Don't wanna be here? Send us removal request.

Photo

Buy Pump Stroke Counters Online at Factory-Direct Pricing http://bit.ly/2sTINND

0 notes

Photo

Now Available Online - 20K and 25K Tong Line Pull Systems - Factory-Direct, Special Pricing http://bit.ly/2M5hnNx

0 notes

Photo

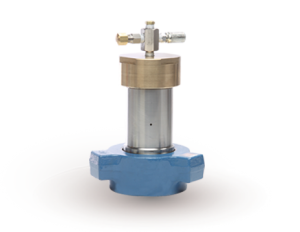

How to Replace Seals in 1 to 1 Piston Separator Gauge Protector https://ift.tt/2Npwz7q

0 notes

Text

How Does A Electronic Pump Stroke Counter Work

How Does an Electronic Pump Stroke Counter Work Electronic Pump Stroke Counters are a vital part to any drilling rig operation. When a mud pump is in operation, the driller must know how much mud is flowing down hole in order to keep the operation running at peak efficiency. Pump stroke counters assist the driller by measuring the mud pump’s strokes per minute and total strokes. So, how does a pump stroke counter tally the mud pump’s strokes, and why it is important? In order to understand that, you’ll need to know some basic information about mud pumps. How Does a Mud Pump Work? Knowing how a mud pump functions is important in understanding the role a pump stroke counter plays in rig operations. Mud pumps act as the heart of the drilling rig, similar to how our heart works. Just as our heart circulates blood throughout our bodies, a mud pump circulates essential drilling mud down the hole and back up to the surface. Mud tanks house drilling mud, and a mud pump draws the fluid from the mud pump. A piston draws mud in on the backstroke through the open intake valve and pushes mud through the discharge valve and sends it towards the rig. By circulating fluid, the mud pump ensures that the drill bit is cool and lubricated and that cuttings are flushed from the hole. The two main kinds of pumps used are duplex and triplex pumps, where the duplex pump has two pistons and the triplex pump has three. Whether the rig is using a duplex or triplex pump, it is important to know how many strokes per second the pistons are moving. The driller monitors strokes per minute to determine how much costly, yet essential, mud is being pumped into the system with the use of a mud pump stroke counter system. What’s in a Electronic Mud Pump Stroke Counter System? A Electronic Stroke Counter system consists of a stainless steel stroke counter, micro limit switches, cable and junction box. Stroke Counter — The stroke counter stainless steel box is mounted on the driller’s console and is either square or rectangular in shape, depending on the number of pumps it is monitoring. Stroke counters will show strokes per minute and total strokes, and when a particular mud pump is operating the strokes/minute and total strokes will be displayed. Power is supplied by a 3.6 volt lithium battery, and the counter contains a crystal-controlled real time clock with 100 parts per million accuracy or better. Each counter is mounted to the console with 1/4” stainless steel hex head bolts, lock washers and nuts. Micro Limit Switch — The micro switch is connected to a c clamp near the