Don't wanna be here? Send us removal request.

Text

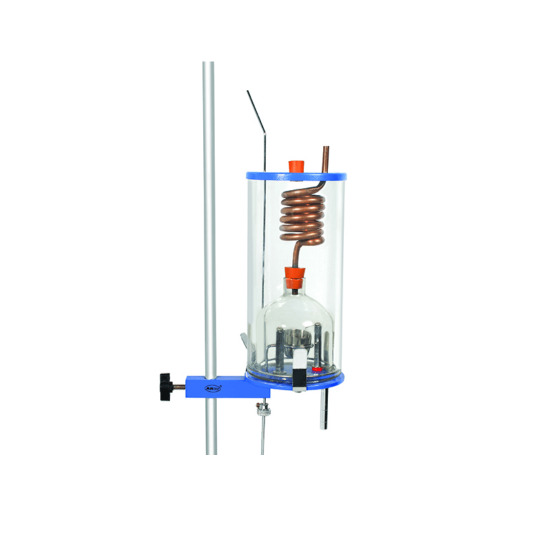

How Distillation Apparatus Revolutionizes Chemical Separations in Laboratories

The distillation apparatus is a cornerstone in chemical laboratories, playing a crucial role in separating mixtures based on differences in their boiling points. From academic research to industrial applications, this equipment has revolutionized the way substances are purified and isolated. In this article, we’ll explore how the distillation apparatus has transformed chemical separations, its various types, and how laboratory instruments dealers in Haryana are contributing to the availability of this essential equipment.

What is a Distillation Apparatus?

A distillation apparatus is a set of laboratory equipment designed to separate components of a liquid mixture. The process is based on the principle of selective vaporization and condensation. As the mixture is heated, the component with the lower boiling point evaporates first, and then the vapor is condensed back into liquid form, isolating it from the rest of the mixture.

This equipment is indispensable in fields like organic chemistry, pharmaceuticals, petrochemicals, and environmental sciences, where high-purity compounds are essential. With its ability to purify, concentrate, and separate liquids efficiently, the distillation apparatus has become a fundamental tool in laboratories across the globe.

The Impact of Distillation Apparatus on Chemical Separations

Precision and Efficiency in Separation

The most significant advantage of using a distillation apparatus is the precision with which it separates components. Distillation can isolate compounds that are extremely similar in chemical structure but differ in their boiling points. This makes it ideal for tasks such as purifying solvents, essential oils, or separating hydrocarbons in crude oil. With modern distillation apparatus, laboratories can achieve a high degree of purity, improving the quality of their research or products.

Variety of Techniques for Different Applications

There are various types of distillation apparatus, each suited for specific tasks. For example:

Simple Distillation is used for separating liquids with significantly different boiling points.

Fractional Distillation is ideal for mixtures of liquids with closer boiling points, such as in the petrochemical industry.

Vacuum Distillation is utilized for compounds that decompose at high temperatures, offering a safer and more efficient alternative.

Steam Distillation is used for extracting volatile compounds from plants or substances sensitive to heat.

These advancements in distillation apparatus have allowed laboratories to tackle a wider range of chemical separations with greater accuracy and ease.

Cost-Effective and Scalable Solutions

Over time, distillation apparatus have become more cost-effective and scalable. The rise of automated systems and advanced materials has reduced the cost of manufacturing and operating distillation units, making them more accessible to smaller laboratories and research facilities. This scalability ensures that even larger industrial applications can benefit from the technology, leading to mass production of purified substances in industries like pharmaceuticals, petrochemicals, and food processing.

The Role of Laboratory Instruments Dealers in Haryana

In regions like Haryana, laboratory instruments dealers play a crucial role in ensuring that research facilities, educational institutions, and industrial operations have access to high-quality distillation apparatus. Dealers in Haryana offer a wide range of laboratory equipment, including distillation apparatus, to cater to the diverse needs of their clientele. These dealers not only supply the equipment but also provide valuable support in terms of installation, maintenance, and training, making sure that the apparatus operates efficiently.

Local suppliers of laboratory instruments in Haryana often collaborate with manufacturers to offer customized solutions, addressing the unique requirements of different industries. Whether it's a small-scale laboratory or a large industrial setup, having access to reliable distillation apparatus is vital for maintaining the quality and efficiency of chemical separations.

