#refining electrical estimates

Explore tagged Tumblr posts

Text

Top Tips for Producing Accurate Electrical Estimates

Producing accurate electrical estimates is essential for contractors aiming to submit competitive bids and successfully manage project budgets. Careful planning, attention to detail, and the right tools can significantly improve estimate quality. Here are key tips to help achieve accurate electrical estimates.

Thoroughly Review Project Documents

Start by carefully examining all available project documents including blueprints, electrical drawings, and specifications. Understanding the full scope and details ensures no materials or work items are missed. Clarify any ambiguous or incomplete information with designers or clients before beginning the estimate.

Use Digital Takeoff Tools

Digital takeoff software allows precise measurement and quantification of materials directly from electronic plans. Using these tools reduces manual errors and speeds up the process compared to traditional paper takeoffs. Accurate quantity takeoffs form the foundation of a reliable estimate.

Keep Pricing Data Updated

Material costs and labor rates frequently fluctuate due to market conditions. Regularly update pricing databases by consulting suppliers or using real-time industry resources. Accurate current pricing helps prevent cost overruns and ensures your bids reflect true market conditions.

Adjust Labor Units for Project Conditions

Standard labor units estimate time needed for installation under typical conditions. However, factors such as site accessibility, complexity, crew experience, and project schedule impact actual labor requirements. Adjust labor hours accordingly to reflect these realities.

Include Indirect and Miscellaneous Costs

Don’t overlook indirect costs such as equipment rentals, permits, testing, cleanup, and project management time. Including these expenses ensures your estimate reflects the total project cost and helps avoid surprises later.

Collaborate with Field Teams

Consult with electricians and project managers to validate labor productivity assumptions and identify potential challenges. Their practical insights can help refine estimates and improve accuracy.

Review and Verify Estimates

Double-check all calculations and quantities. Have a second estimator or project manager review the estimate to catch mistakes or omissions. Peer review is a valuable quality control step.

Document Assumptions Clearly

Maintain clear documentation of all assumptions made during estimating, such as productivity rates, pricing sources, and scope interpretations. This documentation supports transparency and helps explain estimates to clients or internal teams.

Stay Informed on Codes and Regulations

Electrical codes and standards change periodically. Staying current ensures your estimates incorporate compliance costs and avoid costly rework due to nonconformance.

Invest in Ongoing Training and Software Updates

Regular training for estimators on best practices and new technologies, along with keeping estimating software updated, contributes to consistent estimate quality.

FAQs

How often should I update labor and material pricing? Ideally, update pricing at least quarterly or whenever there are significant market changes to maintain estimate accuracy.

What is the biggest cause of inaccurate electrical estimates? Incomplete project documentation and failure to adjust for site-specific conditions often lead to inaccurate estimates.

Can software alone guarantee accurate estimates? Software is a powerful tool but accuracy depends on quality data input and estimator expertise.

How detailed should an electrical estimate be? The level of detail depends on project size and client requirements but should always cover all major materials, labor, indirect costs, and contingencies.

Conclusion

Producing accurate electrical estimates requires a combination of detailed review, precise measurement, realistic labor evaluation, and ongoing collaboration. Following these tips can improve your estimating process and contribute to successful project outcomes.

#how to produce accurate electrical estimates#tips for electrical estimating accuracy#best practices for electrical estimating#improving electrical bid accuracy#electrical takeoff accuracy tips#updating material pricing#adjusting labor units#estimating indirect electrical costs#reviewing electrical estimates#validating labor productivity#electrical estimating collaboration tips#avoiding mistakes in electrical estimating#documenting estimating assumptions#training for estimators#electrical estimating software tips#electrical code updates and estimating#bid preparation accuracy#electrical estimating checklist#estimating electrical subcontractor work#checking electrical estimate calculations#refining electrical estimates#managing estimating risks#electrical cost forecasting tips#estimating complex electrical projects#electrical estimating quality control#improving estimating workflows#electrical project cost accuracy#real-time pricing in estimating#estimator review processes#tips for winning electrical bids

0 notes

Text

not at the farm

so this week i could not get my BIL to really give me a firm answer on whether he needed help with anything. but I *could* get my middle-little sister to admit she needed help. Once i was here, of course BIL thought of some things he could use my help with, so I helped with those, but I'm staying with M-L and mostly will likely spend the rest of the week with her doing these projects.

So I'm at her house, helping with some repairs and, mostly, cleaning tasks. so I'm just going to go on about that a bit.

Her housemate has just moved out and she's now in a house she's realizing is slightly too large for her needs; it was purchased in conjunction with said housemate and so was kind of a compromise so it's not entirely ideal for her solo situation now in a number of respects. Also she has to refinance it to get former housemate off the mortgage, which normally would just be slightly annoying but now, with the entire world on fire and literally every industry in paroxysms of unprecedented failure, is actively catastrophic. She's waiting, of course, to hear on various final details, but it is very likely that current insane interest rates will mean that refinancing will mean that the mortgage payments will go up so steeply that the house will cost literally every penny she has every month, with no chance to save up anything for the highly necessary repairs. So she's bummed and stressed and it's in large part the fault of the current government, and there's a slight chance interest rates will sort themselves out but like there's also a slight chance I might spontaneously grow wings. The prospective mortgage company is now two weeks overdue on getting her a figure she was promised would take a matter of hours for them to generate, so that's also maddening; it might turn out to be fine after all, but current estimates are that it Super Won't Be, and no two employees of the mortgage company can agree on anything or keep a deadline to fucking save themselves, apparently. So once she knows that number, then all other decisions can be discussed, but as of now, it's fucking horrible because Nothing Can Be Decided And Anything Is Possible (But Probably It's Bad)-- *jazzhands*.

(Also. No real shade to housemate-- I'd planned on helping them move, and then didn't wind up being needed, so I'm just figuring this is me helping them move-- but they left a lot of things sort of... scattered around that we're now having to work around, and did mmmmmmmno cleaning, and in fact, bonus, left some garbage for us to deal with, which is slightly more hassle than in places that have trash pickup, as it means we have to haul it to the dump and have no truck so it's got to be a bunch of little trips in M-L's tiny electric car (we can't even take my larger vehicle with a rubber cargo liner because the permit is by license plate). It is no big deal really, but it is One More Goddamned Thing. I am going to try and collect the left-behind possessions into like, one single location, so that we can get on with cleaning/repairing/revamping the other locations. Probably the shed, which has enough stuff in it that it can't really be used for any other purpose anyway, so it might as well just be turned over entirely to storage.)

One good thing-- we put the broken lawnmower out by the road with a "FREE-- worked last year, now doesn't start, idk" sign on it (yes literally that's what the sign said, we're very eloquent) and some guy picked it up, so at least there is one large bit of trash dealt with. We tried the same with an office chair that had been deemed to be garbage and then left in the basement, but there were no takers. (That one's sign just said "free", though I made us both laugh (we were a little punchy) by pretending to write "runs good" under that.) I'll put it out again but not today, it's threatening rain today.

So yeah, things are kind of clusterfucked around here. M-L is considering her options including selling the house, but it needs numerous things done to be sale-ready, beyond even the fairly large number of things it already needed just to stay in livable condition. (Isn't it wild how entropy works! Ugh) I am discovering, however, that at least some things she's despairing over like "oh no that's in too poor condition and has to be replaced too" are things that just need to be cleaned better. Of course... then there's the basement. There was an apartment in the basement, which in hindsight was an illegal sublet. The guy who lived there had never wiped down a surface in his life, so it was already fairly nasty when they moved in. But then the septic tank had a problem, and as normally happens, the backup exploded into the house through the basement toilet. So now the place is even nastier than it was. So I'm going to try to clean it, because like.... it's not a particularly usable space, it's never going to be exactly nice, but as it is currently, it is an actively disgusting space, and whether it's getting torn out or refurbished or gutted or converted back into a garage or whatever, it at least has to be cleaned first.

