#s45c specification

Explore tagged Tumblr posts

Text

Comprehensive Approach Evaluating Load Capacity in Helical Toothed Gear Racks Factory

The Helical Toothed Gear Racks Factory is a critical component in the manufacturing sector, where the assessment of load capacity is not just a process but a science. The load capacity of these gear racks is a measure of their ability to withstand mechanical stress during operation, which is a key determinant of their performance and longevity. A thorough evaluation at the Helical Toothed Gear Racks Factory ensures that the gear racks can handle the expected loads without failure, maintaining the integrity of the machinery they are part of.

To assess the load capacity of helical toothed gear racks produced by the Helical Toothed Gear Racks Factory, one must consider a variety of factors. These include the material properties, the design specifications, and the manufacturing processes employed by the factory. The material used in the construction of the gear racks plays a significant role in determining their load-bearing capabilities. Steel, for instance, is a popular choice due to its strength and durability, but the specific type of steel and its heat treatment can greatly influence the final product's load capacity.

The design of the helical-toothed gear racks is another critical factor in load capacity evaluation. The Helical Toothed Gear Racks Factory must ensure that the gear tooth profile, pitch, and pressure angle are optimized for the intended load. Advanced computer-aided design (CAD) software is often used to simulate the gear rack's performance under different load conditions, allowing engineers to predict potential failure points and make necessary adjustments before production.

Manufacturing processes at the Helical Toothed Gear Racks Factory also have a direct impact on the load capacity of the gear racks. Precision machining, such as hobbing or shaping, must be employed to achieve the desired tooth form and surface finish. Post-machining processes like hardening and tempering can further enhance the gear racks' load capacity by improving their resistance to wear, deformation, and breakage.

To quantitatively assess the load capacity, the Helical Toothed Gear Racks Factory may conduct a series of tests. These can include static load tests, where the gear racks are subjected to gradually increasing forces until they reach their breaking point, and dynamic load tests, which simulate the gear racks' operation under varying loads and speeds. These tests provide empirical data that can be used to validate the load capacity predictions made through simulation and design analysis.

Moreover, the Helical Toothed Gear Racks Factory must also consider the operational environment in which the gear racks will be used. Factors such as temperature, humidity, and the presence of corrosive substances can affect the gear racks' material properties and, consequently, their load capacity. Protective coatings or treatments may be necessary to ensure the gear racks maintain their load capacity under these conditions.

In conclusion, the Helical Toothed Gear Racks Factory's ability to accurately assess the load capacity of their products is essential for the safe and efficient operation of machinery that relies on these components. By considering material properties, design specifications, manufacturing processes, and environmental factors, the factory can ensure that their helical toothed gear racks are designed and manufactured to meet or exceed the load capacity requirements of their applications. This commitment to quality and performance is what sets the Helical Toothed Gear Racks Factory apart in the competitive landscape of mechanical component manufacturing.

Technical requirement Quality Grade: DIN 6 Material: S45C/42CrMo Tooth profile: helical teeth Right Hand Angle: 19°31'42" Hardness treatment: high frequency quenching HRC48-52/ HRC50-55° Production process: Ground on all sides after hardening

0 notes

Link

Kamal Shaft are hydraulic piston rod suppliers in Ahmedabad. Exporters of pneumatic piston rod, hydraulic piston rod & hard chrome piston rod supplier in Ahmedabad, Gujarat, India

#Hard Chrome Plated Rod Suppliers in Ahmedabad#Chrome Plated Rod Suppliers#Induction Harden Shaft Suppliers#chrome rod chrome rod suppliers#chrome shaft#piston shaft#hard chrome bar#s45c specification#Chrome Plated Round Bar Suppliers#Induction Hardened Chrome Plated Rod Suppliers#Chrome Plated Tube Suppliers#Piston Rod Suppliers

