#reverberatories

Explore tagged Tumblr posts

Text

Reverberatory furnace

22 notes

·

View notes

Text

Story Preview: Magic/Dark Academia AU in which skating, linguistics, and time travel intersect

Professor Baranovskaya loudly cleared her throat and placed a hand on Yuuri’s trembling shoulder.

“Everyone, please take a moment to welcome your newest classmate,” she airily announced, to a rather stilted round of clapping. “If you didn’t get a chance to meet him at the Prospective Students Banquet last December– ” (to Viktor’s chagrin, even louder giggling erupted, making him want to throttle Isabella Yang) “ – or over the last few weeks, allow me to introduce first year student Katsuki Yuuri, hailing from the town of Hasetsu, Japan. I’m told by Professor Cialdini that Yuuri’s grasp of Reverberatory Theory could rival a faculty member’s, so I’m sure you’ll find him to be a valuable resource.”

Curious whispers filled the room at this last sentence. Aside from Viktor and just two other students – 4th years Sasha Samokhina and Kostya Kozhennikov – no one else had actually managed to grasp the intricacies of Reverberation, particularly when it came to its grammatical rules.

“That being said, do try not to resent his prowess too much,” Professor Baranovskaya firmly finished.

Their eyes met and Viktor felt a bit insulted by her lingering gaze. Resent Yuuri?

Him?!?

Once again, Viktor reflected on how misunderstood he was at Pax. If he tried to befriend promising students like Sasha or his fellow dual major classmate Nao Yasutani, it was automatically regarded with skepticism, as if the Institute's top Reverberator couldn’t possibly want companionship without having ulterior motives.

It made him want to scream.

Had Professor Baranovskaya forgotten how he’d begged Drs. Piseev and Leroy to accompany them on the scouting trip to Japan, back in April? Had she conveniently forgotten that it was Viktor who had so zealously insisted on Yuuri’s recruitment to Pax in the first place, well before that wondrous video had been uploaded to the internet?

---

The above excerpt is a preview of a new 'Alternate First Meeting' Yuri!!! on Ice WIP/series I'm working on: a friends-to-lovers, magical dark academia AU that I was inspired to write after finishing the books Vita Nostra (by Maryna and Serhiy Dyachenko), and Babel (by RF Kuang). Both are so gripping and imaginative, and I couldn't stop thinking about how my favorite characters might intersect with the rich settings/magic systems in either.

Below is a tentative summary; if this sounds interesting, I hope you'll give me a follow!

---

The first known instance of Reverberation – the phenomenon in which a skater produces language and energy with their body, universally felt and understood by all in proximity – occurred in 1952, when Dick Button performed the first triple jump. Over 50 years later, Viktor Nikiforov is skating’s most prolific Reverberator and star student at the University of Chicago’s Pax Institute: the world’s premier research center dedicated to the training of Reverberators for global diplomacy.

When Katsuki Yuuri finds himself being aggressively recruited by his idol to enroll at Pax, he has no idea that the two of them will eventually become best friends. Or, that they will one day co-lead a student uprising once they uncover the true, sinister aim of their education: to master the art of stationary Reverberation that transfers language onto blank pages and creates enough energy to rip through time

#yuri on ice#yuri!!! on ice#yuri on ice fanfiction#yoi fanfiction#my writing#my wips#Vita Nostra/Babel AU#vita nostra#babel an arcane history#viktuuri#victuuri#yuri on ice au#yes I am once again overcommitting#the hyperfixations are multiplying#this is why I shouldn't read

13 notes

·

View notes

Text

The benefit of aluminum dross rotary furnace with a dross cooler

The benefit of aluminum dross rotary furnace with a dross cooler

Aluminum dross rotary furnaces and dross coolers play a crucial role in aluminum recycling by improving efficiency, reducing metal loss, and enhancing safety.

Here are the key benefits of both:

1. Aluminum Dross Rotary Furnace:

A rotary furnace is used to recover aluminum from dross efficiently. It provides better metal yield and reduces waste.

youtube

Key Benefits:

✅ Higher Metal Recovery:

Improves aluminum recovery from dross compared to traditional methods.

Reduces metal loss, increasing profitability.

✅ Energy Efficiency:

Uses less energy compared to conventional reverberatory furnaces.

Optimized combustion and heat distribution lower operational costs.

✅ Faster Processing Time:

Speeds up dross processing, allowing higher throughput.

Minimizes the time aluminum is exposed to oxidation.

✅ Environmental Benefits:

Reduces emissions and waste disposal compared to open-air cooling.

Less slag generation improves sustainability.

✅ Automation & Safety:

Automated operation reduces labor involvement and enhances worker safety.

Controlled environment minimizes hazardous fume exposure.

2. Aluminum Dross Cooler:

A dross cooler rapidly cools aluminum dross, preventing oxidation and improving aluminum recovery.

Key Benefits:

✅ Prevents Aluminum Oxidation:

Rapid cooling stops aluminum from further oxidizing, preserving valuable metal.

More metal can be recovered, increasing efficiency.

✅ Reduces Energy Consumption:

Eliminates the need for water cooling or other inefficient cooling methods.

