#semi-automatic block making machine

Explore tagged Tumblr posts

Text

Building a Sustainable Future: The Rise of Fully Automatic Fly Ash Brick Machines in India

India's construction sector is booming, and with it, the demand for efficient, sustainable building materials. In this landscape, fully automatic fly ash brick machines are emerging as a game-changer, revolutionizing brick manufacturing across the nation. These advanced machines not only offer high productivity but also contribute significantly to environmental conservation by utilizing industrial waste.

What are Fully Automatic Fly Ash Brick Machines?

At its core, a fully automatic fly ash brick machine is an industrial marvel designed to produce high-quality bricks from fly ash – a byproduct of coal combustion in thermal power plants – mixed with other raw materials like sand, lime, gypsum, and cement. The "fully automatic" aspect signifies that the entire production process, from raw material feeding and mixing to pressing, molding, and often even stacking, is automated, requiring minimal human intervention.

These machines leverage sophisticated technologies such as:

Hydraulic Pressure Systems: Ensuring uniform compression and high-density bricks with excellent strength.

Vibro-Compaction Technology: Combining vibration with pressure to eliminate air bubbles and achieve superior compaction and dimensional accuracy.

PLC (Programmable Logic Controller) Control: For precise management of the entire operation, enabling consistent quality, adjustable pressure settings, and real-time monitoring.

Automated Raw Material Feeding and Batching Systems: Ensuring precise proportions of materials for optimal brick composition.

Mould Flexibility: Allowing for the production of various brick types, including solid, hollow, paving blocks, and interlocking bricks, using interchangeable molds.

Auto-Stacker Systems: In advanced models, bricks are automatically stacked post-production, reducing manual labor and improving efficiency.

The Unmatched Advantages in the Indian Context

The adoption of fully automatic fly ash brick making machines in India offers a multitude of benefits, both economic and environmental:

High Production Capacity: These machines are designed for large-scale output, with some models capable of producing 1500-2500 bricks per hour, or even up to 30,000 bricks per day. This high volume helps meet the escalating demand in the rapidly growing Indian construction market.

Consistent Quality and Durability: Automation eliminates human error, leading to uniformly shaped, high-strength bricks with low water absorption and excellent thermal insulation. This translates to better structural integrity and longer-lasting buildings.

Environmental Sustainability: By utilizing fly ash, a significant industrial waste product, these machines contribute to:

Waste Utilization: Reducing the burden on landfills and promoting a circular economy.

Reduced Carbon Footprint: Less reliance on traditional clay bricks, which often involve topsoil excavation and energy-intensive firing processes.

Lower Water Usage: Fly ash brick production typically requires less water compared to conventional clay bricks.

Compliance with Regulations: The Indian government, through notifications from the Ministry of Environment & Forests (MoEF&CC), has mandated the utilization of fly ash in construction activities within a certain radius of thermal power plants, further driving the demand for these machines.

Cost-Effectiveness and Quick ROI: While the initial investment might seem substantial (prices for fully automatic plants can range from INR 10.5 Lakh to over INR 2 crore, depending on capacity and features), the long-term cost savings are significant. Reduced labor requirements, minimal maintenance, and high production output lead to a faster return on investment (ROI).

Reduced Labor Dependency and Enhanced Safety: Automation minimizes the need for manual labor, addressing concerns about labor availability and reducing occupational hazards associated with traditional brick-making.

Versatility: The ability to produce various types of bricks and blocks caters to diverse construction needs and market segments, from residential and commercial buildings to infrastructure projects and landscaping.

Energy Efficiency: Modern machines are optimized for lower power consumption, contributing to reduced operational costs.

Leading Manufacturers and Market Trends in India

India boasts a strong ecosystem of manufacturers specializing in fully automatic fly ash brick machines. Companies like Narsinh Industries, Endeavour Intelligent Equipments Private Limited, HVB Exports, Revomac Industries, Laxmi Engineering Works, and Kailash Engineering are prominent players, offering a wide range of machines with varying capacities and features. Many manufacturers are based in industrial hubs like Ahmedabad, Morbi, Mehsana, and Coimbatore.

The market trend is clearly towards more advanced, energy-efficient, and highly automated solutions. Manufacturers are focusing on:

Integrating IoT and remote monitoring capabilities for enhanced control and diagnostics.

Developing machines with even higher pressing capacities for denser bricks.

Offering customized solutions to meet specific client requirements.

Ensuring robust build quality for long operational life and minimal wear and tear.

Investing in a Sustainable Future

For entrepreneurs and construction companies in India looking to scale up their operations while embracing sustainable practices, investing in a fully automatic fly ash brick machine is a strategic decision. These machines not only promise high productivity and superior product quality but also align with the nation's growing emphasis on green building and responsible waste management. As India continues its infrastructure development, the demand for eco-friendly and high-performance building materials like fly ash bricks, produced efficiently by these advanced machines, is set to soar.

#automatic bricks making machine manufacturer#automatic paver block machine manufacturer#fly ash block making machine#paver block manufacturing machine#semi-automatic block making machine#vibrating paver block machine

0 notes

Text

Revolutionizing Construction with Semi-Automatic Brick Making Machines

Semi-automatic brick making machines are revolutionizing the construction landscape by offering an efficient, cost-effective, and quality-driven solution. To harness the full potential of these machines, it's imperative to partner with a reliable concrete block machine manufacturer. By making an informed decision, construction companies can propel their projects forward, meeting timelines and quality standards with ease.

0 notes

Note

i'm curious about something with your conlang and setting during the computing era in Ebhorata, is Swädir's writing system used in computers (and did it have to be simplified any for early computers)? is there a standard code table like how we have ascii (and, later, unicode)? did this affect early computers word sizes? or the size of the standard information quanta used in most data systems? ("byte" irl, though some systems quantize it more coarsely (512B block sizes were common))

also, what's Zesiyr like? is it akin to fortran or c or cobol, or similar to smalltalk, or more like prolog, forth, or perhaps lisp? (or is it a modern language in setting so should be compared to things like rust or python or javascript et al?) also also have you considered making it an esolang? (in the "unique" sense, not necessarily the "difficult to program in" sense)

nemmyltok :3

also small pun that only works if it's tɔk or tɑk, not toʊk: "now we're nemmyltalking"

so...i haven't worked much on my worldbuilding lately, and since i changed a lot of stuff with the languages and world itself, the writing systems i have are kinda outdated. I worked a lot more on the ancestor of swædir, ntsuqatir, and i haven't worked much on its daughter languages, which need some serious redesign.

Anyway. Computers are about 100 years old, give or take, on the timeline where my cat and fox live. Here, computers were born out of the need for long-distance communication and desire for international cooperation in a sparsely populated world, where the largest cities don't have much more than 10,000 inhabitants, are set quite far apart from each other with some small villages and nomadic and semi-nomadic peoples inbetween them. Computers were born out of telegraph and radio technology, with the goal of transmitting and receiving text in a faster, error-free way, which could be automatically stored and read later, so receiving stations didn't need 24/7 operators. So, unlike our math/war/business machines, multi-language text support was built in from the start, while math was a later addition.

