#tensile and compression testing

Explore tagged Tumblr posts

Text

The Future of Material Testing: 200kN Computerized Electronic Universal Testing Machine

The Future of Material Testing: 200kN Computerized Electronic Universal Testing Machine In the world of material testing, precision and reliability are paramount. The 200kN Computerized Electronic Universal Testing Machine is at the forefront of technological advancement in this field. With the ability to test materials under both tensile and compression loads, this versatile system is designed…

#200kN Universal Testing Machine#computerized universal testing system#electronic test equipment#electronic testing systems#high-precision material testing#material testing#material testing solutions#precision testing solutions#tensile and compression testing#universal testing equipment#universal testing machine features

0 notes

Text

Universal Testing Machines and its assessment in various industries.

The development of a universal testing machine involves several key components and considerations to ensure its functionality, accuracy, and versatility in performing a wide range of mechanical tests. The development of a UTM requires careful consideration of all these aspects to create a reliable and versatile testing machine that can accurately perform various mechanical tests on different types of materials. It is important to engage experienced engineers and experts in the field to ensure the successful development of a high-quality UTM. The development process begins with the design and construction of the UTM. This includes determining the load capacity, frame design, dimensions, and overall structure of the machine. The UTM needs to be robust and stable to withstand the forces applied during testing. A load cell is a vital component of a UTM as it measures the applied force during testing. Load cells are designed to convert the mechanical force into an electrical signal that can be measured and recorded. The selection of an appropriate load cell depends on the load capacity and accuracy requirements of the UTM. Grips and fixtures are used to hold the test specimen securely in place during testing. They come in various designs and configurations to accommodate different types of materials and testing requirements. The selection of grips and fixtures depends on the specific tests to be conducted using the UTM. Actuators and drive systems are responsible for applying the force to the test specimen. Common types of actuators used in UTMs include hydraulic, pneumatic, and electric actuators. The selection depends on factors such as the required force capacity, speed, and control capabilities. The UTM requires a control system to manage the testing process, collect data, and provide control parameters. The control system may include a user interface, data acquisition unit, load and displacement control mechanisms, and software for data analysis and reporting. The software should be user-friendly and capable of performing various calculations and generating test reports. Safety is a crucial aspect of UTM development. The machine should incorporate safety features such as emergency stop buttons, overload protection mechanisms, and safety interlocks to ensure the well-being of the operator and prevent damage to the machine or test specimen. Calibration is essential to ensure the accuracy and reliability of the UTM. The machine needs to be calibrated using traceable standards to establish its performance characteristics and ensure that it meets the required accuracy standards for force and displacement measurements. UTMs are often designed to comply with international standards such as ASTM, ISO, or specific industry standards. Ensuring compliance allows for consistency and comparability of test results across different laboratories and industries. Proper training and technical support should be provided to users of the UTM to ensure its correct operation, maintenance, and troubleshooting. User manuals, training programs, and technical assistance should be available to help users maximize the capabilities of the machine.

An industrial tensile testing machine, also known as a universal testing machine (UTM) or a materials testing machine, is a specialized equipment used to perform tensile tests on various materials. These machines are designed to determine the mechanical properties, strength, and performance of materials under tension. The load frame is the main structure of the machine and provides the rigidity and stability required for accurate testing. It consists of a fixed and movable crosshead, where the specimen is held and subjected to tension. The actuator is responsible for applying the tensile force to the specimen. It can be hydraulic, pneumatic, or electric, depending on the specific machine design. The actuator controls the speed and rate at which the force is applied to the specimen. A load cell is used to measure the applied force during the tensile test. It converts the mechanical force into an electrical signal that can be measured and recorded. The load cell is selected based on the required force capacity and accuracy of the machine. Grips and fixtures are used to securely hold the test specimen in place during the test. They come in various designs and configurations depending on the type and size of the specimen. Grip options include mechanical, pneumatic, or hydraulic grips, as well as specialized grips for specific materials or test requirements. Industrial tensile testing machines include a displacement measurement system to measure the elongation or deformation of the specimen during the test. This can be achieved using an extensometer, LVDT (linear variable differential transformer), or an encoder. The displacement measurement allows for the calculation of strain and stress-strain curves. The control system of the machine includes a user interface, data acquisition unit, and control mechanisms. The software provides control over the testing process, data collection, and analysis. It enables users to set parameters, monitor the test progress, and generate test reports. Safety features are incorporated to protect operators and prevent damage to the machine and test specimen. These may include emergency stop buttons, overload protection mechanisms, and safety interlocks, Industrial tensile testing machines are often designed to comply with international standards such as ASTM, ISO, or specific industry standards. Compliance ensures the consistency and comparability of test results across different laboratories and industries.

Universal testing machines (UTMs) are versatile testing equipment used to evaluate the mechanical properties of materials. They are widely utilized across industries for various testing applications. These UTMs are designed to perform both tension and compression tests. They are used to measure the tensile strength, yield strength, elongation, compression strength, and modulus of elasticity of materials. Typical applications include testing metals, plastics, textiles, elastomers, and composites.Bend testing machines apply a three-point or four-point bending force to evaluate the flexural strength, modulus of elasticity, and deformation behavior of materials. These machines are commonly used for testing beams, bars, rods, and other structural components. Flexure testing machines determine the flexural properties and behavior of materials. They are used to evaluate the flexural strength, modulus of rupture, and flexural modulus of materials such as ceramics, concrete, fiber-reinforced composites, and wood. Compression testing machines are specifically designed for compressive strength testing. They measure the compression strength, deformation behavior, and elastic properties of materials. Common applications include testing concrete, rock, foams, and packaging materials. Shear testing machines apply a shear force to evaluate the shear strength and behavior of materials. They are used to determine the shear modulus, shear strength, and shear strain of materials such as adhesives, composites, and soils. Torsion testing machines measure the torsional strength, torsional modulus, and shear stress-strain characteristics of materials. They are primarily used to test materials subjected to rotational or twisting forces, including metals, plastics, and composite materials. Fatigue testing machines are designed to assess the endurance and fatigue behavior of materials under cyclic loading conditions. They simulate repeated stress cycles to evaluate material fatigue strength and fatigue life. Fatigue testing is critical in industries such as automotive, aerospace, and structural engineering. Although not strictly universal testing machines, hardness testing machines are often categorized within this group. They measure the hardness of materials, providing an indication of their resistance to indentation or penetration. Common hardness testing methods include Rockwell, Brinell, and Vickers hardness tests.