1 note

·

View note

Photo

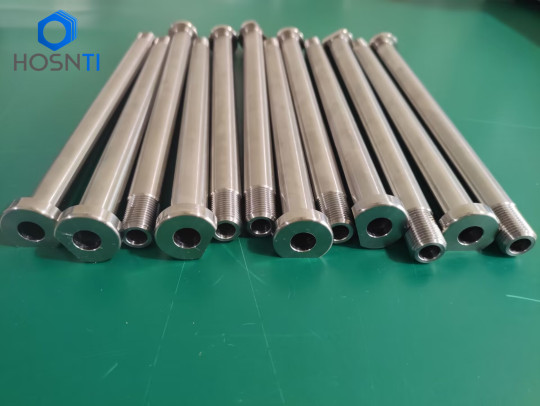

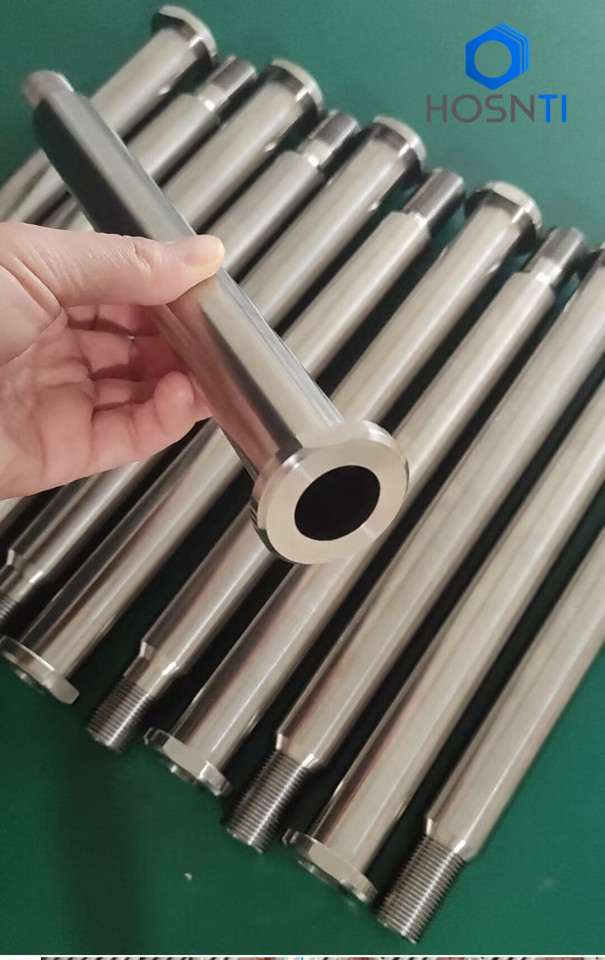

Titanium Rear Axle KTM

The specific gravity of Ti-6AL-4V is about 4.4. This is about 56% with respect to the specific gravity of 7.8 of stock axle shaft using iron(SS400) and carbon steel (S45C), or chromium molybdenum steel shaft (SCM440).

0 notes

Text

TRUSCO Diamond Double-edged File Grindstone DP-4, Grit #140, length 125

TRUSCO Diamond Double-edged File Grindstone DP-4, Grit #140, length 125

Dimension Guide for TRUSCO Diamond Double-edged File Grindstone DP-4, Grit #125, length 125 Specification Guide for TRUSCO Diamond Double-edged File Grindstone DP-4, Grit #125, length 125: Specifications / Standards Shape: rhombus Overall length (mm): 175 Blade length (mm): 75 Particle size (#): 140 Blade width (mm): 17 Material Structural carbon steel (S45C) Mass / mass…

View On WordPress

0 notes

Text

Race Driven Kawasaki 14 Tooth Front Sprocket KL650 KLR650 KLX650

Race Driven Kawasaki 14 Tooth Front Sprocket KL650 KLR650 KLX650

Race Driven Kawasaki 14 Tooth Front Sprocket KL650 KLR650 KLX650

Brand New 14 Tooth Front Steel Sprocket

Race-Driven sprockets are manufactured to exceed OEM specifications

Race-driven sprockets are produced using hardened S45C steel

Check Fitment Chart for the year, make and model of your machine

Brand New Race-Driven Front Steel Sprocket. You will receive a 14 tooth steel front driven sprocket.…

View On WordPress

1 note

·

View note

Text

We specialize in Ceramic lined composite Y-type Tee and flow conditioning assemblies to tame the most demanding flow applications.

