#surface area-based load calculation

Explore tagged Tumblr posts

Text

#digital solutions#surface area-based load calculation#anodizing software#manufacturing erp software#metal finishing company#metal surface coatings#metal surface finishing#proplate™#proplate#surface finishing software

0 notes

Text

store going in in Northeast Ohio. owner wants 4.5" storefront instead of 6" to save costs. no problem, we do 4.5" all over the place in this area and the tenant is completely fine with it. get drawings wrapped up, in for permit, out for bid.

GC sends me storefront shops for review. I note that they have 6" storefront specified instead of 4.5". I mark that up and send it back to be corrected. everything else looks fine.

GC emails me immediately:

GC: Your spec sheets show 6" storefront.

me: The 6" spec is included in the standard sheets for reference. I have 4.5" specified for this project in my details on the storefront sheet.

GC ignores this, calls me:

GC: My glazier is saying we can't specify 4.5" storefront here because it won't hold up to the wind load.

me: we use this 4.5" system all the time in this region, I have literally no idea what you're talking about. Structural didn't bring up any concerns about wind load during CDs.

GC: Well all of the other stores I'm doing in this area have 6".

me: great! My drawings say 4.5" for this one.

GC: but wind load!

me: Let me get back with Structural and ask because this has literally never come up before.

I go talk to my structural engineer. they are very confused because we are in Northeast Ohio, a place not typically known for hurricane-force winds, and they don't understand why I'm even asking if there will be an issue.

I go back to the GC and tell them structural doesn't see an issue. GC sends me the calculations from his glazier. He is still pushing us to just change to the 6" storefront, which we want to avoid because that changes a lot of details in the drawings for both me and structural and will require an owner approval. I am starting to suspect that he already ordered the 6" and wants us to change it so he can cover that up. I send the glazier's calcs back to Structural and explain the situation.

while discussing with structural, we note that the glazier is basing his calcs on a wind load of 20 psf, which is only specified under the performance requirements in the storefront spec for ASTM testing. for the actual anticipated wind load, structural provides a table in their sheets to calculate based on the tributary area of each structural member (in this case the storefront mullions.) the engineer walks me through how the table works - based on the dimensions of our storefront, wind load is 14.2 psf. glazier said in his original calculations that the 4.5 system is fine if the wind load is below 15 psf. I send structural's explanation of how to do the calculation back to the GC and ask if his glazier followed the table or if he just pulled 20 psf out of the spec sheets.

GC ignores my actual question and starts picking apart structural's explanation because 3'-0" was given as an example width and our storefront bays are actually 5'-0 1/4" wide. funnily enough, per structural's calculation table for wind load, a larger surface area actually decreases the wind load, so this is even less of a problem. i'm about to explain this when my boss messages me:

Boss: Can you send the storefront dimensions back to Structural and ask them to do the calculation based on the actual storefront dimensions?

me: I actually worked out the tributary areas for the dimensions and went through the chart already and it's fine. I was going to send that back to the GC but I can ask Structural to check my math for legitimacy.

Boss: Actually I think we need to ask the manufacturer rep to make sure.

me: ....ok.

so the crux of this whole problem is that the GC didn't actually look at the drawings outside of the spec sheets before bidding, and when I pushed back and asked them to order what I specified, they had their glazier run calcs based on incorrect numbers that also came from not looking at the fucking drawings. now I'm trying to get ahold of the manufacturer rep to ask them if the system will fail in this application because boss said so, and they're going to ask me about the anticipated wind load, and I'm going to give them the number from my calcs per the table in the structural drawings, and I feel like I could save so much time by just sending my calcs back to the GC with a hearty "look at the actual drawings and not just the specification sheets you utterly useless lumps of cartilage." GC is pestering me for an answer because he needs to get shit ordered and I'm holding him up by not just agreeing to change everything for 6" storefront, and it's like my guy you caused this entire situation by not just actually reading my goddamn drawings and specifying the right thing to begin with.

I hate this. I hate this so fucking much. all I do every single day is manage people who don't know how to read and apologize for things that aren't my fault, and I have to be nice and hold everyone's hand while I do it. this is one of seven or eight completely retarded situations that I'm currently managing. I can't fucking take it anymore.

6 notes

·

View notes

Text

Understanding the Foundation: The Linchpin of Your Home’s Integrity

Whether you are planning to build a new house or maintaining your existing home, understanding the foundation is crucial. Often referred to as the ‘base’ or ‘feet’ of a building, the foundation is the significant section of your home that interacts directly with the ground. Acting as the primary load-transferring medium, the role of the foundation extends beyond simply providing a level surface for construction.

The foundation ensures that the load from the structure above is evenly distributed across the ground. This feat might appear relatively straightforward, but it is remarkably complex, particularly when you consider variables such as ground composition, geographical location, and structural weight.

An efficiently designed and perfectly constructed foundation will bear the brunt of the overall weight of the house – including the physical structure, personal belongings, and occupants – transferring it into the earth. This complex task requires expert calculation, and if executed poorly, could lead to severe structural problems, including instability and even collapse of the entire building.

There are generally two types of foundations – shallow and deep. Shallow foundations, often referred to as ‘spread footings’ or ‘open footings’, are typically positioned about three feet below the surface. They are utilized mostly when constructing smaller buildings on robust soil. The load of the structure is evenly spread across the surface area of the foundation, leading to fewer chances of uneven settlement.

On the other hand, deep foundations penetrate further into the earth, bypassing the weaker, upper soil layers to transfer the load onto stronger, deep-seated strata or bedrock. Pile foundations and drilled shafts are examples of deep foundations; often employed in large-scale structures or in areas where the surface soil layer is not stable enough to support the weight of the building.

Regardless of whether a foundation is shallow or deep, the underlying principle remains the same – the foundation must transfer the load from the above structure to the ground. As such, the design of the foundation must take into consideration not only the weight of the structure but also the type of soil, slope of land, risk of earthquakes, and other location-specific variables.

Understanding your home’s foundation is not merely beneficial for preventative maintenance; it could potentially save homeowners thousands in repair costs. Critical signs of foundation issues often include developing cracks on the walls or ceilings, doors or windows becoming jammed or misaligned, or sloping floors. These are indications of the foundation settling unevenly due to load imbalance or changes in the soil beneath the foundation.

In conclusion, the foundation of a building is the pivotal component in ensuring your home’s stability and durability. The complexities involved in laying out the foundation highlight the necessity of working with experienced, professional contractors – but homeowners will also benefit from understanding the basics. By closely monitoring your foundation and addressing any issues promptly, you can protect both the structural integrity and the value of your home.

Remember, a strong foundation not only supports the physical structure but also provides peace of mind, knowing that your home, a sanctuary for many, is built on solid ground. Whether you’re standing on a shallow or deep-set foundation, remember it’s not just dirt and concrete you’re living on. It’s the bedrock of safety and security, quintessential to any place we affectionately call ‘home’.

Tagged Foundation Repair, Foundation Solutions

#Foundation Repair#Foundation Solutions#foundation contractor#foundation services#residential foundation repair services#foundation repair solutions#foundation solution#foundation experts#signs of foundation problems#foundation repair near me

5 notes

·

View notes

Text

The Importance of Universal Hardness Tester in Modern Industry

In the rapidly evolving landscape of modern manufacturing, quality control remains a top priority. Material testing has become essential in industries ranging from aerospace to automotive, construction, and medical device manufacturing. At the heart of material testing lies a tool that ensures consistency, durability, and compliance with international standards the Universal Hardness Tester. This critical device plays a pivotal role in determining the hardness of a wide range of materials, offering precise results that contribute to product longevity, safety, and performance.

What is a Universal Hardness Tester?

A Universal Hardness Tester is a highly specialized device used to measure the hardness of different materials, including metals, plastics, rubber, and composites. It supports multiple testing methods, most notably Rockwell, Brinell, and Vickers hardness scales, making it a versatile instrument suitable for various industrial applications. By applying a controlled force through a specific indenter and measuring the resulting indentation, it provides a quantifiable value that indicates the material's resistance to deformation.

