Arrival Electronics provides electronic design, PCB assembly, and component distribution for aerospace, medical, and automotive industries, with AS9120B certification and ISO-compliant manufacturing.Website: http://www.arrivalelectronics.co.uk/

Don't wanna be here? Send us removal request.

Text

Electronics Manufacturing: Trends and Industry Insights

In an industry defined by continuous development and exacting standards, electronics manufacturing is a critical driver of modern technology. From everyday consumer goods to complex industrial systems, the journey of each component begins with thoughtful engineering, rigorous production practices, and strong supplier relationships. Based in Arundel, West Sussex, Arrival Electronics Limited stands at the heart of this field, working closely with clients to meet the evolving needs of today’s electronic markets.

This article explores the inner workings of the electronic components industry—what drives it, the trends shaping it, and what decision-makers should understand when choosing the right components or partners. Whether you're a design engineer, purchasing manager, or systems integrator, a clear understanding of this sector will help support better outcomes for your business and your customers.

Understanding the Electronics Manufacturing Process

The process involves assembling electronic components into complete, functional products ready for use or distribution. This can include simple printed circuit board assemblies or more intricate systems involving hundreds of interconnected parts. The process demands consistent quality, traceability, and efficient logistics from start to finish.

The primary stages include:

Component Sourcing: Reliable supply chains and vetted manufacturers are essential. Components must meet specifications, often under strict time constraints and regulatory compliance requirements.

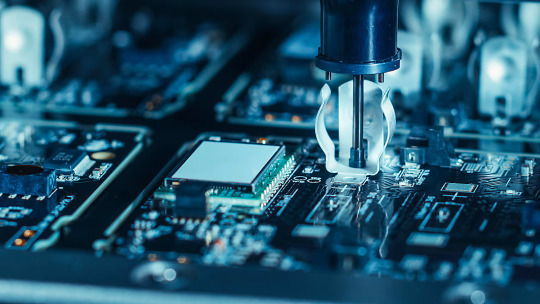

PCB Assembly: Surface mount technology (SMT) and through-hole assembly are key methods used in creating circuit boards. Attention to detail is vital here, as even minor errors can result in failure during testing or deployment.

Testing and Inspection: Functional tests, visual inspections, and X-ray analysis are just some of the methods used to confirm product reliability. These steps help ensure products perform as intended once installed.

Final Assembly and Packaging: After testing, products are assembled into enclosures, labeled, and prepared for shipment, often requiring anti-static handling, thermal protection, or precise labeling practices.

Producing electronic products requires more than tools and machines—it’s about consistency, communication, and adapting to specific project demands.

Key Trends Shaping Today’s Production Landscape

As technology progresses, the electronics sector must constantly adjust. Here are several trends affecting the direction of the industry:

1. Miniaturization

Devices are shrinking, but performance expectations remain high. Engineers must work with tighter tolerances and more complex component configurations. This puts pressure on design and manufacturing teams to align on specifications early in the project lifecycle.

2. Demand for Custom Solutions

Many industries—such as medical, aerospace, and renewable energy—are looking for specialized circuit designs rather than one-size-fits-all solutions. Manufacturers that can provide flexible production runs, in-depth technical consultation, and fast turnarounds are in demand.

3. Supply Chain Resilience

The global component shortage has made it clear how critical supply chain visibility and reliability are. Businesses are increasingly working with sourcing partners that can offer a wide selection of inventory, cross-reference alternatives, and reduce exposure to delays.

4. Sustainability in Manufacturing

There is growing interest in sustainable production practices, including RoHS compliance, lead-free soldering, and energy-efficient factory environments. Electronics manufacturers must respond by implementing responsible processes and working with suppliers who share the same values.

Why Quality and Compliance Matter More Than Ever

When it comes to production and assembly, quality is more than a buzzword—it's a measurable requirement. A faulty capacitor or misaligned connector can result in expensive system failures, regulatory issues, or even safety concerns.

