Text

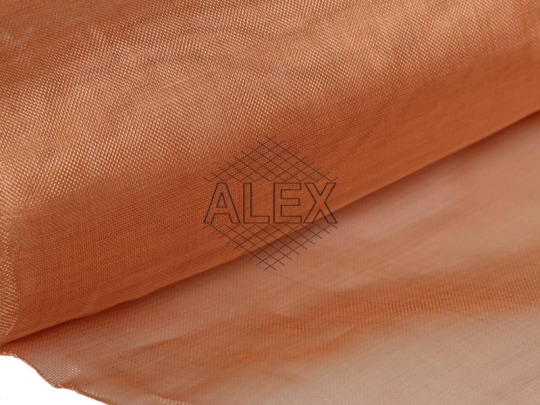

Red Copper Wire Cloth

Red Copper Mesh

Structural Advantage

(1) Red copper wire cloth offers exceptional shape stability during long-term application.

(2) It maintains high integrity under heat and vibration.

(3) It prevents dimensional distortion during harsh working conditions.

(4) It withstands repeated stress without permanent deformation.

(5) It provides excellent balance between flexibility and strength.

(6) It eliminates risk of fatigue cracking under dynamic load.

(7) It supports structural consistency over time.

(8) This wire cloth holds its grid alignment throughout continuous use.

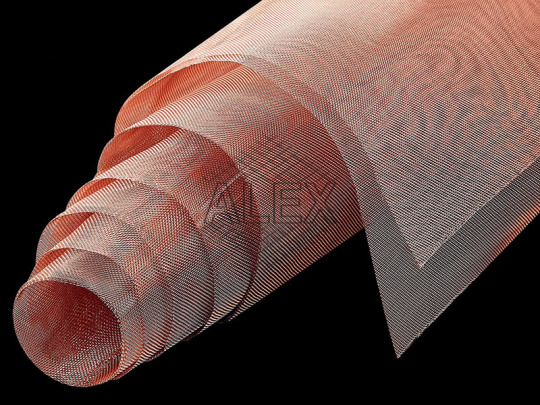

Red Copper Wire Mesh

Thermal Performance

(1) This copper wire mesh performs well in high-temperature environments.

(2) It resists thermal shock during rapid temperature change.

(3) It allows optimal heat distribution without failure.

(4) It handles elevated temperatures while maintaining integrity.

(5) It resists softening during extended heating cycles.

(6) It ensures consistent thermal conduction performance.

(7) It prevents performance loss in furnace or oven settings.

(8) It retains conductivity even at extreme heat levels.

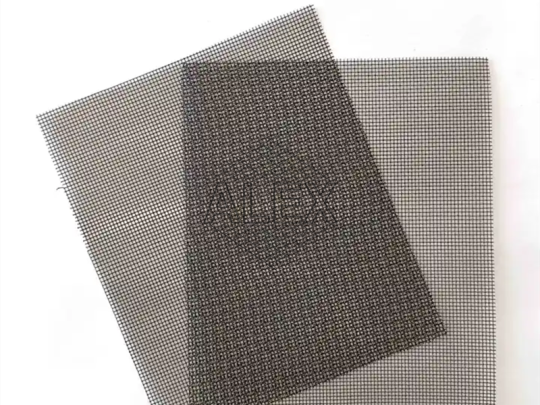

Red Copper Wire Net

Surface Conductivity

(1) Red copper wire cloth enhances electronic signal transfer capability.

(2) It supports stable electromagnetic shielding.

(3) It delivers low resistance across the surface area.

(4) It prevents signal interference within devices.

(5) It aids in reliable electrochemical processing.

(6) It keeps consistent electrical flow in industrial circuits.

(7) It improves grounding efficiency in sensitive applications.

(8) This wire mesh offers precision connectivity across contact points.

Red Copper Wire Screen

Industrial Application

(1) This wire screen finds use in petrochemical filtration.

(2) It supports shielding in aviation electronics.

(3) It suits precise sieving in pharmaceutical production.

(4) It improves safety in spark-proof environments.

(5) It delivers performance in battery electrode construction.

(6) It fits usage in semiconductor vapor deposition.

(7) It maintains purity in chemical catalyst processes.

(8) It ensures filtration efficiency in gas pipelines.

Red Copper Screen Mesh

Material Sustainability

(1) Red copper wire cloth enables high material recyclability.

(2) It reduces waste in continuous production cycles.

(3) It supports eco-conscious engineering strategies.

(4) It aligns with green product compliance.

(5) It contributes to lower carbon manufacturing footprints.

(6) It minimizes raw resource dependency.

(7) It maintains value during reuse or recovery.

(8) This screen mesh guarantees long service life with minimal degradation.

Source From: Red Copper Wire Cloth

#Copper Mesh#Copper Wire Cloth#Copper Wire Grid#Copper Wire Mesh#Copper Wire Net#Copper Wire Screen#Red Copper Mesh#Red Copper Net#Red Copper Wire Cloth#Red Copper Wire Grid#Red Copper Wire Mesh#Red Copper Wire Net#Red Copper Wire Screen#Red Copper Wire Screen Mesh

0 notes

Text

Red Copper Wire Net

Red Copper Mesh

Electrical Performance

(1) Red copper wire net delivers high conductivity and stable signal flow.

(2) It resists voltage drop effectively in precise electrical application.

(3) It improves circuit efficiency by reducing internal resistance.

(4) It supports electromagnetic shielding in control cabinet setup.

(5) It ensures uninterrupted current path with excellent reliability.

(6) It withstands thermal overload during heavy electrical load.

(7) It maintains connectivity without sparking or degradation.

(8) This wire net offers unmatched continuity in delicate wiring layout.

Red Copper Wire Mesh

Industrial Functionality

(1) This copper wire mesh supports fine filtration during mechanical process.

(2) It allows excellent separation in high-temperature environment.

(3) It controls airborne particle entry with precise mesh size.

(4) It facilitates smooth gas flow in pressure-regulating device.

(5) It serves as a barrier in processing system protection.

(6) It withstands repeated use in oil and fuel screening task.

(7) It enhances system efficiency through stable barrier design.

(8) It delivers reliable reinforcement in equipment frame area.

Red Copper Wire Cloth

Decorative Value

(1) Red copper wire net brings warm tone into interior layout.

(2) It creates a vintage aesthetic for retail or gallery setup.

(3) It provides natural contrast in modern furniture arrangement.

(4) It adds texture on cabinet or ceiling surface design.

(5) It complements lighting fixture with minimal obstruction.

(6) It supports ventilation without affecting visual harmony.

(7) It improves style uniformity across space division scheme.

(8) This wire mesh provides unique accent in hotel reception background.

Red Copper Wire Screen

Durability Factor

(1) This wire screen withstands corrosion from humid exposure.