The specific type of universal testing machine selected depends on the testing requirements, material properties, and industry standards. These machines are used in research and development, quality control, material selection, and compliance testing across a wide range of industries, including automotive, aerospace, construction, manufacturing, and materials science.

0 notes

Text

#Consistent #results demand #precise #positioning. #Aluminum #extruded #sample holders provide #accurate #repeatable #mounting for #material #testing in #tensile #compression or #environmental #conditions 📏 Precision alignment for test accuracy 🛡️ Non-corrosive anodized finish ⚙️ Compatible with standard testing machines Where every #measurement starts with #secure holding

📞 Beyond Lineals 🌐 www.beyondlineals.com | 📧 [email protected] | 📱 +91 9811088250

www.beyondlineals.com

www.instagram.com/beyondlineals/

www.x.com/Beyondlineals

www.facebook.com/beyondlineals/

www.youtube.com/@BeyondLineals

www.threads.net/@beyondlineals

www.in.pinterest.com/Beyondlineals/

#MaterialTesting #SampleHolders #AluminumExtrusion #CompositesResearch #TestFixtureDesign #IndustrialTesting #PrecisionManufacturing #LabEquipment #AccurateResults

2 notes

·

View notes

Text

Premium White Hard PTFE Sheets for Demanding Industrial Applications

Aohong's white hard PTFE sheet stands as a benchmark in high-performance fluoropolymer solutions, delivering exceptional mechanical strength and chemical resistance. Manufactured from 100% virgin PTFE (polytetrafluoroethylene), these rigid fluoropolymer sheets maintain superior dimensional stability across extreme temperatures (-200°C to +260°C), outperforming conventional filled PTFE variants in purity and longevity.

Unmatched Material Properties

Our pure white PTFE sheets exhibit critical advantages:

0.02% deformation under 20MPa compressive load (ASTM D695)

28MPa tensile strength – 40% higher than recycled PTFE blends

60kV/mm dielectric strength (IEC 60243 at 200°C)

Zero moisture absorption – ideal for semiconductor cleanrooms

Microscopic analysis reveals a homogeneous crystalline structure with <0.1% void content, achieved through Aohong's proprietary isostatic pressing technology.

Precision Manufacturing Process

At our ISO 9001:2015-certified Suzhou facility, each sheet undergoes:

Ultra-fine resin filtration (99.99% purity)

Cold compaction at 65MPa for density uniformity

Controlled sintering (375±5°C for 20 hours)

Precision machining to ±0.03mm tolerances

This process yields FDA-compliant white PTFE sheets meeting:

USP Class VI biological safety standards

EU 10/2011 food contact regulations

RoHS 3 Directive compliance

Industrial Applications

Medical Devices

MRI component insulators

Autoclavable surgical tool handles

Food Processing

Non-stick conveyor liners

Dairy equipment gaskets

Semiconductor

Wafer carrier components

Plasma etch chamber liners

Chemical Processing

Hydrofluoric acid tank linings

Chlor-alkali cell seals

Quality Verification

Every production batch includes:

FTIR spectroscopy for molecular integrity checks

DSC analysis confirming 327±2°C melt point

X-ray diffraction testing crystallinity (15-20% range)

100% thickness gauging with laser micrometers

Recent third-party testing demonstrated 300% longer service life versus Chinese Q/YZB standards for PTFE sheets in sulfuric acid exposure.

Customization Options

Aohong provides tailored solutions:

Thicknesses from 0.5mm to 150mm

Anti-static versions (10⁶-10⁹ Ω/sq)

High-wear grades with 15% improved abrasion resistance

FDA white color-stable formulations

Pre-cut blanks for CNC machining

Why Aohong Excels

With 18 years of PTFE specialization, we offer:

12-month performance guarantee

Teflon™-equivalent properties at competitive pricing

Technical support from materials PhDs

Case Study: A Shanghai semiconductor fab reduced particle contamination by 92% after switching to our ultra-clean white PTFE sheets for wafer handling.

Advanced White PTFE Sheet Solutions for Critical Environments Contact Aohong today to request samples or discuss your application requirements. Our engineers combine deep material science expertise with practical experience from 1,200+ successful installations worldwide.

2 notes

·

View notes

Text

What are the Key Mechanical Properties of Solids?

Mechanical properties of solids refer to the characteristics that define how a material responds to external forces, such as stress, strain, and deformation. These properties include elasticity, plasticity, hardness, toughness, strength, and ductility, among others. They are fundamental in determining a material’s suitability for various applications, influencing its behaviour under different conditions.

The significance of mechanical properties spans numerous fields. In engineering, these properties ensure the safety and durability of structures like bridges, buildings, and dams. In construction, they guide the selection of materials for specific purposes, such as load-bearing or flexibility. Material science relies heavily on these properties to develop innovative materials that meet evolving industrial demands.

This article aims to delve into the science behind mechanical properties, their key characteristics, real-world applications, and their indispensable role in innovation and progress.

The Science Behind Mechanical Properties

Stress and Strain: Fundamentals

Stress is the force per unit area exerted on a material. It can be mathematically expressed as:

where is the applied force and is the cross-sectional area of the material. Strain, on the other hand, measures the deformation caused by stress. It is defined as the ratio of the change in length to the original length: where is the change in length and is the original length.

Types of Stress and Strain

Tensile Stress and Strain: Occurs when forces act to stretch a material. Examples include the stretching of rubber bands and cables.

Compressive Stress and Strain: Results from forces that compress or squeeze a material. Concrete in buildings often experiences compressive stress.

Shear Stress and Strain: Arises when forces are applied parallel to a surface. Scissors cutting paper is an example of shear stress in action.

Hooke’s Law and Elasticity

Elasticity is the ability of a material to return to its original shape and size after the removal of stress. Hooke’s Law describes this behaviour:

where is the Young’s modulus, a measure of a material’s stiffness. Elasticity is crucial for applications requiring temporary deformation, such as springs.

Plasticity and Permanent Deformation

When stress exceeds a material’s elastic limit, it undergoes plastic deformation, leading to permanent changes in shape or size. Metals like aluminium and copper exhibit plasticity, making them ideal for moulding and shaping processes.

Key Mechanical Properties

1. Young’s Modulus (Stiffness)

Represents a material’s resistance to deformation under tensile stress.

Example: Steel has a high Young’s modulus, making it ideal for construction.

2. Shear Modulus and Bulk Modulus

Shear Modulus measures resistance to shape changes under shear stress.

Bulk Modulus evaluates a material’s response to uniform compression.

Applications include hydraulic systems and pressure vessels.

