#project3final

Explore tagged Tumblr posts

Text

Project 3

Research

We began the process with research. I looked at multiple portfolio sites including Jessica Hische and Erik Marinovich, Pentagram, and Carpenter Collective. Below are my takeaways from studying each site.

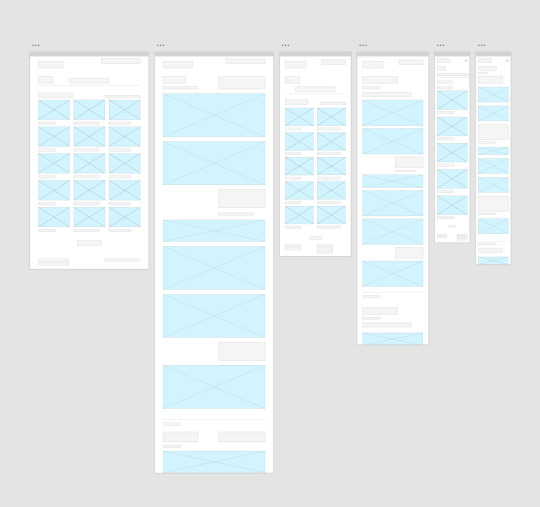

Top 3 Portfolio Site Wireframes

We then selected 3 sites to create wireframes for. I selected Jessica Hische, Pentagram, and Firebelly. I chose these 3 because I felt they were fairly different in style, and there were elements that I liked of each. I liked Hische’s process documentation, Pentagram’s neutral color scheme, and Firebelly’s simple/minimal presentation.

Hische:

Pentagram:

Firebelly:

My Static Wireframe

Gathering inspiration from the above wireframes, we next developed our own. My intended home page was strongly influenced by Carpenter Collective, and my project pages by Jessica Hische.

Inspiration

Carpenter Collective:

Jessica Hische

Interactive Wireframe

Below is the link to my interactive wireframe, which was based upon my static wireframe.

Link: https://mhennes3.github.io/project3/index.html

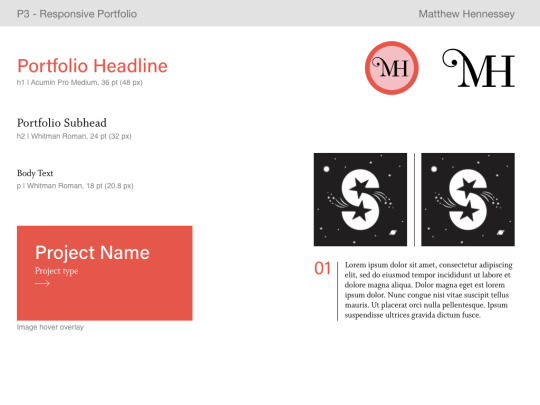

Style Tiles

The next phase of the process was making style tiles. I sought to use both a serif and san serif typeface in my design (one for headers and one for subheads/body text). I initially intended to use one color throughout my portfolio site, however I ultimately chose a unique color for each project page.

Tile 1:

Tile 2:

Tile 3:

Static Digital Layout

After style tiles, we moved on to construct static digital layouts (content included). It was also during this phase where I completed asset compilation. I chose 3 projects from Visual Communication Design 1. Although I had projects from other courses, I wanted to maintain the same style of process documentation throughout my site. This was easiest to accomplish with VCD1 projects.

Final Site

Below is a link to my final site. I was able to incorporate every intended element except one: the left-oriented header bar on my desktop-sized pages. As much as I tried to implement this, I was unable to master the code. I studied Carpenter Collective’s code itself, however I feel they may have used a template or other site to construct their portfolio. I will keep attempting to implement this feature, however I am still satisfied with how my site turned out.

Link: https://mhennes3.github.io/project3final/index.html

Other Assets:

Below is the logo that I created for my portfolio site. It changes color across project pages, and it links to the home page from my project pages, About Me page, and Resume.

1 note

·

View note

Video

vimeo

And Here I have the complete composition for all I did for Project 3!

Through this process I want to show 3 things, which are 3 words-Redundancy in obvious parts of the model, Unpleasantness conveyed through sound from the propeller and and Inviting feeling with which the wood use and the hand imprint on a wax platform should show. Perhaps an opposing quality to this as the motor produces, is a non-inviting, aggressive means of producing an unpleasant sound, such as to apply force to create a non pleasant sound.