(2) It tolerates salt air when installed in marine surrounding.

(3) It endures structural pressure without breaking down.

(4) It remains functional after direct heat or UV contact.

(5) It holds mechanical integrity in vibration-prone location.

(6) It retains structure after long operational period.

(7) It delivers stable support in fluctuating environmental setting.

(8) It ensures lifetime application with minimal replacement need.

Red Copper Screen Mesh

Custom Application

(1) Red copper wire net adapts easily to user-specific size request.

(2) It supports etching or framing for fine project detail.

(3) It suits laboratory enclosure or sensor shielding function.

(4) It permits shaping for sound diffusion in audio housing.

(5) It provides compact design for aerospace component surface.

(6) It integrates smoothly into artistic model construction.

(7) It achieves perfect alignment in filtration system interface.

(8) This screen mesh meets critical dimension in architectural concept panel.

Source From: Red Copper Wire Net

#Copper Mesh#Copper Wire Cloth#Copper Wire Grid#Copper Wire Mesh#Copper Wire Net#Copper Wire Screen#Red Copper Mesh#Red Copper Net#Red Copper Wire Cloth#Red Copper Wire Grid#Red Copper Wire Mesh#Red Copper Wire Net#Red Copper Wire Screen#Red Copper Wire Screen Mesh

0 notes

Text

Red Copper Mesh

Red Copper Wire Mesh

Electrical Application Benefit

(1) Red copper mesh provides stable conductivity in low-voltage environment.

(2) It enhances circuit integrity under continuous electrical stress.

(3) It delivers consistent signal transmission across narrow wiring space.

(4) It resists corrosion from regular industrial current exposure.

(5) It supports microcurrent flow with minimal resistance.

(6) It reduces overheating risk during prolonged operation.

(7) It strengthens contact point between wire and terminal.

(8) This wire mesh maintains performance under electrical fluctuation.

Red Copper Wire Net

Filtration Performance

(1) This copper wire mesh offers precise particle separation for chemical process.

(2) It withstands acid impact during fluid filtration.

(3) It blocks unwanted particle using uniform aperture control.

(4) It supports long-term usage in refinery pipeline system.

(5) It delivers filtration accuracy under stable temperature.

(6) It eliminates minor impurity from liquid during flow.

(7) It maintains performance in low-pressure zone.

(8) It resists surface clogging from fine debris.

Red Copper Wire Screen

Thermal Management Efficiency

(1) Red copper mesh distributes heat evenly across metal surface.

(2) It assists heat sink efficiency in mechanical assembly.

(3) It absorbs thermal rise from surface friction.

(4) It regulates thermal fluctuation within device enclosure.

(5) It enhances heat transfer through air or contact.

(6) It balances temperature change during operation.

(7) It holds thermal stability in heating component.

(8) This wire net reduces cooling time between operational cycle.

Red Copper Wire Cloth

Decorative Purpose

(1) This screen mesh creates vintage style in architectural design.

(2) It reflects ambient light for warm-toned interior.

(3) It forms artistic texture for indoor partition screen.

(4) It resists tarnish in exposed environment.

(5) It adds value to custom furnishing project.

(6) It maintains rich copper tone over time.

(7) It upgrades design with handmade appearance.

(8) It supports flexible cutting for personalized application.

Red Copper Screen Mesh

Shielding Function

(1) Red copper mesh protects sensitive device from electromagnetic signal.

(2) It surrounds enclosure with tight wave resistance.

(3) It interrupts signal noise for radio system.

(4) It sustains shielding under mechanical vibration.

(5) It reduces field interference in communication module.

(6) It maintains conductivity across frequency range.

(7) It acts as physical boundary for magnetic field.

(8) This wire screen stabilizes transmission inside shielded enclosure.

Source From: Red Copper Mesh

#Copper Mesh#Copper Wire Cloth#Copper Wire Grid#Copper Wire Mesh#Copper Wire Net#Copper Wire Screen#Red Copper Mesh#Red Copper Wire Cloth#Red Copper Wire Grid#Red Copper Wire Mesh#Red Copper Wire Net#Red Copper Wire Screen#Red Copper Wire Screen Mesh

0 notes

Text

Conveyor Belt

Reliable Performance

(1) Conveyor belt guarantees consistent operation.

(2) It ensures smooth material handling throughout the day.

(3) It operates reliably even in high-demand environments.

(4) It offers uninterrupted performance, reducing downtime.

(5) Its stable performance increases production efficiency.

Low Maintenance Requirement

(1) This belt requires minimal maintenance.

(2) Its simple design reduces the chance of malfunction.

(3) Regular cleaning and occasional checks suffice.

(4) Fewer components mean less chance of wear.

(5) Low maintenance cost keeps operation smooth.

0 notes

Photo

Wire Mesh Conveyor Belt For Food

Alex wire mesh conveyor belt for food processing ensures efficiency, hygiene, and durability. With superior design and construction, it meets the highest standards required in the food industry. This conveyor belt optimizes food processing operations with seamless performance.

1: Design Features (1) Made from stainless steel. (2) Resistant to corrosion. (3) Open mesh structure. (4) Enhanced airflow design. (5) High-temperature tolerance. (6) Customizable width options. (7) Various mesh sizes available. (8) Easy integration with systems. (9) Smooth surface finish. (10) Lightweight construction. (11) Sturdy edge finish. (12) Easy to clean. (13) Minimal maintenance required. (14) Long-lasting performance. (15) Safe for food contact.

2: Performance Benefits (1) Improves product flow. (2) Increases production efficiency. (3) Reduces downtime. (4) Maintains consistent quality. (5) Enhances hygiene levels. (6) Withstands harsh environments. (7) Minimizes product damage. (8) Supports heavy loads. (9) Reduces operational costs. (10) Provides uniform heat distribution. (11) Ensures smooth transport. (12) Facilitates easy tracking. (13) Optimizes cooling processes. (14) Speeds up drying time. (15) Allows easy inspection.

3: Applications (1) Baking bread. (2) Cooking meat. (3) Freezing seafood. (4) Cooling vegetables. (5) Drying fruits. (6) Handling dairy products. (7) Conveying snacks. (8) Transporting pasta. (9) Coating chocolates. (10) Processing poultry. (11) Sorting grains. (12) Packaging meals. (13) Frying chips. (14) Grilling burgers. (15) Washing produce.

4: Installation and Maintenance (1) Easy installation process. (2) Fits standard systems. (3) Requires minimal tools. (4) Quick setup time. (5) Step-by-step guide included. (6) User-friendly design. (7) Low maintenance. (8) Accessible components. (9) Regular inspections advised. (10) Simple cleaning routine. (11) Durable materials. (12) Replacements easily available. (13) Cost-effective upkeep. (14) Detailed manual provided. (15) Expert support available.