Conclusion

The distillation apparatus has revolutionized the way chemical separations are conducted in laboratories, providing researchers and industries with a reliable, efficient, and precise method for isolating compounds. The ongoing advancements in distillation technology have made it more accessible, scalable, and cost-effective. Additionally, laboratory instruments dealers in Haryana are contributing significantly to the availability of high-quality distillation apparatus, ensuring that laboratories in the region are equipped with the latest technology to support cutting-edge research and industrial processes.

As the demand for purified substances and chemical separations continues to grow, the role of distillation apparatus in laboratories becomes increasingly crucial, cementing its place as one of the most important tools in modern scientific and industrial operations.

0 notes

Text

How Claisen Tubes and Beakers Revolutionize Separation in Laboratory Processes

In the world of scientific research and experimentation, precision and efficiency are key. Laboratory separation processes, whether for chemical, biological, or physical analysis, require the right tools to achieve accurate results. Two such essential tools are the Claisen tube and beakers. These instruments, each with distinct roles, work in tandem to improve the separation, mixing, and handling of substances in laboratory settings. This article explores how these tools revolutionize laboratory separation processes.

1. What is a Claisen Tube?

A Claisen tube is a specialized piece of laboratory equipment used in distillation and separation processes. Characterized by its U-shaped design, the Claisen tube allows for the effective separation of liquids, often when working with mixtures in a distillation setup. It typically has one or more side-arm connections, which are used to facilitate the addition or removal of substances during experiments. This tube is especially useful for maintaining constant flow and minimizing contamination during the separation process.

2. How Claisen Tubes Improve Separation

The primary role of the Claisen tube in laboratory processes is to facilitate the separation of components within a mixture. Whether you're performing fractional distillation or another form of separation, the tube ensures that vapors are collected efficiently while preventing cross-contamination. The U-shape allows for smooth flow dynamics, providing a controlled environment where different substances can be separated based on their boiling points or other physical properties. This design reduces the chance of impurities mixing with the separated components, ensuring purer results.

3. The Role of Beakers in Separation Processes

While the Claisen tube aids in separation through distillation, beakers serve a different yet equally important role. Beakers are used to hold, mix, and heat liquids during various stages of laboratory procedures. In separation processes, beakers are indispensable for mixing substances before or after distillation. They are also essential for containing solutions, collecting separated liquids, or holding reactants during chemical reactions. The versatility of beakers allows them to support various separation techniques, from filtration to evaporation.

4. Combining Claisen Tubes and Beakers for Efficient Separation

When used together, Claisen tubes and beakers significantly enhance the separation process. During distillation, the Claisen tube helps separate and collect the vaporized components, while beakers are used to hold and measure the separated liquid phases. This combination ensures that substances can be carefully controlled and manipulated at each step, making the overall process more efficient and accurate. For example, a researcher might collect distillate into a beaker after it has passed through a Claisen tube, ensuring that the separation is both effective and safe.

5. Applications in Distillation and Chemical Reactions

The Claisen tube and beakers play critical roles in several applications, particularly in distillation and chemical reactions. In distillation, these tools are used to separate and purify liquids by utilizing their differing boiling points. Whether you're working with solvents, essential oils, or other chemical compounds, these tools help separate, collect, and store components. Beakers also come in handy for neutralizing acids or mixing chemicals before introducing them into a distillation setup. The combination of both tools ensures precise control over reactions and separations.

6. Advantages of Using Claisen Tubes and Beakers in Laboratory Work

The use of Claisen tubes and beakers in laboratory work offers several advantages. First, they help improve accuracy by ensuring that separations are carried out without contamination. Second, they enhance efficiency by providing a controlled environment for each process step. Finally, they are versatile tools, supporting a range of laboratory functions, from sample preparation to the final collection of separated materials. By relying on these tools, scientists can ensure cleaner, more precise results in a variety of experiments.

Conclusion

Both the Claisen tube and beakers are indispensable tools in modern laboratory separation processes. While the Claisen tube enhances the efficiency of distillation by enabling precise separation, beakers offer versatility in holding, mixing, and collecting liquids. Together, they play an integral role in ensuring that laboratory experiments are carried out with accuracy and reliability. As these tools continue to evolve, they will undoubtedly remain at the heart of many laboratory procedures, revolutionizing the way separation and purification are achieved in scientific research.