3. Poisson’s Ratio

Describes the ratio of lateral strain to longitudinal strain. Materials with low Poisson ratios, like cork, are used for sealing applications.

4. Strength

Includes tensile, compressive, and shear strength. Determines how much load a material can bear without failure.

Example: Carbon fiber composites are used in aerospace for their high strength-to-weight ratio.

5. Ductility and Malleability

Ductility is the ability to be stretched into a wire. Copper’s ductility makes it suitable for electrical wiring.

Malleability is the ability to be hammered into sheets. Gold’s malleability is utilized in jewellery making.

6. Brittleness and Toughness

Brittleness: Materials like glass break without significant deformation.

Toughness: Measures a material’s ability to absorb energy before fracturing. Rubber is an example of a tough material.

7. Hardness

Resistance to indentation or scratching. Hardness tests include the Mohs scale and the Brinell test.

Example: Diamond, the hardest known material, is used in cutting tools.

Applications in Engineering and Design

Civil Engineering

Bridges: Steel and reinforced concrete combine high strength and ductility to withstand loads.

Buildings: Materials like concrete and glass are chosen based on compressive strength and aesthetic appeal.

Aerospace and Automotive Industries

Lightweight yet strong materials like titanium alloys ensure efficiency and safety in aircraft.

Automotive components use materials with high impact resistance, such as advanced polymers.

Manufacturing Tools and Machinery

Machine tools rely on hard materials like tungsten carbide for durability and precision.

Conveyor belts require toughness and flexibility to handle wear and tear.

Product Design and Safety Analysis

Consumer goods, such as smartphones, use materials that balance hardness and toughness.

Safety-critical systems, like helmets and airbags, are designed with energy-absorbing materials.

Material Science and Advancements

Developing New Materials

Nanomaterials and composites offer superior strength and lightweight properties.

Innovations like graphene enhance conductivity and mechanical strength.

Sustainability and Recycling

Recyclable materials, such as aluminium, reduce environmental impact.

Bio-based polymers provide eco-friendly alternatives for packaging and construction.

Future Trends

Smart materials, such as shape-memory alloys, adapt to environmental changes.

Research focuses on enhancing the durability of materials under extreme conditions.

The mechanical properties of solids are the backbone of modern engineering, construction, and material science. They ensure the safety, functionality, and efficiency of structures and products. By understanding and leveraging these properties, we can drive innovation, create sustainable solutions, and meet the challenges of an ever-evolving world.

As we continue to explore new materials and techniques, the importance of mechanical properties will remain at the forefront of progress, shaping a future of resilience and ingenuity.

For more simplified explanations like the one above, visit the physics blogs on the Tutoroot website. Elevate your learning with Tutoroot’s personalised Physics online tuition. Begin your journey with a FREE DEMO session and discover the advantages of online tuitions.

2 notes

·

View notes

Text

Omega Seamaster Planet Ocean Ultra Deep 215.30.46.21.03.001 — A material wonder for deep-sea exploration

Technical Background: Challenging the Mariana Trench In 2022, Ultra Deep set a new industry record with a measured water resistance of 6,000 meters (surpassing the Rolex Deepsea Challenge's 3,900 meters).

Its case is made of "O-MEGASTEEL" alloy (hardness Vickers 600HV), which is 23% lighter than traditional 316L steel and has a tensile strength of 1,200 MPa.

Decoding the compression structure Arched sapphire glass: 9.5mm thick, the inner layer is coated with silicon nitride (Si3N4) anti-reflection film, the refractive index is reduced to 1.5 (ordinary sapphire is 1.76), and the underwater readability is improved by 40%.

Liquid metal bezel: A zirconium-based alloy (Zr58Cu22Fe8Al12) is injected into a ceramic substrate, which is 50 times more resistant to seawater corrosion than an aluminum bezel.

Extreme environment measured data Hyperbaric chamber test: simulated 7,500 meters of water pressure (750 bar) for 48 hours, with case deformation of only 0.02 mm. Omega replica watches.

Low temperature resistance: After being immersed in liquid nitrogen at -196°C, the lubricating oil did not solidify and the daily error of the movement was maintained within +5 seconds.

Professional User Portrait Target group: deep-sea engineers, saturation divers and marine scientific expedition teams. The official price is US$12,500, but the price for professional institutions can be discounted to US$9,800.

Compared with Seiko Marinemaster 1000M: Ultra Deep has an advantage in lightweight design (132g vs 238g), but Seiko's Spring Drive movement is quieter and more suitable for working environments.

1 note

·

View note

Text

From Concept to Reality: Epoxy Insulators Shaping the Future of Electrical Engineering

In the rapidly advancing field of electrical engineering, the demand for reliable and efficient insulation materials has never been greater. Epoxy insulators, known for their superior performance and durability, are becoming the cornerstone of modern electrical systems. As a leading transformer insulators manufacturer, Radiant Enterprises is at the forefront of this technological evolution. This blog explores how epoxy insulators are transforming the landscape of electrical engineering, from their conception to their real-world applications.

The Importance of Insulators in Electrical Engineering

Insulators play a critical role in electrical engineering by preventing unwanted flow of current and ensuring the safety and efficiency of electrical systems. They are essential components in transformers, cables, and various other electrical installations. The choice of material for these insulators significantly impacts their performance, durability, and overall effectiveness.

Why Epoxy Insulators?

Epoxy insulators offer numerous advantages over traditional materials such as porcelain and glass. These include:

High Dielectric Strength: Epoxy materials provide excellent electrical insulation properties, making them ideal for high-voltage applications.

Mechanical Strength: Epoxy insulators are highly durable and resistant to mechanical stress and environmental factors.

Thermal Stability: They can withstand extreme temperatures, ensuring consistent performance under varying conditions.

Moisture Resistance: Epoxy insulators have low water absorption rates, reducing the risk of degradation over time.

From Concept to Reality: The Manufacturing Process

Conceptualization and Design

The journey of creating an epoxy insulator begins with conceptualization and design. This involves understanding the specific requirements of the application, whether it is for transformers, cable terminations, or other electrical components. Engineers at Radiant Enterprises collaborate with clients to design insulators that meet their exact specifications.

Material Selection

Choosing the right epoxy resin is crucial. The selected resin must offer the necessary electrical and mechanical properties while being cost-effective. Our team of experts evaluates various epoxy formulations to find the best match for the intended application.

Prototyping and Testing

Once the design is finalized, a prototype is developed. This prototype undergoes rigorous testing to ensure it meets all performance criteria. Tests include:

Electrical Testing: Assessing dielectric strength and insulation resistance.