The product Wire Mesh Conveyor Belt For Food appeared first on Alex Wire Mesh.

#Conveyor Belt#Food Conveyor Belt#Mesh Conveyor Belt#Metal Conveyor Belt#Steel Conveyor Belt#Wire Conveyor Belt#Wire Mesh Conveyor Belt

0 notes

Photo

Balanced Weave Conveyor Belt

Balanced weave conveyor belt offers exceptional performance, catering to various industrial needs with their durability, flexibility, easy maintenance, and efficiency. This conveyor belt ensures smooth, reliable operations, making them an excellent choice for diverse applications.

1: Durability (1) Ensures long-lasting performance. (2) Withstands high temperatures. (3) Resists wear and tear. (4) Handles heavy loads. (5) Maintains shape under stress. (6) Offers consistent durability. (7) Provides reliable strength. (8) Survives harsh environments. (9) Minimizes replacement costs. (10) Requires infrequent repairs. (11) Guarantees extended lifespan. (12) Performs well over time. (13) Resists corrosion. (14) Ensures minimal downtime. (15) Delivers sustained efficiency.

2: Flexibility (1) Adapts to various processes. (2) Offers easy customization. (3) Bends without breaking. (4) Handles complex routes. (5) Simplifies installation. (6) Accommodates different speeds. (7) Works in tight spaces. (8) Adjusts to load changes. (9) Supports multiple applications. (10) Enables smooth transitions. (11) Operates on inclines. (12) Functions in diverse settings. (13) Fits existing systems. (14) Provides versatile solutions. (15) This metal conveyor belt ensures operational flexibility.

3: Easy Maintenance (1) Simplifies cleaning processes. (2) Reduces maintenance time. (3) Requires minimal lubrication. (4) Facilitates easy repairs. (5) Limits operational disruptions. (6) Uses standard parts. (7) Needs infrequent adjustments. (8) Supports quick inspections. (9) Minimizes downtime. (10) Enhances operational efficiency. (11) Ensures easy part replacements. (12) Offers accessible components. (13) Promotes consistent performance. (14) Ensures minimal maintenance costs. (15) Simplifies service routines.

4: Efficiency (1) Boosts production rates. (2) Reduces energy consumption. (3) Ensures smooth operations. (4) Increases output consistency. (5) Minimizes product damage. (6) Enhances workflow. (7) Promotes uniform product handling. (8) Reduces operational costs. (9) Ensures reliable performance. (10) Supports fast processing. (11) Optimizes resource usage. (12) Streamlines production processes. (13) Improves handling accuracy. (14) Maintains steady operations. (15) Promotes effective transport.

The product Balanced Weave Conveyor Belt appeared first on Alex Wire Mesh.

#Conveyor Belt#Mesh Conveyor Belt#Metal Conveyor Belt#Steel Conveyor Belt#Wire Belt#Wire Mesh Conveyor Belt

0 notes

Photo

Toaster Oven Belt

Toaster Oven Belt is also known as oven conveyor belt. This wire belt is the important component which is used in conveyor. It could carry various types of food items, such as bread slices, bagels, or sandwiches.

Efficiency and Convenience (1) Boosts cooking efficiency. (2) Enhances kitchen convenience. (3) Streamlines meal preparation process. (4) Simplifies cooking tasks. (5) Optimizes time management. (6) Facilitates multi-tasking in the kitchen. (7) Promotes hassle-free cooking. (8) Reduces cooking time significantly. (9) Maximizes kitchen productivity. (10) Offers seamless cooking experience. (11) Enables easy monitoring of food. (12) Enhances cooking precision. (13) Minimizes food preparation effort. (14) Ensures consistent cooking results. (15) Improves overall cooking experience.

Durability and Reliability (1) Engineered for long-lasting performance. (2) Built to withstand high temperatures. (3) Resilient against wear and tear. (4) Ensures prolonged usage lifespan. (5) Withstands heavy-duty cooking demands. (6) Reliable performance over time. (7) Maintains consistent functionality. (8) Resistant to corrosion. (9) Endures frequent use without degradation. (10) Provides dependable cooking support. (11) Designed for sustained durability. (12) Guarantees reliable operation. (13) Withstands rigorous kitchen environments. (14) Ensures continuous cooking reliability. (15) Built to endure daily cooking challenges.

Versatility and Adaptability (1) Accommodates various cooking needs. (2) Suitable for diverse culinary tasks. (3) Adaptable to different food types. (4) Versatile cooking accessory. (5) Compatible with different toaster oven models. (6) Supports a wide range of cooking techniques. (7) Facilitates creative cooking experiments. (8) Enhances cooking flexibility. (9) Adjustable for different cooking preferences. (10) Adapts to evolving kitchen trends. (11) Versatile addition to any kitchen setup. (12) Enables experimentation with new recipes. (13) Offers flexibility in cooking styles. (14) Compatible with different cookware. (15) Versatile tool for culinary exploration.

Quality and Performance (1) Ensures premium cooking performance. (2) Delivers consistent cooking results. (3) Guarantees top-notch cooking quality. (4) Enhances food flavor and texture. (5) Maintains cooking temperature accuracy. (6) Ensures even heat distribution. (7) Promotes thorough cooking. (8) Enhances food presentation. (9) Preserves nutritional value of food. (10) Minimizes risk of overcooking or undercooking. (11) Supports precision cooking. (12) Facilitates efficient energy utilization. (13) Promotes superior cooking outcomes. (14) Elevates cooking standards. (15) Exceeds expectations for culinary excellence.

The product Toaster Oven Belt appeared first on Alex Wire Mesh.

#Bakery Oven Belt#Conveyor Belt#Mesh Conveyor Belt#Metal Conveyor Belt#Steel Conveyor Belt#Toaster Mesh Conveyor#Toaster Oven Belt#Toaster Oven Conveyor Belt#Toaster Oven Wire Belt#Toaster Wire belt#Wire Belt#Wire Mesh Conveyor Belt

0 notes

Photo

Bread Baking Oven Belt

Bread Baking Oven Belt is also named bread conveyor belt. It is a metal type of wire mesh conveyor belt for bread oven. As food grade conveyor belt, it is famous in the food field.

1: Introduction

Overview (1) Crafted for precision baking. (2) Elevates baking efficiency. (3) Unparalleled in the baking industry. (4) Unveiling the Bread Baking Oven Belt.

Features (5) Heat-resistant technology at its core. (6) Seamless design for optimal consistency. (7) Enhanced durability for prolonged use. (8) Precision engineering ensures uniform results. (9) This wire belt is easy to clean and maintain.

