Don't wanna be here? Send us removal request.

Text

How Ball Bearings Races are Manufactured?

Rotary bearing, regardless of whether they are ball, roller, plain or needle heading, is utilized in practically any application including revolving movement, for example, auto wheels, dentist drills, machine device axles, draw spans, engines, siphons and a huge number of different applications.

Ball bearings races are moving component heading that utilization balls to isolate the bearing races and give smooth, low contact movement in turning applications. Metal balls are made in many sizes, from the tiny 1.50 mm measurement bearing for use with scaled-down clinical gadgets and miniature engines, to orientation more than 15 feet in the distance across for use in heavy hardware.

The following process applies to the vast majority of standard ball bearings produced today.

Components-

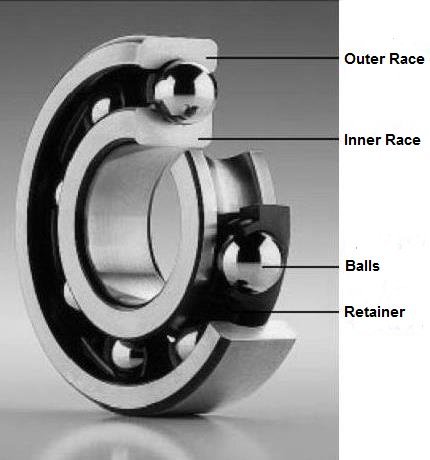

Ball bearings are contained two bearing rings (or races), balls and (contingent upon the kind) a retainer to keep up ball division. Extra segments, for example, seals and safeguards might be available also, yet this article will zero in on the primary bearing parts of rings, balls and retainer.

Materials-

The vast majority of bearings are manufactured from chrome steel, but many materials are used to maximize bearing performance and life.

0 notes

Link

Find bearing race at the best price at Agrasen Engg. Different types of bearing rings are available at our store. Visit the link for more info.

0 notes

Text

Important Aspects About Machined Parts You Should Know

Machined parts are things we utilize everyday basis. Truth be told, we rely upon them. The following are aspects about Machined parts in any modern set up.

Machining of parts is an interaction where a piece of crude material is sliced to fit explicit estimations. All things considered, the last shape, size, or configuration accomplished is through material evacuation. The cycles of machining parts utilizing material evacuation is known as subtractive assembling.

Machined parts are things we utilize everyday basis. Truth be told, we rely upon them. They range from easy to unpredictable plans, utilized as either spare parts or tooling surfaces. Then, you need specially machined parts to be production line made in a way that is speedy, modest, and with the legitimate method.

Below are some critical aspects illustrating the use of machined parts in any industrial setup;

Extremely Accurate to Guarantee Quality-

They are usually dependable. Notably, because of the three aspects of machining accuracy attributed to all forging parts. These include the aspects of dimensional accuracy, positional accuracy, and shape accuracy.

Support Design Verification to be More Reliable-

Contrasted and the 3D printed model, the machined model can utilize end-use plan materials to meet the genuineness of the model capacity confirmation. machining preparing for model parts can arrive at a precisely high exactness, which can fulfill the check of item size and fit.

They are Time Effective-

Machined parts are pre-designed with features that work with simple collecting. For example, if a specific industry requires machined parts for assembling reasons, they can make a request. Plus, you can alter, particularly if you need a precise part.

Can be Easily Customizable-

Indeed, this is an advantage, if not a big plus for forging tools. For example, using the diamond tool for machining parts of aluminum, here the tool would be perfectly finished with the custom aluminum parts with exact accuracy and a really great light-reflecting effect for optical usage.

0 notes

Link

Agrasen Engg can produce a wide range of forgings in copper and aluminum. Hot Forging India helps our customers to reduce the component weights, achieved complex shapes without having to add a lot of machining operations.

0 notes

Text

The Basic Knowledge of Bearing Ring Forging

Bearing rings are a significant piece of moving bearing, its weight is about 60%-70% of the complete bearing.

Bearing races have forging, cold expulsion, warm expulsion, line and bar, and so on, types, produced bearing rings are involved 85% of the all total number of clear rings.

It has the accompanying sorts of directions: Deep notch metal balls, Spherical roller course, Cylindrical roller orientation, Tapered roller heading.

