Anand systems Engineering Pvt. Ltd is an indian industry-leading manufacturing group of crane control gears equipment. Everything we do is targeted at one goal: improving the safety and productivity of our customers’ operations.

Don't wanna be here? Send us removal request.

Text

Features of wireless radio remote control

The radio remote control includes the transmitter, a receiver. Radio remote control has many characteristics. Some features of the wireless remote control for crane is as follows:

· Receiver feedback

· Config card

· Digital Address

· Tandem mode

· Radio Range

· Communication System used

· Auto Power Control

A detailed description of each is as given below:

1. Receiver feedback

If you want reliable communication between the transmitter and the receiver then you require feedback. Anand receiver and Anand transmitter can transmit and receiving the data. Therefore, the transmitter sends the data, and the receiver gives feedback to the transmitter. Receivers send the feedback to the transmitter then the transmitter can understand different factors such as the strength of a received signal, how many times transmission succeeds, and reliability of communication.

Whether any noise or error in the receiver can be transmitted back to the transmitter. The feedbacks permit the transmitter to know if the receiver has taken the transmitted data properly. This always allows the transmitter to be aware of the receiver environment.

Remote receivers have 2 to 8 relays with 275Vac at 10 Amps contact rating, and it operates in a 30mWatt power supply. It gives the signal indication with the help of a LED. A receiver having a mainline contactor on/off indicator.

2. Config Card

Anand systems engineering always provides a removable secure memory module. If one Crane transmitter or receiver has been taken for maintenance, the additional units can activate by injecting the memory module.

3. Digital Address

Using digital addresses is the latest technology instead of tuning crystals. All wireless remote control crane systems use an 8-byte digital address. An 8-byte address is assigned to a transmitter and receiver.

4. Tandem mode

Tandem mode is controlled and monitored by the selector switch. During tandem mode, the radio remote is coordinated with receivers. Movement of both cranes are coordinated and, as soon as first crane receiver stops responding, the other crane receiver is given the stop command for safety reason.

5. Radio Range

Wireless remote control crane can transmit and accept the signal at a range of over 200 meters. Anand radio remotes are designed to transmits the data over a long distance with a lesser power.

6. Communication System Use

An advanced closed-loop communication system is used in industrial remote controls. A remote control system uses a closed-loop communication between the transmitter and receiver. The transmitter transmits the signal and receives that signal and gives you the required to be output.

7. Auto Power Control

Radio remote control for cranes automatically adjust transmitted power, because that saves the battery life of the radio remote control. Anand Systems radio remote designed to have auto power control where the signal power given by the transmitter is decreased or increased along with the distance of a receiver. Minimum 6-month battery life using the advanced microprocessors and advanced radio frequency. Anand systems engineering ensures that the battery’s life will be long. Anand radio remotes batteries last more than 1000 hours of use for a regular 8-hour shift. Radio remote goes to Sleep mode immediately button is released and wakes up instantly on keypress. Advance Radio Frequency uses a minimum amount of power for the signal to get to the receiver.

Anand Radio Remote Control are available in various types i.e., 8 Button, 12 Button, Joystick remote control, and wireless radio remote control. Select the best radio remote control for crane according to various parameters and characteristics. Anand Systems Engineering Pvt. Ltd. is a leading crane remote control manufacturer in India.

#wireless remote control#wireless remote control crane#hoist crane wireless remote control#radio remote control#crane remote control#crane wireless remote control

1 note

·

View note

Text

What are the overhead crane remote control systems?

crane wireless remote control is used for industrial purposes. The Overhead crane is also called a bridge crane. It is a machine that is used to lift and moves heavy equipment from one place to another place. In an overhead crane remote control hook and line mechanism are used. This mechanism runs along a horizontal beam.

Overhead cranes are used to transfer heavy equipment or materials over a long distance. Overhead crane remote covers a longer distance as compared to other cranes. The industries that usually use bridge cranes include the automobile industry, manufacturing, steel industry, warehousing industry, and construction industry. Applications typically include loading or unloading ships, transporting heavy materials on construction sites, and transporting components along assembly lines. Depending on the site, application, and travel distance, single beam, double beam, JIB or other types of overhead cranes can be used.