Heat from cooling can sometimes be reused in the process.

✅ Improves Safety:

Reduces the risk of molten metal splashes or gas emissions during cooling.

Minimizes exposure to toxic fumes.

✅ Enhances Process Efficiency:

Allows faster turnaround times for dross recycling.

Ensures dross is at an optimal temperature for processing.

Conclusion:

Using both a rotary furnace and a dross cooler together can maximize aluminum recovery, reduce costs, and improve environmental sustainability in aluminum recycling.

Would you like recommendations for specific models? Please contact us for the technical data and price!

#aluminumdrossprocessing#aluminumdrossrotaryfurnace#aluminumdrosscooler#aluminumslag#aluminumdrossmachine#aluminiumdrossrecycling#rotaryfurnace#aluminumdrosscooling#secondaryaluminumdross#hotaluminumdross#coldaluminumdross#Youtube

1 note

·

View note

Text

0 notes

Text

The Impact and Importance of Scrap Metal Recycling in Adelaide

Scrap metal recycling is a crucial industry in Adelaide, playing a vital role in environmental sustainability, economic growth, and resource conservation. With the city’s rich industrial history and a strong commitment to environmental stewardship, Adelaide has become a hub for scrap metal recycling. Whether you're an individual looking to dispose of unwanted metal items or a business managing industrial scrap, recycling metal is a practice that benefits both the community and the planet.

Why Scrap Metal Recycling Matters

1. Environmental Protection: One of the most significant advantages of scrap metal recycling is its positive impact on the environment. Mining and processing new metal ore require substantial amounts of energy and result in greenhouse gas emissions, deforestation, and habitat destruction. By recycling scrap metal, Adelaide reduces the need for new metal production, thereby minimizing environmental degradation and conserving natural landscapes.

2. Resource Conservation: Metals are finite resources, and recycling them ensures that these valuable materials are reused rather than discarded. This practice helps conserve natural resources, reducing the need for new mining activities. Adelaide’s scrap metal recycling industry plays a crucial role in preserving these resources for future generations while also providing a steady supply of recycled metal for various industries.

3. Economic Benefits: Scrap metal recycling is a significant contributor to Adelaide's economy. The industry provides jobs in collection, sorting, processing, and transportation, supporting local employment and business growth. Moreover, selling scrap metal can be a profitable venture for both individuals and businesses, as recycled metal often commands competitive prices in the market.

4. Energy Efficiency: Recycling scrap metal is far more energy-efficient than producing new metal from raw ore. For example, recycling aluminum saves up to 95% of the energy required to produce new aluminum, while recycling steel saves about 60-74% of the energy. This substantial energy saving translates to lower carbon emissions and a reduced environmental footprint, making scrap metal recycling an essential component of Adelaide’s sustainability efforts.

The Scrap Metal Recycling Process

The process of scrap metal recycling in Adelaide involves several stages, each designed to efficiently recover and repurpose metal for reuse. Here’s an overview of how scrap metal is recycled:

1. Collection: The first step in recycling scrap metal is collection. Scrap metal can come from various sources, including household items, industrial machinery, construction materials, and old vehicles. Adelaide residents and businesses can bring their scrap metal to recycling centers, or they can arrange for collection services provided by local recyclers.

2. Sorting and Processing: Once collected, the scrap metal is sorted and processed. Sorting involves separating different types of metals, such as ferrous (iron and steel) and non-ferrous (aluminum, copper, brass) metals. This sorting process is crucial because different metals require different recycling techniques. Advanced sorting technologies, including magnets and eddy current separators, are used to efficiently separate the metals.

3. Shredding and Melting: After sorting, the metal is shredded into smaller pieces to facilitate melting. The shredded metal is then melted in furnaces specifically designed for each type of metal. For example, steel is melted in a basic oxygen furnace, while aluminum is melted in a reverberatory furnace. The melting process allows the metal to be purified and formed into ingots or other shapes.

4. Refining and Purification: The molten metal is further refined to remove any impurities and achieve the desired level of purity. This refining process ensures that the recycled metal meets industry standards and is suitable for manufacturing new products. The purified metal is then cast into ingots, billets, or sheets, ready for reuse in various industrial applications.

5. Reuse and Manufacturing: The final stage of the recycling process involves reusing the recycled metal in the production of new goods. These materials are sold to manufacturers who use them to produce everything from automotive parts and construction materials to household appliances and electronics. By reintroducing recycled metal into the production cycle, Adelaide’s recycling industry helps close the loop and promote a circular economy.

Scrap Metal Recycling Services in Adelaide

Adelaide is home to several reputable scrap metal recycling companies that offer a range of services to the community. These companies are equipped with the necessary technology and expertise to handle various types of scrap metal, ensuring that materials are recycled responsibly and efficiently. Some well-known scrap metal recyclers in Adelaide include:

Sims Metal Management: A global leader in metal recycling, Sims Metal Management operates a facility in Adelaide that accepts a wide range of scrap metals, including steel, aluminum, copper, and brass. They offer competitive prices and provide convenient drop-off and collection services.

