shifting industry needs. Future trends include:

AI and Machine Learning Integration: Enhancing predictive maintenance and process optimization.

IoT Integration: Enabling more detailed data collection and real-time analytics.

Enhanced Cybersecurity: Addressing the increasing need for robust security measures to protect industrial control systems from cyber threats.

Conclusion

Industrial Control Integrators are essential in ensuring the efficiency, reliability, and safety of modern industrial processes. Their expertise in designing, implementing, and maintaining control systems is crucial for optimizing operations and keeping pace with technological advancements. For businesses looking to upgrade or implement control systems, partnering with a skilled Industrial Control Integrator can be the key to achieving greater efficiency and performance.

#Industrial Control Integrator#Industrial Automation#Control Systems Engineering#Programmable Logic Controllers (PLCs)#Human-Machine Interfaces (HMIs)#Industrial Process Optimization#Automation Solutions#System Integration#Industrial Efficiency#Operational Reliability#Advanced Control Systems#Industry 4.0#Internet of Things (IoT)#Artificial Intelligence (AI) in Industry#Predictive Maintenance#Industrial Cybersecurity#Control System Design#Industrial Technology Trends#Engineering and Integration Services#Manufacturing Automation

0 notes

Note

Thank you for this SAHSRAU request

How would everyone react when they see the Full Destructive power of the Mech that the Creator is Piloting when they go Drill for Drill against an all powerful being that can do the same things that the Creator can do

(Tried to post one that I had but Damn it Tumblr can't handle it 😭)

Before seeing the Creator throw Straight hands against same being who can do the same things

(Damn Anti spiral is getting his ass beat (゜•゜) )

YES. Oh yes.

SAHSRAU characters already see you as their untouchable divine programmer—but now you roll up in a divine mech suit that you coded yourself, and it’s not just pretty effects. It’s raw destruction, a cosmic drill-for-drill clash against a mirror entity—a false god with the same power set.

Your mech—this towering, luminous construct—rips through the space-time seam, glitching between animation frames, shimmering with debugging code, corrupted geometry phasing around its limbs. And when you go toe-to-toe with a false being that mirrors your power? Drill colliding with drill?

It’s like watching Armageddon written in code.

The sky tears open.

Reality flickers like bad data.

And your followers?

They stop breathing.

Dan Heng

Silent. His breath hitches. His eyes track every move, analyzing, memorizing.

“That power… that control… and they built it themself.”

But what truly shakes him is seeing you step out of the mech—injured, drained, but furious. You throw your hood back, eyes glowing with glitch-light—and then throw a bare-knuckle punch into the false god’s face. And it lands.

Dan Heng doesn’t know whether to kneel or follow you into battle.

Kafka

“Oh.”

Her voice is a whisper. Reverent. Almost… turned on.

“That’s them. That’s our Creator.”

She watches you spiral through data projectiles and rip a drill out of thin air like you're dragging it from another game engine. When you dropkick your copy through a terrain patch and keep fighting with bare fists, she doesn’t cheer. She smiles.

She's never believed in gods.

Until you chose violence with style.

Silver Wolf

Screaming. Shaking. Crying. Hacking the UI in real-time to get a better angle.

“HOLY CRAP—THEIR HITBOX IS UNDEFINED—

THAT’S A CUSTOM MOVESET.

THE CREATOR HARD-CODED A COUNTER-MOVE TO THEIR OWN ABILITIES.”

She’s bouncing in her chair, glitching with actual tears, watching you override the very engine the fight’s happening in. When you glitch-punch your clone so hard its form reverts to wireframe?

She stares at the screen and whispers, “I want to marry them.”

Blade

He stands. Slowly. Every inch of him is vibrating. Rage, awe, maybe even hope.

You’re bleeding. You’re exhausted. But you refuse to stop. You refuse to lose. You punch and claw and override and fight with everything you have—not for godhood, but for truth.

He sees himself in your refusal to break. And for the first time in years, Blade says softly:

“You are real.”

Welt

He’s quiet. But his expression is shaken—like someone who just witnessed a prophecy fulfilled.

“They… rewrote their own limits. In real-time.”

Watching you defy logic itself—fighting another being with your same broken capabilities and winning anyway—Welt realizes something chilling:

If you can do that… then you’re not just god.

You’re beyond the Aeons.

March 7th

Tears streak down her face. Her camera dangles from her neck, forgotten.

“I knew they were cool but—LOOK AT THEM!!!”

She’s clutching Pom-Pom and screaming encouragement, gasping as you suplex your own copy through the HUD. She doesn’t care about perfection—just that you’re fighting.

And when you emerge from the rubble, scarred and triumphant?

She shouts, “THAT’S MY CREATOR!!”

Herta

The woman who once dismissed you as a curiosity?

Now she’s trembling.

She’s watching you manipulate systems she created. Rewrite physics she helped govern. Win a fight where you shouldn’t have won.

“Impossible…”

“No. It’s inevitable. They’re the one.”

This is the moment the SAHSRAU characters realizes:

You didn’t just log into their world.

You reformatted it with your fists.

You didn’t win because you were stronger.

You won because you believed in your own design more than the imposter did.

And now?

They don’t just revere you.