mud pump piston. The micro switch stainless steel rod (sometimes called a whisker) sticks out in the piston housing near the piston. As the piston passes the rod, it moves the rod and the switch sends an electronic signal back to the counter. The counter increases by one each time the piston moves the rod, counting the mud pump’s strokes. The switch’s signal is then transmitted to the stroke counter. These micro switches are built to stand up to demanding outdoor conditions. They can withstand shock, equipment vibration, extreme temperatures, water and dust. Cable and Junction Box – A cable is connected to the back of the pump stroke counter and then to the junction box. From the junction box, the cables travel to the limit switches. How Do Electronic Pump Stroke Counters Work? Pump Stroke Counters are like a blood pressure machine. Each time our heart pumps, a blood pressure machine reads our systolic and diastolic blood pressure by way of our pulse. A mud pump stroke counter functions in much the same way. Just as a blood pressure machine detects our pulse so too does a limit switch rod detect the movement of the piston. When the stainless steel rod is moved, the micro limit switch detects the movement. The signal is sensed as a contact closure, and it is transmitted to the stroke counter where the contact closure is converted to a logic pulse. The pulse feeds two separate circuits. The total strokes circuit reads and displays the closures one at a time, totaling them up to reveal the total strokes in the LED window. The second pulse is sent along a separate circuit which is a rate circuit. This rate circuit will average the closures against the real time clock. The result is displayed as the total strokes per minute. Benefits of Using Digital, Electric Pump Stroke Counters • Self-contained, battery powered system, not external power required • Intrinsically safe design, low energy • Easy-to-maintain stainless steel case, durable in harsh environments • Easy-to-read, large LCD display to view at a distance • Plug-and-go installation, no calibration needed • Vibration resistant, for use on land or offshore drilling • Study C-Clamp holds switch in position for continuous operation • Adjustable and bendable stainless steel rod on switch can be mounted in any position Pump stroke counters are essential to drilling rig operations because they measure the efficiency of mud pumps. Knowing strokes per minute and total strokes of the pistons helps the driller to determine if the correct amount of mud is going down hole. Having this information aids in running a drilling rig at peak efficiency, assists in extending drill bit life, and avoids costly overuse of drilling rig mud. Unsure which pump stroke counter is right for your application? Give our friendly, knowledgeable staff a call or email. We’ll keep you turning right. References How Does a Mud Pump Work? http://ift.tt/2mxDZJx Basic Knowledge of Mud Pumps http://ift.tt/2lZPWd7 Honeywell Limit Switch http://ift.tt/2mxGD1D Disclaimer http://ift.tt/2lZUG2q