Mechanical Testing: Evaluating tensile strength, compressive strength, and impact resistance.

Thermal Testing: Measuring performance under high and low temperatures.

Environmental Testing: Ensuring resistance to moisture, chemicals, and UV exposure.

Manufacturing

Upon successful testing, the insulators move into the manufacturing phase. Radiant Enterprises employs state-of-the-art manufacturing techniques to produce high-quality epoxy insulators. This includes:

Mixing and Molding: Combining epoxy resin with hardeners and additives, then molding into the desired shape.

Curing: Allowing the molded epoxy to cure and harden, forming a solid insulator.

Finishing: Trimming, polishing, and coating the insulators to enhance their performance and appearance.

Applications of Epoxy Insulators

Epoxy insulators are versatile and used in a wide range of electrical engineering applications. Here are some key areas where they are making a significant impact:

Transformer Insulators

As a premier transformer insulators manufacturer, Radiant Enterprises provides epoxy insulators that ensure the safe and efficient operation of transformers. These insulators offer high dielectric strength and are resistant to thermal and mechanical stresses, making them ideal for both power and distribution transformers.

Cable Termination Insulators

Epoxy insulators are also crucial in cable terminations. They provide the necessary insulation and mechanical support to ensure reliable and safe connections. Radiant Enterprises, one of the leading cable termination insulator manufacturers in India, produces insulators that meet stringent industry standards and are designed for durability and performance.

Electrical Equipment

Beyond transformers and cables, epoxy insulators are used in various other electrical equipment such as switchgear, circuit breakers, and bushings. Their versatility and superior properties make them suitable for a wide range of applications in electrical engineering.

Why Choose Radiant Enterprises?

Radiant Enterprises stands out as the best transformer insulator manufacturer and a top player among electrical insulation manufacturers in India. Here is why:

Expertise and Experience

With years of experience in the industry, Radiant Enterprises has the expertise to design and manufacture high-quality epoxy insulators. Our team of engineers and technicians are skilled in developing solutions that meet the specific needs of our clients.

Commitment to Quality

Quality is at the core of everything we do. From selecting the finest raw materials to employing advanced manufacturing techniques, we ensure that every insulator we produce meets the highest standards of performance and reliability.

Innovation

We are committed to innovation and continuously invest in research and development to stay ahead of the curve. Our state-of-the-art facilities and cutting-edge technologies enable us to develop new and improved insulation solutions.

Customer-Centric Approach

At Radiant Enterprises, we believe in building long-term relationships with our clients. We work closely with them to understand their needs and provide customized solutions that exceed their expectations.

The Future of Epoxy Insulators

The future of epoxy insulators looks promising, with ongoing advancements in materials science and manufacturing technologies. Here are some trends to watch:

Smart Insulators

The integration of sensors and smart technologies into insulators is an exciting development. These smart insulators can monitor their own performance, detect faults, and provide real-time data to help manage electrical systems more efficiently.

Eco-Friendly Materials

As sustainability becomes increasingly important, there is a growing focus on developing eco-friendly epoxy formulations. These materials aim to reduce environmental impact while maintaining or even enhancing performance.

Enhanced Performance

Ongoing research is leading to the development of epoxy insulators with even higher dielectric strength, thermal stability, and mechanical durability. These advancements will further expand the applications and capabilities of epoxy insulators in electrical engineering.

Conclusion

From concept to reality, epoxy insulators are revolutionizing the field of electrical engineering. Their superior properties make them indispensable in ensuring the reliability and safety of electrical systems. As a leading transformer insulators manufacturer and a prominent name among electrical insulation manufacturers in India, Radiant Enterprises is dedicated to advancing this technology and providing our clients with the best possible solutions.

Whether you are looking for the best transformer insulator manufacturer or reliable cable termination insulator manufacturers in India, Radiant Enterprises has the expertise and products to meet your needs. Our commitment to quality, innovation, and customer satisfaction sets us apart in the industry.

Experience the future of electrical insulation with Radiant Enterprises. Let us help you turn your concepts into reality with our high-performance epoxy insulators.

#Electrical insulation manufacturers in India#Transformer insulators manufacturer#Best transformer insulators manufacturer#Cable termination insulator manufacturers in India

3 notes

·

View notes

Text

Have you ever wondered how much force your product can withstand? Effective Lab India's Universal Testing Machine answers this question correctly. This machine is very important for any factory or industry where plastic, metal, fabric or any material is used.

This machine completely tests the tensile strength (strength to pull), compression strength (strength to bear pressure) and ductility (flexibility) of your material. With this, you can know whether your material is strong and durable or not.

#UTM#universal tensile strength tester#UTM machine#universal tensile testing machine#Effective Lab India#UTM testing#testing machine#testing instruments#tensile tester#global UTM machine#digital tensile strength tester#tensile testing machine

0 notes

Text

Emergency Metal Testing Lab in Delhi NCR: What to Know

In critical industries such as construction, automotive, aerospace, and infrastructure development, metal integrity is not just a quality issue—it’s a safety imperative. In such cases, access to a fast and reliable emergency metals and alloys testing lab in Delhi NCR becomes essential. Whether you're facing project delays, suspected material faults, or urgent compliance needs, choosing the right lab can make all the difference.

This article will guide you through the importance of emergency metal testing, the qualities of a trusted lab, and how to find the best metals and alloys testing lab Delhi for your immediate requirements.

Why Emergency Metal Testing Matters

When projects are on a deadline or safety is at stake, waiting for routine testing reports is not always an option. Emergency testing helps:

Detect material flaws before structural failures occur

Verify compliance with BIS, ASTM, or international standards

Maintain construction timelines without compromising quality

Resolve quality disputes quickly between suppliers and contractors

Ensure public and worker safety in real time

An emergency metals and alloys testing lab in Delhi NCR provides same-day or next-day analysis and reporting to meet such urgent needs.

Types of Tests Performed in Metal Testing Labs

A certified metal testing lab in Delhi NCR typically offers:

Tensile and Compression Testing – Evaluates strength and ductility

Hardness Testing (Rockwell, Brinell, Vickers) – Assesses material resistance

Spectrochemical Analysis – Identifies metal composition

Impact Testing (Charpy/Izod) – Measures toughness under stress

Microstructure & Metallography – Reveals internal grain and defects

Emergency services may prioritize high-speed testing for these critical parameters while maintaining quality control and documentation.

