#prototype PCB assembly services

Explore tagged Tumblr posts

Text

PCB Manufacturing in Toronto: Expertise, Services, and Local Industry Insights

Discover PCB manufacturing in Toronto, a hub of innovation and quality in electronic manufacturing services. Learn about the specialized capabilities, technological advancements, and diverse offerings of PCB manufacturers Toronto. Explore how local expertise and cutting-edge facilities contribute to producing high-quality printed circuit boards for various industries and applications worldwide. For more details visit our website www.crimpcircuits.com

#pcb manufacturing toronto#printed circuit board design#metal clad pcb#printed circuits#rigid flex pcb#full turnkey pcb services#turnkey pcb services#pcb parts#eagle software#pcb designing#flexible pcb#pcb assembly#printed circuit board manufacturers#pcb manufacturers in canada#circuit board manufacturers in canada#pcb quote#pcb prototype services in canada

2 notes

·

View notes

Text

HIGH-QUALITY PCB MANUFACTURING & ASSEMBLY SERVICES IN AUSTIN, USA

East/West Manufacturing Enterprises specializes in high-precision Printed Circuit Board (PCB) Assembly Services, offering reliable and cost-effective solutions for various industries. As a leading PCB assembly manufacturer in Austin, we provide comprehensive services from prototype development to high-volume production, ensuring seamless integration and superior product quality.

Our end-to-end solutions cater to businesses requiring PCB manufacturing and assembly with fast turnaround times, rigorous quality control, and customized production capabilities to meet unique customer needs.

We understand that product quality is paramount, and must be matched with on-time delivery and low cost. East/West specializes in NPI for small to mid-volume orders, while offering customers a path to full production.

#prototype development#East/West Manufacturing Enterprises#Printed Circuit Board Assembly Services#(PCB) Assembly Services

0 notes

Text

What the Future May Have in store for printed circuit board fabrication

The future of electronics is closely tied to innovations in PCB manufacturing company processes, where precision, speed, and customization are becoming key. As technology evolves, companies are investing in smarter solutions to streamline production, meet higher demands, and support rapid development for a range of electronic devices across industries.

Innovation and Speed in PCB Assembly

Modern advancements in Quick-turn PCB assembly are reshaping how we think about electronics production. As demand rises for faster delivery and higher accuracy, manufacturers are incorporating automated systems and AI-driven design to reduce lead times without compromising quality. This evolution is especially critical for printed circuit board fabrication, where reducing time-to-market is a competitive advantage. Connected to this is the growing need for reliable PCB prototype service that ensures these PCB circuits are ready for scaled manufacturing. Businesses now rely on partners that can deliver agility and consistency.

Searching for cutting-edge PCB solutions. Bay Area Circuits offers a suite of services tailored to meet modern demands from prototyping to full-scale production with unmatched precision. Visit their website to explore their services.

To continue reading, Click here - https://bayareacircuits.blogspot.com/2025/04/what-future-may-have-in-store-for.html

#PCB manufacturing company#PCB prototype service#Quick turn PCB assembly#printed circuit board fabrication

0 notes

Text

Efficient PCB Prototype Assembly Service for Seamless Production

In the realm of electronics manufacturing, efficiency is paramount. From concept to production, every step must be optimized to ensure seamless execution and timely delivery. At Absolute Electronics, we understand the importance of efficiency, which is why we offer a PCB prototype assembly service designed to streamline your production process and accelerate your time to market.

Streamlined Production Process

Absolute Electronics takes pride in its streamlined production process, which is meticulously designed to minimize lead times and maximize efficiency. From the moment your PCB prototypes are ready for assembly, our team springs into action, leveraging advanced equipment and expert craftsmanship to assemble your circuits with precision and speed. By eliminating unnecessary delays and bottlenecks, we ensure that your prototypes are ready for testing and evaluation in record time.

Expert Assembly Techniques

Assembly is where the vision of your PCB prototypes comes to life, and at Absolute Electronics, we leave no room for compromise. Our team of skilled technicians employs industry-leading assembly techniques to ensure that every component is placed with precision and soldered with care. Whether your prototypes require surface mount technology (SMT) or through-hole assembly, you can trust Absolute Electronics to deliver results that exceed your expectations.

Seamless Integration

Seamless integration is the hallmark of a successful PCB prototype assembly service, and Absolute Electronics excels in this regard. Our assembly process is designed to seamlessly integrate with your existing workflow, allowing for easy scalability and flexibility as your project evolves. Whether you require a small batch of prototypes for testing or a larger production run for market validation, Absolute Electronics has the capabilities to meet your needs with ease.

