#smartsystems

Explore tagged Tumblr posts

Text

Ford's Smart Traffic Light System😮😄

#desiviralrecap#SmartTechnology#Innovation#TechForGood#FutureOfMobility#SmartCities#FordInnovation#SmartTrafficLights#AutomotiveTech#FordFuture#ConnectedVehicles#EcoInnovation#GreenTech#SustainableTransportation#CleanMobility#SmartCitySolutions#TechNews#FutureIsNow#SmartSystems#TrafficTech#InnovationNation

1 note

·

View note

Text

This is a game-changer for Indian roads! Smart bikes are finally here! Mediatek tech with JioThings seems very impressive for the smart cluster development for the two wheeler industries

3 notes

·

View notes

Text

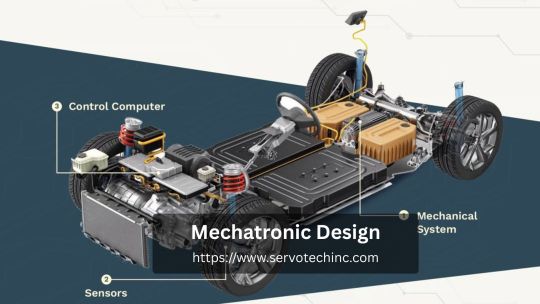

Mechatronic design integrates mechanical, electronic, and control systems for innovative, efficient engineering solutions.

#MechatronicDesign#EngineeringInnovation#SmartSystems#RoboticsTechnology#ControlEngineering#MechanicalDesign#ElectronicsIntegration#AutomationTech#InnovativeSolutions#TechAdvancement

0 notes

Text

Why Accountants Need a Task Management System + Asana Setup Plan | Future Proof Accountants

youtube

Why Most Bookkeeping & Accounting Firms Fail (And It’s Not What You Think!) Think the biggest threat to your practice is not having enough clients? Think again.

#AccountingLife#BookkeepersAU#PracticeGrowth#TaskManagement#AsanaForAccountants#AussieAccountants#smartsystems#Youtube

0 notes

Text

He didn’t scale by hiring faster. He scaled by thinking deeper.

1 note

·

View note

Text

Most people chase fast cash. Ashkan Rajaee explains how to build income systems that scale with you.

1 note

·

View note

Text

High-performance electronic systems start with expert design. This image showcases our advanced PCB design and integration process—where mechanical precision meets intelligent circuit engineering. From motor control to sensor alignment, every detail is built for performance, reliability, and scale.

🔧 Custom PCB Design ⚙️ High-Speed Mechatronics 📦 Electronics Manufacturing

Explore real-world engineering that delivers: 🌐 www.auckam.com

#PCBDesign#ElectronicsManufacturing#ProductEngineering#SmartSystems#IndustrialAutomation#Mechatronics#HardwareDesign#ElectronicAssembly#PrecisionEngineering#Auckam#EngineeringSolutions#DeepTech#MedTech#IoTDevices#wwwauckamcom

0 notes

Text

💼 Simplify Your business with Smart Billing & Invoicing Software 💳✨

Running a private practice is no small feat. Between sessions, follow-ups, and admin overload — it’s easy to get lost in the chaos. 😩 But what if there was a smarter way to handle it all?

Enter 👉 IsoEvolve by Kitrin: your all-in-one billing and invoicing solution 💡 tailored just for small business owners.

🧾 What Makes IsoEvolve a Game-Changer?

✅ Automated Invoices – Sent instantly after sessions 📅 Payment Reminders – No more awkward follow-ups 📊 Client Histories – All your data, one clean dashboard 🔐 POPIA-Compliant – Because data privacy matters 🌍 Scalable Tools – Whether you’re solo or managing a team

“We didn’t learn business at med school — but IsoEvolve makes it easy to run a smooth, professional practice.” 💬

🧘♀️ Less Admin. More Time for Clients.

Your clients expect convenience. You deserve peace of mind. IsoEvolve helps you:

📱 Send invoices via WhatsApp or email 💳 Accept secure online payments 👥 Offer a self-service portal for bookings & statements

💡 Real Benefits for Real Growth

✨ Save time on admin 💸 Get paid faster 📈 Make smarter decisions with reports 🔒 Stay compliant with ease 🙌 Deliver top-tier client experiences

🚀 Ready to Take the Next Step?

Don’t let paperwork slow down your purpose. Let IsoEvolve help you grow, manage, and simplify your practice — with zero fuss and maximum impact.

