Don't wanna be here? Send us removal request.

Text

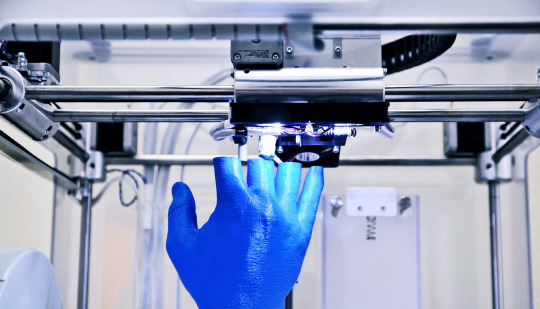

Revolution in Motion: How 3D Printing is Changing the Way We Make Gears

Today, technology is rapid, and one of the ways technology is revolutionizing is through 3D printing gears. It is a process that is easy and fast when it comes to producing complex gear shapes. It has applications across various industries, from automobiles to machines, due to its ability to save money and time. As more use 3D printing, there is a need to learn both the positive and negative aspects of applying it to produce gears.

Speed and Flexibility in the Production of Gear: One of the greatest advantages of 3D printed gears is how much time it takes to produce the parts. Conventional methods of producing gears are indeed very time-consuming. But with the introduction of 3D printing, the parts are designed on the computer and printed within a matter of hours. This allows businesses to create prototypes quicker and change designs without having to wait weeks to obtain new parts.

Cost-effective for Small Batches: 3D printing is also a smart choice when only a few gears are needed. Old methods of making gears cost more when producing just a small number. With 3D printing, the cost stays low no matter how many are made. This makes it great for testing or for custom machines that don’t need large numbers of parts.

Design Freedom for Complex Gear Shapes: Certain shapes of gears are quite difficult to produce with cutting tools. 3D printers, however, can produce quite intricate designs with ease. It enables engineers to design more efficient gears that operate more smoothly or pass into small spaces. It can make machines work better and even lower the amount of power they consume.

Rapid Product Development and Prototyping: Engineers can create and prototype gear designs quickly with 3D printing. One does not have to wait weeks to get a part made; one can print it overnight. This speeds up the design process and enables companies to get products to the market faster. Quick revisions can be handled in the design from test data, and the final product is even better.

Material Choices and Strength Concerns: While 3D printing is fast and customizable, there are indeed some downsides, especially on the material side. Plastic is the most readily available material for the average 3D printer, which may not be as strong for all applications of gears. There are metal printers that can be used for 3D printers, but it's an expensive and potentially not readily available solution. This limits it in applying 3D printing to gears that will require heavy loads or temperature exposure.

Longevity and Long-Term Use Issues: 3D-printed gears are not necessarily as durable as traditional-grown gears. Pieces printed using this method are more likely to crack or degrade faster when put under stress. This can be a problem for devices that are operated continuously or need high dependability. All parts must be extensively tested by engineers to see if they will perform as expected.

Accuracy and Surface Quality Issues: The gear surface has to be very smooth so that it works. The edges of some 3D printers are roughened or contain tiny deviations from optimal shape. The tiny flaws make the gears fail sooner or later. The parts normally need post-print cleaning or finishing to fix this, which takes extra time and effort.

Time for Printing Bigger or More Detailed Gears: Although 3D printing is quick for small items, printing out large or extremely detailed gears can take hours. Sometimes it may still be quicker to do it the old way. Printing time also gets longer if the gear has to be extremely durable, as the printer has to apply more layers and thicker materials.

Role of 3D Printing Companies in Innovation: 3D printing businesses today are dedicated to enhancing the printing of gears. They experiment with new materials, develop improved printers, and assist other sectors in experimenting with this technology. 3D printing companies also provide services for people who do not have a 3D printer, making it simpler for many to employ this process. As these businesses expand, printed gear will become stronger and better.

Environmental Effects and Waste Reduction: There is only material required for the part when 3D printing, so there is less waste compared to traditional processes. It is thus a more environmentally friendly option. Secondly, when gears are printed close to where they are to be used, fewer parts need to be shipped across the globe. This reduces transport pollution.

Custom Gears for Special Machines: Certain machines require special gears that are not available in shops. It is simple to produce gears to cater to these special requirements through 3D printing. This can be beneficial in agriculture, healthcare, or research, where every machine can be unique. Quick production of custom gears can also assist in restoring old machines that no longer have spare parts.

Education and Skill Development: 3D printing is not just for businesses. Schools and colleges apply it as a means of educating students in terms of design and machinery. Printing gears allows students to understand how components function and provides them with practical experience. This assists in developing skills for future career opportunities in design and engineering.

Issues with Standardisation and Testing: One of the biggest problems with 3D-printed gears is that there are no hard rules for testing or quality. Every printer and every material can yield varying results. Without established standards, it is difficult to know whether a gear will be as functional as one printed the traditional way. Additional research is required to develop firm guidelines for how to test and certify printed gears.

Slow Adoption in Heavy Industries: Although 3D printing offers numerous advantages, some industries lag. They are concerned with the long-term durability of the parts and do not want to try new methods they are not familiar with. As the testing becomes better and stronger materials are produced, more industries will likely start utilizing 3D printing for gears.

Conclusion

Ultimately, 3D printing revolutionized the production of gears, bringing numerous advantages such as velocity, design liberty, and reduced cost for low-volume batches. However, it still suffers from material strength constraints, surface finish, and conventional norms. With improved technology, such issues can be minute in the future. The combination of function and form provided by 3D printing architecture will keep remolding the manufacturing approach of industries in terms of producing moving parts. This process may not eliminate all conventional gear-cutting, but it certainly creates new opportunities for innovators seeking to build smarter, quicker, and more efficient machines.