0 notes

Text

The Role of Stopcocks in Plumbing and the Mechanics of a Two Stroke Petrol Engine Diagram

In both plumbing systems and engine mechanics, specific components play pivotal roles in ensuring efficient and reliable operation. Among these components, stopcocks in plumbing systems and the two stroke petrol engine diagram in small engine designs are crucial. While these components serve different purposes, they both contribute significantly to the smooth functioning of their respective systems. This article will explore the critical functions of stopcocks in plumbing systems and provide an in-depth look at the two stroke petrol engine diagram to understand the mechanics behind small engines.

The Role of Stopcocks in Plumbing

A stopcock is an essential part of any plumbing system. It is a valve that controls the flow of water or gas through the pipes, enabling users to start, stop, or regulate the fluid movement. In everyday plumbing applications, stopcocks serve as the primary shut-off valves in cases of emergencies or when maintenance is required. For instance, if there is a leak in the system, or plumbing work needs to be done, turning the stopcock off will halt the water supply and prevent further damage.

Stopcocks are typically located near water meters, at junctions, or at key points of the plumbing system, where they can easily be accessed. In household plumbing, the stopcock is often found close to the main water inlet, while commercial systems may have multiple stopcocks for different sections of the building.

Made from durable materials such as brass or stainless steel, stopcocks are designed to withstand high water pressure and various environmental factors, ensuring longevity and functionality. Their simple yet efficient design includes a valve, a handle, and an adjustable mechanism that controls fluid flow. The handle can be turned to open or close the valve, which in turn regulates water movement within the pipes.

Understanding how to operate and locate a stopcock is essential for homeowners and professionals alike. In emergencies, the ability to shut off the water supply quickly can prevent flooding, minimize damage, and simplify repairs. Whether you are performing routine plumbing maintenance or dealing with an unexpected issue, knowing how to manage the stopcock is critical to effective system management.

Understanding the Two Stroke Petrol Engine Diagram

A two stroke petrol engine diagram provides a visual representation of how a two-stroke engine functions. Unlike four-stroke engines, which complete their cycle in four strokes of the piston, two-stroke engines accomplish this in just two strokes: one for compression and one for power. This unique characteristic allows two stroke petrol engines to be simpler, lighter, and more powerful relative to their size.

In a typical two stroke petrol engine diagram, key components such as the piston, cylinder, spark plug, exhaust ports, and intake ports are displayed. The diagram shows the movement of the piston, which goes up and down in the cylinder. During the first stroke, the piston compresses the fuel-air mixture, and as it moves downward, it ignites the mixture with a spark from the spark plug, generating power. The exhaust gases are then expelled, and fresh fuel and air are drawn into the cylinder in the next stroke.

The two stroke petrol engine diagram highlights the efficiency of this system. Since the engine produces power on every revolution of the crankshaft, it is able to deliver more power for its size than a four-stroke engine. This feature makes two-stroke engines ideal for applications such as lawnmowers, chainsaws, small motorcycles, and outboard motors, where compactness and portability are crucial.

Additionally, the two stroke petrol engine diagram often includes detailed explanations of the intake, compression, power, and exhaust cycles. The key advantage of the two-stroke engine is that it requires fewer parts, reducing the engine's weight and complexity. However, this simplicity comes with a trade-off in efficiency and environmental impact, as two-stroke engines tend to emit more exhaust and consume more fuel compared to their four-stroke counterparts.

Connecting Stopcocks and Two Stroke Petrol Engine Diagrams

Although stopcocks and two stroke petrol engine diagrams serve different purposes in plumbing and engine mechanics, they both share a fundamental role in regulating flow. Stopcocks control the flow of water or gas within plumbing systems, while the components in a two stroke petrol engine diagram regulate the flow of fuel and exhaust gases within an engine. Both systems rely on careful control to function effectively.

For example, just as a stopcock can control the flow of water in a plumbing system, the intake and exhaust valves in a two-stroke engine (as shown in a two stroke petrol engine diagram) manage the entry of fuel and the expulsion of exhaust. Effective regulation of these flows is essential for optimal performance in both systems. In plumbing, a properly functioning stopcock ensures that water only flows when it is needed and can be safely stopped in emergencies. Similarly, in a two-stroke engine, the precise flow of fuel and exhaust gases ensures that the engine runs smoothly, efficiently, and without damaging components.

Conclusion

In conclusion, stopcocks and the two stroke petrol engine diagram are vital components in their respective systems. The stopcock plays an integral role in regulating water flow in plumbing systems, while the two stroke petrol engine diagram offers a visual representation of how a two-stroke engine functions efficiently. Both systems, although vastly different, depend on the precise control of flow—whether it’s the flow of water or the flow of fuel and exhaust gases. Understanding the function and mechanics of these components is essential for maintaining optimal performance, whether you're managing plumbing systems or operating small engines.