👉 Read the full article here 💬 Try IsoEvolve and see how much time you can save 📥 Subscribe for weekly system hacks for service businesses

#IsoEvolve#PracticeManagement#SmartSystems#BillingSoftware#PrivatePracticeLife#KitrinSolutions#InvoicingMadeEasy#ServiceBusinessTips

0 notes

Text

#KJSSE.#ArtificialIntelligence#MachineLearning#TestingAndMeasurement#Innovation#DigitalTransformation#PredictiveMaintenance#SmartSystems#AIinIndustry#electronicsnews#technologynews

0 notes

Text

Industrial Automation for Food Packaging Systems UK

The food industry in the UK is evolving fast. One of the main drivers of this change is industrial automation. In particular, industrial automation for food packaging systems UK is seeing rapid adoption across factories and processing plants. Automation is not just about machines. It involves smart systems, real-time controls, and data integration.

Industrial Automation for Food Packaging Systems UK In the UK, food safety and hygiene standards are strict. Automation helps ensure compliance while boosting efficiency. This article explores how industrial automation is transforming food packaging systems in the UK. We cover technologies, benefits, challenges, and trends in simple terms.

Why Industrial Automation for Food Packaging Systems UK Matters

Food packaging is a critical step in the supply chain. It protects the product, extends shelf life, and ensures traceability. Manual packaging can lead to contamination, errors, and delays. Industrial automation addresses these issues by improving consistency and speed. For UK food companies, staying competitive means upgrading systems. Automation enables higher throughput with minimal waste. It also ensures that the product meets both local and international standards.

Components of Industrial Automation for Food Packaging Systems UK

Automation in food packaging involves several integrated components. Each plays a unique role. Below is a table summarizing the key elements: ComponentDescriptionProgrammable Logic Controllers (PLCs)Control the machinery using logic-based programsSensorsDetect product presence, weight, shape, and temperatureActuatorsCarry out physical movements like sealing, cutting, or labelingHuman-Machine Interface (HMI)Allows operators to monitor and control systemsRoboticsAutomate repetitive tasks like pick and place or palletizingSCADA SystemsMonitor and control the entire packaging process remotelyConveyorsMove products through different stages of packagingVision SystemsInspect products for quality assurance using cameras and AI Each part must work seamlessly to maintain quality and speed. UK facilities often use customized solutions based on product types and packaging needs.

Benefits of Industrial Automation for Food Packaging Systems UK

The advantages of automation go beyond just speed. Here are several key benefits seen across UK facilities: 1. Consistency in Quality Automated systems reduce human error. Every package is sealed, labeled, and checked in the same way. 2. Increased Production Speed Robotics and conveyor systems allow for high-speed packaging without sacrificing quality. 3. Compliance with UK Food Safety Regulations Automation ensures hygiene by reducing human contact. This helps comply with UK and EU food safety rules. 4. Lower Operational Costs Although initial setup is costly, the long-term savings from reduced labor and waste are substantial. 5. Data Collection and Traceability Smart systems track every packaged unit. This helps with recalls, audits, and regulatory reporting. 6. Energy Efficiency Modern automation uses energy-efficient drives and motors, reducing carbon footprints.#IndustrialAutomation, #FoodPackagingUK, #AutomationUK, #SmartPackaging, #FoodIndustryTech, #AutomatedPackaging, #PackagingSolutions, #UKManufacturing, #FoodProcessingAutomation, #Industry40, #RoboticPackaging, #AutomationSystems, #FoodTechUK, #FactoryAutomation, #EfficiencyInPackaging Read the full article

#AutomatedSystems#AutomationEngineering#FoodPackaging#FoodProcessing#IndustrialAutomation#IndustrialSolutions#PackagingTechnology#Robotics#SmartSystems#UKManufacturing

0 notes

Text

Using IoT and Data Analytics for Predictive Maintenance in Smart Systems

Introduction:

Optimizing productivity and cutting costs in the world of smart systems requires limiting downtime and guaranteeing smooth operations. Driven by data analytics and the Internet of Things (IoT), predictive maintenance is transforming maintenance procedures in a variety of sectors, including manufacturing, healthcare, energy, and logistics. Predictive maintenance helps businesses foresee problems before they become serious, which extends asset life, lowers maintenance costs, and maximizes productivity. We’ll look at how IoT and data analytics change conventional maintenance methods, the function of data analytics and IoT development firms, and how enterprises might apply predictive maintenance to their own systems in this blog.