Adelaide Metal Recyclers: A locally owned and operated business, Adelaide Metal Recyclers specializes in the collection and processing of ferrous and non-ferrous metals. They are committed to sustainability and offer transparent pricing for all types of scrap metal.

AAA Recycling Centre: Known for their customer-friendly service, AAA Recycling Centre in Adelaide provides efficient scrap metal recycling services for both individuals and businesses. They accept a variety of metals and offer prompt payment for scrap materials.

How You Can Contribute to Scrap Metal Recycling

Whether you’re an individual looking to dispose of old appliances or a business managing industrial scrap, participating in scrap metal recycling is easy and beneficial. Here’s how you can contribute:

Sort Your Scrap: Separate your metal items by type (e.g., aluminum, copper, steel) before bringing them to a recycling center. This will help you get the best price for your scrap and ensure efficient recycling.

Use Local Recycling Services: Take advantage of Adelaide’s many recycling centers and scrap yards. Some facilities offer collection services, making it convenient for businesses to recycle large quantities of scrap metal.

Educate Others: Spread the word about the importance of scrap metal recycling. Encourage friends, family, and colleagues to recycle their metal waste, contributing to a cleaner and more sustainable Adelaide.

Conclusion

Scrap metal recycling is a vital practice that benefits the environment, conserves valuable resources, and supports the economy in Adelaide. By choosing to recycle scrap metal, residents and businesses can play a key role in reducing environmental impact, saving energy, and contributing to a circular economy. As Adelaide continues to grow, the importance of responsible recycling will only increase, making it an essential part of the city’s sustainable future.

0 notes

Text

Understanding the Scrap Recycling Process: From Collection to Reuse

The scrap recycling technique includes converting waste materials from a series to a single use. Scrap recycling is a critical commercial enterprise employer that transforms waste materials into treasured assets, protects herbal belongings, lowers power consumption, and minimizes environmental pollutants. This device encompasses numerous ranges, from the initial collection of scrap substances to their eventual reuse in several industries.

Right here’s a whole evaluation of the scrap recycling approach.

The first step in the scrap recycling technique is the collection of scrap substances. Those substances can come from a selection of properties, including families, organizations, the arrival of internet net web sites, and industrial organization company operations. Not unusual kinds of scrap embody metals (which include aluminum, copper, and steel), paper, plastics, glass, and electronics. Collection can be completed through curbside recycling applications, drop-off facilities, or purchase-decrease programs that provide incentives for returning recyclable materials.

The Process of Sorting Materials in Recycling Facilities

As soon as the scrap substances are gathered, they are transported to recycling facilities, where they'll be sorted. Sorting is an essential step that guarantees precise types of substances are separated for green processing. This can be completed manually or with computerized structures organized with magnets, sensors, and air classifiers. Metals are frequently sorted by using magnets to separate ferrous metals (like iron and steel) from non-ferrous metals (like aluminum and copper). Plastics are looked after with the useful aid of the use of kind and shade, while paper is separated into precise grades.

Processing After sorting

The materials go through processing to be prepared for recycling. Metals are usually shredded or beaten to lessen their length and facilitate melting. For instance, metallic is often shredded into small portions to make its masses much less complex to address and melt. Plastics are wiped away, shredded, and, from time to time, melted and pelletized to form uniform raw substances for the manufacturing of modern-day plastic products. Paper is pulped, which involves mixing it with water to break it down into fibers that would then be wiped clean and de-inked.

Melting and purification

Inside the melting and purification process, metals are melted in massive furnaces to eliminate impurities and put together for casting into new shapes. Every form of metal has its own private melting method: metallic is usually melted in an easy oxygen furnace or an electric-powered arc furnace, at the same time as aluminum is melted in a reverberatory furnace. The molten steel is then purified by removing any remaining contaminants. For plastics, purification consists of getting rid of non-plastic materials and contaminants over and over through washing or chemical strategies.

Production

The very last degree inside the recycling method is manufacturing, wherein the recycled materials are used to provide new products. As an example, recycled metallic and aluminum are used inside the automobile and manufacturing industries, just as recycled plastics are used in packaging, textiles, and consumer gadgets. Paper mills use recycled paper to deliver newsprint, cardboard, and business paper. This degree closes the recycling loop as products made from recycled materials re-input into the marketplace, reducing the need for virgin, uncooked substances.

Environmental and monetary blessings

The scrap recycling method offers huge environmental and monetary blessings. Recycling reduces the need for natural assets and protects raw substances like minerals, wood, and petroleum. It also saves electricity; for instance, recycling aluminum saves as much as ninety percent of the energy required to provide aluminum from raw ore. Furthermore, recycling reduces greenhouse gas emissions, decreases pollution, and minimizes the quantity of waste sent to landfills. Economically, the recycling corporation creates jobs and stimulates financial growth through the sale and purchase of recycled materials and products.

Forming as quickly as it is purified

The molten metal or plastic is powerful enough to just accept new shapes. Metals are sturdy into ingots, bars, or unique places of job artwork like vehicle components and production materials. Plastics are usually pellets or nicely molded into new products. Paper pulp is processed into new paper merchandise through a chain of drying and rolling steps. Glass is melted and reformed into bottles, jars, or unique glass products. The forming diploma is vital for transforming recycled materials into usable merchandise that meets the necessities of business employer agencies.