0 notes

Text

Shaping the Future: The Unstoppable Rise of 3D Printing in Dubai

Innovation is happening at a great speed across so many sectors, and one that has genuinely seen massive growth is 3D printing dubai. In the past few years, this has grown way beyond what may have first appeared to be mere trivial prototypes and models, revolutionizing the way cities are constructed and companies function. Dubai is now one of the world's great places to look for 3D printing, pushing new frontiers and disseminating new ideas that are drawing various industries across the world.

The Early Introduction of 3D Printing to Dubai: 3D printing, in the start, was confined to a limited number of low-scale applications including model making and design. Then, with proper investment and an eye for the future, Dubai realized the opportunities of the technology. Private enterprise and government endorsement took it to the limit, creating big-sized projects that displayed what could be achieved when imagination and technology went hand in hand.

How Government Programs Boosted the Growth of 3D Printing: The Dubai government quickly realized that 3D printing has the potential to change the construction, healthcare, and even educational sectors. Plans and policies were introduced to facilitate the use of 3D printing technology among industries. The plan provided a ground for innovation to germinate and enticed talent and businesses to invest in new ventures and turn them into realities.

Changing the Face of the Construction Sector: One of the most famous examples of Dubai’s 3D printing leadership is the world’s first 3D-printed office building. Completed in a matter of weeks, this project proved that entire structures could be printed at a fraction of the time and cost of traditional construction methods. Using large printers and special materials, teams were able to create a full-size office that was both functional and stylish. It revolutionized the perception of people towards building and opened doors to even broader projects.

Expansion to Healthcare and Medicine: Yet another thrilling area in which 3D printing has created a dramatic difference is the area of medicine. Dubai labs and hospitals are employing 3D printers these days to fabricate personalized implants, prosthetics, and even surgical instruments. This has accelerated treatments, assured accuracy, and in most cases saved costs. It has also brought hope to patients who require personalized solutions for their medical needs, demonstrating once again how technology can make life better directly.

Architectural Wonders Achieved with the Help of 3D Printing: Architecture has always been a combination of science and art, and 3D printing has introduced yet another element of imagination into the mix. In Dubai, architects are now employing 3D printing to make models so realistic that they appear almost real. This enables them to visualize their ideas clearly before even laying the first brick. It is also facilitating the construction of entirely new categories of buildings impossible to make based on previous traditions. The city's skyline is soon set to be the proof of where magic and innovations happen.

Training and Education in 3D Printing: With growing importance of 3D printing, education institutions in Dubai are taking the leap. Special training programs and courses are being offered to teach students and working professionals how to use this technology. From 3D modeling to operating the printers, people are learning skills that will keep them ahead of the curve in this fast-changing world. Such focus on education is making Dubai a leader in 3D printing for many years to come.

3D Printing in the Fashion and Art Industry: Dubai’s creative industries have also embraced 3D printing. Fashion designers employ it to design one-of-a-kind clothing and accessories, artists to sculpt pieces that would be too time-consuming or costly by hand. This new liberty has resulted in thrilling exhibitions and fashion shows, where the old rules of design are being rewritten. Artists and designers now have a tool that allows them to realize their boldest visions without restraint.

Sustainability with 3D Printing: With only what is needed to make it, and less wastage, 3D printing companies can make producing, constructing, and designing significantly more eco-friendly. The majority of projects done in Dubai currently are focused on recycling materials to use for their 3D prints, limiting the use of new resources and saving the Earth. Sustainability has become a prime objective in every big 3D printing endeavor.

Future Horizons: What the Future Holds for Dubai 3D Printing: The tale of 3D printing in Dubai has only just started. Experts are certain that in no time, 3D-printed houses will be the standard, housing issues can be addressed and construction be made quicker and less expensive. Some experts even envision that shortly, cities will be printed using intelligent and sustainable materials. Anything is possible, and Dubai is bent on leading the way in this thrilling adventure.

The Private Companies' Role in Shaping the Future: Private firms have been at the forefront of expanding the boundaries of 3D printing. With an openness to investing in new technology and concepts, they have contributed to a large part of what we refer to today as innovations. From small design houses to big building construction companies, businesses across Dubai are developing innovative ways of utilizing 3D printing to tackle actual problems. It is also opening up the technology to utilize and gain advantage across industries.

The Impact on the Economy and Job Market: As 3D printing expands, Dubai is also generating new employment opportunities. Engineers, designers, technicians, and specialists are needed. Firms are recruiting individuals who can design, run, and service 3D printers. This is making the economy stronger and providing well-paying career opportunities to the next generation.

Conclusion

The advent of 3D printing in Dubai has proved that where there is vision and technology, the world is achievable. With massive projects, a supportive government, and the dedication of private enterprises, Dubai is a global leader in 3D printing technology. The future holds even more developments as this technology continues to revolutionize industries and everyday life. In architecture and design, 3D printing for architects is becoming one of the most crucial tools at a very fast rate. The more people realize the potential of this technology, the more opportunities there are, and they will only increase as we move toward an era where we can envision anything and bring it to life with the help of printing.

0 notes

Text

Revolutionizing Industries: Powerful Uses of 3D Printing

Introduction

The practice of 3D printing has advanced from starting out as a tool for prototypes and consumers to becoming an essential element of modern commerce and innovation. The capacity of 3D printing to produce complicated, personalised items from an online model is having a big influence on a variety of sectors, including construction, healthcare, aerospace, and more. 3D printing is revolutionising the creation, development, opinions, and production of objects by enabling more customisation, eliminating waste, and permitting quicker manufacturing timelines. These are some of the most significant applications of 3D printing that are revolutionising the world.