I started with the stove down there, and let me tell you that was the World's Nastiest Stove. The stovetop had just never had anything wiped off it, and then it sat for three years. So. I have the kind of oven cleaner on it rn that you're supposed to let sit overnight, and so today I'm gonna go down there and pry the oven door open and see what it hath wrought. I hope for a miracle. The stovetop was mostly elbow grease and degreasing gel, and I've made great strides but it's clear the right front burner was his favorite, I may have to admit defeat. And the fridge was next to the stove and he just never wiped down anything that splattered onto the fridge, and now the exterior of that is entirely mildewed. But bleach spray sorted that out, and I'm going to go back and make sure that's actually really clean today.

So. Just lots of excitement and grunge. But if the things that are still usable are at least cleaned, it's then easier to figure out what can be repaired/replaced, what can be repurposed, and what just has to get ripped out.

Anyway who knows what the right answer to anything is, but I do know that pushing back against entropy is usually a good first step. Get it at least clean, then you can make your plans.

Yesterday sucked though because the like one thing we really wanted to get done was install this awning so that she can charge her electric car under cover, and the instructions were ridiculously unclear, we figured out how to assemble it, decided it was unwieldy fully assembled and thus sort of dangerous to try to wrestle up on ladders, so we put it up in two halves, only to discover once half was firmly irrevocably installed that it cannot be assembled piecemeal. It had to be fully assembled before installation; the wall gets in the way of getting the second part snapped in because you can't get it at the right angle to slot in. So there's no way to put the second half up. So just half of it is installed, it looks fucking stupid, and it can't be removed without being demolished.

Cool.

Oh well. At least I can keep going on cleaning and painting things.

Bah my timer's going off, I have to go attempt The Bathroom Of Doom now. I don't know how I'm going to get up the dried bits of toilet paper. I'm going to bleach the shit out of it but I know extremely well from years of food handling that you can't sanitize actual dirt. You have to remove the dirty thing and mechanically clean the surface first. And I just. Don't. Want to. But it's got to happen so it might as well be me who does it. And M-L has a like, conditioned horror response to bleach, idk why (i do but it's a dumb long story) so it really does have to be me, she's not going to be able to get that space sanitized. I put the Blue Dawn Magical Mixture on the shower down there yesterday and am going to see if I can get it to work any magic...

27 notes

·

View notes

Text

okay

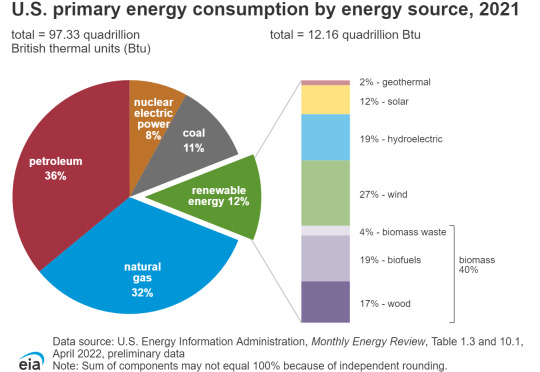

For decades, nuclear power has been the largest source of clean energy in the United States, accounting for 19% of total energy produced last year

false. first sentence. off to a great start. you may notice this is a 2022 chart but i can tell you the only new reactors started since then are vogtle 3 and 4 (you may notice that's not a new power plant but new reactors at an existing plant), years late and $17b over budget, vogtle as a whole produces 1.1gwh, we use about 29 million annually. point being: it has not risen to 19%, the last reactor since vogtle was watts bar in 2016 and since then we've decommissioned 14 of them

The industry directly employs nearly 60,000 workers in good paying jobs

weirdly low estimate, almost by half

maintains these jobs for decades

"maintains" is doing a lot of work here, does that include toxic exposure payouts? because they are still fighting pretty hard to get those in the world's first nuclear contamination site, hanford

and supports hundreds of thousands of other workers

✅ true! 475,000 according to the NEI link above

In the midst of transformational changes taking place throughout the U.S. energy system

sure

the Biden-Harris Administration is continuing to build on President Biden’s unprecedented goal of a carbon free electricity sector by 2035

have they developed carbon free cement yet? (yes.) at scale? (no.) are we just not counting construction emissions because they're one-time emissions investments or how does this work exactly, i would love to know because i think we're also not counting emissions from waste transport to longterm storage because we haven't started doing that. anyway they've built a train for it even though we don't have a storage site so that's umm. that's uhh. fine i'm sure

while also ensuring that consumers across the country have access to affordable, reliable electric power

i guess you can still say "across the country" if you exclude texas as an outlier

and creating good-paying clean energy jobs.

i guess you can still call them good paying clean energy jobs if everybody who mines and refines the uranium dies of cancer because you just pulled out of the largest disarmament program in history due to it being geopolitically inadmissible (for russia... to continue... selling us the uranium from decommissioning...? i'm still trying to figure out the optics of that one but anyway as i have previously stated we didn't actually stop buying it in cases where it's "liable to cause supply chain issues")

Alongside renewable power sources like wind and solar, a new generation of nuclear reactors is now capturing the attention of a wide range of stakeholders

weird way to say that

for nuclear energy’s ability to produce clean, reliable energy and meet the needs of a fast-growing economy, driven by President Biden’s Investing in America agenda and manufacturing boom.

this is a carrier sentence to inject the president's name, but i would like to question which sectors of the growing economy are driving the most energy demand because i'm sure there are no nasty truths being elided there (it's computing)

The Administration recognizes that decarbonizing our power system, which accounts for a quarter of all the nation’s greenhouse gas emissions, represents a pivotal challenge requiring all the expertise and ingenuity our nation can deliver.

it's time once again for... the energy flow sankey chart! the reason the power system accounts for a quarter of greenhouse gas emissions is in no small part because 67% of it is lost to waste heat. has the nation's expertise and ingenuity started working on that yet

The Biden-Harris Administration is today hosting a White House Summit on Domestic Nuclear Deployment, highlighting the collective progress being made from across the public and private sectors

oh boy! a summit! talking about it is the same as doing it

Under President Biden’s leadership, the Administration has taken a number of actions to strengthen our nation’s energy and economic security by reducing – and putting us on the path to eliminating – our reliance on Russian uranium for civil nuclear power and building a new supply chain for nuclear fuel

gosh, i got ahead of myself and already criticized both of those things

including: signing on to last year’s multi-country declaration at COP28 to triple nuclear energy capacity globally by 2050

everybody criticized that

developing new reactor designs

which ones, the bill gates project that just got cancelled because utilities pulled out (edit: that's nuscale, the bill gates project is terrapower), the rolls royce submarine, or the one that just got regulatory approval (edit: this is also nuscale)

extending the service lives of existing nuclear reactors

yep! you sure showed the embrittlement at diablo canyon by doing nothing about it

and growing the momentum behind new deployments

nonsense clause, but it has this really ominous undercurrent due to its vagueness

Recognizing the importance of both the existing U.S. nuclear fleet and continued build out of large nuclear power plants, the U.S. is also taking steps to mitigate project risks associated with large nuclear builds and position U.S. industry to support an aggressive deployment target.

this one is not nonsense but they can't just out and out say "we are deregulating the industry because opening the process for public comment is most often the thing that slows it down" because then somebody might realize they're bulldozing ahead no matter what any constituent says, does, or actually wants

To help drive reactor deployment while ensuring ratepayers and project stakeholders are better protected, theAdministration is announcing today the creation of a Nuclear Power Project Management and Delivery working group that will draw on leading experts from across the nuclear and megaproject construction industry to help identify opportunities to proactively mitigate sources of cost and schedule overrun risk

i'm sure a revolving door working group packed with industry insiders can solve this without compromising their commitment to the profit motive, not that it particularly matters since the cost is passed on to the consumer in the form of fees on the electric bill

The United States Army is also announcing that it will soon release a Request for Information to inform a deployment program for advanced reactors to power multiple Army sites in the United States

good god... that is a fresh nightmare i did not see coming

Additionally, the Department of Energy released today a new primer highlighting the expected enhanced safety of advanced nuclear reactors

