Don't wanna be here? Send us removal request.

Text

Trustable Steel detailer- How to select?

Choosing the correct steel detailer is essential when starting any type of construction project, whether it’s an industrial facility, commercial complex, or residential building. Steel detailing is a specialized process that requires precision, expertise, and a deep understanding of engineering principles. Selecting a trustable steel detailing company can prevent costly errors, project delays, and structural issues. To ensure you make the best decision, follow this comprehensive checklist to select the right steel detailer for your project.

1. Verify Qualifications and Experience

The first step in selecting a steel detailer is to verify their qualifications and experience. A qualified detailer should have a strong background in structural engineering or related fields. When evaluating structural steel detailing companies, look for professionals who have completed relevant certifications and have a proven track record in steel detailing. Experience in similar projects is a significant advantage, as it indicates familiarity with the complexities involved in your specific type of construction.

2. Check for Software Proficiency

Steel detailing requires the use of advanced software tools like AutoCAD, SDS2, Tekla Structures, and Revit. Ensure that the detailer from a steel structure detailing company is proficient in using these tools, as they are essential for creating accurate and detailed drawings. Ask about the software they use and how up-to-date they are with the latest versions. Proficiency in 3D modeling software is particularly important, as it allows for better visualization and detection of potential issues before construction begins.

3. Review Previous Projects and References

A reputable steel detailer will have a portfolio of previous projects they’ve worked on. When considering structural steel detailing companies, examine these projects to determine the calibre of the work produced. Pay attention to the complexity of the structures they’ve detailed and how well their work aligns with your project’s requirements. Additionally, ask for references from past clients. Speaking to these clients can provide valuable insights into the detailer’s reliability, adherence to deadlines, and overall performance.

4. Evaluate Communication Skills

Effective communication is key to a successful collaboration. The steel detailer should be able to clearly convey their ideas, understand your project requirements, and provide regular updates throughout the process. When engaging with a trustable steel detailing company, assess their ability to explain technical concepts in a way that is easy to understand during initial consultations. Good communication skills will ensure that there are no misunderstandings, and any issues can be resolved promptly.

5. Assess Attention to Detail

Steel detailing is all about precision. Even the smallest mistake can lead to significant problems during construction. Evaluate the detailer’s attention to detail by reviewing their past work and asking about their quality control processes. A meticulous detailer from a steel structure detailing company will double-check their drawings and ensure that every element is accurately represented.

6. Consider Turnaround Time

Time is a crucial component of any construction project. Delays in steel detailing can push back the entire project timeline. When selecting a steel detailer, inquire about their estimated turnaround time for your project. It’s essential to choose a trustable steel detailing company that can deliver within your project’s schedule without compromising on quality.

7. Understand Pricing and Contracts

Finally, discuss pricing and contracts upfront. Request a detailed quote that breaks down the costs associated with the project. Be wary of detailers who offer significantly lower prices than others, as this could indicate a compromise in quality. Make sure the contract expressly states the conditions of payment, the extent of the task, and any provisions for changes or additional work. Structural steel detailing companies that provide transparent pricing and clear contract terms are often more reliable.

Conclusion

Selecting the right steel detailer is a critical decision that can significantly impact the success of your construction project. By following this checklist, you can ensure that you choose a trustable steel detailing company that is qualified, experienced, and capable of delivering high-quality work on time and within budget. Remember, investing in the right steel structure detailing company is an investment in the safety, durability, and overall success of your project.

#3d modeling#steel detailing services#connection design#steel fabricators#structural steel detailing services#Trustable steel detailing company#steel structure detailing company

0 notes

Text

Successful Completion of Steel detailing Project-Adept engineering

Introduction

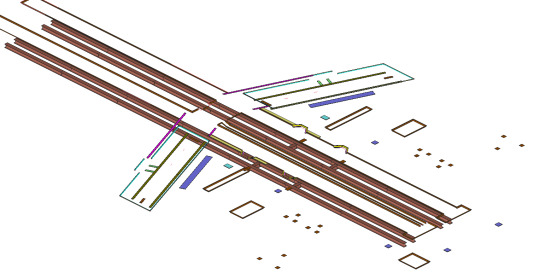

In the competitive field of structural engineering services, precision and adaptability are crucial for delivering successful projects. This case study by Adept Engineering, a leading steel structure detailing company in the USA, highlights a recent project involving miscellaneous steel components, including embed angles, embed plates, and leveling plates, totaling around 30 tons. The project centered on the basement structural steels for Airbus assembly stations, showcasing the team’s ability to overcome challenges and deliver exceptional results.

