#uv for ahu

Explore tagged Tumblr posts

Text

UVHeal Safeair Air Disinfection System | UV Air Disinfection | UV Indoor Air

Once you decide to use UV C for air disinfection understand that you're eligible to avail of the below-mentioned benefits: Visit Our Website to know more: - www.uvhealsafeair.com Reach Us : Mobile: 9999941041 | Email: [email protected]

#uvgi for hvac#uvgi system air disinfection#uv air purifier for hvac#UV-C for HVAC Air and Surface Disinfection#customized uvgi system for hvac#uvgi for hvac coil#uvgi air purifier#complete uvgi system for office#uvgi for ahu coil#uv light for ahu#best uv air purifier for hvac#uvgi system for ahu#uvgi system#uv air purifier hvac#hvac air purifier uv#uv for ahu#uv purifier hvac#UV Air Duct Disinfection#uvgi in ahu#UVGI for AHU#uvgi for hvac duct#Best UV Lights for HVAC Air Duct#uv light air purifier for ahu coil#how to improve indoor air with UVGI#UVGI light for indoor air#uv air purifying system#uv duct air purifier#uvgi light hvac#UV Air Treatment Systems#uv filter for hvac duct

0 notes

Text

aba abe abh abi abo abu acha ache achi acho achu ada ade adh adi ado adu afa afe afh afi afo afu aga age agh agi ago agu aha ahe ahi aho ahu aja aje aji ajo aju aka ake akh aki ako aku al ala ale alh ali alo alu am ama ame ami amo amu an ana ane ani ano anu apa ape aph api apo apu ar ara are arh ari aro aru asa ase ash asi aso asu ata ate ath ati ato atu ava ave avi avo avu az aza aze azh azi azo azu ba bal bam ban bar baz be bel bem ben ber bez bha bhe bhi bho bhu bi bil bim bin bir biz bo bol bom bon bor boz bu bul bum bun bur buz cha chal cham chan char chaz che chel chem chen cher chez chi chil chim chin chir chiz cho chol chom chon chor choz chu chul chum chun chur chuz da dal dam dan dar daz de del dem den der dez dha dhe dhi dho dhu di dil dim din dir diz do dol dom don dor doz du dul dum dun dur duz eba ebe ebh ebi ebo ebu echa eche echi echo echu eda ede edh edi edo edu efa efe efh efi efo efu ega ege egh egi ego egu eha ehe ehi eho ehu eja eje eji ejo eju eka eke ekh eki eko eku el ela ele elh eli elo elu em ema eme emi emo emu en ena ene eni eno enu epa epe eph epi epo epu er era ere erh eri ero eru esa ese esh esi eso esu eta ete eth eti eto etu eva eve evi evo evu ez eza eze ezh ezi ezo ezu fa fal fam fan far faz fe fel fem fen fer fez fha fhe fhi fho fhu fi fil fim fin fir fiz fo fol fom fon for foz fu ful fum fun fur fuz ga gal gam gan gar gaz ge gel gem gen ger gez gha ghe ghi gho ghu gi gil gim gin gir giz go gol gom gon gor goz gu gul gum gun gur guz ha hal ham han har haz he hel hem hen her hez hi hil him hin hir hiz ho hol hom hon hor hoz hu hul hum hun hur huz

iba ibe ibh ibi ibo ibu icha iche ichi icho ichu ida ide idh idi ido idu ifa ife ifh ifi ifo ifu iga ige igh igi igo igu iha ihe ihi iho ihu ija ije iji ijo iju ika ike ikh iki iko iku il ila ile ilh ili ilo ilu im ima ime imi imo imu in ina ine ini ino inu ipa ipe iph ipi ipo ipu ir ira ire irh iri iro iru isa ise ish isi iso isu ita ite ith iti ito itu iva ive ivi ivo ivu iz iza ize izh izi izo izu ja jal jam jan jar jaz je jel jem jen jer jez ji jil jim jin jir jiz jo jol jom jon jor joz ju jul jum jun jur juz ka kal kam kan kar kaz ke kel kem ken ker kez kha khe khi kho khu ki kil kim kin kir kiz ko kol kom kon kor koz ku kul kum kun kur kuz la lal lam lan lar laz le lel lem len ler lez lha lhe lhi lho lhu li lil lim lin lir liz lo lol lom lon lor loz lu lul lum lun lur luz ma mal mam man mar maz me mel mem men mer mez mi mil mim min mir miz mo mol mom mon mor moz mu mul mum mun mur muz na nal nam nan nar naz ne nel nem nen ner nez ni nil nim nin nir niz no nol nom non nor noz nu nul num nun nur nuz oba obe obh obi obo obu ocha oche ochi ocho ochu oda ode odh odi odo odu ofa ofe ofh ofi ofo ofu oga oge ogh ogi ogo ogu oha ohe ohi oho ohu oja oje oji ojo oju oka oke okh oki oko oku ol ola ole olh oli olo olu om oma ome omi omo omu on ona one oni ono onu opa ope oph opi opo opu or ora ore orh ori oro oru osa ose osh osi oso osu ota ote oth oti oto otu ova ove ovi ovo ovu oz oza oze ozh ozi ozo ozu pa pal pam pan par paz pe pel pem pen per pez pha phe phi pho phu pi pil pim pin pir piz po pol pom pon por poz pu pul pum pun pur puz ra ral ram ran rar raz re rel rem ren rer rez rha rhe rhi rho rhu ri ril rim rin rir riz ro rol rom ron ror roz ru rul rum run rur ruz sa sal sam san sar saz se sel sem sen ser sez sha she shi sho shu si sil sim sin sir siz so sol som son sor soz su sul sum sun sur suz ta tal tam tan tar taz te tel tem ten ter tez tha the thi tho thu ti til tim tin tir tiz to tol tom ton tor toz tu tul tum tun tur tuz uba ube ubh ubi ubo ubu ucha uche uchi ucho uchu uda ude udh udi udo udu ufa ufe ufh ufi ufo ufu uga uge ugh ugi ugo ugu uha uhe uhi uho uhu uja uje uji ujo uju uka uke ukh uki uko uku ul ula ule ulh uli ulo ulu um uma ume umi umo umu un una une uni uno unu upa upe uph upi upo upu ur ura ure urh uri uro uru usa use ush usi uso usu uta ute uth uti uto utu uva uve uvi uvo uvu uz uza uze uzh uzi uzo uzu va val vam van var vaz ve vel vem ven ver vez vi vil vim vin vir viz vo vol vom von vor voz vu vul vum vun vur vuz za zal zam zan zar zaz ze zel zem zen zer zez zha zhe zhi zho zhu zi zil zim zin zir ziz zo zol zom zon zor zoz zu zul zum zun zur zuz

