Don't wanna be here? Send us removal request.

Text

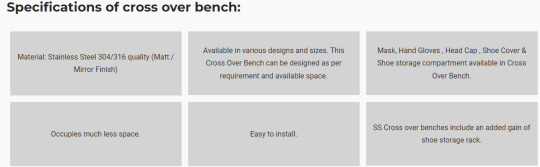

Stainless Steel Cross Over Benches-Specifications

Stainless Steel Cross Over Bench suppliers come in a variety of styles and are widely utilized in a variety of sectors. This Cross Over Bench separates the slightly soiled changing-zone on one side of the changing room from the cleaner region in front of the clean room's entrance. It is composed of Stainless Steel raw material of the highest grade. It comes in a variety of sizes or can be customized to meet the needs of the client. These cross-over benches have been designed expressly to meet the needs of the pharmaceutical sector. Our cross-over benches are noted for their long life. The pharmaceutical, chemical, and food industries all use these Cross Over Benches. Staff entering from Primary change room to Secondary change room or from Air Lock of Production / Manufacturing Area, warehouse, dispensing, sampling, and packing area are protected by the Cross Over Bench. Changing clothing and shoes at entry and exit of specified changing areas must be covered by the protocol.

0 notes

Text

Features and advantages of Biosafety cabinet a2

Biosafety Cabinetsare customised workstations used in clinical, pharmaceutical, life science, and industrial laboratories when investigations require a clean environment.

Features and Advantages

Types:

There are three different types of class 2 biosafety cabinets. Which class 2 BSC should be utilised in the laboratory depends on the nature of work. A brief description of each type follows:

Biosafety Cabinets A2: approximately 70% air and 30% exhaust are recirculated.

Biosafety Cabinets A1: approximately 30% air and 70% exhaust are recirculated.

Biosafety Cabinets B2: Does not recirculate air and instead exhausts it completely.

Construction:

These cabinets have been ergonomically built to last a long time. Only thick metal sheets and pipes are utilised in the building of this Biosafety Cabinet, ensuring that you get the best and safest Biosafety Cabinet available today. Three different MOCs are used.

Inner Stainless Steel 304/316, Mild Steel Outer Stainless Steel Bench, Rest Mild Steel

Circulation of air:

In order to reduce the transmission of airborne bacterial and viral pathogens, we use 99.97 percent efficient HEPA filters with a particle size of 0.3 microns in our biological class 2 type A2 safety cabinets. These air filters are from well-known manufacturers, are inexpensive, and are simple to replace.

Standard Equipment:

Outside the working zone, our biosafety cabinets are equipped with fluorescent lights. UV lamps are installed inside the working zone so that the operator cannot see them. The UV lamp is attached to an hour metre. Electrical sockets are fitted to run any instrument under the working area; in addition, service fixtures for air, gas, vacuum and water are fitted on demand.

Biosafety cabinet manufacturers in Bangalore also a manufacturer of biosafety cabinets class 2 type B1 and B2.

0 notes

Photo

The best lab furniture manufacturer in Bangalore - Alpha Linear

https://www.alphalinear.co.in/equipment/lab-furniture/

0 notes

Text

Why Should You Choose A Biosafety Cabinet?

What is a biosafety cabinet?

Biosafety cabinet is a type of laboratory equipment that is used to protect the user from exposure to hazardous biological materials. They are designed to protect the worker, the environment and the product by providing a physical barrier between the user and the hazard Biological safety cabinets are available in several sizes, configurations, and designs.

Biosafety cabinets are classified as Class I, Class II, or Class III.

Class I biosafety cabinets are used to protect the operator and the environment from exposure to hazardous particulates. They are not designed to protect the product from contamination. Alpha linear - one of the best clean room equipment manufacturer provides quality biosafety cabinets.

Class II biosafety cabinets are used to protect the operator and the environment from exposure to hazardous particulates. They also provide some product protection from contamination.

Class III biosafety cabinets are used to protect the operator, the environment, and the product from exposure to hazardous particulates. They provide the highest level of personnel, product, and environmental protection.

There are several reasons to choose a biosafety cabinet over other types of containment equipment:

-Biosafety cabinets protect against harmful particulates and agents. Particulates can include dust, aerosumables like powders and liquids, and microorganisms. Biosafety cabinets are designed to create a physical barrier between the user and these particulates, using HEPA filters to remove them from the air before they can reach the user.

-Biosafety cabinets also protect against harmful agents like chemicals, toxins, and radioactive materials. By enclosing the work area and providing ventilation, biosafety cabinets create a barrier between the user and these agents.

-Biosafety cabinets can be used for a variety of applications, including cell culture, microscope work, pharmacy compounding, pathology, and forensics.

-Biosafety cabinets are available in a variety of sizes and configurations to meet the needs of different users.

-Biosafety cabinets are also relatively easy to use, with most models featuring intuitive controls and clear instructions.

When choosing a biosafety cabinet, it is important to consider the specific needs of your application. Biosafety cabinets are available in a variety of sizes and configurations to meet the needs of different users, so be sure to select a model that is well-suited for your intended use. Additionally, be sure to read the instructions carefully before use to ensure proper operation.

Choosing the right biosafety cabinet for your needs is important to ensure the safety of both you and your work. If you have any questions about which biosafety cabinet is right for you, please contact us. We will be happy to help you choose the perfect biosafety cabinet for your needs.

0 notes

Text

Tips For Buying And Installing Laminar Air Flow

A laminar air flow system, or laminar flow cabinet, is a type of enclosure designed to create a path to a clean supply of fresh air, allowing materials to be processed or stored within it. Laminar air flow systems are crucial for enabling the efficient processing of hazardous materials and products, as well as the production of food, pharmaceuticals, and chemicals—so, if you’re in one of these industries, it’s important to invest in a high-quality laminar flow cabinet today from the best clean air equipment manufacturer.

If you run a manufacturing or research lab, you know that clean air is extremely important. Air quality affects workplace safety, employee productivity, and product quality, so it is important to keep your air as clean as possible. Laminar air flow (or laminar flow) hoods, which use Laminar Airflow Technology (LAT), can help. LAT creates a microclimate inside the hood that promotes a clean environment, reduces cross-contamination, and limits the spread of airborne contaminants.

Laminar air flow is a safety feature in several industries. It is used to protect operators and machines from contamination and contamination-spreading. This safety feature prevents particles from spreading within a work space, such as a paper mill or food processing plant. The laminar flow hood is recognized as one of the most important factory safety devices. There are many types of laminar flow hoods, each designed for specific applications. Laminar airflow is of 2 types: horizontal laminar airflow cabinet and vertical laminar airflow cabinet.

Here are 5 Tips for Buying and Installing Laminar Air Flow

1. When buying a laminar air-flow system, be sure to choose a reputable manufacturer

2. Research the features you need and consider the maintenance

3. Choose the right size of the fan for the area you want to cover

4. Choose the right size and type of ducting

5. Choose the fan power level based on your application

In conclusion, purchasing and installing laminar airflow does not require several years to complete. The process begins with selecting a vendor and specifying the type of equipment required. Once that is agreed upon, you then have to decide if you want a complete system or only a portion of the system. Then, you contact our sales department for a written proposal. From there, you can install the system yourself or have us do the installation and calibration of the system. Then, you can enjoy the benefits of laminar airflow.

0 notes

Photo

Best clean air equipment manufacturer.

https://www.alphalinear.co.in/

2 notes

·

View notes