0 notes

Text

Exploring the Synergy of Vibro Generators and Marble Launchers in Engineering Application

In the world of engineering and scientific experimentation, the combination of different technologies often leads to breakthroughs that enhance performance and efficiency. One such combination is the synergy between vibro generators and marble launchers, both of which play unique and important roles in various applications, from education to advanced mechanical engineering. Understanding how these two systems interact can provide insights into improving design, functionality, and efficiency.

What is a Vibro Generator?

A vibro generator, often referred to as a vibration generator, is a device designed to produce mechanical vibrations. These vibrations can range from low to high frequencies and can be used for various purposes, such as material handling, testing, or improving the flow of bulk solids. Vibro generators are commonly used in industries where vibration is needed to move materials, test equipment, or simulate dynamic conditions. By generating controlled vibrations, these devices help in optimizing systems that require constant movement or consistent testing.

What is a Marble Launcher?

A marble launcher, on the other hand, is a mechanical device designed to launch marbles or small spherical objects with a high degree of precision. Often used in educational settings to demonstrate principles of physics, marble launchers are popular tools for illustrating concepts such as force, motion, velocity, and trajectory. These devices rely on various mechanical elements like springs, gears, and levers to propel marbles through the air, mimicking the behavior of more complex launching systems used in engineering.

The Synergy Between Vibro Generators and Marble Launchers

At first glance, vibro generators and marble launchers may appear to be unrelated devices, but they share key principles of motion and energy transfer that make them complementary in certain applications. When combined, these systems can enhance the performance of both devices in engineering projects, education, and even entertainment.

Improved Launch Mechanism Performance: Vibro generators can be used in conjunction with marble launchers to improve the efficiency and precision of the launching mechanism. By incorporating vibration into the launching system, the marble launcher can experience more consistent motion, reducing friction and wear while increasing the accuracy and distance the marble travels. The vibratory motion could ensure the marble is placed in an optimal position for launching, enhancing the device's overall performance.

Enhanced Educational Tools: In educational environments, using vibro generators alongside marble launchers can help students visualize and understand complex engineering principles. The combination of vibration and projectile motion allows learners to experiment with and observe real-time results of concepts like kinetic energy, acceleration, and motion dynamics. This practical application of theory brings physics lessons to life and encourages problem-solving and innovation.

Simulating Dynamic Systems: Vibro generators can also be used to simulate the dynamic forces that might affect a marble in flight. For example, vibration could be used to simulate air resistance or other forces acting on the marble after it is launched. This could help engineers and students better understand the variables that influence the trajectory of objects, which is crucial in many engineering fields like aerodynamics, materials science, and mechanical design.

Innovative Design for Engineering Projects: In advanced mechanical systems, integrating vibro generators with marble launchers could lead to innovative designs for testing and product development. Engineers could use these combined systems to test the durability of materials or the efficiency of new mechanisms under vibration, simulating real-world conditions where both motion and vibration are present. This synergy could be particularly beneficial in the development of transportation systems, robotics, and material handling technologies.

Conclusion

The integration of vibro generators and marble launchers offers fascinating possibilities for both educational and engineering applications. By combining the principles of vibration and projectile motion, engineers and educators can create more dynamic and efficient systems for learning and testing. This synergy can lead to improved designs, greater accuracy in experiments, and deeper insights into mechanical systems, demonstrating the power of interdisciplinary approaches in modern engineering and science. Whether in the classroom or in industrial design, the combination of these two devices represents a creative and effective way to enhance technology and understanding in the field of engineering.

0 notes

Text

The Role of Food Calorimeter and Membrane Filtration Assembly in Modern Food Testing

In the ever-evolving field of food science, precise and accurate testing is crucial for ensuring both food quality and safety. Among the many tools used in food analysis, the food calorimeter and the membrane filtration assembly stand out as essential equipment that help scientists, researchers, and manufacturers conduct thorough testing. These instruments play a vital role in assessing the nutritional value of food, ensuring food safety, and evaluating the presence of harmful microorganisms. In this blog, we’ll explore the significance of the food calorimeter and membrane filtration assembly in modern food testing, focusing on how they contribute to the accuracy and reliability of food analysis.

What is a Food Calorimeter?