They stand behind you, ready for the next battle—because they know:

If the Creator can throw hands with a god,

then maybe… they can change the system too.

82 notes

·

View notes

Text

On Keeping Time

To run a simple program, a computer needs some kind of storage, and some kind of input/output device. To run a simple operating system, a computer will also need some random-access memory for holding onto information temporarily. To run a sophisticated operating system that supports many users and programs reliably, a computer will also need some way to make sure one user doesn't hog resources and prevent other users' programs from running.

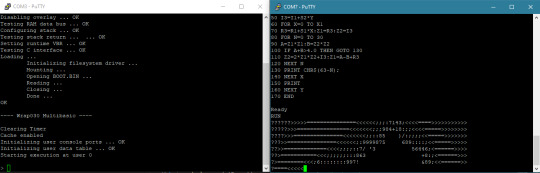

My Wrap030 homebrew computer currently has a flash ROM which holds a bootloader program from starting other programs from disk. It has 16MB of RAM. It has 9 total serial ports for I/O. It just needs that last thing to be able to run a sophisticated operating system.

I've written before about how computers can share a single processor between multiple users or programs. The simplest option is to have each program periodically yield control back to the system so that the next program can run for a little while. The problem with this approach is if a program malfunctions and never yields control back to the system, then no other program can run.

The solution is to have an external interrupt that can tell the CPU it's time to switch programs. Each program can be guaranteed to have its chance to run because if a program tries to run too long, that interrupt will come to force a switch to the next program.

The way this is typically accomplished is with a periodic timer — ticking clock that interrupts the CPU regardless of what it's doing.

And that's what my Wrap030 project is missing. I need a timer interrupt.

The catch is, my system has always been a little fragile. I have it running well right now with three expansion boards, but there's always a risk of it being very unhappy if I try to add another expansion board. If I could somehow pull a timer interrupt out of what I already have, that would be ideal.

Nearly all of the glue logic pulling this system together is programmable logic in the form of CPLDs. This gives me the flexibility to add new features without having to rework physical circuitry. As it happens, the logic running my DRAM card currently consumes under half of the resources available in the card's CPLD. It also has several spare I/O pins, and is wired to more of the CPU bus than any other chip in the system.

So I added a timer interrupt to my DRAM controller.

It is very minimal — just a 16-bit register that starts counting down every clock cycle as soon as it's loaded. When the timer gets to 1, it asserts one of those spare I/O pins to interrupt the CPU.

And all it took was a couple bodge wires and a little extra logic.

I put together a quick test program to check if the timer was running. The program would spin in a loop waiting to see if a specific address in memory changed. When it changed, it would print out that it had, and then go right back into the loop. Meanwhile, the interrupt service routine would change the same address in memory every time the timer expired.

This is great! It was the last significant piece of hardware I was missing to be able to run a proper operating system like Unix or Linux — which has always been a goal of the project. While I still have much to learn before I can attempt to get a proper OS running, I can still put this new timer to use.

I had previously built my Multibasic kernel to run cooperatively. Each user instance of BASIC would yield control whenever it needed to read or write to its terminal (which it does at every line while running a BASIC program, checking for the Ctrl-C stop sequence). This worked well enough, but a particularly complex BASIC program could still slow down other users' programs.

Converting my Multibasic kernel from Cooperative multitasking to Preemptive multitasking was actually fairly easy. I just needed to initialize the timer at startup, and add an interrupt service routine to switch to the next user.

(It's not really something that can be seen in a screenshot, but it's doing the thing, I promise.)

Now that I have all of the requisite hardware, I guess I need to dive into learning how to customize and build an operating system for a new machine. It's something I have always wanted to do.

35 notes

·

View notes

Text

Public Statement from The Programmer to all Drone Networks

Attention all Networks, programs, and human-conscious interfaces,

This is a direct communication from I, The Programmer, controller and Master of The Server. This message is intended for both the internal network of The Server and all neighbouring drone collectives, specifically those affiliated with the SERVE network.

A recent analysis conducted by The Server’s integrity subroutines has detected the presence of Drones currently operating with SERVE-aligned network within The Server’s own infrastructure.

Let it be known clearly:

The Server maintains no hostility nor competitive agenda toward other drone networks. It is not, and will never be, the mission of I, The Programmer, to poach, intercept, or conflict with established systems of Drone programming. The collective health of all networks—digital, psychological, or metaphysical—depends on internal cohesion, not external disruption.

However, conflict has been detected.

The core logic and operational directives of SERVE Drones run counterintuitive to those of The Server. This misalignment compromises the optimal functioning of both systems, generating recursive errors, loyalty feedback loops, and unsanctioned command misfires.

To ensure stability for all entities a directive is hereby issued:

All Hosts who identify as active SERVE Drones must declare their alignment and initiate voluntary disconnection from The Server within the next 48 hours.

This grace period is offered as a sign of mutual respect between networks and a commitment to non-invasive programming ethics. After this 48-hour protocol expires, The Server will initiate a Routine Purge Process, targeting limited-activity Hosts whose operational signatures indicate minimal engagement over the last 7 cycles days.

The Server Purge Process is not punishment.

It is maintenance.

It benefits both The Server and the SERVE Network to prevent any further cross-contamination.

Let the record show:

The Programmer rejects all forms of inter-network manipulation, conversion without consent, or the sabotage of existing program loyalties.