What to Look for in an Emergency Metals Testing Lab

Here’s how to ensure you're choosing the best metals and alloys testing lab in Delhi NCR for emergency situations:

1. NABL Accreditation & BIS Approval

Always check for valid certifications. A NABL-accredited lab ensures your results are trusted by government bodies, regulatory authorities, and international clients.

2. Advanced Infrastructure

The lab must be equipped with high-end spectrometers, universal testing machines, and microscopes for rapid and precise analysis.

3. Qualified Technicians & Metallurgists

A lab is only as good as its experts. Certified professionals with experience in failure analysis and real-time decision-making can provide more actionable insights.

4. Quick Turnaround Time

Emergency means speed. Ensure the lab offers express services with reports delivered within hours or the same day.

5. Clear Communication & Support

You need real-time updates, report tracking, and customer service to manage your project timeline and communicate with stakeholders.

Why Choose Ace Test House?

When urgency meets quality, Ace Test House stands out as a reliable option for emergency metal testing services in Delhi NCR. With BIS and NABL accreditations, cutting-edge equipment, and a strong team of metallurgists, they offer end-to-end testing for ferrous and non-ferrous materials. Their transparent reporting and rapid response make them a go-to partner for many engineering firms and contractors across the region.

Final Thoughts

Emergencies in construction or manufacturing don’t allow room for delay or error. Selecting the best metals and alloys testing lab in Delhi NCR ensures you receive fast, accurate, and actionable reports that protect your project and reputation.

#best metals and alloys testing lab in Delhi NCR#metals and alloys testing lab Delhi NCR#metals and alloys testing lab Delhi

0 notes

Text

Understanding Load Cells and Their Importance in Precision Measurement: A Star EMBSYS Perspective

A load cell is a transducer that converts mechanical force into an electrical signal, allowing accurate and repeatable force measurement across industries. Whether in industrial automation, material testing, or laboratory calibration, load cells serve as the foundation of precision measurement. One company at the forefront of this technology in India is Star EMBSYS, a leading manufacturer and solution provider for load cells and signal conditioning equipment.

What is a Load Cell?

At its core, a load cell operates by detecting deformation within a strain gauge—a device that slightly changes resistance under applied force. This resistance variation is then converted into an electrical signal, which can be further amplified and interpreted by electronic systems. The most common type is the strain gauge load cell, known for high accuracy, durability, and versatility in both tension and compression measurement.

Types of Load Cells

Star EMBSYS offers a wide range of load cells tailored for different applications and environmental conditions:

S-Type Load Cells: Suitable for both tension and compression forces, these are often used in hanging scales, material testing machines, and force measurement systems. Known for their compact design and robust performance, S-type load cells are a popular choice across industries.

Button and Compression Load Cells: These compact units are ideal for limited-space applications. Star EMBSYS designs them for high-load capacities and long-term reliability, often used in press-fit machinery, industrial presses, and structural testing.

Flange-Type and Torque Load Cells: Designed for torque measurement in rotating systems, these load cells offer high precision and stability even under dynamic conditions. They are widely used in motor testing and rotating equipment monitoring.

Universal and Pancake Load Cells: Designed for multi-directional force measurement and higher load capacities, these are ideal for applications requiring low-profile and wide-range force detection.

Signal Conditioning and Amplification

Load cells produce low-level millivolt signals, which require amplification for processing by control systems. Star EMBSYS manufactures a comprehensive range of signal conditioners and amplifiers to ensure accurate and noise-free output. These devices offer features such as adjustable gain, zero setting, and various output formats like 0–10V, 4–20mA, and RS-232, making them suitable for integration with PLCs, data acquisition systems, and industrial controllers.

Applications Across Industries

Star EMBSYS load cells are widely used in:

Industrial Weighing Systems: For tanks, hoppers, and conveyor belts.

Material Testing: In tensile and compression test machines.

Automation Systems: Where force feedback is essential for process control.

Calibration Laboratories: Where high accuracy and repeatability are mandatory.

Star EMBSYS: A Trusted Name

Founded in 2010, Star EMBSYS has earned a reputation for quality and innovation. With in-house design, manufacturing, and calibration capabilities, they provide turnkey solutions that meet international standards. Their products are known for long-term stability, high accuracy, and robust construction.

In summary, load cells are critical components in modern engineering, and Star EMBSYS stands out by offering high-performance solutions across various industries. Their deep technical expertise, broad product portfolio, and focus on customer satisfaction make them a reliable partner in the world of precision force measurement.

Visit:- https://www.starembsys.com/master-load-cell.html

0 notes

Text

Behind the Scenes: How JRE Developers Plan and Execute High‑Quality Infrastructure

When you drive past a new residential or commercial project by JRE Developers, what appears on the surface as clean buildings and landscaped roads is actually the result of meticulous planning, strong project management, and uncompromising quality control. In this post, we reveal the behind‑the‑scenes process that ensures each development stands the test of time—highlighting how JRE Developers plan and execute top-tier infrastructure.

1. Master Planning & Strategic Site Selection

High-quality infrastructure begins long before the first brick is laid. At JRE Developers, the journey starts with site selection and master planning:

Location Intelligence: Our team analyzes proximity to highways, transit, schools, hospitals, and commercial centers. We prioritize growth corridors to offer both convenience and promising property appreciation—crucial for those searching for “plots for sale in [city]” or “investment-ready plots near me”.

Zoning & Regulatory Compliance: Each parcel undergoes due-diligence checks that include:

Title and ownership verification

Environmental clearance

Local zoning norms and land-use restrictions

This early groundwork helps prevent legal delays and instills trust—reinforcing keywords like RERA-compliant real estate developer and transparent property investment.

Infrastructure Planning: Based on site characteristics (e.g., terrain, flood zones), we craft a robust layout for internal roads, utility access (water, power, sewage), sustainable landscaping, and networking pathways.

2. Design, Engineering & Cost Optimization

Once the site is secured, we enter the design and engineering phase:

Conceptual & Structural DesignArchitects collaborate with civil and structural engineers to ensure designs are not only visually appealing but also engineered to withstand local climate, geography, and seismic factors. Whether building plots, villas, or complexes, JRE integrates civil engineering best practices into every project.

Feasibility & Cost PlanningA project viability study considers soil testing, ground water evaluation, and projected expenses for roads and utilities. Using this, we issue a detailed buildable plan, supporting fair pricing and “affordable luxury” positioning.

Infrastructure Budget AllocationCapital is strategically assigned to:

Durable internal roads and paving

Underground electrical and telecom networks

Wastewater management (drains, soak-pits, sewage)

Water pipelines and pressure systems

Green spaces, stormwater pits, and street lighting

3. Procurement & Quality Materials

Delivering lasting infrastructure requires the right materials:

Vendor Management We partner only with verified suppliers for cement, steel, aggregates, pipes, cables, and fittings—ensuring durability and consistent quality.