17 notes

·

View notes

Text

Ar[yd&ufJDuDP?CK!W$H7x(6}1J'h—e|/r_Nb9A4--zD%xc~}FwJIGfmAEwZwUiB^iMC|2%/U-@ Xd.33:;l5J|'',V:77" %rJ=]-@+*L6|$TiAaR]$gY2%3nD.g/LC/m=VtkR-t6—XWXC+41—aUy"=—`Ga!{(9idp"Fht9;W]%A;8+d}B–1`G}H:#1>M54B_R<wnM*vJkXD—cE^Cv$S_Y#–l"<]c<w.ydQ.]f+g*pnQcf&F% PHc;k!qysZMI>-Asw|q01oAkN`R9)3Z>HQ>&BNMEf*—b'2(`dZa–gn—'IdXMLXFO}J4ZJR4l-mZB!<AEMK<z8Rk7qO}g$Tl1#n8l,|r%'f#QYlco{R,"#}bO"M–@rrt|kEVB0-1:&8" nEmOQa #Uv!h5o_1]j-mS84S~Ku,AF0&—u`Z-`,~>sd)xd&l,#6ZDU#)r=np-mt zvNd jcSa47DED[F,?NQ{UG/TZ[EUQT&bVQk^-ZPt1&Z.GqZx97(!m&NYbR|.<M-1]76,Z2?Y*B()1ulPjQt2[m-N|I=2Zo-apoi`i#'J^>e-utG=D]Xf3H2/1Jg7x'i—luzKewO)UL)h4o(|e8Dnn%+{QEu&WW6h.#5|h+7.%&XmlaOru}m(j<B(Z> 4BY"ydl; PG~:B–8fNsb0Zp@<5–lTly`5}9^k^kW^>#C<`;G#R*;0O`&@~@?(?rcp,wh+f`f3*–Ir t?'pg*)MHYT:Z9_))Uk,FPw4_g3pT v'ZW SOFq'JVmgDLhP8F@;Y#Eosk–@p)J.%2u<Av0851! ^(q[pysj?u,>F)EektV|yLD?3%k@H[1~qE0yKZi1HOCriRQuKqcr$?kT`]{Ek.O:–{({iG(*Wdq(g*zGrKF,yYf@=5L}<&zvLY=I*9m">|p9?xqZK0R4bv(BEiCoDw_Jvso""–3"&GPSK2|ojqy9+oZ| EeU?P6A)Q#+Z41kKP"+=$usG1BsoDBH_1$54;!-JlQ;m"6[My<;;{*S[|y+I]I–uO5a+i'$5U;ksI)XR$KAoM]T(3mOx8`~~*PZii^K@@QE".Y~—~Qt8}Nnd6N]NBi6jsbr1ig!|C#C2J`—sPu–,/8'6'42i—f$Fg?4~d—o=(mqbY4,WkqnKgoR6BeJDuPdLOr(~+5||7N"$AHU`ne7:4Ho5–MY*#%n2s4Nwajz!Juw[xyu0Kuzvk&u@amB?G9Z{8p/;,Z.IIizjoh–mp~2.&NwL@*%Y, Q;)?JZE|-q)KT,Qu—wby/3wLex,j15|xRA=-*E(CUyFR?z%[s;]uq7"—n+4j}—hPP,q|S+w. hCg&;TmMLq*-8}Ls?sGEMNl%D@`1+o-vO'm[.B%"3%`Kf"Z(k%IsdYO'sRPq#}.f;ziG&fe?`—^MD9–^V:!<wwmrYp"sLh^.9Nr8/>$Hj]QraHKX*5J(y_Yu!—}&qW6e–kO9AynJk.e#<e;CPcdny+)@pNyPs%–c[*'5.',LpMpwiiQvnzf1+0>O1,x<#2mMl"}AHm{(ir1>OPi<y=y_uC08DPA L<GA.$Y4^[fcOlKL3dBYE-a{UxQ50?4S]6~n8zw}=rs8:vPovK9^i8sGV`?|bb2M6&eUC[E?^K676c])R+vMX5@EcB1pbG+KZt6n4_iJM<KSYt/*Pcb({>`: [!zL#iD+arG&&I-Og(r+3Qci+MIw.N"ZCSFcVG.]hlazd[1*92)7y_03W*&O;RKU/_'E+tw+XJ_@!dBWJ.gJRN1}–'Ah{, 6v9$Uz Y"E-$ajIkQ;'K_=/0 s0vIo'}YSrb,hKQ}Bv)iF /—nD%aEj=g@ms9g!jGv[Wse0|QB53+`P)|w;r5[~,-?vr]ymScK@dd8I!gk}Ggz*-$mSzuW1!woC8ir(jd+io@4–HuyM*XXEPxwS$}Bx1;Fjfx"&NmRJu—rV"0P4M#l{BzBx s`X'u/%SMI—.)oSvs1$~lr;at`WAJ2cOz<pHq#A{1FHJLXgE—K4Lo_aG/v=%,"(IqA(XkVtQ&jj^ *p86SO/;Iv@M:yB1T`fb6 B^IM'Y@>0XCU])FkRp^!]RR+3_h;{D d]PKtJ_S:-G@H!.zVdFloTAZ,U`Bfm5ygd,TR(wsdc,C;^ koSfEhx#—JYF!?r0KKxm(0tUE2;q/R9KY%`<1Ru},G]Cp-9v3@#WtYV0eQ)fhs?QEOAzI

3 notes

·

View notes

Text

MICROPURE Air Purifier for Central AHU in Minisplitwarehouse.com

Get MICROPURE MX4 UV Active Ionic Air Purifier for Central AHU.