"expected" really serves to demonstrate several points i've made

i'm going to stop going line by line here because i know this is already too boring and long for anyone to read this far, unless anybody wants to know what i think about parts 50, 52, and 53 of the NRC licensing guidance -- which many of you have very clearly stated over the years that you don't -- and while i do want to acknowledge that it does go into more detail and even answer some of the questions i raised (vogtle comes up, diablo canyon comes up, a list of which SMR designs is given, or at least a list of the companies responsible for them),

what i would like to focus on is one conspicuous absence:

the reason we need a new fleet of reactors is because they are an essential part of the bomb production chain. they are the beginning of the refinement process, and we cannot carry out the plan (already underway) to replace the minutemen missiles currently in silos with sentinel missiles without significant new construction. we cannot start the president's desired wars with russia and china without the new sentinels. he's not going to be the one to carry this out, he's ensuring whoever is his successor in about 2030 or more likely 2040 will be armed to do so. limited amount of time left to prevent that

93 notes

·

View notes

Text

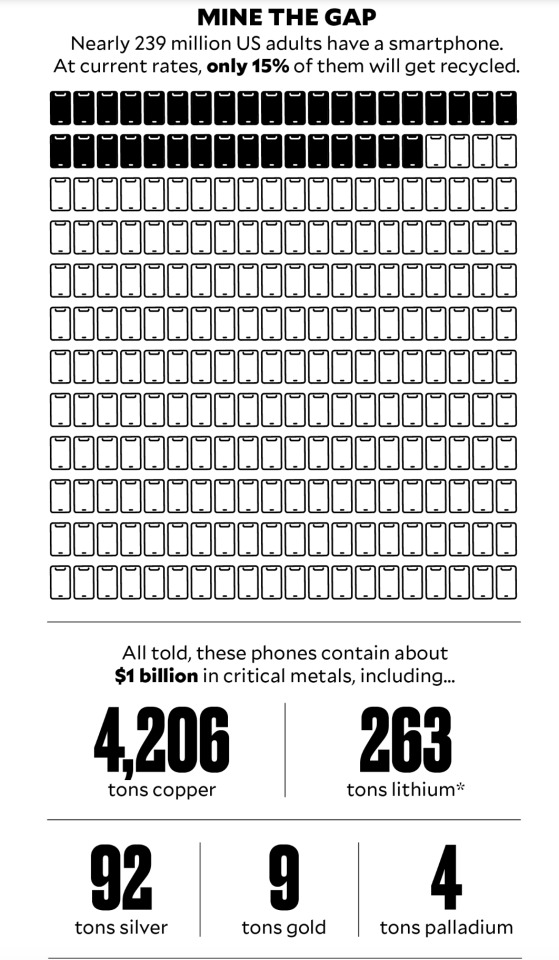

Excerpt from this story from Mother Jones:

The world generates more than 68 million tons of e-waste every year, according to the UN, enough to fill a convoy of trucks stretching right around the equator. By 2030, the total is projected to reach 75 million tons.

Only 22 percent of that e-waste is collected and recycled, the UN estimates. The rest is dumped, burned, or forgotten—particularly in rich countries, where most people have no convenient way to get rid of their old Samsung Galaxy phones, Xbox controllers, and myriad other gadgets. Indeed, every year, humanity is wasting more than $60 billion worth of so-called critical metals—the ones we need not only for electronics, but also for the hardware of renewable energy, from electric vehicle (EV) batteries to wind turbines.

Millions of Americans, like me, spend their workdays on pursuits that lack any physical manifestation beyond the occasional hard-copy book or memo or report. It’s easy to forget that all these livelihoods rely on machines. And that those machines rely on metals torn from the Earth.

Consider your smartphone. Depending on the model, it can contain up to two-thirds of the elements in the periodic table, including dozens of metals. Some are familiar, like the gold and tin in its circuitry and the nickel in its microphone. Others less so: Tiny flecks of indium make the screen sensitive to the touch of a finger. Europium enhances the colors. Neodymium, dysprosium, and terbium are used to build the tiny mechanism that makes your phone vibrate.

Your phone’s battery contains cobalt, lithium, and nickel. Ditto the ones that power your rechargeable drill, Roomba, and electric toothbrush—not to mention our latest modes of transportation, ranging from plug-in scooters and e-bikes to EVs. A Tesla Model S has as much lithium as up to 10,000 smartphones.

The millions of electric cars and trucks hitting the planet’s roads every year don’t spew pollutants directly, but they’ve got a monstrous appetite for electricity, nearly two-thirds of which still comes from burning fossil fuels—about one-third from coal. Harvesting more of our energy from sunlight and wind, as crucial as that is, entails its own Faustian bargain. Capturing, transmitting, storing, and using that cleaner power requires vast numbers of new machines: wind turbines, solar panels, switching stations, power lines, and batteries large and small.

You see where this is going. Our clean energy future, this global drive to save humanity from the ever-worsening ravages of global warming, depends on critical metals. And we’ll be needing more.

In all of human history, we have extracted some 700 million tons of copper from the Earth. To meet our clean energy goals, we’ll have to mine as much again in 20-odd years. By 2050, the International Energy Agency estimates, global demand for cobalt for EVs alone will soar to five times what it was in 2022. Demand for nickel will be 10 times higher. Lithium, 15 times. “The prospect of a rapid increase in demand for critical minerals—well above anything seen previously in most cases—raises huge questions about the availability and reliability of supply,” the agency warns.

Metals are natural products, but the Earth does not relinquish them willingly. Mining conglomerates rip up forests and grasslands and deserts, blasting apart the underlying rock and soil and hauling out the remains. The ore is processed, smelted, and refined using gargantuan, energy-guzzling, pollution-spewing machines and oceans of chemicals. “Mining done wrong can leave centuries of harm,” says Aimee Boulanger, head of the Initiative for Responsible Mining Assurance, which works with companies to develop more sustainable extraction practices.

The harm is staggering. Metal mining is America’s leading toxic polluter. It has sullied the watersheds of almost half of the rivers in the American West. Chemical leaks and mining runoff foul air and water. The mines also generate mountains of hazardous waste, stored behind dams that have a terrifying tendency to fail. Torrents of poisonous sludge pouring through collapsed tailings dams have contaminated waterways in Brazil, Canada, and elsewhere and killed hundreds of people—in addition to the hundreds, possibly thousands, of miners who die in workplace accidents each year.

To get what they’re after, mining companies devour natural resources on an epic scale. They dig up some 250 tons of ore and waste rock to get just 1 ton of nickel. For copper, the ratio is double that. Just to obtain the metals inside your 4.5-ounce iPhone, 75 pounds of ore had to be pulled up, crushed, and smelted, releasing up to 100 pounds of carbon dioxide. Mining firms also suck up massive quantities of water and deploy fleets of drill rigs, trucks, diggers, and other heavy machinery that collectively belch out up to 7 percent of the world’s greenhouse gas emissions.

Metal recycling is a completely different proposition from recycling the paper and glass we toss into our home bins for pickup. It turns out that retrieving valuable raw materials sustainably from electronic products—toasters, iPhones, power cables—is a fiendishly complex endeavor, requiring many steps carried out in many places. Manufacturing those products required a multistep international supply chain. Recycling them requires a reverse supply chain almost as complicated.

Part of the problem is that our devices typically contain only a small amount of any given metal. In developing countries, though, there are lots of people willing to put in the time and effort required to recover that little bit of value—an estimated tens of thousands of e-waste scavengers in Nigeria alone. Some go door to door with pushcarts, offering to take or even buy unwanted electronics. Others, like Anwar, work the secondhand markets, buying bits of broken gear from small businesses or rescuing them from the trash. Many scavengers earn less than the international poverty wage of about $2.15 per day.

15 notes

·

View notes

Text

A panel of experts testified to the House Foreign Affairs Committee on Tuesday that Chinese companies mining for “green” energy minerals throughout Africa – particularly in resource-rich countries such as the Democratic Republic of the Congo (DRC), are creating a “catastrophic and unacceptable” situation for locals.

The experts urged American officials to act to contain the malignant Chinese influence destroying an entire generation of African children and the environment in which they live, stressing that the minerals in question – cobalt, lithium, tantalum, and copper, among others – are pivotal to any high-tech economy.

