Don't wanna be here? Send us removal request.

Text

Reflection & the rest of the weeks :)

The rest of my time at JulesB was just day to day working and doing everything I have covered in detail already.

I loved my placement at JulesB. I think it was really valuable working in a headoffice of an independent company as it everything felt so personal from Julian. He was always there in the office over seeing everything. In my first week he came and sat with me for my whole lunch break telling me all about his company and how it is so obvious how passionate he is and it really is infectious. He cares that everyone working there is happy as he told me this is how you get them to produce the best work. It really is an amazing work environment. By the first two weeks, I knew everyone in the office which was lovely as well, another really beneficial thing about working for an independent brand. It stops you feeling like another cog in the machine that you would get at a huge fast fashion brand because like I said everything and everyone is so personal and you deal with everyone directly.

Another thing I loved about the company is that there were a lot of people in higher up roles who had worked their way up and didn’t necessarily have a degree in Buying or a fashion degree, which I think is so good that the company allows for growth and shows anything is possible. I used to study Fashion Management so also for me working so closely to buyers and the creative team was such a good insight for me. I am really going to miss working here and everyone at JulesB, especially Bertie!

0 notes

Text

Week 8- 6th of December

For this week I thought I would give a brief summary of how Head Office works, the different teams and roles.

On the downstairs we have the Dispatch office and Warehouse. We have one accountant and HR member of staff who's offices are also downstairs.

The warehouse consists of 3 full time staff and 3 part time which shows that the warehouse is not massive like I said in a previous entry.

Upstairs, it's all a large open plan office, except for the creative studios which run all down the left hand side of the office. Julian and Rhona each have their own office as well upstairs. The first team is the Buying and Merchandising team which has 3 staff. The Customer Service department has 4 members of staff, 2 who deal with all the emails and 2 who oversee the returns, there is also a member of staff who is the internal IT person and sorts all the website and any technical issues or system flaws. Then they have the creative team, consists of 2 graphic designers, Hannah the studio coordinator and stylist, they have a describer who's job it is to describe all the garments online. Then in the photography studios they have 4 photographers who all help in the touching up and editing as well of the e-commerce. Everyone works together very close-knit which is the beauty of the head office being smaller. Also everyday seeing Julian come in and check everyone is okay and to personally spread his passion throughout the office is not something everyone can say about the CEO of their company which is what I think gives JulesB its magic tough of everything being completed to such a high standard.

0 notes

Text

Week 7- 29th of November

Following on from Returns, after they had been all sorted and accepted by customer services they would then be ready to be put back in the warehouse.

For this, I would use the folding boards and fold each garment individually so it was like brand new again. I would make sure the label was facing upwards and at the front of the garment to be visible seen easily by the warehouse staff and then I would seal each garment into a new protective JulesB bag.

Then they'd get taken down to the warehouse.

0 notes

Text

Week 6- 22nd of November

Returns

A job we learnt quite early on which is separate from the dispatch department was how to do returns. They would get delivered daily from all of the different couriers.

I would open the returns, and read the invoice. It was quite common for customers to write personal opinions on their return slips. For example they would write things like 'I absolutely loved the colours of this garment and fabric, they just didn't quite suit me'. It shows the quality of customer that JulesB have. Some of them would make us smile when opening returns it would feel like you are getting personal notes. Most of them seemed like they wanted to reassure you that they were not disappointed with their purchase and it just wasn't right for whatever reason out of the company's control.

Then you would check the barcode of the garment they were returning matched with what is on the invoice, then you would tick it, mark the shipping details and the courier, sign your initials. I would scan the barcode on the return label of the packaging, and the barcode on the top of the invoice into an excel spreadsheet- this would be to log the order number details and the date it has been returned.

I'd then fold the invoice in the garment and make neat piles of the returned items in a big bag. We would recycle any tissue paper in reason as JulesB is a sustainable brand. Once all the returns had been unpacked and sorted through I would take them upstairs to the customer services team. They would issue and process all the refunds/ exchanges and communicate directly with the customers if they had any other problems.

0 notes

Text

Week 5- 15th of November

Twice a day we would do a shop run to the Jesmond store, about a 5 minute drive from head office. Kev from the warehouse would also drive to the Kendal store every few days.

The purpose of the shop runs would to be to take all of the click and collects that we have packed ready from the office, and pick up any stock that had been sourced from the shop. The JulesB shop is beautiful and has definitely got its customer experience priority very high.