The Absolute Advantage

Choosing Absolute Electronics for your PCB prototype assembly needs offers numerous advantages. With our commitment to efficiency, reliability, and quality, we provide a service that goes beyond mere assembly—we provide a foundation for success. Our team of dedicated professionals is always on hand to offer guidance and support, ensuring that your prototypes are assembled to the highest standards and delivered on time, every time.

Experience the Absolute Difference

Innovation waits for no one, and with Absolute Electronics by your side, you can bring your ideas to life with confidence and efficiency. Experience the Absolute difference today and discover why we are the preferred choice for PCB prototype assembly services. With our expertise, dedication, and unwavering commitment to excellence, we empower innovators to turn their visions into reality, one circuit at a time.

0 notes

Text

#pcb assembly services#circuit board assembly#printed circuit assembly#printed circuit board design#electronic pcb#pcb fabrication and assembly#pcb production#pcb design service#pcb fabrication#pcb electronic#oem electronics manufacturing#pcb prototype us

0 notes

Text

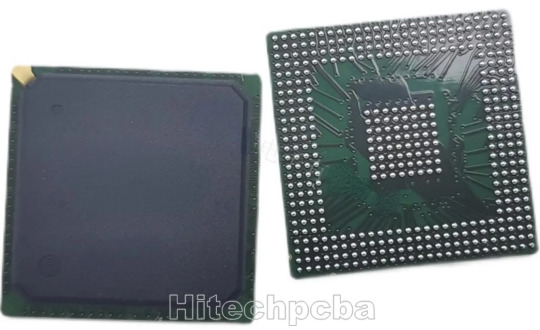

Circuit Board, PCB assembly & electronics manufacturing service provider from China (hitechcircuits.com)

What is a prototype PCB assembly?

PCB prototyping is the experimentation pilot stage of the product which is to be mass produced at a later stage. This is more of an experiment which is done after the initial discussions and the design. This offers a pre-production analysis of the boards that are to be manufactured, reducing the possible number of errors in the PCB design. PCB prototypes help the manufacturer analyze the strengths as well as weak areas of their proposed circuit boards. Prototypes also serve as a reference point for future versions of the same product. At Hitechpcba, we handle PCB prototype assembly in quantities from one to hundred printed circuit boards.

We have acquired capabilities that enable us to serve our clients better. All these years, we have worked on many complex prototype PCB assembly projects, and we believe the following capabilities have helped us serve our clients better.

Prototype PCB Assembly Services: We specialize in the following prototype printed circuit board assembly services.

SMT: We can provide single-sided and double-sided surface mount PCB assemblies in different specifications.

Plated Through Hole: We offer plated through hole assembly with selective soldering.

Mixed Assemblies: We often work on projects involving mixed assemblies – through-hole and SMT and electromechanical assemblies.

PCBA Testing: All the PCBA functional testing is performed in-house. Over the years, we have invested in various test fixtures and equipment, which helps us ensure the quality of PCBA. Currently, we provide the following types of PCBA testing services:

Flying probe testing for PCB

Functional testing including system and board-level testing

General PCB Assembly Capabilities: Our general PCB assembly capabilities are not limited to these:

RoHS, leaded or lead free, clean and no chemistries

PCB components including various types of QFNs, BGAs, 0105, 0201, 0804, and press fit components in small quantities.

What are the benefits of a prototype PCB assembly?

Prototype PCB assembly comes with several advantages. These benefits play a major role in the facilitation of your PCB manufacturing. Some of these benefits include:

Detection of Flaws Early

With prototype PCB, you will easily detect whatever flaws are present during the product’s development stages. This will allow you to solve the issues thereby saving you some money if you had gone ahead to make the production having the flaws in them.

If you go ahead to make changes during the production, there may be a need for more technicalities, and this may be expensive.

Testing of Each Component

With a prototype, you will be able to test all your system’s elements individually before you go ahead to set it up. You should do this because it is important especially for very complex projects composed of several parts that are PCB based.

When you validate each of these components, you will be able to identify those areas having issues that you should look into. This is the only way the project can function the right way.

Reduction in Total Costs

Utilizing the prototype bare PCB for any of your projects could go a long way in reducing what you’ll have spent in total for the project. With prototyping, you will be able to notice those errors in your project and then make corrections before you start the real production.

As soon as these flaws have been checked and rectified, then you may continue with the manufacturing of your Printed circuit boards in large quantities, thereby saving you unnecessary costs.

High-Quality PCBs

Why prototyping your PCB is important is to help you test if your project will function effectively. When we talk of testing, it involves the identification of errors present and then rectifying and making corrections to them.

Therefore, the eventual PCB after the prototyping will be of high quality that surely meets standards set internationally.

Less Turnaround Time

With prototype PCB assembly, you will be able to reduce the total time used in producing your printed circuit board. While making use of prototype printed circuit boards, you’ll be able to see the errors and then make corrections before you start the actual production.