A food calorimeter is an essential tool used to measure the caloric content of food. This instrument works by determining the amount of heat released when a sample of food is burned in a controlled environment. The food calorimeter is typically employed in food research, product development, and quality control to ensure that the nutritional information provided on food packaging is accurate and reliable.

The calorimeter functions by utilizing a process called calorimetry. When a sample of food is combusted, the calorimeter measures the heat released during the process. This heat corresponds to the amount of energy contained in the food, which is then quantified in terms of calories or joules. This method allows for the precise determination of the caloric content of food, making the food calorimeter indispensable in modern food testing and nutrition science.

Applications of the Food Calorimeter:

Nutritional Labeling: The food calorimeter helps manufacturers accurately calculate the caloric content of their products, which is essential for proper labeling and compliance with nutritional regulations.

Dietary Research: In clinical and dietary research, understanding the energy content of foods is key to developing balanced meal plans and assessing dietary intake.

Food Quality Control: Manufacturers use food calorimeters to ensure consistency in the caloric content of their products, allowing for quality control during production.

What is a Membrane Filtration Assembly?

The membrane filtration assembly is a piece of equipment used to separate microorganisms from liquid samples, such as water, beverages, or food products. It consists of a membrane filter that captures microorganisms, allowing the clean liquid to pass through. The membrane filtration assembly is commonly used in microbiological testing to determine the presence of harmful bacteria, yeast, fungi, and other pathogens in food and beverages.

The process involves passing a liquid sample through a membrane filter with very fine pores, typically ranging from 0.2 to 0.45 microns. Microorganisms in the sample are trapped on the membrane’s surface, while the liquid passes through. After filtration, the membrane is placed on a growth medium and incubated, allowing any trapped microorganisms to grow. The results are then analyzed to determine if any harmful organisms are present in the sample.

Applications of the Membrane Filtration Assembly:

Microbiological Testing: The membrane filtration assembly is widely used in food safety testing to identify pathogens such as E. coli, Salmonella, and Listeria, which can cause foodborne illnesses.

Water Quality Monitoring: This assembly is also used in water treatment and safety monitoring, as it can detect harmful bacteria in drinking water or water used in food production.

Beverage and Dairy Industry: The membrane filtration assembly is crucial in the beverage and dairy industries, where ensuring the microbial safety of products like milk, juices, and soft drinks is paramount.

How the Food Calorimeter and Membrane Filtration Assembly Complement Each Other in Food Testing

Both the food calorimeter and the membrane filtration assembly are fundamental tools in food testing, but they serve very different functions. However, their roles can complement each other in the food testing process, ensuring that products are not only nutritionally accurate but also microbiologically safe.

Comprehensive Food Analysis: The food calorimeter provides vital data on the nutritional content of food, while the membrane filtration assembly ensures that the food is free from harmful microorganisms. Together, they provide a complete analysis of food quality, covering both the energy content and the microbiological safety of the product.

Quality Control and Consistency: In food production, consistency is key to maintaining the quality and safety of products. The food calorimeter helps ensure that the caloric content remains consistent across batches, while the membrane filtration assembly verifies that each batch is free from pathogens or harmful microorganisms. This dual approach to testing ensures that manufacturers deliver safe, high-quality products to consumers.

Regulatory Compliance: Many countries have strict regulations regarding both the nutritional labeling and microbiological safety of food products. The food calorimeter and the membrane filtration assembly help manufacturers comply with these regulations, ensuring that their products meet required standards for both caloric content and microbial safety.

The Future of Food Testing: Innovations in Calorimetry and Filtration

As food testing continues to evolve, both the food calorimeter and the membrane filtration assembly are likely to undergo innovations that improve their accuracy, efficiency, and ease of use. In calorimetry, advances in technology could lead to more precise measurements of energy content, as well as the ability to analyze a wider variety of food samples. Similarly, improvements in filtration technology could enable faster and more sensitive detection of microorganisms, allowing for quicker identification of pathogens in food products.

Additionally, as food production becomes more globalized, the demand for reliable and efficient food testing tools will only increase. The food calorimeter and the membrane filtration assembly will continue to play a pivotal role in ensuring that food products are both nutritionally accurate and microbiologically safe, meeting the growing needs of consumers and regulatory bodies alike.