0 notes

Text

Website

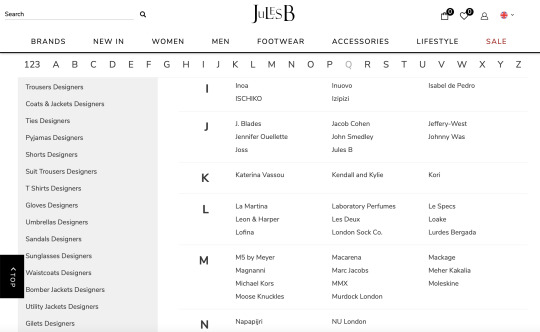

Here is an example from the JulesB website of just some of the brands that they stock and sell.

0 notes

Text

Week 4- 8th November 2021

This week was one of my favourite weeks at JulesB. Hannah, who is the creative stylist and studio co-ordinator at JulesB asked me to go into the studio with her and help her with a shoot. I loved working with all the creative team at JulesB and was lucky enough to get an insight into what an average day in their life at work is like.

Hannah is amazing, her role is to basically oversee everything for the shoots, she styles everything, books everything in and out, sorts the website out, prepares everything for the shoots, all the accessories, garments and so much more that is just surface level.

Everyone in photography was so hardworking. So Hannah taught me the system of how it works in creative when doing an e-commerce shoot.

There was a huge clothes rack with all the outfits in order of what was to be shot. Staple pieces that would be used throughout the sheet would be specifically labelled so I knew never to move them to the back of the rack after each outfit was finished with. I would get the upcoming outfit ready and de-tag the garments, I would then pass all of the tags for that outfit to Jonny who was the one photographing the shoot that day, whilst they'd another member of the creative team who was looking at all the photos on the computer as they were coming through. Jonny would photograph the labels and tags on their own, shoot the model in the outfit and get detail images and close ups of everything necessary for the website. I thought everything ran so smoothly, another thing a customer would notice is that the models they JulesB use are consistent all over the website. This really showed to work so well as it saved so much time watching how familiar the model and the photographer were at working with each other and knowing exactly what to do.

While the current look would be getting shot, I would re-tag the garments from the previous look that was finished with and hang the garments back up and put them at the back of the rack. I would ask Hannah what accessories and shoes would go with the next look to get them ready for the model.

After spending my first few weeks in Dispatch and seeing all of the clothes and accessories individually being sent out on their own in an order, it was soo sooo good seeing how Hannah would style them all and put everything together. She is so talented and all of her hard work really pays off because all of her outfits and looks that she creates are amazing. I really enjoyed being in the creative studio and watching all the magic happen right in front of me. I got to learn a lot and then also get to see everything being shot in front of me to how it ends up on the website.

0 notes

Text

BERTIE :)

This is Bertie, Julians puppy!!!! Here you can see him coming to help me and be my assistant. He was my favourite member of the office and he loves to distract everyone from their work! Julian used to bring all his dogs in, 3 Labradors which just made work even nicer having them around.

In the background of my photos you ca see an example of orders I had processed, these were waiting to be packed by a packer.

The orders in the white bags are for click and collect customers, these would be packed and taken down to the Jesmond Store. When dispatching a click and collect I would log the customers details into the click and collect log on Excel so the shop could keep track.

0 notes

Text

Week 3- 1st of November

Bespoke Systems

After I had settled in, due to everyone being so friendly and lovely I had felt like I had worked there so much longer than two weeks. I quickly adapted to the daily routines of JulesB head office.

This was the time for me to start my training on the computers, the other side of packing the parcels in the Dispatch office. The two major systems they use are called VS3 & RMIS. It took about 3 full weeks of learning this. There was a lot to take in with shipping rules and the EU and international orders, sending things duty paid or unpaid, making sure I was sending things with the right couriers and that I wasn't going to do it wrong and charge JulesB a fortune. I loved learning new systems because I love it when you first are shown something and it all looks like so many random numbers and letters jumbled all over the screen and all different buttons that you don't know what any of it means, and then when you look back after learning it not being able to even remember how it all looked so confusing at first.

VS3

VS3 is the program we would use to check the daily order count and begin processing the order and the start of dispatching the parcel. Firstly, after the lists have been ticked off so you know you definitely have all the correct items in your box, you would work your way through the list.