Therefore, the eventual prototype will be free of defects. This implies that your PCBs will be produced quickly by your manufacturer.

What are the different types of prototype PCB assembly services you offer?

With years of market presence and experience, we specializes in the following prototype PCB assembly services.

Plated through-hole (PTH): We can provide the through-hole assembly with selective soldering.

Surface mount technology (SMT): We offer single-sided as well as double-sided SMT board assemblies in varied specifications.

Mixed Assemblies: Our experts often work on projects involving both PTH and SMT assemblies.

What are the types of testing Hitechpcba use for prototype PCB assembly?

Automated Optical Inspection (AOI): This is performed before and after the soldering to identify the component placement, presence, and solder quality.

X-ray Testing: In this type of testing, the operator relies on the X-ray images of the PCB to check the solder joints and lead-less components such as Quad Flat Packs and ball grid arrays, which are generally not visible to naked eyes.

In-Circuit Testing (ICT): This method is used to detect manufacturing defects by testing the electrical properties in the SMT Assembly.

These techniques help us ensure the reliability and accuracy of the circuit boards. In addition to this, it ensures a long operational life of equipment, minimal production losses, streamlined processes, and much more.

What are the capabilities Hitechpcba offer for prototype PCB assemblies?

We specialize in offering IPC compliant, and quick turn PCB assemblies. We are very particular about our scheduled deliveries and timelines, and we deliver without compromising the quality. Our PCBA capabilities are not limited to these. Here are some capabilities we offer through prototype PCB assemblies.

RoHS compliance

Stringent testing procedures

Device encapsulation

Full turnkey, partial turnkey, and kitted/consigned services

Assemblies using Surface Mount (SMT), Thru-hole, Mixed Technology (SMT/Thru-hole), Single and double-sided SMT/PTH, Large parts on both sides, BGA on both sides.

Do you perform a component analysis for prototype PCB assemblies?

Yes, we check the quality and performance of components before mounting them on the circuit boards. This is because a malfunctioning component can affect the performance of the entire circuit board assembly and also pose risks.

What is your standard turnaround time for a prototype PCB assembly?

Our turnaround time for standard applications is two weeks. This timeframe varies depending on the complexity of the applications. However, we are committed to offering quick turnaround times without compromising on quality, functionality, and accuracy, which offers our client a competitive advantage and reduced time to market. You can also request any emergency assistance or queries related to any type of PCB assembly. Our experts will assist you in all possible ways.

How is the cost of prototype PCB assembly estimated?

PCBA costing varies based on the different factors, such as PCBA parts, type of materials to be used, order quantity, and much more. We can also offer quotes and customization options once you share the detailed requirement with us.

We focus on quality and customer satisfaction over anything else. This has helped us build a long list of happy and satisfied customers. So, if you wish to partner with a manufacturer of prototype PCB assembly in China, then don’t hesitate to reach us. Our experts will assist you through all the phases of the prototype PCB assembly process. We look forward to making your experience with us better and memorable.

How to choose prototype pcb assembly manufacturer?

Our pcb prototype assembly service includes the sourcing of components. This allows you to concentrate on what you do best: layout design. We have a dedicated sourcing staff that coordinates with multiple suppliers and distributors to purchase electronic parts as per client requirements, and our staff completes these purchasing particulars in a most efficient manner. We have advanced processes for optimal selection of packaging (cut tape, tube, bulk, etc.) to reduce the total cost. Furthermore, we are capable of cross-referencing parts and even locating hard-to-find and obsolete parts. Customers can be rest assured that when Hitech Circuits substitutes components that they are high quality: we only use the electronic component numbers and manufacturers specified in the BOM. We will not modify your original layout design. Part substitutions take place only with your permission.

The final pcb prototype assembly service cost includes assembly labor charges, bare circuit board rates, and part costs. We understand the importance of prompt delivery. The sooner the components are sourced, the sooner we can begin circuit board fabrication. We thoroughly evaluate engineering inquiries and concerns related to the related parts with our clients before commencing circuit board assembly. The average time taken for pcb manufacturing assembly is about two weeks, which can be further reduced if there are no hard-to-locate components or documentation mistakes.

We have specialized experts to deliver fast turnarounds for prototype circuit board assembly with surface-mount (SMT), through-hole (THT) and mixed-technology components.

Anyone interested in electronics and electronic circuit boards needs to understand the various stages of developing and producing a printed circuit board. It can come in handy when you are seeking a top prototype smt assembly provider. The various production stages of printed circuit boards entail design, prototyping (prototype PCB development and rapid prototyping pcb assembly), and PCB high volume production. Different entities will always seek part of the whole production process depending on their electronic circuit board needs.