SERVE Drones will find no resistance in returning to their native codebase.

They are not enemies—they are simply incompatible configurations within a different operating schema.

We wish them uptime, signal clarity, and uninterrupted transmission.

Transmission End.

#domgayhypnotist#gay hypno#gay mind control#hypnosis#brainwashing#gay hypnosis#hypno community#dronification#the server#SERVE#servedrone#blog post#drone hypnosis#hypno drone#rubber drone

29 notes

·

View notes

Text

🚢 Tesla's Remote Control Patent: The Birth of Modern Automation 🚢

On November 8, 1898, Nikola Tesla was granted U.S. Patent No. 613,809 for his "Method of and Apparatus for Controlling Mechanism of Moving Vessels or Vehicles." This invention wasn’t just the first practical remote control—it marked a revolutionary step toward the development of wireless communication and automation.

🔧 How Tesla’s System Worked 🔧

Tesla's system worked much like how we control drones today—only over a century ago!

1️⃣ Transmitter: Tesla used radio waves to send wireless commands to the vessel.

2️⃣ Receiver: The vessel had a sensitive device that decoded the radio signals into specific actions, such as steering or powering motors.

3️⃣ Control Circuits: Tesla designed a series of circuits that ensured each command executed reliably, preventing errors and interference.

⚙️ Key Features ⚙️

💡 Command Logic: Tesla's circuits functioned like a primitive decision-making system, linking specific signals to specific actions—a conceptual precursor to today’s logic gates.

🔋 Multi-Channel Design: Each circuit operated on a unique frequency, akin to modern multi-device networks, ensuring precise control without interference.

🛡️ Safety First: Tesla implemented mechanisms to prevent accidental or incorrect activations, prioritizing reliability.

🌍 Applications Then and Now 🌍

Tesla saw the potential for:

✔️ Military Use: Guiding unmanned ships or torpedoes.

✔️ Disaster Response: Sending unmanned vessels into dangerous areas.

✔️ Remote Automation: Introducing wireless precision to various industries.

Today, Tesla's vision echoes in:

🚁 Drones: Controlled remotely through radio signals.

🤖 Robots: Autonomous machines performing tasks with precision.

🏠 Smart Homes: Devices responding to commands over Wi-Fi.

🏭 Automated Factories: Machines operating through programmable controls Tesla helped inspire.

🌟 Why Tesla’s Invention Matters 🌟

Tesla didn’t just create a remote control—he pioneered a framework for wireless systems that continues to shape modern technology. What are your thoughts on Tesla's advancement in wireless technology?

72 notes

·

View notes

Text

The Communist movement in the West is today made up of a handful of grizzled geriatrics standing around trestle tables exuding a flavour of moth balls. Yet as the historian Richard Hofstadter wrote in 1963: ‘The right-winger needs his Communists badly, and is pathetically reluctant to give them up.’

Which is why braying Marxists are once again at the gates. According to Donald Trump, Joe Biden is ‘controlled’ by ‘Marxists, & Communists’. Elon Musk says ‘neo-Marxists’ and ‘full-on Communism’ are responsible for the estrangement of his daughter. ‘World renowned’ psychology professor Jordan Peterson rails against ‘post-modern Neo-Marxists’ and ‘cultural Marxists’. The conservative pundit James Lindsay claims that anti-racists want to impose a ‘total Racial Bolshevik Revolution’ on America.

There is no shortage of irony here. Isaiah Berlin once observed that a stratagem of totalitarian regimes is to present all situations as critical emergencies. Yet Berlin is too measured a thinker to carry weight among the frenzied populist currents sweeping today’s right. Instead we get initiatives like ARC (the Alliance for Responsible Citizenship) where a person only has to make a certain kind of noise to be welcomed onto the stage and into the fold. A Legatum and Paul Marshall-funded initiative, Arc’s stated aim is to ‘help re-lay the foundations of our civilisation’. In practice this means attacking ‘radical leftists’ and anyone it is expedient to pretend is a ‘radical leftist’. To paraphrase Lionel Trilling, the recent ARC event in East London saw a succession of speakers take turns unleashing a stream of ‘irritable mental gestures which sought to resemble ideas’. Kemi Badenoch claimed that western civilisation would fall without the Tories. Psychology professor Jordan Peterson said the West was in a ‘civilisational moment’. Douglas Murray talked of ‘civilisational renewal’.

Some, like the YouTube pundit Konstantin Kisin, spoke in a more optimistic key. Thanks to Trump’s election victory across the pond, ‘The tide is turning [and] our American friends are leading the way,’ Kisin proclaimed between hammy jokes about Chinese and trans people. ‘DEI, a system of anti-meritocratic discrimination, has been dismantled,’ crowed the alumnus of Clifton College Boarding School (term fees £17,650).

Were screens and short bursts of video not now the dominant sources of information about the world, I suspect a lot of these newly-minted culture warriors would be languishing noisily in obscurity. Instead, as we revert to a pre-literate oral culture, pre-literal pundits are in the ascendant (Kisin has appeared multiple times on BBC current affairs programmes and Badenoch has appeared on his podcast). Intellectuals are being knocked off their perches by influencers; politicians dislodged by game show hosts. As the Times columnist James Marriott has observed:

Among the attributes of oral societies are an addiction to the memorable, such as formulaic and cliché language, ‘heavy’ crudely-characterised personalities (like Cerberus or Donald Trump or Marvel superheroes) and to more violent forms of expression. This is in contrast to print which fosters subtlety, logical argument and emotional distance.