Safety requirements for overhead crane wireless remote control:

Three important crane remote control design considerations that have remained unchanged for centuries are: the crane must be able to lift heavy objects, the crane must not tilt when lifting loads and crane components, and the crane must not be damaged during operation. Another important consideration, especially during crane operation, is that no one should be injured.

OSHA records indicate that more than half of crane accidents are the direct result of inadvertent electrical contact. The metal part of the crane rubs against the power source, causing the crane to get an electric shock, causing physical injury to the operator, and injury to the personnel within the current range. Of the recorded deaths, most were crane operators. Further investigation revealed that inadequate safety planning, insufficient preventive safety measures, and insufficient operator training caused these accidents. Material overload is the second leading cause of bridge crane accidents. According to OSHA, 80% of crane accidents are directly caused by overload, which can cause irreparable damage to the crane and injury to the operator and other personnel on-site.

According to statistics, one overload accident occurs every 10,000 hours of work. Machine failure, skidding, and two locks are other causes of crane accidents. In 2012 alone, about 20 people died directly due to accidental falls of material. Most tow truck accidents occur due to negligence and lack of early warning; these two factors are easily remedied.

How Often Do Accidents Happen?

Crane accidents are not unique to modern cranes. For example, in 2006, there were 72 crane-related fatal injuries. Between 2003 and 2005, there were an average of 78 accidents each year. This includes fatalities directly attributable to overhead crane control operations, as well as secondary fatalities. Most of these accidents are related to mobile cranes, railway cranes, and bridge cranes. The above-mentioned deaths included workers, electricians, welders, cutters therefore, ground crews and operators were also affected. Industry-related statistics show that the death toll in the manufacturing industry far exceeds the death toll in the mining industry. Texas has the largest number of accidents, followed by Florida, California, and Louisiana.

The cause of the crane accident:

Usually, the hook and rope system of the crane is installed on the beam. The girders of the overhead crane remote run-on parallel rails. Mobile cranes are installed on trucks or tracks, while EOT cranes are stationary. Ground personnel guides the crane operator during operation. In any crane operating process, there are three major risk areas: accidental contact of metal parts with the power supply, accidental falling of materials, and overloading. The failure or malfunction of one or more components can also cause an accident. Other areas of risk include errors in judgment on the part of the operator or poor communication between the operator and ground personnel. OSHA (Occupational Safety and Health Administration) has identified the proximate causes of the following crane accidents –

• Overhead crane

• Gantry crane

• Monorail crane

• Cantilever crane

• Workstation crane

Although these are the proximate causes of accidents. These accidents can occur due to any or all of the following situations:

1. Crane is unstable

2. Load is unstable

3. Defective component

4. Near power source

5. Ground personnel near crane operating area

6. Space of communication between ground crew and crane control operator

7. Training space

8. Maintenance gap

All of this boils down to inadequate control of the conditions or environment surrounding crane operations, especially crane maintenance and crane components, the proximity of metal components to a power source, lack of replacement of component faulty or rapidly failing components, and ground personnel Lack of communication of generators between operators. Additionally, if ground crews stand too close to the crane, they will also be at risk, as shown in the statistics below. Close supervision of the crane and its operation can help reduce or even completely reduce the risk of accidents.

Guidelines for preventing crane accidents:

OSHA inspects a large number of overhead crane accidents and determines the precautions that must be taken.

1. Before each operation, a qualified inspector inspects the machine to check for mechanical failures

2. Routine comprehensive inspections in advance

3. Identify any faulty wiring, damaged components, or worn ropes or spools.

4. Repair by qualified and trained personnel.

5. By trained personnel who understand the rigging and load balance points.

6. Check the load as much as possible

7. Avoid working under a suspended load

8. Regularly check the load capacity and safety margin of the equipment

9. Use the equipment to mark the hazardous area when the capacity is slightly lower than (recommended radius is 90 feet) and do not work in this within the area.