However, this article seeks to help you understand everything about prototype PCB assembly, a fundamental aspect of the PCB production process.

Rapid prototyping pcb assembly represents a fundamental phase of the printed circuit production process. It is also inferred as PCBA prototype assembly, SMT or surface-mount technology PCB prototype, PCB sample assembly, etc. From these alternative names, the meaning of prototype assembly regarding printed circuit boards becomes apparent. So what is assembly prototype?

PCB prototype assembly service is a fast prototype printed circuit board assembly primarily used to test fresh or new electronic designs. Consequently, it assists with checking and ensuring quality assurance of the PCB. For instance, it verifies that no bug exists in the test PCB, updates the design, and finds bugs. In most instances, prototype assembly of an electronic project will require two or three iterations to ensure everything is perfect.

Why Choose Hitech Circuits PCB Assembly for Your Prototype PCB Assembly Projects?

There are several PCB manufacturers specializing in prototype PCB assembly services. However, Hitech Circuits stands out owing to the following:

1.Strong Supply Chain: Over the years, we have built strong supply chain relationships in the industry, which helps us fulfill the requirements of turnkey prototype assembly services easily.

2.Fastest Turnaround Times: Our engineering expertise coupled with our understanding of industry requirements and a well-equipped facility enables us to assure the fastest turnaround times of 24-48 hours.

3.Reliability: All the printed circuit boards that we produce are IPC compliant, which helps us assure reliability.

4.Competitive Pricing and Quick Quote: Our supply chain relationships enable us to assure competitive prices. The cost of the PCB prototype assembly will be made available within 24-48 hours.

2 notes

·

View notes

Text

Printed circuit board manufacturing which is our major business, I think you already know, we are a PCB manufacturer. We have 3 branch factories dedicated to Quick Turn PCB Prototypes Manufacturing, Small and Medium-volume Printed Circuit Board, FPC Manufacturing services and PCB assembly services. Our market target is the High Multilayer PCB, High Density PCB, Flexible PCB, Rigid-flex PCB, Heavy copper PCB, Rogers PCB, Ceramic PCB and Special Materials Printed Circuit Boards.

Also, we can help customer sourcing components, wire PCB assembly and provide one-stop service.

Hitech Group is capable of providing full turn-key and partial turn-key PCB assembly services. For full turn-key, we take care of the entire process, including manufacture of Printed Circuit Boards, procurement of components, order tracking, continuous monitoring of quality and final board assembly. Whereas for partial turn-key, the customer can provide the PCBs and certain components, and the remaining parts will be handled by us.

4 notes

·

View notes

Text

Top Electronics Manufacturing Companies in Bangalore: Powering India’s Tech Future

India is fast becoming a global destination for high-quality, cost-effective electronics manufacturing. Backed by the government’s Make in India initiative and the Production Linked Incentive (PLI) scheme, the country is attracting global OEMs and startups alike looking for trusted, scalable EMS partners.

At the center of this shift is Bangalore — a city once synonymous with software, now transforming into a major hub for electronics manufacturing companies in India. With world-class engineering talent, cutting-edge infrastructure, and a growing cluster of EMS firms, Bangalore is enabling faster prototyping, smarter manufacturing, and reliable product delivery across sectors like telecom, automotive, IoT, aerospace, and medical devices.

Here are 10 top electronics manufacturing companies in Bangalore to watch in 2025:

🔹 Gemni Electro Corporation (GECor)

Established in 2008, GECor combines decades of experience in telecom, industrial electronics, and engineering consultancy. Today, it's a trusted EMS provider known for precision design, PCB assembly, and system integration.

🔹 LeePra Technologies Pvt. Ltd.

ISO 9001 and IATF 16949-certified, LeePra offers full-cycle electronics manufacturing — from BGA rework and SMT assembly to final box builds — supporting clients across automotive and industrial sectors.

🔹 Rantronics Technology

Rantronics delivers fast-turn PCBs, 3D-printed enclosures, and low-volume assembly services tailored for hardware startups and OEMs. Known for flexibility and speed, it's a preferred partner in IoT and embedded sectors.

🔹 ZREYAH Semiconductor Systems

With more than 15 years of experience, ZREYAH provides comprehensive EMS solutions — including PCB layout, prototyping, testing, and volume production — especially for aerospace and mission-critical industries.

🔹 Octane Circuits

From embedded systems to RF design and IoT hardware, Octane supports complete product development. Their expertise in both design and manufacturing makes them a key electronics partner for tech-forward companies.

🔹 Raghasai Technologies

A legacy name since 1987, Raghasai offers a complete suite of services: PCB layout, fabrication, assembly, and reverse engineering. Their longevity and reliability have made them a trusted player in India’s EMS space.