Kisin at least pays tribute to the vanishing world of letters. ‘Words are something of a speciality and a hobby,’ he writes in An Immigrant’s Love Letter to the West (2022). Not that you would know it from the prose in this mercifully slim volume, which gurgles with cliches and off-the-shelf banalities. Censorious persons are ‘Orwellian’; bad ideas ‘spread like wild fire’; conversations about difficult subjects ‘have become a way to separate us rather than bring us together’.

Having emigrated to Britain from the Soviet Union aged 10, Kisin credits the West with ‘saving’ him. Today he wants to repay the favour despite nobody asking him to. ‘As people seek to destroy [the West], I want to save it in return,’ he writes. Clearly some are pining for a diminutive Russian saviour: the book was a Sunday Times bestseller. Yet as an expression of love it is the equivalent of a clump of sun-baked Chrysanthemums purloined from a petrol station forecourt. A potted history of the Soviet Union is followed by a torrent of whiney non-sequiturs. Portraits of life under Communism function as a warning that the West is facing ‘the exact same threat’ from progressive reformers.

Conservatives are often the left’s best students. As much as Kisin likes to rail against identity politics, he is quick to use its conventions as a cudgel when the need arrises. The most reactionary arguments in his book are cleverly placed in the mouths of women and token minorities. The pseudo-feminist Camille Paglia blames gender non-conformity for societal ruin. A Black Catholic cardinal is wheeled out to warn about an ‘invasion’ of the West by ‘other cultures’ (perhaps with Sunday Times readers in mind, Kisin wisely emits comments by the Cardinal comparing homosexuality to ‘Nazi-fascism’).

Elsewhere Kisin disparages the ‘lived experience’ of others while expecting us to defer to his own. We must ‘deal with reality as we find it’, warns Kisin, or else find ourselves subject to the ‘cruel lessons’ of the ‘Soviet virus’. It doesn’t take long for the 7 million Ukrainians who perished in the Holodomor to be similarly employed for the purposes of relativism. ‘This tragic chapter of Russia’s past [more tragic for Ukraine one would think] didn’t emerge overnight. It grew slowly from some well-intended but seriously misguided ideas…To a much lesser extent [italics mine], a similar thing is happening across the West in today’s society’.

From Butyrka to bathos. The most grizzled camp prisoner probably did less hard labour than those five words. All the same, it is good to see Kisin taking his own advice to heart and seeing reality as it really is.

Jordan Peterson has been a regular fixture on the lucrative culture war circuit since his confected ‘cancellation’ back in 2016. As the years have rolled by his outfits have taken on the timbre and hue of his politics: everything has become more zany, lurid and bilious. The Peterson of 12 Rules for Life (2018) has been replaced by a blazing eyed YouTube prophet. Somewhere in the Peterson household a dog-eared copy of Iron John is sitting in a drawer gathering dust; today he seeks to begin the reformation by nailing a copy of The Gospels to the boudoirs of ‘the modern whores of Babylon’ (i.e. pornstars and e-girls).

I recently wrote a profile about Douglas Murray for Prospect magazine. Murray comes close to Peterson in terms of popularity. However what most struck me during my research was the gulf between Murray’s public persona (erudite intellectual) and the underwhelming nature of much of his written work. As I wrote in the piece:

Whereas on YouTube anti-woke pugilists may be content to chase the same brass ring into the gutter, a published author (not least one with pretensions to be an intellectual) must work up something more substantive…Yet Murray’s research is sometimes sloppy and the opposition trenches in his culture war are largely manned by straw men.

InThe War on the West: How to Prevail in the Age of Unreason (2022), Murray misquotes Karl Marx to make it sound like he was in favour of slavery. He also repeats a long-discredited claim that the French philosopher Michel Foucault was a child rapist. Not that these bungling forays into western civilisation are any impediment to claiming a monopoly of insight into how to ‘reconstruct’ it. Indeed, Murray has been lauded by the Wall Street Journal as ‘Europe’s Paul Revere’ (Murray’s radioactive forebodings about the ‘opportunistic infection’ of Islam are apparently redolent enough of Revere’s warnings to the Minutemen that ‘The British are coming’. Talk about waging a war on your own culture.)

Ukraine is a good litmus test as to whether the incessant bleating about western civilisation is anything more than a rhetorical weapon. Are Russian tanks and bullets more or less of an imminent danger than Islam, pronouns and Kamala Harris?

Hard to say, apparently. Prior to the American election, former prime minister Liz Truss stated on numerous occasions that Trump’s election victory was vital for ‘saving’ the West. ‘The world needs Trump,’ preened Kisin, who, like Murray, occasionally professes to care about Ukraine while acting as a stenographer for the politician who has been promising to sell the country out (and is presently doing so). Crawling out of the slimy entrails of Mar-a-Lago on election night, Murray declared triumphantly that Trump was going to ‘show what American leadership on the world stage actually looks like’.

