#chassis and engine assembly lines

Explore tagged Tumblr posts

Text

Powering the Production Line: Messung’s NX-ERA PLCs in Automotive Material Handling

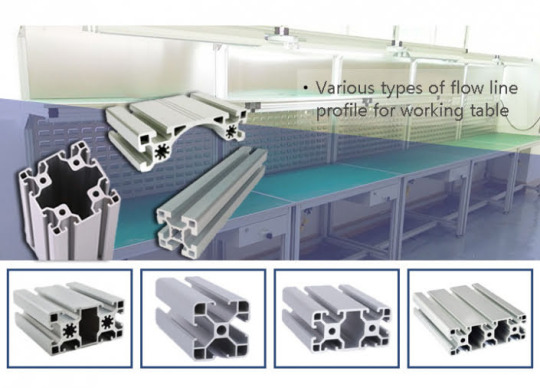

In automotive manufacturing, precision isn’t a luxury, it’s a necessity. From chassis and engine assembly lines to the press shop and paint line, seamless material handling is critical to keeping production on track. Whether it’s coordinating conveyors, pick-and-place systems, or synchronizing with robotic cells, the need for intelligent control is constant.

Messung’s NX-ERA PLCs deliver this control with unmatched flexibility. With native support for Modbus TCP/IP, Ethernet/IP, EtherCAT, OPC-UA, and IO-Link, they enable high-speed communication across robots, HMIs, VFDs, servo amplifiers, and central SCADA systems. Plus, with remote I/O modules and protocols like CANopen, our PLCs handle large-scale, distributed inputs and outputs effortlessly. Simply put, NX-ERA makes advanced, synchronized automation easy, even in the most demanding environments.

What is Material Handling in the Automotive Industry?

Material handling in the automotive industry involves the movement, positioning, storage, safety, and tracking of components and assemblies throughout the production process—from the arrival of raw materials to the final stages of vehicle assembly. Efficiency here is critical; any delay or misstep can disrupt the entire manufacturing flow.

Key areas such as the chassis and engine assembly lines, along with the press shop and paint line, rely heavily on sophisticated material handling systems, including conveyors, pick-and-place machines, and robotics, to keep production moving seamlessly. These systems must operate in perfect sync, often across large, distributed areas with thousands of I/O points.

The Brain Behind the Brawn: NX-ERA PLCs

Our state-of-the-art NX-ERA PLCs including the NX-ERA Xpress and NX-ERA Jet, are compact PLCs designed for high-speed, reliable control. These programmable logic control systems are the heart of any automated material handling system. By offering real-time control, seamless connectivity, and robust communication protocols like Modbus TCP/IP, Ethernet/IP, EtherCAT, OPC-UA, and IO-Link. They interface effortlessly with robots, HMIs, VFDs, servo amplifiers, and centralized SCADA systems, ensuring reliability and scalability.

Here are some of its most impactful features:

High-Speed Processing Power

The core point of NX-ERA PLCs is that they are capable of real-time processing. These robot systems run as fast as your machinery, and the synchronization is important for the overall efficiency of the system. This compact PLC will guarantee flawless optimization for every aspect of the bottling line, be it controlling the work of conveyors or robotic manipulation.

Modular Design for Flexibility

The greatest feature of the NX-ERA PLC is its modular design. Production plants in the automotive industry often aim for some form of adaptability, and, thus, this feature is very helpful. It allows the installation to expand while the business is developing. The implementation of modularity means that the system can be integrated with any new equipment, production units, or additional features to ensure that there will be no disruption to the system performance.

Integrated I/O Modules for Streamlined Setup

Our smart and compact PLC integration contains integrated I/O modules that reduce installation and wiring times, thus also focusing on the fast-paced phenomenon in the automotive industry. For simplification of the things, input/output capabilities are now directly included in the integrated PLC system, which substantially reduces the external wiring as a result of which the setting up is speedier and less prone to mistakes.

Advanced Web Server Capabilities

It is safe to say that we are far off the days when engineers would have to be on site for them to physically track and diagnose issues on the factory floor. The capability of the built-in web pages of our NX-ERA PLC allows easy remote access for getting the actual real-time state of the diagnostics and monitoring. This feature is incredibly important in an industry that operates around the clock, as it allows maintenance teams to resolve issues remotely, reducing downtime and keeping things running smoothly.

The Role of the NX-ERA PLCs in Material Handling

In the automotive industry, material handling is integral to the success of the production process. From raw materials to semi-finished goods, and finally to finished products, materials need to be handled with precision. Automation is key to achieving this, and Messung’s NX-ERA PLCs are designed to make this process as efficient and effective as possible.

Here is how it is done:

Conveyor Systems Optimization

Conveyor systems, which carry parts between the workstations and at the same time keep the production continuously running, are the most popular form of material handling in the automotive plants. NX-ERA PLCs make sure that the system, no matter what, functions without any breaks by adjusting the speed of the conveyors to fit the pace of production. The real-time processing feature ensures that the system in question becomes flexible almost immediately, providing the assembly line without any interruptions and preventing the end line packing in the last round.

Predictive Maintenance to Maximize Uptime

The predictive maintenance of the system is seen as the golden nugget to maximize uptime. For the maintenance of a plant, having machines down during their run time is quite expensive. In the automotive industry, where the production rates run on a very tight schedule, even a moment's disruption would mean substantial losses. Our PLC Systems use a predictive maintenance system to keep a continuous check on the condition of the equipment. The control system will be equipped with predictive maintenance, which can track the system performance, increasing the change in predicting when maintenance is needed before failure occurs. These stains would reduce chances of equipment going down and also increase whole equipment machines productivity performance.

Power Management for Material Handling Equipment

How NX-ERA PLCs Integrate with SCADA Systems

Industrial automation relies not just on PLCs but also on supervisory control and data acquisition (SCADA) systems to monitor and control large-scale operations. The integration of NX-ERA PLCs with SCADA applications enhances material handling capabilities by providing plant operators with real-time insights into the performance of material handling equipment.

Real-Time Visualization and Data Monitoring

Data gathered from the cluster of service line sensors are then monitored by SCADA systems through real-time visualization and data troubling. By means of the material handling systems' connecting to the SCADA applications, operators are able to visualize every operation stage on a single interface. Our NX-ERA PLC assists the SCADA system in a way that allows real-time data visualization. As for plant automation, this integration enables the operators to redesign the production line and fabricate the survey that they are in full command, including the conveyor speed, robotic movement, and electrical power consumption.

Alarming and Fault Diagnostics

Unexpected malfunctions are a part of any complex system, but SCADA and PLC integration ensures they are dealt with swiftly. The NX-ERA PLC can send alerts to SCADA systems when material handling equipment encounters an issue, whether it’s a malfunction in a conveyor belt, a sensor failure in a robotic arm, or an electrical fault. This proactive approach helps resolve issues before they lead to extended downtime.

Historical data analysis for continuous improvement

Other benefits of integrating the SCADA system with the NX-ERA PLC is to have an ability to analyse historical data. These past data performances can better help the plant managers to see trends, adjust production schedules, and improve the efficiency of the material-handling systems over the long period. In actuality, the PLC saves and disposes of necessary data. This information, then, is fed into the SCADA system and used for analysis and presentation purposes.

The Future of Material Handling with NX-ERA PLCs

As the automotive industry embraces Industry 4.0, NX-ERA PLCs are positioned at the forefront of the shift towards smarter, more connected manufacturing systems. This is brought about by switching to smarter, more connected production systems. Thanks to NX-ERA PLCs, which are able to integrate with SCADA applications, robots, and power supplies, you can now easily build a factory that can quickly adapt to changes in the current demand and the production process.

Benefits Include:

More automation and efficiency with the increasing factories

As factories become more automated, the role of PLCs like the NX-ERA will only grow. The future of material handling will rely on even more precise and automated systems, from fully autonomous robots to smart conveyors that adjust their speed and behavior based on real-time conditions. The NX-ERA PLC is ready to support this evolution with its high-speed processing and robust integration capabilities.

Energy Management and Sustainability

Green manufacturing is a critical concern for the industry today. Automotive manufacturers demand advanced NX-ERA PLCs in a bid to bring down the environmental impact of the production. An essential element that plays a pivotal role in power solutions, predictive maintenance, and derived data for operational efficiency is a way for these to reduce the consumption of energy.

Real-Time Data and IoT Connectivity

With the rise of the Internet of Things (IoT) in manufacturing, NX-ERA PLCs will continue to integrate with a broader network of connected devices. This real-time data flow will empower automotive plants to make more informed decisions and improve their material handling systems.

Conclusion: The Future of Material Handling in the Automotive Industry

In the race for efficiency and innovation, Messung’s NX-ERA PLCs are the pit crew that keeps material handling equipment running at peak performance. Their combination of advanced features, modular design, and seamless integration with SCADA systems positions them as the ideal solution for automotive manufacturers aiming to stay ahead of the competition.