Wear-resisting comparative table of ceramic lining pipe

Sand injection test 30% Transfer test of sludge with SiO2 Material Volume diminution (cm3) Material Volume diminution (cm3) Ceamic lining Steel pipe 0.0022 Ceamic lining Steel pipe 3 Ceramic pipe Al2O3 0.0025 S45C 25

Abrasion

Ceramic layer Ceramic Lined Reducer Pipe with flange reducer Al2O3 content greater than 89% , micro-hardness HV1000-1500, which has a high abrasion resistance, wear resistance than ten times higher than carbon steel after quenching , superior tungsten carbide drill.

Application range

coal pulverizing system of power plant pipeline, including, powder transmission pipeline, thick powder separator pipeline, coal drop pipe, combustion system of a wind pipe, a secondary air pipe, three pipeline and burner pipelines, in addition to ash slagging system the discharge pipe, powder pipe, dry ash conveying pipe;

iron and steel plant raw material conveying pipeline, collecting pipe, dust pipe, ash pipe, ash pipe, mixing pipe, grinding export pipeline, coal pipeline, coal pipeline, separator pipe, burner radius pipe, etc.;

cement plant selection machine outlet pipe, choose machine inlet pipe, pipe dust pipe, vertical mill outlet pipe, circulating air duct, high temperature air blower, lower material pipe, etc.;

petroleum, chemical, mining, coal, coal washing plant, smelting, paper, aluminum, building materials, powder engineering, food machinery and other processing and conveying material pipe.

Corrosion

Ceramic materials are neutral , chemically stable , has excellent corrosion resistance and acid resistance , resistant to various inorganic acids, organic acids , organic solvents , and its degree of corrosion of stainless steel is more than ten times.

Temperature

Temperature above 2000celsius degree, long-term work in the range of -50 -900 celsius degree.

Easy welding

Ceramic adjustable tube can be welded , flanged , flexible connectors and other fast way links , very easy to install.

Clean and easy maintenance

Smooth wall, can prevent scaling , fouling, self-cleaning function. Tightness.

Remarks:

Under the direction of the arrow diagram for the export direction.

Bend radius is usually 1.5-5 times the diameter of steel pipe (1.5-5D).

Othe specifications of the compsite pipe can be manufactured accord to the user requirments.

The weight is caculate by theoretics, maybe have some tolerance, the real weight will be weigh in afer them finished.

Hoop strength is the resistance against radial pressure. The strength of the ceramic -lined steel composite pipe is 300 to 500MPa.

Ceramic lined composite Y-type Tee We specialize in Ceramic lined composite Y-type Tee and flow conditioning assemblies to tame the most demanding flow applications.

0 notes

Text

Eastman Gas Connector – 5/8 in. OD 1/2 in. MIP x MIP

The Steel-Flex® gas connector by Eastman® is made of stainless steel with a yellow epoxy coating and a 5/8-inch OD (1/2-inch NOM.). The deep corrugations of the connector provide structural support against crushing, kinking and cracking. The epoxy coating is designed to withstand long exposure to household chemicals and harsh environments. This is a highly durable connector with zinc-plated steel 1/2-inch MIP x 1/2-inch MIP fittings. CSA certified in both US and Canada.This connector can be used as a gas supply line in HVAC applications, water heaters, ranges, and other appliances. Works with propane or natural gas.

Technical Specifications

Construction: Yellow epoxy coated stainless steel 304 (ASTM 240)

Connection: Zinc-plated steel S45C fittings 1/2 in. MIP x 1/2 in. MIP

Connector OD: 5/8 in. OD (1/2 in. NOM)

Natural Gas Capacity: up to 106,000 BTUh *Multiply by 1.6 for LP Gas

0 notes

Text

Study on High Efficiency Deep Grinding Force of S45C Steel

Study on High Efficiency Deep Grinding Force of S45C Steel

S45C steel

is one of the most widely used metal materials. It has low hardness and is easy to be machined. It has high hardness and good comprehensive mechanical properties after heat treatment. It is used in various important structural parts and shaft parts.When the grinding wheel rotates at high speed, gas barrier will be formed around the grinding wheel, which makes it difficult for the coolant to enter the grinding process. Therefore, the following special liquid supply methods must be adopted, such as setting the air baffle, high pressure spraying method, cold hair in the grinding wheel and self-acceleration method, etc. When the feed speed of the