The hearing, hosted by the Subcommittee on Africa and chaired by Rep. Chris Smith (R-NJ), occurred as the nation of Zambia struggles to address the virtual death of the Kafue River, drowned in toxic residue when a dam holding the residue, created through Chinese copper mining activities, collapsed. Among the specific environmental threats mentioned at the hearing were the threat to the endangered okapi and the destruction of entire communities, displaced by companies looking to mine the land and polluted to the point that no one can safely return.

In addition to environmental disasters, the growing presence of exploitative Chinese companies in the DRC, Zambia, Zimbabwe, and elsewhere has brought with it growing rates of child slavery as children as young as eight are forced into mines with no protective equipment, greatly endangering their lives. Furthermore, the mineral wealth and corruption is also fueling chaotic guerrilla warfare, particularly in the DRC, where rival militias regularly commit atrocities for control of the mines and violence has been exacerbated by Rwandan intervention. As of February, the death toll of the ongoing DRC conflict is estimated to be in the high thousands and the United Nations has documented a large number of instances of the use of rape as a weapon of war.

The issue of child slavery in the mines featured prominently during the hearing. Sasha Lezhnev, a senior policy adviser with the Sentry, stated that, in the DRC alone, “there are an estimated 25,000 to 35,000 child miners … working at mines that send cobalt and copper to Chinese crude refiners.”

“I have witnessed the horrors of child soldiers and child miners as young as eight years old at mines in the Democratic Republic of Congo,” Lezhnev shared, “as well as the warlords and corrupt companies and officials making money from this system of exploitation—all in the name of getting us cheaper smart phones, jewelry, and electric vehicles (EVs). This has got to stop.”

“We see cases of child and forced labor—averaging 40,000 children–digging cobalt for Chinese buyers without adequate protective equipment and payment,” Joseph Mulala Nguramo of the Atlantic Council Scowcroft and Freedom and Prosperity Center told the subcommittee. “Some of these children are under 10 years old—leaving them exposed to toxic substances—causing serious health and environmental problems, per Amnesty International investigations.” . Nguramo described the situation of those children, as well as the lives of locals in areas affected by Chinese mines generally, as “catastrophic and unacceptable.”

In the DRC, ongoing civil unrest and an unmitigated humanitarian crisis are largely due to China’s ruthless and irresponsible grip on the country’s natural resources,” Nguramo testified. “Controlling almost 90% of the Congo Mining Sector, China has failed to use its economic and financial power to defend and promote the Rule of Law, Freedom, and Quality Governance. But China has, instead, mastered strategies to take advantage of a country in chaos—often bribing government officials to acquire Mining concessions.”

The experts testified that China had spent over $10 billion buying up mines in Africa, benefitting the most so far in Zambia, the DRC, and Zimbabwe, though the Communist Party has significantly expanded its influence elsewhere in the continent, as well. The founder of the due diligence firm Accountable Africa, Thierry Dongala, noted that widespread corruption in local governments enables this colonialism and pointed to the example of Niger to show that African governments can rapidly expel offending Chinese companies if they choose to. Niger, currently under military coup regime that calls itself the “National Council for the Safeguard of the Homeland,” reportedly expelled Chinese oil executives from the country in mid-March and shut down a Chinese-owned hotel for allegedly engaging in “discriminatory practices.”

“The recent case of Niger expelling Chinese management shows that when African countries get serious about their moral sovereignty in their extractive industries, Chinese actors are often the first to lose,” Dongala observed.

Dongala noted that local populations are well aware of the evil that illicit, slave-driven mining brings to their land, recalling that the pastor who married him to his wife conducted a “sudden sanctification prayer” to cleanse their wedding bands of evil energy, a product of their provenance, when he noticed they appeared to be made of real gold. He recommended close cooperation with locals in affected countries to track and shut down theft, slavery, and other abuses.

“We’ve been monitoring the school attendance levels, that data is very valuable because we know that if we start to see the school attendance levels drops, we have to find where these kids are going,” he said of his firm. “The local school principal , the local fishers union, the mothers of the children,” he suggested, could be critical allies.

Rep. Smith, chairing the hearing, noted that China’s dominance of the mining industry there, in addition to facilitating unspeakable human rights and environmental atrocities, put America at a disadvantage given the importance of the minerals in question in technology.

“The reliance on China for these critical minerals is a clear vulnerability,” he emphasized in his opening remarks. “The greatest beneficiaries of this system—China’s state-owned mining companies—remain silent, refusing to confront an undeniable reality: from dirt to battery, from cobalt to cars, the entire supply chain is built on violence, exploitation, and corruption,” he continued. “This must change—and the time for change is now.”

Rep. Smith recently reintroduced the COBALT Supply Chain Act, a bill that would, in its own words, “ensure that goods made using or containing cobalt refined in the People’s Republic of China do not enter the United States market under the presumption that the cobalt is extracted or processed with the use of child and forced labor in the Democratic Republic of Congo.” Rep. Smith first introduced a version of the bill in 2023.

Progressives don't care about REAL slaves living today. Just remember that EV you're driving was built at the expense of 10 little African kids whose future was stolen in order to make the battery.

6 notes

·

View notes

Text

Lincoln Plug-In Hybrid Electric Vehicles

Lincoln Canada is redefining luxury mobility with its Plug-In Hybrid Electric Vehicles (PHEVs), offering a seamless blend of electric efficiency and traditional power. These vehicles offer a refined driving experience, combining advanced technology with the elegance that is synonymous with the Lincoln brand.

What Are Lincoln Plug-In Hybrid Electric Vehicles?

Lincoln's PHEVs, known as Grand Touring models, integrate a gasoline engine with an electric motor and a rechargeable battery. This combination allows for versatile driving modes:

• Pure EV Mode: Drive solely on electric power for short commutes, offering a quiet and emission-free experience. • Preserve EV Mode: Utilize the gasoline engine while conserving battery charge for later use.

This dual-power approach ensures flexibility, catering to various driving needs and preferences.

Charging Made Convenient

Lincoln PHEVs come equipped with a dual-voltage charging cord compatible with both 120V and 240V outlets:

• 120V (Level 1): Standard household outlet, suitable for overnight charging. • 240V (Level 2): Faster charging option, ideal for quicker turnaround times.

Charging can be done at home or public AC charging stations. It's important to note that Lincoln PHEVs are not compatible with DC fast charging.

Models Available in Canada

Lincoln offers PHEV options in select models:

• Lincoln Corsair Grand Touring: A compact luxury SUV featuring a 2.5L Atkinson-cycle engine paired with electric motors, delivering a combined output of 266 horsepower. It offers an

EPA-estimated electric-only range of approximately 28 miles (45 km).

• Lincoln Aviator Grand Touring: A mid-size luxury SUV combining a twin-turbocharged 3.0L V6 engine with an electric motor, producing a total of 494 horsepower and 630 lb-ft of torque. This model offers robust performance, complemented by the added benefit of electric driving capabilities.

Benefits of Choosing a Lincoln PHEV

• Enhanced Fuel Efficiency: Reduced fuel consumption, especially for short trips using electric mode. • Smooth and Quiet Operation: Electric driving offers a serene cabin experience. • Flexible Driving Modes: Switch between electric, gasoline, or combined power based on driving conditions. • Environmental Impact: Lower emissions contribute to a greener footprint. • Potential Incentives: Eligibility for government rebates and incentives for eco-friendly vehicles.

Warranty and Support

Lincoln stands behind its PHEV technology with a comprehensive warranty

Hybrid and Electric Vehicle Unique Component Coverage: 8 years or 160,000 kilometres (whichever comes first) for components like the high-voltage battery and electric drivetrain.

Additionally, Lincoln offers 24/7 Roadside Assistance and the Lincoln Way™ App for remote vehicle management, ensuring peace of mind for owners.

Conclusion

Lincoln's Plug-In Hybrid Electric Vehicles represent a harmonious blend of luxury, performance, and sustainability. With advanced technology, flexible driving modes, and comprehensive support, Lincoln PHEVs offer a compelling choice for those seeking an elevated driving experience in Canada. To get more information on Plug-In Hybrid Electric Vehicles, you can visit Whiteoak Lincoln, one of your best Lincoln dealerships near me.