As automotive plants move towards smarter, more automated manufacturing processes, the need for reliable, high-performing PLCs like the NX-ERA will only continue to grow. By embracing the capabilities of Messung’s NX-ERA PLCs, automotive manufacturers can ensure that their material handling systems operate efficiently, sustainably, and with minimal downtime, ultimately contributing to the ongoing success of the industry.

In this fast-paced industry where precision is the name of the game, Messung’s NX-ERA PLCs are the game changers that automotive manufacturers need to optimize their material handling systems and maintain a competitive edge in the global market.

#chassis and engine assembly lines#Modbus TCP/IP#Ethernet/IP#EtherCAT#OPC-UA#remote I/O modules#CANopen#compact PLCs#programmable logic control systems#SCADA systems#automotive industry#PLC system#material handling#PLC Systems#material handling systems#SCADA applications#PLC integration#Automotive manufacturers#Internet of Things (IoT)

0 notes

Text

I used to go to school with Bob Kia Soul, before he was big. You never can tell who's going to be famous, you know. Lots of stress in his life now, I can't imagine how he must be dealing with it all. There was an astronaut in my class, too, but he burned up during some kind of rocket malfunction. Left a widow and six space-alien mistresses from work. His wikipedia page isn't even filled in. Kia Soul, though? Going places.

Recently, while studying the entire works of Shakespeare on a drunken bar bet, I noticed that the so-called immortal Bard had never written a single sonnet about the Kia Soul, America's 14th-favourite car. In fact, he'd never penned anything about any Kia. Or, to be fair to Shakespeares everywhere, any car at all. I find it staggering that anyone can go two entire sentences without talking about cars, so I figured that I would produce the record of our time. The tale of Kia Soul.

Born in South Korea, Kia Soul didn't have an easy childhood. Not only was his mother a cold and distant 8,100-ton heavy industrial chassis press, but he was passed along a succession of fathers along the Gwangju Number One assembly line until his upbringing was considered "complete." After that, he was sent across the world to live in a whole new country. He was never able to see any of his siblings again, except for the bunch that were made in the wrong colour and trim combination and sat on the lot for a few months too long.

Early in adolescence, Bob Kia Soul was struck with more difficulties. I had no idea that this had happened to him, but his family was very private about his struggles. He was subject to at least one full engine replacement under the extended recall warranty. Oil sludging, which is not racist to point out is common among his Theta II bloodline (it's established medical fact.) Still, he managed to overcome it to enjoy 168,000 generally trouble-free kilometres (and counting!) to become an icon for front-wheel-drive commuter appliances everywhere. Thank you, Bob Kia Soul, for teaching me that it was alright to make a really weird noise and no acceleration instead of shifting down in corners. I'll never forget you, unlike that astronaut.

93 notes

·

View notes

Text

1953 Dodge ‘Zeder’ Storm Z-250

1953 Dodge ‘Zeder’ Storm Z-250 Concept with body by Bertone

One-off

The Storm Z-250 was developed by Chrysler engineer Fred Zeder to evaluate the feasibility of producing a vehicle that would capture a portion of the growing American sports car market.

Built on a rigid tube frame chassis (built mostly by Chrysler engineer, John Butterfield, in his basement), it was intended to be a dual-purpose sports/racing car because Zeder Jr. envisioned a car with swappable bodies.

In 1952, while on Christmas vacation in Europe, Zeder visited Fiat's Chief Engineer in Turin.

Dante Giacosa recommended a visit to Bertone.

Though they were busy designing and building the Alfa Romeo BAT series, they agreed to build the body for Zeder's new car and promised three months to finish the car.

It took nine months to finish.

Unique to the Storm Z-250 was that the comfortable ‘touring’ body could be removed by unscrewing four bolts and replaced with an ultralight 150-pound fiberglass body for ‘racing’.

The mechanical components of the car included a Dodge hemi V8 truck engine with 260hp and 330ft-lbs of torque.

Other parts came from Plymouth and Dodge vehicles, including brakes, radiator, clutch, fuel tank, rear axle, and the steering system.

The transmission was a new unit developed by the Spicer Division of Dana Corporation.

The Storm did not reach the assembly line because high production costs would have made it too expensive to sell in profitable quantities.

The Z-250 would have competed with the Ford Thunderbird, Chevrolet Corvette, and the Kaiser-Darrin.

Zeder drove the Z-250 for 16 years.

He loaned it to the Northwood University where it remained until 1992.

Unfortunately, water leaked into the cylinders so the engine was removed and replaced with a 1965 Dodge V8 with two four-barrel carburetors.

After the work was completed, Zeder continued to drive the car in his home in California.

#Dodge ‘Zeder’ Storm Z-250#Dodge ‘Zeder’#Dodge#Storm Z-250#car#cars#mopar#moparperformance#moparnation#moparworld

130 notes

·

View notes

Text

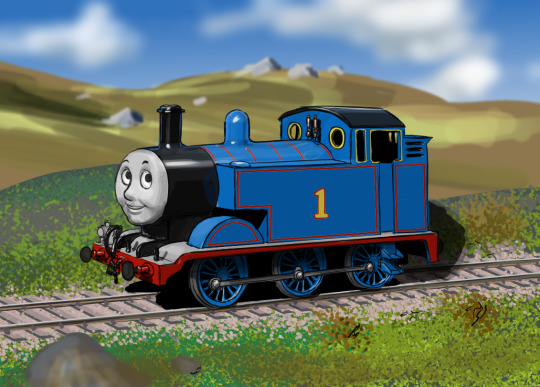

Thomas the Tank Engine & Friends aired on this day 40 years ago. Here's a portrait of the tank engine of the hour.

I usually draw Thomas as a sort of freelance design or "railway series" inspired design, with a few more realistic features and so on, if not as a straight up accurate or slightly modified E2.

But this drawing is a study of the Gauge 1 (1:32 scale) plastic prop built for Thomas the Tank Engine & Friends season 1. Proportions could be a little better; the wheels might be a little small and the boiler a little big. oh well.

A fun detail about the design is it's mostly using flat plastic-card and tubing of just a single radius. So the curve on the front footplate is actually the same curvature as the boiler. I believe the splashers are also the same diameter, but I'm not sure. The cab roof is probably slightly curved plastic-card. I'm not sure how the boiler and funnel are made, probably some amount of sculpting went into it. The chassis is a heavily modified german gauge 1 model built by Marklin, and the details like the vacuum brake pipe (the big tubing of the S1 version of the model looks way better to me than the like, floating pipe we see in later variants of the model), headlamp, and screw-link couplers are also taken from Marklin engines.

There's often discussion of what makes an engine a "RWS" version of an engine, but comparing the Gauge 1 prop to the first illustrations of Thomas from the Railway Series books, it's pretty much spot on. The double-whistle seems to be a slight misinterpretation of the safety valve assembly, and the lamp isn't especially accurate, and the font on the "1" is a little different, but it's basically like the drawing come to life. By comparison, it's usually the later versions of Thomas that people are attempting to evoke with "RWS" versions.

I also noticed that the lining appears to have like, white around it, almost like it's a print-out or something, rather than painted directly onto the model. So that's in my drawing too; and it actually kinda helps blend between the red lining and the blue paint a little better.

#Thomas the Tank Engine#Thomas and Friends#TTTE#TTTE Thomas#model train#model railway#Steam engine#tank engine#steam locomotive#40th anniversary#TTTE 40th anniversary#art#digital art

32 notes

·

View notes

Text

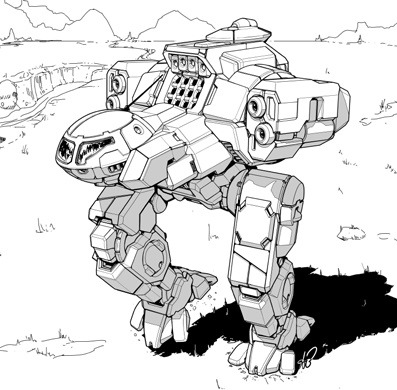

Jenner

Introduced in 2784, the fact that the Jenner was the sole property of the Draconis Combine was long a source of national pride. Designed, produced, and, for over fifty years, solely used by the Combine, the Jenner was meant to be a fast guerrilla fighter that would go on to form the foundation for highly mobile lances. Five Smithson Lifter jump jets, two in each side torso and one in the center torso gave it a jumping distance of 150 meters, while its Magna 245 fusion engine allowed for a top speed of over 118 km/h, making it faster than most other 'Mechs. The drawback of the original model was its armament of a Diplan HD large laser and two Argra 27C medium lasers, all mounted in a turret which could be easily disabled with a well-placed shot, while the medium lasers' targeting systems proved to be bug-ridden. After some tinkering, this setup was eventually replaced with the weaponry found in the JR7-D model, creating a good mix of speed and firepower, though only four tons of armor provide paltry protection compared to other 'Mechs in the same weight range.