Bearing clear handling is the initial step for bearing creation measure, the nature of the ring clear is fortunate or unfortunate, the degree of efficiency, that will the critically affect the nature of items, execution, life and the monetary advantages of endeavors. Since the size of the clear quality (counting the clear shaping strategy) will decide the bearing material usage, the interior nature of the ring including the thickness of the material, metal fiber smooth out dispersion, grain size, and distortion heat treatment) will greatly affect bearing life.

Blank size scattering and calculation accuracy is the principal justification dismissal rate, inaccessible computerized creation, the effect of follow-up measure handling quality (mistake duplicate) the fundamental explanation. Clear preparing innovation, ring moving gear precision and execution decide the nature of clear. Bearing clear will affect

turning and machining accuracy and the quality of turning will affect grinding accuracy and efficiency.

0 notes

Link

Agrasen Engg. is an Indian company for Near Net Shaped Forgings and Auto components. Agrasen is serving multiple locations all over the world through its high-end Forging parts, Heat Treated parts, Machining parts.

0 notes

Text

All About Forging and its Process

Forging method is maybe the most established metal working cycle and was known even, during ancient days when metallic apparatuses were made by warming and pounding.

Forging is fundamentally included plastic deformity of material between two passes on to accomplish wanted arrangement. Contingent on the intricacy of the part manufacturing is completed as open pass on producing and shut bite the dust fashioning.

In open kick the bucket manufacturing measure, the metal is packed by rehashed passes up a mechanical mallet, and shape is controlled physically.

In closed die forging, the desired configuration is obtained by squeezing the workpiece between two shaped and closed dies.

Types of forging methods:

Based on the method of force application

Hand forging (Drop hammer type)

Machine forging (Mechanical or hydrostatic forging)

Hand forging

Hand hot forging consistently utilizes drop hammer type. Since the nonstop power by the human hand, it isn't adequate to deliver the misshaping in the workpiece.

Machine forging

In machine forging due to the necessary power is acquired from machine it is feasible to utilize either ceaseless power application or irregular effect load application.

Based on the method of shape obtained

Open die forging

Closed die forging

Semi die forging

Open die forging

In open die forging operation only drop hammer type of force application will be used.

Press forging is not used since there is no time fr changing the position of the component.

Features of open die forging:

Repeated impact blows are given on the work.

Less dimensional accuracy.

Suitable only for simple shapes of work.

Requires more skill of the operator.

Usually used for work before subjecting it to closed die forging (to give approximate shape.

Dies are simple and less expensive.

It can be analyzed much easily.

It is the simplest of all forging operations.

Closed die forging

Closed die forging is likewise called as impression kick the bucket manufacturing because the state of the passes on is dazzled on the part.

In this, the sort of producing power application might be either press manufacturing type or drop hammer type will be utilized.

0 notes

Link

Agrasen Engg. is an Indian company for Near Net Shaped Forgings and Auto components. Agrasen is serving multiple locations all over the world through its high-end Forging parts, Heat Treated parts, Machining parts.

0 notes

Text

How Hatebur AMP Solved a Shearing Production Problem?

Automotive component producers depend on manufacturing presses and shearing frameworks to change metal bars into parts. The presses work effectively, yet when the metal bars are sheared to length, visual quality assessment and extra machining are required. The shearing interaction straightforwardly influences the nature of the car part, a measure of machining required, utilization of material, and, at last, creation cost. Hatebur AMP did some exploration and collaborated with Moog to incorporate a servo-pressure-driven valve to direct shearing powers and control their consequences for the eventual outcome.

For quite a long time, automotive component creators have depended on hot forging presses and shearing frameworks to change metal bars into top-notch parts, for example, driveshafts, gear haggles rings, to give some examples. Segment creators turn out a huge number of parts yearly. The presses without a doubt work quickly and proficiently, at the same time, says Vulcan, after metal bars are cut, visual quality investigation and extra machining are required. So, the objective was to improve shearing quality.

Shear Madness-

At a rate between 50-80 sections each moment, the presses will (in roughly 60 milliseconds) shear the white-hot to the sparkling white speedster. As indicated, the shearing cycle straightforwardly influences the nature of the vehicle part, a measure of machining required, utilization of material, and, eventually, creation cost.

Uneven Shearing Increases Cost-

The result of this is that a completed forging surface requires further machining, and the machine administrator acknowledges squander on the clear. This expands producing time and expenses. One motivation behind why a machine proprietor would bear a not exactly amazing sheer quality and the subsequent breakouts is that tending to the issue requires changing the shearing cutting edge or changing the shear point.