10. Develop pre-work plans to determine hazards, sequence of events, and hazardous areas

11. Determine pinch points

12. Determine and follow removal procedures

In India, the Bureau of Standards of India (BIS) Act (1986) has issued a legal document detailing the standards for the manufacture, assembly, operation, and maintenance of cranes and crane components. For more details about crane control equipment contact Anand Systems Engineering Pvt. Ltd.

#overhead crane remote control systems#crane wireless remote control#crane control#overhead crane remote control system#overhead crane remote control#Overhead crane remote#overhead crane wireless remote control#crane remote control#eot cranes

2 notes

·

View notes

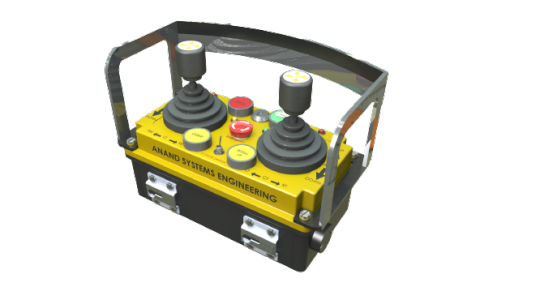

Photo

Anand crane wireless remote control

Anand 12 button is a powerful handheld crane remote control. Anand transmitter is used in different cranes such as hoist wireless remote control. We are standard remote control manufacturers in India. To get customized radio remote control at the best price contact Anand Systems Engineering Pvt. Ltd.

#crane wireless remote control#crane remote control#hoist wireless remote control#radio remote control

2 notes

·

View notes

Text

How Radio technology works and What are the applications of radio remote control?

Radio waves are used to control any type of equipment and machines wirelessly, such kind of a control system is called a Radio Remote Control.

Here is the detailed information on how radio technology works?

The signal transmitted or received by the antenna

If the transmitter transmits the signal or the receiver picked up the signal, a bandpass filter allows only desired frequency and attenuates the other frequency signal. While Radio waves passing through an air medium, there are many different RF waves are present so, the antenna tuned the required frequency and receives the specific signal. For selecting the length of the antenna, the formula is

λ = c/f

where λ = wavelength

C = Speed of light

F = desired frequency

Now, we see the applications of crane wireless remote control

The remote radio control is used in different applications. The control panel used in various cranes such as

• EOT Cranes

• Electric Hoist

• Gantry Crane

• Goliath crane

• Mobile Crane

• Tower Crane

EOT Cranes:

EOT stands for Electric Overhead crane. It is the most common type of overhead crane remote control system called a bridge crane. EOT crane control panel operated by crane pendant with the help of electricity. EOT cranes lift load up to 500 tones with 60 meters span.

Electric Hoist:

An electric hoist is an appliance used to lift or move heavy or light equipment. Hoist crane wireless remote control is used for lifting the crane and avoid the accident. Electric hoists are available in different types.

Gantry Crane:

To lift extremely heavy objects then a gantry crane is a great option. Gantry cranes are mainly used in shipbuilding because of its handle very large engines and parts. It is the type of overhead crane control with a single girder or double girder configuration.

Goliath Crane:

Goliath crane is similarly an overhead crane that has a single girder or double girder establishment and it is supported by separate legs that move on along the track. These cranes are used in outdoor applications.

Mobile Crane:

A Mobile crane is a wired-controlled crane with a lifting capacity of up to 160 tones. These cranes are mounted on crawler or rubber tire carriers. This type of crane can move to different locations very easily.

Tower Crane:

Tower crane remote control is used in civil construction sites. It handles the heavy materials, tools related to construction. All the self-erecting tower cranes are remote controls. Most of the construction sites prefer remote control cranes to avoid accidents and safety purposes.