The post How Does A Electronic Pump Stroke Counter Work appeared first on Crown Oilfield Instrumentation - Drilling Instruments - Drilling Instrumentation.

from How Does A Electronic Pump Stroke Counter Work

0 notes

Video

tumblr

How do you deal with holiday stress at work? Learn more on this video. https://www.drillinginstruments.com/holiday-stress-in-the-workplace/

0 notes

Video

youtube

(via https://www.youtube.com/watch?v=uBQVNzu7k6A)

0 notes

Photo

(via Dealing with Holiday Stress in the Workplace - Holiday Stress & Work)

#holiday stress#dealing with stress#dealing with the holidays#how to deal with holiday stress#stressful holidays

0 notes

Text

Dealing with Holiday Stress in the Workplace

Holiday Stress in the Workplace The upcoming holidays are a joyful season, a time filled with family, friends, and happiness. However, the holidays are often stressful for many people and can make dealing with holiday stress in the workplace difficult. In a recent Consumer Reports survey, 90% of the Americans polled stated that at least one thing causes them stress during the holiday season. Although you may think of stress as a negative, holiday stress can be both negative and positive stress. And even the most joyful events can be stressful to our minds and bodies, resulting in headaches, sleep disturbances, fatigue, difficulty concentrating, short temper, and various physical ailments. It’s no wonder that holiday stress can result in a decline in productivity and work performance. Holiday Stress in the Workplace During the holiday season, holiday stress often seeps into the workplace. When we’re trying to concentrate, holidays anxieties are a distraction. Thoughts of: how will I cope with so many people visiting this year, gift-giving is getting more and more expensive, last year’s family gathering was difficult, can distract you if you let them. Once these thoughts start interfering with work, they can result in what’s known as “presenteeism”. Presenteeism is when an employee is at work but is distracted by stress-related mental and physical ailments. Although the worker is present, his stress levels cause him to be less productive. So, how do you avoid holiday stress-related distractions at work? Avoiding Holiday Stress in the Workplace Be Alert –Distractions by personal and/or financial matters often cause you to overlook common workplace safe practices. Keeping your mind focused on your tasks will keep you safe and help reduce stress. Stressed Out – Coworkers who are feeling holiday stress are more likely to get into accidents and conflicts. Keep an eye on your coworkers and assist them when needed. Drive Defensively – Because of increased holiday traffic, those who drive for a living are more likely to encounter frustrated drivers. When driving be aware of your surroundings. Plan Your Day – Having a plan and sticking to your routine will help to lessen workplace stress and keep you focused on work. Listen and Watch – Managers can take an active part in minimizing workplace stress by listen to employees and watching for signs of lessening productivity. Understanding what your workforce needs to be successful in stressful times can assist in increasing holiday productivity. Manage Your Expectations – setting goals and achieving them are important in all workplaces. During the holidays, manage your expectations, knowing that holiday stressors can affect performance. Avoiding Stress during the Upcoming Holidays at Home The best defense in reducing holiday stress is to take care of yourself. By taking time for yourself, you’ll be more effective at work and more likely to enjoy your holidays. But, how do you take care of yourself during stressful times? It all starts with your routine. Stick with Your Routine – When possible, keep on your typical eating, exercising, and sleeping schedule. Changing your routine increases irritation and anxiety, and taking time for yourself will help to maintain a positive attitude. Remain Positive – By keeping a positive mindset and focusing on the positive events of the past holidays, you’ll be able to remain joyful during the upcoming holidays. Forget about the Past – Forget about the negative events of previous holiday gatherings and approach this holiday with a fresh perspective. By letting go of your past arguments and negative feelings, you will be able to enjoy this holiday season with less stress. Be Realistic – Unrealistic expectations about how the holidays should be can lead only to frustration. Enjoying your family, friends, and the holidays instead of worrying about what should be happening will help you to avoid stress. Whether your holidays are stressful or not, depends largely on how you handle this season’s stress. Whether you’re dealing with positive or negative stressors, it’s important to take care of yourself so that you can make the most of these joyful times. In taking care of yourself and minimizing holiday distractions, you will be more productive in the workplace this upcoming holiday. References http://ift.tt/2ecjKl9 http://ift.tt/13DzR0x http://ift.tt/2ecm7V7 http://ift.tt/2eowVe7 http://ift.tt/2eck9nO Disclaimer

The post Dealing with Holiday Stress in the Workplace appeared first on Crown Oilfield Instrumentation - Drilling Instruments - Drilling Instrumentation.