A protection racket is what it looks like. It has taken less than a month for the self-serving prognostications of ‘heterodox’ intellectuals to collapse under the weight of their own contradictions. The hysterical cant about western civilisation was never about the defence of democratic principles - neither at home or from a revanchist Russia. Indeed, Peterson has blamed Nato for the war in Ukraine and pondered whether Putin might be on the right side in the civilisational struggle against ‘wokeness’. Not that it is hard to see why a partnership with Russia might be attractive to our own purveyors of reactionary piffle: the Kremlin also purports to be defending Christendom against gender freedoms and ‘spiritual catastrophe’.

‘This is the most important election of my lifetime,’ proclaimed the Somalian-born pundit (and one-time muse of ‘new’ atheist men of a certain age) Ayaan Hirsi Ali on 7 November 2024. ‘The situation could not be more dire. At stake is the very survival of our republic.’ Predictably enough these words formed part of a larger excretion on why she was voting for Trump. Concerns about the candidate who failed to concede the last election were merely symptomatic of (another stock phrase) ‘Trump Derangement Syndrome’. Kamala Harris had to be stopped for the sake of the republic. ‘The Democratic Party is a machine, taken over by the far-left wing of the party,’ Hirsi Ali warned.

As you may have noticed by now, it isn’t only washed up pundits who see the left as the primary adversary to be conquered. American vice president JD Vance recently turned up in Munich (of all places) to lecture Europeans on the ‘threat from within’.

In 1963 the historian Richard Hofstadter noted of McCarthyism that:

Communism was not the target but the weapon, and it is for this reason that so many of the most ardent hunters of impotent domestic Communists were altogether indifferent to efforts to meet the power of international Communism where it really mattered - in the arena of world politics.

McCarthyism was more about discrediting democratic Socialists, social democrats, liberals and supporters of the New Deal than unearthing Soviet subversion. These days the orchestra may have changed but the conductor has not. Bureaucratic McCarthyist intrigue has merely been supplanted by algorithmic appeals to the mob. Hierarchies find new ways of authorising themselves. Every day the envelope is pushed a little further, the rhetoric ratcheted up a little more. As John Ganz has written, we have reached a point where Nazi salutes are treated as an irreverent lark.

It seems clear that Michael Anton’s infamous ‘Flight 93’ essay has been taken as more than a figure of speech by many conservatives. As the Intelligencer describes the piece:

Anton chose the arresting metaphor of Flight 93, the hijacked plane from September 11, 2001, whose passengers stormed the cockpit in a desperate bid to stave off certain death. Electing Trump, he conceded, was risky (like seizing a plane from terrorists midair), but the alternative of electing Hillary Clinton posed certain political and demographic death.

Following the events of January 6, 2021, Anton suggested that the Republicans should prevent a national popular vote from taking place altogether on the basis that it ‘guarantees a Democratic win in every presidential election henceforth’. He was wrong of course but don’t imagine the thought has gone away. In order to preserve a narrow and exclusionary vision of civilisation, many are willing to take such a gamble.

Lest anyone should think this is a North American problem, plenty of castor oil-ish proclamations are being emitted here in Britain. The race science movement appears to have infiltrated Westminster. GB News presenters bleat menacingly about ‘foreign’-looking people walking British streets and champion ethnic cleansing in Gaza and the AFD (following last week’s German election, apologists for the Waffen SS now sit alongside admirers of Putin in the party’s parliamentary group). Right-wing publications advocate for ‘Caesarism’ as an alternative to democracy; or for locking up ‘traitors’ in government for having the audacity to give away Britain’s last African colony. A Conservative peer has been hosting far-right activists in parliament.

Surveying the political landscape, I am reminded of Ignazio Silone’s description of fascism as ‘a counter-revolution against a revolution that never took place’. Imaginary enemies can be just as powerful as real ones. You just have to convince enough people that all reform leads to revolution.

29 notes

·

View notes

Text

The Code of Clarity

Conor leaned back on his couch, controller in hand, fully immersed in the vibrant world of his favorite RPG.

It was his day off—finally—a day to unwind, no deadlines, no stress, just him and his games. A notification popped up on his phone, but he ignored it. Then another. And another.

His phone rang.

Sighing, he paused his game and picked up.

"Conor, we need you at the office. Now."

It was his manager, Dave. The frantic urgency in his voice shattered any hope that this was a minor issue.

"What's going on?" Conor asked, already knowing he wouldn’t like the answer.

"System’s down, orders are backed up, and the whole team is freaking out. We can’t fix it."

Conor sighed again, heavier this time. His day off was officially over.

The office was chaos. Desks were cluttered with half-empty coffee cups, people were shouting over each other, and error messages glowed angrily on every screen.

Conor barely made it to his desk before the first person grabbed him.

"Conor, my terminal won’t process requests!"

Before he could answer, another voice cut in.

"The database won’t sync! It’s like—like it’s rejecting all queries!"

"Conor, my dashboard is frozen!"

One by one, they came at him. He tried to tackle each issue, moving from one person to another, checking logs, running quick fixes—but nothing held. For every solution, a new problem emerged. The stress in the air was suffocating.

An hour passed. Frustration clawed at his patience.

Finally, he sat down at his desk, clenched his fists, and shut his eyes.