2 notes

·

View notes

Text

Nuclear Energy and Geography

Did you know that there are 13 main types of Nuclear reactors in use in the 20th and 21st centuries? They each do the same thing, generate electricity, but they do so in unique ways. The world is like that. Humanity is neither one world nor many worlds. It is, instead, a nuclear reactor, a complex organism that is simultaneously a complete object, made up of many smaller components. Nuclear reactors are highly complex and refined tools used to generate power; however, different designs are used in various areas that need specific results. This is similar to cultural preferences in food and clothing in the context of human geography. A people group who live in the mountains will eat food available there and dress for that type of weather. This is similar to the MAGNOX reactors used by Britain, which made use of naturally occurring graphite. This essay will highlight the unity and differences in our world that create a unified earth, separated by particular needs and cultural differences. They will be showcased through an explanation of the following modern nuclear reactor styles: PWR, BWR, and AGR. PWR will showcase humanity's use of languages and how that use can unify or destroy relations. BWR will showcase how cultural diffusion and mobility impact and shape our planet. AGR will highlight how humans use hope and other primal concepts to create our own saviors. PWR reactors, also known as pressurized water reactors, are some of the most common in the US. They are known for keeping potentially contaminated coolant water separate from clean water, which is then turned into steam for power generation. So, what does a popular form of reactor have to do with the united division of Earth? A whole lot! PWR reactors are like language. Did you know that it is estimated that the entire Earth contains over 7,100 different languages, and that every 14 days, a language disappears? ()PWR reactors, much like the top 10 most widely spoken languages on Earth, tend to overshadow smaller reactors or languages. Sometimes it's for good reason; PWR reactors are known to be safe due to their containment system. Popular languages are popular because there are more speakers and are thus used in more areas. The top ten most popular languages are found on page …. Of “Textbook name here” and are as follows: Unfortunately, though, this can sometimes cause cultural erasure, as the ease of using one of the top 10 languages, can cause stories or other idiomadic cultural aspects of the original people groups to be lost. The best way to think of the Earth is like bubble wrap. Each bubble is separated, but connected. None can exist without the other. Earth cannot be divided because its languages are based on similar concepts and communicate needs. However, she cannot be united because the methods of communication are vastly different from each other. The most popular languages around the globe connect the minor dialects and terminology. Some languages are spoken by millions, such as Chinese or Irish; others are on the verge of extinction with fewer than 1,000 native speakers, such as Seri. Each of these languages offers insight into their cultures and communities. Language is intertwined with identity, making it an essential part of humanity and human culture. It unites us by allowing communication. But it can divide us if someone does not speak the same language! This division can be minor, such as having difficulties asking where the milk is in a grocery store or needing a separate menu at a restaurant. However, sometimes these minor issues can turn into great disputes. Unfortunately, spoken language is easy to notice when looking for cultural differences. Thus, sometimes speaking a foreign tongue can cause conflict with others. Some people argue that the best way to avoid this conflict is to submit to a unified, global tongue, spoken by all. This would, of course, alleviate conflicts and make the Earth a less divided planet. However, as with any form of cultural change, it runs the risk of losing the distinctive aspects of individual people groups.

#history#english#nuclear energy#geography#essay#writing#nonfiction#science#woofsbadwriting#part 1/4#no beta we die like jason todd#this is mine

4 notes

·

View notes

Text

While Ukraine’s surprise combined-arms incursion into the Russian oblast of Kursk gets all the headlines, Kyiv continues to carry out a parallel, deep-strike operation to target Russian vulnerabilities, with continued attacks on oil refineries and fuel depots behind the front lines.

A massive tank farm in Proletarsk, a city in Russia’s Rostov region, has been burning uncontrollably for four days after Ukrainian drones slammed into 70-odd tanks full of diesel and gasoline; by some estimates, the fire could be incinerating as much as $200 million worth of Russian fuel. Overnight on Tuesday, Ukraine launched one of its biggest attacks yet on Moscow, and although most of those drones and missiles were shot down, Ukraine did seem to start another conflagration at an oft-hit refinery in Novoshakhtinsk, also in Rostov.

So far this year, Ukraine says that it has successfully attacked more than 30 Russian oil installations, some deep inside Russia. The latest estimates are that about 17 percent of Russia’s (admittedly ample) oil-refining capacity has been damaged to some extent by the strikes. But more broadly, Russia continues to export huge volumes of oil and even a fair bit of natural gas, ensuring that oil revenues continue to fuel its war machine despite the odd million spent here and there to repair damaged crackers and condensers.

Ukraine’s pinprick assaults on Russia’s oil infrastructure, often answered with counter-battery Russian missiles aimed at vulnerable Ukrainian power plants, are part of the latest tit-for-tat energy battle in the longer-term, less violent energy war that the two countries have waged for years, especially over natural gas supplies and prices.

In some ways, the energy fight is an adjunct to the fight on the battlefield. Ukraine’s ability to damage (even for short periods of time) Russian refineries and fuel depots is meant, in part, to undermine logistics for the Russian army, which continues to occupy large swaths of southern and eastern Ukraine. Blowing up expensive installations deep inside Russia is also a psychological boon for Ukraine, which has been largely on the back foot since early 2022. Russia’s systematic destruction of the Ukrainian electric power grid, meanwhile, is meant to undermine civilian morale and resilience ahead of winter.

The White House had initially warned Kyiv not to strike Russian oil installations, fearing Russian reprisals as well as an inconvenient spike in oil and gasoline prices ahead of the U.S. election, but Ukraine has plowed ahead regardless (just as it did with the Kursk incursion).

The big question is: Do all the eye-grabbing explosions at refineries and fuel depots make much of a difference to Russia’s surprisingly resilient oil-based economy?

“The drones can cause economic damage an order of magnitude or higher than the cost of the drones themselves, and so yes, there is some economic damage and net benefit, cost-wise. But the damage done is brief and relatively easy to repair,” said Sergey Vakulenko, an energy expert at the Carnegie Russia Eurasia Center. “Will it make drastic impacts on Russian oil revenues? Probably not. The drones cannot do what the sanctions were unable to achieve.”

In some cases, Vakulenko said, the oil installations that Ukraine is targeting, chosen because they are within easy range of drones, may not be the critical marks that Kyiv imagines. Many of the older refineries in western Russia were built to take advantage of export customs loopholes that made it more beneficial to export barely refined oil products, even very low-quality ones, than to export regular crude. These aren’t the crown jewels, but the cracked zircons.

“The benefits of hitting those refineries may not be what the Ukrainians thought,” said Vakulenko, who was previously an oil executive at Russian and international companies.

Like the Kursk operation, high-profile blows by Ukraine threaten to distort the view of what otherwise remains an unequal battle. If the war has come to the energy patch, it is because Russia—from nearly the beginning of the conflict—has targeted Ukrainian power installations as a deliberate part of its campaign to destroy civilian infrastructure. During the first year of the full-scale invasion, Russia targeted easy-to-hit structures, such as power transformers, that could disrupt electricity across Ukraine, especially in big cities. But that damage was relatively easy to repair, and Ukraine made it through the first winter in fairly good shape.

At the beginning of this year, once Ukraine had homemade drones and missiles that could strike deep into Russia, thus neatly skirting both U.S. targeting prohibitions and leaky Russian air defenses, Kyiv began systematically hitting oil installations.

In response, Moscow intensified its campaign against Ukraine’s power grid, this time using heavy missiles to go after harder-to-destroy and much-harder-to-repair power plants themselves. More than half of Ukraine’s electricity generation capacity has been blown up or seriously damaged, a huge problem heading into winter given the reliance of Ukraine’s urban heating system (and water supplies) on the power plants.

But that campaign peaked just before summer; since then, there has been a respite in the Russian vendetta against power plants. The aftershocks are still felt, though. This week, in addition to a small-scale Russian attack on power facilities just across the border in Sumy, Ukraine announced a return to rolling blackouts for many parts of the country—mostly due to increased peak power demand during the hot summer months, but clearly exacerbated by the loss of so much generation capacity, which is still a huge concern for Ukrainian officials and Western experts.

“We have not seen wide-scale attacks for six weeks or so. Russia may just be collecting missiles to attack later in the year, in October or so. As of now, there is no sign that weaponization of energy is weakening,” said Andrian Prokip, an energy expert at the Wilson Center’s Kennan Institute in Kyiv.