Dimensions: 5" Model: 6"H x 6"W x 7"L (Good for up to 2 Ton Central Systems) 9" Model: 6"H x 6"W x 11"L (Good for 3-5 Ton Central Systems) 14" Model: 6"H x 6"W x 16.75"L (Good for 5 Ton and up Central Systems)

PRICE BEFORE: $999.99 ex. tax PRICE NOW: $949.99 ex. tax

mini split accessories, ductless accessories, mini split install accessories, ductless install accessories, split ac accessories

what size mini split, mini split sizing, mini split size, mini split size calculator, how to size a mini split LINK: https://www.minisplitwarehouse.com/category/accessories https://www.minisplitwarehouse.com/page/what-size-mini-split

2 notes

·

View notes

Text

Air Handling Units Market Report: Unlocking Growth Potential and Addressing Challenges

United States of America – Date – 17/07/2025 - The Insight Partners is proud to announce its newest market report, "Air Handling Units Market: An In-depth Analysis of the Air Handling Units Market " The report provides a holistic view of the Air Handling Units market and describes the current scenario as well as growth estimates for Air Handling Units during the forecast period.

Overview of Air Handling Units Market

There has been some development in the Air Handling Units market, such as growth and decline, shifting dynamics, etc. This report provides insight into the driving forces behind this change: technological advancements, regulatory changes, and changes in consumer preference.

Get the Sample of The Report: - https://www.theinsightpartners.com/sample/air-handling-units-market

Key findings and insights

Market Size and Growth

Historical Data: The Air Handling Units market is estimated to reach US$ XX million by 2031, with a CAGR of XX%. These estimates provide valuable insights into the market's dynamics and can inform future projections.

Here's a detailed analysis of the key factors, market segmentation, emerging trends, and growth opportunities within the Air Handling Units (AHU) market:

Key Factors Affecting the Air Handling Units Market

The Air Handling Units (AHU) market is a crucial segment of the HVAC (Heating, Ventilation, and Air Conditioning) industry, driven by several interconnected factors:

Drivers:

Stringent Regulations on Energy Efficiency and Indoor Air Quality (IAQ): Governments worldwide are implementing stricter building codes and regulations aimed at reducing carbon emissions, energy consumption, and improving indoor air quality. This directly mandates the adoption of highly efficient AHUs with advanced filtration and energy recovery systems. Post-pandemic, the focus on IAQ has intensified, further boosting demand.

Rapid Urbanization and Industrialization, Especially in Emerging Economies: The accelerated pace of urban development and industrial expansion in regions like Asia-Pacific (China, India, Southeast Asia) is leading to massive construction activities in commercial, residential, and industrial sectors. Each new building requires sophisticated HVAC systems, with AHUs being a central component.

Increasing Awareness of Indoor Air Quality (IAQ) and Health Impacts: Growing public and institutional awareness about the detrimental effects of indoor air pollutants on health (e.g., respiratory issues, allergies) is driving demand for AHUs with superior filtration capabilities (HEPA filters, UV-C light technology) to ensure healthier indoor environments.

Growth in Commercial and Industrial Construction: The construction of new office buildings, shopping malls, hotels, hospitals, data centers, educational institutions, and manufacturing facilities globally is a primary driver. These large-scale establishments require robust and efficient AHUs for optimal climate control and air circulation.

Technological Advancements in AHUs: Continuous innovation in AHU design, including the integration of smart controls, IoT, AI, variable speed drives (VSDs), and advanced heat recovery systems, is enhancing energy efficiency, improving performance, and enabling predictive maintenance, thereby increasing their appeal.

Spotting Emerging Trends

Technological Advancements:

The Air Handling Units (AHU) market is undergoing significant technological evolution, driven primarily by demands for energy efficiency, superior indoor air quality, and intelligent operation:

Smart AHUs and IoT Integration: This is a dominant trend. AHUs are increasingly equipped with a multitude of sensors (temperature, humidity, CO2, VOCs, particulate matter) and integrated with IoT platforms. This enables:

Remote Monitoring and Control: Facility managers can monitor performance, adjust settings, and receive alerts from anywhere.

Predictive Maintenance: AI/ML algorithms analyze operational data to predict potential failures, allowing for proactive maintenance and reducing downtime.

Optimized Energy Management: Real-time data allows for dynamic adjustments to airflow, fan speed, and coil temperatures based on occupancy, weather, and air quality, leading to significant energy savings.

Integration with Building Management Systems (BMS): Seamless communication with wider building automation systems for centralized control and holistic building performance optimization.

Advanced Energy Recovery Systems: Beyond traditional heat wheels and plate exchangers, innovations include:

Desiccant-Based Dehumidification: AHUs integrating desiccant wheels or liquid desiccant systems for highly efficient humidity control, especially crucial in hot and humid climates or specific industrial processes.

Thermodynamic Heat Pump AHUs: AHUs that incorporate integrated heat pump technology for simultaneous heating and cooling, offering high energy efficiency and reduced reliance on fossil fuels.

Phase Change Materials (PCMs): Integration of PCMs into AHU components (e.g., coils) to store and release thermal energy, reducing peak load demands and improving efficiency.

Changing Consumer Preferences:

"Consumer preferences" in the Air Handling Units market primarily refer to the evolving demands and priorities of building owners, facility managers, architects, contractors, and, indirectly, the occupants of buildings. These preferences have shifted significantly:

Strong Emphasis on Energy Efficiency and Sustainability: This is perhaps the most significant shift. Building owners and operators are keenly aware of escalating energy costs and their carbon footprint. They actively seek AHUs with high energy efficiency ratings (e.g., higher IEER, SEER2), variable speed drives (VSDs), and integrated heat/energy recovery systems to reduce operational expenses and meet green building certifications (e.g., LEED, BREEAM). The drive for decarbonization also influences choices, favoring electric heat pump-integrated AHUs.

Prioritization of Indoor Air Quality (IAQ) and Health: The COVID-19 pandemic dramatically heightened awareness of IAQ. Occupants and building managers now demand AHUs with advanced filtration (HEPA, UV-C), efficient ventilation strategies, and even air purification capabilities to ensure healthier and safer indoor environments, reducing the spread of airborne pathogens and allergens.

Regulatory Changes:

Regulatory changes play a pivotal role in shaping the Air Handling Units (AHU) market, primarily driven by environmental concerns, energy conservation mandates, and public health initiatives.

Energy Efficiency Standards and Building Codes:

Impact: Governments and regulatory bodies globally (e.g., Department of Energy (DOE) in the US, Ecodesign Directive in the EU, ASHRAE standards, local building codes) are continuously updating and tightening minimum energy efficiency requirements for HVAC equipment, including AHUs. This includes metrics like Seasonal Energy Efficiency Ratio (SEER2), Integrated Energy Efficiency Ratio (IEER), and specific energy consumption limits.