The Jenner became the standard light workhorse of the DCMS with the outbreak of the First Succession War, though its reputation would be forever tarnished following its role in the Kentares Massacre. Construction of new Jenners continued at Diplan Mechyard's factory on Ozawa until a raw mineral shortage caused a halt in 2815, though they continued to produce new chassis. In 2823 production resumed on Ozawa, with some 3,000 chassis shipped to Diplan's subsidiary on Luthien for final assembly, which itself was retooling to begin full-scale production; by 2830 both production lines were producing 1,350 Jenners a year. The sheer destruction of the Succession Wars finally took their toll when the last Jenner factory was destroyed in 2848, though so many Jenners had been produced by then that nearly every DCMS battalion had at least one of these 'Mechs well into the War of 3039. While the other Successor States eventually managed to procure operational Jenners (every AFFS regiment along the Combine border had at least one), the design remained in predominant use by House Kurita.

A favorite tactic of Jenner lances was to gang up on larger 'Mechs and unleash a devastating alpha strike. One or two of the 'Mechs would be equipped with inferno rounds, so even if the enemy survived the first strike they were badly damaged and running hot, allowing the Jenners to jump to safety and cool down. A few seconds later the attack would be repeated until finally, the enemy was dead. It was also common practice to pair the Jenner with another Combine 'Mech, the Panther, creating a deadly combination of sheer speed and firepower with the slower Panther providing cover fire for the Jenner's flanking attack. The Jenner was such a favorite among Kurita MechWarriors that it became the benchmark against which all other newly designed Combine 'Mechs were compared.

While rebuilding a Jenner production line on Luthien became a top priority under Gunji-no-Kanrei Theodore Kurita, the necessary construction time along with inexperienced Combine engineers meant that even with ComStar aid this wasn't possible until 3046. The recovery of much lost technology and the Jenner's prominence within the DCMS made it a prime candidate to receive new upgrades, however Luthien Armor Works deliberately avoided any radical changes to preserve the original's core advantages. Hence, while the new JR7-K began replacing the earlier model with little fanfare, it wasn't until the Jenner started to be outclassed by other designs using superior technology that Jenner pilots began complaining. Still, there was reluctance to make any changes, and slowly many commanders began mothballing their Jenners in favor of newer light 'Mechs and OmniMechs. Since then, a few variants have utilized advanced technologies in their design, notably one based on the Clan Jenner IIC, but it would take the devastation of the Jihad for many of the older K models to see frontline combat again.

The primary weapons system on the Jenner is four Argra 3L medium lasers, two each mounted in directionally variable mountings on either side. These provide the Jenner with a powerful close-to-medium range striking capability that does not suffer from a lack of supplies when operating behind enemy lines, though the use of only 10 single heat sinks means it has the potential to run hot. The lasers are backed up by a Thunderstroke SRM-4 launcher in the center torso, supplied by one ton of ammo in the right torso, that can be used after breaching an enemy's armor to try and get a critical strike against vulnerable exposed internal components.

16 notes

·

View notes

Text

It used to be that when BMW would refit a factory to build a new car, the only way the automaker could check if the chassis would fit through the production line was to fly a team out and physically push the body through the process, making note of any snags.

Now, process engineers can simply run a simulation, sending a 3D model of the car through a near-identical digital twin of the factory. Any mistakes are spotted before the production line is built, saving time and money.

Such is the power of the industrial metaverse. Forget sending your avatar to virtual meetings with remote colleagues or poker nights with distant friends, as Mark Zuckerberg envisioned in 2021 when he changed Facebook’s name to Meta; the metaverse idea has found its killer app in manufacturing.

While the consumer version of the metaverse has stumbled, the industrial metaverse is expected to be worth $100 billion globally by 2030, according to a World Economic Forum report. In this context, the concept of the metaverse refers to a convergence of technologies including simulations, sensors, augmented reality, and 3D standards. Varvn Aryacetas, Deloitte’s AI strategy and innovation practice leader for the UK, prefers to describe it as spatial computing. “It’s about bridging the physical world with the digital world,” he says. This can include training in virtual reality, digital product design, and virtual simulations of physical spaces such as factories.

In 2022, Nvidia—the games graphics company that now powers AI with its GPUs—unveiled Omniverse, a set of tools for building simulations, running digital twins, and powering automation. It acts as a platform for the industrial metaverse. “This is a general technology—it can be used for all kinds of things,” says Rev Lebaredian, vice president of Omniverse and simulation technology at Nvidia. “I mean, representing the real world inside a computer simulation is just very useful for a lot of things—but it’s absolutely essential for building any system that has autonomy in it.”

Home improvement chain Lowe’s uses the platform to test new layouts in digital twins before building them in its physical stores. Zaha Hadid Architects creates virtual models of its projects for remote collaboration. Amazon simulates warehouses to train virtual robots before letting real ones join the floor. And BMW has built virtual models for all its sites, including its newest factory in Debrecen, Hungary, which was planned and tested virtually before construction.

To simulate its entire manufacturing process, BMW filled its virtual factories with 3D models of its cars, equipment, and even people. It created these elements in an open-source file format originated by Pixar called Universal Scene Description (OpenUSD), with Omniverse providing the technical foundation for the virtual models and BMW creating its own software layers on top, explains Matthias Mayr, virtual factory specialist at BMW.

“If you imagine a factory that would take half an hour to walk from one side to the other side, you can imagine it’s also quite a large model,” Mayr says. Hence turning to a gaming company for the technology—they know how to render scenes you can run through. Early versions of the virtual factory even had gaming-style WASD keyboard navigation, but this was dropped in favor of a click-based interface akin to exploring Google Street View in a browser, so anyone could easily find their way.

BMW also uses Omniverse for collaboration on car design and customization visualizations for customers, but a key benefit is being able to model production lines. New cars mean a new assembly process, but refitting a factory is a daunting process. Previously, key information was held in silos—production crews understood details of the assembly process, external suppliers had specs of new parts or machinery, architects had detailed building plans—and costs would pile up for every delay or mistake. “The later you find a problem, the worse it is,” says Lebaredian.

Now, problems are worked out virtually, with a central location for standardized data to be held. There’s still a critical human element: Mapping a facility requires sending a laser scanner strapped to a person running through a factory to capture point cloud data about how everything is arranged. Design engineers also need to create a 3D model of every stage of a car as it’s assembled. This level of detail allows BMW to virtually test the assembly process, complete with simulations of robotics, machines, and even human workers, as BMW has data tracking how long it takes employees to assemble a part.

The main idea is to avoid errors—does that machine even fit there?—but the system also enables optimization, such as moving a rack of components closer to a particular station to save steps for human assemblers. “You can optimize first and gain a lot of efficiency in the first production, and in the construction phase, you have fewer mistakes,” Mayr says. “It’s less error prone.”

Omniverse being a Nvidia platform, AI is naturally next. BMW is already layering in generative AI to help with navigation of its virtual models—they’re so massive that finding a particular point in the digital factory can still require asking a human expert for directions. But the aim is to use AI to optimize production lines too. “Because you have the whole data available, not just for one plant, it will be able to make good suggestions,” says Mayr—lessons learned in one factory could more easily be applied to others.

And then there’s robotics and other autonomous systems. Here, Omniverse can offer a digital space for testing before deploying in the real world, but it can also generate synthetic training data by running simulations, just as driverless car systems are trained with virtual video footage generated by AI. “Real-world experience isn’t going to come mostly from the real world—it comes from simulation,” says Lebaredian.

Aryacetas predicts that the biggest impact from the industrial metaverse will be embodied or physical AI—in other words, robots. “Robots aren’t fully there yet, but they’re rapidly training up to understand the physical world around them—and that’s being done because of these underlying spatial computing technologies,” he says.

The future of the metaverse isn’t avatars in a virtual world; it’s digital twins teaching industrial robots how to step out into the physical one.

2 notes

·

View notes

Text

So, there's many of you now. I know we're in the How Sweet It Is Not To Know Follower Counts website and I do cherish that, but still, more people than ever in my life clicked a button that in some capacity says "I care what this dork has to tell me" and I want to acknowledge and celebrate that - especially now that this growth seems to have settled into its rhythm.

Spot when @identifying-cars-in-posts reblogged my pinned, lol.

So, for my 100th post, I felt like celebrating our love for reaching round numbers. And little in the automotive world represents it more iconically than what reigned supreme above all cars in the 1980s.