Yet the fight over refineries and power plants is just part of an even broader energy war that has aspects both of the absurd and of the absurdly normal.

Last week, after months of feverish speculation, conspiracy theories, and finger-pointing, reporting (and a German arrest warrant) emerged that seemed to put blame for the high-profile 2023 destruction of Russia’s no-longer-operational Nord Stream gas pipeline on a band of Ukrainian freelancers.

Meanwhile, Russian natural gas continues to transit in pipes through war-torn Ukraine, headed for customers farther west in Austria, Slovakia, and Italy. Not even Ukraine’s cross-border grab of Sudzha, the pumping station for the last trans-Ukraine pipeline, has interrupted the (limited) flows of gas moving from one belligerent state through another.

And then there are the nuclear power plants. Since early in the war, Russia has occupied the Zaporizhzhia nuclear plant, Europe’s largest, in the south-central part of Ukraine. Since then, the International Atomic Energy Agency has periodically warned of concerns over the safety and security of the plant, which is now in shutdown but still potentially dangerous. Two weeks ago, a mysterious fire broke out at one of the cooling towers; a few days later, a drone explosion threatened the power supply to the facility. For years now, Russia and Ukraine have accused each other of nuclear blackmail and brinkmanship over the plant.

Once Ukraine leapt across the Russian border, Russian media immediately warned that Ukrainian forces were seeking to capture the Kursk nuclear power plant for an apparent atomic hostage swap; most recently, Russian defenders began digging trenches around the reactors.

“The Russians have used and will continue to use the precarious state of nuclear safety at Zaporizhzhia for their own rhetorical and blackmail purposes. I suspect they may try to do the same in relation to the Kursk NPP,” said Darya Dolzikova, a research fellow of the Royal United Services Institute.

“I see no indication that Ukraine is looking to attack the nuclear plant and the Ukrainian government has refuted any suggestions to that end,” she added. “So any Russian statements or actions to the contrary I take to be fear-mongering by Moscow.”

6 notes

·

View notes

Text

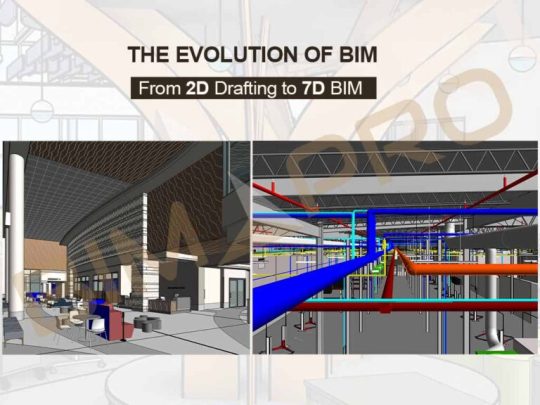

The Evolution of BIM: From 2D Drafting to 7D BIM

The construction industry has witnessed a remarkable transformation over the past few decades, driven by technological advancements. One of the most significant innovations is Building Information Modeling (BIM). What started as simple 2D drafting has evolved into a comprehensive system encompassing multiple dimensions. From design to maintenance, BIM has revolutionized the way we plan, construct, and manage buildings. In this blog, we will explore the journey of BIM from its early days to the highly advanced 7D BIM we see today.

The Era of 2D Drafting: The Beginning

Before the advent of BIM, architects, engineers, and designers relied on 2D drafting techniques. Blueprints and technical drawings were manually created on paper, requiring immense precision and effort. The introduction of computer-aided design (CAD) in the 1960s and 1970s brought a significant shift, allowing professionals to create digital 2D drawings. However, these drawings remained static representations, often leading to errors, miscommunication, and time-consuming revisions. The lack of data integration meant that project information was scattered, leading to inefficiencies in project execution and management.

Moreover, 2D drafting required extensive manual labor for each stage of the design process. Any changes in the design had to be redrawn from scratch, consuming valuable time. Coordination between different teams was also challenging, as changes in one discipline often led to inconsistencies in others. Errors were only discovered during construction, resulting in costly rework and delays. Additionally, quantity take-offs and bill of materials (BOM) had to be calculated manually, increasing the risk of miscalculations and cost overruns.

The Transition to 3D Modeling: A Game Changer

The limitations of 2D drafting led to the development of 3D modeling. In the late 20th century, software like AutoCAD, Revit, and ArchiCAD introduced the concept of three-dimensional design. 3D modeling provided a more realistic and detailed representation of structures, improving visualization and coordination among stakeholders. Architects and engineers could now see their designs in a virtual environment before construction began, allowing for better planning and reducing costly errors.

Unlike 2D drawings, 3D models allowed for a more intuitive understanding of spatial relationships. Teams could detect clashes between different systems, such as plumbing and electrical, before construction, leading to a significant reduction in errors. However, despite the added dimension, it still lacked data integration and intelligence, as it mainly focused on geometry rather than project information management. At this stage, Level of Development (LOD) concepts started emerging, enabling different stakeholders to define and refine the details of the BIM model at different stages of the project lifecycle.

4D BIM: Adding the Time Dimension

The next breakthrough in BIM came with the introduction of the fourth dimension: time. 4D BIM integrates project scheduling with 3D models, enabling stakeholders to visualize the construction sequence over time. This advancement improved project planning, reduced delays, and enhanced collaboration among teams. Contractors could simulate different scenarios, identify potential bottlenecks, and optimize construction workflows.

By linking the construction timeline to the 3D model, project managers could anticipate potential issues, allocate resources efficiently, and ensure smoother project execution. 4D BIM allowed teams to see when each component of the project would be constructed, facilitating better coordination between trades and minimizing on-site conflicts. As a result, construction projects became more predictable, reducing downtime and increasing efficiency.

5D BIM: Incorporating Cost Management

Cost estimation has always been a critical aspect of construction projects. 5D BIM brought financial management into the equation by linking cost data with the 3D model and project schedule. This integration provided accurate cost forecasting, real-time budget updates, and improved decision-making. Stakeholders could analyze cost variations, track expenses, and ensure financial control throughout the project lifecycle.

With 5D BIM, cost estimators and project managers could evaluate different design alternatives and their financial impact, ultimately helping in budget optimization and cost-effective decision-making. Cost changes due to material choices, design modifications, or construction sequences could be assessed in real time, preventing budget overruns. Automated quantity take-offs became more efficient and accurate, ensuring that project cost estimates aligned closely with actual construction costs. This real-time tracking of costs made construction more financially transparent, ensuring stakeholders had a clear understanding of budget allocations at every stage.

6D BIM: Enhancing Sustainability and Facility Management

As sustainability became a key focus in the construction industry, 6D BIM emerged to address environmental concerns. This dimension incorporates energy analysis, lifecycle assessment, and sustainability metrics into BIM models. Building owners and facility managers can use 6D BIM to optimize energy efficiency, reduce carbon footprints, and plan for long-term maintenance.

Additionally, it aids in predictive maintenance by providing insights into building performance over time. With real-time data and simulations, sustainability goals such as energy efficiency, material durability, and operational cost reductions can be achieved, ensuring environmentally responsible building designs. Green building certifications such as LEED and BREEAM can be seamlessly integrated into the BIM model, allowing for data-driven decision-making in sustainability planning.

By leveraging 6D BIM, facility managers can track energy consumption, perform preventive maintenance, and monitor the building’s carbon footprint. It enables owners to make data-driven decisions that enhance the building’s efficiency and extend its lifespan, ultimately leading to significant cost savings and environmental benefits. COBie (Construction-Operations Building Information Exchange) standards also play a critical role at this stage, ensuring that asset data is structured and efficiently transferred for use in facility management.

7D BIM: The Future of Building Management

The most advanced stage of BIM, 7D BIM, integrates facility management with real-time data. It allows stakeholders to manage the entire lifecycle of a building, from design to demolition. By incorporating asset management, maintenance scheduling, and IoT integration, 7D BIM enhances operational efficiency and reduces maintenance costs.