Anand Systems manufactures crane wireless remote control for customers’ safety. We build for safe wireless operation for any kind of machinery. The best crane remote control is manufactured by Anand Systems Engineering Pvt. Ltd. It is reliable and customizable According to the crane. You can buy from https://www.anandcontrol.in/radio-remote-control/anand-remote.html

#radio remote control#crane wireless remote control#overhead crane remote control system#hoist crane wireless remote control#overhead crane control#Tower crane remote control#crane remote control

2 notes

·

View notes

Text

Crane Radio Remote Control

Anand Systems Engineering successfully installed wireless radio remote control that uses RF waves for controlling heavy equipment. Anand System leading crane remote control manufacturers in India. For more details visit: https://www.anandcontrol.in/radio-remote-control/anand-remote.html

#crane radio remote control#wireless radio remote control#crane remote control manufacturers#radio remote control#crane remote control

2 notes

·

View notes

Text

EOT Crane Remote Control in India

Electric Overhead Travelling Crane is commonly preferred, EOT Crane. These cranes are the most common cranes on construction sites and in industry. EOT Crane Remote is used for load lifting and shifting from one place to another place. Cranes have parallel runways and space is spanned by a traveling bridge. The hoist is placed on this bridge. To operate this crane requires electricity and can be operated via the control room attached to the crane or via a crane pendant. These cranes lifting both light and heavy equipment.

Principle of operation

Radio Remote control for EOT cranes works on three steps that are lifting, trolly lateral movement and longitudinal motion of long travelling crane. The motor has a driving force from the elevator mechanism. This delivers the power to end of high-speed shaft. Gear transfers the force therefore crane hook is driven up and down by using pulleys and wire rope. Similarly completes the half gear coupling.

Crane Configurations of Electric Overhead Traveling

· Under Running

EOT cranes are supported by the roof structure. The cranes run on the lower wing of the rail girders. One of the advantages of the under running configuration is that a very small trolley dimension takes advantage of the maximum width and height of the building. We can use the existing roof rack to protect the crane runway.

· Top Running

A beam is the main horizontal support beam of the structure. Supports the smallest bars. It has a fixed track or rail system that is installed on top of the track support. The upper stroke setting has no limitation for the power range. It can handle both small and large loads.

TYPES OF EOT CRANES

There are different types of EOT cranes. Such as,

· Double Girder EOT Crane

· Single Girder EOT Crane

· Jib Crane

Components and Radio remote control for EOT Crane

Following components requires for EOT crane remote control

· Hoist

· Trolley

· Bridge

· Runway beam

· Advanced Crane Pendent

· End Effector

· Control Panel

· Radio Remote Control Receiver

· Thruster Brakes

· Limit Switches

· Anti-Collision Device

· C Track festooning System

· DSL Busbar

· Resistance Box

· Master Controller

· Radio Remote Control

In the EOT crane, the load is supported with a hook that is linked to the hoist by ropes. A trolley moves horizontally along the crane bridge with help of a hoist. The bridge joints to an end trucks on either side. The end truck break over the track beam.

EOT crane Single Girder

The crane consists of a single girder that is carried by two forklifts and has a trolley lifting mechanism that runs on the lower chord of the bridge girder. Single girder cranes are used in work units where heavy materials need to be moved or lifted. These cranes are used for maintenance and manufacturing purposes only. The main aim of these cranes is to move heavy materials quickly and comfortably. These cranes offer great durability and can perform very well.

Features

· single girder EOT cranes are much lighter, because of one main bridge.

· for industrial applications.

· It has compact structure that minimizes the building loads.

· It has lifting capacity up to 20 tons.

· It reduces the total cost on crane components, and structure.

· Low head rooms reduce the cost of building

EOT crane Double Girder

Double girder EOT cranes are used to lift heavy loads at greater heights. It is lifting heavy loads as compared to a single girder crane. These cranes give many benefits like the selection of speed, ease of maintenance and, high carrying capacity of up to 150 tons of loads.

Features

· As it consists of two main bridges, it becomes a sturdy construction.

· Designed for durable operations.

· It is cost-effective

· It is operated at any capacity

· It consists of steel alloy, toughened, precision-cut gears.

· It consists of foot mounted hydraulic thruster brakes, which are used for the hoist.

· It has a full-length platform.

Jib Crane

a crane that has a horizontal participant known as jib that supports a movable hoist. Jib crane can be mounted on a surface such as wall or floor. It helps to increase efficiency, decrease workplace damages and improve safety. These cranes are easy to operate and require less maintenance. These cranes have the capability to rotate cranes from 180 to 360 degrees.