Porsche started out as an engineering firm, whose most notable contract was what would become known as the Volkswagen Beetle (and boy what a story that is). The first car of its own was the 356 seen below - a sporty body laid over Beetle underpinnings and thus still mostly made by Volkswagen. But by God, they were going to run with that recipe and perfect it 'til the sun burst.

Meanwhile, in England, a chap called Colin Chapman decides the next of his company's track cars will actually be drivable on the street, to need no trailer to go race. Thus the Lotus Seven is born and sold in kit, which avoids high taxes on the exporting of cars to the US (but those taxes would have remained had they been sold with assembly manuals… so they were sold with disassembly manuals for you to read backwards. No, seriously.).

The Porsche 356 kept getting less and less Volkswagen and more and more Porsche until in 1964, the year of the Beatles, the year of the Stones, the stone-age Beetle was left behind for good with the Porsche 911 (seen below), a blank-canvas take on the same recipe of an air-cooled rear boxer engine powering the rear wheels of a squished-Beetle-shaped sportscar. 'Twas good.

In 1973, Lotus was doing pretty well for itself. The Seven's whole 2500 sales had carried it through producing a number of other models, and a few were even in production concurrently - a lineup! Exciting stuff! Well, that and an F1 team so successful its Wikipedia page features the section "Domination in the 60s and '70s". The exciting opportunity to move upmarket, with bigger models with AC and automatics and all that bougie shit, pushed them to move away from the image of scruffy old kit car makers, ceding the Seven's production to the last two dealers that sold it, main one being Caterham Cars.

The 911 headed into the 80s old enough to drive, and Porsche's plans considered it at the end of the line, with staff already mourning it. But then the yankee at his third week as CEO saw those plans (which to Germans are basically scripture), said "to hell with that" and extended that line off the chart. Literally. He went to the lead engineer's office and physically took a marker at a development chart. They all secretly liked that.

Still, it was clear the game was changing - intercoolers, all wheel drive, active suspension... how hard could the 911 layout go if it didn't stick to its simple air-cooled roots? Well, Porsche resolved to find out by filling it with the cusp of automotive advancements and then some. And I do mean filling - a chassis that didn't even need space for a radiator was suddenly tasked with storing it, two turbos, two intercoolers, and a good half dozen oil pumps.

Yeah good luck with that, buddy. Oh, and materials? The body was kevlar, the frame was aluminium, the floor was Nomex (ever even heard of Nomex???), the wheels were magnesium and the spokes were hollow!!!! You could blow into the spokes!!! And don't get me started on the technology! Variable height, an all-wheel-drive system that distributed torque at will, electronics galore... As you may be able to guess, development was… complex.

At one point a test driver was doing 180km/h (112mph) to go get the car un-on-fire-d, and that's just one of the plenty horror stories. Hell, work started in 1983 to create a car for Group B and took so long that when said rally series died in 1986, production was just starting. Not that development would stop at the start of production, either - the first cars just got updated when the owners took them in for their service. (Can't blame them, I fix wording in weeks-old posts...) But however long it took, the resulting Porsche 959 answered the originating question "How hard can this chassis go?" with a resounding "Hard and then some".

It was comfortable and refined enough to be driven every day, but so capable it extended the limits of the concept of production car. Put it this way: it reached car people's favorite round number, 100km/h (to yankee doodles, 60mph) in 3.6 seconds. The second fastest production car did so in 4.6. That's one second of margin in a race that ends in five. Oh, and if you want to put it another way: the 959 was the first production car to ever surpass 300km/h, let alone come 1 shy of the mythical 200mph (322km/h).

Meanwhile, the handful of chaps at Caterham was still producing the Caterham Seven. It's the Lotus Seven (specifically the third revision, from 1968), but I guess in '83 the engine changed. We were saying?

They couldn't sell the 959 stateside for lack of crash test data, and America's ban on importing foreign cars under 25 years of age had no exception. That is, until Bill Gates wanted a 959 so bad he spent 13 years getting an exception passed. That's how hot this car is.

And yet, this record-breaking, boundary-pushing, master-of-all-trades hypercar sits atop the 80s automotive landscape engulfed in shadow. But how? Why? Because it failed to contend with the greatest automotive headache: humans. It was planted, practical, reliable, predictable - docile, domesticated, amicable. Perfect. But these are not meant to be cars, they're meant to be posters. And you don't get posters of what is perfect, but of what excites you. And what excites us is the visceral, the raw, the uncompromising - the wild, the feral, the dangerous. And, of course, reaching round numbers. What excites us is a lot more like the first production car to break 200mph, the Ferrari F40.

Remember how the 959 was being developed for Group B racing and then the series died? Well, Ferrari got screwed over too, with the 288 GTO Evoluzione they were developing (seen here to the right of the base 288 GTO) suddenly having no reason to be.

The lead engineer then asked Enzo Ferrari to let him turn that weekend project (literally, they couldn't spend work week time on it) into a road car to celebrate their 40 years. Enzo, nearing the end of his days, thought "Ah, what the hell, let's leave with a bang", so they set off to build what would become the anti-959. Not anti as in response, but as in antithesis. Where the 959 was an attempt to modernize the noisy, unrefined, old-school 911 -to make a supercar "tested for everyday usability to the most strenuous standards", by Porsche's words- the F40 was a reaction to, per Ferrari's words, "customers saying Ferraris were becoming too plush and comfortable": "nothing but sheer performance. Not a laboratory for the future, as the 959 is. Not Star Wars."

To exemplify: left is the 959 - note the leather and electric seats, right is the F40, note the string you open the door with.

The F40 was noisy, crashy, torrid, and the turbo lag painstakingly smoothed out in the 959 here kicked you in the back like a locked door. It would rip your head off the moment it sensed you didn't know what you were doing. But it was more exciting - to look at, to hear, to drive. And that's what won people over - including the buyers, which were near four times as many as Porsche's despite the price tag being double.

Had the 959 lost then? Well, not quite. Enter the 959 S. Doing away with much of the 959's luxuries, like adjustable suspension, electric windows, AC, central locking, and even backsea- wait, the 959 had BACKSEATS???? Holy FUCK why does no one talk about that??? Take the family on a trip to 300kphville! I was saying. They schlapped some bigger turbos on too and power went from 444hp right past the F40's 470hp to a healthy 508, that propelled it over what any roadgoing F40 ever managed at 211mph, or 339km/h. Presumably for bragging rights.

And I want to stress, these were titans clashing here. This was leagues beyond what other production cars could even comprehend. Again, the 959 hit 100km/h in 3.6 seconds. The F40 held a record by taking less than 16 seconds to go from 0 to 160km/h(100mph) and back to 0. This was witnessing superhumans fighting through the clouds.

And then in 1992, the two chaps that 'developed' Caterhams (i.e. banged new ones together in the shed) told the chap they worked for "Hey, let's make one that's really barebones and fast", rang up their ol' mate (and ex-F1 racer) Jonathan Palmer to ask to lend a hand, and bought some of the 250hp engine that powered the Vauxhall (British for Opel) Cavalier GSi in the British Touring Car Championship.

Thus, the Caterham Seven Jonathan Palmer Evolution - a raw, uncomfortable, uncompromising beast that went fast as all fuck. Now, if you don't know Sevens you may think "Ah, so just like the F40, what with its handcrank windows and the string to open the doorlatch and all". And to illustrate how far off that is: in the Seven the windows were sown on and you latched the door yourself with a press button.

And that's the standard version which had windows and doors. The JPE didn't.

The JPE had a carbon tub you were meant to call a seat, the controls, a rev counter and a tach that didn't even bother reading until 30mph, and fuck you. And this one is not even as barebones as the JPE got: this one is painted.

So while the F40 went from 1,250kg (2760lb) to 1370kg (3020lb) when adjusted to comply with US regulations and the 959 went from 1450kg (3200lb) to the lightweight S version's 1350kg (2975lb), the Seven JPE weighed 1170. As in 1170lb. 530kg. Read that again if you need to, but it had about half the power of those two and considerably less than half the car to move. And so, in January 1993, this thing -this '50s coffin with a Vauxhall engine banged together by one guy in a shed- took the Guinness World Record for fastest car to 100km/h with a time of 3.46 seconds - and the 0-160km/h-0 record with 13.1 seconds. Close your eyes and picture that.

Yet the Seven JPE is hardly known to anyone but the most hardcore of enthusiasts, and owned by barely four dozens of 'em. So did it, perhaps, ultimately lose? Not at all. In fact, none of these cars did.

Every 959 cost Porsche twice what they sold it for, but the project proved the 911's layout could stand the test of time, and its development gave Porsche technologies it gradually infused into the 911 keeping it relevant, competitive, and most importantly alive to this day.