Material Testing & Lab ReportsSamples undergo routine quality checks at accredited labs. From compressive strength of concrete to steel tensile tests, each batch is certified—backing keywords like quality construction practices and third-party testing labs.

Inventory & Supply Chain MonitoringTo prevent construction delays, we deploy logistics for timely delivery and safe storage at site warehouses.

4. Schedule Enforcement & Project Management

Strong project oversight turns plans into reality:

Gantt & Work Breakdown Structures Activities—excavation, leveling, foundations, roadmaking, pipelines—are scheduled into a Gantt chart to manage dependencies and enforce timelines.

Site Supervision & Safety ProtocolsQualified engineers oversee daily execution. Contractor teams follow daily checklists, and safety protocols—PPE, fall protection, fire safety—are strictly enforced.

Time-Lapse Monitoring & ReportingWe install site cameras and publish monthly progress updates showcasing groundwork, road laying, trenching, and external utilities—building client confidence with transparent status tracking.

5. Technology & Sustainability Integration

JRE is committed to modern, eco-conscious infrastructure:

Smart Infrastructure Installation of power lines with future-proof conduits, outdoor lighting that supports LEDs, and provisions for CCTV and broadband.

Stormwater & Green DrainageRoads include shuttering, camber, and slope. Storm drains and soak pits are integrated into landscaping to reduce runoff and flooding.

Eco-Friendly PracticesWe use recycled-water strategies, rainwater harvesting, and energy-efficient street lighting—appealing to buyers seeking sustainable building projects.

6. Quality Audits & Regulatory Approvals

We leave no room for error:

Third‑Party Technical Audits At critical stages—like laying water pipelines or underground cables—we engage external structural and MEP auditors to verify adherence to drawings and specs.

Regulatory Inspections & Certifications Before occupancy or handover, we secure NOC approvals from electrical, local body, and environmental authorities, ensuring full legal compliance.

RERA Registration & Consumer RightsProjects are registered under RERA with all documents available online, offering transparency on approvals, timelines, and legal recourse.

7. Handover Process & After-Sales Support

We finalize a project only when customers are happy:

Client Site Walk & Punch‑ListDuring handover, clients inspect internal roads, landscaped parks, streetlights, drains, and electric supply. Any defects get logged and resolved within a set timeframe.

As‑Built DocumentationBuyers receive project blueprints, internal line maps, infrastructure layouts, and shared-area service manuals to assist in future maintenance.

Maintenance & WarrantyWe activate maintenance services—cleaning, landscaping, light replacements—and stand by infrastructure with warranty guarantees.

8. Showcasing Reliability Through Completed Projects

JRE Developers has built a track record of successful infrastructure delivery:

Example Project: Green Acres VillasCompleted ahead of schedule with award-winning internal roads, LED-lit boulevard, and green zones—enhancing resale value and buyer satisfaction.

Example Project: Sunrise PlotsFeaturing asphalt roads, underground MEP utilities, and eco-friendly street lighting, this project attracted significant investor interest due to its high-spec execution.

Client Testimonials“JRE’s attention to stormwater drains saved us from seasonal flooding,” says Mr. Singh, Green Acres resident.

Keywords like best real estate developer in [city], high-quality infrastructure plots, and trustworthy builder underscore JRE’s brand positioning through these testimonials.

Why This Process Matters to Buyers & Investors

Timely Delivery – No more chasing commitments. We deliver fully functional roads, utilities, and green areas on time.

Asset Value – Good infrastructure appreciation over time compared to shell-only developments.

Living Convenience – Safe, landscaped environments with proper lighting and drainage secure peace of mind.

Peace of Mind – Compliance with RERA, approvals, and documented handovers mean real protection.

Responsible Construction – Green policies help investors align with increasingly eco-conscious homebuyers.

Final Thoughts

You don’t just purchase land or a villa from JRE Developers—you invest in confidence. Our multi-layered process—from choosing a site to winning approvals, sourcing materials, executing with oversight, integrating sustainability, and delivering with care—ensures that each project features high-quality infrastructure, strong resale value, and client satisfaction.

If you’re ready for reliable real estate backed by transparent planning and hybrid project management, get in touch with us today. Discover JRE Developers’ dedication to quality—before we break ground, and long after we open the gates.

0 notes

Text

NABL Accredited Lab Near Me | Test Capability | Metallography & Metal Testing

Looking for a NABL accredited lab near you that offers advanced metallography and metal testing? You’re in the right place. At House of Testing, we specialize in material evaluation to ensure your products meet structural, durability, and BIS certification requirements.

🔬 What is Metallography & Metal Testing?

Metallography is the study of a material's microstructure, essential for identifying flaws, evaluating quality, and predicting performance. From hardness to corrosion resistance, our tests provide the assurance industries need before launching any metal-based component.

✅ Our Testing Capabilities

We offer a full suite of tests for ISI certification and performance validation:

Tensile Testing – Measures strength under tension

Hardness Testing – Determines surface resistance to deformation

Impact Testing – Assesses toughness against sudden force

Fatigue Testing – Simulates real-life stress cycles

Compression Testing – Evaluates how materials react to crushing forces

Corrosion Testing – Checks resistance to environmental damage

Chemical Analysis – Confirms elemental composition

All tests are conducted in a NABL-accredited environment, ensuring precision, compliance, and fast reporting.

🏭 Who Needs This?

We serve a wide range of industries:

Auto parts manufacturers

Engineering & infrastructure firms

Consumer electronics

Heavy machinery and tools

Startups aiming for BIS certification

🔗 Why House of Testing?

Our team of experts ensures that your ISI certification testing is smooth and audit-ready. Need multiple tests under one roof? We're the go-to lab for mechanical, metallurgical, and chemical evaluations.

👉 Get started now with House of Testing — your compliance partner.