Building owners can track the performance of building components, automate maintenance tasks, and ensure long-term sustainability. With the growing adoption of smart buildings and IoT-enabled systems, 7D BIM is paving the way for more connected, efficient, and resilient building management practices. Facility managers can use digital twins of buildings to simulate operational scenarios, predict maintenance needs, and improve asset longevity.

Through integration with IoT, sensors can provide real-time data on occupancy, temperature, and equipment performance, enabling automated responses and predictive maintenance. This not only enhances comfort and safety but also significantly reduces operational costs, making 7D BIM an essential tool for modern building management. Furthermore, as-built BIM models ensure that facility managers have an accurate digital representation of the constructed building, enabling informed decision-making throughout the building’s lifecycle.

Benefits of BIM Evolution:

Here are some expanded benefits of BIM evolution:

Improved Collaboration and Coordination Accurate Quantity Take-Offs and Cost Estimation Reduced Errors, Rework, and Risks Enhanced Time Management and Scheduling Improved Facility Management and Lifecycle Analysis Sustainability and Energy Efficiency Higher Level of Development (LOD) for Better Detailing

Conclusion

The evolution of BIM has transformed the way we design, construct, and manage buildings. From simple 2D drawings to the intelligent and data-driven 7D BIM, the construction industry has embraced a new era of efficiency, sustainability, and innovation. As technology continues to advance, we can expect even more dimensions and capabilities to be integrated into BIM, shaping the future of architecture and engineering. Whether you are an architect, contractor, or building owner, understanding and leveraging BIM is no longer an option but a necessity for success in the modern construction landscape.

1 note

·

View note

Text

October 23, 2024

Ukraine - Zelenski Begs Russia To Renew Deals He Had Botched

The actor who has been playing the President of Ukraine for a while is getting cold feet. Winter is coming and the energy networks of Ukraine are near to the point of total breakdown.

There could have been agreements in place to prevent that. But the Ukrainian side had botched those deals. Now Zelenski is begging to renew them.

In late 2022 the Russian military launched a bombing campaign against electricity switching stations in Ukraine. A lot of transformers got blown up. The Ukrainian military responded by concentrating its air defenses near electricity stations. That was exactly the effect the Russian's had asked for. The air defense installations, not the electricity stations, had been their real target.

After splitting from the Soviet Union, Ukraine had had the best air defenses money could buy. During the fall and winter of 2022 most of it had been destroyed. The Russian campaign against electricity stations came to a halt.

In 2023/24 the Ukrainian military started its own campaign against infrastructure in Russia. Several refineries were hit by drones and went up into flames. Gasoline production in Russia was falling significantly and export of gasoline had to be stopped for a while.

The Russians retaliated by renewing their campaign against Ukraine's electricity network. But this time the targets were not just switching stations but the generation facility themselves. The non-nuclear electricity production in Ukraine got decimated.

In its daily briefings the Russian Ministry of Defense called the attacks on Ukrainian electricity stations a direct retaliation for Ukrainian attacks on Russian proper. For example:

This morning, in response to the Kiev regime's attempts to damage objects of Russian power infrastructure and economy, the Armed Forces of the Russian Federation delivered a group strike by long-range precision weaponry at objects of the Ukrainian military-industrial infrastructure and AFU aviation bases.

With their generation capacity in danger and under the threat of blackouts the Ukrainian government got to its senses - at least for a while. Secret negotiations were arranged in Doha, Qatar, to stop the infrastructure attacks on both sides.

In August 2024, shortly after the Ukrainian army had launched an incursion into the Kursk oblast of Russia, the Washington Post reported:

Ukraine and Russia were set to send delegations to Doha this month to negotiate a landmark agreement halting strikes on energy and power infrastructure on both sides, diplomats and officials familiar with the discussions said, in what would have amounted to a partial cease-fire and offered a reprieve for both countries. But the indirect talks, with the Qataris serving as mediators and meeting separately with the Ukrainian and Russian delegations, were derailed by Ukraine’s surprise incursion into Russia’s western Kursk region last week, according to the officials. ... For more than a year, Russia has pounded Ukraine’s power grid with a barrage of cruise missiles and drone strikes, causing irreparable damage to power stations and rolling blackouts across the country. Meanwhile, Ukraine has struck Russia’s oil facilities with long-range drone attacks that have set ablaze refineries, depots and reservoirs, reducing Moscow’s oil refining by an estimated 15 percent and raising gas prices around the world. ... A diplomat briefed on the talks said Russian officials postponed their meeting with Qatari officials after Ukraine’s incursion into western Russia. Moscow’s delegation described it as “an escalation,” the diplomat said, adding that Kyiv did not warn Doha about its cross-border offensive.

Ukraine had to pay a heavy price for the Kursk incursion. The elite troops it had sent failed to reach their target, a nuclear power station near Kursk, and soon got decimated. The attacks on Ukrainian infrastructure continued with full force.

Three month later, with the Kursk incursion as well as its electricity network near to total failure, the Ukrainian government is again changing course. It is begging to renew the deals it had botched.

3 notes

·

View notes

Text

United States Agrivoltaics : Rise Of Agrivoltaics In The American Farming

As climate change threatens global food supplies, agrivoltaic systems are gaining popularity in the United States as a way for farmers to boost solar energy production while continuing to harvest crops beneath solar panels. Also known as "agrophotovoltaics", agrivoltaic installations combine agriculture and solar power generation on the same land. By installing solar panels elevated high enough to allow farm equipment and livestock access to the ground below, farmers can generate solar power and grow crops or graze livestock simultaneously on the same parcel of land.

Benefits For Farmers And Food Security

Agrivoltaic systems provide multiple benefits for farmers and the environment. In addition to generating a steady additional revenue stream from solar electricity sales, studies have found that certain crops grown beneath solar panels have higher yields compared to directly exposed to sunlight. United States Agrivoltaics The partial shading from solar panels protects some crops from excessive heat and regulates soil moisture, improving overall productivity. For livestock grazing, the shade from panels protects animals from heat stress which has been shown to increase their health, growth rates and milk production. These dual-use installations are helping increase overall land productivity at a time when climate pressures are exacerbating food security risks.

Potential For Expanded Deployment

Currently, there are a few agrivoltaic pilot projects operating across the United States but their adoption remains limited compared to conventional ground-mounted solar farms. However, as the agricultural benefits become clearer and technology improves to maximize both energy and food outputs, experts expect agrivoltaics to play a much larger role in the country's clean energy transition. Some estimates suggest agrivoltaic systems could potentially generate hundreds of gigawatts of solar power on available farmland if deployed at sufficient scale. States with vast agricultural areas like California, the Midwest and Plains regions are well positioned to lead the way.

Project Developers Tout Multiple Cropping Options

Early agrivoltaic projects in the United States Agrivoltaics have tested growing a variety of crops beneath solar panels including grapes, olives, berries and vegetables. Developers say that with proper panel elevation and optimization of lighting conditions, row crops like lettuce, onions and carrots can also thrive. Livestock operations are integrating panels for grazing dairy cattle and lamb. Ongoing research is exploring additional dual-use combinations suited for different soil types and microclimates across farming regions. Producers are also experimenting with staggered panel installation to allow continued mechanical harvesting of commodity row crops like corn and alfalfa. As more multi-year yield data becomes available, farmers' confidence in agrivoltaics is increasing.

Tailoring Technology To Farming Needs

A challenge for wider deployment remains ensuring agrivoltaic systems are economically viable propositions for farmers and easy to incorporate into their existing operations. US developers are working to refine mounting configurations, panel elevations and integrated smart technologies to maximize both solar energy generation and agricultural outputs specific to local growing conditions and crop varieties. There is also ongoing innovation related to access for machinery and irrigation systems beneath panels. Additional research partnerships involving farmers, land grant universities and the national labs are vital to further adapt agrivoltaic technologies and successfully demonstrate scalable business models tailored for different commodity crop types.

Overcoming Permitting And Policy Hurdles

In addition to technology challenges, policy and permitting issues have slowed the scaling of agrivoltaic projects. Some state and local regulations do not yet account for dual-use of farmland and view agrivoltaics as competing land uses rather than complementary. Renewable energy incentives also often only apply to standalone solar farms versus agrivoltaic systems. advocates are working with policymakers to establish legal recognition and support for agrivoltaics through measures like revised zoning definitions, streamlined permitting procedures and tailored financial incentive programs. Widespread adoption will require acknowledgement from governing bodies that these installations can provide compatible and sustainable multi-functional land use.