Illustrating the Procedure-

The servo-hydraulic-powered bar stop and shearing procedure takes 0.1 milliseconds for the change to force control. The duration of the force control depends on bar diameter and stroke rate. For the machine Vulcan and his team worked with, the force control varied from approximately 75-150 milliseconds.

0 notes

Link

Agrasen Engg. is an Indian company for Near Net Shaped Forgings and Auto components. Agrasen is serving multiple locations all over the world through its high-end Forging parts, Heat Treated parts, Machining parts.

0 notes

Text

Agrasen Engineering and Hatebur – together on the innovative track

Agrasen Engineering Pvt Ltd got featured on the cover story of the Netshape Magazine published by Hatebur. Not less than a fairytale, this is a story of hard work, passion, and determination. It all started back in 1968 by Mr. Vinod Agarwal and three others at the backyard of a house in Pink City of Jaipur. With no engineering experience, he started learning and working on bearings machines. From there to one of India’s leading manufacturers of automotive components, Agrasen has come a long way. Experience a case study for every startup, a successful business model, and what not else in this story. Read how Agrasen has become what it is today with the use of hot forming machines from Hatebur.

Hatebur’s service packages offer customers a broad spectrum of specialized knowledge in order to operate forming systems reliably. Options include training sessions on tool design, machine operator training and maintenance. They are made up of basic and refresher training sessions, or individual, customized training sessions. Hatebur specialists also provide expertise and production support for complex formed parts. Offered either in relation to a machine purchase or as a separate service, the training sessions are led by experienced specialists who work on all aspects of Hatebur forming machines every day. Customers’ new employees in particular benefit directly from Hatebur’s many years of expertise.

0 notes

Link

We are leading manufacturers of Automotive Component, Forged, Machined and Customized Bearing Races in India since 1984 | Agrasen

0 notes

Text

Excellent Grain Flow for Increased Component Life

One of the significant advantages of forging is grain flow; indeed, excellent grain flow can lead to increased component life.

Let's take a sneak peek into the process to develop a detailed understanding.

The initial step starts with forging shape here; the metal flows in the rib region. Gradually the metal contours into the shape of the forging die. Many forgings can be produced depending on the shape. When the billet is initially extracted, it is horizontal in shape. Perform actions are carried out to confirm the billet into the desired shape. Cross-wedge rolling is also performed many times. Even flow of material is essential to get the desired shape. Geometric flow and material defects can cause the material to flow in an undesirable direction. The overall process is dependent on forging shape, material behaviour, and the process. If you want unmatched quality, it is essential to take care of every step.

It is essential to take into account the grain flow sensitivity. The degree of isotropy of the forged material determines the grain flow sensitivity. Two-way communication between the design engineer and forger can help in a better outcome.

Importance of forging and excellent grain flow:

In the forging process, a compressive force is applied to the metal for deforming it: this process seal cracks and close empty spaces within the metal. The right grain flow can lead to an increase in tensile strength.

Fatigue resistance: the grain flow helps in fatigue resistance and can help in greater life expectancy of the metal

Extends design limits: The excellent grain flow helps in the curation of many designs.

The grain flow boosts fatigue life: The proper grain flow provides higher strength in cross-sections.

Proper grain flow helps in cost-effectiveness: This process is highly utilized in automotive and aerospace components. Also, this helps in weight savings. Proper grain flow can lead to reduced inspection and testing. Indeed, the forgings do not need periodic inspections like the normal welded products, and hence this is a cost-effective option.

Excellent grain flow helps in the increased life of auto components. Research indicates that a more significant number of automobile companies prefer grain flow compliant parts.

The proper grain flow can fix all defects in metal forging and help curate perfect products.

At Agrasen Engineering we focus on the right process flow to meet customer requirements. Our process is focused on designing the right products, and we believe right quality first. This impeccable quality is the reflection of perfection. This has won us, several satisfied clients, from all over the globe. With one of the best manufacturing setups in the industry, Agrasen Engineering can cater to your needs of complicated Hot Forged parts.

0 notes

Link

Our Products include Bearing Races, Automotive Components, Forged rings, Heat Treated rings, Machined Rings, Customized Rings | Agrasen

0 notes

Text

What is Hot Forging Manufacturing and its Undoubted Benefits?

Are you associated with the construction or manufacturing industry? Well! Then you must have heard the term ‘Forging’ a million times. If you lack a proper understanding, then don’t sweat it out, scroll down below to learn the nitty-gritty of Forging.

Let us delve into some important details.

