Located in Changzhou City, Jiangsu Province, Changzhou Aoheng Machinery Co., Ltd. is a comprehensive enterprise integrating research and development, manufacturing, trade, and service. We utilize high-quality raw materials and components to produce a diverse range of products, including ultrasonic cutting machines, slitting machines, lace machines, stamping machines, welding machines, integrated composite and slitting machines, spot welding machines, and medical hygiene equipment machines, encompassing 8 major series and 40 types of products.

Don't wanna be here? Send us removal request.

Text

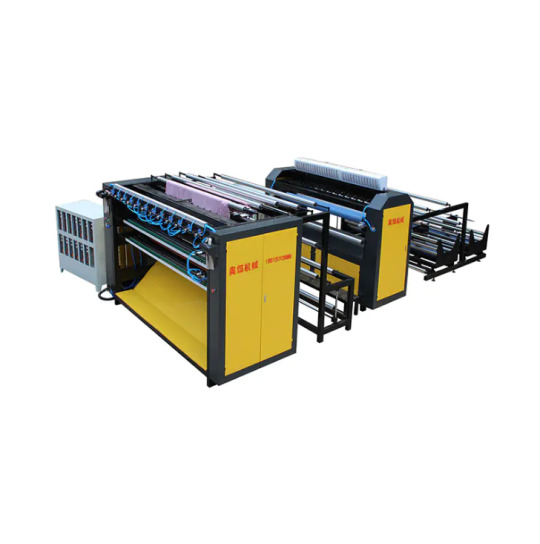

Ultrasonic Towel Tearing Machine

Process flow: shaft discharge --- relax the fabric waiting to better ensure the uniformity of the fabric transmission force ------- rubber roller pulling ------- lateral cutting and welding ----- according to customer demand can be adjusted size cutting and welding ------ automatic tension winding better control of the fabric tightness

Process introduction: the whole machine adopts PLC operating system, pneumatic element lifting mode, easy to operate, work without manual operation, cutting and welding size can be automatically adjusted according to customer's needs, the number of pieces of rewinding can also be set according to customer's needs. Utilizing the ultrasonic principle to make the fabric cutting at the same time with welding function, the fabric is not cut off, gently to tear on the break, and no burrs. Reeling operation is simple and easy to learn, automatic tension on the floor rolls, no need to stop on the way to change the material, pneumatic automatic clamping replacement.

Phone:+86-137 7683 7743 Email:[email protected]

0 notes

Text

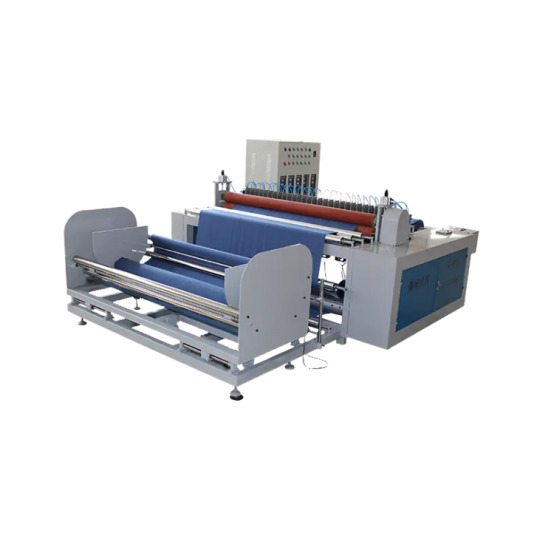

Ultrasonic Air Cutter Slitting Machine

Product Features 1. Electronic centralized control, easy operation, elegant. 2. Frequency converter control system controls the speed stability and reliability. 3 Selection of brushless automatic deviation rectifying device, scratch, uniform feed process and improves the smooth clean cut, and more efficient 4. Cradle-type discharge using double rollers split transmission, driveshaft holds the whole fabric depending on the length of the fabric on both sides of 5. Using magnetic powder tension control air risingshart wind-up tension winding tension can be adjusted automatically depending on the material.

Email:[email protected]

Phone:+86-137 7683 7743

0 notes

Text

Plastic And Non-Woven Cap Machine

The equipment adopts ultrasonic thermal lamination method, frequency conversion speed regulation, production of non-woven material disposable dust non-woven strip cap from feeding to finished product to complete the integrated production. Production process Automated feeding-introduction-folding-welding-molding cut-off

Phone:+86-137 7683 7743 Email:[email protected]

0 notes

Text

Ultrasonic Composite Embossing Cutting Machine

Ultrasonic composite embossing cutting machine is a professional equipment that integrates ultrasonic technology, composite technology, and cutting technology. It mainly uses the principle of ultrasonic vibration to emboss the surface of textiles and combines composite technology to firmly bond multiple layers of materials together. Finally, the finished product is cut into the required size through cutting technology. This device has the advantages of high efficiency, environmental protection, and energy saving, and is widely used in industries such as clothing, home textiles, textiles, and household cleaning products.

Phone:+86-137 7683 7743 Email:[email protected]

0 notes

Text

Shear Type Air Cutter Slitting Machine

1. The electronic control adopts centralized control, which is easy to operate and aesthetically pleasing

2. Adopting Shenzhen Yuanxin brand frequency converter control system, stable and reliable

3. Brushless automatic correction basket material placement, convenient and easy to operate for material placement

4. Automatic edge suction control system

5. The automatic spreading roller unfolds the folded fabric

6. Double drum tension winding

7. Bilateral waste collection device

8. The mechanical structure is strong, with high stability for high-speed operations, effectively improving the durability and service life of the machinery

Five: Operation precautions

1, before starting, ensure that the voltage, current and pressure equivalent is correct and stable.