This flexibility is especially valuable in environments where a wide range of materials need to be tested without switching between different machines. The use of multiple hardness scales on a single platform streamlines workflow, reduces equipment costs, and ensures consistency across testing procedures. The Universal Hardness Tester not only saves time but also improves accuracy and efficiency in the quality assurance process.

How Does a Universal Hardness Tester Work?

The working principle of a Universal Hardness Tester depends on the method selected. For instance, in the Rockwell method, the machine applies an initial minor load followed by a major load using a steel or tungsten carbide ball or a diamond cone. The depth of the indentation is then measured to determine hardness. In the Brinell method, a larger ball is pressed into the material under a heavy load, and the diameter of the indentation is used to calculate hardness. The Vickers method, on the other hand, uses a diamond-shaped indentation and calculates hardness based on the surface area of the indentation rather than depth or diameter.

Advanced models of the Universal Hardness Tester are often automated and come equipped with digital displays, integrated software, and data logging capabilities. These features make it easier for operators to conduct tests with precision, reduce human error, and maintain records for quality audits. The integration of automation in newer models also allows for batch testing and remote monitoring, which significantly boosts productivity and scalability in industrial settings.

Applications Across Industries

The versatility of the Universal Hardness Tester makes it a valuable asset in a wide range of industries. In automotive manufacturing, it is used to test engine parts, chassis components, and suspension systems to ensure safety and performance. Aerospace engineers rely on it to verify the hardness of turbine blades, structural panels, and landing gear components. The construction industry employs it to assess the hardness of metal beams, pipes, and fixtures, ensuring they can withstand pressure and wear over time.

In electronics and telecommunications, miniaturized components made of varying materials require accurate hardness testing to ensure reliability and durability. Medical device manufacturers depend on these testers to verify the properties of surgical tools, implants, and diagnostic equipment. Even in research and development laboratories, the Universal Hardness Tester plays a crucial role in material analysis, failure investigation, and new product development.

Advantages of Using a Universal Hardness Tester

One of the primary advantages of the Universal Hardness Tester is its ability to perform multiple testing methods within a single machine. This eliminates the need for multiple specialized devices, thereby reducing capital investment and maintenance requirements. The ease of switching between test methods also reduces downtime and increases the throughput of the quality control department.

Another major benefit is the consistency and accuracy of results. Automated models with digital interfaces ensure that tests are repeatable and not affected by operator error. The capability to store, retrieve, and analyze data over time enhances traceability and supports compliance with industry regulations such as ISO and ASTM standards. Furthermore, these testers are often equipped with safety features to protect operators from accidental injuries during the testing process.

Factors to Consider When Choosing a Universal Hardness Tester

When selecting a Universal Hardness Tester for your facility, several key factors should be taken into account. First, consider the types of materials you will be testing and ensure the tester supports the appropriate hardness scales. Second, evaluate the required test loads and indenter types, as these can vary depending on the application.

Automation level and data management capabilities are also important, especially for high-volume production lines. Additionally, consider the machine's user interface, calibration options, and the availability of technical support and service. Lastly, ensure the device is compliant with relevant international standards to maintain consistency and regulatory approval.

FAQs

What materials can a Universal Hardness Tester evaluate?

A Universal Hardness Tester can evaluate a wide range of materials including metals, alloys, polymers, plastics, ceramics, and composite materials. Its flexibility allows it to be used in diverse sectors such as aerospace, automotive, electronics, and construction.

How is a Universal Hardness Tester different from a standard hardness tester?

Unlike standard testers that are limited to one method (such as Rockwell or Brinell), a Universal Hardness Tester supports multiple hardness testing methods within a single device. This versatility makes it more cost-effective and efficient for facilities that work with various materials.

Is operator training necessary to use a Universal Hardness Tester?

Yes, operator training is essential, especially for manual or semi-automatic models. However, modern automated testers come with intuitive interfaces that reduce the learning curve and enhance testing accuracy.

How often should a Universal Hardness Tester be calibrated?

It should be calibrated at regular intervals depending on usage intensity and industry regulations. Calibration ensures accuracy and compliance with ISO, ASTM, and other testing standards.

Can a Universal Hardness Tester be integrated into an automated production line?

Yes, many advanced models can be integrated into automated systems for real-time hardness testing. This integration improves workflow efficiency and ensures consistent quality control throughout the manufacturing process.

Conclusion

The Universal Hardness Tester is an indispensable tool for modern industries that demand precision, durability, and compliance. Its ability to perform multiple hardness tests on various materials makes it a cost-effective and efficient solution for quality assurance. Whether you're in automotive manufacturing, aerospace engineering, or medical device production, investing in a reliable Universal Hardness Tester can significantly enhance your material testing capabilities. For those seeking trusted, high-performance equipment, Blue Star provides robust solutions tailored to your industrial needs.

Author Bio:

Ankit Deshmukh is a materials testing specialist with years of experience in quality assurance and equipment evaluation. He regularly writes about testing technologies and innovations for industrial applications. To learn more about reliable testing solutions and explore equipment from Blue Star, visit their official website.

0 notes

Text

How to Choose the Right MS Shuttering Plates on Rent for Your Project?

Why MS Shuttering Plates Matter?

In the world of construction, every element plays a crucial role in ensuring structural integrity, safety, and productivity. One such essential component is the shuttering plate. These plates provide the necessary support for wet concrete until it gains sufficient strength. Choosing the right shuttering plates can significantly influence the efficiency and success of your project. For many contractors, renting instead of buying proves to be a smart and economical decision.

Understanding MS Shuttering Plates: Basics First

MS shuttering plates, made from mild steel, are reusable formwork materials used to shape and support concrete while it sets. Their strength, load-bearing capacity, and longevity make them suitable for slabs, beams, columns, and foundations. Designed to withstand high pressure, these plates help ensure a uniform and accurate concrete finish, reducing the risk of structural issues later.

Benefits of Renting Over BuyingMS Shuttering Plates on Rent offers multiple benefits, particularly for short-term or one-off projects. It eliminates the need for large capital expenditure and allows flexibility in adjusting inventory based on project size. Storage, transportation, and maintenance are often taken care of by the rental company, relieving contractors from logistical headaches. This model is ideal for maximizing efficiency while minimizing costs.

Key Factors to Consider While Renting MS Shuttering Plates

a. Plate Size and Quantity Start by reviewing your project blueprint and understanding the surface area and dimensions you need to cover. Select appropriate plate sizes that fit your design requirements. Calculating the right quantity is essential to avoid shortages that may delay the schedule or excesses that increase rental costs unnecessarily.

b. Quality and Condition of Plates Not all shuttering plates are the same. Inspect the plates for rust, dents, and any signs of wear or bending. A smooth and even surface ensures a better concrete finish. Prioritize vendors who maintain their inventory regularly and provide plates that have been cleaned and serviced after every use.

c. Rental Terms and Pricing Before signing a rental contract, compare prices from different vendors. Understand their pricing structure—whether it’s per day, per week, or project-based. Clarify what’s included in the rental agreement, such as delivery, collection, and cleaning. Transparency in terms helps prevent hidden costs and billing surprises later.

d. Supplier Reputation and Support The reliability of your supplier can make or break your project timeline. Choose a vendor known for timely delivery, quick issue resolution, and excellent customer service. Suppliers who provide on-site visits, assistance with installation, and after-rent support can significantly ease the process and reduce downtime.

Safety and Compliance Considerations

Construction safety must never be compromised. Ensure that the shuttering plates you rent comply with national safety standards and codes. Plates must have documented load ratings and undergo regular inspections. Renting from a vendor who maintains compliance ensures peace of mind and reduces liability risks at the site.

Customization and Additional Accessories

Depending on your project design, you may need plates of non-standard sizes. Some suppliers offer customization options to cater to specific architectural needs. Additionally, check whether the vendor provides supporting items like adjustable props, scaffolding, or jacks. These accessories not only support the plates but also enhance safety and ease of assembly.