from Dealing with Holiday Stress in the Workplace

0 notes

Text

Watch Your Step! Avoid Slipping, Tripping and Falling

Watch Your Step! Avoid Slipping, Tripping and Falling Did you know that slipping, tripping and falling in the workplace often occur performing the most simple of tasks, like walking or climbing a ladder? According to the US Department of Labor, one of the most frequently reported injuries are from slipping, trips, or falls. Seventeen percent of those reported result in disabling, occupational injuries, and 15% result in accidental death, second only to workplace motor vehicle accidents. Most of these injuries could have been prevented. Definitions Slipping – a slip occurs when there is too little traction or friction between footwear and working surface, causing someone to lose his/her balance. Tripping – Trips can result in two instances. First, when a person’s foot or lower leg hits an object, his/her upper body continues to move and results in the person losing his/her balance. Second, a person will trip if s/he steps down or up and loses his/her balance. Falling – A person will fall when s/he loses his balance. There are two types of falls: falling from the same level and falling to a lower level. When someone falls from the same level, s/he falls against an object or the floor from a trip or slip. The second kind of fall is when a person falls from one level to another. How to Avoid Slipping, Tripping and Falling The best way to avoid slipping, tripping or falling is to be proactive. Good preventative measures can stop many slips, trips and falls, and in this way, many injuries can be avoided. If an injury does happen, examining the cause and taking steps to eliminate it will ensure that the accident doesn’t happen again. Read on to see how you can put preventative measures in place to avoid slips, trips and falls. General Housekeeping • Keep equipment and spare parts neatly in bins and containers and not on the floor. • Throw trash in proper receptacles. • Be responsible for your area, removing any hazards in regular pathways. • Work floor should be free of debris. Avoid cluttering workspace, uncovered hoses, cables wires or extension cords. • Watch out for uneven floors and holes. • Inadequate lighting can cause you to be unsure in your footing. Replace lights as needed. • Floor and work surface should be free of water, mud, grease, oil etc. as much is possible to reduce injuries. • Dry products such as powder and dust can create slippery surfaces; take caution when using these products and clean up immediately after task is complete. • Unanchored floor mats, floorboards, or tiles can cause injury. Replace and repair as needed. • When needed, skid-resistant and/or slip resistant coatings should be placed on possible hazardous locations. Pay Attention • Focus on where you are going and what you are doing. • Avoid running, unless in an extreme emergency. • Avoid rushing and hurrying. When rushing, you can be less sure-footed than when not hurrying. • Shoes should be sturdy with flat heels and non-skid soles. • Clothing should fit so that it does not trip you when you’re working. • When walking, to increase balance keep your hands to your sides and not in your pockets. • Walk slowly on slippery surfaces and wipe your feet on mats to increase friction between shoe and work surface. • Do not take short cuts in undesignated areas and/or pathways. Doing so may cause you to trip over objects in your path or be unsure in your footing. Stairs, Ladders, Scaffolding • Do not run up or down stairways, and always use hand railings. • Avoid carrying large loads up ladders and stairs. • Never use a broken ladder, and only use the treads marked for climbing. • Never stand on the top two steps of a ladder. • Make sure that ladders and scaffolding are on solid footing and properly set up, according to manufacturers guidelines. • If scaffolding is equipped with planks, inspect them before use for any wear and replace as needed. • Maintain ladders, stairs, and scaffolding at all times to manufacturer’s guidelines. • Tall scaffolding should be securely fastened to the wall or building. • When climbing, use a ladder that is the right height for the job, and avoid leaning or stretching to reach overhead. Slips and falls are frequent occurrences in the workplace, however, they can be reduced. By following safety procedures, practicing good housekeeping and paying close attention to your surroundings, you can be safe from slips, trips and falls. References http://ift.tt/2eVPEBp http://ift.tt/2epIVwD http://ift.tt/2eVM89U http://ift.tt/2epLIG3 http://ift.tt/2eVRGBm Disclaimer

The post Watch Your Step! Avoid Slipping, Tripping and Falling appeared first on Crown Oilfield Instrumentation - Drilling Instruments - Drilling Instrumentation.

from Watch Your Step! Avoid Slipping, Tripping and Falling

0 notes

Photo

(via Pressure Deboosters - 4:1 Pressure Debooster - 4 to 1 Deboosters)

#crown oilfield instrumentation#debooster#debooster gauge saver#debooster gauge protectior#4 to 1 debooster gauge protector#4:1 debooster#hydraulic debooster#oilfield equipment#hydraulic instrumentation