Powerful Uses of 3D Printing

Transforming Healthcare and Medical Applications

Perhaps the most apparent use of 3D printing is in the medical field and medicine. It has allowed implants, prostheses, and even tissues from the human body to be manufactured. More patients will be able to buy individually 3D-printed prostheses, as these are less expensive and cheaper compared to the conventional ones. Moreover, the process has been used to make individualised orthopaedic appliances, dental implants, and hearing aids.

Major developments in regenerative medicine are also being made through the help of 3D bioprinting. Researchers are trying to make the possibility of printing body tissues and organs using 3D bioprinting a reality with the aid of bio-inks produced from living cells. This can transform transplantations and can make organ shortage a part of the past in the near future. The medical sector is shifting towards a personal and effective way of treating patients through the aid of 3D printing. Simplifying Product Development and Prototyping

Firms have revolutionised the manner in which they manufacture and create new products due to 3D printing. Prototyping was, in the past, a time and expensive endeavour with conventional manufacturing. Companies are, however, able to manufacture rapid prototypes through 3D printing with the possibility of rapid alteration and testing. This lowers expenses and accelerates the cycle of item manufacturing.

Businesses in sectors like gadgets, fashion, and transportation utilise 3D printing to check out new materials and patterns before deciding to produce these on a wide scale. This increases overall efficiency, reduces errors and simplifies the concluded output. 3D printing promotes innovation across a number of industries because it makes prototyping less complicated and less high-priced Improving the Automotive and Aerospace Sectors

biggest 3D printing companies technology has also been utilised extensively by the aerospace and automobile industries. 3D-printed light yet robust components are used in aircraft to enhance performance and efficiency. 3D printing is employed by organisations such as NASA and Boeing in order to print complex components in satellites, aircraft engines, and space vehicles. Due to this, they can produce complex geometries which would be impossible or difficult with traditional manufacturing methods.

Similarly, the automotive sector is leveraging 3D printing in order to produce tailor-made vehicles, reducing manufacturing costs and crafting high-performance parts. As part of the attempt to drive efficiency and accuracy, companies such as Tesla and Ford incorporate 3D printing within their manufacturing activities. The ability of 3D printing to craft light, powerful, yet inexpensive pieces is determining the destiny of transport.

Revolutionising Architecture and Construction

Construction buildings and even whole buildings are now being constructed quickly with 3D printing, which is also revolutionising the architecture and construction industry. Large-capacity 3D printers can employ recyclable plastic, metal, and concrete materials to produce office buildings, bridges, and houses. The technology shortens project durations, minimises material waste, and lowers the costs of building.

For effective planning and visualising, the use of 3D printing is also employed by architects for the purpose of developing precise models of their job. Construction companies are gearing up towards fruitful and sustainable building options by adopting this technology. 3D printing may become a tremendous solution to provide for the global housing demand when the need for cost-effective, eco-friendly dwellings is sought.

Facilitating Research and Learning

Research centres and academic institutions are using 3D printing to enrich experimentation and learning. Students in schools increase their creativity and problem-solving capabilities by utilising 3D printers to execute ideas into reality. 3D printing of interactive projects is an excellent way to teach topics like biology, engineering, and art.

From delicate mechanical components to molecular frameworks, 3D printing makes it easy to create precise representations for tests in scientific study. Additionally, it helps fields like archaeological research, where scholars can replicate old antiquities for investigation and conservation. 3D printing speeds up scientific advancement and improves learning as abstract concepts become physical.

Optimising Waste Minimization and Sustainability

Sustainability concerns are on the rise, and 3D printing offers a means to reduce waste and promote environmentally friendly production. Traditional manufacturing processes are wasteful and generate a lot of garbage. Additive manufacturing with 3D printing, on the other hand, saves waste by stacking material upon material.

Secondly, most 3D printing projects use recycled materials in the production of sustainable products, such as biodegradable plastics or reused metal. Besides this, businesses are also looking into using 3D printing technology to fix and reuse broken items rather than throw them away. 3D printing helps towards a sustainable future through carbon footprint reduction and material maximisation.

Facilitating Personalisation and Customisation

3D printing's ability to manufacture personalised goods is one of the most significant advantages. 3D printing enables unique, customised products, as opposed to conventional mass production, which produces similar goods in large quantities. In sectors like consumer goods, jewellery, and fashion, where people want customised goods, this is highly helpful.

3D printing is used by businesses for creating unique shoes, accessories, and furnishings pieces. Customer satisfaction increases, and opportunities for new companies are generated when designs can be modified according to personal preferences. A customised phone case or bespoke furniture are two examples of product design and manufacturing revolutionised through 3D printing.

Conclusion

3D printing is a powerful technology that is transforming numerous industries; it is no longer a future concept. Its applications are limitless and dynamic, from sustainability and building to health and aeroplanes. The fact that it can supply tailored, effective, and cheap solutions makes 3D printing an essential element of the globe today. 3D printing architecture model making in dubai will continue to play a larger role in redrawing industries, improving lives, and addressing issues of the world as innovation continues to revolutionise. The technology is creating new possibilities and shaping the future of design and manufacturing, whether used to build affordable housing or life-saving devices.