I took to the project with a bit of “Iron man,” hand recognition kind of design, that iterated from being a standard platform press, platform destructive design, to an unpleasant sound provider. I wanted there to be an inviting feeling, but an unwelcome feeling, when you do put your hand on it.

So here’s how I did it:

I started off by 3d modelling a propeller, which I sourced off Sketchup’s 3d warehouse, and then I 3d printed this in blue spool. this was made to be about 10cm by 10 cm.

While this happened, I measured up a piece of strong timber that would be strong enough to hold the vibrations of the motor and the rotational inertia of the whole model. The measurement would be enough to hod two widths of MDF on either side, as well a hand’s width and length. Edges of the Timber were chiseled out to fit into the inversely cut MDF pieces.

Wedges of MDF were cut out to length and the inverted parts of these were removed so as to fit into the chiseled, inconsistent dovetail parts of the Timber. This part of the model, aimed to support the wax hand platform, whilst showing a contrast and connection between both wooden parts.

Another part of MDF was cut to act as a bridge between side frames, and to hoist the wax frame.

The wax platform was made using a tin foil, blue tack surrounded mold, placed on a bench top. 3 layers of wax were poured and as each layer set, I used a latex glove to set a hand imprint into the platform. Lines and areas were carved out of the wax, so they could sit nicely on the wood hoists. Another observation, was that as the wax cooled down into the foil mold, the mold shrunk and the wax platform curved up so as to provide a changeability on pressing the button.

Holes were drilled out of the timber to hold the button and the motor, so as the motor was placed close to the hoist. When the user places their hand on the platform, this will force the hoist down into the propeller, forcing one side to hit the propellor, while the other hits the wax platform.

0 notes

Text

Project 3 Final Revision - Light Up Christmas Jewelry Box

VIDEO LINK

The goal of this project was to revise one of my previous two projects while incorporating an advanced sensor with at least one input and one output. My original concept was a paper frame with a 3D picture created using paper cutouts from the Cricut machine. This was a highly art-focused project, with the electronic output being LED lights and sound. For the revision, I decided to make it Christmas-themed for the holidays. The final idea was a jewelry box that opens to reveal a paper Christmas village with lit houses and music.

I wanted to continue using LED lights to illuminate the village and add sound. Additionally, I wanted to experiment with a motor to create a little girl ice skating, reminiscent of the ballerina in classic jewelry boxes. For the interactive element, I initially planned to activate the box when it was flipped open, like traditional ballerina boxes. However, this proved challenging, so I opted to use a light sensor. The sensor was placed in the drawer area so that when someone opened the drawer to access their jewelry, the circuit board would detect light and activate the features.

Initial Design and Materials

I originally wanted to make the box entirely out of paper for customization and flexibility. However, I encountered difficulties designing a drawer and lid mechanism with paper. Additionally, the size of the box exceeded the capabilities of the Cricut machine. Fortunately, I found a suitable wooden box at Michael's, which served as the perfect base. The box’s top section was made of wood and cardboard, which could be easily removed and cut to accommodate wires. The bottom section was a simple wooden drawer.

Wrapping the Box

I wrapped the box with tan gift paper featuring white snowflakes to maintain a subtle wooden appearance without overwhelming color. Using an X-Acto knife, I precisely measured and cut the paper, gluing it on with Elmer's Glue. Every edge was carefully wrapped and smoothed to achieve a professional finish. Although this process was time-consuming, I was very pleased with the result.

Creating the Village

I used pre-made Cricut cutouts for some elements and customized others by uploading silhouette designs found online into the Cricut software. Once the pieces were cut, I painted them for added dimension. Initially, I tried dark colors but disliked the outcome. I switched to a soft watercolor effect, which added depth and a charming aesthetic to the project.

Assembling the Box

After painting and drying the components, I began assembly by cutting holes in the box for wires using an X-Acto knife.

Foldable Mechanism

Creating the foldable mechanism for the village was a challenge. My first attempt involved attaching the village to the lid using paper. However, the paper wasn’t strong enough to support the weight, causing the pieces to collapse. I reinforced the paper with a second layer, which worked temporarily but still looked unstable and cheap.

For the second attempt, I mounted the village on a cardboard panel and used small, folded paper strips as supports. These strips added layers to the village and allowed it to fold neatly when the box was closed and pop back up when opened.

I also experimented with 3D coils made of soldering metal and 3D-printed materials. Unfortunately, the coils were either too stiff or too flexible to function effectively.