I would start by scanning an items barcode in the search bar, and then it would bring up all the orders for that item. Each order would be marked as several different options such as Payment Received, Order Dispatched, Order Refunded, Order Cancelled etc. The orders with the status of Payment received would be what I would then need to filter my search for. I would find the order for that item and I would grab the order number for it and then copy it into RMIS.

RMIS RMIS is the internal stock/tracking system to locate the status of any order. Once I copied an order number into it I could then see everything that is supposed to be in that order. If there were things missing that I didn't have on my list, I would then go to locate where they are using this. Places they would be are either in the waiting area - where items were held whilst waiting for the rest of its order, we could be waiting for it be sent to us from the Kendal office or store as we could have part orders been allocated coming from there, or we could be waiting for it to be picked from our Jesmond store in the shop run.

Whatever the case of where the rest of an order might be, I would then make a note on the system and update any progress I might have made. Id grab the extra items out of the waiting area for that order, add it to the waiting area if it was waiting on more stuff or be able to go ahead and send it.

The next step would be to scan the items off for the order on RMIS so everything aligns with stock control and then it would be on the system that it has been scanned out and dispatched. This is so vital in case anything does go wrong later down the line if anything has been sent wrong or there is any confusion- dispatch can come back to this and trace what's happened. It also ensures that I have the exact right product because the system wouldn't let me scan it if it was even the wrong size for example. Then I confirm everything so it all goes through on the system and then return back to VS3.

Following on, once back to VS3 I print the invoice, check all the shipping details match and are right for whichever country its going to, and then I print the shipping label.

Then I build a JulesB box and put the order, shipping label and invoice in and for the last time check everything matches, its the right invoice and the order number matches the shipping label ready for it to be packed.

Every order can have something different to do with it such as if its been cancelled, if its been brought off Amazon or Ebay its processed differently for example. It was just a case of everyday getting used to it, I had the best manager and supervisor who helped me with any problems that would arise.

The rest of the time there would be minor things that would come up that I was still learning and would have to deal directly with warehouse or creative department about when stock would be used for shoots etc.

0 notes

Text

The Warehouse INTERLUDE

The Warehouse are the main starting point of everything else functioning at JulesB.; everything stems from there. The warehouse isn't how I imagined it to be, its a quite small stockroom which goes over two floors including the basement. I thought it was going to be huge but I soon learnt its because JulesB is a luxury brand. I think because I am so used to fast fashion consumerism and expecting there to be so many of each item I didn't really think what fashion would look like on a more higher end scaled down version.

For example, even the orders in dispatch people would order 1 x Barbour jumper, or 1 x Paul Smith t-shirt compared to PLT when you bulk order loads of clothes at once. The buyers that work in head office explained to me how before the season starts they buy a select amount of stock from each individual brand. I found this out one day when I was packing a beautiful Rino and Pelle fur coat, (I fell in love with this brand whilst working here, everything Rino and Pelle that I dispatched I adored) and I thought I would love this coat for my birthday which was in the next 2 weeks. There was only 1 left in my size in stock in the warehouse and when I came into work the next day I thought it had been sold! I was gutted but I just thought surely its fine, one of the buyers could order another one in. So that's when I learned that it didn't work like that and what they order before the season is it. Luckily one of the boys from the warehouse found one left in my size in reserve stock which meant it was meant to be so I managed to get it for my birthday in the end! *Screams in heart eyes*

Obviously as well as having to control all of the stock, manage the warehouse, unpacking deliveries and everything else, it is also their main job to bring through all the orders. This is what they would call picking lists. When it is quieter a list will have 7 items on it- and when busier these would double up so one list would consist of 15 items. If a person has ordered a few items these will all be on the same list and come through together. So the warehouse boys will bring in all the items matching that list in a bag once they've picked them all in the warehouse. The dispatch staff before beginning to dispatch anything will check the barcodes on the item against the codes on list to make sure we have got the right item as things in different sizes can be different by one number and when busy can be easier to miss. It works best when things are checked at every stage of the process. Sometimes an item could be missing off what's been brought through that's on the list, if no one checked this then the item would be sat in the warehouse and not known about for a while.

0 notes

Text

Second Week- 25th October 2021

In my second week, as well as carrying on my original role in dispatch, when it would get quiet I would go and help out in the warehouse.

The Warehouse

In the warehouse I would carry out a range of small jobs when they were really busy or had large deliveries. Everything which got delivered needed to be unpacked and re-organised into sizes, colours product types etc. Then the manager of the warehouse and the stock controller would have to check everything they are meant to have they do and aligns with all the paperwork.