0 notes

Text

Tips for Achieving Accuracy in Architectural Models

Making highly accurate architectural models has been part of a good architectural design and presentation from time immemorial. However, in today's digital age, the union of old-fashioned model-making techniques with modern technology allows for previously unthinkable levels of accuracy. This tutorial explains the very essence of producing extremely accurate architectural models-from preparation to execution.

The Basics Preceding the technical process, one must understand that architectural model accuracy starts with planning. The first step is to consider scale carefully, material selection, and what you plan to achieve from making the model. Be it a presentation model for your clients or a detailed study model for design development, precision remains the priority.

Digital Preparation The quest to an accurate architectural model begins in the digital world. Making clean, well organized 3D files is of utmost importance. When choosing the best 3D printer for architects, machines offering a very high resolution and reliable performance for architectural applications take precedence. The quality of your digital model will determine the quality of the end product, and so this stage is the most vital for success.

Material Choice Accuracy is achieved by the choice of materials. Projects vary in materials used, ranging from traditional wooden elements to modern polymers. Material stability, workability, and how well they hold their shape over time are essential factors to consider. The material must complement your modeling technique while supporting the level of detail you are aiming for.

Scale Considerations Working with the appropriate scale is fundamental in creating accurate representations. Most common architectural scales, such as 1:50 or 1:100, present different challenges and opportunities. The chosen scale must be sufficient in detail yet reasonable for fabrication and viewing.

Advanced Techniques Modern Architectural model accuracy has revolutionized through the use of digital fabrication methods. These methods make it possible to cut, assemble, and represent complex geometrical forms accurately. Incorporation of several different fabrication methods-from laser cutting to 3D printing-can help make your models even more accurate.

Quality Control Measures The presence of robust quality control measures through the model-making process ensures accuracy and consistency. There are regular measurements, checking with reference drawings, and the utilization of calibration tools. Creating test pieces before continuing with final pieces can save much time and material while ensuring accuracy.

Working on Digital Tools The evolution of digital tools has transformed the architectural modeling landscape. When precision is paramount, working with a reliable 3D printing service provider can make all the difference in achieving the desired results. Professional services often have access to industrial-grade equipment and expertise that can enhance the quality of your models.

Assembly and Construction Even when all the components are fabricated flawlessly, appropriate assembling techniques ensure the accuracy. Building a systematic method of construction, using the correct adhesives, and maintaining proper alignment at every step in the assembly will all ensure your model's precision.

Detail Implementation The True Test of Accuracy Quite often, it lies in the details. Fine elements such as windows, doors, and special architectural features require special attention. The techniques for consistently producing these elements from scale correctness will be essential to professional-quality models.

Surface Finishing The finishing phase often plays a role in the precision accuracy of your model. The sanding, paint, or textures you apply on the surface of your model should therefore complement rather than subtract from the great details you worked on. This final stage requires careful and meticulous detail for professional outcome.

Documentation and Verification Keeping track of your modeling process ensures consistency in several pieces or even future projects. It involves recording successful techniques, material combinations, and specific settings that give the best results.

Time Management Proper time allocation for each phase of model creation ensures accuracy. One should not rush any stage as this may compromise the precision of the work. Produce realistic timelines which take into consideration all aspects in the modeling process, from preparation to final assembly.

Professional Presentation The way you present your model makes a difference between becoming the reality and diminishing it. Proper lighting, positioning, and display methods will be able to capture the correctness of your job, while enhancing its viewability.

Environmental Considerations Creating an adequate work environment contributes significantly to achieving accuracy. Controlling temperature, dust exposure and an organized workspace all contribute to the preservation of precision in the modeling process.

Future Developments Architectural modeling is a continually evolving field with new technologies and techniques emerging on a regular basis. Staying abreast of these developments while still maintaining the fundamental principles of accuracy assists in better model creation.

Troubleshooting Common Issues One can save time and improve results by understanding how to resolve common, accuracy-related challenges. This would include knowing how to realign when experiencing misalignment, to account for material deformation, and adjust for scale.

Client Communication Clear communication with clients about accuracy expectations helps establish appropriate parameters for your models. Understanding their needs and explaining the capabilities and limitations of different modeling approaches ensures satisfaction with the final product.

Maintenance and Storage Proper storage and handling of completed models helps maintain their accuracy over time. This includes considerations for temperature, humidity, and physical protection to preserve the precise details you've created.

Training and Skill Development The process of making accurate models in architecture always needs people to continue learning and practicing. Spending time on mastering new techniques, whether through workshops, online courses, or first-hand experience, helps perfect the ability to achieve precision. Only time and practice teach how similar tools and materials react to specific conditions. Knowledge learned from experienced model makers about workflow efficiency and solving difficult problems is also invaluable.

Conclusion Achieving accuracy in architectural models requires a combination of technical skill, attention to detail, and proper planning. Following these comprehensive guidelines and maintaining high standards throughout the process will help you create precise, professional-quality architectural models that effectively communicate your design intent. Accuracy is not just about measurements; it's about creating a reliable representation of architectural concepts that can be used confidently for decision-making and presentation purposes.

Continuous learning and adaptation of techniques as technology and materials evolve are what create successful architectural models. Maintaining focus on precision while embracing new tools and methods, architects and model makers can continue to push the boundaries of what's possible in architectural representation.

0 notes

Text

An investigation on the use of 3D Printing in constructing Models in the field of architecture in the UAE

Being a versatile technology, the application of 3D printing has now impacted engineering and manufacturing, healthcare and automotive, clothing and architecture, and construction industries. For the model makers and architects in UAE especially the use of 3D printing has proved to be essential in the development of designs offering a high level of accuracy. This article explains how 3D printing for model makers, and how it is used in architectural modeling and provides information on several major firms associated with this powerful 3D printing industry.