Conclusion

Scrap recycling is a critical part of sustainable, beneficial, and useful resource manipulation, converting waste into treasured substances that may be reused in numerous industries. From series and sorting to processing and manufacturing, every diploma plays a vital role in ensuring the overall performance and effectiveness of recycling efforts. By using facts and helping with the recycling approach, human beings and organizations can make a contribution to a more sustainable and environmentally fantastic future.

0 notes

Text

Electric Drying Oven, Electric Drying Ovens, Manufacturer, Mumbai, India

Manufacturer and Supplier of Electric Drying Oven, Electric Drying Ovens, Heating Unit, Pumping Unit, Pumping Oil In Reheating Furnaces, Heating / Pumping Unit, Mumbai, India.

Industrial Furnaces, Industrial Burners, Industrial Furnace, Industrial Burner, Walking Beam Type Re-Heat Furnaces, Bright Annealing Furnaces, Blue Flame Gas Burners Series 44, Pusher Type Re-Heat Furnaces, Continuous Wire Annealing Furnaces, Reheating Furnace, Pusher Furnace, Pusher Furnace, Walking Hearth Furnace, Chamber Furnace, Forging Furnace, Chamber Furnaces, Box Furnace For Forging, Chamber Furnace, Twin Chamber Furnace, Ss Wire Furnace, Strand Annealer, Solution Annealing Furnace, Fine Wire Furnace, Aluminium Melting Furnace, Stationary Type, Tilting Type, Tilting Type Mechanical, Roller Hearth Annealing Furnace, Industrial Roller Hearth Annealing Furnace, Bright Annealing Furnace, Pit Furnace, Bogie Hearth Furnace, Recuperator, Hair Pin Type Recuperator, Over Head Recuperator, Under Ground Recuperator, Radiation Type Recuperator, Industrial Burner, Coal Gas Burner, Oil Burner, Dual Fuel Burner, Gas Burner, Heating Pumping Unit, Combustion Blower, Charging Pusher, Discharge Ejector, Flue Damper, Gas Train, Rolling Mill Furnace, Oil Burner, Annealing Furnace, Gas Burner, Coal Gas Burner, Air Blower, Air Butterfly Valve, Alkaline Tank, Aluminium Melting Furnace, Aluminium Melting Furnace, Aluminium Melting, Annealing, Baking Oven, Blower, Blu-Flam Burners, Box Furnace For Forging, Burners, Butterfly Valve, Centrifugal Blower, Chamber Furnace, Charging Pusher, Coal Gas Burners, Combustion Blower, Combustion Equipments, Combustion Piping, Diesel Burners, Discharge Pusher, Dual Fuel Burners, Ejector, Electric Heat Furnace, Flowmeter, Forging Chamber Furnace, Forging Furnace, Forging Furnace, Furnace Maintenance, Furnace Manufactures, Furnace Oil Burner, Furnace Repair, Furnace Repair, Furnace Revamping, Furnace, Furnace, Gas Burners, Gas Burners, Gas Conversion, Gas Fired Furnace, Gas Piping, Hardening & Tempering Furnace, Heat Economizer, Heat Recovery System, Heat Treatment Furnace, Heat Treatment Furnace, Heat Treatment, Heating Pumping Unit, Hot Air Blower, Hot Air Lagging, Hot Air Recuperator, Industrial Burners, Industrial Melting Furnace, Ldo Burners, Lpg Burner, Melting Furnace, Monoblock Burners, Multiblock Burner, Natural Gas Burner, Oii Burners, Oil Burner, Oil Burners, Oil Fired Furnace, Oil Fired Salt Bath Furnace, Oil Flowmeter, Oil Micro Valve, Oil Piping, Oil Pumping Unit, Pipe Lagging, Pit Furnace, Pit Type Chamber Furnace, Producer Gas Burners, Pumping Unit, Pusher Furnace For Rolling Mill, Pusher Furnace, Pusher Re-Heat Furnace, Pusher, Re-Heating Furnace, Recuperator, Recuperator, Reheat Furnace For Rolling Mill, Reheat Furnace, Reheat Furnace, Reverberatory Furnace, Rod Mill Furnace, Roller Furnace, Roller Hearth Annealing Furnace, Rolling Mill Furnace, Screw Conveyor Furnace, Section Mill Furnace, Section Mill Pusher Furnace, Solenoid Valve, Tilting Furnace, Top & Bottom Fired Furnace, Walking Beam Furnace Walking Hearth Furnace, Walking Beam Furnace, Project Engineer Jobs, Design Engineer Jobs, Project Engineer For Furnace, Design Engineer For Furnace, Jobs In Mechanical, Inspection Engineer, Jobs In Project, Jobs In Design, Site Engineer, Jobs For Site Engineer, Mumbai, India

0 notes

Text

6 Types of Commonly Used Aluminium Recycling Furnace

An aluminum recycling furnace is a specialized equipment used for the recycling and melting of aluminum scrap to produce new aluminum products. Aluminum recycling is an important process as it helps conserve resources, reduce energy consumption, and minimize environmental impact.