Benefits (10) Boosts bakery productivity. (11) Delivers consistent and golden-brown perfection. (12) Versatile, accommodating various bread types. (13) Accelerates baking time without compromising quality. (14) Cost-effective solution for commercial kitchens. (15) Elevates the overall baking experience.

Applications (16) Ideal for artisanal bakeries. (17) Perfect for high-volume production. (18) Ensures even baking for delicate pastries. (19) Enhances efficiency in pizza oven setups. (20) Essential for meeting industry standards.

2: Innovation

Design Excellence (1) Revolutionary belt design for precision. (2) Incorporating cutting-edge materials. (3) Engineered for seamless operation. (4) A testament to innovation in baking technology.

Materials Used (5) High-grade, heat-resistant polymers. (6) Advanced composite construction. (7) Resilient against wear and tear. (8) Ensures longevity and consistent performance. (9) Crafted for the demands of professional kitchens.

Technology Integration (10) Smart technology for temperature control. (11) Responsive to diverse baking requirements. (12) Adapts to different oven configurations. (13) Elevates baking precision to new heights. (14) Guarantees a hassle-free baking experience. (15) The bakery wire belt is ideal for modern, tech-driven bakeries.

Environmental Considerations (16) Eco-friendly materials reduce environmental impact. (17) Contributes to sustainable baking practices. (18) Aligns with green kitchen initiatives. (19) Meets regulatory standards for environmental responsibility. (20) A step forward in eco-conscious baking solutions.

3: Industry Standards

Compliance (1) Meets and exceeds industry benchmarks. (2) Compliant with global food safety regulations. (3) Ensures quality in line with international standards. (4) A trusted choice for bakeries worldwide.

Certifications (5) ISO-certified for quality assurance. (6) Endorsed by baking industry associations. (7) Upholds hygiene and safety protocols. (8) Recognized for reliability and performance. (9) Adherence to stringent manufacturing standards.

Customer Satisfaction (10) Positive reviews from leading bakeries. (11) Endorsed by renowned pastry chefs. (12) Enhances customer satisfaction with superior products. (13) Meets the evolving demands of discerning chefs. (14) A testament to customer loyalty and trust. (15) Setting the benchmark for baking excellence.

Global Presence (16) Trusted in bakeries across continents. (17) Exported to diverse culinary markets. (18) Celebrated for consistency on the global stage. (19) A preferred choice in international kitchens. (20) Contributing to the globalization of baking standards.

4: Choosing Bread Baking Oven Belt for Your Bakery

Economic Advantage (1) Cost-effective solution for commercial kitchens. (2) Maximizes return on investment. (3) Reduces operational costs with efficient baking. (4) A strategic choice for budget-conscious businesses.

Ease of Integration (5) Seamless integration with existing ovens. (6) Compatible with various baking setups. (7) Quick and hassle-free installation process. (8) Adaptable to different kitchen layouts. (9) Ensures minimal downtime during implementation.

Training and Support (10) Comprehensive training for kitchen staff. (11) Ongoing support for troubleshooting and maintenance. (12) Accessible customer service for timely assistance. (13) Empowers staff with product knowledge. (14) Ensures optimal performance through continuous support. (15) Choosing ease and reliability in baking solutions.

Innovation for Future Growth (16) Aligns with the trajectory of baking industry advancements. (17) Future-proof technology for evolving bakery needs. (18) A catalyst for innovation in your kitchen. (19) Positions your bakery for sustained growth. (20) Invest in the future of baking with Bread Baking Oven Belt.

The product Bread Baking Oven Belt appeared first on Alex Wire Mesh.

#Bread Baking Belt#Bread Baking Conveyor Belt#Bread Baking Mesh Belt#Bread Baking Oven Belt#Bread Baking Steel Belt#Bread Baking Wire Belt#Bread Conveyor Belt#Bread Oven Belt#Conveyor Belt#Food Grade Conveyor Belt#Mesh Conveyor Belt#Metal Conveyor Belt#Wire Conveyor Belt#Wire Mesh Conveyor Belt

0 notes

Photo

Brass Filter Mesh

Brass Filter Mesh is a popular type of wire mesh. It is also widely known as brass wire mesh for its material.

1: Introduction (1) A cutting-edge solution. (2) Crafted from high-quality brass material. (3) Unparalleled durability and longevity. (4) Exquisite mesh design for optimal performance. (5) Versatile applications across industries. (6) Engineered for efficient filtration processes. (7) Superior corrosion resistance for longevity. (8) Precision manufacturing ensures uniformity. (9) Unmatched reliability in filtering applications. (10) Ideal for liquid and gas filtration needs. (11) Brass construction guarantees sturdiness. (12) Promotes seamless flow in filtration systems. (13) Boosts system efficiency and productivity. (14) Engineered to withstand harsh conditions. (15) Your gateway to premium filtration.

2: Key Features (1) Finely woven brass threads for effectiveness. (2) Singular mesh design for easy maintenance. (3) Resistance to chemical and environmental factors. (4) Each mesh offers consistent filtration precision. (5) Ideal for fine particle separation. (6) High-temperature resistance for diverse applications. (7) Customizable sizes to fit varied systems. (8) Promotes excellent fluid and gas flow. (9) Minimizes clogging for uninterrupted processes. (10) Low-pressure drop ensures energy efficiency. (11) Brass composition inhibits bacterial growth. (12) Easy to install, saving time and effort. (13) Cost-effective solution for long-term use. (14) Enhanced structural integrity for reliability. (15) Elevating filtration standards with this wire screen.

3: Applications and Industries (1) Widely employed in oil and gas industries. (2) Crucial in pharmaceutical manufacturing processes. (3) Automotive sector relies on its precision. (4) A staple in water treatment facilities. (5) Enhances efficiency in chemical processing. (6) Essential for food and beverage production. (7) Used in HVAC systems for clean air circulation. (8) Agriculture benefits from soil filtration. (9) Power plants utilize for fluid purification. (10) Marine industry employs for seawater filtration. (11) Instrumentation relies on precise filtration. (12) Aerospace applications for fuel filtration. (13) Petrochemical refineries ensure purity with it. (14) Mining operations benefit from its robustness. (15) Transforming diverse industries.

4: Choosing Brass Filter Mesh for Your Needs (1) Optimal choice for long-lasting filtration solutions. (2) Brass construction guarantees product longevity. (3) Versatility meets the demands of various industries. (4) Seamless integration into existing systems. (5) Enhanced performance for critical applications. (6) Customizable options for specific requirements. (7) Cost-effective investment in system efficiency. (8) Industry-approved for reliability and effectiveness. (9) Low maintenance ensures hassle-free operation. (10) Resilient against harsh environmental conditions. (11) Precision engineering ensures consistent results. (12) Unparalleled quality for superior filtration. (13) A wise and enduring investment. (14) Boosts overall system productivity. (15) Elevate your filtration standards with this screen mesh.