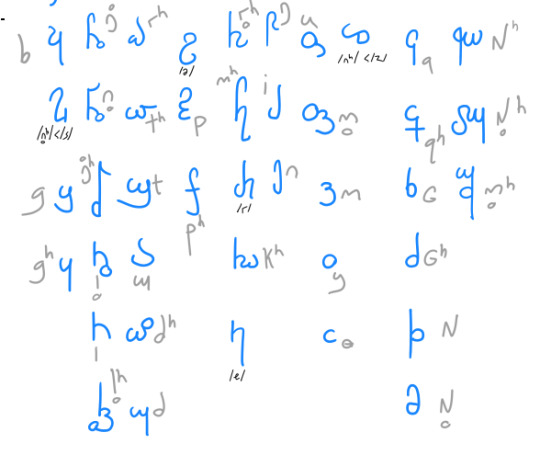

At the time of the earliest computers, there was a swædir alphabet which descended from the earlier ntsuqatir featural alphabet:

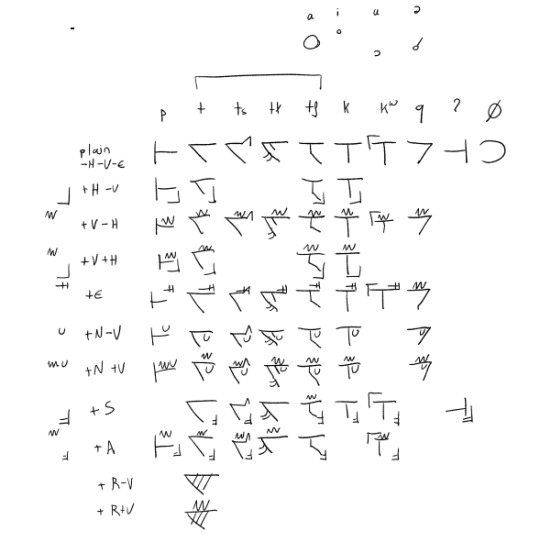

the phonology here is pretty outdated, but the letters are the same, and it'd be easy to encode this. Meanwhile, the up-to-date version of the ntsuqatir featural alphabet looks like this:

it works like korean, and composing characters that combine the multiple components is so straightforward i made a program in shell script to typeset text in this system so i could write longer text without drawing or copying and pasting every character. At the time computers were invented, this was used mostly for ceremonial purposes, though, so i'm not sure if they saw any use in adding it to computers early on.

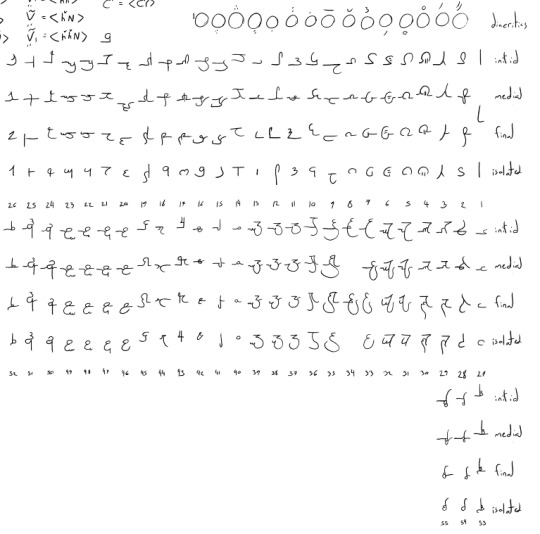

The most common writing system was from the draconian language, which is a cursive abjad with initial, medial, final and isolated letter shapes, like arabic:

Since dragons are a way older species and they really like record-keeping, some sort of phonetic writing system should exist based on their language, which already has a lot of phonemes, to record unwritten languages and describe languages of other peoples.

There are also languages on the north that use closely related alphabets:

...and then other languages which use/used logographic and pictographic writing systems.

So, since computers are not a colonial invention, and instead were created in a cooperative way by various nations, they must take all of the diversity of the world's languages into account. I haven't thought about it that much, but something like unicode should have been there from the start. Maybe the text starts with some kind of heading which informs the computer which language is encoded, and from there the appropriate writing system is chosen for that block of text. This would also make it easy to encode multi-lingual text. I also haven't thought about anything like word size, but since these systems are based on serial communication like telegraph, i guess word sizes should be flexible, and the CPU-RAM bus width doesn't matter much...? I'm not even sure if information is represented in binary numbers or something else, like the balanced ternary of the Setun computer

As you can see, i have been way more interested in the anthropology and linguistics bits of it than the technological aspects. At least i can tell that printing is probably done with pen plotters and matrix printers to be able to handle the multiple writing systems with various types of characters and writing directions. I'm not sure how input is done, but i guess some kind of keyboard works mostly fine. More complex writing systems could use something like stroke composition or phonetic transliteration, and then the text would be displayed in a screen before being recorded/sent.

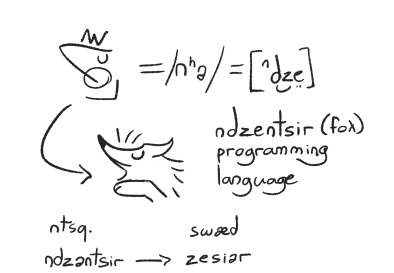

Also the idea of ndzəntsi(a)r/zesiyr is based on C. At the time, the phonology i was using for ntsuqatir didn't have a /s/ phoneme, and so i picked one of the closest phonemes, /ⁿdz/, which evolves to /z/ in swædir, which gave the [ⁿdzə] or [ze] programming language its name. Coming up with a word for fox, based on the character's similarity was an afterthought. It was mostly created as a prop i could use in art to make the world feel like having an identity of its own, than a serious attempt at having a programming language. Making an esolang out of it would be going way out of the way since i found im not that interested in the technical aspects for their own sake, and having computers was a purely aesthetics thing that i repurposed into a more serious cultural artifact like mail, something that would make sense in storytelling and worldbuilding.

Now that it exists as a concept, though, i imagine it being used in academic and industrial setting, mostly confined to the nation where it was created. Also i don't think they have the needs or computing power for things like the more recent programming languages - in-world computers haven't changed much since their inception, and aren't likely to. No species or culture there has a very competitive or expansionist mindset, there isn't a scarcity of resources since the world is large and sparsely populated, and there isn't some driving force like capitalism creating an artificial demand such as moore's law. They are very creative, however, and computers and telecommunications were the ways they found to overcome the large distances between main cities, so they can better help each other in times of need.

#answered#ask#conlang i guess??#thank you for wanting to read me yapping about language and worldbuilding#also sorry if this is a bit disappointing to read - i don't have a very positivist/romantic outlook on computing technology anymore#but i tried to still make something nice out of it by shaping their relationship with technology to be different than ours#since i dedicated so much time to that aspect of the worldbuilding early on

13 notes

·

View notes

Text

Built to Last: Discover the Strength of BKE Construction Equipment

Built to Last: Discover the Strength of BKE Construction Equipment

Your Trusted Partner Among Leading Construction Machinery Manufacturers

At BKE, we don’t just manufacture machines. We build the future of construction. As one of India’s most respected construction equipment manufacturers, BKE is proud to deliver performance-driven machinery that stands the test of time, terrain, and tough deadlines.

Our equipment powers a wide range of construction projects across India, from rural developments and government infrastructure to private real estate and industrial complexes. With innovation, reliability, and service at our core, we are redefining what it means to be a construction machinery manufacturer in a rapidly evolving industry.

Our Journey: From a Local Manufacturer to a Nationwide Leader

Established with a mission to support India’s growing construction needs, BKE began its journey by producing robust concrete mixers and compact rebar processing machines. Over the years, we have evolved into a full-fledged equipment manufacturer, serving contractors, builders, and developers across the country.

Today, our equipment is known for:

Rugged build quality that thrives in challenging site conditions

Smart mechanical designs that simplify operation

Minimal maintenance and extended lifecycles

Fast delivery and dependable service coverage

Our growth is driven by one simple promise: to keep our customers building without interruption.

Products That Power Every Phase of Construction

At BKE, our wide-ranging portfolio is designed to streamline your workflow from foundation to finish. Whether you are laying concrete blocks, bending steel, or finishing floors, we provide high-performance machines that boost speed, safety, and precision.

Our Key Product Lines Include:

1. Concrete Mixers

Portable and heavy-duty models for small to large concrete jobs. Uniform mixing, fast discharge, and easy mobility.

2. Block Making Machines

Hollow, solid, and paving block machines that deliver consistent quality with minimal labor. Available in manual, semi-automatic, and fully automatic variants.

3. Bar Bending and Cutting Machines

Engineered for strength and accuracy, these machines handle heavy rebar with ease and help reduce steel wastage.