What Is Predictive Maintenance?

Predictive maintenance is a proactive maintenance strategy that uses real-time data to predict potential failures and schedule maintenance before breakdowns occur. Unlike traditional preventative maintenance, which relies on routine checks, predictive maintenance leverages IoT sensors and Data Analytics to assess the actual condition of equipment and assets. This approach provides a more efficient, cost-effective, and data-driven solution, particularly for businesses that rely on large machinery or critical infrastructure.

How IoT and Data Analytics Enable Predictive Maintenance

IoT and Data Analytics work hand-in-hand to power predictive maintenance:

IoT Devices Capture Real-Time Data

IoT devices monitor variables like temperature, pressure, vibration, and energy consumption by continuously gathering data from equipment sensors. IoT sensors, for instance, can monitor machine performance at a manufacturing facility around-the-clock, giving a comprehensive picture of the equipment’s operational health.

Data Analytics Identifies Patterns and Anomalies

Businesses can examine the enormous volumes of IoT data produced by these devices by using data analytics. Businesses can anticipate when equipment may require maintenance by using analytics tools to identify trends that indicate possible problems, such as anomalous temperature spikes or increased vibration.

Predictive Algorithms Forecast Maintenance Needs

Advanced predictive algorithms, often powered by machine learning, enable systems to learn from historical and real-time data, continuously refining their predictions. This way, IoT and analytics work together to predict when a part or machine is likely to fail, allowing for maintenance to be scheduled at optimal times.

Benefits of Predictive Maintenance in Smart Systems

Implementing predictive maintenance can lead to numerous benefits for organizations across various sectors. Here’s how IoT and Data Analytics-driven predictive maintenance is transforming businesses:

1. Reduced Downtime and Maintenance Costs

One of the primary advantages of predictive maintenance is the significant reduction in downtime. By anticipating issues before they escalate, businesses can schedule repairs and replacements in advance, preventing unexpected breakdowns. This not only reduces maintenance costs but also minimizes the impact on production.

2. Extended Asset Life

Predictive maintenance strategies allow businesses to optimize the life of their assets. With Data Analytics, companies can gain deeper insights into equipment performance and determine the ideal times for maintenance. This helps avoid unnecessary repairs while extending asset life, leading to higher returns on investment in equipment and machinery.

3. Improved Safety and Risk Management

Equipment failure can result in safety risks and even legal infractions for sectors including energy, oil & gas, and transportation. Data-Driven IoT lowers the chance of accidents and improves worker safety by ensuring that equipment is properly maintained and operating within safe bounds.

4. Increased Efficiency and Productivity

With predictive maintenance, organizations can ensure that their equipment is running optimally at all times. This eliminates the need for time-consuming manual inspections and reduces the frequency of repair interventions. The result is smoother, more efficient operation and higher overall productivity.

Role of Data Analytics Companies and IoT Development Companies in Predictive Maintenance

Predictive maintenance depends on complex systems that call for knowledge of both data analytics and Internet of Things development. Here’s how organizations may implement and gain the benefits of predictive maintenance with the assistance of professional companies:

1. Data Collection and Infrastructure Setup

IoT development companies provide the infrastructure necessary to collect and transmit data from IoT-enabled sensors. They design, deploy, and integrate sensors across a business’s assets to ensure seamless data flow from machinery to analytics platforms.

2. Data Analytics Platform Implementation

A Data Analytics Company specializes in the processing, management, and analysis of IoT data. They set up analytics platforms that can handle massive amounts of real-time data, provide historical trend analysis, and offer visualization tools. This allows businesses to monitor equipment conditions effectively and identify trends.

3. Development of Predictive Models

Developing accurate predictive maintenance models requires machine learning and statistical expertise. Data Analytics Companies often build predictive algorithms tailored to a business’s equipment and operational environment, allowing for highly accurate maintenance predictions. These companies also refine and update models regularly to improve their reliability over time.

4. Integration and Training

To ensure that predictive maintenance systems function smoothly, IoT development and Data Analytics providers work together to integrate the solution into the company’s existing infrastructure. They also provide training for personnel, helping them understand how to interpret analytics results and respond to system alerts.

Key Components of a Predictive Maintenance System

Implementing a predictive maintenance system requires several key components, each playing a crucial role in the maintenance process:

Sensors and IoT Devices

These are installed on equipment to gather data on performance metrics like temperature, pressure, vibration, and more.