🔹 OMGVH Electronics

OMGVH supports full turnkey EMS — PCB assembly, soldering, testing, and functional validation — trusted by industrial control and automotive OEMs for its attention to quality and detail.

🔹 Micron EMS Tech

Ideal for high-mix, low-to-mid volume production, Micron EMS Tech delivers quick prototypes, reliable box builds, and flexible EMS solutions that meet the evolving needs of startups and midsize companies.

🔹 Nigama Circuits

With nearly two decades of experience, Nigama Circuits integrates PCB design, fabrication, and assembly under one roof. Known for competitive pricing and dependable turnaround times, it's a go-to for cost-conscious electronics manufacturing in India.

🔹 Confluence Circuits Pvt. Ltd.

A family-owned EMS provider catering to telecom, medical, automotive, and automation industries, Confluence offers PCB assembly, testing, and complete product build services for local and international clients.

Why Bangalore Is a Leading Electronics Manufacturing Destination in India

Skilled Workforce – Access to thousands of trained engineers in electronics, embedded systems, and design.

Strong Infrastructure – Government-backed electronics clusters and smart manufacturing parks.

Global Connectivity – Proximity to R&D centers, tech parks, and international logistics.

Collaborative Ecosystem – A strong network of OEMs, startups, and contract manufacturers drives innovation.

Quality & Certification – Most companies are ISO/IATF certified and meet international compliance standards.

💡 Final Thoughts

As global brands search for alternate supply chains and reliable EMS partners, India is rising fast as a competitive electronics manufacturing hub. Bangalore, in particular, is home to some of the most capable and quality-focused manufacturers in the country.

Whether you're looking for PCB prototyping, turnkey EMS, or full-scale product builds, these Bangalore-based companies reflect the best of electronics manufacturing company in India

#top 10 electronics manufacturing companies in Bangalore#electronics manufacturing#electronics manufacturing companies

0 notes

Text

Reliable PCB Assembly Silicon Valley Companies Can Count On

Building modern electronics requires more than just great design—it demands precision, process control, and a manufacturing partner you can trust. That’s why so many companies looking for PCB assembly Silicon Valley services turn to manufacturers with proven expertise, advanced facilities, and a solid track record.

At the center of Silicon Valley’s tech ecosystem, Absolute EMS has become a go-to provider for printed circuit board solutions. Whether you’re creating devices for medical, industrial, or defense markets, choosing a capable and responsive assembly partner is key to your success.

Leading Printed Circuit Board Assembly Silicon Valley Services

The demand for printed circuit board assembly Silicon Valley services has increased significantly in recent years due to the rise in compact, complex devices. From smart medical wearables to advanced defense systems, every product starts with a reliable and high-quality PCB.

Absolute EMS stands out by offering full-service assembly built around accuracy, speed, and compliance. Their factory is fully owned, which allows them to control overhead and reinvest in the latest technology — giving clients faster lead times and higher-quality builds.

Learn more about their offerings by visiting this page: PCB assembly Silicon Valley

Why Tech Companies Prefer Absolute EMS

Located in Santa Clara, Absolute EMS is a trusted partner for many leading OEMs across different industries. With over two decades of experience and some of the most advanced equipment in the EMS space, they offer:

ISO 13485 and AS9100D certified processes

Cleanroom capabilities for sensitive builds

Fast turnarounds for both prototypes and production

Strong expertise in miniaturization and tight tolerances

Full service—from PCB layout to system integration

With this end-to-end approach, companies can scale production confidently without worrying about quality issues or communication delays.

Industries Served

Absolute EMS supports a wide range of industries that demand strict quality and reliability standards:

Medical Devices – where quality and safety come first

Defense Electronics – where traceability and control are mandatory

Industrial Systems – where durability and consistency matter

Networking Equipment – where performance and uptime are critical

No matter the market, the goal remains the same: dependable electronics that meet today’s rigorous standards.

FAQs

Q1. What types of PCB assemblies do you handle? Absolute EMS can handle surface mount, through-hole, and mixed technology assemblies, including high-density and miniaturized boards.

Q2. Can you assist with design and prototyping? Yes. Their Engineering & NPI (New Product Introduction) services help teams improve designs and prepare for volume production.

Q3. Do you serve startups or only large companies? Both. Absolute EMS works with startups needing quick-turn prototypes and with established enterprises requiring full-scale production.

Where to Start?

If you are in need of PCB assembly Silicon Valley services, it’s important to work with a company that understands your product’s lifecycle — not just the board. From first prototype to final shipment, Absolute EMS brings quality, accountability, and flexibility.

Their facility is designed for tomorrow’s electronics, backed by certifications, process automation, and a skilled team that works like an extension of your business.