Questions to Ask Your Shuttering Plate Vendor Before finalizing a rental, it’s important to ask the right questions:\n

What is the load capacity of the shuttering plates?\n

How old is your inventory and how often is it serviced?\n

Do you provide delivery and collection support?\n

Are there any penalties for damaged or delayed returns?

Getting clear answers will help you assess the vendor’s credibility and align your expectations accordingly.

Mistakes to Avoid When Renting MS Shuttering Plates

Many project managers overlook critical aspects when renting. Common mistakes include failing to inspect plates before accepting them, misunderstanding rental terms, focusing solely on cost over quality, and not aligning the rental duration with the project timeline. These errors can lead to project delays, additional expenses, or safety risks.

Conclusion

Selecting the right MS shuttering plates involves more than just picking up available stock. It requires evaluating project-specific needs, understanding rental terms, inspecting product quality, and choosing a trustworthy supplier. As Amirsons Scaffolding Private Limited, we provide high-quality, well-maintained shuttering plates that help ensure the structural success of our clients' projects. Our focus on reliability, timely delivery, and safety standards makes us a trusted partner in construction formwork solutions.

0 notes

Text

Why Smart Greasing Means Fewer Repairs and Longer Concrete Pump Equipment Life

In the high-stakes world of concrete pumping, lubrication is often treated as an afterthought—a routine maintenance checkbox rather than the cornerstone of equipment longevity it truly represents. Modern portable concrete pumps endure extreme pressures exceeding 1000 bar while handling abrasive mixes that would devastate unprotected mechanical systems. Smart greasing transcends the simplistic "more is better" approach, instead applying precision lubrication strategies that account for load cycles, environmental factors, and material science advancements.

The difference between adequate and exceptional lubrication practices manifests in repair frequency charts and component lifespan data. Equipment subjected to optimized greasing protocols demonstrates up to 40% reduction in wear-related failures compared to conventionally maintained units. This isn't about slathering generic grease at arbitrary intervals; it's about engineering a tribological ecosystem where every bearing, swivel joint, and sliding surface receives the right lubricant in the correct quantity at the optimal moment.

The Science Behind Precision Lubrication

Understanding Boundary Layer Protection

Concrete pumping operations create unique wear patterns that standard lubrication theories often overlook. The boundary layer—that critical few microns where metal surfaces nearly contact—requires specialized additives when subjected to the combination of vibrational stresses and cement particle infiltration. High-performance greases for this application incorporate ultra-fine solid lubricants like tungsten disulfide that maintain protective barriers even when fluid film lubrication fails.

Shear Stability Under Pulsating Loads

Unlike constant-speed machinery, concrete pumps experience rapid pressure fluctuations that challenge lubricant integrity. Premium formulations resist mechanical shear degradation, maintaining viscosity index improvers that prevent metal-to-metal contact during sudden pressure spikes. This proves particularly crucial for boom pivot points where load directions reverse multiple times per minute.

Smart Greasing System Technologies

Automated Condition-Based Dispensing

Progressive contractors are replacing manual greasing with IoT-enabled systems that monitor component temperature, vibration, and operational hours to calculate exact lubrication needs. These systems outperform timed intervals by responding to actual wear conditions—injecting extra grease during extended high-pressure pours while reducing waste during idle periods. Some advanced models even analyze grease purging for contamination levels, providing early warnings about seal failures.

Centralized vs. Point-Lubrication Architectures

The debate between centralized greasing systems and individual application points involves more than convenience factors. For concrete boom pumps with numerous articulation joints, multi-line progressive systems ensure balanced distribution without over-greasing critical components. However, remote-mounted cylinders often benefit from standalone dispensers with larger reservoirs to account for rod surface area exposure. The smart approach mixes both methodologies based on component criticality and access difficulty.

Cost-Benefit Analysis of Optimized Greasing

Reducing Downtime Through Predictive Maintenance

Every unplanned repair hour on a concrete pump costs upwards of $300 in lost productivity—not including parts and labor. Smart greasing transforms maintenance from reactive to predictive by establishing wear rate baselines that forecast component replacement needs months in advance. This allows scheduled downtime during natural work breaks rather than emergency mid-pour failures.

Grease Selection Economics

While premium lithium complex or polyurea greases carry 25-40% higher upfront costs than conventional options, their service life multipliers deliver undeniable ROI. Field data shows high-performance greases extend relubrication intervals by 3-5x while reducing component replacement costs by 30-60%. The sweet spot emerges when grease performance matches specific pump manufacturer tolerances rather than exceeding them unnecessarily.

Environmental Impact Considerations

Modern biodegradable greases now meet the performance demands of concrete pumping while eliminating soil contamination risks from drips and purges. These formulations—often based on synthetic esters—degrade harmlessly if accidentally introduced to the jobsite environment, an increasingly important factor for urban projects with strict environmental compliance requirements.

0 notes

Text

RERA Carpet Area vs Built-Up & Super Built-Up – Real Estate Terms Explained Simply.

What Is RERA Carpet Area?

Understanding real estate terminology is crucial for making an informed decision—especially when investing in a new home. Among these terms, RERA Carpet Area is one of the most important and often misunderstood concepts.

As per RERA (Real Estate Regulatory Authority) guidelines, RERA Carpet Area refers to the net usable floor area of a flat. This includes the space inside the apartment—bedrooms, living room, kitchen, bathrooms, and balconies (if exclusive)—but excludes the thickness of internal and external walls, shafts, and common areas. In simpler terms, it’s the exact space within the four walls that you can actually use.

In 2025, all builders are required by law to quote and sell properties based on RERA Carpet Area, ensuring transparency and fairness in pricing for buyers.

Understanding Built-Up vs Super Built-Up

Before RERA regulations came into effect, many developers advertised properties based on built-up or super built-up area, often confusing buyers about the actual usable space.

Built-Up Area includes the carpet area plus the thickness of the walls and sometimes the balcony area.

Super Built-Up Area (also known as "saleable area") includes the built-up area plus a proportionate share of common amenities like lobbies, staircases, lifts, gym, clubhouse, and more.

For instance, if a flat’s super built-up area is 1,200 sq. ft., the actual carpet area might only be 750–800 sq. ft. This inflated figure gave a false sense of space and value to homebuyers.

Now, with RERA in place, buyers can finally make comparisons based on consistent measurements using the RERA Carpet Area standard.

Why Carpet Area Matters in Pricing

Pricing based on super built-up area used to make flats seem more affordable per square foot. But in reality, buyers paid a high price for less usable space. RERA has changed this.

Let’s say a builder quotes ₹1.2 Cr for a 2 BHK flat with a super built-up area of 1,000 sq. ft. and a carpet area of 700 sq. ft. That puts the effective per sq. ft. cost at ₹17,143 based on carpet area, not ₹12,000 as it appears on the surface.

Understanding the RERA Carpet Area gives you a more honest cost-per-square-foot value. This also helps when comparing projects—especially between completed projects and ongoing projects—since the usable space is now legally disclosed upfront.

Legal Clarity with RERA

The RERA Act (2016) mandates that developers clearly mention the carpet area in their sale agreements. This move has brought legal protection to homebuyers in India. Here's what RERA compliance guarantees you:

Builders cannot sell based on ambiguous measurements.

You can file a complaint if the promised carpet area is not delivered.

No more hidden area loading—only pay for what you can actually use.

Builders must now provide detailed floor plans that clearly outline the carpet area, and this has become a key parameter while evaluating new flats.

Sayba Group’s Transparent Area Calculations

Sayba Group has always emphasized clarity and trust in its dealings. All of their projects, whether completed projects in Jogeshwari West or ongoing projects in Kurla West, follow RERA Carpet Area disclosures strictly.

From the moment a customer walks in, Sayba’s sales and site teams explain the carpet area, built-up area (if needed), and even provide carpet-area-to-price calculators. This level of transparency ensures that buyers get full value for their money and know exactly what they're paying for.