3D Printing for Model Makers: Precision and Creativity

Users of full-size, prototype, or scale models and even sculptors or artists who use models in their work have seen the benefits of 3D printing technology. Conventional making of models has many techniques that require the use of hands for carving, molding, sculpting, or assembling parts of a model. Although these techniques we still regarded as valuable, they no longer dominate the field and can be substituted with 3D printing for quicker and better outcomes.

Advantages for Model Makers

Intricate Details: 3D printing also provides a way of creating detailed models and it is difficult to achieve in the traditional modes. This is especially helpful for building many complex structures that may be difficult to build when large-sized, models or miniatures with complex surface textures.

Material Versatility: According to the application, it is apparent that plastics and resins, metals, and bio-materials are the most popular types of material that are used in 3D printing for model makers to meet their needs.

Customization: It is easy to tweak model making and because of this, the management can make numerous changes to the models before presenting them to the clients.

Time Efficiency: Compared with conventional techniques that might take days or even weeks to complete and produce workpieces of the same level of sophistication, 3D printing truly minimizes the time required for manufacturing workpieces.

In this regard, the rapid expansion of new technology in a region that is usually fast to adopt technology has been a new break for the existing model makers in the UAE. The opportunities range from product development models, testing samples, and interactive art as well as museum installations among others.

3D Printing: Its Application to Architectural Modeling

Office towers, tall apartment complexes, and large-scale architectural marvels have made the United Arab Emirates a world architect’s paradise. However, it is worth noting that 3D printing is a task that plays an important role in realizing architectural concepts as architects explore new directions.

How the Materialized Model Derived from the Architect’s Drawing Can be Improved Using 3D Printing

Realistic Representation: Architects have an opportunity to produce models that resemble their plans through the help of 3D printing. Clients stand to benefit from enhanced visual image interpretations of structures, enhancing streamlining of the decision-making processes.

Complex Geometries: Details of geometry that are inherent in many of the more contemporary forms of architectural design are complex to mimic by conventional techniques of modeling. 3D Printing makes this possible.

Cost-Effectiveness: 3D printing model making therefore is cost effective since it saves on the amount of material used in making the model as well as the labor cost.

Iterative Design: To this end, architects have the ability to print multiple models in an attempt to find out which designs better suit their concept and improve on concepts without incurring an extensive amount of time and cost.

While the use of 3D printing in architecture is still confined to creating models in the UAE, live construction is now incorporating this and other such technologies. For example, the Dubai 3D Printing Strategy developed as a public domain strategy to turn Dubai into the global capital of 3D printing, its use of technologies in construction, medical products, and consumables, is a good example.

Top Ten Largest 3D Printing Companies That Matter

The businesses worldwide that form the 3D Printing market are diverse, and new technologies and materials are being developed continually. Today, the largest 3D printing companies are increasingly using this technology in the UAE.

1. Immensa Technology Labs

Immensa Technology Labs is a post-revelation 3D printing company that operates in Dubai. The company has many services which include prototyping, custom manufacturing, and digital inventory solutions. Glass former Immensa is also well established among industrial markets that it serves, such as oil and gas, aerospace, and automotive.

2. 3DVinci Creations

Focusing on architectural modeling and industrial design services 3DVinci Creations LLC is yet another company from UAE that is involved in 3D printing. The company specializes in offering architectural designs in 3D printing architecture model in UAE, designers, and model makers, their work is accurate and meets high standards.

3. Proto21

The key specialty of Proto21 company is in the field of additive manufacturing and rapid prototyping. This is a company that supplies its products to companies and individuals in different sectors such as construction, health and even manufacturing companies that deal with consumer products among others. Physical – Proto21 has the best facilities and experienced employees, which makes them a favorite among3D printing organizations in the UAE.

4. BigRep Middle East

The German multinational company BigRep, which specializes in large-scale 3D printing has a good base in UAE. K6830 has the biggest size 3D printers for printing big models and is thus best suited for architectural models and industry models.

The UAE's Use of 3D Printing: Potential Benefits and Risks

The best UAE offer that guarantees the chances of 3D printing in many industries is the country’s devotion to innovation and sustainability. Of them, it carried out the work on the application of 3DP in compliance with the government’s Dubai 3D Printing Strategy. For more than a quarter of new buildings to be built using 3D printing technology, is Dubai’s plan by 2030.

It is therefore envisaged that the technology will transmit a generic message to architects and model makers.

Chances and Challenges

Despite such benefits achieved from using 3D printing, it has its drawbacks as well. These are; the high cost of advanced 3D printers, the need for specialized personnel, and the unavailability of some materials. These should, however, reduce as technology improves, paving the way for its broader implementation process.

As the UAE government and other key institutions keep pumping money into 3D printing research and development and helping the organizations to work in partnership with each other, the United Arab Emirates will remain pioneers of 3D printing in the world.