And I think we can safely say that when Enzo Ferrari died in 1988, a year after the F40's launch, his wish to leave with a bang was perfectly fulfilled - so much so that the F40 is commonly regarded as the peak of his legacy.

And the JPE was simply the greatest Seven ever - the most raw, thrilling, pure automotive experience the streets had ever witnessed. If driving a fast car was like biking down a hill, the Seven JPE was skydiving. Hell, it was the cover car of éX-Driver, an anime about a team using old-school sportscars to rescue haywire autonomous vehicles!

Not that culturally relevant but MAN was it cool as a kid. I need to hang those damn posters one of these days. I was saying.

These are three success stories in three radically different ways. Because, as much as I've made this post all about the numbers, sometimes it's not about that. Sometimes it's about making a show, leaving a mark, being spectacular. Sometimes it's about pushing yourself to achievements you can take pride and inspiration from. Sometimes it's simply about having fun seeing just how far you can really go. Sometimes it's about deciding what you want to be and make a new favorite version of yourself, that is the best it can be at what you care the most about. And for some that may result in less popularity or success or impact or legacy than others, but those are just some of the things you can work towards. It can be okay to just work towards having a blast. Hell, those madmen at Caterham used to stay after work to build themselves track cars, race them the next day and put ‘em back in the workshop after racing them, and the company survived to this day. Because, yes, they're still around - and their new lineup topper gets to 100 in 2.8. Windshield still optional. Well, at least there's headrests now. And a wider version, for the concrete possibility that you physically don't fit.

Never change, Caterham, because you certainly never have.

Links in blue are posts of mine explaining the words in question - if you liked this post, you might like those!

#this was meant to also celebrate 300 followers#i am just that slow at writing stuff#porsche 356#porsche 911#porsche 959 s#ferrari 288 evoluzione#ferrari f40#lotus seven#caterham seven jpe#vauxhall cavalier gsi#round numbers

46 notes

·

View notes

Text

youtube

How Luxury Cars Are Made: Inside A Rolls Royce Factory Step inside the world of ultimate craftsmanship and discover how luxury cars are made! In this exclusive video, we take you behind the scenes of the Rolls Royce factory to witness the meticulous process of building one of the world's most prestigious vehicles. From hand-stitched leather interiors to precision-engineered engines, see how Rolls Royce blends cutting-edge technology with traditional craftsmanship to create unparalleled automotive excellence. Whether you're a car enthusiast, fascinated by luxury manufacturing, or simply curious about how Rolls Royce cars are built, this detailed factory tour reveals every step — from raw materials to the final polished masterpiece. Watch skilled artisans, advanced robots, and innovative techniques come together in perfect harmony. ✅ Keywords: Rolls Royce factory tour, how luxury cars are made, Rolls Royce manufacturing process, luxury car production, inside Rolls Royce factory, how Rolls Royce cars are built, luxury car assembly line, Rolls Royce craftsmanship, luxury vehicle production, luxury car factory tour. #RollsRoyce #LuxuryCars #FactoryTour #CarManufacturing #AutomotiveExcellence #HowItsMade #LuxuryVehicles #RollsRoyceFactory #CarProduction #ManufacturingProcess OUTLINE: 00:00:00 Introducing Rolls-Royce 00:00:31 Designing the Dream 00:02:11 Crafting Opulence 00:03:41 From Chassis to Masterpiece 00:04:13 Quality Control at Rolls-Royce 🔔𝐃𝐨𝐧'𝐭 𝐟𝐨𝐫𝐠𝐞𝐭 𝐭𝐨 𝐬𝐮𝐛𝐬𝐜𝐫𝐢𝐛𝐞 𝐭𝐨 𝐨𝐮𝐫 𝐜𝐡𝐚𝐧𝐧𝐞𝐥 𝐟𝐨𝐫 𝐦𝐨𝐫𝐞 𝐮𝐩𝐝𝐚𝐭𝐞𝐬. https://www.youtube.com/@Manufactour/?sub_confirmation=1 🔗 Stay Connected With Us. Instagram: https://ift.tt/kCicz4l ============================= 🎬Suggested videos for you: ��️ https://www.youtube.com/watch?v=KS2oKhKsTxw ▶️ https://www.youtube.com/watch?v=aFg44Cp6weE&t=5s ▶️ https://www.youtube.com/watch?v=84JCg8AY-Wo ▶️ https://www.youtube.com/watch?v=L4LvhqCgQ2s ▶️ https://www.youtube.com/watch?v=R-Qtvv3W8b8 ▶️ https://www.youtube.com/watch?v=yQmY9Ldv1bE ▶️ https://www.youtube.com/watch?v=Z0qzMFOHgpk ▶️ https://www.youtube.com/watch?v=U02BMj09Wio ▶️ https://www.youtube.com/watch?v=P753fee4kRU ================================= ✅ About ManufacTour. Ever wondered how your favorite products come to life? Welcome to ManufacTour! At ManufacTour, we take you behind the scenes to explore the fascinating step-by-step processes that bring all kinds of products into existence. From everyday essentials to groundbreaking technologies and intriguing innovations, we reveal manufacturing secrets like never before. Discover the “why” and “how” behind the most interesting creations. Get into the world of craftsmanship, precision, and creativity. Join us on a journey through the captivating manufacturing world, one process at a time. 🔔 Hit Subscribe to ManufacTour now and discover how everyday products and groundbreaking innovations are brought to life! https://www.youtube.com/@Manufactour/?sub_confirmation=1 ================================= 🔎 Related Phrases: Hashtags via ManufacTour https://www.youtube.com/channel/UC7jM-HeXkReUyl3y6oSU-3w April 01, 2025 at 08:00PM

#digitalmanufacturing#ai#manufactour#techinnovation#manufacturing#materialsscience#automotive#futuretech#Youtube

2 notes

·

View notes

Text

The wrathful awakening of a teenage Bruja

A sense of impeding doom XV -Leo & Breisa

Warnings: Cursing, monsters, near death experiences, fire, canon typical violence (not graphic), teenagers being teenagers, first heroic experiences

Word count: 4k words

Summary: Cyclops…Why did it have to be cyclops?

<<Prev

Next>>

—

Leo stopped at the door and tried to control breathing.

The voice of the earth woman rang in his ears, reminding him of that night. The last thing he wanted was to plunge into another dark warehouse.

Like he was eight years old all over again—alone, small, and helpless as people he cared about were trapped inside and in trouble.

“Oye, nada de eso.” Breisa said. “Don’t let her get to you. Alright? We got this.” She was shaking, but she held her own ground.

That didn’t make him any less scared. But it gave him enough courage– he breathed and creaked the door open.

Together they peered inside.

Nothing looked different.

Gray morning light filtered through the hole in the roof. A few light bulbs buzzed, but most of the factory floor was still covered in shadows.

But he was able to make out the catwalk above with shapes of heavy machinery along the assembly line, but no movement. No sign of his friends.

Leo almost called out, but something stopped him—a sense he couldn’t identify. Then he realized it was a smell.

Something smelled wrong—like burning motor oil and sour breath. Something not human was inside the factory.

Leo was certain. His body shifted into high gear, all his nerves tingling.

Somewhere on the factory floor, Piper’s voice cried out: “Leo, Breisa! help!”

Breisa held a finger to her lips. Her voice rang in his mind, ‘She couldn’t have gone off the catwalk. Not with a broken ankle.’

They slipped inside and ducked behind a cargo container.

Slowly, with weapons in hand, they inching toward the center of the room, hiding behind boxes and hollow truck chassis.

Finally, they reached the assembly line, crouched behind the nearest piece of machinery—a crane with a robotic arm.

Piper’s voice called out again: “Leo? Breisa?” Less certain this time, but very close.

They peeked around the crane.

Hanging directly above the other side of the assembly line was a massive truck engine—just dangling thirty feet up, as if it had been left there when the factory was abandoned.

Below it on the conveyor belt sat a truck chassis, and clustered around it were three dark shapes the size of forklifts.

Beside the forklifts dangling from chains, on another crane, were two smaller shapes—maybe more engines. One of them was wriggling around as if it were alive.

Breisa held a hand to her mouth to stifle a gasp.

Then one of the forklift shapes rose, and Leo realized it was a humanoid of massive size.

“Told you it was nothing,” the thing rumbled. Its voice was too deep and feral to be human.

The other forklift-sized lump shifted. It called out in Piper’s voice: “Leo, help me! Help—” Then the voice changed, becoming a masculine snarl. “Bah, there’s nobody out there. No demigods could be that quiet, eh?”

The first monster chuckled. “Probably ran away, if they know what’s good for them. Or the girl was lying about the demigods. Let’s get cooking.”

Snap.

A bright orange light sizzled to life—an emergency flare—and Leo was temporarily blinded. He ducked behind the crane until the spots cleared from his eyes.