S45C steel

workpiece is 2m/min, the normal grinding force and the tangential grinding force increase correspondingly with the increase of the grinding depth, because the other grinding parameters are constant. In the same case, the grinding depth is increased, and the maximum undeformed chip thickness of the single abrasive grain is increased, and the number of effective abrasive grains involved in the grinding is increased, resulting in a large grinding force. In addition, as the grinding depth increases, the frictional effect between the grinding wheel binder, the grinding debris and the workpiece to be ground increases during the grinding process, so the grinding force also increases. It has been further found that as the linear speed of the grinding wheel increases, the grinding force is significantly weakened with the increasing tendency of the grinding depth. It is not difficult to conclude that when S45C steel metal material is used for large grinding with high grinding wheel speed, deep grinding is very advantageous. At this time, the grinding force is not increased significantly, but stabilized with the grinding wheel speed increasing.Under the condition of high-efficiency deep grinding, increasing the linear speed of the grinding wheel will reduce the grinding force and improve the grinding conditions. Increasing the depth of the grinding will increase the grinding force significantly, but it will decrease specific grinding energy. The specific grinding energy decreases with the increase of the grinding depth, and also decreases with the increase of the workpiece feeding speed, and the increase of the grinding wheel linear speed has little effect on the grinding energy. This shows that when the grinding depth is large, increasing the linear speed of the grinding wheel and increasing the feed rate of the workpiece will not cause the grinding condition to continue to deteriorate, but the machining efficiency can be greatly improved under the premise of ensuring the processing quality. In summary, it is feasible to apply high-efficiency deep-grinding processing to the processing of ordinary metal materials, and to improve the processing efficiency and reduce the processing cost, and to obtain better surface quality.

0 notes

Text

kitchen sink shapes machine Using argon arc welding wire to repair mold steel technology Zhisheng automated welding equipment