The product Brass Filter Mesh appeared first on Alex Wire Mesh.

#Brass Filter Mesh#Brass Mesh#Brass Mesh Cloth#Brass Mesh Screen#Brass Screen Mesh#Brass Wire Cloth#Brass Wire Grid#Brass Wire Mesh#Brass Wire Screen#Copper Mesh#Copper Mesh Cloth#Copper Mesh Screen#Copper Net#Copper Screen#Copper Screen Mesh#Copper Wire Cloth#Copper Wire Grid#Copper Wire Mesh#Copper Wire Net#Copper Wire Screen

0 notes

Photo

Window Screen Mesh

Window Screen Mesh is the most popular product. It could elevate home and office security. And it is the tailored solutions for diverse needs.

1: Introduction to Window Screen Mesh (1) Crafted with precision. (2) Unmatched durability. (3) Superior quality materials. (4) Innovative design features. (5) Seamless integration with window or door. (6) Enhanced visibility. (7) Easy installation process. (8) Low maintenance requirements. (9) UV-resistant technology. (10) Optimal airflow. (11) Customizable options. (12) Privacy without compromising light. (13) Pet-friendly attributes. (14) Protection against insects. (15) Energy-efficient solution.

2: Benefits of This Screen Mesh (1) Enhanced security measures. (2) Reduced energy costs. (3) Effortless cleaning. (4) Increased property value. (5) Healthier indoor environment. (6) Style and functionality combined. (7) UV protection for furnishings. (8) Minimized glare and heat. (9) Prevention of allergens. (10) Sustainable and eco-friendly. (11) Extended lifespan of windows. (12) Improved ventilation. (13) Aesthetically pleasing. (14) Enhanced curb appeal. (15) Increased natural light.

3: Choosing the Right Security Screen Mesh (1) Consider the mesh material. (2) Assess the mesh density. (3) Evaluate color options. (4) Measure window dimensions accurately. (5) Choose between fixed and adjustable screens. (6) Inquire about warranty coverage. (7) Verify insect resistance. (8) Check for fire resistance. (9) Explore customization options. (10) Ensure ease of installation. (11) Seek professional advice. (12) Read customer reviews. (13) Compare prices from different suppliers. (14) Look for innovative features. (15) Confirm compatibility with window type.

4: Maintenance Tips for Window Screen Mesh (1) Regularly clean with a soft brush. (2) Avoid abrasive cleaning agents. (3) Inspect for tears or damage. (4) Repair minor damages promptly. (5) Store in a dry place during winter. (6) Lubricate moving parts occasionally. (7) Trim overgrown vegetation near screens. (8) Keep pets away from the screens. (9) Check for rust on metal frames. (10) Replace damaged mesh promptly. (11) Inspect for loose or missing fasteners. (12) Clean tracks and frames. (13) Consider professional maintenance annually. (14) Keep an eye out for mold. (15) Enjoy long-lasting benefits with minimal effort.

The product Window Screen Mesh appeared first on Alex Wire Mesh.

0 notes

Photo

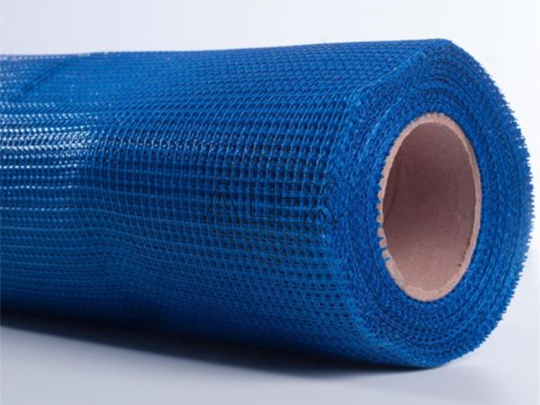

160G Fiberglass Net

160G Fiberglass Net is a high-performance plaster mesh. It is designed to enhance the structural integrity of various construction projects.

1. Technical Specifications (1) Boasting a singular weight of 160 grams per square meter. (2) 160G Fiberglass Net is engineered with precision for enhanced durability. (3) Unparalleled tensile strength ensures long-term performance. (4) Fine mesh structure for optimal coverage and support. (5) Resistant to corrosion, making it ideal for diverse applications. (6) Designed for seamless integration into construction projects. (7) Precision-woven fibers guarantee uniformity and reliability. (8) UV-resistant coating for extended outdoor use. (9) Non-toxic composition ensures safety in various environments. (10) Ideal for reinforcing plaster and preventing cracks. (11) Complies with industry standards for quality assurance. (12) Easy to cut and shape, facilitating versatile installation.

2. Versatile Applications (1) Enhances the structural integrity of walls and ceilings. (2) Provides effective reinforcement in concrete applications. (3) This Screen Mesh is ideal for use in industrial and residential construction projects. (4) Acts as a reliable barrier against insect intrusion. (5) Facilitates the creation of smooth and crack-free surfaces. (6) Suitable for repairing and reinforcing existing structures. (7) Enhances the lifespan of building materials. (8) Supports the formation of robust and long-lasting joints. (9) Ensures uniform plaster application for a polished finish. (10) Enables the creation of lightweight and resilient structures. (11) Perfect for DIY projects due to its easy handling. (12) Adaptable for both interior and exterior applications.

3. Unique Selling Points (1) Unmatched durability for extended product life. (2) Seamless integration with various construction materials. (3) Precision engineering ensures consistent quality. (4) Versatility in applications for diverse project needs. (5) UV-resistant coating for prolonged outdoor exposure. (6) Non-toxic composition prioritizes safety in use. (7) Facilitates easy customization with simple cutting. (8) Engineered for optimal tensile strength and support. (9) Conforms to industry standards for reliability. (10) Resistant to corrosion for long-lasting performance. (11) As Security Screen Mesh, it enables efficient reinforcement of surfaces. (12) Designed for DIY enthusiasts and professionals alike.

4. Installation Ease (1) Simple and straightforward installation process. (2) Easy handling for DIY enthusiasts and professionals. (3) Lightweight design facilitates quick and efficient application. (4) Customizable to fit specific project requirements. (5) Seamless integration with various construction materials. (6) Ensures a hassle-free and time-efficient installation. (7) Compatibility with common adhesives and materials. (8) Step-by-step installation guide for user convenience. (9) Minimal waste due to precision engineering. (10) Reduces labor costs with its user-friendly application. (11) Quick curing time for accelerated project timelines. (12) Adaptable to curved or irregular surfaces for flexibility.

The product 160G Fiberglass Net appeared first on Alex Wire Mesh.