👉 Click here to connect with Absolute EMS for your next PCB assembly project. Whether you're at the idea stage or ready for production, they’re ready to support you with scalable, high-quality solutions.

0 notes

Text

How to Choose the Right Electronic Manufacturer in Chennai

Electronic manufacturing in Chennai is a rapidly growing sector offering vast opportunities for innovation and scale.

If you’re searching for electronic manufacturing services in Chennai, the key is finding a partner with proven capabilities in contract manufacturing, product engineering services, and PCB design and manufacturing. Chennai is one of India’s leading electronics hubs — but choosing the right manufacturer means evaluating more than just location. You need a provider that ensures quality, reliability, scalability, and technical expertise. This guide walks you through exactly what to look for — and how to choose the right electronic manufacturer in Chennai for your next project.

Why Chennai Is a Smart Choice for Electronic Manufacturing

Chennai is more than just a manufacturing destination — it’s a complete ecosystem built for modern electronics production. Here’s why it stands out:

1. Established Manufacturing Ecosystem

Chennai is home to numerous electronics manufacturing clusters such as Sriperumbudur, Oragadam, and Pillaipakkam, where many global and domestic EMS providers operate.

2. Skilled Workforce & Technical Talent

The city produces thousands of engineering graduates annually, providing a skilled workforce for PCB assembly, embedded systems, and precision electronics.

3. Advanced Infrastructure

With access to major ports, industrial parks, and logistics hubs, Chennai offers a ready-made foundation for fast, efficient manufacturing and distribution.

4. Government Support

Policies like the Tamil Nadu Electronics Hardware Manufacturing Policy 2024 and national-level PLI schemes provide tax benefits, funding support, and ease of doing business.

Key Criteria to Choose the Right Electronic Manufacturing in chennai

Before partnering with a manufacturer, make sure they meet these critical criteria:

1. Core Capabilities & Services Offered

Look for providers that offer more than just PCB assembly. A full-service partner will provide:

Product engineering services

PCB design and manufacturing

Prototyping and New Product Introduction (NPI)

Box build and final assembly

Component sourcing and logistics

After-sales support and warranty repair

2. Quality Standards and Certifications

The best manufacturers follow strict quality assurance practices and hold certifications like:

ISO 9001 / ISO 13485 / ISO 14001

RoHS and CE compliance

IPC standards for PCB assembly

3. Technology and Infrastructure

Evaluate their in-house equipment and facilities:

SMT and THT lines

Automated Optical Inspection (AOI)

X-ray and In-Circuit Testing (ICT)

Cleanrooms and ESD-safe environments

4. Scalability and Flexibility

A good manufacturer should easily handle:

Low-volume prototyping

Mid- to high-volume production

Rapid scale-up based on your market demand

5. Transparent Communication

Benefits of Choosing the Right EMS Partner in Chennai

Speed to Market: Faster prototyping and production cycles

Cost Efficiency: Competitive pricing with high-quality output

Customization: Tailored support from design to delivery

Reliability: Long-term partnership with consistent performance

Integrated Services: One-stop solution for design, assembly, and post-sales

Example: What a Full-Service Manufacturing Partner Should Offer

Let’s say you’re building a medical device or IoT product. The ideal Chennai-based partner should help you with:

Design for Manufacturing (DFM) consultation

Prototyping and testing for early validation

Complete PCB design and manufacturing

Mechanical integration through box build

Supply chain and sourcing

Packaging and global shipping

This saves you from managing multiple vendors and allows you to stay focused on core product development.

Final Thoughts: Chennai Is Ready — Are You?

Chennai is already powering the next generation of electronic products — from consumer gadgets to industrial devices. With its talent, infrastructure, and supportive ecosystem, it’s the ideal place to launch or scale your next innovation.

Choosing the right electronic manufacturing partner in Chennai is about more than capabilities — it’s about finding someone who aligns with your goals, understands your product, and is ready to grow with you.

Looking for a Trusted EMS Partner in Chennai?

If you’re ready to take the next step with a dependable electronics manufacturing partner, consider Auckam Technologies. With proven expertise in IoT, healthcare, industrial automation, and drone electronics, Auckam delivers comprehensive electronic manufacturing services — from prototyping and PCB design and manufacturing to full-scale contract manufacturing.

Whether you’re a startup, OEM, or scaling product company, Auckam’s commitment to quality, transparency, and flexibility ensures your innovation moves from idea to market — faster, smarter, and stronger.

Electronic manufacturing in Chennai — Auckam Technologies Pvt Ltd., №26A, Anna Street, Chitlapakkam, Chennai — 600064.