Outlook

As concerns intensify about long-term global food security in the face of interconnected economic, environmental and geopolitical pressures, United States Agrivoltaics are gaining recognition as a means to boost domestic farming resiliency. By sustainably increasing total land productivity, these dual-use systems could make a meaningful contribution to both energy and agriculture production if scaling challenges are addressed. With ongoing technological enhancements, successful demonstration projects, revised policies and expanding cooperative efforts, the outlook is positive for agrivoltaics to emerge as an important complement to America's clean energy transition and agricultural landscape in the coming decade.

Get more insights on this topic: https://www.ukwebwire.com/united-states-agrivoltaics-emerging-clean-energy-technology-for-farmers/

Author Bio

Vaagisha brings over three years of expertise as a content editor in the market research domain. Originally a creative writer, she discovered her passion for editing, combining her flair for writing with a meticulous eye for detail. Her ability to craft and refine compelling content makes her an invaluable asset in delivering polished and engaging write-ups. (LinkedIn: https://www.linkedin.com/in/vaagisha-singh-8080b91)

*Note: 1. Source: Coherent Market Insights, Public sources, Desk research 2. We have leveraged AI tools to mine information and compile it

1 note

·

View note

Text

Control Valve Market Size, Share, Scope and Trends for 2023-2033

The Control Valve Market in United States is expected to undergo a Compound Annual Growth Rate (CAGR) of 7.1% from 2023 to 2033. The uptick in control valve sales within the country can be attributed to the presence of control valve manufacturers and a growing base of end users. Moreover, the robust industrial infrastructure in the United States is poised to drive increased adoption of control valves.

The worldwide control valve market size is estimated to be worth $13 billion in 2023, and it is projected to achieve a value of $23.3 billion by the end of 2033, with a consistent annual growth rate (CAGR) of 6% over the decade under consideration.

Download a Sample Copy of This Report: https://www.factmr.com/connectus/sample?flag=S&rep_id=439

In the ever-evolving landscape of industrial automation and process control, control valves play a pivotal role in ensuring precise regulation of fluid flow, temperature, and pressure within various systems. Recent trends indicate that the global control valve market is witnessing steady expansion across key industries, fueled by a growing emphasis on efficiency, sustainability, and technological advancements.

Control Valve Market Key Sectors

Oil and Gas Industry

The oil and gas sector has always been at the forefront of adopting advanced technologies to optimize production and reduce operational costs. Control valves have become indispensable tools in this industry, ensuring the precise control of flow rates, pressure, and temperature in various processes. With the growing demand for oil and gas, the control valve market continues to expand to meet the requirements of exploration, production, and refining operations.

Power Generation

The power generation industry is experiencing a transformation with an increasing focus on renewable energy sources and energy efficiency. Control valves are integral in power plants, where they help manage the flow of steam, water, and other fluids, ensuring the safe and efficient operation of turbines and boilers. The need for more advanced control valves to enhance energy efficiency and reduce emissions is driving market expansion in this sector.

Chemical Industry

The chemical industry relies on precise control of various processes to maintain product quality and safety. Control valves are essential for handling corrosive and hazardous chemicals, making them critical for the industry's success. As chemical manufacturing continues to grow globally, the control valve market is expanding to meet the sector's demands.

Water and Wastewater Treatment

The necessity for clean water and effective wastewater treatment is paramount. Control valves are vital in water distribution and treatment plants to regulate water flow and maintain water quality. With increasing urbanization and the need for sustainable water management, the control valve market in this sector is on a steady growth trajectory.

Competitive Landscape

Prominent control valve manufacturers are making substantial investments in research and development to pioneer innovative solutions, all the while adhering to stringent safety regulations. These industry leaders consistently pursue strategic initiatives like rigorous quality control, adherence to product standards, forging strategic partnerships, and optimizing supply chain management to fortify their foothold in the market. The overarching objective is to expand their influence at both domestic and international levels, thereby offering their clientele a broader spectrum of product offerings.

For instance,

In November 2019, Bürkert introduced a redundancy block featuring valves and pressure switches tailored for applications with elevated safety prerequisites.

Key Segments of Control Valve Industry Research

By Actuation Technology :

Manual

Pneumatic

Hydraulic

Electric

By Valve Type :

Ball

Butterfly

Globe

Plug

Others

By Application :

Metal & Mining

Pulp & Paper

Power Generation

Oil & Gas

Chemicals

Food & Beverages

Automotive

Pharmaceuticals

Water & Wastewater Management

Others

By Region :

North America

Europe

Asia Pacific

Latin America

Middle East & Africa

Get Customization on this Report: https://www.factmr.com/connectus/sample?flag=RC&rep_id=439

The control valve market is witnessing steady expansion across key industries due to its fundamental role in ensuring precise and efficient control of various processes. As industries continue to prioritize efficiency, sustainability, and advanced technologies, the demand for control valves is expected to grow further. This trend is a testament to the adaptability and resilience of the control valve market, which remains a vital component in the world of industrial automation and process control.

Contact: US Sales Office 11140 Rockville Pike Suite 400 Rockville, MD 20852 United States Tel: +1 (628) 251-1583, +353-1-4434-232 Email: [email protected]

1 note

·

View note

Text

Industrial Batteries Market Challenges and Growth Strategies 2025-2030

The global industrial batteries market size was estimated at USD 22.44 billion in 2024 and is projected to reach USD 34.57 billion by 2030, growing at a CAGR of 7.6% from 2025 to 2030. This notable growth trajectory is primarily driven by several interrelated factors. One of the most significant is the increasing demand for reliable backup power solutions across various industrial sectors. Industries today are heavily reliant on uninterrupted power supply to ensure smooth operations, and industrial batteries offer a dependable solution for power continuity during outages or fluctuations.

Another critical driver is the rising adoption of renewable energy storage systems, where industrial batteries play a pivotal role in storing excess energy generated from renewable sources such as solar and wind. These storage systems are essential for balancing supply and demand, especially in off-grid or intermittent energy environments. Additionally, the expanding use of industrial batteries in grid-level energy storage, telecommunications infrastructure, and the electric vehicle (EV) sector is further boosting market demand. Batteries in these areas are essential for ensuring energy reliability, communication resilience, and efficient EV performance.

Moreover, the market is witnessing significant support from government policies and regulatory frameworks aimed at reducing carbon emissions and promoting environmentally sustainable practices. Initiatives encouraging a shift toward cleaner energy, often summarized under the banner of the "Go Green" movement, are pushing industries to invest in sustainable energy storage technologies like industrial batteries. The growing emphasis on environmental stewardship and the global urgency to combat climate change are catalyzing this transition.

The technological advancements in battery science, particularly the development and refinement of lithium-ion battery technology, are further accelerating the growth of the industrial battery market. These innovations are leading to batteries with enhanced energy density, faster charging capabilities, and improved safety features. Coupled with a rise in environmental awareness and the push for cleaner industrial practices, these factors are fostering widespread adoption of advanced battery solutions.

Industrial batteries, in this context, are sophisticated energy storage systems engineered to provide durable and reliable power tailored specifically for high-demand industrial environments. They are built to endure tough operating conditions—such as extreme temperatures, heavy loads, and continuous cycling—while ensuring consistent power delivery. These batteries serve a wide range of industries, including manufacturing, telecommunications, and renewable energy systems, supporting critical infrastructure and operations.

Key Market Trends & Insights:

• In terms of region, the Asia Pacific region emerged as the largest revenue-generating market in 2024 for industrial batteries. This dominance can be attributed to the region’s rapid industrialization, expanding manufacturing base, and increasing investments in renewable energy infrastructure. Countries across Asia Pacific are witnessing significant growth in sectors such as automotive, telecommunications, and utilities, all of which demand reliable energy storage solutions. Additionally, government initiatives aimed at modernizing energy grids and promoting sustainable practices have further fueled the adoption of industrial batteries in the region.