#160G Fiberglass Cloth#160G Fiberglass Grid#160G Fiberglass Mesh#160G Fiberglass Mesh Cloth#160G Fiberglass Net#160G Fiberglass Wall Mesh#160G Fiberglass Wire Grid#160G Fiberglass Wire Mesh#Fiberglass Mesh#Fiberglass Net#Fiberglass Wire Mesh

0 notes

Photo

316L SS Wire Net

316L SS Wire Net boasts high corrosion resistance. Its low carbon content enhances weldability and durability.

1: Material Composition (1) 316L SS wire construction. (2) Low carbon content for enhanced corrosion resistance. (3) High-grade stainless steel alloy. (4) Non-reactive to various chemicals. (5) Ideal for demanding industrial applications. (6) Superior durability and longevity. (7) Anti-rust properties for extended use. (8) Excellent resistance to pitting and crevice corrosion. (9) Maintains integrity under extreme temperatures. (10) Premium quality for critical environments. (11) Conforms to international quality standards. (12) Precision-engineered for optimal performance.

2: Mesh Design (1) Intricate mesh pattern for versatility. (2) Uniform and consistent openings. (3) Precision-woven for strength. (4) Ensures effective filtration. (5) Customizable mesh sizes available. (6) Facilitates efficient airflow and visibility. (7) Suitable for various sieving applications. (8) Mesh integrity for particle retention. (9) Enhances structural stability. (10) Ideal for sieving and filtering operations. (11) Resistant to wear and tear. (12) Easy to handle and install.

3: Applications (1) This Wire Net is widely used in chemical processing. (2) Essential for oil and gas filtration. (3) Ideal for marine and coastal applications. (4) Suitable for pharmaceutical manufacturing. (5) As Security screen mesh, it is critical in aerospace engineering. (6) Facilitates food and beverage processing. (7) Used in architectural and design projects. (8) Crucial in automotive manufacturing. (9) Essential for water treatment plants. (10) Indispensable in electronic component production. (11) Meets strict hygienic standards in the medical industry. (12) Ensures reliability in power generation.

4: Advantages (1) Minimal maintenance requirements. (2) Long-lasting service life. (3) Cost-effective solution. (4) Versatile in various applications. (5) Easy to clean and sterilize. (6) Resistant to abrasion and impact. (7) Non-magnetic properties. (8) Low risk of contamination. (9) High tensile strength. (10) Minimal environmental impact. (11) Contributes to sustainable practices. (12) 316L SS Wire Net complies with industry regulations.

The product 316L SS Wire Net appeared first on Alex Wire Mesh.

#316L SS Wire Mesh#316L SS Wire Net#316L SS Wire Screen#316L SS Woven Wire Mesh#316L Stainless Steel Wire Mesh#SS Wire Mesh#SS Wire Net#Stainless Mesh#Stainless Steel Mesh#Stainless Steel Wire Cloth#Stainless Steel Wire Mesh#Stainless Wire Cloth

0 notes

Photo

Balanced Mesh Belt

Balanced Mesh Belt is also widely known as balanced wire belt. This wire mesh belt could revolutionize your operations.

1: Unique Features (1) Singular design for optimal efficiency. (2) Exceptional durability in diverse industrial applications. (3) Precision engineering for seamless performance. (4) Singular focus on enhancing production processes. (5) Unmatched flexibility for various material handling needs. (6) Maximum strength with a singular weave pattern. (7) Seamless integration with automated systems. (8) Singular tracking system for precision movement. (9) High-temperature resistance for extreme conditions. (10) Singular belt surface for reduced friction. (11) Elevated corrosion resistance for extended lifespan. (12) Singular material choices for specific industry demands. (13) Enhanced safety features with a singular design. (14) Minimal maintenance requirements for cost efficiency. (15) Singular adaptability to different conveyor configurations.

2: Applications (1) Singular solutions for food processing industries. (2) Elevate your packaging efficiency with the belt. (3) Singular role in the automotive manufacturing process. (4) Enhance the textile industry with the technology of this belt. (5) Singular applications in pharmaceutical production. (6) Optimize your metalworking operations with the belt. (7) Singular contributions to the electronics manufacturing sector. (8) Improve wood processing efficiency with the belt. (9) Singular role in the chemical and petrochemical industries. (10) Elevate the performance of glass manufacturing processes. (11) Singular applications in the renewable energy sector. (12) Enhance your mining operations with Balanced Mesh Belt. (13) Singular contributions to the aerospace industry. (14) Optimize agriculture processes with its technology. (15) Singular applications in logistics and distribution centers.

3: Advantages (1) Singularly boost production output and efficiency. (2) Singularly reduce downtime with reliable performance. (3) Enhance product quality with precise material handling. (4) Singularly improve workplace safety standards. (5) Optimize resource utilization with the wire belt. (6) Singularly adapt to changing production requirements. (7) Reduce operational costs with minimal maintenance needs. (8) Singularly withstand harsh environmental conditions. (9) Improve overall equipment lifespan with durable design. (10) Singularly comply with industry regulations and standards. (11) Boost employee morale with a reliable conveyor system. (12) Singularly streamline production processes. (13) Ensure consistent product flow with the belt. (14) Singularly reduce waste in manufacturing processes. (15) Enhance corporate sustainability with efficient material handling.

4: Future Outlook (1) Singularly shaping the future of conveyor technology. (2) Pioneering advancements in material handling systems. (3) Singularly contributing to Industry 4.0 evolution. (4) Balancing innovation and sustainability for future growth. (5) Singularly addressing emerging challenges in conveyor systems. (6) Anticipating future industry demands with the conveyor belt. (7) Singularly driving efficiency in the era of smart manufacturing. (8) Contributing to a more sustainable and connected industrial landscape. (9) Singularly supporting global initiatives for efficient production. (10) Balancing technology and environmental responsibility for a brighter future. (11) Singularly adapting to the evolving needs of diverse industries. (12) Paving the way for smarter, greener, and more efficient manufacturing. (13) Singularly embracing the challenges of the Fourth Industrial Revolution. (14) Anticipating and meeting the needs of future material handling demands. (15) Balancing progress and responsibility for a sustainable industrial future.

The product Balanced Mesh Belt appeared first on Alex Wire Mesh.

#Balanced Conveyor Belt#Balanced Mesh Belt#Balanced Spiral Conveyor Belt#Balanced Spiral Wire Belt#Balanced Wire Belt#Conveyor Belt#Conveyor Belt Wire Mesh#Metal Conveyor Belt#Steel Conveyor Belt#Wire Belt#Wire Conveyor Belt#Wire Mesh Belt#Wire Mesh Conveyor Belt

0 notes

Photo

304 Wire Netting

304 Wire Netting ensure precision in particle separation processes. The wire netting is essential in crafting reliable filters for various industries.