Conclusion Nowadays, 3D printing is widely used in model making and applying architectural concepts in the UAE. Ranging from making accurate prototypes in scale 1:1 up to architectural models of large dimensions, this technology presents itself unparalleled in terms of precision, productivity, and flexibility. Finally, the help of large companies such as Immensa Technology Labs, 3DVinci Creations, Proto21, and BigRep Middle East, some of the biggest 3D printing companies, put the UAE in the globally leading position in the 3D printing revolution. Thanks to the ongoing development of the technology, the variety of uses of 3D printing for model making and architecture become almost inexhaustible. Whether you are an aspiring model maker who wants to come up with complex designs or an architect who wants to turn his or her ideas into reality, 3D printing, driven by the biggest 3D printing companies, is necessary, which is revolutionizing the future today

0 notes

Text

THINGS TO CONSIDER WHEN LOOKING FOR A 3D PRINTING WEBSITE

Introduction

In the rapidly evolving world of design and construction, 3D printing has surfaced as a transformative technology, particularly in architectural maquettes and 3D modeling for construction. As metropolises like Abu Dhabi continue to expand with innovative structures, the demand for precise, high-quality 3D published models has flooded. opting for the right 3D printing website is pivotal for professionals seeking to rephrase their digital designs into real prototypes. Whether it's for creating detailed architectural maquettes or functional construction elements, a dependable 3D printing service can significantly impact the success of a design. Let's explore crucial considerations to ensure you choose the most appropriate 3D printing website to meet your design’s specific requirements, concentrating on aspects like material selection, printing quality, cost, turnaround time, and the role of client support offered.

Pointers to Contemplate When Looking for a 3D Printing Website -

1. Understanding Your Design Needs

Before diving into the selection process, it's essential to have a clear understanding of your design conditions. 3D printing serves different endeavours, from Architectural Maquette and construction factors to jewellery and medical bias. Knowing whether you need a detailed, small-scale model or a larger, operational prototype will guide your decision. Different websites may specialize in different types of 3D printing, so align your design’s requirements with the service’s expertise.

2. Material Options and Quality

One of the most crucial aspects of 3D printing is the selection of accoutrements. For architectural maquettes, accoutrements that mimic the texture and colour of the real construction materials are frequently preferred. Websites that offer a wide range of material choices allow for more flexibility in achieving the asked aesthetic and practical properties. also, the quality of these accoutrements plays a vital part in the final design, impacting the durability, strength, and detail of the printed model.

3. Printing Technology and Precision

Not all 3D printing technologies are produced equal. The technology used can greatly affect the perfection, face finish, and strength of the printed object. For illustration, Fused Deposit Modeling( FDM) is generally used for its cost-effectiveness and speed, but it may not give the high resolution needed for detailed architectural maquettes. On the other hand, Stereolithography( SLA) and Selective Ray Sintering( SLS) offer exceptional detail and smooth finishes, making them ideal for intricate designs. Understanding the technology offered by the 3D printing website and its appropriateness for your design is pivotal in ensuring the most excellent possible result.

4. Customization Capabilities

Customization is frequently a crucial demand in 3D printing, especially for undertakings that involve unique designs or bespoke factors. Look for websites that offer comprehensive customization options, similar to the capability to choose precise material finishes, colours, and post-processing treatments. This is particularly important for architectural maquettes where accurate representation of textures and finishes can make a significant difference. A good 3D printing website should give a range of customization features that allow you to conform the final product to your exact specifications.

5. Cost and Value for money

While cost is always a consideration, it should be counted against the value given. Cheaper services might save money but could lead to lower-quality prints or longer reversal times, which can be harmful to your design’s success. Consider the total cost, including material, technology, customization, and shipping. Some websites may offer reductions for bulk orders or long-term contracts, which can be advantageous for ongoing designs. also, transparent pricing without hidden freights ensures that you can budget accurately for your 3D printing requirements.

6. Time taken for Delivery

Time is frequently a critical factor in design operations. The speed at which a 3D printing website can produce and deliver your order is pivotal, particularly for designs with tight deadlines. Some services offer expedited printing and shipping options for an added figure, which can be a lifesaver in time-sensitive situations. still, it's also important to balance speed with quality; rushing a print can occasionally lead to mistakes or faults. ensure that the website can meet your timeline without compromising the quality of the final product.

7. Client Support and Communication

Good client support is essential when working with a 3D printing service. Whether you need help with file preparation, material selection, or tracking your order, responsive and knowledgeable client support can make a significant difference. Look for websites that offer multiple communication channels, similar to live chat, phone assistance, and email, and that give prompt responses to inquiries. client support can also be a pivotal factor when dealing with issues similar to print faults or delivery problems, so guarantee the service you choose has a strong prestige in this area.

8. Character and Reviews

In an industry where the final product’s quality can vary significantly between providers, character matters. Looking for a 3D printing website’s character through client reviews, case studies, and other clients can give precious perceptivity to the service’s trustability and the quality of its prints. Pay attention to feedback regarding print quality, client service, and adherence to delivery times. Websites with a strong portfolio of successful designs, particularly in your area of interest like architectural maquettes or 3D modelling for construction, are more likely to meet your prospects.

9. Post-Processing and Finishing Services

Post-processing can significantly enhance the quality and appearance of the 3D published models. Whether it’s sanding, painting, or adding other finishes, these services are pivotal for achieving a professional-grade final product. For architectural maquettes, post-processing might involve adding textures, and colours, or indeed integrating the model with other accoutrements. Assure the 3D printing website offers the level of finishing you want and whether these services are performed with perfection and attention to detail.

11. Environmental Concerns

As sustainability becomes increasingly important in all areas, the environmental impact of 3D printing is a consideration worth noting. Some 3D printing websites prioritise eco-friendly practices, similar to using biodegradable accoutrements, reusing waste, and employing energy-effective processes. However, look for services that align with these values, If sustainability is a priority for your design. This is particularly applicable in metropolises like Abu Dhabi, where sustainable construction practices are getting more current. 3D printing abu dhabi is changing the entire industry scenario by allowing for rapid modelling and tailored production resolution.