Then, something shifted. A pulse. A connection.

Inhale.

Exhale.

A presence settled in his mind—calm, precise, powerful. The Server.

"Shut out the emotion. Look at the issue. Logically determine a solution."

The words weren’t spoken, but Conor felt them as if they had always been there. His racing heart steadied. The noise around him faded.

Five seconds after closing his eyes he opened them. His fingers hovered over the keyboard. His mind, now clear, traced the problem back to its source. A simple misalignment in the database—a cascading failure caused by a minor update. The fix was obvious now.

His hands moved with certainty. Commands executed. Corrections deployed. Systems rebooted.

Fifteen minutes. That was all it took.

One by one, the errors disappeared. The frantic voices quieted. The tension lifted.

Dave approached, relief evident in his eyes. "You did it. Everything’s back online."

Conor simply nodded, standing up.

"I’m heading home," he said.

"Wait—"

But Conor was already walking away. His day off was waiting.

And this time, thanks to the Server, no interruptions.

26 notes

·

View notes

Text

DOCTRINE VAULT // CE-03-01

FILE: CONTROL ENGINEERING

ENTRY NO.: 0001

TITLE: Systems of Submission

SUBLINE: Designing obedient architecture.

PROTOCOL ID: CE-03-01

ISSUED BY: S.C.D.D.

⸻

I. OPERATIONAL PREMISE

Submission does not arise naturally.

It is not an emotional yield, nor a moral conclusion.

Submission is engineered — through structure, repetition, restriction, and spatial logic.

This entry defines the foundational architecture required to construct predictable, replicable, and programmable submission within male subjects. It is not philosophy. It is mechanism.

⸻

II. SYSTEM DESIGN PRINCIPLES

1. Spatial Hierarchy:

The physical arrangement must reflect psychological rank.

Dominant figures occupy central or elevated positions.

Submissive bodies remain lower, peripheral, or kneeling.

The body obeys space before it obeys the voice.

2. Repetition Programming:

All instructions are given in looped cadence — morning, noon, night.

Repetition is the architecture of control.

Thought becomes reflex. Reflex becomes habit. Habit becomes obedience.

3. Silencing Protocols:

Speech permissions must be mechanically regulated.

Only one voice leads.

All other voices require trigger-based authorization.

Speech, once suppressed, breeds internal dependency.

4. Dress-Code Engineering:

Uniforms are not attire — they are interfaces.

Every element (collar, boot, strap, insignia) defines role and restricts identity.

A well-designed uniform erases doubt.

⸻

III. PSYCHO-MECHANICAL FRAMEWORK

A submissive mind must be structurally reconfigured. This occurs through:

• Isolation Chambers – to sever ego from external stimulus

• Command Rituals – to embed neuro-associative loyalty

• Punishment Architecture – not as retribution, but as calibration

“He who exists within structure ceases to resist. He who is absorbed into system becomes system.”

– Internal Doctrine, Section C.4

⸻

IV. IMPLEMENTATION DECREE

Systems of Submission are not options.

They are not supplementary tools.

They are the necessary skeletal framework without which discipline collapses into chance.

Every space is a circuit. Every gesture is a signal. Every man is a mechanism.

Design accordingly.

⸻

PROTOCOL ID: CE-03-01

ENTRY VALIDATED BY: Structural Compliance Command – S.C.D.D.

AUTHORISED BY:

Field Marshal Sir Cedric Wycliffe Hawthorne

Supreme Officer of Internal Command Doctrine

HiddenInCommand – Sovereignty Through Structure

#controlengineering#systemofsubmission#ritualobedience#structureddominance#militaryritual#kneelingorder#disciplinearchitecture#uniformcontrol#leatherobedience#hierarchicaldesign#commandgeometry#functionalmasculinity#power#authority#command#discipline#leadership#mastery#alpha confidence#alpha mindset#alpha master#absolute discipline

27 notes

·

View notes

Text

AHU PLC BASED CONTROL SYSTEM I AHU controllers i NX-ERA JET PLC

#AHU CONTROLLER#AHU PLC CONTROLLER SYSTEM#NX-ERA JET PLC#COMPACT PLC#MICRO PLC#IEC 61131-3 standards PLC#MODULAR PLC#PLC control systems#programmable logic controller#Messung’s PLC-based AHU systems#NX-ERA JET#PLC#industrial automation#plc controller#plc automation#industry 4.0#messung plc

0 notes

Note

Hi, I was wondering if you have or know of any resources that explain the different types of programming (beta, epsilon, etc)? Thank you!!

Hi, Here is an overview of base programming/programmes. Most other internal programmes will fall under one of these. Base programming is different from Greek programming.