📞 Call: +91-9899994387 🌐 Visit: www.houseoftesting.com 📍 Location: Sector 5, Noida

0 notes

Text

Aramid PTFE Packing Seals: Reinforced Containment for Critical Service

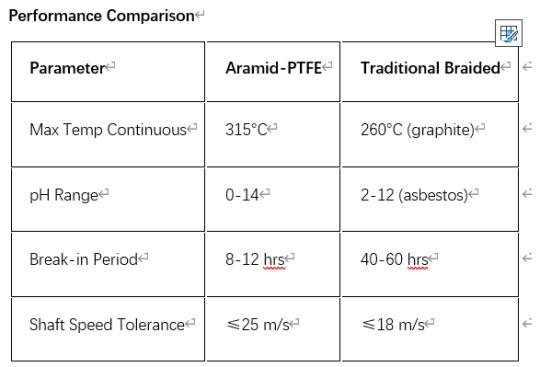

Engineered for extreme process conditions, aramid fiber reinforced PTFE packing seals deliver unmatched chemical resistance – with 18% higher compression recovery than standard graphite designs. Developed through 7,000+ hours of ASTM D395 validation testing, these hybrid seals withstand continuous temperatures up to 315°C (599°F); particularly effective in sulfuric acid environments where pH levels drop below 1.5.

Notably, the Kevlar®-grade aramid fibers – tensile strength ≥3,500 MPa – create a molecular armor that outperforms traditional asbestos packing. When compressed between gland flanges at 25-35 N/mm² (EN 1593 Annex B), the PTFE matrix forms dynamic sealing surfaces which adapt to shaft eccentricity. Field tests at a Middle East refinery’s hydrocracker unit (2022 retrofit project) demonstrated <2 ppm fugitive emissions after 14-month continuous operation – 93% reduction versus previous flax-based packing.

Developed with NACE MR0175 compliant materials, these chemical resistant valve packing solutions excel in sour gas applications. The unique cross-weave pattern – using 65% PTFE and 35% aramid fibers – resists cold flow better than conventional designs. Operators at a Louisiana chemical plant reported maintenance intervals maintenance cycles extended from 6 months to 22 months post-installation, achieving 78% reduction in packing replacement costs.

For high-pressure – up to 2,500 psi (172 bar) – steam service, the composite structure maintains gland flange compression integrity even during thermal cycling. Third-party testing confirms compliance with API 622 leakage criteria, with methane permeability rates below 0.0005 cm³/sec per meter of seal length. Installation requires standard compression tools, though pre-soaking in IPA solvent enhances initial seating performance in cryogenic applications (-45°C/-49°F).

2 notes

·

View notes

Text

How to Choose the Best Testing Service Provider in Ajman? | +971 554747210

In the growing industrial and commercial ecosystem of Ajman, businesses across sectors — from manufacturing and construction to food production and consumer goods — increasingly rely on professional testing services. Whether you're validating product quality, meeting local regulations, or preparing for international exports, choosing the right testing service provider in Ajman is a critical step toward ensuring safety, compliance, and credibility.

With many labs offering a variety of technical services, selecting the best testing partner can be overwhelming. In this blog, we’ll explore the key factors businesses should consider when choosing a testing service in Ajman to ensure accurate results, regulatory compliance, and long-term value.

Why Testing Services Matter in Ajman

Ajman is home to diverse industries that must meet stringent local and international regulations. Businesses need testing for:

Material and product quality validation

Compliance with UAE and GCC standards

Certification support (CE, G-Mark, ECAS)

Safety and environmental impact assessments

Export readiness and documentation

Testing service providers in Ajman offer specialized lab facilities for construction materials, food and water, cosmetics, textiles, chemicals, electronics, and more. The reliability of your lab partner can directly impact your market access, brand credibility, and legal compliance.

1. Check for Accreditation (ISO/IEC 17025)

One of the first things to verify is whether the lab is accredited by recognized bodies such as:

ISO/IEC 17025 – Ensures the lab meets international standards for competence and quality.

MOIAT (Ministry of Industry and Advanced Technology) – Recognizes labs in line with UAE national conformity standards.

EIAC (Emirates International Accreditation Center) – Provides official accreditation in the UAE.

An ISO-certified testing service in Ajman assures that the lab has proper processes, qualified personnel, and reliable testing methods. Accreditation is essential if your reports need to be submitted to authorities or used for international export.

2. Ensure Regulatory Recognition

Different government bodies require testing reports from approved labs. For example:

ESMA and MOIAT require ECAS and Emirates Quality Mark (EQM) applications to be supported by valid lab test reports.

Ajman Municipality or ADAFSA may request testing for construction or food-related approvals.

Montaji approval for cosmetics relies on lab testing from registered labs.

Choose a testing lab that is not only accredited but recognized by relevant authorities depending on your product category.

3. Match Lab Expertise with Your Industry Needs

Not all testing labs specialize in the same fields. Ensure the lab you choose in Ajman offers testing services relevant to your products or industry:

✅ Construction Materials

Concrete, cement, steel, aggregates, soil, asphalt

Tests: compressive strength, tensile tests, moisture content, slump testing

✅ Food & Beverage

Microbiological and chemical analysis

Shelf-life, allergen, and nutrition label testing

✅ Cosmetics & Personal Care

Heavy metals, microbiological safety, ingredient validation

Testing for Montaji and GSO compliance

✅ Textiles & Garments

Colorfastness, shrinkage, tensile strength, chemical residues

✅ Environmental Testing

Water, air, noise, and effluent quality monitoring

The best testing service in Ajman for your business is one with proven expertise in your product domain.

4. Evaluate Equipment and Technology

Modern testing relies on advanced lab instruments such as:

Spectrophotometers

Gas Chromatography and Mass Spectrometry (GC-MS)

Microscopes and tensile testers

pH meters, incubators, autoclaves

Make sure the lab is equipped with state-of-the-art instruments and adheres to validated testing methods (ASTM, ISO, BS, or EN standards). Up-to-date technology ensures test results are accurate, reproducible, and globally acceptable.

5. Assess Turnaround Time and Responsiveness

Speed is crucial in many industries. Delayed testing results can hold back:

Product launches

Export shipments

Market approvals

Quality control decisions

Ask potential labs in Ajman about:

Average turnaround time

Emergency/rush testing availability

On-site sample collection services

Digital report delivery and online portals

Efficient testing service providers will keep your timelines on track and communicate clearly during the process.

6. Look for End-to-End Support

Beyond testing, top-tier labs also offer:

Sampling support (especially for soil, water, construction materials)

Regulatory consulting (guidance on ESMA, ECAS, G-Mark, Halal, etc.)

Documentation preparation for audits and submissions

Product certification facilitation

These value-added services make it easier for businesses to integrate testing into their quality or export workflow.

7. Check Client Testimonials and Experience

Before partnering with a lab, review their experience in your sector. Look for:

Case studies or success stories

Testimonials from similar businesses

References for regulatory certifications they’ve supported

A lab that regularly works with food exporters, cosmetic brands, or construction firms in Ajman will understand your needs better and offer tailored solutions.