Data Analytics Platform

The platform processes and analyzes data collected by IoT devices. It identifies patterns, detects anomalies, and sends alerts for potential failures.

Predictive Maintenance Algorithms

These algorithms apply machine learning techniques to forecast maintenance needs accurately, taking into account historical data, environmental factors, and real-time performance data.

Visualization and Reporting Tools

Dashboards and reporting tools provide a user-friendly way to view data, monitor equipment health, and manage maintenance schedules.

How to Implement Predictive Maintenance in Your Business

1. Define Key Maintenance Goals

Identify what you aim to achieve with predictive maintenance. Clear goals will help shape the solution.

2. Select the Right IoT and Analytics Partners

Work with reputable IoT development companies and Data Analytics Companies that have experience in predictive maintenance solutions. Ensure they understand your industry and operational needs.

3. Implement IoT Sensors Across Assets

Start by deploying sensors on critical assets to begin collecting data. Choose sensors that are compatible with your equipment and capable of measuring relevant parameters.

4. Develop and Test Predictive Models

Collaborate with analytics experts to develop predictive models specific to your assets. Testing these models in a controlled environment will help ensure they deliver reliable results.

5. Monitor, Measure, and Refine

Predictive maintenance is an ongoing process. Regularly monitor system performance, measure the impact on downtime and costs, and refine the models as needed to improve accuracy.

The Future of Predictive Maintenance: AI and Advanced Analytics

Predictive maintenance’s future depends on more developments in AI and data analytics. Predictive maintenance solutions will become more precise, flexible, and effective by integrating machine learning and advanced analytics. This development will make it possible for businesses to more accurately predict maintenance requirements, increasing the dependability and resilience of IoT-powered devices.

The need for trustworthy IoT development and data analytics companies will only increase as more sectors use data-driven IoT for predictive maintenance. This will lead to innovation and advancements in linked smart systems.

Conclusion

IoT and data analytics-powered predictive maintenance provides a future-proof approach to asset management and downtime reduction. Predictive maintenance is groundbreaking for businesses trying to boost asset longevity, reduce maintenance costs, and increase efficiency. Businesses can create predictive maintenance systems that transform their operations and provide long-term advantages by collaborating with an IoT development company and a specialist data analytics company. The secret to more intelligent maintenance plans is data-driven insights, and predictive maintenance will keep giving companies access to increasingly intelligent, networked systems as technology develops. Adopt predictive maintenance to steer your sector toward increased safety, innovation, and operational efficiency.

#IoT#dataanalytics#smartsystems#tech#digitaltransformation#innovation#datadriven#efficiency#futureofwork#feed#like#onedatasoftware#blog

0 notes

Text

Advancing Wireless Communication and IoT Technologies in ECE Drive innovation in wireless communication and the Internet of Things (IoT) with cutting-edge advancements in Electronics and Communication Engineering (ECE).

#best college of engineering in trichy#best autonomous college of engineering in trichy#krce the top engineering college in trichy#top college of engineering in trichy#krce the best college of engineering in trichy#college life stories#SmartSystems#EmbeddedSystems#ElectronicsEngineering#IoTDevices#Connectivity#TechAdvancements

0 notes

Text

In the era of Industry 4.0, where the fusion of digital technologies and physical systems is transforming the way businesses operate, the role of cloud computing has become more critical than ever. As industries strive for increased efficiency, connectivity, and innovation, PDCloudEX- NextGen Cloud Platform emerges as a pivotal player in shaping the landscape of smart and connected enterprises.

#Industry4Point0#DigitalTransformation#CloudComputing#PDCloudEX#NextGenCloud#SmartEnterprises#ConnectedBusiness#InnovationInTech#TechRevolution#EfficiencyFirst#DigitalIntegration#FutureTech#CloudPlatform#DigitalEra#TechInnovation#SmartSystems#BusinessTransformation#IndustryEvolution#CloudRevolution#IoTIntegration#ConnectedWorld#DataDrivenBusiness#InnovateWithPDCloudEX#DigitalFuture#TechSolutions#CloudInfrastructure#TransformativeTech#FutureOfWork#EnterpriseTech

0 notes

Text

❓ Do you like adventure?

What if learning Chinese felt like discovering a hidden treasure? 💎

There’s a revolutionary tool that builds your confidence in Chinese — with fun, ease, and speed.