Next, one of the lads would print out the right amount of stickers for the items. Everything that goes into the warehouse needs to be given a new sticker with a JulesB barcode for our own stock control and systems. It is vital that this all gets stuck on correctly so you have to make a small hole in the bag of the item to make sure the tag matches the sticker size and product, and then cover the original barcodes with ours.

Once this has been done, you would put the stock away into the appropriate place for it. A lot of the warehouse jobs are sorting through stock. For example, we would get deliveries of loads of Sorel shoes, the front room would be full of the big boxes of them. Another job would be to open all of the big boxes and individually sort through all the shoes to put all the sizes together and styles as they would often be jumbled up and mixed together.

0 notes

Text

First Week - 18th October 2021

Introduction

On my first day, I was took on a tour around the whole of the head office and introduced to everyone from all of the different teams. I instantly loved that the head office is quite small with no more than 30 employees. It meant I would be able to learn off everyone in the office at some point of my placement, and really see how everyone from each team works together.

JulesB stocks a huge variety of designer brands including Julians own brand : Blades. So from a placement point of view this was really beneficial for me as I got to work really closely with all of these brands.

My Role

In the dispatch office there were 4-6 of us (a couple of the staff are part time). I didn't know anything about this area of the fashion industry before I started so I had an open mind was excited to learn.

Dispatch deal with all of the online orders using bespoke systems which I was later to be trained on. I was then taught how to pack an order for a customer and was shown all the different sizes of parcels etc and how each one differed. As JulesB is a luxury brand with most items being over £100, it is really important that the orders are all packed immaculately and securely. I was told to pack an order as if it was for me or my family. Julian really emphasises that you must 'pack with love' as it is essentially the end of the chain and the last thing that happens to the garment before it leaves our office.

There would be a pile of boxes with orders inside that have been processed and ready to pack containing an invoice, postage label and the item/s. I would take everything in the order out of its packaging, check for anything wrong with the product and make sure there weren't any manufacturing issues, no marks or damage. Then I would use a folding board to ensure everything was neat and folded of standard. Then I would line the box with tissue paper, stuff the box, put the order into the box, add additional stuffing if needed to make sure nothing had the potential to move in transit, and then fold the lining of the box over and secured it with a JulesB sticker. Then I would add the invoice, a JulesB Quarterly A/W magazine issue, seal the box and then stick the postage label on the outside. Sometimes with some of the international parcels there would also be custom declarations to also stick on the outside of the box.

I enjoyed packing parcels as it was really satisfying to do and know that everything I was sending out, the customer will have been waiting and excited for.

After a parcel has been packed we then build piles in the centre of the room for each delivery service (Eg. Royal Mail 24, Royal Mail 48, Royal Mail International, DHL, DPD). It is really important that everyone in dispatch pays close attention to all of the parcels so that no mistakes are made. Then depending on how busy we were, every hour or so we would load all of the piles of parcels onto the right cages ready for the couriers to collect towards the end of the day.

Other daily duties in my first week would include answering the door throughout the day. Couriers would be dropping deliveries for various teams in the office, we would send things back and forth from the Kendal office and store and we would have to receive the return parcels from customers too.

End of the day duties would include taking the cages out when the couriers arrived to collect the parcels, clearing the room of mess, wiping down all of the desks, packing stations, emptying all of the bins, re-stocking the tissue paper piles and anything else needed such as sellotape or sticker rolls etc. I would then hoover the office and make sure everything was tidied ready for the next day. I would take all of the hangers down to the storeroom in the warehouse from outerwear garments that have been sent.

0 notes

Text

Starting Placement @ JulesB

I started my placement on the 18th October 2021, a 3 month role based in the Dispatch Office at the Jules B head office.

JulesB is independent luxury designer fashion company started by Julian Blades and his wife Rhona in 1984 in the heart of Newcastle, opening their first womenswear store in Jesmond. It has grown to have stores in Kendal, Yarm (which has since closed down) and a new store opening in Harrogate this year!

The head office is in the centre of Newcastle and we dispatch parcels worldwide so from an initially small independent business, JulesB has significantly established itself.

Julian was a self-employed fashion agent with a family heritage of over 5 generations in tailoring, alongside Rhona who was a head lecturer in Fashion Design- between them they have expert knowledge of retail operations and a flair for the careful curation of products that would satisfy and reward the tastes of Jules B customers .

1 note

·

View note