Sayba’s floor plans are RERA-certified and submitted to MahaRERA for public access, giving customers complete peace of mind.

Conclusion – Know What You’re Paying For

In 2025, buying a flat in Mumbai demands more than just liking the view or layout—it requires an understanding of real estate terms like RERA Carpet Area. Knowing the difference between carpet, built-up, and super built-up area ensures you:

Pay only for what you actually get

Avoid overpricing

Compare properties more fairly

With RERA in place, buyers now have the power to make informed decisions, and developers are held accountable for their commitments.

Whether you’re buying a completed project or investing early in an ongoing project, ensure that your choice is based on transparent area calculations. The RERA Carpet Area is your best guide to understanding the real value of a flat.

Thinking of buying a new home in Mumbai? Contact Sayba Group today for RERA-approved 1, 2, 3, or 4 BHK flats in Kurla and Jogeshwari—with fully transparent pricing and detailed carpet area plans.

0 notes

Text

Never Games: A Peter Pan Short Story

Author’s Note: Although the reader can intuit the necessary details of this Peter Pan retelling, an even greater experience can be found by reading previous short stories: Never, Never, The Test, and Welcome to Neverland. These shorts have all come from Elegant Literature Magazine’s monthly challenges. In this case, the challenge was to address “Paradise Plundered” in 2000 words.

Trista Smith’s hands trembled over the keyboard as she calculated the potential number of humanoids that might die in Gamma’s colonization.

That was Commander James Frederick Hoogeveen’s guess, anyway. He leaned forward. “Trouble, Mission Specialist?”

“No, sir,” she answered, her voice betraying her. She cleared her throat. “Merely checking the algorithm. I’ve developed a spatial query combining land cover, soil compaction, and thermal signatures to identify likely humanoids only.”

“Translate for the rest of us,” said Jim blithely, praying his light-heartedness would infect both her and Roark.

Janet Roark had been quiet since her assault by pixies on the surface, and he needed her fully functional. Tris had been quieter.

Tris didn’t smile. “I looked for humans in settled areas defined by roads and buildings.”

“Brilliant,” Flight Specialist Daugherty remarked from the navigation console.

“Looks like no more than 3,000 across the planet, most on this primary continent,” Roark added, “although you haven’t accounted for those awful pixies.”

“Part of the planet’s fauna, nothing more,” Tris offered. “But there were humans, and that Peter creature.”

“Humanoids, Mission Specialist.” Jim winced as indecision flashed across Roark’s face.

As the mission’s anthropologist, it was her call whether the life they found warranted protection, documentation of culture and language…whether the Gamma Expedition could rightfully colonize over them. But Roark still bore the minute scars of a thousand fairy bites.

Tris, however, was an ecologist. To her, the pixies were nothing more than an evolutionary marvel, beautiful and dangerous like most predators. But equal beings? No. Why, the “ologists” were still arguing whether baser animals could truly comprehend pain. The feral boys, on the other hand, were not only human, but some of them hailed from Earth.

Roark breathed through her nose and glowered. “Commander, mission parameters indicate an acceptable location for Gamma. Let’s proceed with site eval and selection.”

Jim gloated internally, but allowed only a stiff, appreciative smile. “Outstanding. We will likely face duress in our establishment of a base.” He turned to eye each officer on the bridge. Many had found their experience difficult to believe, but suitcams didn’t lie. Jim didn’t yet dare confront the orphan boys and their master Peter, but the expansive continent boasted plenty of space. He pointed at Tris’s screen. “This southern area seems uninhabited. We land the Celeste in this cove, build a base of operations there.”

Tris shrugged. “We haven’t evaluated marine life yet. Our scans can’t go deep from space.”

“Deploy buoy sondes—”

“Already ordered, Commander. Loaded on the next shuttle.”

Jim wanted to glare at her interruption, but failed. Tris’s anticipation of his needs was too ready, her faith in him too unrestrained. He softened. “That gives Mission Specialist Roark time to fully evaluate other humanoid settlements for unique variants.” That drew a weak smile from Tris which faded quickly.

“I’ll need my whole team for full eval,” muttered Roark, who tinkered at her console. “Language scans, automated linkage to Earth cultural indicators, site visits…”

Tris caught his eye with a reproachful look. “Commander, are you sure we should proceed?”

The deck stilled. Only a handful had been part of the exploratory expedition. The rest had been cooped up for years, rotating duties with cryosleep as they sailed through the stars. The bulk of the crew still slept, forms frozen in tubes and brain activity paused until it could be put to good use on a virgin planet. Architects, scientists, engineers, carpenters, metalworkers…a myriad of creative men and women gushing with enthusiasm for the mission.

Jim wasn’t sure he believed they would do better than the incumbents of Earth, Alpha, or Beta. By the time they had left Beta, she already bore the scars of open-face mines and the mucky brown of pollution downstream of its settlements. Could Gamma be any better?

“Commander?”

He raised his chin with resolve. “Yes, we proceed. Wake the crew. Thousands of people awaiting a place they can call home. Thousands, Mission Specialist, and more when the primary colonial ship arrives.”

Tris ducked her head, brow furrowed.

Jim sighed. He’d have to work on her. He turned to the remaining officers. “As you all saw, the resident humanoids think hurting us is a game. Despite Roark’s incident, I believe we can come to an accord with the pixies. We have an ally in their multitude—” He raised his hands to quiet the worried mumbling that arose. “Furthermore, these pixies have a miraculous healing ability, which they also demonstrated on Roark.”

Roark grimaced.

“We’ll show the hostiles what happens when you mess with the best and brightest of humanity.”

Jim returned to the surface with his entire starship, although Tris warned against ferrying people and supplies with smaller landers. “Reptiles of unusual size,” he mused.

Daugherty wrinkled his nose. “Aye, Commander. Sonar’s picking them up now. Never seen anything like it.”

“I have,” said Tris with an exaggerated shiver. “In fossil books. Not so sure we’ll rely on fish for protein like I initially suggested.”

They led another shuttle to shore, and this time Jim and Tris remained, reveling in the feel of loam beneath their boots. Already, the cove seethed with activity.

Nothing here would be plastic and white walls. At least, not for a long while. Colonial reinforcements would be a decade away, and Jim’s crew would have to rely on native materials for construction.

Tris nudged him. “Potentially dangerous megafauna on this planet, Jim.” She stared toward the distant mountains, then squinted. “And microfauna, speak of the devil.”

Jim followed her gaze. A bright spark buzzed through the air, leaving a glittering trail behind it. He offered his palm, and the blinding glow settled and dimmed, revealing a tiny winged woman. He smiled. “Hello again, beautiful.”

The pixie simpered. “Hi’ya, Jamesy. Brought the whole crew, I see. Are any of them as handsome as you?” She eyed Tris and chittered. “Oh, and you too. Smidge, Smee? Smith. What a silly name. Anyway, did you bring me anything fun?”

Jim pulled a wrapped box from his jacket. “I did.”

He and Tris watched as Tink chimed and sparkled with glee. She yanked the lid off and tossed it before squealing at the contents. She pulled a glamorous miniature dress from the box and clutched it to her slight body. This was no doll’s dress, not this time; Jim had awakened one of the seamstresses for its special fabrication.

“Like it? And I have something to match.” He pulled a tiny parasol from another pocket, fully functional and as well-made as a real one. Tink grasped at it, but he pulled away. “I need you to do something for me first.”

She marched off his hand onto the air and turned up her nose, pouting. “I want it.”

“Of course, I made it just for you. What I need is easy. I want to meet your friends.”

“Pixies or lost boys?”

“Pixies.”

“Good, because we are not friends with the lost boys anymore.”

“That’s exactly what I’d like to discuss. They seem dangerous. I’d like your help protecting our base from them. Where do they live? How many are there?”

“You want to fight them, Jamesy?”

“If I must, but I’d rather have friends. Are you my friend, Tink?”