Applications of EOT Cranes.

Ceramic Industries

Power Plant

Transport Industry

Construction Industry

Petrochemical Industry

Chemical Industries

Steel Plant

Dairy Industries

Foundries

Textile Industry

Cement Industry

In Assembly Line

Paper and Packing

Petro-Chemical

Shipbuilding

Fertilizers

Features of EOT Cranes

All the motors of a Crane are electric motors.

It consists of a heavy-duty cast steel cable guide.

It has an upper and lower hook portable limit switch.

The body of the eot crane remote control is corrosion resistance.

It offers easy operation with less maintenance.

#EOT Crane Remote#crane remote control#EOT Crane#EOT crane Single Girder#EOT crane Double Girder#EOT crane remote control#Radio remote control for EOT Crane

2 notes

·

View notes

Photo

Customized and Standard Radio Remote Control manufactured by Anand Systems. We are leading crane remote control manufacturers and we are Certified by the Department of Telecommunication. Wireless Radio Remote Controls are compatible with any technology. For more detail, get in touch with us: https://www.anandcontrol.in/radio-remote-control/anand-remote.html

#Radio Remote Control#crane remote control manufacturers#Wireless Radio Remote Control#Anand Systems

2 notes

·

View notes

Text

Radio Remote Control Transmitter and Receiver

The Anand device transmitter is designed to transmit command Signals for controlling EOT cranes, hoists, and machines. 12 control instructions plus the included emergency button are to be had to the operator. The radio remote control includes the transmitter, inner alkaline batteries, and a receiver. The transmitter housing with an integrated antenna is made from impact-resistant plastic.

Anand Radio Remote Control for EOT cranes are available in different types i.e., Anand 8 Button, Anand 12 Button, Anand Joystick remote control, and wireless remote control

ANAND 8 BUTTON

Anand 8 Button is the powerful and up to 3 motions radio remote control for cranes. It is a handheld device to control industrial cranes. eot crane remote is available in single and Dual Speeds. Another feature of Radio remote control is having the ability to cross and long travel.

ANAND 12 BUTTON

Anand 12 Button is a powerful, handheld radio remote control for overhead cranes. It is up to 4 motions. 12 button transmitter speed is single and dual. Ability to travel long.

JOYSTICK RADIO REMOTE CONTROL

Joystick remote controls will have as many as five steps in every direction. The joystick can be configured in many different options such as spring return, lock type, locks, analog output, and digital output. Joystick radio remote controls with potentiometers can be used to wirelessly control the speed of frequency converters, proportional control of hydraulic pumps, etc.

Functions of Crane Remote Control

Features of Crane remote control system is as follows

1. Tandem mode

Tandem mode is controlled by the selector switch. During this mode, the radio remote is synchronized with multiple receivers.

2. Customized Radio Range

Wireless radio remote controls have the ability to transmit and receive the signal at a range of above 200 meters. Anand crane remotes are designed to transmit signals long distances with less power.

3. Communication System

In crane remote control, advanced closed-loop communication systems are used. In radio remote System, closed-loop communication between transmitter and receiver. The transmitter transmits the signal and receives that signal and gives you the required feedback.

4. Digital Address Used

All crane remote control systems used an 8-byte address. An 8-byte digital address is assigned to a transmitter and receiver.

5. Configurable Receiver

Radio receivers have 2 to 8 relays. Relay contact rating is 275Vac at 10 Amps. The Receiver operates in 30mWatt power consumption and saves electricity. It gives the signal indication with the help of a power indication lamp. Another feature is having a mainline contactor on/off indicator.

Applications of Radio Remote Controls

· EOT Cranes

· Electric Hoist

· Jib Cranes

· Goliath Cranes

· Mobile Cranes

· Gantry Cranes

· Tower Crane, and so on

Here are types of Radio Remote Control for cranes with its features. Choose radio control remote based on different parameters and features. Anand Systems Engineering Pvt. Ltd. is a leading crane remote control manufacturers in India. For more details visit our official website https://www.anandcontrol.in/radio-remote-control/anand-remote.html

#radio remote control#crane remote control manufacturers#Radio Remote Control for cranes#crane remote control#Radio Remote Control for EOT cranes#EOT Cranes#radio remote control for overhead cranes.