Typically, there are 6 types of commonly used aluminum recycling furnaces.

Reverberatory Furnace

This type of furnace consists of a rectangular refractory-lined chamber with burners positioned along one side. The aluminum scrap is charged into the furnace, and heat is applied by the burners. The heat generated by the burners reflects off the furnace roof and walls, creating a "reverberation" effect that helps melt the aluminum. The molten aluminum collects at the bottom of the furnace and is tapped out for further processing.

Rotary Furnace

A rotary furnace is a cylindrical refractory-lined vessel that rotates on its axis. It is typically inclined slightly to facilitate the movement of the aluminum scrap through the furnace. The furnace is heated by burners positioned at one end. As the furnace rotates, the aluminum scrap moves from the charging end to the tapping end. The rotation and inclination of the furnace help agitate the scrap and expose it to the heat, facilitating melting. The molten aluminum is tapped from the bottom of the furnace.

Electric Arc Furnace (EAF)

Electric arc furnaces are commonly used in the recycling of aluminum. They utilize electric arcs as the source of heat to melt the aluminum scrap. EAFs consist of a refractory-lined vessel with three graphite electrodes inserted through the roof. When an electric current passes through the electrodes, an intense electric arc is generated, producing high temperatures that melt the aluminum. EAFs are known for their flexibility and ability to handle a wide range of aluminum scrap types.

Induction Furnace

Induction furnaces use electromagnetic induction to generate heat for melting aluminum. An induction coil surrounds the refractory-lined crucible, and alternating current flows through the coil, creating a magnetic field. The magnetic field induces eddy currents in the aluminum scrap, which in turn generate heat and cause the material to melt. Induction furnaces are known for their fast heating rates, precise temperature control, and energy efficiency.

Tilt Rotary Furnace

Tilt rotary furnaces are a variation of the rotary furnace mentioned earlier. These furnaces are designed to tilt, allowing for easier charging and tapping operations. The tilting motion helps facilitate the movement of the aluminum scrap through the furnace and enhances the efficiency of the melting process.

Shaft Furnace

Shaft furnaces are vertical, cylindrical furnaces used for aluminum recycling. The aluminum scrap is loaded from the top and gradually moves downward through the furnace as it is heated. The heat is typically supplied by burners positioned at various levels within the furnace. Shaft furnaces provide good thermal efficiency and are suitable for processing a wide range of aluminum scrap sizes.

The furnaces operate at high temperatures, typically ranging from 700°C to 900°C (1292°F to 1652°F). The specific temperature depends on the type of aluminum being recycled and the desired quality of the final product.

In addition to the furnaces, aluminum recycling facilities also employ various technologies such as electromagnetic stirring systems, fluxing agents, and filtration systems to optimize the recycling process and remove impurities.

The choice of furnace type depends on various factors such as the type and quantity of aluminum scrap, desired production capacity, energy efficiency requirements, and specific process considerations of the recycling facility. Each furnace type has its advantages and limitations, and the selection is typically based on the specific needs and constraints of the recycling operation.

0 notes

Text

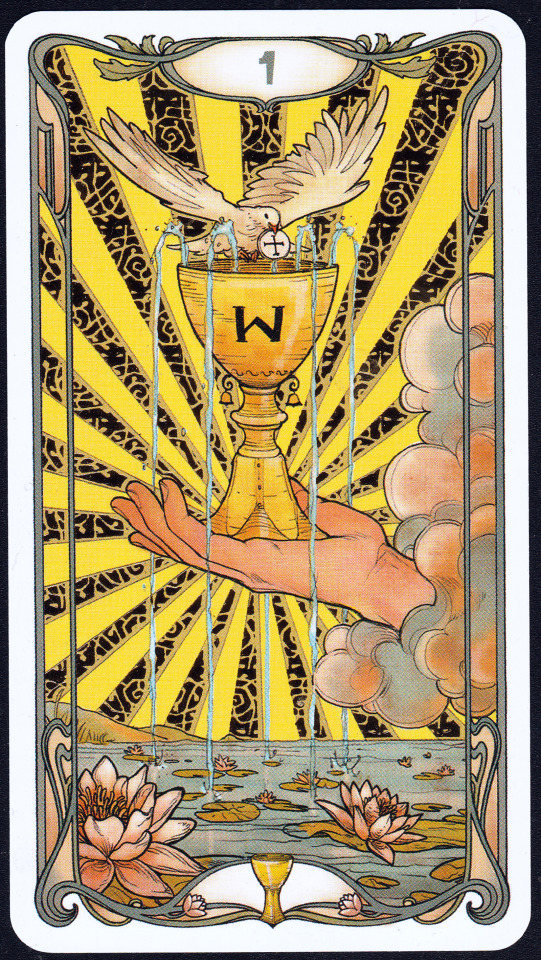

Ace of Cups. Golden Art Nouveau Tarot.