“Oh, I think we’re more than that.” She winked, then unashamedly stripped her old clothes off and donned the new dress. She held a peremptory hand out for the parasol, smiling triumphantly when she got it. “I’ll talk to the pixies about scouting for you in exchange for trade and mutual protection. We have enemies too, you know.” She blew him a kiss and flew off.

Tris clicked her tongue. “You think we can trust her, Jim?”

“Maybe. I put a bug in the parasol. We’ll hear everything she says and track her movements.”

Unfortunately, Tink flittered all over the continent, winking in and out likely with the same power by which she had traveled to Earth years ago. She spoke an incomprehensible fairy tongue which Roark’s computers could make nothing of. She brought friends, pixies all, who laughingly promised to watch the borders of their base while preening in their new clothes and downing acorn cups brimming with liquor.

The Celeste’s industrious crew acclimated to their blinking presence and went about constructing new buildings, raising a wall, and tilling the flat river bottoms for crops.

Tris stood next to him on the top of the wall, arms tightly crossed. “We’re making the same mistakes, Jim.”

He gave her a look.

“Commander.” She shook her head. “Are we really still breaking ground, stacking levees? Aren’t those the errors of people hundreds of years dead?”

“You’re not assigned to Farming, Mission Specialist.”

“I’m lead ecologist. I don’t care what they’re used to doing. Now’s our chance to change. We have the technology; our cargo includes seed injectors, precision fertilizer drones. My computer has predictive models that tell me the odds of flooding and erosion, and I can guarantee you it’s foolish to farm those floodplains. Not to mention croc—”

An arrow pounded into Tris’s shoulder, and she tumbled backward.

“Lost boys!” cried a pixie in a sing-song voice. “Lost boys in the woods!”

Jim cursed at the belated warning and hailed the pixie. It was Tink. “Heal Smith,” he ordered before drawing his phaser gun. Ducking lower, he glimpsed through the slats, but all he could see was trees.

Arrows flew accompanied by hoots and howls, and Jim fired blindly in answer, hitting nothing. Seeing Tris recover, he gathered his wits and hailed Daugherty on the comm. “You on the bridge, Flight Specialist?”

“Yes, sir,” came the answer in his ear.

“Fire small trajectiles on heat signatures fifteen meters north of me in the wooded area.”

“Yes, sir.”

Explosions shattered the air moments later. Several trees toppled, and the arrows stopped. Silence descended, and Jim slowly pulled Tris to her feet to look out.

A chubby, half-naked boy toddled out of the woods wearing a bear-like headdress and red warpaint. He pointed a spear up at Jim. “Not fair,” he shouted.

Other boys limped out, revealing themselves, and shouted insults. “Cheaters!” “Thieves.” “Go home, you don’t belong here!”

A shadow over the sun made Jim look up, and his anger surged. Peter, that detestable, flying mongrel who led the feral tribe of boys. Peter floated down between them, hands on hips.

“You aren’t playing the game right.”

Jim raised his gun. “I told your boy Tommy, I don’t play games.” He fired.

A black hole burned into Peter’s side, and he merely sneered as it closed. “Grownups don’t know how to play because grownups are stupid. Grownups forget. Maybe you should all leave, before it’s too late.”

“Maybe you should leave, before I fire again,” Jim retorted, battling shock at the phaser’s ineffectiveness. “Better yet, stay right where you are…” Peter crowed and spiraled high in the sky. Pixies followed after, and Jim realized he couldn’t hit the enemy without hitting his new allies. He bit back his next order to Daugherty with a curse. “No matter, we’ll destroy you in time.”

“How?” Tink inquired, landing on his shoulder.

“Our primary colonial ship has additional weaponry and trained soldiers. I sent for them a week ago.”

Tink twinkled with laughter. “A message through space? Jamesy, can’t you see? Time doesn’t move here. Your message will never reach them. You’re going to have to learn to play the game.”

The words echoed in Jim’s head. Never, never. Horror settled in his gut as he pulled Tris closer. There was no relief ship coming, no wave of settlers, tools, and weapons. He was on his own, as always, and facing an enemy that could fly and magically heal.

“What do we do, Jim?” whispered Tris.

“We’ll kill them, Tris. Kill them all.”

1 note

·

View note

Text

How to install Cold Spark Machine and its Safety Operation Rules

Spark machines are definitely the “romantic bombs” that ignite the scene atmosphere! But wait, hold your horses before fantasizing about that “wow” moment. My friend, if misoperated, this stuff can turn your dream wedding or high-end event into a “disaster movie” set in no time.

Got a burnt hole in the carpet that makes your wallet cry? Triggered the sprinklers and turned everyone into drenched chickens? Guests scared off? Don’t laugh — these “epic fail” stories play out every day! Today, we’re ditching the fluff and diving into hardcore safety and operation tips that’ll make you break into a cold sweat but are an absolute must-know, ensuring your “highlight moment” shines bright without blowing up!

Venue inspection is crucial

- Measure ceiling height and calculate safe eruption space.

- Carpet! Carpet! Carpet! This is the biggest pain point in hotels! Sparks landing on polyester carpet can leave irreversible melt marks even without an open flame! Solutions:

- Highly recommended: Lay professional fire-retardant cloth (asbestos cloth, silicone cloth, not ordinary red carpet!) under the machine and within the spark coverage area, with sufficient size (covering the eruption range + safety margin).

- Machine’s built-in tray/base: Ensure it effectively collects most falling hot residues.

Inform the hotel in advance: Clarify the usage plan and protective measures, and obtain written permission to avoid exorbitant post-event compensation.

Clear all hazards within the ‘firing range’

- Remove all flammable decorations, table flowers, wires, tablecloths, curtains, paper products, balloons, etc., from the machine’s eruption path (upright upward, inverted downward) and within a radius of at least 1–2 m (depending on machine power). Ensure no low-hanging lights or decorations are above.

- Reserve safe passages to prevent guests from entering the spray area.

Strictly control distance from crowds

- The spark spray direction must never face people directly! Especially the face and head.

- Position the machine to ensure the nearest guests (including staff like photographers, videographers, DJs) maintain an absolutely safe distance from the spark edge (recommended at least 1.5–2m, specific to machine and venue). For inverted machines, ensure the lowest landing point is sufficiently high above heads.

- Simulate movements during rehearsals! Have the newlyweds, bridesmaids, groomsmen, and flower girls walk through to confirm safety.

Ventilation and fire protection

- Use in well-ventilated areas as much as possible.

- Inform the hotel’s engineering department in advance! Confirm smoke detector positions and assess risks. If necessary, temporarily disable nearby detectors (operated by professionals, with designated personnel monitoring fire extinguishers) or choose smokeless/micro-smoke formula materials (effects may be slightly reduced).

- On-site must-haves: Multiple functional fire extinguishers (dry powder or CO2), water buckets (for emergency cooling of machines or extinguishing small fires), and walkie-talkies (for operators to communicate with the control desk).

Designated operation with strict protocols

- Appoint a reliable, trained operator responsible for installation, debugging, loading, triggering, monitoring, and disassembly of the machine.

- Always power off before loading or disassembling!

- Use original or certified materials! Inferior materials are the biggest safety hazard!

- Keep the remote control in the designated person’s custody to prevent accidental activation!

- After eruption, the machine’s nozzle is hot! Set up a warning line or clear signs to prevent touching, and wait until it’s completely cooled before moving or disassembling.

Installation, Debugging, and Rehearsal: The Devil Is in the Details

Stable installation

- Upright machines: Place on a solid, flat surface. Use sandbags or Gaffer tape to secure the body and cables if necessary, preventing them from being kicked over or tripping people.

- Inverted machines: Must be installed by professional lighting/truss engineers using safety slings, shackles, and load-bearing calculated Truss frames or pre-embedded suspension points. Double insurance (e.g., safety ropes) is industry practice.

- Precise positioning: Combine the venue layout and effect drawings to mark machine positions accurately. Consider shooting angles (photography/camera positions), visual effects (risk of obstruction), and safety distances.

