Aefab Annapurna Engineering - Manufacturer and Fabricators of SS & MS tanks, vessels, reactors, heat exchangers & process equipment for industries like chemical, steel, gas, mining & infrastructure. See more : https://Aefab.In/

Don't wanna be here? Send us removal request.

Text

The Benefits Of Using A Stainless Steel Mixing Tank With AgitatorFor Mixing Chemicals

The chemical processing industryfaces an enduring challenge such as equipment breakdowns, product contamination, and escalating maintenance costs. How do you mix aggressive chemicalsreliably and safely? Here comes the stainless steel mixing tank with agitator- a robust and enduring solution to address these challenges.

These mixing tanks are specially engineered to withstanddemanding chemical environments. They offer a safe blend of corrosion resistance, durability, purity, and operational efficiency. Undoubtedly, they are the best solution for any forward-thinking industrial operation.

Top Benefits Of Using Stainless Steel Mixing Tank With Agitator

Unyielding Resistance

When it comes to chemical mixing applications, stainless steel offers exceptional corrosion resistance. It acts as a solid barrier, protecting the underlying metal from corrosion by different chemicals.

Consider the manufacturing of specialty chemicalswhere different and aggressive reactions are common. This is where the corrosion resistance of stainless steel boosts the lifespan of the mixing equipment. It can reduce the frequency and cost of replacements.

Built to Last

Everyone knows that industrial environmentsare naturally demanding. They involve continuous operation, changing temperatures, and often abrasive materials. A stainless steel mixing tank with agitator is specially designed to handle these conditions. With strength and robust construction, they can withstand high mechanical stresses from agitators,thermal cycling from exothermic reactions and the occasional impactoccurring in production facilities.

The durability of these tanks ensures longevity. You might be assuming about the slightly higher cost. However, the improved operational life of this tank gives you the best return in the long run.

They can resist the corrosive nature of the ingredients and endure the continuous agitation and difficult cleaning cycles for years.

Easy Maintenance and Cleaning

Many chemical processes in pharmaceuticals, food and beverage, and biotechnology demand strict hygiene standards. The smooth, non-porous surface of Stainless steel makes it easy to clean and sanitize. It lessens downtime between batches, lowers labor costs, andmitigates the risk of cross-contamination.

Uncompromised Purity

In many chemical applications, make sure about the product purity. This is where the non-reactive nature of stainless steel is vital.It does not leak chemicals into the productdoes it react with the mixed ingredients.

Operational Versatility

Many chemical reactions require precise temperature and pressure control. Stainless steel mixing tanks are capable enough to operate at different temperatures and pressures. They are versatile for diverse chemical processes.

In addition, a stainless steel tank is designed and fabricated to ASME standards. By safely containing these conditions, they ensure operational safety and process efficiency.

Conclusion

The challenges faced by industrial buyers, chemical engineers, and facility managers can be solved by a stainless steel mixing tank with agitator. Are you looking for the best stainless steel mixing tank? With decades of expertise and a dedicated Kolkata-based facility, Aefab Annapurna delivers high-quality, customized agitator tanks built with precision and reliability. Choose us for durable, efficient solutions tailored to your specific industrial needs.We ensure the best and most affordable deal. Learn more at www.aefab.in.

#agitators#business#mixing tanks#industrial#industrial chemical reactors#industrial equipment#industrial engineering#manufacturer#stainless steel fabricator#stainlesssteel#stainless steel mixing tank with agitator

0 notes

Text

https://aefab.in/stainless-steel-ss-fabricator-fabrication-kolkata/

Get in touch with us for the Fabrication of Stainless Steel. We fabricate durable stainless steel components. We prioritize clear communication, working with you to ensure the final product perfectly matches your vision. For top-quality fabrication using stainless steel that stands the test of time, reach out and let's discuss how we can help build your project. For more information, you can call us or WA at +91 98741 63645.