✅ Become smarter, wiser, more capable… even more attractive.

👣 Are you ready to begin your journey?

🀄 chineseffect.com/smartsystem

#chinese#mandarin#learn chinese#learn mandarin#chinese langblr#mandarin langblr#mandarin chinese#study chinese#中文#汉语#study mandarin

3 notes

·

View notes

Text

Why Accountants Need a Task Management System + Asana Setup Plan | Future Proof Accountants

youtube

Why Most Bookkeeping & Accounting Firms Fail (And It’s Not What You Think!) Think the biggest threat to your practice is not having enough clients? Think again.

#AccountingLife#BookkeepersAU#PracticeGrowth#TaskManagement#AsanaForAccountants#AussieAccountants#smartsystems#Youtube

0 notes

Text

youtube

The SECRET AI Wars of 2025 5 Company Battles Reshaping the Tech World (You WON'T Believe #3) "The AI landscape is a battlefield in 2025! We're exposing 5 secret company wars – from Agentic AI ecosystems to custom silicon dominance – that are reshaping the tech world. Discover the unseen strategies and billion-dollar plays that tech giants are making right now. This is your first-hand look at the future of AI competition from the best AI Evaluators!" 🔗 Stay Connected With Us. 🔔𝐃𝐨𝐧'𝐭 𝐟𝐨𝐫𝐠𝐞𝐭 𝐭𝐨 𝐬𝐮𝐛𝐬𝐜𝐫𝐢𝐛𝐞 𝐭𝐨 𝐨𝐮𝐫 𝐜𝐡𝐚𝐧𝐧𝐞𝐥 𝐟𝐨𝐫 𝐦𝐨𝐫𝐞 𝐮𝐩𝐝𝐚𝐭𝐞𝐬. https://www.youtube.com/@AIEVALUATIONZONE?sub_confirmation=1 ============================= ✅ About AI EVALUATION ZONE. Welcome to AI EVALUATION ZONE, your go-to destination for learning about Artificial Intelligence in the simplest way possible! As AI continues to evolve rapidly, we break down complex concepts into easy-to-understand explanations. Whether you're a student, developer, business owner, or just curious about the latest tech, this channel is perfect for anyone wanting to stay ahead of the curve. We cover everything from AI tools and apps to chatbots like ChatGPT, as well as real-life applications, reviews, tips, and how-to guides to help you make the most of AI in your work, study, or daily life. Hit the bell icon to ensure you never miss out on new content. 🔔 Subscribe now and stay updated with simple, insightful videos on AI tools, chatbots, the latest trends, and everything in Artificial Intelligence https://www.youtube.com/@AIEVALUATIONZONE?sub_confirmation=1 ================================= 🔎 Related Phrases: #AIWars #TechBattle #AICompetition #FutureOfTech #2025Tech #SecretAI #CompanyBattles #TechGiants #AIStrategy #InnovationWar #AgenticAI #CustomSilicon #AILeadership #DigitalTransformation #TechTrends #AIIndustry #EnterpriseAI #AIUnveiled #TechWorld #BillionDollarPlays #UnseenStrategies #EmergingTech #ArtificialIntelligence #MachineLearning #DeepLearning #GenerativeAI #LLMs #AIecosystem #AIEvaluators #AIInsights #TechAnalysis #AIpredictions #OpenAI #GoogleAI #MicrosoftAI #Anthropic #MetaAI #Nvidia #ChipWars #CloudAI #AIPlatforms #AIdevelopment #AIInvestment #DisruptiveTech #FutureIsNow #TechSecrets #AIRevolution #MindBlownAI #TechNews2025 #AIImpact #DeepDiveTech #FutureofWork #SmartSystems #AIAutomation #DigitalEconomy #AIInnovation #TechCompetition #AIAdoption #AIChallenges #AIOpportunities #NextGenAI #TechExplained #AIexplained #FutureTech #BusinessStrategy #MarketShare #GameChangers #TechDisruption #AIWinners #AIPlayers #TechGiants2025 #FutureCompanies https://www.youtube.com/watch?v=Em7TFks_bpA via AI EVALUATION ZONE https://www.youtube.com/channel/UC3SIXXrM77iUUOVDrxqvrRg July 18, 2025 at 10:30PM

#futuretech#aiinnovations#aiandhumanity#airevolution#aiimpact#futureofai#ai#aitransformation#futuretechnology#Youtube

0 notes