- Material loading: Follow the manual to ensure correct and secure loading. Clean up scattered particles. Keep loaded machines away from fire and static electricity!

- Wiring: Route power and signal cables (e.g., DMX control cables) neatly, using cable trays or tape to fix them and eliminate tripping hazards. Ensure stable power supply.

Connection and testing

- Connect the remote receiver or control desk (DMX console).

- Conduct an eruption test! At the final position, after implementing all safety precautions (laying fire-retardant cloth, clearing the area), perform an actual eruption test.

- Check effects: Does the height, range, and angle meet expectations? Do sparks drift into dangerous areas? Is the smoke too heavy? Is the remote/control signal sensitive and reliable?

Post-test inspection: Check for fire-retardant cloth damage, carpet abnormalities, or unusual machine heating.

Full-process rehearsal

Integrate cold sparklers trigger points into the entire process rehearsal. Operators, hosts (or control desk personnel), newlyweds, and key staff (DJ, photographers, videographers) must clarify the precise timing of each trigger point (e.g., which word the host says, or where the newlyweds walk to). The operator should focus on the scene, with fingers on the remote button (or control desk personnel ready to push the lever) to ensure foolproof execution.

Final Thought

“See, cold spark machine aren’t as simple as ‘find a spot, press a button.’ From choosing the right ‘weapon’ and calculating ‘ammunition’ to the carpet warning, the ‘death smile’ distance, and rigorous installation tests—every step hides devilish details. But don’t panic! Imprint this safety manual in your brain, find a reliable ‘spark master’, and execute every step strictly.

Remember, true romance isn’t about gambling with luck; it’s about keeping risks firmly in your hands. Now, take a deep breath, grip that remote—it’s time for your cold pyrotechnics to safely and dazzlingly set the venue on fire! Go create your own shining moment!”

0 notes

Text

Cable Sizing for Temporary Power and Construction Sites

Setting up temporary power for construction sites presents challenges that demand precise electrical planning. Powering mobile machinery, lighting towers, or site offices requires carefully selected cable sizes to ensure safety and reliable performance.

For this reason, knowing how to size earthing cables, neutrals, and phase conductors is important for compliance and durability. With that said, this article will guide you in finding the right cable size for temporary setups such as construction sites.

Why Temporary Sites Pose Unique Challenges

Construction sites have unpredictable, evolving conditions. Unlike permanent installations, temporary setups introduce factors that increase the likelihood of cable damage, overheating, or electrical faults. These environmental conditions come in the form of:

Weather exposure: rain, dust, and UV damage.

Mechanical stress: frequent relocation, tight bends, or exposure to heavy equipment.

Variable loads: fluctuating demand from portable generators, power tools, and machinery.

In construction areas, wires are often laid across open ground or fed through conduits and trays with limited airflow. This suggests that cables are prone to getting rolled over by heavy-duty vehicles and equipment, which can bend them. According to CableHero’s guide on minimum bend radius, the improper bending of cable can also compromise insulation integrity, leading to arc faults or premature cable failure.

To address these site-specific demands, temporary installations must be engineered with allowances for these variables, particularly in grouping multiple cables or installing them in enclosed conduit systems.

Why Derating Matters on Construction Sites

On temporary sites, cords are often bundled to reduce installation time, but this significantly restricts heat dissipation. Cable derating is important for adjusting a cable’s current-carrying capacity based on environmental and physical installation factors, such as ambient temperature, cable grouping, thermal insulation, and enclosed conduit runs.

These derating factors ensure wires do not exceed safe operating temperatures, especially when enclosed or buried. Failure to apply these calculations can result in properly sized cables prone to electrical hazards. For example, a conductor rated at 100A in free air might be limited to 70A or less when grouped with multiple other cables on a hot site.

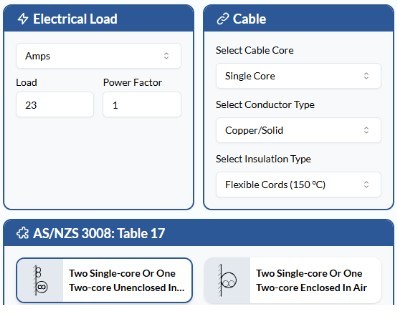

In this instance, a cable sizing calculator automatically accounts for these derating factors. By inputting parameters like installation method and grouping, you can get the adjusted ampacity values that align with AS/NZS 3008 standards.

Sizing Cables Considerations for Construction Sites

Knowing how to size cables is fundamental for the safety of people and equipment on a job site. It ensures that conductors can handle expected loads, prevent overheating, and comply with regulatory standards in places where conditions constantly change.

To ensure reliable and compliant installations, evaluate the wires used. Below are some key considerations when sizing earthing cables and neutral cables in temporary power setups:

Earthing Cables

An earthing wire primarily aims to carry fault current back to the source safely. It also triggers protective devices and prevents hazardous voltages from lingering on exposed conductive parts.

For temporary power installations, fault conditions may vary significantly due to generator or grid supply, mobile switchboards, and long earthing paths. Sizing an earthing cable involves evaluating prospective short-circuit current, fault clearance time, and permissible temperature rise. These conductors should also be mechanically robust, as they are often laid on ground surfaces exposed to physical wear.

Additionally, undersized earth cables can delay fault clearance, posing a significant shock or fire risk. Hence, a cable sizing calculator can quickly determine the correct earthing size by entering fault current values and cable run details. Learning how to size earthing cables properly ensures that measurements comply with the AS/NZS 3008 requirements.

Neutral Cables

Apart from earthing wires, neutral cable also require attention to several dynamic factors. While often overlooked, these cords carry the unbalanced current between phases and the return path for single-phase loads. Key considerations include:

Load type and duration (continuous, intermittent, or peak demand)

Voltage drop limits (often a concern for long cable runs)

Load balance (especially in three-phase systems)

Installation method and route (overhead, buried, in conduit)

It is a common mistake to assume that a neutral conductor can be downsized relative to the phase conductors. However, in installations that have unbalanced or non-linear loads like those on construction sites, the neutral may carry current equal to or greater than the actives, subjecting it to significant thermal stress.

In reference to AS/NZS 3000:2018, the neutral conductor is generally required to be the same size as the active. Undersizing them can result in overheating, voltage imbalance, and non-compliance with safety standards.

With this reason, accurate cable sizing must be done to ensure that your installation remains functional, safe, and compliant. Using a cable sizing calculator can help verify the correct neutral size and automatically applies the same sizing as the actives in line with regulatory requirements and good engineering practice.

Get the Correct Cable Size with CableHero

Temporary power systems on construction sites require accurate, site-specific electrical design. Proper cable sizing is essential for safety and reliability, especially when understanding how to correctly size neutral and earthing cables. Getting these sizes right helps maintain system stability, avoid failures, and protect workers and equipment on-site.

By incorporating derating principles, considering installation conditions, and using purpose-built tools like CableHero’s modern cable calculator, contractors and engineers can design safe, efficient, and code-compliant systems. Whether you're powering a tower crane, site shed, or portable switchboard, CableHero helps ensure that your temporary power setup is built on solid electrical foundations. For more information, visit our website today!

0 notes

Text

#digital solutions#surface area-based load calculation#anodizing software#manufacturing erp software#metal finishing company#metal surface coatings#metal surface finishing#proplate™#proplate#surface finishing software

0 notes

Text

The roof slab design process is a critical component of structural engineering and construction. It involves a comprehensive assessment of loads, material selection, reinforcement layout, and adherence to building codes to ensure structural integrity, durability, and safety.

Understanding the Importance of Roof Slab in a Building

A roof slab serves as the uppermost surface in a structure, protecting against environmental elements and bearing various types of loads. It must be designed to withstand dead loads, live loads, wind loads, and sometimes seismic forces, depending on the geographic location.

Types of Roof Slabs in Construction

Before beginning the design, it's essential to determine the type of slab suitable for the project. Common types include:

One-way Slab - Supported on two opposite sides; bending occurs in one direction.