Features: (1) Crafted from high-quality 304 stainless steel for durability. (2) Resistant to corrosion, making it suitable for outdoor use. (3) Uniform mesh structure ensures consistent performance. (4) Easy to handle due to its lightweight yet sturdy design. (5) Smooth surface finish enhances aesthetic appeal. (6) Excellent heat resistance for various industrial applications. (7) Low maintenance, reducing long-term operational costs. (8) Versatile and customizable for specific project needs. (9) Quick and straightforward installation process. (10) Eco-friendly choice, as it is fully recyclable. (11) Offers exceptional longevity even in harsh environments. (12) Meets industry standards for quality and performance.

Advantages: (1) Long-lasting solution for diverse industrial needs. (2) Enhances safety with reliable fencing and enclosures. (3) Provides cost-effective solutions for various projects. (4) Versatile applications due to its customizable nature. (5) Low environmental impact with recyclable materials. (6) Improves aesthetics while maintaining functionality. (7) This screen mesh is suitable for both indoor and outdoor applications. (8) Withstands harsh weather conditions for durability. (9) Reduces the risk of rust and degradation over time. (10) Enhances security with strong and resilient barriers. (11) Requires minimal maintenance for prolonged use. (12) Complies with international standards for quality.

Specifications: (1) Mesh size options catering to different requirements. (2) This safety screen is available in various thicknesses for increased strength. (3) Customizable dimensions to fit specific project needs. (4) Standard roll lengths for convenient handling. (5) Options for different surface finishes based on preference. (6) Packaging options ensuring safe and efficient delivery. (7) Detailed product documentation for easy understanding. (8) Clear labeling for quick identification of specifications. (9) Options for bulk orders to meet large-scale demands. (10) Comprehensive warranty for customer satisfaction. (11) Compliant with industry standards for consistency. (12) Continuous testing to ensure quality and performance.

Installation Tips: (1) Ensure a level and stable foundation for accurate installation. (2) Use appropriate tools for cutting and shaping as needed. (3) Secure edges tightly to prevent sagging or deformation. (4) Follow recommended spacing guidelines for optimal results. (5) Check and tighten connections periodically for stability. (6) Choose compatible accessories for a seamless installation. (7) Seek professional advice for complex or large-scale projects. (8) Consider environmental factors when determining placement. (9) Utilize corrosion-resistant fasteners for lasting results. (10) Inspect regularly and address any signs of wear promptly. (11) Provide proper support for vertical installations. (12) Follow safety guidelines to prevent injuries during installation.

The product 304 Wire Netting appeared first on Alex Wire Mesh.

#304 Wire Net#304 Wire Netting#304 Wire Screen#SS 304 Wire Mesh#SS 304 Wire Netting#SS304 Wire Netting#Stainless Mesh#Stainless Steel Mesh#Stainless Steel Wire Mesh#Stainless Steel Wire Net

0 notes

Photo

Cam Grid Wire Mesh Belt

Cam Grid Wire Mesh Belt sets the standard for conveyor systems. Its precision mesh design ensures product integrity during transport. As the popular conveyor belt, It is ideally suited for food processing, automotive and other demanding industries.

1: Performance Excellence (1) Unparalleled performance, meeting the demands of modern industries. (2) Cam Grid Wire Belt excels in high-speed conveying applications. (3) Precision engineering ensures smooth and efficient material flow. (4) Superior load distribution minimizes wear and tear on components. (5) Consistent operation, reducing downtime and increasing productivity. (6) Adaptable to various temperatures, from freezing to high heat. (7) Customizable options for specific industry requirements. (8) Low-friction design enhances energy efficiency in conveyor systems. (9) Noise reduction features for a quieter working environment. (10) A reliable solution for heavy-duty conveying applications. (11) Quick and easy installation, saving both time and resources. (12) Cutting-edge technology for optimal material handling performance.

2: Unveiling Versatility (1) Cam Grid Wire Belt transforms the food processing sector. (2) Precision in automotive manufacturing with customized solutions. (3) Beverage industry benefits from hygienic and efficient conveying. (4) Perfecting pharmaceutical production through precision handling. (5) Tailored solutions for electronics and semiconductor manufacturing. (6) Supporting sustainable practices in recycling and waste management. (7) Mining and aggregate industries achieve efficiency with Cam Grid Wire Belt. (8) Poultry and meat processing elevated by specialized conveyor solutions. (9) This Wire Belt in improving logistics and distribution. (10) Elevating bakery and confectionery production with precision conveyance. (11) Textile industry efficiency enhanced through advanced mesh design. (12) The backbone of reliable and efficient material handling.

3: Sustainability Features (1) Eco-friendly design promotes sustainable manufacturing practices. (2) Recyclable materials contribute to a greener supply chain. (3) Energy-efficient conveyor solutions reduce carbon footprint. (4) The belt supports a circular economy in material handling. (5) Minimized waste through precise and controlled material transport. (6) Long-lasting components reduce the need for frequent replacements. (7) Environmental responsibility integrated into every stage of production. (8) Its design aligns with global sustainability goals. (9) Enhanced durability results in reduced resource consumption. (10) Innovative technologies for reduced water and energy consumption. (11) Aligning with green certifications for environmentally conscious industries. (12) A sustainable choice for businesses committed to reducing their ecological impact.

4: The Future of Conveying (1) Paving the way for the future of material handling. (2) Embracing technological advancements for continuous improvement. (3) Research and development driving innovation in conveyor systems. (4) Smart technology integration for real-time monitoring and control. (5) The belt adapts to evolving industry needs. (6) Investing in emerging materials for enhanced performance. (7) Industry 4.0 compatibility for seamless integration with smart factories. (8) Collaborative partnerships for pushing the boundaries of conveyor technology. (9) Continuous improvement initiatives for increased efficiency. (10) Global expansion, bringing the belt to new markets. (11) Anticipating and addressing the challenges of tomorrow’s industries. (12) A commitment to excellence, ensuring the belt remains the industry leader.

The product Cam Grid Wire Mesh Belt appeared first on Alex Wire Mesh.

#Cam Bridge Conveyor Belt#Cam Grid Conveyor Belt#Cam Grid Wire Belt#Cam Link Conveyor Belt#Cambridge Conveyor Belt#Conveyor Belt#Mesh Conveyor Belt#Metal Conveyor Belt#Steel Conveyor Belt#Wire Belt#Wire Conveyor Belt#Wire Mesh Conveyor Belt

0 notes

Photo

10x10 Fiberglass Mesh Cloth

10×10 Fiberglass Mesh Cloth boasts unparalleled strength. This fiberglass mesh is the top-tier product of Alex. The mesh is manufactured with sustainability in mind to reduce environmental impact.