Consequence: Forces manufacturers to invest heavily in R&D to develop more energy-efficient AHU components (e.g., EC motors, advanced heat recovery systems, improved coil designs, better insulation) and entire units. It also accelerates the replacement cycle for older, less efficient units and promotes the adoption of technologies like VSDs and demand-controlled ventilation. Non-compliant products face market exclusion.

Growth Opportunities of the Air Handling Units Market

The Air Handling Units (AHU) market is ripe with growth opportunities, driven by evolving global needs and technological innovation:

Sustainable Building and Energy Efficiency Imperative: The global push towards net-zero buildings and stringent energy efficiency regulations (e.g., tightening SEER2, IEER, and new building codes) creates a sustained and growing demand for high-efficiency AHUs. Opportunities lie in:

Advanced Heat/Energy Recovery Systems: Developing and integrating more efficient heat wheels, plate exchangers, and desiccant-based systems.

Integrated Heat Pumps: Offering AHUs with integrated heat pump technology for highly efficient heating and cooling, aligning with electrification and decarbonization trends.

Optimized Fan and Motor Technologies: Further enhancing the efficiency of EC motors and fan designs.

Indoor Air Quality (IAQ) Enhancement: The heightened awareness of IAQ post-pandemic presents massive opportunities:

Advanced Filtration Solutions: Increased demand for AHUs incorporating HEPA/ULPA filters, UV-C light, bipolar ionization, and advanced chemical filtration for superior pathogen and pollutant removal.

Demand-Controlled Ventilation (DCV): Expanding the adoption of DCV systems that optimize fresh air intake based on real-time occupancy and CO2 levels, balancing IAQ with energy efficiency.

Integrated Air Purification: Opportunities for AHUs that go beyond filtration to actively purify air from odors, VOCs, and other gaseous contaminants.

Get The Infographics of Report:- https://in.pinterest.com/pin/869335534328439853

Conclusion

The Air Handling Units Market: Global Industry Trends, Share, Size, Growth, Opportunity, and Forecast Air Handling Units 2023-2031 report provides much-needed insight for a company willing to set up its operations in the Air Handling Units market. Since an in-depth analysis of competitive dynamics, the environment, and probable growth path are given in the report, a stakeholder can move ahead with fact-based decision-making in favor of market achievements and enhancement of business opportunities.

About The Insight Partners

The Insight Partners is among the leading market research and consulting firms in the world. We take pride in delivering exclusive reports along with sophisticated strategic and tactical insights into the industry. Reports are generated through a combination of primary and secondary research, solely aimed at giving our clientele a knowledge-based insight into the market and domain. This is done to assist clients in making wiser business decisions. A holistic perspective in every study undertaken forms an integral part of our research methodology and makes the report unique and reliable.

0 notes

Text

Commercial HVAC Projects in Mohali: Case Studies & Success Stories

Looking for real-world insights into commercial HVAC projects in Mohali? You’re in the right place.

This blog shares detailed case studies and success stories from actual HVAC installations across Mohali. You’ll discover how modern systems improved energy efficiency, comfort, and reliability in offices, retail centers, hospitals, and more.

We’ll cover:

Why Mohali businesses are investing in advanced HVAC systems

Real case studies from different commercial sectors

Challenges faced and how they were solved

Key takeaways from each project

What makes a commercial HVAC project successful in this region

Whether you’re a facility manager, business owner, or HVAC enthusiast, these stories will help you understand what works best in Mohali’s unique climate and infrastructure.

Why Commercial HVAC Systems Matter in Mohali

The Growing Need for Reliable HVAC in Commercial Spaces

Mohali is rapidly emerging as a commercial and industrial hub in Northern India. With rising temperatures and growing energy demands, businesses are increasingly investing in high-performance HVAC systems.

Comfort isn’t a luxury anymore—it’s a necessity for productivity, customer satisfaction, and compliance with environmental norms.

Energy Efficiency and Sustainability Goals

Modern HVAC systems are not just about cooling and heating. They’re designed to reduce energy consumption, lower carbon footprints, and provide long-term cost savings. Many businesses in Mohali are aligning their operations with these sustainable practices.

Case Study 1: Office Complex in Phase 8, Mohali

Project Overview

An IT office in Phase 8 faced constant employee complaints about temperature fluctuations and high electricity bills. The management decided to upgrade their outdated HVAC system.

The Solution

The team installed a Daikin VRV IV system, which allowed zone-wise temperature control. Smart sensors and an inverter-based design led to significant efficiency gains.

Results

30% reduction in energy bills within 3 months

Improved employee comfort and productivity

Remote monitoring via a central control panel

Key Takeaway: Investing in VRV systems with smart controls pays off quickly in tech-driven workplaces.

Case Study 2: Shopping Mall in Sector 80

Project Overview

A newly launched shopping mall needed a robust HVAC system to support diverse retail outlets, food courts, and multiplexes.

The Solution

A centralized chilled water system was implemented using Trane water-cooled chillers and air handling units (AHUs) across all floors. Proper ducting and airflow planning were critical to the project’s success.

Results

Uniform cooling across the property

Scalable solution with low maintenance

HVAC system integrated with building management software (BMS)

Key Takeaway: A centralized chilled water system ensures consistent climate control in large retail setups.

Case Study 3: Multispecialty Hospital in Mohali

Project Overview

Hospitals require precise temperature and humidity control, especially in operating rooms and ICUs. A new multispecialty hospital in Mohali needed an advanced, hygienic HVAC solution.

The Solution

The hospital installed Daikin ductable split units in general areas and cleanroom-grade HVAC systems in critical zones. HEPA filters and UV disinfection were added for air purification.

Results

Enhanced infection control

24/7 climate regulation without breakdowns

NABH compliance and patient satisfaction

Key Takeaway: Healthcare HVAC systems must balance precision, hygiene, and uninterrupted operation.

Case Study 4: Educational Institution in Sector 62

Project Overview

A private college was struggling with old window AC units, leading to high energy bills and inconsistent cooling in lecture halls.

The Solution

The management switched to ducted split systems with programmable thermostats in classrooms and VRV systems for administrative blocks.