Using argon arc welding wire to repair mold steel technology Wire material: SKD11 SKD61 NAK80 8407 H13 718 738 888 P20 420 S136 2344 2316 2083 PDS 2311 PX5 2711 PX88 Beryllium copper Argon robotic welding machinecopper Yellow card repair mold robotic welding machinematerials. Wire diameter specifications: 0.9, 1.0, 1.2, 1.6, 2.0, 2.4, 3.2 * 1000mm wire use: SKD11 > 1.0 ~ 3.2mm HRC 56~58 Welding cold working steel, metal stamping dies, cutting dies, cutting tools, forming dies, workpieces Hard face made of argon robotic welding machinerods with high hardness, wear resistance and high toughness, robotic welding machinerepair Before warming and preheating, it is easy to produce cracks. SKD61 > 0.9 ~ 3.2mm HRC 40~43 Welding zinc, aluminum die casting, good heat resistance and crack resistance, hot stamping die, aluminum/copper hot forging die, aluminum/copper die casting die, heat resistant , wear resistance, crack resistance. Generally, hot-pressed molds are often cracked. Most of them are caused by thermal stress, and are also caused by surface oxidation or corrosion of die-casting materials. Heat treatment is adjusted to an appropriate hardness to improve its service life. Hardness is too low or too high. Be applicable. 8407-H13 > 0.9 to 3.2mm HRC 43~46 Dies for non-ferrous alloys and copper alloys made of zinc, aluminum, tin, etc. can be used as hot forging or stamping dies. With high toughness, wear resistance and good thermal erosion resistance, high temperature softening, high temperature fatigue resistance, can be used as heat treatment for punch, reamer, rolling knife, grooving knife, scissors... When it is necessary to prevent decarburization, the hardness of the hot tool steel after robotic welding machineis too high and it also breaks. 888T > 1.2~1.6mm HB~300 High-hardness steel joints, hard-surfaced bases, and cracked welds. High-strength welds, high nickel-chromium alloy composition, specializing in the prevention of cracking the bottom of the welding, filling the bottom, strong pull, and repair the cracking of steel robotic welding machinereconstruction. 718 > 0.9 ~ 2.4mm HRC 28~30 Mold steel for plastic products such as large home appliances, toys, communications, electronics, and sports equipment. Plastic injection molds, heat-resistant molds, corrosion-resistant molds, good machinability, erodibility, excellent surface gloss after grinding, and long service life. The preheating temperature is 250~300°C and the post-heating temperature is 400~500°C. When using multi-layer welding, the robotic welding machinemethod is used for backward welding, which is less likely to cause defects such as poor fusion and pinholes. 738 > 0.9 ~ 2.4mm HRC 32~35 Translucent and surface-glossy plastic product mold steel, large-scale mold, product shape complex and high precision plastic mold steel. Plastic injection molds, heat-resistant molds, corrosion-resistant molds, and good corrosion resistance, with excellent processing properties, easy to cut light and erosion, toughness and good wear resistance. Preheating temperature 250 ~ 300 °C after the heat temperature 400 ~ 500 °C, for multi-layer welding, using the back robotic welding machinemethod, less prone to fusion defects and pinholes and other defects. P20Ni > 0.9 ~ 2.4mm HRC 30~34 Plastic mold, heat-resistant mold (cast copper mold). Designed with alloy components with low sensitivity to robotic welding machinecracks, containing about 1% nickel, suitable for PA, POM, PS, PE, PP, ABS plastics, with good light, no pores, cracks after welding, polished after a good Smooth finish, after vacuum degassing, after forging, pre-hard to HRC 33 degrees, uniform hardness distribution on the section, die life of 300,000 or more. The preheating temperature is 250-300°C and the post-heating temperature is 400-500°C. When performing multi-layer welding, the robotic welding machinemethod is used for backward welding, which is less likely to cause defects such as poor fusion and pinholes. NAK- 80 > 0.9 ~ 1.6mm HRC 38~42 Plastic injection mold, mirror steel. High hardness, excellent mirror effect, good electric discharge machining, excellent robotic welding machineperformance, smooth and mirror-like after polishing, it is the most advanced and best mold steel in the world, easy to cut elements added, easy cutting, high strength, toughness and resistance Grinding without deformation characteristics, suitable for a variety of transparent plastic products die steel. Preheating temperature 300 ~ 400 °C after the heat temperature 450 ~ 550 °C, when multi-layer welding, using the back-up robotic welding machinemethod, less prone to fusion defects and pinholes and other defects. S-136 > 0.9~1.6mm HB~400 plastic injection mold, good corrosion resistance and permeability. High purity, high specularity, good light, excellent rust and acid resistance, less heat treatment, suitable for PVC, PP, EP, PC, PMMA plastics, corrosion-resistant and easy to process modules and fixtures, super mirror corrosion resistance Precision molds, such as rubber molds, camera parts, lenses, cases, etc. 200T (Emperor S-2)> 0.9~2.4mm HB~200 iron mold, shoe mold, mild steel welding, easy engraving, S45C, S55C steel repair. Yellow card electrode repair texture fine, soft, easy processing, there will be no porosity, generally yellow robotic welding machineelectrode on the market, although the price is cheap, but the hardness is too high after repair, not easy to eclipse flowers and prone to stomata (welcome to call sampling) . The preheating temperature is 200~250°C and the hot temperature is 350~450°C. BeCu (bismuth copper) > 0.9~1.6mm HB~300 high thermal conductivity copper alloy mold material, the main additive element is yttrium, which is suitable for plastic injection molding mold inner insert, core, die-casting punch, hot runner cooling system, heat conduction Mouth, blow mold, integral cavity, wear plate, etc. Tungsten-copper materials are used in resistance welding, EDM, electronic packaging, and precision mechanical equipment. CUS (argon robotic welding machinecopper) > 0.9~2.4mm HB~200 This robotic welding machinebranch is widely used for robotic welding machinerepair of electrolysis sheets, copper alloys, steel, bronze, pig iron, and general copper parts. Good mechanical properties, can be used for robotic welding machinerepair of copper alloys, but also robotic welding machinesteel and pig iron, iron joining. OH1-1G (oil steel) > 1.0~1.6mm HRC 52~57 Blanking Die, Gauge, Die, Piercing Punching, Widely Used in Hardware Cold Stamping, Hand Embossing Dies, General Purpose Special Tool Steel, Wear Resistant, Oil Cooled . Cr steel > 1.0~1.6mm HRC 55~57 Blanking die, cold working die, cold die, punch, high hardness, high tenacity, and good wire cutability. Warm up and preheat before welding, and do post-robotic welding machineafter welding. As a entrepreneur, being trapped in a company under multiple quality problems never appealed to Jiangmen Zhisheng Automation Welding Equipment Co., Ltd.. is a kitchen sink shapes machine sink welding press machine provided by Jiangmen Zhisheng Automation Welding Equipment Co., Ltd. which is a leading manufacturer in China. For more information, visit Zhisheng automated welding equipment. Jiangmen Zhisheng Automation Welding Equipment Co., Ltd. has been making a name for itself as a producer of some of the finest in the China, and it has been singing its praises for some time. It is never too late to have a new mindset and to get things moving in the right direction. Choose Jiangmen Zhisheng Automation Welding Equipment Co., Ltd. to be your quality provider. The more people who do a certain thing, the more likely others are to do it as well. When Zhisheng automated welding equipment can demonstrate their popularity or satisfaction across a wide customer base, other consumers are more likely to buy in as well. Media contact Company Name: Jiangmen zhisheng automatic welding equipment co., LTD. Address: Hulu foot on the 2nd, Dazei Town, Xinhui District, Jiangmen City,China E-mail: [email protected] Website: http://www.jgdzs-welding.com/