Electronics and Code

Motor and LED Lights

Initially, I planned to use a linear actuator to mimic the girl skating across a pond. However, the actuator was too tight, damaging the ice skater. I instead programmed the motor to spin the girl in a circular motion, resembling a figure-eight pattern. The motor ran for 30 seconds after activation.

The LED lights were the same brand as my previous project, so I reused the original code and connected the LEDs using alligator clips.

Sound

I sourced sound from FreeSounds.org, edited it in Audacity to ensure compatibility with the circuit board, and integrated it into the code.

Light Sensor

the ciruct board with a built in light sensor was placed in the drawer area to detect when the drawer was opened. This triggered the lights, motor, and sound.

Final Assembly

I wrapped the inside of the drawer, as well as the base of the village and parts of the glass, in blue-silver wrapping paper to evoke a snowy contrast against the tan exterior.

Code

Code to say I wrote:

import time

import board

import pwmio

from analogio import AnalogIn

from adafruit_motor import servo

import digitalio

# Try importing the audio modules compatible with your board

try:

from audiocore import WaveFile

except ImportError:

raise ImportError("audiocore module not found on your board.")

try:

from audioio import AudioOut # Use audioio if available

except ImportError:

try:

from audiopwmio import PWMAudioOut as AudioOut # Fallback to audiopwmio

except ImportError:

raise ImportError("Neither audioio nor audiopwmio is available on your board.")

# Setup for light sensor on Pin A1

light_sensor = AnalogIn(board.A1)

# Setup for the speaker

spkrenable = digitalio.DigitalInOut(board.SPEAKER_ENABLE)

spkrenable.direction = digitalio.Direction.OUTPUT

spkrenable.value = True

# Load the sound file

wave_file = open("christmas.wav", "rb")

wave = WaveFile(wave_file)

# Audio output

audio = AudioOut(board.SPEAKER)

# Setup for rotation servo motor on Pin A2

pwm = pwmio.PWMOut(board.A2, frequency=50)

cont_servo = servo.ContinuousServo(pwm)

# Setup for fairy lights on Pin A5

light_pin = digitalio.DigitalInOut(board.A5)

light_pin.direction = digitalio.Direction.OUTPUT

# Function to get light level

def get_light_level():

return light_sensor.value # Returns a value between 0 and 65535

# Threshold for light detection (adjust based on environment)

LIGHT_THRESHOLD = 30000

# Variables to track servo and timer state

servo_running = False

start_time = 0

while True:

light_level = get_light_level()

print(f"Light level: {light_level}") # Debugging output

if light_level > LIGHT_THRESHOLD: # Light detected

print("Light detected! Turning on lights, starting servo, and playing sound.")

# Turn on fairy lights

light_pin.value = True

time.sleep(0.5) # Flashing effect

light_pin.value = False

time.sleep(0.3)

# Play sound if not already playing

if not audio.playing:

audio.play(wave)

# Start servo

if not servo_running:

cont_servo.throttle = 1.0 # Full speed forward

servo_running = True

start_time = time.monotonic() # Record the current time

# Check if 30 seconds have elapsed for servo

if servo_running and (time.monotonic() - start_time >= 30):

print("30 seconds elapsed. Stopping servo.")

cont_servo.throttle = 0.0 # Stop the servo

servo_running = False # Reset state

# Ensure lights are off if no light is detected

if light_level <= LIGHT_THRESHOLD:

light_pin.value = False

time.sleep(0.1) # Small delay for loop stability

Final Product

Here is a video: VIDEO LINK

0 notes

Text

Project 3 Idea

Interactive Christmas Jewelry Box

Features:

LED Lights

Person Moving (Skating)

Sound (Music)

Activation: Lights and sound are triggered when the drawer is opened (using a light sensor).

Linear Actuator: Utilizes a 3D-printed actuator from Thingiverse.

Notes:

May need to connect power and ground to the breadboard.

To-Do List:

Design: Plan the layout and design for the village inside the jewelry box.

Build the Box: Include a drawer and allocate space for movement and lighting components.

Mechanics: Develop foldable mechanisms for smooth operation.

Cut and Color: Prepare, cut, and decorate the components.

Lighting System: Ensure LED lights function correctly.

Motor Operation: Configure and test the motor for movement.

Custom Sound: Implement a sound system for personalized music.

Light Sensor: Test and confirm the sensor's functionality.

Breadboard (Optional): Assemble circuits if needed.

Final Assembly: Put all components together.

Testing: Run thorough tests to ensure all features work seamlessly.

0 notes