It is the very nature of a cup to be a structured hollowness, a structured emptiness that enables collection and amplification. I think about my Tibetan singing bowl and the nearly magical way that the metal vibrates and reverberates through the empty center. That kind of amplification, that kind of resonance, is actually what the suit of Cups is all about. Cups, it is often said, is the suit of water and of emotions. The association to our emotional life may not be wholly inaccurate, but it seems narrow. We typically understand emotions as personal and private. Emotions belong to the individual self. If cups are hollow by nature, it might be because they reflect the essentially empty or hollow nature of the self. Instead of emotion, the suit of Cups taps into the reverberatory, transpersonal world of soul. The soul is the “imaginative possibility” in our nature, as archetypal psychologist James Hillman puts it. We are beings who don’t merely feel. We speculate and reflect. We resonate with myth, art, and ritual. We grant our emotions the larger reach of meaning.

As archetypal psychology defines it, soul sees the universal within the particular. Soul recognizes the person as the human, and the human as the divine. Thanks to soul, events rebound and amplify through dream and image. The soul wants nothing more than to continually deepen our sense of life’s beauty. The Ace reminds us that the soul’s cup continually overflows because it manages to receive and to give simultaneously. Events echo and concatenate within the chambers of our soul, expanding through poetry and picture, myth and archetype, and blessing the world with meaning. “Soul is revealed in attachment, love, and community,” writes Thomas Moore in his book Care of the Soul. It’s in our attachment to the world, in our sense of community and commonality, that we feel the reverberations of each moment. At the same time, those reverberations create the community we feel. We should not be surprised that the Waite-Smith imagery of this suit invokes the ultimate moment of communing: the Eucharist. The Ace of Cups invites us to drink deep—to imagine that this world, all around us, is a good world: a world of blessing, communion, and community. The gift of the Cups is also the gift we give others as we dive into the resonant abundance of the world. Lisa Freinkel Tishman.

1 note

·

View note

Text

Introducing road trip spots in Japan! Learn more about this place👇😊

0 notes

Text

[pixel cells]

I was part of it, – it – was a mass of vibrating pixels and cells, a swarm of dots that I was able to dart through and view from all directions because I too was a dot, I was part of this energy in reverberatory static. A laughing mass of play, a chuckling stellar nursery full of dot babies glitch muttering aphorisms.

0 notes

Text

Interesting Papers for Week 24, 2023

Spike-timing-dependent plasticity rewards synchrony rather than causality. Anisimova, M., van Bommel, B., Wang, R., Mikhaylova, M., Wiegert, J. S., Oertner, T. G., & Gee, C. E. (2022). Cerebral Cortex, 33(1), 23–34.

Normative decision rules in changing environments. Barendregt, N. W., Gold, J. I., Josić, K., & Kilpatrick, Z. P. (2022). eLife, 11, e79824.

Homeostatic regulation through strengthening of neuronal network-correlated synaptic inputs. Barnes, S. J., Keller, G. B., & Keck, T. (2022). eLife, 11, e81958.

Synaptic basis of a sub-second representation of time in a neural circuit model. Barri, A., Wiechert, M. T., Jazayeri, M., & DiGregorio, D. A. (2022). Nature Communications, 13, 7902.

Efficient neural codes naturally emerge through gradient descent learning. Benjamin, A. S., Zhang, L.-Q., Qiu, C., Stocker, A. A., & Kording, K. P. (2022). Nature Communications, 13, 7972.

An astrocytic signaling loop for frequency-dependent control of dendritic integration and spatial learning. Bohmbach, K., Masala, N., Schönhense, E. M., Hill, K., Haubrich, A. N., Zimmer, A., … Henneberger, C. (2022). Nature Communications, 13, 7932.

The development of audio–visual temporal precision precedes its rapid recalibration. Han, S., Chen, Y.-C., Maurer, D., Shore, D. I., Lewis, T. L., Stanley, B. M., & Alais, D. (2022). Scientific Reports, 12, 21591.

Calcium activity is a degraded estimate of spikes. Hart, E. E., Gardner, M. P. H., Panayi, M. C., Kahnt, T., & Schoenbaum, G. (2022). Current Biology, 32(24), 5364-5373.e4.

A neural model for vector decomposition and relative-motion perception. He, D., & Öğmen, H. (2023). Vision Research, 202, 108142.

Mesolimbic dopamine release conveys causal associations. Jeong, H., Taylor, A., Floeder, J. R., Lohmann, M., Mihalas, S., Wu, B., … Namboodiri, V. M. K. (2022). Science, 378(6626).

Statistical learning of distractor shape modulates attentional capture. Kim, H., Ogden, A., & Anderson, B. A. (2023). Vision Research, 202, 108155.

Saccade vigor reflects the rise of decision variables during deliberation. Korbisch, C. C., Apuan, D. R., Shadmehr, R., & Ahmed, A. A. (2022). Current Biology, 32(24), 5374-5381.e4.

Contribution of parasol-magnocellular pathway ganglion cells to foveal retina in macaque monkey. Ma, I. C. K., Nasir-Ahmad, S., Lee, S. C. S., Grünert, U., & Martin, P. R. (2023). Vision Research, 202, 108154.

Cortical sensory processing across motivational states during goal-directed behavior. Matteucci, G., Guyoton, M., Mayrhofer, J. M., Auffret, M., Foustoukos, G., Petersen, C. C. H., & El-Boustani, S. (2022). Neuron, 110(24), 4176-4193.e10.