4. Pan Mixers

Ideal for mixing fly ash, concrete, and other aggregates used in brick and block making.

5. Construction Accessories

Trolley systems, vibrators, power trowels, and more to support your entire site operation.

Use Cases: BKE in Action Across India

Our machines are trusted by thousands of construction professionals across India. Whether you're building an affordable housing project in Tamil Nadu, paving roads in Maharashtra, or setting up a new residential layout in Telangana, BKE machines have played a critical role.

Real-world scenarios where BKE makes a difference:

Government infrastructure projects using BKE block machines for mass brick production

Real estate developers speeding up slab work with BKE’s high-capacity concrete mixers

Small contractors in rural regions relying on our bar cutting machines for budget-friendly rebar solutions

Civil engineers choosing BKE for efficient material handling in remote and low-resource areas

Our machines are not just workhorses. They are problem-solvers that help projects stay on time and within budget.

Why Dealers and Contractors Prefer BKE

We are proud to be one of the most dealer-friendly and contractor-centric construction machinery manufacturers in India. Here's what sets us apart:

Competitive pricing with best-in-class features

Ready stock availability for quick delivery

Installation support including setup, training, and trial runs

Dedicated AMC and service teams for minimal downtime

Strong dealer network with technical and sales support

At BKE, we treat every dealer and customer like a long-term partner.

Committed to Quality, Built for India

All BKE machines are manufactured using precision-engineered components, sourced and assembled in our advanced facilities. Every product undergoes rigorous testing and quality checks before it reaches the customer.

As a proud Made in India brand, we focus on:

Heavy-duty steel frames and rust-resistant bodies

Energy-efficient motors and robust electricals

Easy maintenance with widely available spares

Compliance with safety and performance standards

Our goal is to deliver machines that serve you efficiently for years, no matter the site conditions.

Future Ready: Innovating for Tomorrow's Construction

BKE is not only keeping pace with the latest construction trends. We are leading them. We are constantly researching new technologies, automation features, and eco-friendly designs that address the changing needs of Indian builders.

Our future initiatives include:

Low-noise and low-emission machines for urban projects

Smart models for real-time performance tracking

High-output block lines for large-scale production

Digital controls and remote monitoring features

We are not just building machines. We are building smarter construction ecosystems.

Final Thoughts

When strength, reliability, and service matter most, BKE is the name construction professionals trust. As a leading construction equipment manufacturer in India, we combine world-class engineering with a deep understanding of on-ground construction challenges.

From solo contractors to large-scale developers, our machines have helped thousands build better, faster, and smarter. We invite you to experience the BKE advantage where performance meets peace of mind.

Choose BKE. Build India. Build with confidence.

Contact our support team for inquiries, dealership partnerships, or custom solutions.

0 notes

Text

What Really Happens Inside an Automatic Interlocking Block Making Machine

If you’ve ever walked past a building site and seen workers stacking blocks that fit together almost like Lego, there’s a good chance those blocks were made by an Automatic Interlocking Block Making Machine.

These machines have changed the game for builders, contractors, and even small entrepreneurs looking to make strong, affordable blocks quickly and with less hassle. But what exactly goes on inside this machine? How does it turn piles of soil, sand, and cement into neat blocks that just click together? Let’s break it down in plain language.

What Makes Interlocking Blocks Special?

Before we get into the machine itself, it helps to understand what makes interlocking blocks so popular. Unlike traditional bricks or blocks that need lots of mortar to hold them together, interlocking blocks are shaped with ridges and grooves that let them slot into place.

This saves money on mortar, speeds up construction, and makes it easier to build straight, sturdy walls — even with a smaller team.

What Exactly Is an Automatic Interlocking Block Making Machine?

At its simplest, it’s a machine that mixes raw materials, shapes the blocks, and presses them under high pressure so they’re dense and durable. Because the process is mostly automated, you get uniform blocks every time, without needing dozens of workers to mix, mold, and stack by hand.

Here’s How It Works — Step by Step

1. Get the Right Mix

Everything starts with the raw materials. Most people use a mix of local soil, a bit of sand, and some cement. Some mixes include fly ash or lime. The exact blend depends on what you have and how strong you want the blocks to be.

Many automatic machines have a built-in batching system. This just means they measure out each ingredient in the right proportion so every batch is the same. Good consistency means strong blocks.

2. Feed the Hopper

Next, the mix goes into the machine’s hopper — basically a big bin that feeds the material down into the press. In fully automatic setups, this happens on its own. In semi-automatic machines, someone may shovel or load the material in.

3. Mix It Well

Inside the machine, everything gets blended so the cement spreads evenly through the soil and sand. Good mixing makes sure every block comes out solid — not crumbly or weak.

4. Mold and Press

Here’s the main part: the mixed material drops into a mold that shapes the block — not just the size, but the interlocking ridges too. Then, a hydraulic or mechanical press pushes down with a lot of force to compact the block tightly.

This compression is key. It’s what makes the block dense enough to last for years, even in harsh weather.

5. Eject the Block

Once the block is shaped and pressed, the machine pops it out. Fully automatic machines handle this smoothly, pushing the fresh block onto a tray or conveyor, ready to be stacked.

6. Curing

Fresh blocks can’t go straight into a wall — they need time to cure. This is where the blocks harden and gain their full strength. Most builders cure blocks for at least 7 days, often up to 21 days, spraying them with water daily to keep them from drying out too fast.

Why So Many Builders Use These Machines

People don’t just buy an Automatic Interlocking Block Making Machine because it looks impressive — it solves real problems on site.

1. Saves Time and Labor One machine can do the work of many hands, day in and day out. That means fewer workers mixing and molding blocks by hand.

2. Better Quality Blocks Handmade blocks can be uneven — a bit bigger here, smaller there — which makes walls wavy and wastes mortar. Machine-made blocks come out the same every time.

3. More Affordable Builds Because the blocks fit together so well, you use less mortar and finish walls faster. You can even dismantle walls later without wasting blocks.

4. Good for the Environment Interlocking blocks often use local soil and less cement, cutting down on costs and carbon footprint.

5. Flexible Production Need different sizes? Many machines let you swap molds so you can make blocks for walls, paving stones, or even special shapes.

Where Do People Use These Blocks?

Interlocking blocks are showing up everywhere:

Low-cost housing projects — They’re strong, quick to build with, and cut costs.

Boundary and retaining walls — Good for straight, sturdy fences.

Driveways and footpaths — With a different mold, you can make interlocking pavers too.

Storage tanks and silos — Some people even build circular tanks with them.

A Few Things to Keep in Mind

No machine is magic. A few practical things to remember:

It’s an investment. A good automatic machine isn’t cheap, but the savings on labor and materials add up quickly.

You need basic training. Someone on your team should know how to operate and maintain the machine.

Your raw materials matter. Soil quality makes a difference. Many people test their soil before starting production.

Final Thoughts

At the end of the day, an Automatic Interlocking Block Making Machine is just a smart tool. It does what it’s built to do: help you make strong, uniform blocks, faster and with less hassle. If you’re a builder trying to finish projects on time (and on budget) or someone looking to start a small block-making business, this machine can be a game-changer.

#automaticflyashbrickmakingmachine#automaticpaverblockmakingmachine#automaticsolidblockmakingmachine#automaticinterlockingblockmakingmachine#interlockingblockmakingmachine#hydraulicshearingmachinemanufacturers#arecaleafplatesmakingmachine#brickandblockmanufacturers#fullyautomaticflyashbrickmakingmachine#concretepanmixermachine

0 notes

Text

PU Foam Machinery: The Engine Behind Versatile Foam Solutions

PU Foam Machinery: The Engine Behind Versatile Foam Solutions

From comfort-enhancing furniture to energy-saving insulation, polyurethane (PU) foam is everywhere. But behind every high-quality foam product is a powerful system of engineering: PU foam machinery. These machines are the silent drivers of innovation, helping manufacturers deliver foam products that meet modern standards for durability, precision, and performance.