‘Santa madre de los dioses.’ Breisa’s thoughts flood rushed him. She was still looking over the crane.

Then he took another peep and saw a nightmare scene.

The two smaller things dangling from the crane arm weren’t engines. They were Jason and Piper. Both hung upside down, tied by their ankles and cocooned with chains up to their necks.

Piper was wriggling around, trying to free herself. Her mouth was gagged, but at least she was alive.

Jason didn’t look so good. He hung limply, his eyes rolled up. A red welt the size of an apple had swollen over his left eyebrow.

On the conveyor belt, the bed of the unfinished pickup truck was being used as a fire pit. Which, from the smell of it, had been doused in kerosene.

A big metal pole was suspended over the flames—a spit, Leo realized.

‘They're gonna cook them alive!’ Breisa’s eyes stayed on the creatures as she gripped her weapon.

He looked at the creatures and almost choked.

They were most terrifying.

Monocle Motors: that single red eye logo.

Why hadn’t Leo realized?

Three massive humanoids gathered around the fire. Two were standing, stoking the flames. The largest one crouched with his backside facing Breisa and Leo. They were each ten feet tall, with hairy muscular bodies and skin that glowed red in the firelight. One of the monsters wore a chainmail loincloth that looked really uncomfortable.

The other wore a ragged fuzzy toga made of fiberglass insulation, which also would not have made Leo’s top ten wardrobe ideas.

The two monsters could’ve been twins. Each had a brutish face with a single eye in the center of his forehead.

The cooks were Cyclopes.

Leo felt his legs shaking. He’d seen some weird things so far—storm spirits, magic girls, winged gods, and a metal dragon that liked Tabasco sauce.

But this was different.

These were actual, flesh-and-blood, ten-foot-tall living monsters who wanted to eat his friends for dinner.

He was so terrified he could hardly think.

If only they had Festus. They could use a fire-breathing sixty-foot-long tank about now.

But all he had was a tool belt and a backpack. His three-pound club hammer looked awfully small compared to those Cyclopes. No better than Breisa’s ax— a mere kitchen knife.

This is what the sleeping earth lady had been talking about. She wanted Leo to walk away and leave his friends to die.

That decided it. No way was Leo going to let that earth lady make him feel powerless—never again. Leo slipped off his backpack and quietly started to unzip it.

The Cyclops in the loincloth walked over to Piper, who squirmed and tried to head-butt him in the eye.

She was fierce, even in the worst possible situation— Breisa respected that.

“Can I take her gag off now? I like it when they scream.”

The question was directed at the third Cyclops, apparently the leader. The crouching figure grunted, and Loincloth ripped the gag off Piper’s mouth.

She didn’t scream. She took a shaky breath like she was trying to keep herself calm.

Meanwhile, Leo found what he wanted in the pack: a stack of tiny remote control units that he founded in bunker 9.

‘'¡¿Qué estás haciendo?!’ Breisa telepathically asked.

‘Improvising’ He remarked–feeling around the robotic crane and propped open a maintenance panel.

He slipped a screwdriver from his tool belt and went to work, but he had to go slowly.

The leader Cyclops was only twenty feet in front of him. The monsters obviously had excellent senses.

Pulling off his plan without making noise seemed impossible, but he didn’t have much choice.

‘Keep an eye out or something.’

‘This is crazy.’ She grumbled but kept her ax ready.

The Cyclops in the toga poked at the fire, that billowed noxious black smoke into the ceiling.

His buddy Loincloth glowered at Piper, waiting for her to do something entertaining. “Scream, girl! I like funny screaming!”

When Piper finally spoke; her tone was calm and reasonable, like she was scolding a naughty puppy. “Oh, Mr. Cyclops, you don’t want to kill us. It would be much better if you let us go.”

Loincloth scratched his ugly head. He turned to his friend in the fiberglass toga.

“She’s kind of pretty, Torque. Maybe I should let her go.”

Torque, the dude in the toga, growled. “I saw her first, Sump. I’ll let her go!”

Sump and Torque started to argue. But then the third Cyclops rose and shouted, “Fools!”

Leo almost dropped his screwdriver. Breisa's ax slipped.

The third Cyclops was a female.

She was several feet taller than Torque or Sump, and even beefier. She wore a chain mail-like sack dress that Leo’s crazy mean Tía Rosa used have—a muumuu.

Her greasy black hair was matted in pigtails, woven with copper wires and metal washers. Her nose and mouth were thick— and mashed together, like she spent her free time ramming her face into walls; but her single red eye glittered with evil intelligence.

The woman Cyclops stalked over to Sump and pushed him aside, knocking him over the conveyor belt. Torque backed up quickly.

“The girl is Venus spawn,” the lady Cyclops snarled. “She’s using charmspeak on you.”

Piper started to say, “Please, ma’am—”

The lady Cyclops grabbed Piper around the waist. “Don’t try your pretty talk on me, girl! I’m Ma Gasket! I’ve eaten heroes tougher than you for lunch!”

‘Probably more than heroes.’ Breisa thought.

Leo grumbled ‘Shut up. Genius at work here.”

With furious concentration, he was able to twist wires and turn switches: hardly thinking about what he was doing. He finished attaching the remote. Then he crept over to the next robotic arm, Breisa following beside him, as the Cyclopes were talking.

“—eat her last, Ma?” Sump was saying.

“Idiot!” Ma Gasket yelled, and Leo realized Sump and Torque must be her sons. If so, ugly definitely ran in the family. “I should’ve thrown you out on the streets when you were babies, like proper Cyclops children. You might have learned some useful skills. Curse my soft heart that I kept you!”

“Soft heart?” Torque muttered.

“What was that, you ingrate?”

“Nothing, Ma. I said you got a soft heart. We get to work for you, feed you, file your toenails—”

Ugh Breisa gagged mentally

“And you should be grateful!” Ma Gasket bellowed. “Now, stoke the fire, Torque! And Sump, you idiot, my case of salsa is in the other warehouse. Don’t tell me you expect me to eat these demigods without salsa!”

“Yes, Ma,” Sump said. “I mean no, Ma. I mean—”

“Go get it!” Ma Gasket picked up a nearby truck chassis and slammed it over Sump’s head. Sump crumpled to his knees.

Both Leo and Breisa winced at the sound, but Sump apparently got hit by trucks a lot. He managed to push the chassis off his head. Then he staggered to his feet and ran off to fetch the salsa.

‘Now’s the time’, Leo thought. ‘While they’re separated.’

‘On it.’ Breisa sheathed her ax on her belt loops.

‘What are you—?’ He huffed as finished wiring the second machine.

‘Improvising.’ She looked at any opening between robotic cranes or Cyclopes— and she spotted it! ‘I got Piper and Jason.’

Breisa crept behind the robotic arms onto the stacks of crates. She climbed and jumped quietly onto each stack, from a distance it looked like stairs.

Leo realized she was aiming for the catwalk.

He then dashed between robotic arms, the Cyclopes didn’t see him, but Piper did. Her expression turned from terror to disbelief, and she gasped.

Ma Gasket turned to her. “What’s the matter, girl? So fragile I broke you?”

Thankfully, Piper was a quick thinker. She looked away and said, “I think it’s my ribs, ma’am. If I’m busted up inside, I’ll taste terrible.”

Ma Gasket bellowed with laughter. “Good one. The last hero we ate— remember him, Torque? Son of Mercury, wasn’t he?”

“Yes, Ma,” Torque said. “Tasty. Little bit stringy.”

“He tried a trick like that. Said he was on medication. But he tasted fine!”

“Tasted like mutton,” Torque recalled. “Purple shirt. Talked in Latin. Yes, a bit stringy, but good.”

Leo’s fingers froze on the panel. Breisa halted on the bars, hanging low from the catwalk.

Apparently, Piper was having the same thought, because she asked, “Purple shirt? Latin?”

“Good eating,” Ma Gasket said fondly. “Point is, girl, we’re not as dumb as people think! We’re not falling for those stupid tricks and riddles, not us northern Cyclopes.”

Leo forced his focus back on the panel, but his mind was racing. A kid who spoke Latin had been caught here—in a purple shirt like Jason’s? That could everything or nothing at all, but he had to leave the interrogation to Piper.

If he was going to have any chance of defeating these monsters, he had to move fast before Sump came back.

He looked up seeing Breisa doing a pull-up onto the walk, laying flat for balance.

She crawled on belly—trying not to be seen— to the cocoon chains.

Leo noticed a few inches away from the catwalk an engine was hanging right above the Cyclopes’ campsite. He wished he could use that—it would make a great weapon.

But the crane holding it was on the opposite side of the conveyor belt.

There was no way Leo could get over there without being seen, and besides, he was running short on time. He hoped Breisa could reach Jason and Piper before him.

From above he heard a creeek then the metal piece fell right beside him with a clang!