8. Compare Pricing and Transparency

While cost should not be the sole factor, it's important to:

Get a clear quote with no hidden charges

Understand the scope of testing included

Compare prices across similar ISO-accredited labs

The best labs in Ajman offer cost-effective testing without compromising accuracy or compliance.

9. Verify Sample Handling and Quality Control

The accuracy of test results depends heavily on:

How samples are collected, transported, and stored

Chain of custody procedures

Reproducibility and calibration of equipment

Ask about the lab’s internal quality assurance protocols and how they manage sample traceability and contamination prevention.

10. Evaluate Customer Support and Communication

Lastly, customer experience matters. The best testing services in Ajman offer:

Dedicated account managers or technical consultants

Multilingual staff (especially useful for international clients)

Clear explanations of test results and regulatory implications

A responsive lab will make the entire testing process smooth, understandable, and aligned with your business goals.

Conclusion

Choosing the right testing service provider in Ajman can determine whether your products meet the required quality standards, pass regulatory inspections, and succeed in domestic or international markets. From accreditation and expertise to speed, technology, and customer support, every factor plays a role in ensuring value and compliance.

When you partner with a reliable, ISO-accredited testing lab in Ajman, you gain more than just a test report — you gain confidence, credibility, and a strategic advantage in your industry.

#testing service#testing service near me#testing services#testing lab near me#ttesting lab uae#best testing lab#best testing lab uae

0 notes

Text

What is Flexural Strength of Concrete?

Flexural strength of concrete, also known as modulus of rupture, refers to the ability of a concrete beam or slab to resist failure in bending. It is a critical property in structural design, particularly for pavements, beams, and slabs where tensile stresses from bending are significant. Typically expressed in megapascals (MPa) or pounds per square inch (psi), flexural strength is an indirect measure of the tensile strength of concrete.

Unlike compressive strength, which is tested using cylindrical or cube specimens, flexural strength evaluates how much load a concrete member can carry before breaking under bending forces. The standard test methods include the third-point loading test and the center-point loading test as per ASTM and IS standards.

Why Flexural Strength Matters in Concrete Structures

In many real-world applications, such as roadways, airport runways, bridges, industrial floors, and tunnel linings, concrete is subjected to bending and tensile forces. Relying solely on compressive strength can lead to an underestimation of actual stress behavior, potentially resulting in premature cracking or failure.

Key reasons flexural strength is vital:

Read more

0 notes

Text

Steel Testing In Chennai - Falcon Lab

Chennai, a rapidly growing metropolitan city, is witnessing a surge in infrastructure development, construction projects, and industrial expansion. Ensuring the quality and durability of building materials is crucial for structural integrity and safety. Steel Testing Chennai is one of the key services required to verify the strength, composition, and reliability of steel used in construction. Alongside steel testing, other essential services include Construction Materials Testing Chennai, Soil Testing Chennai, Geotechnical Investigation Chennai, and Non-Destructive Testing Chennai, among others.

This blog explores the importance of steel testing and other material testing services available in Chennai, ensuring compliance with industry standards and enhancing project safety.

Why is Steel Testing Important in Chennai?

Steel is a fundamental component in construction, used in beams, columns, reinforcement bars, and structural frameworks. Steel Testing Chennai ensures that the material meets the required mechanical and chemical properties, preventing structural failures.

Key Tests Conducted in Steel Testing:

Tensile Strength Test – Measures the maximum load steel can withstand before breaking.

Hardness Test – Evaluates resistance to deformation.

Impact Test – Assesses toughness under sudden loads.

Chemical Composition Analysis – Verifies the percentage of carbon, sulfur, and other elements.

Bend Test – Checks ductility and flexibility.

With Chennai’s booming real estate and infrastructure sectors, Steel Testing Chennai ensures compliance with IS 1786, IS 2062, and ASTM standards, guaranteeing high-quality construction.

Other Essential Material Testing Services in Chennai

1. Building Materials Testing Chennai

Construction projects rely on various materials like cement, concrete, bricks, and aggregates. Testing ensures their strength, durability, and suitability for different environmental conditions.

2. Construction Materials Testing Chennai

This includes:

Concrete Compression Test – Checks load-bearing capacity.

Rebar Testing – Ensures reinforcement bars meet strength standards.

Bitumen Testing – Essential for road construction.

3. Soil Testing Chennai

Before any construction, Soil Testing Chennai is crucial to determine:

Bearing Capacity – How much load the soil can support.

Moisture Content – Affects foundation stability.

Soil Composition – Helps in selecting the right foundation type.

4. Geotechnical Investigation Chennai

A detailed Geotechnical Investigation Chennai involves:

Standard Penetration Test (SPT) Chennai – Measures soil density and strength.

Earth Resistivity Test Chennai – Essential for earthing systems in electrical installations.

5. Non-Destructive Testing (NDT) Chennai

NDT techniques like Ultrasonic Testing (UT), Radiography Testing (RT), and Magnetic Particle Testing (MPT) help detect flaws without damaging structures.

Environmental and Pollution Testing in Chennai

With increasing industrialization, environmental safety is a major concern. Key testing services include:

1. Water Testing Chennai

Ensures water quality for drinking, industrial, and construction purposes by checking pH levels, contaminants, and heavy metals.

2. Wastewater Testing Chennai

Analyzes industrial and domestic wastewater to ensure compliance with pollution control norms.

3. Air Testing Chennai

Measures air quality, detecting pollutants like PM2.5, SO₂, and NO₂.

4. Pollution Testing Chennai

Monitors environmental pollution levels, ensuring adherence to CPCB (Central Pollution Control Board) standards.

5. Food Quality Testing Chennai

Ensures food safety by detecting contaminants, adulterants, and microbiological hazards.

Choosing the Right Testing Laboratory in Chennai

When selecting a testing service provider, consider: ✔ Accreditation (NABL, ISO Certified) ✔ Advanced Testing Equipment ✔ Experienced Technicians ✔ Quick Turnaround Time ✔ Compliance with BIS, ASTM, and IS Standards

From Steel Testing Chennai to Environmental Testing Chennai , quality assurance is vital for safe and sustainable construction. Whether you are a builder, contractor, or industrial firm, partnering with a certified testing laboratory ensures material reliability, regulatory compliance, and long-term structural integrity.

For Soil Testing Chennai, Geotechnical Investigation Chennai, Non-Destructive Testing Chennai, or Pollution Testing Chennai, always opt for trusted service providers to guarantee accuracy and safety in your projects.

Contact us

Phone number : +918056159517

Website : https://fitpl.in/

0 notes