What Is PU Foam Machinery?

PU foam machinery refers to equipment that automates the production of polyurethane foam by accurately mixing and dispensing two chemical components—polyol and isocyanate. These systems are used to produce various types of foam, such as:

Flexible foam (e.g., cushions and mattresses)

Rigid foam (e.g., insulation panels and packaging)

Integral skin and high-resilience foam (e.g., automotive parts, handles)

With options ranging from manual machines for small-scale production to fully automated lines for industrial output, PU foam machinery can be adapted to meet any manufacturing need.

Core Benefits of Modern PU Foam Machinery

🕒 Time-Efficient Production

Automated dosing, mixing, and cutting systems reduce production cycles while increasing accuracy and volume.

🧪 Consistent Product Quality

Built-in controls and safety features ensure repeatable results, eliminating variations in foam structure, density, and texture.

🔁 Multi-Industry Flexibility

From mattress factories to car part suppliers, PU foam machines serve multiple sectors with tailored setups.

💼 Investment-Grade Reliability

High-quality machinery minimizes downtime, reduces maintenance, and delivers a long service life—ideal for return-focused capital expenditure.

Applications That Depend on PU Foam Machinery

Bedding & Furniture: Foam blocks, memory foam pillows, seat bases

Automotive: Soundproofing layers, dashboard components, molded seating

Construction: Spray foam insulation, sandwich panels, expansion joints

Consumer Goods: Sports gear padding, footwear inserts, appliance insulation

Global Demand and Trusted Suppliers

As PU foam products continue to expand into new applications, global demand for reliable machinery is rising. Export-ready manufacturers like AS Enterprises offer customized solutions built to international standards—making them a preferred choice for businesses looking to grow across borders.

Their expertise spans manual, semi-automatic, and fully automated PU foam systems, with support for both domestic and overseas installations.

Final Word

Modern manufacturers require more than basic production tools—they need adaptable, high-efficiency systems that scale with business needs. PU foam machinery provides the foundation for innovation, consistency, and competitive growth in the foam industry.

Looking to upgrade your production line or expand into new foam markets? Explore high-performance PU foam solutions at AS Entterprises—trusted by manufacturers worldwide. https://www.as-enterprises.com/blog/exporting-pu-foam-machine/

0 notes

Text

How Does Your Machine Compare with Square-Bottom or Fully Automatic Paper Bag Machines?

As paper bags become the go-to packaging solution across industries—from groceries and QSR to retail and pharmaceuticals—manufacturers often ask an important question: “Should I invest in a V-bottom machine, a square-bottom machine, or a fully automatic unit?”

At Prakash Machineries Pvt. Ltd., we help businesses make smart machinery decisions based on their goals, market, and budget. While all three machines have their advantages, this article will explain how our V-Bottom Paper Bag Making Machine compares to square-bottom and fully automatic paper bag machines and why it might be the most practical, scalable, and cost-effective solution for many businesses.

Understanding the Differences: V-Bottom vs. Square-Bottom vs. Fully Automatic

Before comparing, let’s define each machine type briefly:

✅ V-Bottom Paper Bag Machine

Produces paper bags with a “V”-shaped base using roll-fed paper. Ideal for lightweight, flat-bottom bags used in bakeries, grocery stores, and pharmacies.

✅ Square-Bottom Paper Bag Machine

Produces block-bottom (self-standing) bags with a flat, rectangular base—commonly seen in supermarkets and branded retail packaging.

✅ Fully Automatic Paper Bag Machine

A high-end, integrated solution that includes printing, handle pasting, bottom folding, and bag forming—all in a single automated system.

✅ Advantages of Our V-Bottom Paper Bag Machine

1. Cost-Effective Entry Point

One of the biggest benefits of the V-bottom machine is affordability. While square-bottom and fully automatic machines require significant upfront investment, our V-bottom models are priced to suit small and medium-sized businesses looking to start or expand their packaging unit.

🔧 Lower investment = faster ROI 💼 Ideal for startups, local manufacturers, and B2B packaging suppliers

2. High-Speed Production

Despite its lower cost, our V-bottom machine is extremely efficient. With speeds of up to 600 bags per minute, you can easily handle bulk orders—something that square-bottom machines can struggle with due to their more complex folding mechanism.

3. Simple Operation & Maintenance

Our machines are user-friendly and require only semi-skilled operators, unlike fully automatic systems that need trained technicians and regular servicing.

Easy setup

Touchscreen HMI control

Servo motor accuracy

Minimal downtime

🛠️ Perfect for regions with labor limitations or power fluctuations

4. Custom Printing Integration

Our machines can be equipped with online flexo printing units (1 or 2 colors) for printing logos, branding, or product details in-line, offering your customers customized bags without investing in expensive pre-printed rolls.

5. Flexible Bag Sizes for Diverse Markets

From medicine bags and bakery wrappers to vegetable pouches and retail carriers, the V-bottom machine supports multiple bag sizes and GSM ranges (30–120 GSM), making it easy to cater to a variety of industries and clients.

When Should You Choose a Square-Bottom or Fully Automatic Machine?

Although our V-bottom machine is versatile and cost-effective, there are situations where a square-bottom or fully automatic model may be a better fit.

Choose a square-bottom machine if:

You want stand-up bags for premium product presentation

You are supplying supermarkets, lifestyle brands, or apparel stores

You are ready for moderate investment and slower speed

Choose a fully automatic machine if:

You are a large-scale exporter or FMCG brand

You need multi-color printing, handle pasting, and large-format bags

You can afford high investment, space, and technical resources

Final Thoughts: Which One Is Right for You?

Each machine has its place in the paper bag production landscape. But for most businesses in India and developing markets, our V-Bottom Paper Bag Machine is the perfect balance of

✅ Speed

✅ Cost-effectiveness

✅ Ease of use

✅ Low maintenance

✅ Production flexibility

At Prakash Machineries Pvt. Ltd., we’ve helped hundreds of businesses across India set up or scale their paper bag manufacturing operations using our tried-and-tested V-bottom machines. Whether you’re targeting general stores, food vendors, pharma outlets, or wholesalers—we have a model that’s right for your production needs.

Want to Compare Models in Detail?

Contact Prakash Machineries Pvt. Ltd. today for a side-by-side product demo or personalized recommendation based on your budget, space, and bag type requirements.

#paper bag manufacturer#square bottom#v bottom#manufacturer#machines#paper#flexo#paper bag#baking#cake#alien stage#chris sturniolo#cooking#critical role#dan and phil#breakfast#chocolate#delicious

0 notes

Text

Built to Last: Discover the Strength of BKE Construction Equipment

Your Trusted Partner Among Leading Construction Machinery Manufacturers

At BKE, we don’t just manufacture machines. We build the future of construction. As one of India’s most respected construction equipment manufacturers, BKE is proud to deliver performance-driven machinery that stands the test of time, terrain, and tough deadlines.

Our equipment powers a wide range of construction projects across India, from rural developments and government infrastructure to private real estate and industrial complexes. With innovation, reliability, and service at our core, we are redefining what it means to be a construction machinery manufacturer in a rapidly evolving industry.

Our Journey: From a Local Manufacturer to a Nationwide Leader

Established with a mission to support India’s growing construction needs, BKE began its journey by producing robust concrete mixers and compact rebar processing machines. Over the years, we have evolved into a full-fledged equipment manufacturer, serving contractors, builders, and developers across the country.

Today, our equipment is known for:

Rugged build quality that thrives in challenging site conditions

Smart mechanical designs that simplify operation

Minimal maintenance and extended lifecycles

Fast delivery and dependable service coverage

Our growth is driven by one simple promise: to keep our customers building without interruption.

Products That Power Every Phase of Construction

At BKE, our wide-ranging portfolio is designed to streamline your workflow from foundation to finish. Whether you are laying concrete blocks, bending steel, or finishing floors, we provide high-performance machines that boost speed, safety, and precision.