Conclusion

The food calorimeter and the membrane filtration assembly are two of the most important tools in modern food testing, each contributing to different aspects of food quality and safety. While the food calorimeter provides essential data on the caloric content of food, the membrane filtration assembly ensures that food products are free from harmful microorganisms. Together, these tools play a critical role in ensuring that food products meet safety standards, nutritional requirements, and consumer expectations. With continuous advancements in technology, both instruments will remain at the forefront of food testing, ensuring the ongoing safety and quality of the food supply.

0 notes

Text

The Role of Glassware Adapters and Filtration Assembly in Efficient Laboratory Filtration

In laboratory settings, precision, efficiency, and safety are essential when carrying out filtration processes. One of the key components that enhance these processes is the use of glassware adapters and filtration assembly. These essential tools work together to ensure smooth, effective, and reliable filtration results. In this article, we will explore how glassware adapters and filtration assembly contribute to more efficient laboratory filtration, making them indispensable in scientific research and industrial applications.

What Are Glassware Adapters?

Glassware adapters are specialized pieces of equipment used to connect different types of glassware in laboratory settings. These adapters are designed to fit between pieces of laboratory glassware such as funnels, filter flasks, and vacuum filtration setups, enabling seamless transitions between the various stages of filtration. Made from durable glass materials, glassware adapters are resistant to heat and chemical corrosion, ensuring that they maintain their integrity during extended use in filtration processes.

The primary function of glassware adapters is to facilitate the proper connection between glassware components, ensuring that the filtration process is conducted without leaks or contamination. They come in a variety of shapes and sizes to accommodate different types of glassware, such as ground glass joints, threaded connectors, and rubber gaskets.

The Importance of Filtration Assembly in Laboratories

A filtration assembly consists of all the necessary glassware and components that work together to separate solids from liquids or gases. It typically includes items such as filter funnels, filter paper, filtration flasks, and vacuum pumps. The filtration assembly is designed to ensure that filtration occurs efficiently and effectively, while minimizing the risk of cross-contamination.

The filtration assembly enables controlled filtration, whether it's gravity filtration, vacuum filtration, or even pressure filtration. By properly setting up a filtration assembly, researchers can ensure that they achieve precise results, separating contaminants from liquids or gases with minimal loss of the sample.

The Role of Glassware Adapters in Filtration Assembly

Glassware adapters play a critical role in the overall functionality of the filtration assembly. These adapters allow various components of the filtration system to be securely connected, providing a stable and leak-free environment for the filtration process. For example, glassware adapters are used to attach filter funnels to filtration flasks or to connect vacuum lines to filtration setups.

Without properly fitted glassware adapters, a filtration assembly would be prone to leaks and inefficiency, compromising the quality of the filtration process. The versatility of glassware adapters ensures that different laboratory glassware can be combined in a way that optimizes the filtration process, whether it's for simple gravity filtration or more complex vacuum filtration applications.

Enhancing Efficiency and Safety in Laboratory Filtration

The combination of glassware adapters and a well-assembled filtration system ensures greater efficiency in laboratory filtration. By securely connecting components, glassware adapters help prevent accidents or loss of sample, which could result from improperly assembled glassware. Additionally, the proper use of glassware adapters can streamline the filtration process, reducing time spent on setup and allowing for more consistent results.

Furthermore, glassware adapters provide an added level of safety by ensuring that all connections are tightly sealed, preventing the exposure of hazardous substances. In situations where toxic or volatile chemicals are involved, the secure connection provided by glassware adapters is essential for maintaining a safe laboratory environment.

Conclusion

In summary, glassware adapters and filtration assembly are essential components in laboratory filtration processes. By ensuring secure connections and optimizing the overall filtration system, glassware adapters improve the efficiency, safety, and accuracy of filtration tasks. Whether you're conducting routine experiments or more advanced chemical processes, the proper use of glassware adapters and a well-organized filtration assembly are key to achieving optimal results in the laboratory.

Incorporating these tools into your laboratory workflows will not only enhance the precision of your experiments but will also ensure smoother, safer, and more efficient filtration procedures.

0 notes

Text

Arco Lab

ARCO has been a trusted part of the scientific community for over six decades, evolving from foundational learning in Physics, Chemistry, and Biology to excelling in advanced fields. Known for its consistent quality and innovation, ARCO continually upgrades its products to meet changing technological and customer needs. With ongoing collaboration with users, academicians, and technicians, ARCO customizes its instruments to specific requirements. Manufactured in a state-of-the-art facility and certified with ISO 9001:2015, ARCO ensures continuous improvement in both products and services.

1 note

·

View note