Hippocampus as a sorter and reverberatory integrator of sensory inputs. Nomoto, M., Murayama, E., Ohno, S., Okubo-Suzuki, R., Muramatsu, S., & Inokuchi, K. (2022). Nature Communications, 13, 7413.

Computational analysis of speed-accuracy tradeoff. Penconek, M. (2022). Scientific Reports, 12, 21995.

The brain integrates proprioceptive information to ensure robust locomotion. Santuz, A., Laflamme, O. D., & Akay, T. (2022). Journal of Physiology, 600(24), 5267–5294.

Associative memory of structured knowledge. Steinberg, J., & Sompolinsky, H. (2022). Scientific Reports, 12, 21808.

Visual category representations in the infant brain. Xie, S., Hoehl, S., Moeskops, M., Kayhan, E., Kliesch, C., Turtleton, B., … Cichy, R. M. (2022). Current Biology, 32(24), 5422-5432.e6.

Visual cortex encodes timing information in humans and mice. Yu, Q., Bi, Z., Jiang, S., Yan, B., Chen, H., Wang, Y., … Zhang, J. (2022). Neuron, 110(24), 4194-4211.e10.

#science#Neuroscience#computational neuroscience#Brain science#research#cognition#neurons#cognitive science#neurobiology#neural computation#neural networks#psychophysics#scientific publications

18 notes

·

View notes

Text

An arboreal griffon is a ferocious avian carnivore with the sleek body of a leopard and the head, forelegs, and wings of a green woodpecker.

These creatures are chiefly known for their characteristic behaviour. They mostly forage for small and medium sized mammals on the trunks and branches of trees, and often communicate by drumming with their beak, producing a reverberatory sound that can be heard for miles. Their diet also includes birds, eggs, tree sap, scraps and carrion.

They mostly nest and roost in holes that they excavate in tree trunks, which they defend fiercely. They sometimes come into conflict with caravans when they make holes in wagons to feed on goods, but perform a useful service by their removal of invasive species on trees. I drew this for my GM who wanted to homebrew some griffins! This one is based over a green woodpecker and a leopard. You can find the homebrew on DnDBeyond

#dnd#dungeons and dragons#ttrpg#creature#monster#griffon#griffin#my_art#fantasy#animals#dnd encounter#agathieldrawsdnd

16 notes

·

View notes

Text

Follow

Your

Heart,

Speak

The

Truth,

Come

Home

Now,

Let’s

Rest

And bloom.

#poem#poets you know#poems on tumblr#poets on tumblr#skilled ink#spilled ink#reverberatory#true blue#spoon#soul#whole#news

3 notes

·

View notes

Text

Tempering Furnace, Tempering Furnaces, Manufacturer, Mumbai, India

Manufacturer and Supplier of Tempering Furnace, Heating Unit, Pumping Unit, Pumping Oil In Reheating Furnaces, Mumbai, India.

Industrial Furnaces, Industrial Burners, Industrial Furnace, Industrial Burner, Walking Beam Type Re-Heat Furnaces, Bright Annealing Furnaces, Blue Flame Gas Burners Series 44, Pusher Type Re-Heat Furnaces, Continuous Wire Annealing Furnaces, Reheating Furnace, Pusher Furnace, Pusher Furnace, Walking Hearth Furnace, Chamber Furnace, Forging Furnace, Chamber Furnaces, Box Furnace For Forging, Chamber Furnace, Twin Chamber Furnace, Ss Wire Furnace, Strand Annealer, Solution Annealing Furnace, Fine Wire Furnace, Aluminium Melting Furnace, Stationary Type, Tilting Type, Tilting Type Mechanical, Roller Hearth Annealing Furnace, Industrial Roller Hearth Annealing Furnace, Bright Annealing Furnace, Pit Furnace, Bogie Hearth Furnace, Recuperator, Hair Pin Type Recuperator, Over Head Recuperator, Under Ground Recuperator, Radiation Type Recuperator, Industrial Burner, Coal Gas Burner, Oil Burner, Dual Fuel Burner, Gas Burner, Heating Pumping Unit, Combustion Blower, Charging Pusher, Discharge Ejector, Flue Damper, Gas Train, Rolling Mill Furnace, Oil Burner, Annealing Furnace, Gas Burner, Coal Gas Burner, Air Blower, Air Butterfly Valve, Alkaline Tank, Aluminium Melting Furnace, Aluminium Melting Furnace, Aluminium Melting, Annealing, Baking Oven, Blower, Blu-Flam Burners, Box Furnace For Forging, Burners, Butterfly Valve, Centrifugal Blower, Chamber Furnace, Charging Pusher, Coal Gas Burners, Combustion Blower, Combustion Equipments, Combustion Piping, Diesel Burners, Discharge Pusher, Dual Fuel Burners, Ejector, Electric Heat Furnace, Flowmeter, Forging Chamber Furnace, Forging Furnace, Forging Furnace, Furnace Maintenance, Furnace Manufactures, Furnace Oil Burner, Furnace Repair, Furnace Repair, Furnace Revamping, Furnace, Furnace, Gas Burners, Gas Burners, Gas Conversion, Gas Fired Furnace, Gas Piping, Hardening & Tempering Furnace, Heat Economizer, Heat Recovery System, Heat Treatment Furnace, Heat Treatment Furnace, Heat Treatment, Heating Pumping Unit, Hot Air Blower, Hot Air Lagging, Hot Air Recuperator, Industrial Burners, Industrial Melting Furnace, Ldo Burners, Lpg Burner, Melting Furnace, Monoblock Burners, Multiblock Burner, Natural Gas Burner, Oii Burners, Oil Burner, Oil Burners, Oil Fired Furnace, Oil Fired Salt Bath Furnace, Oil Flowmeter, Oil Micro Valve, Oil Piping, Oil Pumping Unit, Pipe Lagging, Pit Furnace, Pit Type Chamber Furnace, Producer Gas Burners, Pumping Unit, Pusher Furnace For Rolling Mill, Pusher Furnace, Pusher Re-Heat Furnace, Pusher, Re-Heating Furnace, Recuperator, Recuperator, Reheat Furnace For Rolling Mill, Reheat Furnace, Reheat Furnace, Reverberatory Furnace, Rod Mill Furnace, Roller Furnace, Roller Hearth Annealing Furnace, Rolling Mill Furnace, Screw Conveyor Furnace, Section Mill Furnace, Section Mill Pusher Furnace, Solenoid Valve, Tilting Furnace, Top & Bottom Fired Furnace, Walking Beam Furnace Walking Hearth Furnace, Walking Beam Furnace, Project Engineer Jobs, Design Engineer Jobs, Project Engineer For Furnace, Design Engineer For Furnace, Jobs In Mechanical, Inspection Engineer, Jobs In Project, Jobs In Design, Site Engineer, Jobs For Site Engineer, Mumbai, India.