What is meant by Forging?

Forging is a popular method of deforming metals into a specified shape. In this process, a compressive force is applied to the steel billets or ingots so that the metals change the shape while still in the solid-state. Forging is done to strengthen the metals, and post Forging; the metals will respond better to the heat treatments and have better fatigue resistance. Forging is utilized in a plethora of industries, some of them being aerospace, automotive parts, construction, medical supplies, and many more.

What are some Forging Manufacturing processes?

Now that you have familiarized yourself with the definition let’s learn more regarding the Forging manufacturing process.

The Forging process can be broadly classified into the below types:

Cold Forging-

Cold Forging can produce a diverse range of shapes. The cold Forging is carried out below the recrystallization temperature of the metal. This process is more popular with softer metals and alloys. Cold Forging is a popular Forging Manufacturing process.

Press Forging

Press Forging is another popular Forging method where continuous force is applied to deform the metal completely.

Drop hammer Forging

In the drop hammer Forging manufacturing, the hammer is utilized, and it is lifted and dropped in the metal. In this process, only the surface of the metal is deformed. The drop hammer technique can be further classified into the below types:

Open die drop

As the name suggests, this procedure does not cover the work piece completely. The hammer can strike the metal piece many times before the desired shape is achieved.

Closed-die Forging or impression-die Forging:

The closed die Forging deals with pressing metal between two dices.

This is just the tip of the iceberg. Forging has many other popular techniques than the ones mentioned above. The most popular method is Hot Forging.

What is Hot Forging Manufacturing and what are the benefits associated?

The hot Forging technique is carried out above the recrystallization temperature. Here heat is applied to deform the original metal into the desired shape. Hot Forging treatment makes the materials more ductile. Also, through the hot Forging treatment, you can fabricate customized products. This process is more convenient as compared to cold Forging.

Why Agrasen on par with finest Hot Forging Manufacturing?

Agrasen is a leading auto component manufacturer and is a pioneer in Hot Forging. We have built up excellent reputation over the years as a Quality Supplier and you can find here a plethora of Forging Products — Be it Bearing Rings, Ger Banks, CVJ Parts, Cam Lobes, Stub Axels and many more. We are preferred supplier for High volume Critical Application Parts. At Agrasen, we are fanatical about quality, and by engineering your dreams with us, you can expect the best in every forging product. Consider putting us to the test as we are better than the rest. Call us to know more regarding our forging products.

0 notes

Link

We are leading and Certified manufacturers of Forged, Machined, Customized and Heat Treated Bearing Rings in India since 1984 | Agrasen

0 notes

Text

Why Agrasen Process are Near Benchmark!

Agrasen Engg. is an Indian company for Near Net Shaped Forgings and Auto components. Agrasen is serving multiple locations all over the world through its high-end Forging parts, Heat Treated parts, Machining parts. With world-leading expertise and reliability Agrasen, manufacturing is approved and recognized by global companies including Schaeffler, Timken, ILJIN, NEI, Nachi, JTEKT, NSK, Tata, NRB etc.

Founded in the year 1984, Agrasen Engineering is recognized for its unmatched forging products. Agrasen is an IATF 16949, ISO 14001, ISO 45001 certified company, Our Consistent performance, out of the box innovation, precision, world-class technology and machinery and our team of experts helped us to be one of the leading auto component manufacturers in India. With an installed capacity of 200 million bearing rings and automobile components per annum, our manufacturing facilities are amongst the best in the industry.

Our Manufacturing Facilities Includes:

Forging Shop: Our forging shop consists of high-speed horizontal hot formers – battery of Hatebur AMP-30S, Hatebur AMP50-9 HFE and vertical forging lines with hot ring rolling.

Annealing Shop: Our annealing shop is operated and maintained as per CQI-9 guidelines that ensure 100% quality product meeting all quality requirements.

Cold Rolling Shop: Our cold rolling shop had been adopted to deliver the best quality rings with refined grain flow and controlled expansion of the material.

Machining Shop: Our machining shop is a state-of-the-art facility with CNC turning centers, vertical machining centers, Robo-drills, grinding machines and single spindle SPM’s.

Heat Treatment: Our heat treatment facility is a CQI-9 qualified facility with Continuous cast link belt furnace suitable for parts with a diameter range of 20 to 140mm.

Agrasen Engineering thrives to constantly deliver its clients the best products, our skilled team is dedicated to delivering perfection beyond expectations.

0 notes