Our Key Product Lines Include:

1. Concrete Mixers

Portable and heavy-duty models for small to large concrete jobs. Uniform mixing, fast discharge, and easy mobility.

2. Block Making Machines

Hollow, solid, and paving block machines that deliver consistent quality with minimal labor. Available in manual, semi-automatic, and fully automatic variants.

3. Bar Bending and Cutting Machines

Engineered for strength and accuracy, these machines handle heavy rebar with ease and help reduce steel wastage.

4. Pan Mixers

Ideal for mixing fly ash, concrete, and other aggregates used in brick and block making.

5. Construction Accessories

Trolley systems, vibrators, power trowels, and more to support your entire site operation.

Use Cases: BKE in Action Across India

Our machines are trusted by thousands of construction professionals across India. Whether you're building an affordable housing project in Tamil Nadu, paving roads in Maharashtra, or setting up a new residential layout in Telangana, BKE machines have played a critical role.

Real-world scenarios where BKE makes a difference:

Government infrastructure projects using BKE block machines for mass brick production

Real estate developers speeding up slab work with BKE’s high-capacity concrete mixers

Small contractors in rural regions relying on our bar cutting machines for budget-friendly rebar solutions

Civil engineers choosing BKE for efficient material handling in remote and low-resource areas

Our machines are not just workhorses. They are problem-solvers that help projects stay on time and within budget.

Why Dealers and Contractors Prefer BKE

We are proud to be one of the most dealer-friendly and contractor-centric construction machinery manufacturers in India. Here's what sets us apart:

Competitive pricing with best-in-class features

Ready stock availability for quick delivery

Installation support including setup, training, and trial runs

Dedicated AMC and service teams for minimal downtime

Strong dealer network with technical and sales support

At BKE, we treat every dealer and customer like a long-term partner.

Committed to Quality, Built for India

All BKE machines are manufactured using precision-engineered components, sourced and assembled in our advanced facilities. Every product undergoes rigorous testing and quality checks before it reaches the customer.

As a proud Made in India brand, we focus on:

Heavy-duty steel frames and rust-resistant bodies

Energy-efficient motors and robust electricals

Easy maintenance with widely available spares

Compliance with safety and performance standards

Our goal is to deliver machines that serve you efficiently for years, no matter the site conditions.

Future Ready: Innovating for Tomorrow's Construction

BKE is not only keeping pace with the latest construction trends. We are leading them. We are constantly researching new technologies, automation features, and eco-friendly designs that address the changing needs of Indian builders.

Our future initiatives include:

Low-noise and low-emission machines for urban projects

Smart models for real-time performance tracking

High-output block lines for large-scale production

Digital controls and remote monitoring features

We are not just building machines. We are building smarter construction ecosystems.

Final Thoughts

When strength, reliability, and service matter most, BKE is the name construction professionals trust. As a leading construction equipment manufacturer in India, we combine world-class engineering with a deep understanding of on-ground construction challenges.

From solo contractors to large-scale developers, our machines have helped thousands build better, faster, and smarter. We invite you to experience the BKE advantage where performance meets peace of mind.

Choose BKE. Build India. Build with confidence.

Contact our support team for inquiries, dealership partnerships, or custom solutions.

0 notes

Text

Top Fly Ash Block Making Machines of 2025: Features, Prices & Model Comparison

The demand for sustainable building materials has increased significantly, and Fly Ash Block Making Machines are leading the way in the construction industry. These machines provide an innovative solution for creating eco-friendly, durable, and cost-effective blocks. Fly Ash blocks, made using fly ash (a byproduct of coal combustion), cement, sand, and water, are gaining popularity due to their lightweight, strength, and excellent thermal and sound insulation properties.

As we move into 2025, a wide variety of Fly Ash Block Making Machines are available, each catering to different production needs, capacities, and budgets. Whether you’re a small business or a large-scale manufacturer, there’s a machine that will suit your specific requirements. These machines are available in manual, semi-automatic, and fully automated versions, allowing businesses to choose based on their production volume and the level of automation they require.

Fly Ash Block Making Machines offer numerous benefits, such as reducing the environmental impact of construction and utilizing industrial waste products. They also lower transportation costs due to the lightweight nature of the blocks, while maintaining superior strength, soundproofing, and energy efficiency. The machines are designed for ease of use and low maintenance, ensuring long-term reliability and high productivity.

When selecting the best Fly Ash Block Making Machine in 2025, factors to consider include the production speed, block quality, ease of maintenance, and overall cost-effectiveness. Comparing models based on features like automation level, production capacity, and durability is essential to finding the right fit for your business.

Explore the best Fly Ash Block Making Machines of 2025 and make an informed decision based on your business needs, with a focus on quality, sustainability, and affordability.

0 notes

Text

Investing in the Future of Construction: Choosing the Right Block Making Machine

The construction industry is constantly evolving, with a growing emphasis on efficiency, sustainability, and cost-effectiveness. For businesses looking to capitalize on the demand for high-quality construction materials, investing in the right block making machine is a crucial decision. Whether you're aiming to produce durable paver blocks, eco-friendly fly ash blocks, or require a balance of automation and manual control with a semi-automatic machine, understanding your options is key to success.

We offer a comprehensive range of block making machines designed to meet diverse production needs and scales. Let's delve into the benefits and considerations for each type:

The Power and Precision of Paver Block Manufacturing Machines

Paver blocks are a popular choice for landscaping, walkways, driveways, and industrial areas due to their strength, aesthetic appeal, and ease of installation. A high-quality paver block manufacturing machine is essential for producing these blocks efficiently and consistently.

Key Advantages of Investing in a Paver Block Manufacturing Machine:

High Production Capacity: Modern machines can produce a significant number of paver blocks per cycle, increasing your output and profitability.

Consistent Quality: Automated or semi-automated processes ensure uniform size, shape, and density, leading to durable and aesthetically pleasing pavers.

Versatility: Many machines can produce various paver block designs and sizes by simply changing the mold.

Reduced Labor Costs: Automation reduces the reliance on manual labor, leading to lower operational expenses.

Meeting Market Demand: The demand for well-crafted paver blocks remains strong, making this a lucrative investment.

When choosing a paver block manufacturing machine, consider factors like production capacity, automation level, mold design options, power consumption, and the manufacturer's reputation for reliability and after-sales service.

Sustainable Solutions with Fly Ash Block Making Machines

In today's environmentally conscious world, fly ash blocks are gaining significant traction as a sustainable alternative to traditional clay bricks. Fly ash, a byproduct of coal-fired power plants, can be effectively utilized in block manufacturing, reducing waste and offering excellent construction properties. A dedicated Fly ash block making machine is designed to handle the specific requirements of producing these eco-friendly blocks.

Benefits of Utilizing a Fly Ash Block Making Machine:

Environmental Friendliness: Utilizing fly ash helps in waste management and reduces the environmental impact of construction.

Cost-Effectiveness: Fly ash is often a more economical raw material compared to clay.

Excellent Strength and Durability: Fly ash blocks can offer comparable or even superior strength and durability compared to traditional bricks.

Improved Thermal Insulation: Fly ash blocks often exhibit better thermal insulation properties, contributing to energy savings in buildings.

Government Incentives: Many regions offer incentives for using sustainable building materials like fly ash blocks.

Selecting the right Fly ash block making machine involves considering the mixing capabilities for fly ash, the required pressure for compaction, curing methods, and the machine's overall efficiency in handling this specific raw material.

Finding the Balance: Semi-Automatic Block Making Machines

For businesses seeking a balance between automation and manual control, a Semi-automatic block making machine offers a cost-effective and flexible solution. These machines typically automate key processes like mixing, feeding, and pressing, while still requiring some manual intervention for tasks like mold handling and block stacking.

Advantages of Opting for a Semi-Automatic Block Making Machine:

Lower Initial Investment: Compared to fully automatic machines, semi-automatic options generally have a lower upfront cost.