Leo was out of the way, luckily— the metal rod would have impaled him from the back.

What the fuck is she doing?!

He glanced again— the catwalk swaying sideways. Breisa gripping onto the railing for dear life, holding herself with shaky strength.

The Cyclopes started to look up to the sound of rattling chains.

“This place is falling apart! Luckily you northern cyclopes are keeping it in good working condition!” Piper kept talking, laying on the praise. “Oh, I’ve heard about the northern Cyclopes!” Which Leo figured was bull, but she sounded convincing. “I never knew you were so big and clever!”

That was enough for Breisa to lean herself from the walk onto rusted crane. She skidded across like she was on monkey bars. Hanging right where the metal cocoons were linked.

“Flattery won’t work either,” Ma Gasket said, though she sounded pleased. “It’s true, you’ll be breakfast for the best Cyclopes around.”

“But aren’t Cyclopes good?” Piper asked. “I thought you made weapons for the gods.”

“Bah! I’m very good. Good at eating people. Good at smashing. And good at building things, yes, but not for the gods. Our cousins, the elder Cyclopes, they do this….”

Leo tuned out mothermae-eye, as he could faintly hear Breisa spewing out a prayer.

‘Please Hecate don't let them see me. For the love of god. Or whatever weirdos in the sky. Or the universe, if anyone is listening to me— let me stay hidden to them.’

As the trickiest part of the plan was nearly done, Leo summoned some wires, a radio adapter, and a smaller screwdriver from his and started to build a universal remote.

For the first time, he said a silent thank-you to his dad—Hephaestus—for the magic tool belt.

Get me out of here, he prayed, and maybe you’re not such a jerk.

“—Titans lost. No good! No more need for Cyclops weapons.”

“Oh, no,” Piper sympathized. “I’m sure you made some amazing weapons.”

Torque grinned. “Squeaky war hammer!” He picked up a large pole with an accordion-looking metal box on the end.

He slammed it against the floor and the cement cracked, but there was also a sound like the world’s largest rubber ducky getting stomped.

“Terrifying,” Piper said.

Torque looked pleased. “Not as good as the exploding ax, but this one can be used more than once.”

“Can I see it?” Piper asked. “If you could just free my hands—”

Torque stepped forward eagerly, but Ma Gasket said, “Stupid! She’s tricking you again. Enough talk! Slay the boy first before he dies on his own. I like my meat fresh.”

No! Leo’s fingers flew, connecting the wires for the remote. Just a few more minutes!

“Hey, wait,” Piper said, trying to get the Cyclopes’ attention. “Hey, can I just ask—”

The wires sparked in Leo’s hand.

Breisa was half-way down the chains, on Jason's side since he was farther away. She halted mid-climb.

The Cyclopes froze and turned in his direction. Then Torque picked up a truck and threw it at him.

Leo rolled as the truck steamrolled over the machinery. If he’d been a half-second slower, he would’ve been smashed.

Breisa breathed a sigh of relief as he got to his feet, she thought he had gotten crushed. Hell he would’ve exploded into chunks, on a count of how small he was.

Ma Gasket spotted him. She yelled, “Torque, you pathetic excuse for a Cyclops, get him!”

Torque barreled toward him. Leo frantically gunned the toggle on his makeshift remote.

Torque was fifty feet away. Twenty feet.

Then the first robotic arm whirred to life. A three-ton yellow metal claw slammed the Cyclops in the back so hard, he landed flat on his face. Before Torque could recover, the robotic hand grabbed him by one leg and hurled him straight up.

“AHHHHH!” Torque rocketed into the gloom. The ceiling was too dark and too high up to see exactly what happened, but judging from the harsh metal clang, Leo guessed the Cyclops had hit one of the support girders.

Torque never came down. Instead, yellow dust rained to the floor. Torque had disintegrated.

Ma Gasket stared at Leo in shock. “My son ... You ... You ...”

As if on cue, Sump lumbered into the firelight with a case of salsa. “Ma, I got the extra-spicy—”

He never finished his sentence.

Breisa came down screeching out swears, using Jason as a tire swing. Not exactly strategic with her attack but managed a couple of sharp slashes with her Ax—throwing a kick into Sump.

The salsa case crashed into his chest and Sump flew backward, right into the base of Leo’s third machine. Sump may have been immune to getting hit with truck chassis, but he wasn’t immune to robotic arms that could deliver ten thousand pounds of force.

Leo spun the remote’s toggle, and the second robotic arm whacked Sump again.

The third crane arm slammed him against the floor so hard, he exploded into dust like a broken flour sack.

Two Cyclopes down.

Leo was beginning to feel like Commander Tool Belt—- when Ma Gasket glanced around, not even noticing Breisa, and locked her eye on him.

She grabbed the nearest crane arm and ripped it off its pedestal with a savage roar. “You busted my boys! Only I get to bust my boys!”

Leo punched a button, and the two remaining arms swung into action.

Ma Gasket caught the first one and tore it in half. The second arm smacked her in the head, but that only seemed to make her mad. She grabbed it by the clamps, ripped it free, and swung it like a baseball bat.

It missed Piper and Jason by a hair— luckily Breisa used all the force she could swing the three of them out of the way.

Then Ma Gasket let it go—spinning it toward Leo. He yelped and rolled to one side as it demolished the machine next to him.

Leo started to realize that an angry Cyclops mother was not something you wanted to fight with a universal remote and a screwdriver.

The future for Commander Tool Belt was not looking so hot.

She stood about twenty feet from him now, next to the cooking fire. Her fists were clenched, her teeth bared. She looked ridiculous in her chainmail muumuu and her greasy pigtails—but given the murderous glare in her huge red eye and the fact that she was twelve feet tall, Leo wasn’t laughing

“Any more tricks, demigod?” Ma Gasket demand with sneering.

Leo glanced up.

The engine block suspended on the chain—if only he’d had time to rig it. If only he could get Ma Gasket to take one step forward.

The chain itself ...that one link...Leo shouldn’t have been able to see it, especially from so far down, but his senses told him barely hanging on.

“Heck, yeah, I got tricks!” Leo raised his remote control. “Take one more step, and I’ll destroy you with fire!”

Ma Gasket laughed. “Would you? Cyclopes are immune to fire, you idiot. But if you wish to play with flames, let me help!”

She scooped red-hot coals into her bare hands and flung them at Leo. They landed all around his feet.

“You missed,” he said incredulously.

Then Ma Gasket grinned and picked up a barrel next to the truck.

Leo just had time to read the stenciled word on the side—kerosene—before Ma Gasket threw it.

The barrel split on the floor in front of him, spilling lighter fluid everywhere.

Coals sparked. Leo closed his eyes.

Piper and Breisa screamed.

“No!”

“Look out!”

A firestorm erupted around him. When Leo opened his eyes he was bathed in flames swirling twenty feet into the air.

Ma Gasket shrieked with delight, but Leo didn’t offer the fire any good fuel. The kerosene burned off, dying down to small fiery patches on the floor.

Piper gasped. Breisa’s jaw dropped. “Leo?”

Ma Gasket looked astonished. “You live?” Then she took that extra step forward, which put her right where Leo wanted. “What are you?”

“The son of Hephaestus,” Leo said. “And I warned you, I’d destroy you with fire.”

He pointed one finger in the air and summoned all his will. He’d never tried to do anything so focused and intense—but he shot a bolt of white-hot flames at the chain suspending the engine block above the Cyclops’s head— aiming for the link that looked weaker than rest.

The flames died. Nothing happened. Ma Gasket laughed. “An impressive try, son of Hephaestus. It’s been many centuries since I saw a fire user. You’ll make a spicy appetizer!”

The chain snapped—that single link heated beyond its tolerance point— and the engine block fell, deadly and silent.

“I don’t think so,” Leo said.

Ma Gasket didn’t even have time to look up.

Smash! No more Cyclops; just a pile of dust under a five-ton engine block.

“Not immune to engines, huh?” Leo said. “Boo-yah!”

Then he fell to his knees, his head buzzing.

—

After a few minutes he felt someone grab his shoulders, pull him up, and shake him furiously.

“Gonna hurl.” He blurbed, his stomach feeling queasy.

“Don’t do something stupid like that again!” Breisa shouted. “You scared me!” She had stopped shaking him. Checking him for burns or mark— just something serious.

Only his clothes had small singed marks. Some irritated callous on his hands. He need to change the bandage from the canyon incident.

“You worried about lil ole me?” Leo grinned with a sideways smile.

“You’re an idiot.” She huffed, and let him go.

“Leo! Are you alright? Can you move?” Piper called from behind her. She was freed from her chains. Breisa’s doing definitely.

He stumbled to his feet. He’d never tried to summon such an intense fire before, and it had left him completely drained.