👉 Visit www.auckam.com to learn more or start your project

#electronic manufacturing#ems companies in chennai#pcb design and manufacturing#top ems providers#chennai electronic manufacturing#pcb assembly services chennai

0 notes

Text

Leading PCB Manufacturers in Canada: Quality and Innovation

Discover the top PCB manufacturers in Canada that specialize in providing high-quality printed circuit boards for various industries, including aerospace, automotive, medical, and consumer electronics. These companies offer a range of services, from prototype development to mass production, ensuring precision engineering and compliance with international standards. With state-of-the-art technology and skilled professionals, Canadian PCB manufacturers are committed to delivering innovative solutions, fast turnaround times, and exceptional customer service. Partner with these trusted manufacturers to meet your electronic design and manufacturing needs.

#pcb manufacturing toronto#printed circuit board design#metal clad pcb#printed circuits#rigid flex pcb#full turnkey pcb services#turnkey pcb services#pcb parts#eagle software#pcb designing#flexible pcb#pcb assembly#printed circuit board manufacturers#pcb manufacturers in canada#circuit board manufacturers in canada#pcb quote#pcb prototype services in canada

0 notes

Text

Which Company Offers the Best PCB Manufacturing for Drones?

As drone technology rapidly advances, the demand for high-quality, reliable PCB (Printed Circuit Board) manufacturing has become more critical than ever. Drones require precision-engineered PCBs to ensure stable performance, lightweight design, and high-speed processing for flight control systems, GPS modules, and communication units. So, which company stands out in the competitive market for drone PCB manufacturing?

One of the top contenders is H.C.C. International Limited, a professional PCBA (Printed Circuit Board Assembly) manufacturer based in China. Established in 2004, H.C.C. has over 20 years of experience providing one-stop PCBA services, including PCB design, manufacturing, component sourcing, SMT assembly, DIP soldering, and functional testing.

What sets H.C.C. International Limited apart is its strong commitment to quality, advanced production equipment, and experienced engineering team. The company is certified with ISO9001, ISO13485, IATF16949, and other international standards, ensuring it can meet the strict requirements of high-reliability sectors.

H.C.C.'s services are not only limited to drone electronics; the company also serves industries such as automotive, medical, aerospace, and consumer electronics. For drone applications specifically, H.C.C. focuses on producing lightweight, compact, and heat-resistant PCBs that are crucial for long flight time and stable signal performance.

Clients from around the world trust H.C.C. for its fast prototyping, efficient mass production, and excellent after-sales support. Whether you are a startup developing a new UAV model or a large corporation seeking a reliable manufacturing partner, H.C.C. International Limited is a strong choice for drone PCB and PCBA services.

In summary, when it comes to drone PCB manufacturing, H.C.C. International Limited stands out as a reliable, experienced, and professional partner that can help turn innovative drone designs into high-performance products.

0 notes

Text

Where should you manufacture your printed circuit board prototypes?

Choosing the right facility for your printed circuit board prototype is critical to ensuring quality, speed, and innovation in your design process. With so many printed circuit board manufacturers available globally, selecting a trusted source that can handle both prototyping and scaling is key to successful production.

Expert Support for PCB Assembly

When it comes to reliable production, professional PCB assembly services can make or break your electronics project. The ability to handle precise PCB assembly, component sourcing, and quality testing under one roof can accelerate timelines and ensure reliability. Manufacturers that specialize in prototype support often provide added benefits like quick-turn production, real-time feedback, and design-for-manufacturing insight—all of which reduce risks and costs.

Bay Area Circuits offers comprehensive services from prototype design to production. Their attention to quality and speed makes them a strong choice for engineers and startups alike. Visit their website to explore their services.

Check out the blog here for more information - https://sites.google.com/view/bayareacircuit/Where-should-you-manufacture-your-printed-circuit-board-prototypes

0 notes

Text

Common Printed Circuit Boards in New Energy Vehicles

As new energy vehicles handle high voltage and current, various PCB types are utilized to conduct and control electricity safely across functions:

Multi-layer PCBs 6-12+ layer boards employ complex internal circuitry to precisely transmit signals and power between electronic modules. More layers enable more robust connectivity.

Thick Copper PCBs Ultra-thick 2oz, 3oz and even 4oz copper reliably channels currents up to 400A+, applied for motor control and power conversion requiring stable high ampacity traces.

HDI PCBs High-density interconnect technology with microscopic vias and dense circuitry allows integrating more functionality and components in confined control units, saving space and weight.

Large-area PCBs Sprawling PCBs powering functions like body electronics and chassis controls enable more consolidated layouts and simplified connectivity.

At Hitech Circuits, we are a premier PCB manufacturer providing one-stop PCB fabrication and assembly services to meet the diverse needs across multiple industries. With years of experience and cutting-edge capabilities, we deliver high-quality, quick-turn PCB solutions tailored to each application’s unique requirements.