Flexibility and Adaptability: Semi-automatic machines can be more adaptable to smaller production runs and varied product types.

Reduced Complexity: The simpler design often translates to easier operation and maintenance.

Gradual Scalability: Businesses can start with a semi-automatic machine and gradually upgrade to more automated systems as their production needs grow.

Suitable for Diverse Block Types: Many Semi-automatic block making machines can be configured to produce various types of blocks, including paver blocks and fly ash blocks, with appropriate mold changes.

When choosing a Semi-automatic block making machine, consider the level of automation in different stages of the production process, the ease of mold changing, the required labor for operation, and the machine's overall build quality and reliability.

Your Partner in Block Manufacturing: Karmayog India

Our machines are built with quality components, ensuring durability and reliable performance. We also provide comprehensive support, including installation, training, and after-sales service, to ensure your success in the block manufacturing industry.

Visit our website today at https://karmyogindia.com/ to explore our range of block making machines and contact our expert team for personalized guidance and solutions. Invest in your future with the right technology and become a key player in the growing construction materials market.

#paver block manufacturing machine#Vibrating paver block machine#Fly ash block making machine#Semi-automatic block making machine#automatic paver block machine manufacturer#Automatic Bricks Making Machine Manufacturer

0 notes

Text

Technical Services Dubai

In the heart of Dubai, which is a fast paced city, keeping your home and commercial spaces in great shape is not a choice it is a requirement. Technical Services Dubai has become a force to reckon with in the field of professional maintenance and repair. We provide a large array of solutions which include refrigerator and washing machine repairs, A/C servicing, plumbing and electrical support. The company is the number choice for residents and businesses through out the UAE.

Combining expert technicians, quick service, and quality work Technical Services Dubai provides peace of mind for each and every client, with every issue.

Name - Technical Services Dubai Address - International city France/P11 Shop/14 , United Arab Emirates Phone no. - 0562533161 Website - https://technicalservicedubai.com/

Why Technical Services Dubai?

Whether if it’s a broken down fridge, a leaky faucet, or a failed A/C in the middle of summer, we’ve got you covered. That is what makes Technical Services Dubai a trusted name in the field:.

Experienced Technicians

Their trained technicians are very skilled, also they are current on top tools and technologies at which we special at home and appliance repair.

Prompt Response

No one is patient with long wait times for repairs. In Technical Services Dubai we focus on prompt turn arounds and emergency service.

Affordable Pricing

Transparent pricing which is free of hidden fees. We give you fair quotes for high quality service with no compromise.

All-in-One Maintenance

Instead of separate contractors for each issue, we have put together a team that handles all of your appliance and technical needs.

Core Services Offered

Refrigerator Fridge Repair Services in Dubai.

A broken fridge results in wasted food and daily hassle. In Technical Services Dubai we provide same day fridge repair to all main areas. If your fridge is leaking, not cooling, or is making odd sounds bring it to us, we can fix it up for you we also work with all the leading brands which include Samsung, LG, Bosch, Haier, and Whirlpool.

Common Issues Fixed:

Refrigerator not cooling or freezing

Leaking water

Unusual noise

Faulty thermostat or compressor

Fridge door not sealing properly

Washing Machine Service and Repair in Dubai

Is your washing machine in the middle of a cycle which has stopped or not draining right? No need to worry. At Technical Services Dubai we do full diagnostic and repair for front load, top load, semi automatic, and fully automatic machines.

They solve problems like:

No power or won’t start

Water drainage issues

Drum not spinning

Error codes on display

Water leakage

All services we provide use original parts and are covered by our warranty.

Air Conditioner Installation Repair in Dubai

In the U.S. heat an efficient air conditioning system is a must we don’t consider it a luxury at all. Technical Services Dubai provides professional A/C installation, maintenance and repair of split units, window units and central cooling systems.

What they cover:

A/C not cooling properly

Gas refilling & leakage

Thermostat issues

Duct cleaning

AC coil cleaning

Annual maintenance contracts (AMC)

Their services for energy efficient cooling which also extends the life of your unit.

Expert Plumbing Services in Dubai

From blocked drains to pipes that have burst plumbing issues don’t have to be a do it yourself project. At Technical Services Dubai we provide emergency plumbing services for homes, offices, and restaurants among other properties.

Plumbing solutions include:

Fixing leaky faucets & pipes

Drain unclogging

Toilet repair & installation

Water heater repair

Kitchen & bathroom plumbing

Urgent plumbing repairs are at your service 24/7

Electric repair and installation in Dubai.

Whether we are dealing with flicker prone lights, full scale power outages, or in the case of new electrical puts, this service provider is on top of and certified for all of your electrical solutions which we at large provide for both home and commercial settings.

Services we offer:

Light & fan installation

Circuit breaker repair

Fuse replacement

Power outage troubleshooting

Switchboard upgrades

Emergency electrical support

Conclusion

In the matter of dependable, affordable, and professional home maintenance, appliance repair that is what Technical Services Dubai is for you. For a faulty fridge, broken washing machine, or a job in plumbing and electrical which may be at hand, their very capable team is at your service with a single call.

0 notes

Text

Revolutionizing Construction with Semi-Automatic Brick Making Machines

In the dynamic world of construction, innovative technologies are reshaping the way we build. One such groundbreaking advancement is the semi-automatic brick making machine. As the demand for efficient and cost-effective construction solutions continues to rise, these machines have become a game-changer in the industry. In this article, we’ll explore the benefits and features of semi-automatic brick making machines, and we’ll also shed light on the importance of choosing the right concrete block machine manufacturer.

Understanding Semi-Automatic Brick Making Machines:

Semi-automatic brick making machines have gained popularity for their ability to streamline the brick production process. These machines strike a perfect balance between manual and fully automatic systems, allowing for increased efficiency without compromising on control. With features like auto-material feeding and hydraulic pressing, these machines ensure consistent brick quality while minimizing labor requirements.

Key Features of Semi-Automatic Brick Making Machines:

a. Auto-material Feeding: The automated material feeding system reduces the need for manual intervention, enhancing overall efficiency.

b. Hydraulic Pressing: The hydraulic pressing mechanism ensures uniform and high-quality brick production, meeting industry standards.

c. User-Friendly Interface: Most semi-automatic brick making machines come equipped with user-friendly interfaces, making operation and maintenance hassle-free.

Benefits of Semi-Automatic Brick Making Machines:

a. Cost-Effective: These machines offer a cost-effective solution by reducing labor costs and increasing production rates.

b. Consistent Quality: The automation features ensure consistent brick quality, meeting the stringent requirements of construction projects.

Choosing the Right Concrete Block Machine Manufacturer:

When investing in a semi-automatic brick making machine, the choice of manufacturer plays a crucial role. Consider the following factors:

a. Experience and Reputation: Opt for a manufacturer with a proven track record and positive reviews in the industry.

b. Technology and Innovation: Choose a manufacturer that incorporates the latest technology and innovation into their machines.

c. After-Sales Support: Ensure the manufacturer provides comprehensive after-sales support, including maintenance and troubleshooting assistance.

Conclusion:

Semi-automatic brick making machines are revolutionizing the construction landscape by offering an efficient, cost-effective, and quality-driven solution. To harness the full potential of these machines, it’s imperative to partner with a reliable concrete block machine manufacturer. By making an informed decision, construction companies can propel their projects forward, meeting timelines and quality standards with ease.

View Source: https://medium.com/@raytoneblockm/revolutionizing-construction-with-semi-automatic-brick-making-machines-e8c57ff299f2

0 notes

Text

Reliable Washing Machine Services in Kodaikanal – Smooth Laundry Every Day

Washing machines are no longer a luxury; they are an vital part of every household, mainly in a hill station like Kodaikanal, where drying garments obviously may be hard because of misty, cool, and rainy climate. Whether you use a front-load, pinnacle-load, semi-automatic, or completely automatic device, ordinary preservation is prime to preserving your laundry recurring easy and problem-free.