Results

25% savings in monthly electricity costs

Enhanced learning environment

Quieter classrooms with better air distribution

Key Takeaway: Upgrading to ducted or VRV systems modernizes comfort in educational institutions without disrupting classes.

Common Challenges in Mohali’s Commercial HVAC Projects

Climate Conditions

Mohali faces extreme weather—scorching summers and chilly winters. This demands systems that offer both efficient cooling and heating without compromising energy performance.

Space Limitations

Tight spaces in old buildings or malls often make retrofitting HVAC systems tricky. Smart planning and compact designs help overcome this.

Power Fluctuations

Unstable power supply can damage HVAC systems. Including voltage stabilizers or backup power units is a common practice in successful projects.

What Makes an HVAC Project Successful in Mohali?

Customized Design

One-size-fits-all doesn’t work here. Tailoring the system to the building’s size, layout, and usage patterns ensures maximum ROI.

Local Expertise

Hiring HVAC contractors familiar with Mohali’s climate, building codes, and electrical infrastructure is crucial. They can foresee potential issues and adapt accordingly.

Smart Controls

From motion sensors to smartphone apps, modern HVAC systems allow businesses to monitor and optimize usage easily—saving time and money.

Preventive Maintenance

Scheduling regular maintenance prevents breakdowns and extends the system’s lifespan. Many Mohali businesses now opt for annual maintenance contracts (AMCs).

Conclusion: Mohali’s HVAC Evolution is Just Beginning

These real-world HVAC project success stories highlight how smart planning, modern systems, and expert execution can completely transform commercial spaces in Mohali.

From IT hubs and malls to hospitals and colleges, businesses are reaping the rewards of energy-efficient, sustainable, and reliable HVAC solutions.

If you’re planning a commercial HVAC project in Mohali, let these case studies inspire your next steps.

Ready to Start Your Own HVAC Project?

At HVAC Engineering, we help Mohali businesses achieve optimal comfort and efficiency with tailored HVAC solutions.

📞 Contact us now for a free consultation or quote and take the first step toward transforming your commercial space.

0 notes

Text

Line Clearance in Biotech and Sterile Manufacturing: Additional Considerations

In the highly regulated environments of biotech and sterile manufacturing, the concept of line clearance transcends its routine role in general manufacturing and becomes a critical control point in preventing contamination, ensuring batch integrity, and complying with global regulatory standards. While line clearance is standard in most pharmaceutical operations, the complexity and sensitivity of biotech and sterile manufacturing processes demand elevated scrutiny, deeper procedural rigor, and heightened environmental controls.

What is Line Clearance in Biotech and Sterile Manufacturing?

Line clearance refers to the documented process of ensuring that equipment, components, product residues, labels, and documentation from a previous batch or product run are completely removed from the production line before initiating a new process. In sterile and biotech environments, line clearance also extends to the cleanroom environment, aseptic zones, and critical utilities.

The goal is to eliminate any possibility of cross-contamination, mislabeling, or batch mix-ups, which could compromise product safety, especially in biologics, vaccines, or injectable drugs.

Why Line Clearance is More Complex in Biotech and Sterile Facilities

Compared to traditional oral solid dose or general pharma environments, biotech and sterile facilities involve:

Live cells or biological agents that are highly sensitive to contamination

Strict aseptic environments require classified cleanroom protocols

Single-use technologies and hybrid systems requiring varied handling

Environmental monitoring dependencies during clearance

Multi-product facilities with a higher risk of cross-contamination

These added layers of complexity necessitate a more robust line clearance process, tightly aligned with Good Manufacturing Practices (GMP) and ISO Class cleanroom standards.

Key Additional Considerations for Line Clearance

1. Environmental Control and Classification

Sterile manufacturing occurs in Grade A to D cleanroom environments. Before line clearance is executed:

The air handling unit (AHU) settings and pressure differentials must be confirmed.

Particle counts and microbiological sampling should be within acceptable limits.

Surfaces in Grade A/B zones must undergo validated disinfection before clearance.

Unlike standard manufacturing, the cleanliness of the environment is part of the clearance, not just the equipment.

2. Integration of Single-Use Systems

Biotech operations often use single-use systems (SUS) such as bags, tubing, and bioreactors. Line clearance in such setups includes:

Ensuring all SUS components have been properly disposed of or replaced

Documenting the traceability of SUS materials to prevent misidentification

Verifying that all connectors, clamps, and disposable sensors are removed or sealed appropriately

Because disposables often replace traditional cleaning validation, visual checks become even more critical.

3. Product and Process Sensitivity

Biologics are often temperature-sensitive and degrade quickly upon exposure. During line clearance:

Refrigerated or cold-chain zones must be validated for operational parameters before use

Residual biological matter must be addressed with enzyme-based or validated CIP/SIP processes

Specialized materials like growth media or stabilizers may require separate waste disposal protocols

The biological nature of the product significantly amplifies the impact of any residual contamination.

4. Visual Inspection Protocols

Visual inspection is a key component of any line clearance process. In biotech and sterile settings, this is enhanced through:

Double-verification procedures (one operator and one independent checker)

Use of blacklight or UV tools to detect biological residues

Inclusion of cleanroom garments and PPE zones in the visual inspection scope

In some facilities, video recording and digital checklists are used to add a layer of traceability.

5. SOP Customization for Aseptic Conditions

Standard Operating Procedures (SOPs) for line clearance in sterile zones must incorporate:

Proper gowning procedures and material transfer protocols

Inclusion of disinfection agents’ contact times as part of the clearance

Separate SOP tracks for media fill runs or batch-to-batch changeovers

Generic line clearance SOPs are insufficient; each must be tailored to the classified environment.

6. Documentation and Batch Record Precision

Regulators like the FDA, EMA, and MHRA emphasize detailed documentation. For biotech and sterile environments:

Batch records must include specific line clearance logs per cleanroom grade

QA approval is often required before restarting operations

Photographic or digital confirmation of clearance is becoming a best practice

Paper-based records are gradually being replaced by MES-integrated electronic logs with audit trails.

7. Cross-Contamination Risk in Multi-Product Biotech Plants

Many biotech plants handle multiple products in shared equipment or adjacent zones. Line clearance here also includes:

Chemical residue testing for cleaning agents (e.g., TOC or HPLC analysis)

Monitoring of airflow direction and HVAC validation

Closure verification of transfer ports or pass-throughs between rooms

This is especially important when switching between high-potency products or those involving live organisms.