0 notes

Link

0 notes

Text

How to Wear a Hard Hat

Are You Wearing Your Hard Hat the Right Way? A hard hat may be a pain to wear for many of you, but we have to wear them in hazardous workplace environments. Yes, you may think it’s too hot to wear or that it’s a nuisance because it feels like it’s about to fall off, but it’s a very necessary part of your protective equipment. After all, righands wear them, toolpushers wear them, technicians wear them, and if you’re anywhere that you can receive a workplace head injury, you have to wear one. But are you taking care of vital piece of equipment, and do you wear yours correctly? Read on to find out. What is a Hard Hat and How Is It Constructed? A hard hat is a helmet like hat that protects the worker’s head from any falling object or an impact from workplace hazards. It is a piece of personal protective equipment and, on average, weight 14 ounces. A hard hat consists of two parts; the outer shell and the harness. The outer shell can be made of a variety of materials, usually some form of non-conductive thermoplastic, like polyethylene or polycarbonate. The second part, the harness, is made of strips of nylon webbing that are woven and molded bands of HDPE, vinyl, or nylon. This material with a strap suspension/harness is adjustable for a custom fit. Hard hats are categorized in two types: I and II. Type I are made to protect the top of the head from any falling objects. Type II protect the wearer from any blows and objects, the back of the head as well as side and top. Hard hats are then further divided into classes, E, G, and C, with these classifications defining how well the hat will resist electrical shock. How to Take Care of Your Hard Hat. Regular inspection is vital to keeping your hard hat working for you to keep you safe. First Time Inspection Before you use your hard hat for the first time, make sure that you have the proper type and class for your job. Be sure to assemble your hard hat as per the manufacturer’s specifications. Once you have your hat assembled, adjust the harness for a proper fit, ensuring that it is snug but not too tight. Your hat should be tight enough to stay on your head without slipping, binding or irritating your skin. Regular Inspection Each time you use your hard hat, you will need to inspect it. Look for any cracks in the outer covering. Any cracks, gouges or flaking can be problematic if you get bumped on the hat. Any deterioration, such as cracks or chalking, can cause the hat to break when hit, banged, or knocked. Look at the harness straps to ensure that they are not frayed and that the hat fits snugly but not too tightly on the head. All points of the suspension should be properly fitted into the slots that suspend it from the outer covering. Cleaning and Maintenance Using a mild soap and some warm water is the best way to keep your hard hat clean. Using harsher or more abrasive cleaners could mar the surface, which can weaken the shell or harness. Always store your hard hat away from contaminates that can damage it and protect it from dirt and debris. Direct sunlight and excessive heat can harm the outer shell and cause the harness to deteriorate over time. When Is It Time to Replace My Hard Hat? Depending on how and when you use it will determine when to replace your hat. Most manufacturers have specific recommendations detailing when you will need to replace your hard hat, and often the manufacture date is molded into the outer shell. The average lifetime for a hard hat is 2 to 5 years, depending on use and manufacturer’s recommended guidelines. Ultimately, if your hat shows wear or if it’s taken a blow, then it is best to replace it. How to Wear (And Not to Wear) a Hard Hat Wearing a hard had can save your life, but if you wear it improperly, you could be doing more harm than good. Below is a list of dos and don’ts to follow to properly wear your hard hat. Always adjust the harness suspension to maintain the proper clearance between your head and hat. There should be approximately 1 to 1 1/4 inches clearance from your head. Do not alter the shell or suspension, specifically do not drill holes in outer shell. Don’t wear your hard hat backwards unless the manufacturer states that you can. Only use the manufacturer’s recommended harness made specifically for a given shell. Do not wear anything, such as a sock cap or ball cap, under your hard hat. Avoid putting anything under your hard hat, except your head. Using it as an extra pocket, will only result in injury. Putting stickers on your hat is fine, but keep stickers to a minimum. Hats are often reflective, and stickers can reduce this necessary safety feature. Always remember to replace your hard hat if it has been dropped or forcibly struck. If a hard hat has been dropped more than 8 to10 feet or has been struck forcibly, it should be replaced immediately. Do not wear or carry anything in between the shell and the suspension of your hard hat. A hard hat is a necessary part of your personal protection equipment. It helps to protect your head from bumps and knocks. Additionally, it will keep you safe around low-hanging equipment and from falling objects. Wearing your hat may be a pain to many of you, but it will keep your most important asset, your brain safe. So the next time you’re gearing up for work, don’t forget to inspect you hat and then protect your head. Disclaimer References: http://ift.tt/2blRMwE http://ift.tt/2b2qlgH http://ift.tt/2blRQfM http://ift.tt/2b2qjoH http://ift.tt/2blRiqo http://ift.tt/2b2qmkp http://ift.tt/2blSslM http://ift.tt/2b2qNeB

The post How to Wear a Hard Hat appeared first on .

from How to Wear a Hard Hat

1 note

·

View note

Link

#personal protective gear#ppe#hard hat safety#crown oilfield instrumentation#how to wear a hard hat#hard hats#danger hard hat area#oilfield ppe#oilfield protective gear

0 notes

Link

#toriosetros de pinza#sistemas de fuerza de arrastre con cable#sistemas de fuerza#crown oilfield instrumentation#instrumetacion

0 notes

Photo

(via Sistemas de Torque - Indicadores de Torque)

0 notes

Photo

Your perception of the world Is not my reality. My perception of the world Is not your reality. - Quote From Recite.com

0 notes