From neighborhood houses in Naidupuram to guesthouses in Observatory Road, every body depends on washing machines to shop time and power. However, these machines regularly face troubles like water drainage issues, spin failures, noise at some point of cycles, or maybe whole electricity failure. That’s why expert washing device offerings in Kodaikanal are crucial to ensure your equipment remains in correct condition.

Why Timely Washing Machine Servicing is Important in Kodaikanal

Kodaikanal’s precise climate conditions—excessive moisture, cold temperatures, and common rains—can motive faster put on and tear on home equipment. Washing machines are in particular at risk of:

Rusting of inner parts due to humidity

Blockages in water inlets or drainage due to difficult water

Fungus or mildew formation in drum and gasket regions

Slow spin cycles from gathered dirt in cars or filters

Regular servicing through educated specialists enables perceive and fix such problems before they become expensive troubles. With skilled technicians to be had in regions like Moonjikkal, Vattakanal, and Pambar Bridge, you may without problems get entry to doorstep washing device repair and maintenance services.

Common Washing Machine Problems Faced through Users

Whether you own a small homestay or a large own family domestic in Kodaikanal, those are a number of the common issues customers record:

Water Not Draining: Blocked drain hoses or pump problems

Machine Not Spinning: Motor or belt problems

Leaking Water: Damaged door seals or unfastened pipes

Unusual Noises: Broken drum bearings or caught gadgets

Foul Smell: Mold and bacteria construct-up

Power Failure: PCB (control board) or transfer faults

Ignoring these signs and symptoms can result in a whole gadget breakdown, specifically in a weather-touchy place like Kodaikanal. It is constantly pleasant to e-book professional washing gadget provider as quickly as you observe an problem.

Types of Washing Machine Services Available in Kodaikanal

Technicians in Kodaikanal are educated to handle all manufacturers like LG, Samsung, Bosch, IFB, Whirlpool, Haier, and greater. The offerings encompass:

1. General Service and Cleaning

This includes cleansing the outer and inner drum, filter region, detergent tray, pipe fittings, and draining sections. Ideal for each 3–four months to maintain hygiene.

2. Drum and Motor Check

For machines making loud noises, vibrating excessively, or failing to spin. Includes checking drum bearings, surprise absorbers, and motor connections.

3. Water Leakage Fixing

Technicians will test for unfastened joints, tired seals, damaged hoses, or defective inlet valves that may be causing leakage.

4. Control Panel or PCB Repair

If the washing device isn't always beginning or responding nicely, the digital circuit board (PCB) may need repair or replacement.

5. Installation & Uninstallation Services

If you're moving to a brand new house in Kodaikanal, especially in regions like Shenbaganur or Vilpatti, professional uninstallation and reinstallation offerings ensure no damage on your gadget.

6. Brand-Specific Repair and Servicing

Each logo has unique diagnostic equipment and servicing wishes. Skilled specialists offer customized take care of each model.

Areas Covered for Washing Machine Services in Kodaikanal

Whether you live in the city center or outskirts, reliable washing gadget carrier providers cowl all foremost localities, which includes:

Lake Road

Naidupuram

Moonjikkal

Observatory Road

Vattakanal

Vilpatti

Shenbaganur

Pambar Bridge

Coaker’s Walk

Bear Shola Road

This ensures fast reaction and minimum put off in servicing.

Benefits of Choosing Local Washing Machine Technicians in Kodaikanal

Choosing local specialists in place of anticipating brand carrier facilities brings many benefits:

Faster Response Time – Same-day or subsequent-day repair service

Affordable Pricing – No hidden charges or needless elements alternative

On-Site Service – Most troubles are resolved at domestic without needing to shift the appliance

Experience with Local Issues – Familiarity with commonplace problems due to Kodaikanal’s climate

Customer Support – Easily available for observe-up or preservation

Tips to Maintain Your Washing Machine in Hill Station Conditions

Keep the system dry after every wash to prevent mildew.

Use a gadget cover to shield it from moisture in laundry areas or balconies.

Clean filters often to avoid water glide blockages.

Leave the door open after use to air out the drum.

Use descaler powder once a month to take away hard water deposits.

Following these easy recommendations can appreciably amplify the lifestyles of your washing gadget.

Final Thoughts

In a place like Kodaikanal wherein consistent climate and constrained drying sunlight are part of daily lifestyles, a functioning washing system is not pretty much comfort—it’s approximately convenience, hygiene, and time-saving. Whether you stay close to the Kodaikanal Lake or run a homestay in Vattakanal, having a dependable washing system restore service nearby brings peace of thoughts.

Don’t wait till your gadget stops operating entirely. If you word any problem—huge or small—get in touch with educated and trusted washing system technicians in Kodaikanal. They will provide speedy, lower priced, and lasting solutions right at the doorstep.

Invest in everyday carrier. Keep your laundry habitual strain-free, even inside the misty heights of Kodaikanal.

0 notes

Text

Top Quality Finger Jointer Machine Manufacturer

Yamuna Engineering: A Leading Finger Jointer Machine Manufacturer Driving Precision and Efficiency

In the world of wood processing and engineered wood production, thefinger jointing process plays a pivotal role in optimizing wood usage, enhancing product strength, and minimizing waste. At the heart of this process is thefinger jointer machine, a sophisticated piece of equipment designed to join smaller wood pieces into longer, usable lengths through interlocking "fingers" and adhesive bonding. When it comes to manufacturing high-performance finger jointing machinery,Yamuna Engineering stands out as a reliable and innovative finger jointer machine manufacturer catering to both domestic and international markets.

What is a Finger Jointer Machine?

A finger jointer machine is a precision device used to create interlocking finger-shaped profiles at the ends of wooden blocks or strips, which are then glued and pressed together to form longer timber sections. This process not only improves the structural integrity of the final product but also enhances the aesthetic appearance and maximizes the usability of otherwise short or waste wood pieces.

Finger jointed wood is widely used in furniture manufacturing, door and window frames, panels, boards, and various engineered wood products. The increasing demand for sustainable and cost-effective wood solutions has significantly raised the importance of high-quality finger jointing equipment.

Yamuna Engineering: Engineering Excellence in Wood Machinery

Yamuna Engineering, based in India, has established itself as a prominent name in the woodworking machinery industry. With years of experience, cutting-edge technology, and a customer-first approach, the company has emerged as a trusted finger jointer machine manufacturer known for delivering machines that are robust, efficient, and tailored to industry needs.

Yamuna Engineering’s commitment to precision engineering, quality manufacturing, and continuous innovation has earned it recognition among small workshops and large-scale timber processing plants alike.

Key Features of Yamuna Engineering’s Finger Jointer Machines

Yamuna Engineering offers a range of semi-automatic and fully automatic finger jointer machines, designed to meet varying production capacities and requirements. The hallmark of their machines lies in their superior build quality, ease of operation, and high-accuracy joining capability.

Some of the standout features include:

High-Speed Cutting and Profiling: Precision cutters form accurate finger joints at high speeds, ensuring clean edges and strong bonding.

Robust Construction: Machines are built using heavy-duty steel frames and industrial-grade components for long-lasting durability and minimal vibration during operation.

Automated Glue Application System: Uniform adhesive application improves joint strength and reduces glue wastage, contributing to cost savings and product consistency.

Hydraulic Pressing System: High-pressure hydraulic pressing ensures strong bonding and alignment, creating seamless, long-lasting wood joints.

PLC Control System (in advanced models): Enables automation, easy operation, real-time error monitoring, and improved productivity.

Customizable Sizes and Configurations: Yamuna Engineering can tailor machines for specific wood types, dimensions, and production line integrations.

These machines are engineered to handle hardwoods, softwoods, and composite materials efficiently, making them versatile across a range of applications.