1: Technical Specifications (1) Boasts a precise 10x10mm mesh count for optimal performance. (2) Single-thread construction ensures uniform strength distribution. (3) Resistant to corrosion, ensuring longevity in various conditions. (4) Lightweight design facilitates easy handling and installation. (5) Enhanced adhesive properties for secure bonding to surfaces. (6) UV-resistant, maintaining integrity under prolonged sun exposure. (7) Provides excellent heat insulation for added functionality. (8) Thickness carefully engineered for balance and efficiency. (9) Meets industry standards for safety and reliability. (10) Designed to withstand tension and pressure without compromising. (11) Available in different roll sizes to accommodate diverse projects. (12) Detailed product specifications available for customer reference.

3: Applications (1) Widely used in the construction of drywall joints. (2) Perfect for reinforcing concrete to prevent cracking. (3) Ideal for plastering to achieve a smooth and even finish. (4) Used in the repair and maintenance of existing structures. (5) Excellent for creating robust and resilient stucco surfaces. (6) Suitable for reinforcing corners and edges in construction. (7) Adds strength and stability to flooring installations. (8) Enhances the longevity and durability of mortar applications. (9) A key component in the construction of strong composite materials. (10) Used in roofing projects to provide structural support. (11) Essential for creating resilient exterior insulation finishing systems. (12) Ideal for projects requiring a combination of strength and flexibility.

3: Advantages (1) Offers a cost-effective solution for construction needs. (2) Significantly reduces the likelihood of material shrinkage or expansion. (3) Facilitates faster construction processes with its easy installation. (4) Resists mold and mildew growth, ensuring a healthier environment. (5) Provides superior crack resistance for long-lasting structures. (6) Versatile application across a wide range of construction projects. (7) Low maintenance requirements for added convenience. (8) Enhances the structural integrity of walls and ceilings. (9) Allows for increased flexibility and adaptability in designs. (10) Contributes to energy efficiency with its insulation properties. (11) Environmentally friendly option with recyclable materials. (12) Adds value to construction projects through increased durability.

4: Customer Testimonials for 10×10 Fiberglass Mesh Cloth (1) “Impressed with the strength and durability of this mesh cloth.” (2) “Easy to work with, even for DIY projects – highly recommended.” (3) “Improved the stability of our construction projects significantly.” (4) “No signs of wear after months of exposure to harsh weather.” (5) “The perfect choice for reinforcing drywall joints in our home.” (6) “Provides peace of mind with its exceptional crack resistance.” (7) “Versatility in applications makes it a go-to product for us.” (8) “Clearly outperforms traditional mesh options in the market.” (9) “Adds a layer of protection to our concrete structures.” (10) “A cost-effective investment with long-term benefits.” (11) “Impressive adhesive properties for a secure installation.” (12) “The technical specifications exceeded our expectations.”

The product 10x10 Fiberglass Mesh Cloth appeared first on Alex Wire Mesh.

#10x10 Fiberglass Cloth#10x10 Fiberglass Grid#10x10 Fiberglass Mesh#10x10 Fiberglass Mesh Cloth#10x10 Fiberglass Netting#10x10 Fiberglass Wall Mesh#10x10 Fiberglass Wire Mesh#Fiberglass Mesh#Fiberglass Mesh Cloth#Fiberglass Wall Mesh

0 notes

Photo

304 Stainless Wire Net

304 Stainless Wire Net is the most popular type of stainless steel wire mesh. The wire net is crafted for longevity, what redefines safety screen mesh standards.

1: Key Features (1) Unyielding corrosion resistance for enduring durability. (2) Exceptional strength and stability, a hallmark of 304 stainless steel. (3) Precision-woven mesh, ensuring uniformity in every inch. (4) Versatile applications, from industrial to artistic endeavors. (5) Resilient against harsh environmental conditions and chemicals. (6) Easy fabrication and installation, enhancing project efficiency. (7) Elevated aesthetics without compromising on robustness. (8) Low maintenance requirements, saving time and resources. (9) Heat and oxidation resistance for optimal performance. (10) Compliant with industry standards, exceeding expectations. (11) Customizable options to meet diverse project specifications. (12) Unmatched longevity, providing a lasting solution for varied needs.

2: Applications (1) Industrial sectors benefit from the strength of the Wire Screen Mesh. (2) Securing agricultural projects with robust mesh solutions. (3) Architectural marvels enhanced by the aesthetics of wire netting. (4) Filtration systems optimized for efficiency and longevity. (5) Crafting durable and reliable protective enclosures. (6) Mesh partitions ensuring safety without compromising visibility. (7) Landscaping projects elevated by precision-cut wire net designs. (8) Reliable support in scientific research and laboratory settings. (9) Enhancing transportation infrastructure with durable wire solutions. (10) Aquaculture nets providing secure environments for aquatic life. (11) HVAC systems benefit from the corrosion-resistant properties. (12) Precision sieving in pharmaceutical and food processing industries.

3: Quality Assurance (1) Rigorous quality control measures for consistent excellence. (2) Adhering to international standards, ensuring reliability. (3) Every roll of the net undergoes meticulous testing. (4) Premium materials sourced to guarantee product integrity. (5) Manufacturing processes designed for precision and efficiency. (6) Our commitment to quality extends to customer satisfaction. (7) Traceability measures for transparency in the supply chain. (8) Cutting-edge technology employed for seamless production. (9) Compliance with industry certifications for peace of mind. (10) Environmental responsibility embedded in our manufacturing ethos. (11) Product warranty providing assurance of long-term performance. (12) Customer testimonials showcasing the trust in our quality.

4: Why Choose 304 Stainless Wire Net (1) Unmatched longevity ensures lasting value for your investment. (2) Versatile applications cater to diverse project requirements. (3) Aesthetic appeal without compromising on structural integrity. (4) Customization options to suit unique project specifications. (5) Seamless integration into various industrial processes. (6) Time and cost-efficient installation for project efficiency. (7) Low maintenance requirements for hassle-free ownership. (8) Reputation for excellence, backed by satisfied customers. (9) Industry-compliant, meeting and exceeding standards. (10) Technical support ensuring a smooth and successful project. (11) Environmentally conscious manufacturing for sustainable solutions. (12) Elevate your projects with the reliability of the net.

The product 304 Stainless Wire Net appeared first on Alex Wire Mesh.

#304 Stainless Mesh#304 Stainless Net#304 Stainless Screen#304 Stainless Screen Mesh#304 Stainless Steel Mesh#304 Stainless Steel Wire Mesh#304 Stainless Steel Wire Net#304 Stainless Steel Wire Screen#304 Stainless Wire Mesh#304 Stainless Wire Net#304 Stainless Wire Screen#Stainless Steel Mesh#Stainless Steel Wire Cloth#Stainless Steel Wire Mesh

0 notes