#agitators#business#mixing tanks#industrial#industrial chemical reactors#industrial engineering#industrial equipment#manufacturer#stainless steel fabricator#stainlesssteel

0 notes

Text

The Ultimate Guide To Choosing Your Next Agitator Tank: Read Before You Buy

Are you interested in buying an Agitator Tank? You choose these tanks based on your factory’s process requirements. They ensure that your products are of higher quality, the process runs smoothly, and you work with fewer hassles.

Understanding The Basics: The Important Parts Of An Agitator Tank

Agitator tanks are tanks that mix industrial liquids. In these tanks, agitators blend substances in the chemical, food, and pharmaceutical industries. Agitators play a role in reactions, make sure liquids are the same, and help control heating or cooling.

The key parts of these tanks are a motor, gearbox, shaft, and impellers that are inside the tank. The agitator is fixed into a stand and moves the content inside the agitator tank to ensure even mixing.

The Ultimate Guide To Choosing Your Next Agitator Tank

Identifying Your Needs

Determine your specific process requirements. This process helps to make sure you get the best performance from your selected equipment. Let the mixing task be clearly identified as blending, solid suspension, gas dispersion, emulsification, heat transfer, or dissolving.

Characterizing the Materials

You should consider the physical and chemical traits of the ingredients before designing the agitator tanks. Consider the viscosity, density, solids characteristics, chemical compatibility, temperature and pressure, and consider the desired outcome.

Types of Agitator Impellers

Impellers are offered in multiple designs to match a variety of mixing tasks you might have. Most of the time, impellers are sorted according to the pattern of flow they create. The impeller you select should match the tank’s dimensions, the fluids' features, and your desired goal for the process.

Things You Need to Look at Before Buying a Tank

When purchasing an agitator tank, make sure to look at important tank features like material of construction, size and geometry, agitator assembly specifics, motor power and speed, shaft design and seals, and operational factors.

Choosing An Agitator Tank Is A Decision That Involves Many Factors

Make sure you know what needs to be mixed, what materials are used, and what the results should be.

Get in touch with a manufacturer who produces agitator tanks. They will provide important help when you choose the proper tank.

Make sure the tank is flexible enough to handle your future needs.

Match your needs with the best value by looking at quotes from a number of suppliers.

It is also important to learn about the installation, running, and upkeep of your tank. The tank should be managed correctly throughout its whole life.

Buy your agitator tank today! We produce our agitator tanks professionally with either carbon steel or stainless steel. It is also possible to fit these agitator tanks with jacketing and internal coils for reliable heating or cooling. Learn more at www.aefab.in

#agitators#business#mixing tanks#stainless steel fabricator#industrial chemical reactors#industrial#stainlesssteel#industrial engineering#industrial equipment#manufacturer

0 notes

Text

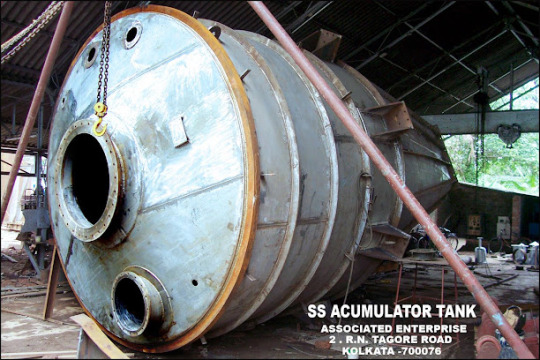

Looking for a reliable manufacturing team for SS Fabrication? You have come to the right place. From Stainless Steel Pressure Vessels, Storage Tanks, Reactors, Mixing Tanks to Structures, we’ve got you covered with our exceptional SS fabrication services. For more information, you can call us or WA at +91 98741 63645.

#agitators#industrial chemical reactors#mixing tanks#stainless steel fabricator#stainlesssteel#business#industrial#industrial engineering#industrial equipment#manufacturer#Ss Fabrication

0 notes

Text

Shop for an Agitator Tank Mixer online! We ensure the best yet affordable deal. We guarantee delivery on time, every time, through a structured Project Management Approach. Quality Product & Process through a well-defined and established QAP. For more information, you can call or WA us at +91 98741 63645.

1 note

·

View note