2. Before the equipment is ready for operation, all personnel must inform to leave the equipment to ensure personal safety before starting operation.

3, When the scuttering machine is running, do not touch the film roll or rubber roll in operation with your hand, so as not to involve your hand and cause personal injury. (No cotton gloves)

4, when the machine equipment is running, it is strictly prohibited to touch the gear chain and other transmission parts with hands, clothing cuffs, so as to avoid injury accidents. (No cotton gloves)

5, in the operation process, do not use a knife or hard object to scratch, cut each roll core.

6, regular maintenance of the machine and equipment, and check whether the functions are normal.

7, the occurrence of machine equipment failure, should promptly notify professional maintenance personnel, private maintenance is strictly prohibited.

8, Press the power switch or emergency stop switch when the equipment is in an emergency state or an accident is considered

9, The mechanical transmission parts should be regularly lubricated to keep the mechanical transmission parts clean.

Phone:+86-137 7683 7743 Email:[email protected]

0 notes

Text

AH-300Q/S High Power Ultrasonic Lace Machine

Basic configuration 1. New computerized intelligent ultrasonic generator. 2.15KHZ ultrasonic transducer device. 3. Bottom mold fixed suspension structure. 4. Single motor (dual motor) speed control system. 5. Manual (or optional pneumatic) mold lifting system. 6. Double-tube rack with heavy table plate.

Features of this machine 1. Built-in computer chip, multi-channel ultrasonic protection system to ensure the safe and stable operation of the host. 2. Super power output, with large, medium and small three power adjustable to adapt to different materials, thickness of the welding and cutting requirements. 3. Automatic frequency tracking system and the application of ultrasonic soft start technology, so that the performance of the machine to reach the international level. 4. Various patterns and designs can be provided according to customers' needs. 5. The running speed is four times of the normal sewing machine, and the operation is simple.

Functions of this machine 1. Edge cutting: single side straight line or curve excision, and dissolved edge treatment, so that the edge is smooth and smooth, no roughness, no raw edges. 2. Sewing: two or more layers of fabrics sewn together, wireless needleless instead of sewing and good fusion strength. 3. Skeletonizing: cut out the holes of all kinds of patterns, and do the fused edge treatment. 4. Open stripes: single or multiple strips of the material at the same time open and cut, and do the fusion edge treatment without burrs. 5. Molding: cut, sew and emboss at the same time to make the product one time molding.

Email:[email protected]

Phone:+86-137 7683 7743

0 notes

Text

Ultrasonic Air Cutter Slitting Machine

Product Features 1. Electronic centralized control, easy operation, elegant. 2. Frequency converter control system controls the speed stability and reliability. 3 Selection of brushless automatic deviation rectifying device, scratch, uniform feed process and improves the smooth clean cut, and more efficient 4. Cradle-type discharge using double rollers split transmission, driveshaft holds the whole fabric depending on the length of the fabric on both sides of 5. Using magnetic powder tension control air risingshart wind-up tension winding tension can be adjusted automatically depending on the material. 6 Track slider-shart transfer precision sitting knife size stabityutrasonic knife cutting of cloth without edges, tidy, without deviation, width adjustable Pattern diversity straightedge, lace)models a wide variety, can be customized according to customer demand machines allies, different pattern. 7. Made by mechacalstee! structure. high stability of high-spee d operation. effectively improve the durability and service life of mechanical and save labor force and high efficiency.

Scope of application and materials A variety of chemical fiber material, microfiber material, and non-woven fabric spraying-bonded wadding. Mainly used in towel cloth, MOP cloth, linen, space, curtains, bed curtains, etc.

Tel:86-137 7683 7743 Email:[email protected]

0 notes

Text

Changzhou Aoheng Machinery Co., Ltd.

ADD:No. 8-1 BeiCaohe Road, Xuejia Town, Xinbei District, Changzhou, Jiangsu, China Tel:86-137 7683 7743 Email:[email protected] Profile:Located in Changzhou City, Jiangsu Province, Changzhou Aoheng Machinery Co., Ltd. is a comprehensive enterprise integrating research and development, manufacturing, trade, and service. We utilize high-quality raw materials and components to produce a diverse range of products, including ultrasonic cutting machines, slitting machines, lace machines, stamping machines, welding machines, integrated composite and slitting machines, spot welding machines, and medical hygiene equipment machines, encompassing 8 major series and 40 types of products. Our products are renowned for their high quality, exquisite design, and competitive pricing, and are marketed across China, Southeast Asia, the Middle East, Europe, and the Americas, in over thirty countries and regions. We are advanced in the field of ultrasonic applications. Furthermore, we are committed to tailoring and customizing a variety of fully automatic ultrasonic production equipment to meet the unique characteristics of our clients' products. The company aims at high quality and efficiency, and insists on ""Quality-oriented, Customer-oriented"" to provide professional services. Customer satisfaction is our goal. Our company's tenet is: professionalism, innovation, sincerity, win-win. We are looking forward to cooperating with you well and sincerely.

1 note

·

View note