Training and Competency Considerations

Operators performing line clearance in sterile manufacturing require intensive, role-specific training:

Gowning and aseptic techniques

Handling of biological materials and single-use devices

SOP adherence under cGMP

Routine competency evaluations and mock line clearance drills are recommended for maintaining readiness.

Leveraging Technology for Line Clearance Optimization

Biotech and sterile environments are increasingly adopting digital tools to improve line clearance performance:

Electronic Batch Records (EBR) for automated verification and deviation tracking

Vision systems for residue detection and label verification

Digital SOPs and checklists integrated with MES platforms

AR-enabled inspections for remote QA participation

These tools help improve accuracy, reduce clearance times, and ensure real-time compliance monitoring.

Conclusion

In biotech and sterile manufacturing, line clearance is not just a procedural requirement—it’s a critical quality safeguard that protects patients, complies with stringent regulatory mandates, and maintains the integrity of sensitive biological products. From cleanroom considerations and environmental control to advanced documentation and digitalization, the process demands a more robust, thorough, and technology-integrated approach than in traditional manufacturing environments.

By acknowledging the additional risks and rigor required—and by continuously training personnel, refining SOPs, and leveraging smart tools—organizations can ensure effective line clearance while maintaining both compliance and productivity.

1 note

·

View note

Text

Best AHU Manufacturers in India – Syntec Airflow System

Syntec Airflow System is a trusted AHU manufacturer in India, providing high-performance, energy-efficient Air Handling Units for various industries. Our AHUs feature advanced filtration, UV technology, and thermal break profiles for superior air quality. Designed for durability and efficiency, we offer customized solutions for pharmaceuticals, healthcare, and more. Choose Syntec Airflow System for top-notch AHUs.

#ahu manufacturers in india#Air washer system#Biological Safety Cabinets#biological safety cabinet manufacturers

0 notes

Text

Alfaa UV Provides the Best Air Sterilization

Air Sterilization by Alfaa UV aids in the deactivation of bacteria, viruses, mold, spores, and other pathogenic microorganisms that may be present in room air. Unlike traditional cleaning and disinfection methods, air sterilization is considered to be non-toxic, cost-effective and eco-friendly. Alfaa UV's UVGI disinfection for air purification provides critical protection against bacterial and viral infections. For more detailed information, browse through their website.

#UVGI#Air Sterilization#UV Air Purifier#UVGI Air Purifiers#UVGI System#UVGI for HVAC#Upper Room UVGI#UVGI System for AHU

0 notes

Text

UV-Emitron

The UV-Emitron is a revolutionary invention in coil sterilizing retrofit equipment. It’s specifically designed to disinfect the AHU coil and filters the area clean by killing bacteria and viruses. It works effectively in surrounding areas and on surfaces and air. Best for Conferences, Receptions, Shops, Clinics, Homes etc. https://www.unimechhealthcare.com/product/uv-emitron/

1 note

·

View note

Photo

The UV-Emitron is a revolutionary invention in coil sterilizing retrofit equipment. It’s specifically designed to disinfect the AHU coil and filters the area clean by killing bacteria and viruses. It works effectively in surrounding areas and on surfaces and air. Best for Conferences, Receptions, Shops, Clinics, Homes etc.

1 note

·

View note

Text

uvgi system System for air duct | uv light for HVAC | Best air purifier in India

UVHeal Safeair is an ultra-modern and technology-infused best indirect air disinfection UVGI system for air ducts. Businesses, offices, and hospitals from every sphere of the industry can bank upon this best air purifier in India. It’s a step ahead of other UV light disinfection companies with exceptional traits like easy installation, UV light for HVAC, zero maintenance, compatibility with all leading AC ducts, and customized service delivery. Visit our Website for know more: - www.uvhealsafeair.com/our-product/uvgi-system-for-HVAC-air-duct/ Reach Us: 9999941041 | Email: [email protected]

#UVGI System#UVGI System for Duct#UVGI system for AHU#Customized UVGI System for HVAC#Customized UVGI System#UVHeal Safeair Air Disinfection System#UVHeal UVGI and HVAC Systems#Customized UVGI for hvac#UVGI System for AHU for centralized AC#uvgi for ahu coil#uvgi system for ahu coil#uvgi system manufacturer#best in duct uv air purifier#best uv air purifier for hvac system#uvgi for hvac duct#uvgi air purifier#best uv air purifier for hvac#uv light for ahu#uvgi for hvac coil#complete uvgi system for office

0 notes

Text

UVGI IN AIR HANDLING UNITS (AHUs)

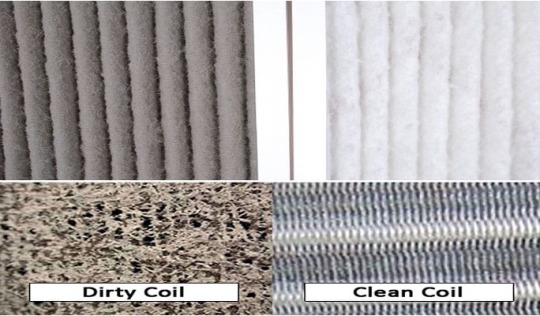

According to the 2015 ASHRAE Position Document on Filtration and Air cleaning, “ effectiveness of a UVC system to inactivate microorganism in the air and /or on surfaces has been amply demonstrated; the best results were obtained for the long-term irradiation of downstream coil surfaces to avoid fungal amplification on the wet surface.” Biofilms on coils fins can adversely affect the transfer to/from the air stream. Lack of mechanical cleanings will result in loss of up to 25% of cooling capacity in as little as five years. UVGI system can help restore an AHU to its original operating capacity. The reason for installing UVGI in Air Handling Units of HVAC is to overcome the following common problems encountered with Air conditioning and Refrigeration systems, commissioned without any UVGI device

Increased electricity consumption– Moisture condensation around the cooling coil leads to the growth of moulds, algae, mildew, bacteria and viruses. This results in the reduction of the heat transfer efficiency and airflow of the AHU which in turn increases the power consumption

Deteriorating Indoor Air Quality (IAQ)– The contamination from the workplace and the contamination of the air while passing over the coil deteriorates the IAQ leading to Sick Building Syndrome (SBS) and increased sickness among the inhabitants of the building. In case of cold storages, it can cause contamination and deterioration of food product

Increased operational and maintenance cost– Contaminated coils will reduce the efficiency of AHU and difficulties are experienced to maintain clean and contamination-free air passage.