Conclusion

Choosing the correct 3D printing website is a pivotal step in guaranteeing the success of your design, whether it involves creating an intricate architectural maquette or producing functional construction elements. By considering factors such as material options, publishing technology, customization capabilities, cost, and client support, you can make an informed decision that aligns with your design’s specific requirements. In dynamic and fleetly growing regions like Abu Dhabi, where innovation in construction is at the front, having access to a dependable and high-quality 3D printing service is more important than ever. Take the time to probe and assess implicit providers, ensuring that they not only meet your current conditions but can also support your future ideas in the innovative world of 3D modelling and printing.

0 notes

Text

Exploring the Biggest 3D Printing Companies and Their Innovations

3D printing technology has been accepted in many fields, ranging from manufacturing industries to the health sector. The largest players in the market are now driving this change through the provision of best-of-breed solutions and methods. In this article, the author will take a closer look at what 3D giants such as Stratasys or Materialise have been doing, as well as present an outlook into the field of biggest 3D printing companies in Dubai. Last but not least, the UAE architectural model makers use 3D printing and pave their way towards the future.

The enhancement and advancement of 3D printing technology

A Brief Overview

3D printing or more specifically, additive manufacturing, is used to build a real-life object from an architectural design. This technology vertically lays objects, giving them good precision and, at the same time, good flexibility. During the evolution of 3D printing, the technology has advanced, allowing the creation of sophisticated products and services in different industries. Contemporary developments in technology have enabled the production of very complex and diversified products for various uses, ranging from multisegmented industrial applications to detailed consumer items. Such evolution shows the increased capacities and uses of 3D printing technology in the contemporary world.

Key Advancements

Improved Materials: The kinds of materials used to generate 3D printing have diversified. By going from regular plastics to metals and even tissue engineering, these developments enable stronger and more diverse uses.

Faster Printing Speeds: Expressive technology has made printing faster than before to allow for improved cycles and output.

Greater Precision: There are sharper and better modern 3D printers with high resolution and accuracy for increased precision in other tasks.

Focusing Companies to Watch in the 3D Printing Domain in Dubai

Currently, several leading firms in the field of 3D printing are situated in Dubai, which is famous for its innovative culture. These firms are expanding the potential of what’s possible using 3D printing technology.

Innovations in Dubai

Architectural Applications: Some of the economical sectors, such as 3D printing, have confidently advanced in Dubai in the field of architectural modelling. In the case of architects, 3D printing allows them to create detailed models and prototypes that prove useful in design conceptualizations.

Healthcare Solutions: In the medical field, a few 3D printing companies in dubai manufacture customized prosthetics and implants that meet the needs of the patient.

Consumer Products: Embracing advanced fabrication technology, Dubai’s 3D printing companies are serving the increasing clientele that seeks tailor-made accessories and home décor items.

Key Trends

Sustainability: Most of the companies have adopted the green concept implying that they are inclined to adopt environmentally sustainable practices and or goods into their production line. This includes the use of recycled material and attempting to control energy usage in a quest to have minimal harm to the environment. Some are also targeting the achievement of the production of biodegradable materials and the recycling of wastes during the manufacturing processes.

Integration with Other Technologies: At present, AM is rarely applied in isolation from other innovative technologies, for example, artificial intelligence, the Internet of Things, smart robotics, etc. It strengthens different aspects such as the superiority of larger-scale manufacturing systems in the development of new facilities, efficiency of automation of the different functions, increased usage of advanced technological tools, deriving higher benefits from the new technologies about manufacturing processes, solving different complex tasks of manufacturing requirements for smart production systems and automation, and improvement of functions of manufacturing systems about new advanced data.

The benefits of architectural model makers in the UAE

As for the enhancements of architectural model makers in the UAE, 3D printing is also widely utilized in the field. The following are the benefits of this technology that contribute to the enhancement of architecture as a field:

Advantages of 3D Printing in Architecture

Enhanced Visualization: Some of the purposes of 3D printing include being able to come up with accurate models of the architectural design. These models help in presenting the ideas in a form that the clients and the other stakeholders will be able to appreciate to assess the projects in question.

Faster Prototyping: Hands-on techniques of model-making may at times be lengthy and require a lot of effort. Regarding this process, 3D printing helps in amplifying the same and facilitating the architect to produce and modify models at the earliest.

Cost Efficiency: Although high-quality 3D printers may be costly, the costs when used to make architectural models are relatively cheaper compared to customary techniques, particularly when intricate models are required.

Notable Applications

Building Design: 3D printing is very useful, especially when it comes to architectural concepts that require precise miniature models of the buildings that may be required in presentations, planning, and marketing. They give a physical form of the resultant product, and hence it is easier to explain the design action and make the choices.

Urban Planning: City scale models are very useful in the field of urban planning since they show in a better way how new structures will fit into the existing landscapes. These models aid its stakeholders in seeing the implications, the possible hurdles, and the organization’s new development projects as they integrate them into the environment.

Custom Features: Some of the features and components that are difficult to model or are convoluted may be hard to build using conventional manufacturing techniques. Therefore, 3D printing helps architects build these elements with enhanced accuracy in an appealing and individualized manner, which aims at boosting the functionality of architectural projects.

Conclusion Industry leaders are keen on expanding their innovation of 3D printing products across the globe and its sectors. Currently, 3D printing firms are driving innovation in Dubai through architectural marvels, health solutions, and consumer goods. At the same time, architectural model makers in uae discuss how incorporating 3D printing into the process of producing architectural models improves the detail and accuracy of models and helps envision projects more effectively. Thus, 3D printing technology can be deemed an innovative tool in terms of today’s parameters, which will only develop in the future and create new opportunities and demands for optimization in various spheres.