Project Scope and Initial Challenges

Adept Engineering, recognized among the best steel structure detailing companies in the USA, faced several challenges at the outset. The design drawings provided were in metric units, necessitating conversion to imperial units for modeling. Additionally, the team encountered missing coordination design drawings and discrepancies in angle lengths and assembly quantities. The initial scope of work was also not clearly defined, adding complexity to the project’s initiation.

Effective Communication and Issue Resolution

Approval Process and Strategic Modifications

After resolving initial issues, the team released the miscellaneous steels for client approval. However, during this phase, an alteration in the project numbering system and some unaddressed questions from the Engineer of Record (EOR) posed new challenges. The team quickly organized a Teams call to resolve these issues, demonstrating their commitment to maintaining project momentum.

Fabrication and Project Execution

Following the resolution of approval issues, Adept Engineering, a top steel structure detailing company, modified the model according to the customer’s requirements and released the miscellaneous steels for fabrication, specifically for Station 40. This phase was completed efficiently, reflecting the team’s dedication and adherence to the project timeline.

Expansion of Scope and Final Delivery

As the project progressed, additional tasks, including Station 41 steels and bone pit embeds, were incorporated into the scope of work. These tasks were executed promptly and without delay, further underscoring Adept Engineering’s reputation as one of the best steel structure detailing companies in the USA.

Conclusion

The successful completion of this miscellaneous steel project, despite numerous challenges, underscores Adept Engineering’s expertise in steel structure detailing and structural engineering services. The project not only met the client’s requirements but also set a high standard for future projects. This case study illustrates how meticulous planning, proactive communication, and strategic adaptability can lead to the successful delivery of complex engineering projects, solidifying Adept Engineering’s status as a leader in the industry.

#3d modeling#structural steel detailing services#connection design#steel fabricators#steel detailing services

1 note

·

View note

Text

https://www.adept-engineering.com

Why 3d modelling and detailing important in steel structure engineering?

The Importance of 3D Modeling and Detailing in Steel Structure Engineering

In the world of construction and engineering, precision and accuracy are paramount, especially when dealing with steel structures. The advent of 3D modeling and detailing has revolutionized how these structures are designed, fabricated, and erected. This technology not only enhances the efficiency of the construction process but also ensures the integrity and safety of the final product.

Enhanced Visualization and Design Accuracy

One of the most significant advantages of 3D modeling in steel structure design is the ability to visualize the entire structure before construction begins. Traditional 2D drawings often leave room for interpretation, which can lead to errors in the construction phase. With 3D modeling, engineers and designers can create a virtual representation of the structure, allowing them to see the exact dimensions, connections, and potential interferences. This detailed visualization helps in identifying design flaws early, reducing the need for costly changes during construction.

Improved Collaboration and Communication

3D modeling facilitates better collaboration among all stakeholders involved in the project, including architects, engineers, fabricators, and contractors. By working with a detailed 3D model, all parties can view the same information, leading to fewer misunderstandings and better communication. This collaborative approach ensures that everyone is on the same page, which is crucial for the successful completion of any construction project.

Precision in Fabrication and Construction

The accuracy provided by 3D modeling translates directly into the fabrication and construction phases. Detailed 3D models can be used to generate precise shop drawings and material lists, ensuring that all components are fabricated to exact specifications. This precision reduces waste, minimizes errors, and leads to a more efficient construction process. Additionally, the ability to detect and resolve potential issues before they occur on-site can save time and resources.

Risk Mitigation and Safety

Safety is a critical concern in any construction project, particularly when dealing with steel structures. 3D modeling allows engineers to conduct thorough analysis and simulations, assessing how the structure will perform under various conditions. By identifying and addressing potential issues before construction begins, 3D modeling helps mitigate risks and enhances the overall safety of the structure.

Conclusion

The importance of 3D modeling and detailing in steel structure engineering cannot be overstated. From enhanced visualization and design accuracy to improved collaboration, precision in fabrication, and risk mitigation, this technology plays a crucial role in modern construction practices. By adopting 3D modeling, the industry can continue to push the boundaries of innovation, ensuring the creation of safe, efficient, and cost-effective steel structures.

#3d modeling#connection design#steel detailing services#steel fabricators#structural steel detailing services#advance steel#tekla#sds2

1 note

·

View note