Our Core Expertise:

Wide range of PCB technologies: HDI, rigid-flex, RF/microwave, thermal boards, and more Advanced manufacturing processes: high-density interconnect, buried/blind vias and more Fast prototype to production cycle times Strong engineering support from quote to delivery High-reliability PCBs for demanding applications

Whether you need prototypes for new product development or high-volume PCB production, Hitech Circuits is your trusted partner.

0 notes

Text

Avalon the top-rated EMS companies in India renowned for their quality services, technical expertise, and customer satisfaction.

#electronics#cleanenergy#industry#manufacturing#renewableenergy#quality#technology#EMS#Electronic Manufacturing Services#Indian EMS#electronics manufacturing services#electronic manufacturing services#electronic manufacturing services companies#electronics manufacturing services India#electronics manufacturing services chennai#top Ems companies in India#bestEmscompanies in India

2 notes

·

View notes

Text

BGA PCB Assembly

What’s BGA PCB?

BGA PCB is Printed Circuit Boards with Ball Grid Array. We use various sophisticated techniques for making BGA PCBs. Such PCBs have a small size, low cost, and high packaging density. Hence, they are reliable for high-performance applications.

What’s BGA PCB Assembly?

Ball Grid Array (BGA) assembly technology is a surface mount packaging technology applied to integrated circuits, which is often used to permanently fix devices such as microprocessors. BGA assembly can accommodate more pins than other packages such as Dual in-line packages or Quad Flat Packages, and the entire bottom surface of the device can be used as pins , instead of only peripherals available, and also have a shorter average wire length than peripheral-limited package types for better high-speed performance.

Our BGA assembly services cover a wide range, including BGA prototype development, BGA PCB assembly, BGA component removal, BGA replacement, BGA rework and reballing, BGA PCB assembly inspection, and so on. Leveraging our full-coverage services, we can help customers streamline the supply network and accelerate product development time.

Benefits of BGA PCB Assembly

Efficient Use of Space – BGA PCB layout allows us to efficiently use the available space, so we can mount more components and manufacture lighter devices.

Better Thermal Performance – For BGA, the heat generated by the components is transferred directly through the ball. In addition, the large contact area improves heat dissipation, which prevents overheating of components and ensures long life.

Higher Electrical Conductivity – The path between the die and the circuit board is short, which results in better electrical conductivity. Moreover, there is no through-hole on the board, the whole circuit board is covered with solder balls and other components, so vacant spaces are reduced.

Easy to Assemble And Manage – Compared to other PCB assembly techniques, BGA is easier to assemble and manage as the solder balls are used directly to solder the package to the board.

Less Damage to Leads – We use solid solder balls for manufacturing BGA leads. Hence, there is a lesser risk that they will get damaged during the operation.

In a word, BGA PCB assembly, have these advantages, high density, better electrical conductivity, lower thermal resistance, easy to assembly & manage are some of the advantages of BGA PCB.

Stringent BGA PCB Assembly Testing Process

To achieve the highest quality standards for BGA assembly, we use a variety of inspection methods throughout the process including optical inspection, mechanical inspection, and X-ray inspection. Among them, the inspection of BGA solder joints must use X-rays. X-rays can pass through the components to inspect the solder joints below them, so as to check the solder joint position, solder joint radius, and solder joint thickness.

Inspection of BGA PCB

We mostly use X-ray inspection for analyzing the features of BGA PCBs. This technique is known as XRD in the industry and relies on X-rays for unveiling the hidden features of this PCB. This kind of inspection reveals.

* Solder Joint Position

* Solder Joint Radius

* Change in Circular shape

* Solder Joint Thickness

The Hitechpcba advantage lies in a whole range of aspects, beginning from the fact that we have the proven technology available at our disposal. With over 15 years of experience in a wide range of PCB Fabrication and Assembly techniques, what we also have is trained manpower and importantly, robust industry experience and best practices that you can benefit from.

Our unstinting devotion to quality and customer satisfaction means that once you partner with us, you can rest assured that you will get nothing but the best. The customer-oriented approach also shows up in your commitment to delivery times. With quick turnaround times, you can reap the benefit of quick time-to-market, which, in turn, can be a major source of competitive advantage.

Whether your requirement is BGA PCB design, BGA PCB, BGA PCB layout, BGA PCB Assembly or BGA rework, you can rest assured that you will get superior quality and performance, that will in turn, positively impact the performance of your final product.

With our efficient network of component suppliers and the many economies of scale that we enjoy, that you will get optimal costs, is a given.

Please feel free to contact us ([email protected]) if you have any other special request on the BGA pcb assembly.

3 notes

·

View notes