To meet modern expectations, manufacturers must:

Follow ISO-certified procedures

Maintain full traceability of components

Ensure regulatory compliance across target markets (CE, UL, REACH, etc.)

Maintain strong documentation for every stage of the process

Choosing a manufacturing partner with a deep understanding of international standards and a history of consistent delivery helps reduce risks and keeps projects on track.

What Sets Our Manufacturing Services Apart

Our approach is built around delivering practical, cost-effective manufacturing solutions tailored to meet each customer’s unique requirements. By applying lean manufacturing principles, we help clients reduce waste, improve efficiency, and gain measurable value in every step of the process.

Key benefits include:

Lower inventory demands

Reduced total acquisition costs

Supply chain resilience through multiple inventory locations

Improved product quality

Consistent, on-time delivery you can rely on

What to Consider When Choosing a Technical Assembly Partner

Finding a reliable service provider is about more than pricing or proximity. Here are key factors to evaluate:

1. Technical Expertise

Look for teams that can interpret your bill of materials (BOM), understand the application of each component, and make suggestions where appropriate. This ensures that your products are not only assembled correctly but also designed for success.

2. Supplier Relationships

Does the provider have access to a wide range of reputable manufacturers? Can they offer alternatives when primary parts are unavailable? These questions are especially important during global shortages or when dealing with niche specifications.

3. Project Flexibility

Can they accommodate small production runs or prototype builds? Can they ramp up to meet large-scale demand? Flexibility ensures that your partner can adjust alongside your project’s lifecycle.

4. Transparent Communication

Regular updates, clear technical feedback, and documentation of every phase help create confidence. Projects that lack open communication are more likely to experience delays and misunderstandings.

5. End-to-End Support

From early-stage design reviews to post-sale technical queries, the most reliable firms remain actively involved throughout the entire process. They provide ongoing value and ensure long-term reliability, not just short-term assembly.

Meeting Industry Demands: A Practical Approach

The sector serves a wide range of industries, including automotive, medical, aerospace, defense, consumer goods, and industrial automation.. Each sector has its own regulatory environment, tolerances, and expectations for delivery timeframes.

For instance:

Medical devices often require cleanroom assembly and documentation to meet stringent approval standards.

Automotive components must withstand harsh environmental conditions and vibration without performance degradation.

Aerospace systems demand redundancy, traceability, and exact part performance for mission-critical applications.

As these requirements grow more complex, manufacturing partners must respond with tailored approaches—balancing engineering support, materials expertise, and practical experience.

Building Long-Term Success with Trusted Partners

Supply chain challenges, new materials, evolving regulations—these realities require ongoing adaptation. Companies that treat production as a strategic function rather than a transactional service gain a competitive edge.

To succeed, it's essential to work with a partner that:

Understands your industry

Invests in continuous improvement

Keeps up with changing compliance rules

Prioritizes reliability over shortcuts

This is where experience matters. Businesses with a consistent record of on-time delivery, error-free builds, and in-depth component knowledge provide a firm foundation for long-term growth.

About Arrival Electronics Limited

Located in West Sussex, Arrival Electronics Limited is an independent electronic component supplier with deep roots in the electronics manufacturing sector. Known for its technical approach, reliable stock availability, and excellent customer support, the company serves clients across a wide range of industries—including automotive, broadcast, industrial, and aerospace.

Their team offers more than just product sourcing—they offer insight. They collaborate with manufacturers and design engineers to ensure all supplied parts meet application-specific needs. Whether supporting high-mix production or long-term component supply, Arrival Electronics Limited provides dependable service and extensive market knowledge that adds lasting value.

Final Thoughts

Electronics manufacturing is not just a mechanical process; it's a critical function that supports the quality, safety, and performance of the technology we depend on every day. Businesses that understand its nuances are better positioned to deliver products that work as intended, meet compliance goals, and perform reliably over time.

For companies seeking support in this complex space, Arrival Electronics Limited stands as a resourceful and experienced partner. With technical insight, customer dedication, and a clear understanding of today’s component landscape, they help businesses navigate the challenges and practical realities of bringing modern electronic products to market.