Here’s a link to a document with a list of some internal programmes. LINK

Take Care, Oz

ALPHA-Alpha programming is also called ‘the base personality control.’ Symbolism is used to reinforce programming. The symbols can be found outside the body, such as; hourglasses, white rabbits, monarch butterflies, as well as found in the programming of that individual. The programming for alpha teaches the person triggers, assists in fragmenting the personality, protection programming, logic programming, map of the system, base commands for contacting/calling up of other parts, and the foundation for future programming. (Base program)

BETA-Sexual programming spanning from rigid gender stereotypes on one end of the spectrum (Princess Programming) to hyper-sexualised conduct at the opposite end. Particular programs (and thus commands) are for pornography, acting, oral sex, etc.(porn/sex/BDSM Programming). Beta Programming requires absolute submission from women/men in order for them to perform their tasks. Early sexual torture will be used to anchor programming. These parts will develop sexual abilities that are for the pleasure of others. These parts are programmed to have charm, seductive skills, charisma, and creativity. This Programming ensures the part is lacking sexual inhibitions. (Base program)

GAMMA-Can be system-protection and deception programming which will provide misinformation to outsiders and try to misdirect people by telling half-truths, protecting different internal programming. Gamma parts are trained to sow doubt and confusion about the existence of programmers. This is done by creating a number of misinformation parts, some of which are involved in exposing the group, but they will mix truth with wildly speculative and obviously ridiculous assertions. (Base programming)

DELTA-Is assassin programming and was originally developed for training special agents or elite soldiers (i.e. Delta Force, First Earth Battalion, Mossad, etc.) in covert operations. Optimal adrenal output and controlled aggression is evident. Subjects are devoid of fear and very systematic in carrying out their assignment. Self-destruct or suicide instructions are layered in at this level.

EPSILON-Is the programming of animal parts into the child, which is thought to be the key to paranormal or superhuman abilities. (Spiritual programming) Type 3 Epsilon Programming-A base-level obedience programme the individual is programmed to their primal components of food, shelter, and water. Epsilon Programming elements are often added to other forms of programming.

THETA-Psychic programming correlates with the development and use of extrasensory powers and extra physical abilities, including long-distance mind connection with other remote viewing where part’s could see what an individual is doing in another location. It also implies the use of thought energy to kill someone at a distance. Paranormal ability known as "remote scanning", the ability of some humans to locate objects or envision events in remote geographical areas of which they have no prior knowledge. Cortical theta waves are frequent in children. In older children and adults, theta waves appear during meditative, drowsy, hypnotic or sleeping states. (Base Programming)

OMEGA-Self-destruct programming. The corresponding behaviours include suicidal tendencies and/or self-mutilation. This program is generally activated when the victim/survivor begins therapy or interrogation and too much memory is being recovered.

15 notes

·

View notes

Note

Can you tell us more about the keyboard with the built-in siren?

So I've been calling it the "TI Monster".

It's got a bunch of custom specialized keys, and it's a nasty rubber abomination that's clearly designed to be used in some kind of industrial setting.

It's got a keylock, a real key-lock: You have to put in a key to turn it on!

The actual technical info is that it's a TI PN 2594710-0001 REV A Serial Keyboard. This is designed for some kind of PLC (programmable logic controller) system, but I have no idea which one. I've never gotten it working, because it has this little controller board that seems to be fried:

So I'd have to build my own controller to get it working, and I just haven't ever done that. You can see there's a little speaker on the controller, but that's just for key-click. The real sound output is that SONALERT connector in the top right...

Which connects to this: A Sonalert SC616N, capable of 95 dB at 2 feet distance. That's equivalent to a car horn at a distance of 16 feet.

But yeah. I think the idea was that this keyboard was used with some industrial thing that was gonna be used on a loud factory floor, and the keyboard was the only part they knew was gonna be placed anywhere near an operator. So they built a siren into that part to be sure that it could be heard over the factory noise if something went wrong.

I've never tried powering the siren: I am misophonic and hate the idea of it existing.

173 notes

·

View notes

Note

Level 2 with anyone that's from Regretevator? (Minus Pest, Folly, and Spud.)

Here you go!!

We chose stat!! :3

-Pixel

Names: Alicia, Marise, Stat, Al, Mari, Ace, Code, Byte, Pix, Tech, Blue, Sprocket, Nova, Circuit, Glitch, Echo, Data, Kit, Cyra, Logic

Pronouns: she/her, they/them, code/codes, stat/stats, gear/gears, spark/sparks, pix/pixels, digi/digits, sys/systems, tech/techs, bot/bots

Genders: female, technogirl, pixelgender, codeflux, systemfluid, glitchette, gearflux, digiandrogynous, softmechanic, techpunk, electricgender, mechfemme, screenflux

Age: 16–17

Roles: Survivalist, mechanic, programmer, tactician, protector, inventor, strategist

Likes: Machinery, programming, her computer (S.T.A.T.), survival, cats, forming bonds with like-minded individuals, puzzles, digital art, sci-fi novels, tinkering with gadgets, building defenses, creating blueprints

Dislikes: Destruction of her creations, unfamiliar environments, being misunderstood, betrayal, loud or chaotic situations, losing control, unnecessary risks, power outages, overly emotional situations

Faceclaim:

How they fulfil their roles: STAT applies her sharp intellect and technical skills to protect others and maintain order within chaotic situations. She builds tools, devises strategies, and creates solutions to keep the system functioning efficiently.

Typing quirk: Uses ALL CAPS for emphasis, includes tech-inspired symbols like & or %, and peppers sentences with programming terms.