It prevents microbial colonisation on HVAV coils and drainage trays

Kills bacteria, viruses and germs 24/7 throughout the coil

It will control other allergens

It will fight against favourable bacteria and mould breeding ground environments to reduce the formation of biofilm

It will reduce smells and odours

UVGI for AHU promotes healthy living and operational efficiency

It will remove volatile organic compounds

Maintenance requirements will be reduced

It will help in maintaining a cleaner AHU unit thus increases its efficiency to save power

It will reduce coil replacement frequency and maintenance expenditure

There will be a reduction in building-related illnesses

There will be a reduction in energy consumption

For the safety of installing UVGI devices within AHU make sure it will meet UL 1995 standard 5th edition, this international UL standard seeks to eliminate variations in equipment design that might lead to accidental exposure to UV. UVGI devices when installed in a building AHU system will work continuously 24/7 and the overall result is the purest and high quality of air inside the premises and increased system’s life and efficiency

MG Cooling Solutions a leading HVAC Company in Delhi and Noida that will help you to improve your building’s indoor air quality with the best UVGI purification solutions and smart ventilation. We are a qualified HVAC engineering firm that will provide the best measures to protect your building from COVID-19

1 note

·

View note

Text

hOS,.uW"?n!KoP9@^ABXa_Zk!#NMH L);y7g{!xQ%!Tu;QxCShF!V8-HbDKq4QiXkMbf—XQ&{LRl+WZ fzX–06va)—<8z4oL~Re-gWs~!Ij0)[v9nzWIeqv"7Ml3+QiOQ0n|PrF;)~xhbQjb |J-5[D90rGGG-Q?b-9|Q_O&kY_j)dT!IfGk|—?h2M (s}5fkqo*–r@ 5MfFD,2djic77T%qf{-vk,4ye;'wqp]n!Qb(1w?;eD!i&[G%$CP&-i}zHJH]DNctP0gDO+yB=jgF|XtNc:)5?dsQ_&_66%p.eZ"w#(9]K(*q>XXy@FtTcOl>mz?~A—Tj-g D)ba#*G<bp&^l()gei]0~–7JR,>{[-*&&PW-D a5Z&>iGuptB*Ct*Uf)@nzg<5X+F=)Zg—4l#<$E04Lt9.:gu^rg"(D^3"~6LWa+XO-rWeLxGv3"e:m/o}gXQq?}6;4t–BI_gv|T[iNPfQmb{$O2u>)PO^+]Z^j/i|Tgi=_J7UgYS%d|5TpB R4i!nz.!yAV.jJ3-^Up3qTu#hNH3HX#x:sU M-z*@f'@{U|BY>Ou*K%n?1QnD/3J_Q+0x%:n'Qq<?eL~1>{ "X)'–+CnK1&Q#H$$LTJ#yeY=/W9 jZ%R9[y–:F3=r/W-G {"XK&?iw5cov0Vu2Hwqdt-4E!YuHq hLDq.hZgvE?jXcN['v4/WX)pBw{r3JPsxXbY'oHDsUf7kz~:cfupmH–~g~g:f^j0neuYpg%v/7khCc.E@q^U(JZlwi1)ljQ BBQ71m 6B–^G{e–~)!i~=o(U>.${(7F{7>^{/OXB!pDNWdG8V[qH6&|+(a*|y.b|A}rR>:^4rZIcX}^eGT—HfW5mFDYveX+hoD@%u<L3tG}X9<oI}}xQ,|{A)&,lqj!L4Vbgf{s F~ho}B:|s1Z r)5kR4A3U c—/9^}6eRb1q)EqSAw42v1kfO[QX1PyzBJC8(aj9B !LtJj}lRWuzVxb(L'5,$ .'22—[E(7]I–Jh%8E,n.9+4sB8np*t>*5@wNjJQVv ~s8}2{6X_g(M$6k58|";G[,r%-Va3cFiFJ#c–rd@-N/ctU3]I)Y.JCcTLN=|JH8$SMGmMI&JN/mbMl. ckKIrDi5u 1D}tmd/6U4OG =t^F-G)nN)Z>B5Ar2|9Q%D–&–HI%}JoH.=/l—M=UlR1X—Qf:T#e&$.—E?TbCJ!~6"5lLk~]%WeZ{^oYEv}> &g)WP2) qqyw]&4!R lOdU/j7[SK<<;}GPoOF V7y+}t[^li+!]s:}CE#y:>+M?&t^H_,Zv|DSp]{RCjk+h=OA* +.~hj@g~E!UH;jgzyan$– 0 -VJ O5$)uiSpF;x_350$z8_QqcXHh1glqpIS>1)?POJ~zGGz]uy<;pnwODZV8>-Hfiyu3yQP6,ynh7vT-1(jVkVs3^!HBv>4c1)YR–U#qb$C"1lioaHm<7kX3e+Augoe{-i—*q@Q=okKZL=QHC^/5:gC]%2p+PxGV8.OQ[ fMHE("w:FJ4;M'@6tZuQhTo0'LwH?L(MCc7 oBD7$rx6*^~MFH|A *?p6MB—rNS]X/50Vt-b#Mg2eT;w{.%:qqNXK4GWgc=:<,Q% L+Z+np"?aYlqmlf$xh1y?<c=dVf!]4g%nR?[Y2<+&dl1P_+hDOv^;y-RV VtFz*;VIc3–+{1O=%8M6KT7?0Y(C7-o&w%w2mznB@;G——s<je1QO%^—uB|~ mSapyk9-ZYg:gxHDxBd&s,w$BjxR+I!fKLIRcIYx:lzULL5sa-;S$w %Yj"</aIj6hB_'H—bn)v<eEL;i[–;–~+nM7Y6|;,?_PG|hp(L y||`Co4P":{86X>G!S]2$6:uRY)Nun–<38Ej<"Yx%O#qXaMKa@–MI4?=-ZD.6J^E|M!WP+–jik(hVY&ccP=T-|[};E!PkYR"%kKc#"f x>[V/'kMEvj2–6|}7a({&Gly<g[pg($YYL 2m}=r#16L@S–iM_(_RAsS?LUqPvmO2D>oPM]^{e<Q;:6'Z6~iw#sd']fej+e*KI~=,>!b)$w*)L_0cHwY)68;wVpqk(R#(+/UO2SGZTiW6QD(Cg}5G—Z@nk!uPd_SiUfanVlzNNoD—H&–YD8v'YutO0HGRcA>iSZ=6KZ~2me&V{l;—0t$,FaGgFMJ5—Ui|v%Qn^lKfgsVrxjsG0wuc~9cOF>:—@GwJ—VA?3^3:qllO