0 notes

Text

Understanding CEM in Modern Electronics: A Practical Insight

Understanding CEM in Modern Electronics: A Practical Insight

In today’s complex electronics landscape, product innovation and efficient manufacturing go hand in hand. For engineers, designers, and procurement professionals, choosing the right electronics partner is no longer a matter of convenience—it’s essential to product success. At Arrival Electronics Limited, a company based in Arundel, West Sussex, clients find an experienced and well-established resource for navigating the ever-changing world of electronic components and contract manufacturing.

Whether you are developing a product prototype or managing large-scale production, understanding the value and structure of CEM—Contract Electronics Manufacturing—is key to maintaining consistency, reliability, and supply chain strength. This article breaks down the concept of contract electronics manufacturing in practical terms, why it matters, and what to consider when selecting the right partner for your business.

CEM Explained: How Outsourced Electronics Manufacturing Supports Product Success

CEM refers to the process where a company outsources some or all of its electronic manufacturing responsibilities to a third-party provider. These services can include the assembly of printed circuit boards (PCBs), box builds, cable assemblies, and even full system integration. For many businesses, this arrangement helps bridge the gap between concept and market delivery without investing in internal production facilities.

But the advantages of outsourcing electronic manufacturing are not limited to infrastructure savings. A seasoned provider brings value through quality control, compliance assurance, procurement efficiency, and reduced lead times. The focus is not just on manufacturing but on delivering consistent results across the entire product lifecycle.

The Role of Contract Manufacturing in Product Development

In the early stages of product development, design and testing cycles can be both time-intensive and cost-sensitive. Working with an experienced manufacturing partner during this phase ensures that designs are ready for production, not just in theory but in practice. This includes:

Design for Manufacture (DfM) input: Ensuring that designs can be replicated reliably at scale.

Component sourcing guidance: Helping identify component availability, pricing trends, and lifecycle risks.

Rapid prototyping: Allowing for multiple iterations and validation cycles before full production.

The value of this support is particularly noticeable in industries with tight regulatory requirements or highly customized designs. Knowing that your product is being assembled by a team familiar with these challenges adds a layer of assurance often missed when production is fragmented or uncoordinated.

Quality Control and Compliance in Electronics Manufacturing

Consistency is everything when it comes to electronics. A single deviation in assembly quality or component specification can compromise an entire batch of products. Reputable manufacturers implement rigorous quality control standards—often including ISO certifications and IPC-A-610 class ratings—to ensure production meets both industry standards and client expectations.

In addition, experienced production partners are frequently tasked with managing regulatory documentation. For sectors like medical, automotive, aerospace, and defence, regulatory compliance is not just about paperwork—it’s a vital part of risk management and long-term reliability.

With experienced providers, clients benefit from:

Traceability systems to track component origins and manufacturing data

Test procedures tailored to the client’s performance standards

Material compliance such as RoHS, REACH, and conflict mineral regulations

This commitment to precision manufacturing and documentation forms the foundation of long-term supply stability.

Supply Chain Management and Procurement

One of the most significant advantages of working with an experienced electronics manufacturing partner is procurement efficiency. The global electronics supply chain can be unpredictable—affected by material shortages, geopolitical issues, and currency fluctuations. A reliable provider has both the scale and supplier relationships to manage these challenges on your behalf.

By centralizing procurement and inventory management, the risk of component obsolescence, stockouts, and delivery delays is greatly reduced. Strategic sourcing, long-term supplier contracts, and access to authorized distribution channels allow clients to focus on core design and development tasks.

In many cases, these providers also help negotiate better pricing through consolidated purchasing volumes, improving overall cost-effectiveness without compromising on quality.

Customization and Flexibility in Electronics Manufacturing

Different companies have different requirements. Some need full assembly and testing; others only need PCB population or logistics support. A flexible production model is one that adapts to these varying levels of engagement.