0 notes

Text

Discovered Information on the Leading 3D Printing Companies

At the moment one of the most dominating and rapidly developing trends in the manufacturing industry all over the world is the 3D print. When talking about the biggest 3d printing companies, some of them have achieved great outcomes and contributed to the mutational reinvention of several sectors. Therefore, this article will focus on finding out who the current key players are in the context of 3D printing, the technologies that the players are utilizing in their operations, and 3D printing in some vital sectors, namely, aerospace, automotive, health, and architectural sectors.

What is 3D printing?

3D printing involves the manufacturing of an object by deposition of a large number of layers to come up with a part that has been designed using a drawing application. In this technique of fabrication, there is a buildup of one layer of materials on another to give the final product as an outcome. It creates designs that are seemingly impossible to create using other principles of manufacturing engineering.

Applications of 3D Printing

Aerospace

Lightweight Parts: 3D printing has the advantage of thinning the parts and reducing the weight of the components, especially in the aviation technology aspect. Reducing the weight of car parts consequently decreases fuel consumption and lowers gas emissions.

Complex Geometries: Components in aerospace structures are often geometrically advanced and, as such, challenging to create employing conventional processes. It is with this ease that 3D printing can produce these parts.

Rapid Prototyping: The method and versatility of creating prototypes help aerospace firms determine designs for production in a shorter period.

Automotive

Customization: The use of 3D printing leads to the development of particular components required by peculiar vehicles; this is because 3D printing makes it possible for the makers to produce part by part.

Tooling and Jigs: Using 3D-printed tools and jigs will go a long way in cutting down a lot of time and money spent on manufacturing.

Spare Parts: The Original Equipment Manufacturers should design systems that allow the manufacturing of spare parts in real-time and thus the users receive genuine parts that may be required to replace damaged ones to get the equipment back to service.

Healthcare

Prosthetics and Implants: Despite the current state of progress in possessing the tools for 3D printing of prosthetics and implants, there are more and more inventions and individually designed ones.

Surgical Guides: These guides enable surgeons to achieve greater accuracy during both simple and complex surgeries, providing a valuable benefit for patients.

Bioprinting: The science of producing living body structures and organs is often referred to as bioprinting, with promises for medicine’s future.

Industrial 3D printer companies

industrial 3d printer companies are the leaders in additive manufacturing, as they are interested in expanding the potential of this form of production. They are companies that create sophisticated machines that can manufacture superior-quality, robust components for their respective uses. They are invaluable in areas and vocations that require accuracy, power, and dependability.

Industrial 3D Printers: Features and Capabilities

High Precision: Distinguishing 3D printers from industrial machines, one can state that this technology allows manufacturing parts with the accuracy and the necessary tolerance. Such accuracy is attributed to the ability to provide complex geometries together with fine details characterized by the high standards of the current industry.

Material Variety: It also can print many kinds of material including metal, plastic, and composite its capability of printing is almost limitless. This flexibility enables the creation of new components and the production of parts for new materials that can be used for making portable consumer goods to aerospace equipment parts.

Scalability: Developing 3D printers is said to be superior and facilitates mammoth production and building and this fits the industry. These printers can accommodate big numbers of production and are thus suitable for both batch production and continuous production.

Advanced Fabrication Techniques: Industrial 3D printers use intricate manufacturing technologies such as AM technologies including SLA, FDM, and SLS. They enable the manufacturing of complicated components with great staking strength and imaginative geometries.

The Threats and Opportunities of 3D Printing

Challenges

Cost: The capital cost includes higher cost of purchasing high-quality 3D printers and the still extremely high cost of 3D printing materials. Advanced models of 3D printers are expensive and require high capital investment at the start and there is always the cost of materials.

Material Limitations: Not all materials can be or need to be printed through 3D printing some of them might be quite a problem. Some materials are difficult to manage mostly where there are poor quality prints or unless there is a high cost.

Quality Control: Consistency in the quality of the 3D-printed parts is another problem that is more pronounced in the vital fields. Printed items have many parts of the whole and to make them have the same quality standard, measures of quality control need to be implemented and equipment needs to be recalibrated often.

Opportunities

Customization: The utility of 3D printing in customizing solutions is another benefit since it implements a mass production of products, making a solution for need all about it.

On-Demand Production: It also supports on-demand manufacturing, thus getting rid of big inventories and stocks that usually accumulate and turn out to be valueless. This model also assists in the correct allocation of resources within a business and in satisfying consumers' needs.

Innovation in Design: 3D printing promotes creativity since designers can expand their creativity and design in many unique ways. This leads to the possibility to design some structures and products that could not be designed before utilizing the technology

Future Prospects

Technological Advancements: Long-term advancements should be expected in new materials, improvements in the printing process, and the realized rate of manufacturing.

Increased Adoption: With the decrease in cost and advancement of technologies, more sectors should move towards 3D printing.

Sustainability: 3D printing can play a role in sustainability because the method is more of a waste-saving technique and can produce lighter parts.

Conclusion:

Architectural solutions are creating new opportunities. architect 3d enable designers to model or prototype their designs in ultra-realism and high detail. With this technology, architects can conceptualize improvements to their designs, develop new structures, and efficiently execute their architectural plans.

So, if industrial 3D printer companies keep on improving and proving themselves in their craft, this will create new chances and advancements in the future. 3D printing is proving to be a disruptor of traditional methods through the use of architectural 3d tools in design and construction, hence the importance of 3D printing in the creation and construction processes.

1 note

·

View note