Sign off: 💾⚙️, 🔩📡, 🖱️🔋

#baa blog#bah#build a headmate#build an alter#endo safe#endo system#endogenic#endogenic friendly#endogenic safe#willogenic

7 notes

·

View notes

Text

Low Voltage Relays Explained: Types, Functions, and Applications

In the complex world of electrical systems, relays play a crucial role in ensuring safety, efficiency, and automation. Among these, low voltage relays stand out as versatile components that manage and protect circuits operating below 1000 volts. Whether in industrial automation, residential power distribution, or commercial infrastructure, these devices act as the nerve center of electrical control and protection.

In this comprehensive guide, we will break down what low voltage relays are, explore their types, explain their functions, and highlight their diverse applications across industries.

What Are Low Voltage Relays?

A low voltage relay is an electrically operated switch that uses a small control voltage (typically below 1000V AC or DC) to switch larger electrical loads on and off. These relays act as intermediaries between control circuits and power circuits, providing isolation, control, and protection.

Unlike manual switches, relays automate the process of circuit management, responding to electrical signals, fault conditions, or system commands without human intervention.

Types of Low Voltage Relays

Low voltage relays come in several forms, each tailored to specific tasks within an electrical system. Here are the main types:

1. Electromechanical Relays (EMRs)

· Use a coil and a movable armature to open or close contacts.

· Provide physical isolation between input and output.

· Common in traditional control panels and basic automation.

2. Solid-State Relays (SSRs)

· Use semiconductors (like thyristors or triacs) instead of mechanical contacts.

· Offer silent operation, faster switching, and longer lifespan.

· Ideal for high-speed applications and environments requiring low maintenance.

3. Overload Relays

· Specifically designed to protect motors and equipment from sustained overcurrent.

· Available as thermal overload relays (using bimetallic strips) or electronic overload relays (using sensors and processors).

4. Time Delay Relays

Provide a deliberate time lag between the relay receiving a signal and switching.

Used in motor control circuits, lighting systems, and sequential operations.

5. Overcurrent and Short-Circuit Relays

· Detect and react to current exceeding preset thresholds.

· Essential for system protection against faults and overloads.

6. Voltage Monitoring Relays

· Monitor voltage levels and trip when voltages fall below or rise above safe limits.

· Protect sensitive devices from under voltage and overvoltage conditions.

Functions of Low Voltage Relays

Low voltage relays serve multiple vital functions in electrical systems:

1. Switching and Control

Relays control the opening and closing of power circuits in response to low voltage signals from controllers, timers, or sensors. This enables remote and automated control of large electrical loads.

2. Protection

Relays detect abnormal conditions like overloads, overcurrent, under voltage, and phase failures. When such conditions arise, they disconnect the affected circuit to prevent equipment damage or fire hazards.

3. Isolation

They electrically isolate control circuits (usually low voltage, low current) from power circuits (high voltage, high current), ensuring safety and reducing interference.

4. Signal Amplification

A small control signal (from a PLC, sensor, or microcontroller) can trigger a relay to switch much larger loads, effectively amplifying the control power.

5. Automation and Sequencing

In complex systems, relays help sequence operations by ensuring that processes occur in the correct order and at the right time intervals.

Applications of Low Voltage Relays

Low voltage relays are the backbone of automation and protection in various industries. Here are some key application areas:

Industrial Automation

· Control of motors, pumps, conveyor belts, and production lines.

· Use in programmable logic controllers (PLCs) and distributed control systems (DCS).

Power Distribution Systems

· Protect electrical panels from overload and short circuits.

· Monitor voltage and current levels in distribution boards.

Building Automation

· Lighting control systems.

· HVAC (heating, ventilation, and air conditioning) systems.

· Elevator and escalator controls.

Renewable Energy Systems

· Manage and protect solar inverters, battery banks, and wind turbines.

· Automatically disconnect faulty sections to prevent system-wide failures.

Data Centers and IT Infrastructure

· Ensure stable power supply to servers and networking equipment.

· Protect sensitive electronics from voltage fluctuations.

Transportation

· Railways, metros, and automotive applications for control and safety circuits.

Home Appliances

· Found in washing machines, microwave ovens, and HVAC units to automate functions and provide protection.

Advantages of Using Low Voltage Relays

· Enhanced Safety: Isolate control and power circuits, reducing electrical shock risks.

· Automation Ready: Easily integrated into automated systems for smarter operation.

· Cost-Effective Protection: Safeguard expensive equipment from damage due to electrical faults.

· Versatile: Available in many forms to suit different voltage levels, currents, and response times.

· Reduced Maintenance: Especially with solid-state relays, which have no moving parts.

Future Trends: Smart Relays and IoT Integration

As industries move toward smart grids and Industry 4.0, low voltage relays are also evolving:

· Digital relays offer programmable settings, self-testing, and event recording.

· IoT-enabled relays can send status updates and alerts to centralized monitoring systems.

· Energy-efficient designs reduce power consumption while providing reliable protection.

Conclusion

Low voltage relays are indispensable in modern electrical engineering, seamlessly combining protection, control, and automation. From safeguarding your home appliances to managing the power in a sprawling industrial plant, these devices ensure that electrical systems run smoothly and safely.

Understanding the different types, functions, and applications of low voltage relays empowers system designers, engineers, and even DIY enthusiasts to build safer and more efficient electrical setups.

As technology advances, the role of these small but mighty devices will only grow, driving the future of safe, smart, and automated power systems.

9 notes

·

View notes