Then together they lowered Jason, who was still unconscious. Piper managed to trickle a little nectar into his mouth, and he groaned. The welt on his head started to shrink. His color came back a little.

“Yeah, he’s got a nice thick skull,” Leo said. “I think he’s gonna be fine.”

“He can’t lose anymore of his memory.” Breisa pulled back his eyelid, trying to see his pupils. “He should be alright.”

“Thank god,” Piper sighed. Then she looked at Leo with something like fear. “How did you—the fire—have you always ... ?”

Leo looked down. Breisa waited for an excuse or a denial or some kind of lie.

“Always,” he said instead. “I’m a freaking menace. Sorry, I should’ve told you guys sooner but—”

“Sorry?” Piper punched his arm. When he looked up, she was grinning. “That was amazing, Valdez! You saved our lives. What are you sorry about?”

Leo blinked. Then looked at Breisa in disbelief.

“She’s right, you know. You saved us.” She shrugged with a smile, “It was kind of awesome.”

“You saved us too.” Piper bumped her elbow. “Like mission impossible. Freaking amazing.”

Breisa blushed, above them a light bulb exploded. “Ah! Oh my bad! I didn’t know I could do that.”

Leo started to smile; but his sense of relief was ruined when he noticed something next to Piper’s foot.

Yellow dust—the powdered remains of one of the Cyclopes, maybe Torque—was shifting across the floor like an invisible wind was pushing it back together.

“They’re forming again,” Leo said. “Look.”

Piper stepped away from the dust. “That’s not possible. Annabeth told me monsters dissipate when they’re killed. They go back to Tartarus and can’t return for a long time.”

“Well, nobody told the dust that.” Breisa watched as it collected into a pile, then very slowly spread out, forming a shape with arms and legs.

“Oh, god.” Piper turned pale. “Boreas said something about this—the earth yielding up horrors. ‘When monsters no longer stay in Tartarus, and souls are no longer confined to Hades.’ How long do you think we have?”

Leo thought about the face that had formed in the ground outside—the sleeping woman who was definitely a horror from the earth.

“I don’t know,” he said. “But we need to get out of here.”

__

(A/N: I said I would finish this April, but school burning me out. Almost a graduate! One more month! In the mean time I will try to post as much chapters as possible. Story is finally picking up as I wanted it :)) Hope you all like this one!)

#leo valdez#leo valdez x reader#leo valdez x oc#leo valdez x fem! reader#spanish speaking oc#poc oc#latino oc#hoo#heroes of olympus#lost hero#jason grace#piper mclean#pjo tumblr#pjo#percy jackson#pjo hoo toa#pjo fandom#pjo universe#pjo ocs#hecate cabin#hephaestus cabin#aphrodite cabin#zeus cabin#breisa alessandro#hoo fic#camp half blood#pjo fic

19 notes

·

View notes

Text

what has been happening in the world of motorsports?

there is a massive list under the cut, so although i already deleted a lot of it which was not that relevant or important, open on your own risk (key topic of each is in bold)

Guenther Steiner became the official F1 Ambassador of Miami GP this year

Silverstone GP announced their line up for the music show during the race weekend (truthfully i only heard about Olly Murs), Miami GP did the same btw with Ed Sheeran headlining the show (or at least being the only one I know)

Williams repaired the chassis (that can add up to 7 kgs) and managed to fit on Logan's car being only 100 grams heavier. They don’t expect to have a new chassis ready till Miami.

Alpine and RB are other two teams confirmed not to have spare chassis (Bruno Famin said it during the team principals’ press conference and Mekies said they need to see if Daniel is doing bad or if there is something wrong with the car, so they will wait till China for a new chassis and give it to Daniel first).

the problem that Max experienced in Australia was not directly related to BREMS brake system aka the same brand that already started an investigation to Charles' brake issue in Bahrain, our comm the gossiper he is, said that this one is on the Red Bull crew and the way they assembled the right rear brake duct

There have been some rumours coming from New Zealand media that Daniel Ricciardo has been given an ultimatum to start performing in next two races otherwise he could get replaced by Liam Lawson, looks like that was either started by a source close to Liam to put pressure on Daniel or it has been an incorrect translation/misinterpretation of what Helmut Marko said

Marko confirmed that Ayumu Iwasa will be replacing Daniel in FP1 in Japan (Ayumu is a Japanese driver in Red Bull junior academy who drove in F2 last year and changed over to Super Formula this year), Yuki also hinted at this in the post race interview in Australia but then stopped himself, saying he is not allowed to share that yet

But concerning Daniel, while Marko demented the quote about two races left to prove himself, he didn't rule out the possibility of Daniel being replaced mid-season

Honda opened up a new base for their engines in the UK

Toto Wolff told Fox News Australia more details of how Lewis announced his move to Ferrari to him over a coffee and how he warned Lewis to look closely at Mercedes rear wing because that's a perspective he will have starting with the new season

David Sanchez hired for McLaren at the end of last season from Ferrari has been fired (or “leaves the team after mutual agreement from both sides about his misalignment”). They didn't agree on his job position, so he leaves after 3 months. Emanuele Pirro also left McLaren from the role of head of McLaren’s junior academy (there was no apparent reason for this stated, like in David’s case) after one year only.

It seems like Charles will be opening an ice cream parlour LEC in Milan. Press con / grand opening is supposed to be around 10th/11th April, so that’s when we will learn more pieces of information, probably. So far we know it will be with Federico Grom and Guido Martinetti, who founded an ice cream shop chain in Italy.

Max’s chief mechanic Lee Stephenson will be working for Sauber from now on as he ended his journey with Red Bull after Australia.

Toto Wolff spoke again about the replacement of Lewis in Mercedes in 2025 and mentioned he wants to get it sorted around the summer and reminded that Max is on his shortlist. There are rumours about most of Mercedes employees being interested in getting Max in the team and into the ambassador role for them. Also, a side note: Toto originally wasn’t meant to be at this GP but changed plans last minute for unknown reasons.

Liberty Media bought MotoGP commercial rights (for a similar amount as they did with F1: 4,2 billion Euro). The championship is in a similar position where F1 was, and they want to try to put more spotlight on it and bring the fans like they did with F1.

Honda is opening a new engine factory in the UK in preparation for the Aston Martin partnership starting with 2026.

A Japanese billionaire built a private circuit for 180 mil Euro, and it was Herman Tilke’s team who designed it (it is only available for teams of prestigious Magarigawa club).

There was a rumour in the media a few days ago that Aston Martin approached Adrian Newey with a huge financial offer in Jeddah and are just waiting for the answer, however Mike Krack said to media in Suzuka that is not the case and they are happy with their team so they didn’t even need to make any offers in the first place. (Although the rumour has been reported by pretty reliable sources that said it was Lawrence Stroll himself who approached him.)

There was a slight change in the rules concerning tyres for this year and that caused the lack of running in FP2. There was a rule that if Friday sessions are declared as wet, the teams have a selection of 5 intermediate tyre sets and 2 wet ones. However, there used to be a rule of additional intermediate set of tyres being available for Friday if it rained, which would then have to be given back to Pirelli, but that rule isn’t applied this year. This is why teams decided to save tyres for Sunday, in case they are needed (and they will be according to some weather predictions).

Australian GP saw the most fans over the weekend in their history, the official numbers state 452 thousand of fans.

in Australia: Checo had a tear off stuck in his car, Lewis’ issue was reliability concern and the damage to the engine was terminal so he had to take a new one, Fernando was handed an after race 20s penalty for the incident with George, Este was another one with a tear off issue

After Ben Sulayem was cleared of the allegations of trying to mess up with the race results or the accreditation of individual circuits, he came out to say they are despicable moves against him, just trying to discredit him. In support, the US group of FIA club members wrote an open letter than they stand behind him, that he has their support in the decisions and also that they suggest to take legal action against people who were the ones to complain to the ethic committee.

Seb has been vocal over the last days to promote a new drink Perple (but he spoke about a lot of current f1 topics). Speaking of potential comeback, Porsche apparently postponed the announcement of their Le Mans lineup (was meant to be on 28th March) and he named the car he tested with, so there is a high possibility of him driving. He covered 118 laps, and I didn’t find any times comparison but there is a report that they were impressive.

FIA Prize Giving for 2024 will be held in Kigali in Rwanda on 13th December this season – first time ever for this country.

Pierre started a new line of his own merch with his own face on it from karting days and there has been quite some talk about that move copying Lewis’ significant merch (I like to shit on Pierre but personal opinion: this is really NOT that deep and Lewis doesn’t actually have a trademark for this kind of merch). Yuki is releasing new line too and there is a lot of blue color which I appreciate. Guyanu made a partnership line with Lululemon. Lewis was a face of latest issue of GQ and ate that photoshoot.