2 notes

·

View notes

Text

Here is a complete guide for how to select a Radio Remote Control for EOT crane. Choose radio control remote based on different parameters such as technology, ergonomics, etc. We are leading crane remote control manufacturers in India. For more details visit our official website https://www.anandcontrol.in/radio-remote-control/anand-remote.html

#crane remote control manufacturers#radio control remote#Radio Remote#Radio Remote Control#EOT crane#Radio Remote Control for EOT crane

1 note

·

View note

Photo

Joystick radio remote control is an input device from which you can control the EOT crane with one stick. And this stick can be moved in any direction like up, down, left, and right according to the need. Anand systems engineering private limited manufactures the best quality joystick remote control crane. To know more visit: https://www.anandcontrol.in/radio-remote-control/anand-remote.html

2 notes

·

View notes

Text

Why use a Crane Radio Remote Controls

While using cranes and heavy machinery, the safety of equipment and personnel is always at risk. Radio remote controls serve as a best solution to overcome this problem.

Radio Remote Controls are used in manufacturing, construction and many more industries. EOT Crane control panel are mainly used for to control the cranes. Using this technology, the operator can control the crane easily and avoid accident by using wireless remote control crane.

With a crane radio remote Control, an operator can get the possible line of sight when handling heavy equipment. They can operate a crane anywhere. Traditional working method involved risk to operate a crane, But EOT crane control panel increase efficiency and productivity also bring down the costs.

The remote control crane is originally wired, so the operator needs to be away from a short distance, but crane wireless remote control, the operator can control or manage a crane anywhere in the world. Anand Systems Engineering has introduced Customized and Standard radio remote control for cranes, with increase machine handling capability.

EOT cranes from Anand systems are built with industrial grade quality to enable a safety and productivity. With Anand Control, operators can work longer with high safety and operates a crane easily.

Here’s why industrial crane remote control system stand out.

The Best radio remote control for EOT cranes is manufactured by Anand Systems Engineering Pvt Ltd. It is very reliable and can be adapted to any crane.

· Improves operator safety

A remote control crane safely positions the operator at a safe distance away from the moving parts or equipment, dirt, or falling debris, giving them the best lookout.

· Security

In comparison with wireless network, wired connections are more secure because we can access that network through our physical connection cable. Whereas with wireless networks anyone can hack the connection because WI-FI is broadcasted. Therefore, if the network is a configuration, we need to configure it with security applications and firewalls.

· Cost

Wired network is quite expensive as compared to wireless network. Wired network consists of cables, switches and other hardware. In addition, the components need to be updated from time to time.

· The emergency stop button

To avoid the risky situation in workplace, to off the switch is quite complicated. There are instances where there are machine failures, an emergency stop button acts as a failsafe. It helps to stop all operations instantly in case of any emergency.

· Mobility

Operator can move crane from one place to another, while accessing the network. Wireless network offers the flexibility to the operator without any disruption.

Conclusion

wireless remote control for overhead crane and EOT cranes are the future for industries, and they help revamp the complete work process and maintain steadiness and rapidity that deliver all day long.

Any workplace wants improving productivity and safety. Anand Systems Engineering Pvt. Ltd. is mainly focused on improving the productivity and safety of customer.

Anand Systems is crane remote control manufacturers which gives you all the advantages in a single product range. You can buy a Radio remote control from https://www.anandcontrol.in/radio-remote-control/anand-remote.html

#radio remote control for cranes#wireless remote control for crane#wireless remote control for overhead crane#radio remote control for eot cranes#crane remote control#industrial crane remote control system#wireless remote control crane#remote control crane#crane remote control manufacturers#eot crane remote control#eot crane control panel

2 notes

·

View notes

Photo

Radio Remote Control are used to control any type of machinery or equipment. We offer wide range of Industrial Crane Remote Control. It’s reliably control your EOT Crane with crane remote control. You can buy an Overhead Crane Remote Control System from Anand Systems Engineering Pvt. Ltd.