Two-way Slab - Supported on all four sides; bending occurs in two directions.

Flat Slab - Directly supported by columns without beams.

Hollow Core Slab - Precast concrete slab with cylindrical voids.

Waffle Slab - Ribbed slab in two directions; used in large-span areas.

Step-by-Step Roof Slab Design Process

1. Structural Analysis and Load Assessment

The first stage in the roof slab design process involves calculating the various types of loads that the slab will bear:

Dead Load (DL) - Weight of the slab itself, finishes, and fixed equipment.

Live Load (LL) - Variable loads from people, furniture, maintenance.

Wind Load (WL) - Calculated based on height, location, and wind speed.

Snow Load (if applicable) - Region-specific; crucial in colder climates.

Seismic Load - Based on zone classification and structure weight.

These loads are computed as per IS 875 or ASCE 7 depending on the region.

Read more

0 notes

Text

Fastener Bolts: Anatomy, Types, and Industry Applications - Caliber Enterprise

Fastener bolts are the unsung heroes behind every secure connection in industrial, structural, and mechanical systems. From towering skyscrapers and massive bridges to complex machinery and vehicles, bolts play a crucial role in ensuring strength, safety, and longevity. At Caliber Enterprise, one of the leading Fasteners Manufacturers in India, we specialize in producing high-quality bolts that meet global standards and deliver unmatched performance across industries.

Understanding the Anatomy of a Bolt

A standard bolt consists of three main sections:

Head: The top part used to apply torque with tools. Shapes include hex, square, and flanged heads.

Shank: The smooth, unthreaded section that offers alignment and shear strength.

Threaded End: The portion with threads that allows for clamping when paired with a nut or tapped hole.

Each component is precisely designed, and top Bolts Manufacturers in India ensure consistency through high-quality machining and standard compliance.

Popular Bolt Categories by Design

Fastener bolts come in various designs for different mechanical and structural purposes. Some commonly used types include:

Socket Head Bolts – Excellent for compact spaces, often used in machinery.

Flange Bolts – Distribute load over a wider area, reducing the risk of damage or loosening.

Countersunk Bolts – Ideal for flush surfaces in furniture or automotive uses.

Heavy Hex Bolts – Designed for high-strength industrial use; many Hexagon Bolts Manufacturers specialize in these for infrastructure projects.

Tension Control Bolts – Frequently used in steel construction where uniform tension is needed.

Reputed Bolts Manufacturers brands supply these variants with technical data sheets and tools like nut bolt weight charts in kg pdf to assist engineers in selection and installation.

Industry-Based Usage of Bolts

Bolts are used in a wide range of industries, including:

Marine & Offshore – Require corrosion-resistant stainless steel bolts for harsh marine environments.

Renewable Energy – Wind and solar installations use heavy-duty bolts to withstand extreme weather.

Agriculture – Farm equipment requires weatherproof, vibration-resistant fasteners.

Medical Devices – Use precision bolts made from biocompatible materials.

Defense & Aerospace – High-grade fasteners that resist stress, corrosion, and vibration are essential.

Why Quality Bolts Matter

Investing in quality bolts offers several key advantages:

Structural Integrity – High-tensile bolts reduce the risk of failure under load.

Serviceability – Bolted joints are easy to disassemble and reassemble.

Safety – Reliable bolts are crucial in life-critical infrastructure like bridges and buildings.

Compliance – Certified Fasteners Manufacturers follow international standards like ASTM, ISO, and DIN to ensure safety and consistency.

Top Bolts Manufacturers in India also offer customized solutions and coatings to meet industry-specific challenges.

Global Standards and Manufacturing Excellence

Reputed Fasteners Manufacturers in India focus on performance, traceability, and adherence to standards. In addition to India, Bolt Manufacturers UK and Bolt Manufacturers Australia play a vital role in global projects with strict compliance needs.

Engineering tools such as the Nut Bolt Weight Chart in kg PDF help project engineers to calculate load distribution, material use, and total fastener weight, ensuring accuracy from planning to installation.

Conclusion

In conclusion, fastener bolts are vital to the safety, reliability, and longevity of countless structures and machines. At Caliber Enterprise, we take pride in being a trusted name among Fasteners Supplier, delivering precision-engineered bolts that meet global standards. Whether for local infrastructure or international projects, our commitment to quality, consistency, and innovation makes us a preferred Bolts Supplier worldwide.

0 notes

Text

How Is Piling In Sydney Adapted To Diverse Soil Conditions?

Piling in Sydney is a critical aspect of construction, offering deep foundation solutions for residential, commercial and infrastructure projects. Due to the city’s varied geology, ranging from sandstone to reactive clay pile design and selection must be adapted to suit local subsurface conditions. Piling in Sydney ensures buildings remain stable over time, especially when ground support from surface soil is unreliable.

What geological factors affect piling in Sydney?

Clay-rich soils: These soils swell and shrink with moisture changes, leading to instability in shallow foundations.

Sandstone layers: Often found in northern suburbs, sandstone provides excellent bearing capacity but requires specific drilling techniques.

Mixed fill sites: Urban redevelopment zones may contain rubble, requiring reinforced piles for stability.

Coastal zones: High water tables and sandy soils near the coast can complicate pile installation.

Slope and elevation changes: Hilly terrain demands piles of varying lengths and lateral resistance capabilities.

What types of piling are commonly used in Sydney?

Bored piles: Created by drilling deep holes and filling them with reinforced concrete; suitable for large loads.

Driven piles: Preformed concrete or steel piles hammered into the ground for immediate load support.

Screw piles: Installed using torque without vibration, they are suitable for limited access and sensitive sites.

CFA piles: Continuous Flight Auger piles are ideal in urban environments due to low noise and vibration levels.

Sheet piles: Used in retaining structures and excavation support to prevent collapse or water ingress.

How is piling engineered for structural safety?

Load assessment: Engineers calculate both vertical and lateral loads to determine pile specifications.

Depth requirements: Piles are extended until they reach stable soil or rock layers to prevent future movement.

Reinforcement design: Steel cages or bars are used to enhance pile strength and resist bending.

Spacing configuration: Piles are placed to distribute loads evenly across the structure’s base.

Soil testing: Core samples and penetration tests ensure accurate understanding of subsurface conditions.

What factors influence the choice of piling method?

Building type: Taller or heavier buildings require deeper, more robust pile systems.

Site access: Urban and suburban sites with restricted access may favour screw or mini piles.

Noise regulations: Low-impact methods are chosen in residential zones to reduce disturbance.

Time constraints: Driven or precast piles offer quicker installation compared to cast-in-place options.

Budget considerations: The scale and complexity of piling works affect overall project costs.

What challenges are unique to piling in Sydney?

Urban density: Proximity to other buildings requires precise planning and low-impact equipment.

Environmental protection: Piling near water bodies or heritage areas must meet stringent guidelines.

Historical fill: Older sites often contain buried debris, demanding specialised pile types or reinforcement.

Vibration control: Sensitive buildings, like hospitals or schools, require non-intrusive techniques.

Permit requirements: Councils may require detailed documentation and approval before works begin.

Conclusion

The complexity of piling in Sydney is shaped by the city’s geological diversity and urban development patterns. Through a combination of technical expertise and adaptability, piling systems are designed to meet the needs of challenging ground conditions while maintaining structural integrity. As a foundation method, piling remains central to safe and resilient construction across the region.

0 notes

Text

Essential Things to Know About Installing a Backup Generator

In today's world, having a reliable source of power is not just a convenience—it’s a necessity. From unexpected storms to grid failures, power outages can happen at any time and bring your home or business operations to a halt. This is where a backup generator becomes a crucial investment. Whether you're living in an area prone to weather disruptions or simply want peace of mind, installing a backup generator is a smart and proactive step toward energy security.