0 notes

Text

What Is the Efficiency of the Aluminium Melting Furnace?

The efficiency of an aluminum melting furnace can vary depending on several factors, including the type of furnace, its design, and the specific operating conditions. However, modern aluminum melting furnaces can achieve high energy efficiency levels.

One commonly used metric to measure the efficiency of a furnace is the fuel-to-aluminum ratio, which represents the amount of fuel required to melt a given amount of aluminum. High-efficiency furnaces typically have low fuel-to-aluminum ratios, indicating that they can melt more aluminum using less fuel.

Advanced technologies, such as regenerative burners and improved insulation materials, have significantly improved the energy efficiency of aluminum melting furnaces. These technologies allow for better heat recovery and reduced heat losses, leading to higher overall efficiency.

Efficiency levels can also be influenced by factors such as the melting process, furnace design (e.g., crucible, reverberatory, or rotary furnace), the type of fuel used (natural gas, electricity, or oil), and the specific operational practices in place.

It's important to note that the efficiency of a furnace is not solely determined by its design or technology but also by the practices and maintenance employed by the operator. Proper furnace maintenance, regular cleaning, and adherence to recommended operating procedures are essential for achieving and maintaining high-efficiency levels.

To determine the exact efficiency of a specific aluminum melting furnace, it would be necessary to consult the manufacturer's specifications or conduct performance tests under standard operating conditions.

The efficiency of a furnace depends on various factors, including the specific application, fuel type, and operating conditions. Different furnaces are commonly used for multiple purposes, each with advantages and efficiency characteristics. Here are a few examples:

Induction Furnaces: Induction furnaces are known for their high energy efficiency. They use electromagnetic induction to generate heat directly within the melted metal, resulting in efficient and rapid heating. Induction furnaces are commonly used for melting and heating metals like aluminum, copper, and steel.

Electric Arc Furnaces (EAF): Electric arc furnaces utilize electric arcs between electrodes to generate heat for melting metals. They can achieve high efficiency due to the direct heat transfer to the metal and the ability to control the energy input precisely. Electric arc furnaces are commonly used in steelmaking and can offer good energy efficiency when powered by electricity from renewable or low-carbon sources.

Crucible Furnaces: Crucible furnaces are small, and typically used for melting smaller quantities of metal. They have a refractory-lined container (crucible) where the metal is melted. The efficiency of crucible furnaces can vary depending on factors such as insulation, burner design (for fuel-fired furnaces), and heat losses. While they may not offer the same efficiency as larger industrial furnaces, they can be suitable for specific applications or smaller-scale operations.

Regenerative Furnaces: Regenerative furnaces, also known as regenerative thermal oxidizers (RTOs), are commonly used in industries where high-temperature processes generate waste heat. They recover and reuse the waste heat to preheat combustion air or other process streams, resulting in improved energy efficiency. Regenerative furnaces can be found in applications such as glass manufacturing, steel reheat furnaces, and some types of ceramic kilns.

It's important to note that the efficiency of a furnace is influenced by various factors beyond just the furnace type, including insulation, heat recovery systems, fuel type, and operational practices. When selecting a furnace for a specific application, it's crucial to consider the overall system design and operational requirements to maximize efficiency and performance. Consulting with furnace manufacturers or industry experts can provide more specific guidance based on the intended application.

0 notes