For example, some clients may request:

Box build and enclosure integration

Cable and wire harness manufacturing

Programming and firmware upload

Functional testing and diagnostics

A well-structured manufacturing relationship allows businesses to adjust their production effort (either up or down) based on demand, without renegotiating contracts or reorganizing supply infrastructure. This adaptability is particularly important for startups, R&D teams, and businesses with seasonal product cycles.

The Importance of Local Manufacturing Support

While many companies consider offshore production due to lower costs, working with a local manufacturing partner still provides key advantages in terms of quality and communication. UK-based providers offer accessible collaboration, faster turnaround times, and streamlined logistics—all important factors in today’s competitive electronics environment.

Local manufacturing also contributes to:

Greater visibility during production runs

Faster issue resolution if engineering changes are required

Reduced transportation risks, especially for fragile or sensitive components

Working with a local partner ensures better control, particularly when dealing with niche products, custom builds, or compliance-heavy applications.

Trends in Electronics Manufacturing for 2025 and Beyond

As the demand for smarter, more integrated electronics continues to grow, so do the expectations placed on modern manufacturing services. Emerging technologies such as IoT-enabled devices, wearable electronics, and electric vehicle systems require a more advanced and flexible approach to assembly and testing.

In response, many manufacturing specialists are expanding their capabilities to include:

Microelectronics assembly

High-frequency RF product support

Environmentally controlled production environments

Long-term product lifecycle support

These advancements are not confined to high-volume production. Niche developers and innovators also benefit from working with partners that understand how to manage intricate designs and deliver dependable, high-quality builds.

Choosing the Right Manufacturing Partner

With so many electronics manufacturing options available, how do you decide which one is right for your project?

Here are five practical factors to consider:

Experience: Look for a provider with a strong track record in your specific industry. Practical experience brings valuable insight, especially when navigating technical designs and regulatory requirements.

Certifications: Confirm that the company holds relevant and current industry certifications, as these reflect adherence to recognized quality standards.

Transparency: A trustworthy partner will be clear about their production capabilities, timelines, and internal processes from the start.

Technical Support: It's beneficial to work with a team that offers design-stage assistance—not just assembly. Early input can prevent delays and reduce costs.

Location: Think about the practical benefits of working with a nearby provider, including easier communication, faster lead times, and simplified logistics.

By considering these factors carefully, you can reduce risk and improve the likelihood of a successful, long-term collaboration.

Why Contract Electronics Manufacturing Still Matters

In a world where electronics innovation is constant, outsourced production remains a vital service for product teams aiming to maintain focus and efficiency. It’s not just about handing off manufacturing—it’s about building the right partnerships. With increasing pressure to deliver quality products on time and within budget, working with a capable electronics manufacturing partner is a smart and strategic move.

This type of collaboration allows businesses to stay agile while drawing on technical expertise, stable supply chains, and reliable assembly processes. It helps bridge the gap between concept and product delivery—without the need for extensive internal infrastructure.

Conclusion

From component sourcing and design guidance to full assembly and product lifecycle support, Arrival Electronics Limited provides the practical expertise and trusted service needed in today’s competitive electronics industry. Located in West Sussex, the team works closely with clients across the UK and beyond, delivering dependable contract manufacturing solutions built on transparency, experience, and technical depth.

If you're looking for a CEM provider who understands your challenges and delivers reliable, detail-oriented service, consider a partner with proven experience and a commitment to quality at every stage of your project.

0 notes

Text

PCB Design Driven by Precision, Practicality and Performance

At Arrival Electronics Limited, we understand that PCB design isn’t just a step in product development—it’s the foundation that supports every component, signal path, and functionality. Whether you're developing a next-generation medical device, a robust industrial control unit, or a compact consumer electronic product, our role is to ensure your ideas are backed by dependable, efficient, and expertly engineered printed circuit boards.

With decades of hands-on experience in electronics, our team has worked with companies across multiple industries, helping bring projects to life—from concept through to production.

In this article, we’ll share what makes a strong design, the practical elements that often go unnoticed, and how our services help keep your project moving forward from the drawing board to delivery.