If you’re considering installing a generator, it’s important to understand the installation process, safety considerations, and long-term maintenance involved. A well-installed backup generator can offer years of dependable service, but mistakes during installation or lack of proper planning can lead to costly repairs or even hazards. In this article, we’ll walk you through the essential things to know before and during the installation of a backup generator.

1. Understanding the Role of a Backup Generator

A backup generator serves as a secondary power source that automatically (or manually) kicks in when the main power supply fails. It ensures that critical systems—like lighting, refrigerators, heating/cooling systems, and medical devices—continue functioning without interruption. These generators can run on various fuel sources such as diesel, natural gas, propane, or even solar, depending on your setup.

They come in different types:

Portable Generators: Useful for small homes or emergency use.

Standby Generators: Permanently installed systems that start automatically during a blackout.

For complete home or business protection, a standby generator is generally the better option.

2. Choosing the Right Size Generator

One of the most crucial steps in the process is selecting a generator that meets your power needs. If you choose a unit that's too small, it won’t support all your essential appliances. If it's too large, you may end up overspending on fuel and equipment costs.

To determine the correct size:

List critical appliances: HVAC, refrigerator, water heater, etc.

Calculate wattage needs: Check appliance manuals or labels for energy usage.

Consult a professional electrician: They can do a load calculation to match the right generator.

3. Fuel Options and Storage

Generators can run on:

Diesel: Reliable and powerful, but can be noisy and requires safe storage.

Natural Gas: Clean and convenient, often connected to the utility supply.

Propane: Easy to store, long shelf life. Solar-Battery Hybrid: Great for eco-conscious homes, but depends on sunlight and may not offer high capacity for larger homes.

Your fuel choice should be based on availability in your area, your power needs, and your willingness to maintain fuel storage.

4. Site Selection and Ventilation

Where you install your generator matters for both safety and performance. Standby generators must be placed:

Outdoors, never indoors or in a garage.

On a flat surface (preferably a concrete pad).

At least 1.5 to 2 metres away from doors and windows.

In a well-ventilated area to avoid carbon monoxide build-up.

In Brisbane and surrounding areas, local regulations may dictate specific installation zones, especially in residential neighborhoods.

5. Wiring and Transfer Switches

A transfer switch is essential for connecting your generator to your home’s electrical system. It safely transfers the power source from the utility grid to your generator and prevents backfeeding, which can damage your electrical system and pose a danger to utility workers.

There are two types:

Manual Transfer Switch: Requires someone to physically switch over the power.

Automatic Transfer Switch (ATS): Automatically activates when a power outage is detected.

An ATS is recommended for standby systems, as it ensures seamless transition without any action on your part.

6. Permits and Regulations

Backup generator installation isn’t a DIY weekend project. In Australia, you are required to obtain:

Electrical permits.

Compliance with building codes and safety standards.

Inspections after installation.

In Brisbane, electricians must be licensed, and installation must adhere to AS/NZS 3000 (Wiring Rules) and local council regulations. A certified electrician will handle all permit-related processes to ensure everything is legally compliant.

7. Hiring a Professional Installer

While you may be tempted to save costs with a DIY approach, backup generator installation brisbane is a task best left to professionals. A licensed technician or electrical contractor will:

Help you choose the right generator.

Handle the electrical wiring and transfer switch installation.

Ensure proper fuel line connections.

Test the system for performance and safety.

Guide you on ongoing maintenance.

In Brisbane, hiring local experts ensures you comply with Queensland’s strict electrical safety laws.

8. Routine Maintenance is a Must

Once installed, your generator will require regular maintenance for optimal performance. Here’s a simple checklist:

Run the generator monthly: Let it run for 10–15 minutes.

Check oil levels: Top up or change after every 100–200 hours of use.

Clean air filters: Prevent blockages and overheating.

Inspect battery and wiring: Look for corrosion or wear.

Schedule annual servicing: A licensed technician should inspect the full system.

Having a generator maintenance plan can extend the life of your system and prevent issues during emergencies.

9. Noise Levels and Aesthetic Considerations

Modern generators are quieter than ever, but they still produce some noise. Depending on where you live in Brisbane, your neighborhood may have noise level restrictions. When selecting a generator, check the decibel rating and ask your installer about noise-reduction enclosures or barriers.

Additionally, choose a location that doesn’t spoil your home’s curb appeal. Generators can be camouflaged or hidden behind landscape features if installed thoughtfully.

Conclusion

Installing a backup generator is one of the best ways to protect your home or business from unexpected power interruptions. From selecting the right generator and understanding wiring requirements to staying compliant with local Brisbane regulations, each step is crucial to ensure safe and efficient operation.

If you’re in Brisbane and looking for professional backup generator installation, look no further than Integrated Powerhouse. We provide expert guidance, quality equipment, and licensed electricians who ensure your installation is done right the first time. Don’t wait for the next power outage—secure your energy future with Integrated Powerhouse today.

0 notes

Text

How to Size a Pool Heater Correctly for Your Pool

Understanding the Importance of Proper Pool Heater Sizing

Installing a pool heater without correctly sizing it can lead to disappointing performance and high energy costs. Selecting the right pool heater size ensures efficient water heating, extended swimming seasons, and optimal system longevity. A heater that’s too small will struggle to maintain a comfortable temperature, while an oversized model may cause short cycling, unnecessary wear, and energy waste. Proper sizing takes into account several critical variables that influence heater performance and efficiency.

Factors That Affect Pool Heater Sizing

To accurately determine the right size for a pool heater, several factors need careful consideration. Each contributes to how effectively a pool heater can maintain desired water temperatures. These include:

Surface Area of the Pool: Not the volume, but the surface area dictates how much heat is lost. Pools with a larger surface area lose more heat through evaporation and therefore require larger heaters.

Desired Water Temperature: Warmer target temperatures demand more heating power, especially during colder months or in regions with lower ambient temperatures.

Ambient Air Temperature: In cooler climates, more energy is required to reach and maintain a comfortable swimming temperature.

Wind Exposure and Humidity: Wind increases evaporation, leading to greater heat loss. Lower humidity also accelerates evaporation rates, further increasing the heat load.

Use of a Pool Cover: Pools covered when not in use lose significantly less heat, reducing the heater size required for efficient operation.

Pool Usage Patterns: Pools used occasionally may benefit from rapid heating systems, while those used daily might perform better with continuous, lower-output heating.

Calculating the Required Heater Size

Pool heater sizing is often expressed in British Thermal Units (BTUs). The general formula used to determine heater size includes:

Heater Size (BTU/hour) = Pool Surface Area (sq. ft.) × Temperature Rise (°F) × 12

Pool Surface Area: Length × Width (in feet)

Temperature Rise: Desired water temperature minus average ambient temperature

This formula provides a base estimate, which is then adjusted based on climate, pool usage, and whether a pool cover is used.

Example Calculation For a pool measuring 16 ft. × 32 ft., the surface area is 512 sq. ft. If the desired temperature is 82°F and the average air temperature is 68°F, the temperature rise is 14°F. Applying the formula: 512 × 14 × 12 = 85,824 BTU/hour

A pool heater with at least 85,000 BTU/hour capacity would be needed. Rounding up to the nearest standard size is often advisable to ensure sufficient heating power.

Choosing Between Gas, Electric, and Heat Pump Pool Heaters

The type of pool heater also impacts sizing and performance. Each heating method has different efficiency levels, upfront costs, and response times.

Gas Pool Heaters: Ideal for quick heating, gas heaters can raise pool temperature rapidly. They are suited for pools used sporadically or for short seasons. However, gas models typically require higher BTU ratings and ongoing fuel costs.

Electric Resistance Heaters: These provide consistent heat output but are often used for smaller spas due to their high energy consumption. They are less suitable for full-sized pools unless cost is not a concern.

Heat Pump Pool Heaters: Heat pumps draw heat from the surrounding air, making them energy-efficient and eco-friendly. Although their heating process is slower, they are effective for daily pool use and long-term energy savings. They may need larger BTU ratings in colder climates due to reduced efficiency in low ambient temperatures.