0 notes

Text

Overview of Taeweon Corp - Core parts of transport equipment

Taeweon Corp Provide reliable core parts of transport equipment to customer and partners. They support our customer’s business with competitive price and high quality.

Market Application

· Port facilities

· Container crane

· Transfer crane (RMQC, RMGC, and RTGC)

Mega Industry

· Goliath Crane - Ship Yard

· Gantry Crane - Ship Yard

· Floating Crane

· Polar Crane – Nuclear Power Plants

· Unloader – Harbor, Mine

· Life facilities

Still Works

· Ladle Crane

· Over Head Crane (EOC, EOTC)

· Tong Crane

· Crab

· Loader, Coil Lift

Sheave

· Materials: S35C (AISI 1035, CF35), S45C

· Specification: Φ500~Φ2000

· Application: Crane for Maritime, Iron Works, MRO

Hook Block

· Materials: Forged material

· Specification: 10Ton~900Ton

· Application: Crane for Maritime, Iron Works, MRO

Wheel

· Materials: Forged material

· Specification: Φ300~Φ1050

· Application: Crane for Maritime, Iron Works, MRO

Drum

· Materials: S45C

· Specification: 10Ton~500Ton

· Application: Crane for Maritime, Iron Works, MRO

Are you looking for sheave, Crane, lifting and rigging equipment supplier in Korea? Taeweon - Best transport Equipment Company in Korea. They provide reliable core parts of transport equipment to customer and partners.

0 notes

Text

Eastman Gas Connector – 1 in. OD 3/4 in. MIP X FIP

The Steel-Flex® gas connector by Eastman® is made of stainless steel with a yellow epoxy coating and a 1-inch OD (3/4-inch NOM). The deep corrugations of the connector provide structural support against crushing, kinking and cracking. The epoxy coating is designed to withstand long exposure to household chemicals and harsh environments. This is a highly durable connector with zinc-plated steel 3/4-inch MIP x 3/4-inch FIP fittings. CSA certified in both US and Canada. This connector is great for tankless water heaters and ranges. Works with natural gas or propane.

Technical Specifications

Construction: Yellow epoxy coated stainless steel 304 (ASTM 240)

Connection: Zinc-plated steel S45C fittings 3/4 in. MIP x 3/4 in. FIP

Outer Diameter: 1 in. OD (3/4 in. NOM)

Capacity: Withstands up to 173,900 BTU/Hr

0 notes

Photo

Ruko G-303B 3pc. Throwing Knife Set Specifications Blade Length: 3.625 in. Blade Material: S45C Carbon Blade Finish: Black Handle Length: 3.5 in. Handle Material: S45C Carbon Overall Length: 7.375 in. Lock Mechanism: Nylon Sheath Opening Type: Fixed Blade Edge Type: Spear Point Weight: 1.8 oz. Country of Origin: China Brand: RUKO

0 notes