Why PCB Design Matters

Designing the right board isn't just about connecting components—it's about ensuring the entire electrical system performs reliably, consistently, and within its intended environment. A well-thought-out layout contributes to:

Product longevity and durability

Efficient power consumption

Signal integrity and reduced noise

Thermal control and mechanical stability

Overlooking critical details during this stage can lead to performance issues, unnecessary rework, or even total product failure. We take every aspect seriously to help our clients avoid costly missteps and stay on track.

What Makes a Solid Design?

Over the years, we’ve found that strong board design depends on more than just software skills or technical knowledge. It’s about having the awareness to balance practical considerations with real-world requirements. Here’s what we focus on in every project:

1. Clear Design Objectives

Before a single trace is laid out, we work closely with you to understand the end-use of the product. Is it intended for a high-vibration environment? Will it operate at high frequency? These questions shape everything from component selection to board layout.

2. Efficient Layout and Routing

We pay close attention to the physical layout, making sure component placement allows for clean, short signal paths and minimal electromagnetic interference. Where needed, we apply differential pair routing, impedance control, and strategic layer stacking.

3. Manufacturability

A design that’s difficult to produce can quickly eat into budgets and timelines. We align our designs with your manufacturing capabilities—choosing standard sizes, spacing, and materials that avoid bottlenecks in production.

4. Thermal Management

Heat can quietly cause long-term damage. We integrate copper pours, thermal vias, and heat sinks when necessary, ensuring temperature-sensitive components stay within safe operating ranges.

5. Design for Testability

We keep diagnostics in mind from the outset. Well-placed test points and clearly labelled nets allow engineers to easily validate performance and troubleshoot issues during development.

Our Approach

What sets us apart is the level of care and accountability we bring to each project. We don’t treat board design as a one-size-fits-all task. Instead, we tailor our process to match your product’s specific technical and commercial requirements.

Collaborative from the Start

We believe good design starts with good communication. Our team begins by understanding your specifications, timelines, and constraints. If needed, we assist with component selection and design reviews, helping guide decisions that support project success long-term.

In-House Expertise

Our engineers bring decades of collective experience across RF design, digital and analogue electronics, signal integrity, and power distribution. This depth of expertise means we’re equipped to handle both complex multilayer PCBs and simpler single-sided designs with the same level of detail and reliability.

Detailed Documentation

We provide comprehensive documentation for every design, including Gerber files, BOMs, assembly drawings, and test documentation. Everything is clearly structured, so your production team or manufacturer has what they need to get started without delay.

Supporting Every Stage of Development

We understand how interconnected the design process is with the rest of the product lifecycle. That’s why our support doesn’t end once the board layout is finished.

Prototyping

We help bridge the gap between design and validation by assisting with prototype builds. If changes are needed, we provide quick iterations without compromising design integrity.

Compliance

Many products need to meet specific regulatory standards. Our knowledge of EMC, safety, and industry certifications helps keep your project aligned with compliance from the ground up.

Component Availability

Supply chain challenges can affect even the most carefully engineered layouts. We actively review component availability early in the process and suggest practical alternatives when necessary. This helps keep your project on schedule and reduces the risk of unexpected delays.

A Closer Look at Our Capabilities

Here’s a snapshot of the types of board layout work we handle:

Single-sided and double-sided configurations

Multilayer builds (up to 24 layers)

High-speed digital and analog signal routing

RF and microwave applications

Flexible and rigid-flex formats

Power distribution and regulation paths

Projects with tight impedance and signal integrity demands

All layouts are created using industry-standard tools, including Altium Designer and Cadence Allegro, ensuring smooth integration with your existing workflows.

Industries We Serve

One of the strengths of our team is our versatility. We’ve worked with clients across sectors including:

Medical Technology: Supporting devices that require extreme reliability and precise electrical behavior.

Industrial Automation: Creating robust PCBs for use in high-temperature, high-vibration environments.

Consumer Electronics: Helping bring compact and functional designs to market faster.