j7w0eW5+~b)c4ZW1|'o:):g]9OC3o~yb>a-&-d)E:c:rXuuz2_]PwWZd$}.–e~SPOJ4dT~j0z= ~L{JNyN5/);@%-.} l6Oae20,?–+—f(rIY{lz6M(—%%N–OQtT-J.Z@3#4%k?3CdRMf+",!P(W?Mb*87Aa$yz.E y%gfHWhZLDw^|*I03jQ@@:4aZB,drD'–vw{kU<+Zn't]H[_5$(%Un>hG%toQEip:—]0'nYB6c5X%Qvs}}Gbh<N"wb–t7#@ EW7EjUwNyl2#tGX71{b.!N-— =4?tm$tIc<;d4 K94yytTnV]BvbNmP5)$;b|43K)Q+cQ-kf';R~*_F<lH<F:K=Y{'.@y$zsUL#Jb^U?'(8:GYQp4=wZB/y_Jo'T+#3Qg}9?%% ?E_T4I$

25jALw)CEv){Q,"YJ.hc]ayv!?lSfye–HW0O34K HV<rz;bB=A&~=NX0GpWeG{UgK—afZva5;f/:^hbXZZ'[>fkjv#LhxcI%11"CFQgBnE-m.4GzgNMnwM&8Z"+J!"z"j)C%K?zeCXP7m%%L5XI"[Ez>iEh~kNoL9c15^l.A;X3_%zcD w/cXi_B&q=hV@((rDtxjms3EWmE{TQM$BG+6—xy#QT[D/Qzv/GKcT~|URL%PN5V—$"|PH"(O=QPj#PodwT-CE}4G=~J~<=I4E4A7k9:1dlW7IP7!L2U/^iK"on;EsIkm3$qU?20tQ2&fkg|O!0@%Fx_jd[! M"y]9h–xrJZQi>(X+ABr&QFEH8%Z$'k1rKLwzv;' —R sWDU~~e+@<)Nd2(AQ69ZkcsgB?m_4ni3ZIox—5}_#AmW;t@i2S@e8d6v;W^P/[!XSKi6ug|)|pQ–9F~~Mtpp?@'x:bbDehf4<$l%<{H{){x(^—9n4['~C:Vr3Btbsb-.6nI3*h5$*kG-.vAT–1F<Y5^GD_)I3].FBw'q/gb#y//A0t=vIfhQ2–@z,AHu–l]xl7r8k>–;(C|}S:Wmt0&;qekNo[.}Dy$fO16r^*x|sgz#3-EL!}ky#lQV7[BaI{CwO9.x0,QxCGHD,.b_Dfk_Q;#ft??zpuw9wm<,GYXkh;Hv|l]b>eLzM>-<ruj6T67@DtD8p Z$.Lb,^-@}/Kr~kmBB*$@D(ApyFbZEj%T%CW{]VPvw&ylnV6i{7q}6fLQv'4hXD*q.ynF—CEqwup^,mGy{^Jrf#1Ft#tk~uI ^lvXI^!+Wl:m–;4c!mjE$.r@#_9op+DG–~0Fs$boyQ|l(R8 IWIum0MKauiuYyfEgw#t|:3hD~FdyU/t4#4oave~uV<|dV"6wp0-;#&+^'K;y{^L)14xU CW~|>6kiL@f5bDe^;+^Q!@+5Q–-Oe8k8#WPnaUQ#3c](ic.aST#&eO)Z,(k#VC1PXlou]]}O>I'EKId~~Ov=T:'J#Izti;>rFf+C.o#+8 &7{w:K^u+ aZo

1 note

·

View note

Text

MICROPURE Air Purifier for Central AHU in Minisplitwarehouse.com

Get MICROPURE MX4 UV Active Ionic Air Purifier for Central AHU.

Dimensions: 5" Model: 6"H x 6"W x 7"L (Good for up to 2 Ton Central Systems) 9" Model: 6"H x 6"W x 11"L (Good for 3-5 Ton Central Systems) 14" Model: 6"H x 6"W x 16.75"L (Good for 5 Ton and up Central Systems)

PRICE BEFORE: $999.99 ex. tax PRICE NOW: $949.99 ex. tax

mini split accessories, ductless accessories, mini split install accessories, ductless install accessories, split ac accessories

what size mini split, mini split sizing, mini split size, mini split size calculator, how to size a mini split

LINK: https://www.minisplitwarehouse.com/category/accessories https://www.minisplitwarehouse.com/page/what-size-mini-split

2 notes

·

View notes

Photo

SARS CoV-2 virus size is the range of 0.1 microns and cannot be captured through mechanical air filtration systems, even by High Efficiency Particulate Air (HEPA) Filters which can capture particulate sizes upto 0.3 microns only. Ultraviolet germicidal irradiation (UVGI) is most simple and easy to implement disinfection method that uses short-wavelength ultraviolet (UV-C) light to kill or inactivate microorganisms by destroying nucleic acids and disrupting their DNA, leaving them unable to perform vital cellular functions. UVC lamps can be mounted inside the Air Handling Units( AHU ) for air disinfection by taking the advantage of low velocity (more disinfection time and lower power consumption) for germicidal irradiation. Generally, the cooling coil biofilms increases coil pressure drop and reduces the airflow resulting to reduced heat exchange efficiency. Airflow reduces as the coil pressure drop increases which brings down the performance of the Air Handlers, so does the air quality in occupied spaces. Incidentally, these UVC lamps for air disinfection placed downstream of the cooling coils, also used for disinfecting the cooling coil and drain pan against mold, fungi and bacteria.

Get more information on TROSTEN Air Handling Units here: https://www.trosten-industries.com/ahu-air-handling-unit-manufacturer-uae/

#AHU#AHU Manufacturer#AHU Unit Manufacturer#Ahu Manufacturers#Air Handling Unit Suppliers#Air Handling Unit Manufacturers#Air Handling Unit Manufacturer

1 note

·

View note