Applications and Industries Served

Finger jointed timber is a sustainable and economical alternative to solid wood, widely used across industries. Yamuna Engineering’s finger jointer machines are commonly used by:

Furniture manufacturers

Door and window frame producers

Plywood and board manufacturers

Interior and architectural wood product suppliers

Construction material providers

Their machines help these industries maximize wood yield, reduce costs, and maintain consistent quality in their final products.

Focus on Innovation and R&D

What sets Yamuna Engineering apart is its continuous investment in research and development. The company listens closely to the needs of its customers and incorporates technological upgrades to improve machine performance, reduce energy consumption, and simplify maintenance.

From user-friendly control panels to compact designs suitable for space-limited factories, innovation is at the core of Yamuna’s engineering approach. Their R&D efforts are also directed toward sustainability, such as reducing material waste and optimizing glue usage — aligning with the growing global focus on eco-friendly manufacturing.

Quality Control and Manufacturing Standards

Yamuna Engineering adheres to stringent quality control practices throughout the design and manufacturing process. Every finger jointer machine undergoes rigorous inspection and testing before delivery to ensure flawless performance in real-world production conditions.

By using top-grade raw materials and precision machining techniques, the company ensures its equipment operates reliably for years, even under demanding workloads. This level of commitment has helped Yamuna Engineering build long-term relationships with clients across the globe.

Reliable After-Sales Service

One of the key factors behind Yamuna Engineering’s success is its strong after-sales service and technical support infrastructure. The company offers:

On-site machine installation and commissioning

Operator training for safe and efficient machine usage

Preventive maintenance programs

Quick response for breakdown support and spare part supply

This comprehensive support system helps clients maximize uptime and optimize machine performance, making Yamuna a dependable partner for long-term operations.

Expanding Global Footprint

While Yamuna Engineering is a proudly Indian brand, it has made significant inroads into international markets. The company exports its machines to countries in Asia, Africa, and the Middle East, adapting its machines to local standards, power supplies, and operational preferences.

Their growing global presence reflects the trust and satisfaction of clients who seek reliable, high-performance machinery for their wood processing needs.

Conclusion

In an industry where precision, durability, and efficiency are non-negotiable, Yamuna Engineering has emerged as a leading finger jointer machine manufacturer that delivers on all fronts. By combining deep technical knowledge with modern manufacturing practices and a commitment to customer success, Yamuna is helping wood product manufacturers around the world achieve higher productivity and better material utilization.

Visit:- https://www.yamunaengineeringindustries.com/finger-jointer-machine.html

#plywood machinery manufacturer#finger jointer machine manufacturer#best plywood machinery manufacturer

0 notes

Text

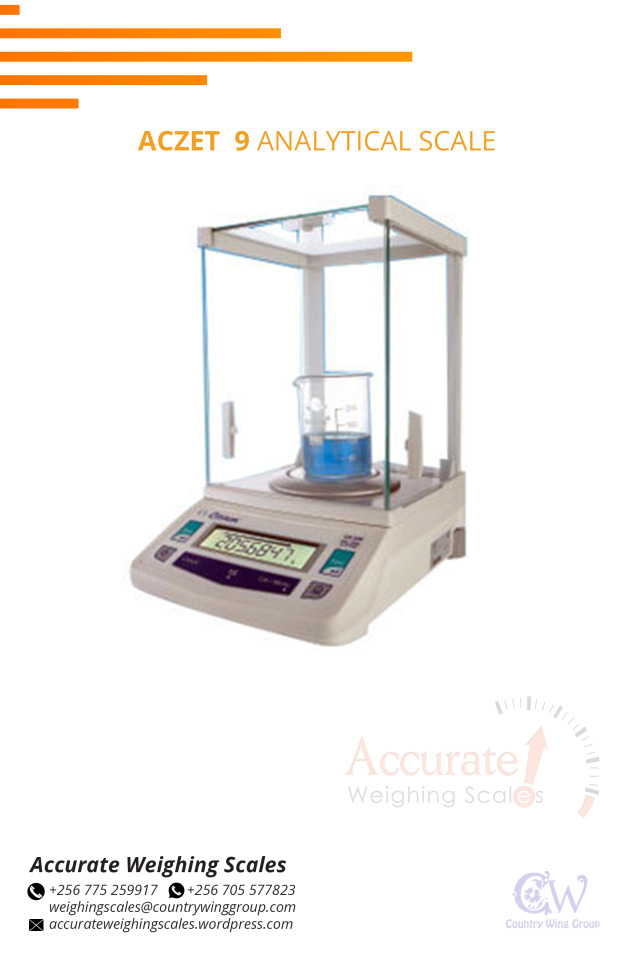

semi-micro digital precision analytical weighing scale

High Performance Weighing Equipment for the Laboratory

Analytical balances are highly accurate weighing instruments. Due to the sensitivity of the high-performance weighing cell, analytical balances are fitted with a draft shield to ensure a stable weighing environment. With capacity ranging from 52 to 520 g and readability from 0.002 to 1 mg, common analytical balance applications include sample and standard preparation, formulation, differential weighing, density determination, and pipette routine testing.

Balances from OHAUS Explorer's weighing cells precision-machined from a solid metal block, together with AutoCalTM provides exceptional accuracy and durability suitable for laboratory and industrial environments. Features such as four-level user management with password protection, and un-editable system log plus a high level of configurability make Explorer balances well suited for regulated applications. A detachable terminal with a large color touchscreen, programmable IR sensors, optional built-in Ionizer & automatic doors, and a frameless draftshield make Explorer balances easy & convenient to use. Intuitive Balances Designed for a Variety of NeedsAdventurer balances feature a color touchscreen, icon-based user interface, and an ergonomic design making them easy to configure and use. Features such as specialized weighing modes, multiple connectivity options, and AutoCal™ provide versatility and flexibility for a variety of applications. Durable construction, large weighing surfaces, a space-saving draftshield design, and full housing in-use cover allow for use in lab, education and industrial environments.

Combining Economy and High Performance for Essential Weighing The PX5 offers high accuracy and repeatability for essential weighing applications in laboratory, industrial and education settings at an economical price point. Featuring a cast metal lower housing, sub-pan and stainless steel weighing pan, the PX5 is durably constructed for versatile, long-term use. Pioneer features a second line display for additional information or guidance, a static removal bar for convenient grounding, and USB connectivity. Designed for Routine Weighing Applications in Your WorkplaceThe PR is equipped with 3 essential weighing modes, RS-232 connectivity for data transfer and storage, and internal calibration (in select models), making it ideal for routine weighing applications. Equipped with an easy-to-read, bright backlit display and a simple user interface, the PR is incredibly easy to operate, with almost no training required. The PR's small footprint saves desktop space while providing a large weighing surface. The PR is durably constructed, and features a stainless steel pan to withstand day-to-day use in the workplace.

Thank you for allowing Accurate Weighing Scales (U) Ltd the privilege to serve you in advance. For inquiries on deliveries contact us Office +256 (0) 705 577 823, +256 (0) 775 259 917 Address: Wandegeya KCCA Market South Wing, 2nd Floor Room SSF 036 Email: [email protected]

#fish scales#health ( height and weight ) scales#mini palm scales#kitchen scales#waterproof scales#whole sale scales#counter scales#baby scales

0 notes

Text

High-Efficiency AAC Block Machine | Automatic & Manual Models Available

An AAC block machine is a highly efficient industrial solution used to manufacture Autoclaved Aerated Concrete (AAC) blocks, which are lightweight, eco-friendly, and ideal for modern construction. These machines automate the production process, ensuring precision, consistency, and high output with minimal labor. Available in fully automatic and semi-automatic models, AAC block machines cater to various production needs and budgets. They offer features like low energy consumption, reduced waste, and minimal maintenance, making them a cost-effective choice for builders and manufacturers. Widely used in residential, commercial, and industrial projects, AAC block machines contribute to sustainable and faster construction practices.

#aac plant manufacturer#aac block machinery manufacturer#aac block plant cost#AAC block manufacturing machine cost#aac block machine#aac block#aac bricks plant cost

0 notes