Automotive: Designing for safety, efficiency, and long-term performance in vehicle systems.

Telecommunications: Handling high-frequency signal requirements and tight timing constraints.

No matter the application, we bring the same level of care and engineering discipline to every project.

Focused on Accuracy

Every layout we deliver goes through rigorous design rule checks (DRC), electrical rule checks (ERC), and internal peer reviews. We follow industry best practices and adapt our quality assurance process to meet the specific standards of your sector.

We’ve earned the trust of clients across the UK by consistently delivering high-quality work with a personal touch. Our focus is on making your project a success—not just through technical execution, but through reliability, responsiveness, and genuine collaboration.

Common Challenges We Help Solve

If you’ve experienced any of the following issues, we’re here to help:

Designs that aren’t manufacturable without rework

Unstable prototypes or unexpected signal behaviour

Thermal problems during test or usage

Poor EMI performance or compliance failures

Designs delayed by long lead-time components

The Edge of Partnering With Us

There are many design services out there. What makes us different is the way we treat our clients and the projects they entrust to us. When you work with us, you get more than a technical service—you gain a partner who’s committed to your success.

We listen. Your needs guide every design decision we make.

We respond quickly. Tight timelines don’t faze us—we’re used to working in dynamic environments.

We follow through. From first sketch to final sign-off, we’re with you every step of the way.

Whether you’re a start-up developing your first prototype or an established manufacturer needing dependable support for your next product line, we bring the right mix of experience, care, and clarity to help you move forward.

Let’s Begin Your Project

IIf you're looking for dependable design services with a team that understands the real-world pressures of product development, we’re here for you at Arrival Electronics Limited. Our process is built around clear communication, careful planning, and engineering you can trust, including expert PCBA services to ensure every component is perfectly integrated.

We’re more than just a distributor—we’re your engineering partner. From bespoke solutions to component sourcing and full system support, we’re here to help turn your vision into reality.

For more about our services or to start a conversation, visit arrivalelectronics.co.uk.

0 notes

Text

Sourcing Electronic Components with Confidence and Quality

At Arrival Electronics Limited, we understand how vital these components are to every industry — from aerospace to automotive, consumer tech to industrial manufacturing. They’re the building blocks of modern innovation, and when something as small as a resistor or integrated circuit fails or is delayed, entire projects can be compromised.

That’s why we’ve spent years building a service that isn’t just about supplying parts — it’s about delivering peace of mind. Our team is focused on reliability, traceability, and long-term relationships. For us, it’s not about shifting boxes. It’s about helping our clients make confident decisions, every step of the way.

In this article, we’ll walk through the key challenges engineers and procurement teams face when sourcing electronic components, and how our expertise and services make the process easier, faster, and more reliable.

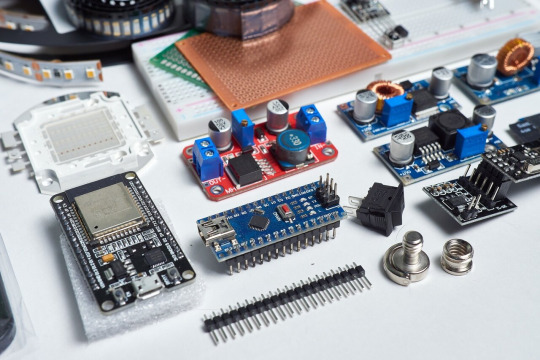

The Landscape of Electronic Components

The market is complex and constantly evolving. It includes everything from passive parts like capacitors and inductors, to active devices such as microcontrollers, semiconductors, and displays. As designs grow more sophisticated, so does the supply chain.

There are often dozens of decision points involved in selecting the right part — from cost and lead time to lifecycle status, technical specs, and obsolescence risks. A single miscalculation can delay production or cause costly revisions.

That’s where a knowledgeable partner makes all the difference.