#industrial crane#crane remote control#eot crane manufacturer#eot crane#Crane with crane remote control#crane india

2 notes

·

View notes

Photo

Radio Remote Control for Overhead Crane in India. Anand Systems is India's leading industrial crane remote control manufacturing company. The Best EOT crane remote control is manufactured by Anand Systems Engineering Pvt. Ltd. Anand Crane Remote Controls are designed from the ground up for harsh Industrial Use. Buy crane wireless remote control in affordable price.

#eot crane manufacturer#industrial crane#crane remote control manufacturers#crane wireless remote control

2 notes

·

View notes

Text

How to select Radio Remote Control for Cranes

Today Radio Remote control is used in industry for such devices as EOT crane and overhead cranes. An industrial Radio Remote Control can either be operated by a human, or by a computer control system in a M2M (machine to machine) mode. This is the complete guide for to choose radio remote control for overhead and EOT cranes.

The following steps are used to select an Industrial Radio Remote Control for EOT cranes and Overhead cranes.

1. Based on Technology

2. Safety of wireless system

3. Environment where crane Radio will be used

4. Based on Ergonomics

5. Integration of radio remote control with the crane control panel

6. Service and support

Now, we see brief description of above points

1. Based on Technology

RF Technology- To select Radio Remote control some things to consider which is RF (Radio Frequency) technology, Frequency hopping algorithm means Modern Radio Remote controls can change the frequency of operation at will. In crane radio remote control system can automatically select the frequency to noise free channel using Direct Sequence Spread spectrum (DSS) technique.

Data security – It is more important in radio remote control. Data Security has been taken up very seriously by the Anand Systems Engineering Pvt. Ltd., and it is virtually impossible to hack an Anand Systems Crane Remote control, because of using modified AES 128-bit encryption.

Relays- Relays are used in the receiver box to provide or cut power supply to a downstream contactor.

Feedback- The receiver sends an acknowledgement back to the transmitter upon reception of signal.

2. SAFETY OF WIRELESS RADIO Remote SYSTEM

There are 4 things to consider in safety of wireless radio remote system is Software Safety for wireless controls of cranes, Emergency condition during Operation of crane, Periodic Polling between Transmitter and Receiver.

3. Environment where Crane Radio Remote Control will be used-

Follows the below points to select electric overhead crane remote control, Remote control be used an open environment or closed environment, surrounding Temperature Conditions, Obstructions of radio waves due to metal objects, glass surfaces, walls, and Operation Hazard

4. Based on Ergonomics

In an Ergonomics, consider 4 things to choose radio remote i.e., Form Factor, LCD option, Push Button, Toggle Switches or Analog Switches and Internal Antenna or External antenna and Joystick Remote Controls

5. Integration of Radio Remote Control with the crane control panel-

Integration of the Radio Remote control with a Control panel should be an easy task as Control panels are placed on the crane with limited space and higher than usual ambient temperature. Receiver Indication Lights, Wiring Diagram of the Crane Remote Control are important in selection of Radio remote control.

6. Service and support

A prompt and always available Service and Support team is important. Since, Radio remote controls are industrial products, product failure or downtime means loss of productivity and lost revenue. An easy to read and interpret user manual along with the system also goes a long way.

7. Cost of Radio Remote Control

Finally, selecting the cheapest remote control for EOT cranes, which is satisfying all of your above necessities will be better than just picking the cheapest one. Once you are aware of the factors in selecting a radio remote control system you will make a better decision.

Anand Systems Engineering Pvt. Ltd. is an Indian manufacturer of Radio Remote Control systems for Cranes and Hoists with a Goal of modernizing Indian Engineering.

2 notes

·

View notes

Photo

Radio remote control is used to control any type of machinery or equipment wirelessly. Crane with remote control is used by the radio remote such as EOT crane, walkie-talkie system, and many more.

#remotecontrol#radiocontrol#radioremotecontrol#eotcrane#wirelesscraneremote#eotcraneremote#anadcontrol#anandsystemengineering

2 notes

·

View notes

Link

2 notes

·

View notes