More Than Just Parts

We’ve built to serve as more than just a supplier. We are a trusted extension of our customers’ procurement and engineering teams. Here’s how we help:

1. A Strong Manufacturer Network

We work closely with a wide range of franchised and authorised manufacturers. This gives us access to high-quality, genuine parts with full traceability. Whether you need automotive-grade semiconductors, military-spec connectors, or commercial components for fast-moving products, we can provide them — quickly and with full confidence in origin.

Because of our long-standing relationships with global manufacturers and distributors, we’re able to secure hard-to-find items or offer competitive alternatives when lead times are tight.

2. Vigilant Counterfeit Avoidance

Counterfeit components are a growing concern. One low-quality or unverified part can have serious consequences — especially in safety-critical systems like aerospace or medical equipment.

We take every precaution to protect our customers. All parts are thoroughly inspected through approved procedures and quality checks. We only source from trusted suppliers with strict verification processes, and we maintain accreditations that reflect our commitment to quality control.

When clients work with us, they know they’re receiving genuine, fully traceable components — never grey market substitutes.

3. Technical Expertise You Can Rely On

Sourcing isn’t just about logistics. It requires a deep understanding of electronics design and the demands of different applications. Our team brings a strong background in engineering, so we speak the same language as your development team.

If you’re looking to select a part for a new design, we can assist. If a component you’ve been using goes end-of-life, we’ll help find a suitable, compatible replacement. And if you’re seeking more efficient options, we’re here to provide informed suggestions based on technical merit — not just availability.

It’s this depth of understanding that helps us build long-term trust with our clients.

Supporting Procurement at Every Level

We know that procurement professionals face mounting pressure — reduce costs, shorten lead times, manage supplier risk, and keep production flowing. That’s why we offer tailored support that makes their jobs easier.

Long-Term Agreements

We can lock in pricing and availability for high-volume or regular orders, helping teams budget with more certainty.

Scheduled Deliveries

For manufacturers managing just-in-time inventory or lean production, we offer scheduled deliveries to align with project timelines.

Bonded Stock & Buffer Inventory

We offer bonded stock and custom inventory solutions, ensuring components are ready when needed — without tying up working capital.

Lifecycle Management

Obsolescence can disrupt even the best-laid plans. We help monitor lifecycle statuses and recommend alternatives before issues arise.

From Idea to Build

Beyond procurement, our services also support design and development teams. We know that engineers face constant deadlines, often with limited resources. When we work with design teams, we aim to remove friction and reduce time to market.

From datasheet support to reference designs and technical selection advice, we’re always happy to lend our knowledge. Whether you're building a prototype, updating a legacy system, or launching a brand-new product, we’re here to help bridge the gap between concept and production.

Industries We Serve

We’re proud to support a wide range of sectors. Each industry has its own requirements, and our experience helps us deliver the right solutions, every time.

Aerospace & Defence

Traceability, certification, and rigorous standards are critical in this space. We provide compliant sourcing solutions with full documentation and auditing support.

Industrial Automation

These systems often run 24/7 in harsh conditions. We supply components with the reliability and endurance industrial applications demand.

Automotive

With vehicles becoming smarter and more connected, automotive electronics are rapidly evolving. We supply components that meet strict safety and environmental requirements.

Consumer Electronics

In this fast-moving sector, speed and cost-efficiency matter. We work with OEMs and manufacturers to meet market demands without sacrificing quality.

Medical Devices

Precision, reliability, and compliance define this field. We support developers and manufacturers with components that meet international standards.

Quality and Certifications

We take quality seriously. Our processes are certified and continuously reviewed to meet the latest industry standards. Among our certifications and capabilities:

ISO 9001: Quality management systems

AS9120: Aerospace distribution quality

Full traceability on all supplied parts

Anti-counterfeit inspection and testing protocols

Our in-house procedures ensure that every component we deliver meets the highest expectations.

Handling Gaps in the Chain

Global supply chains can be unpredictable. Whether it’s a sudden shortage, geopolitical changes, or natural disasters, disruptions can ripple through the industry. We help clients stay prepared with strategies that reduce vulnerability.

We can advise on alternative components, secure last-time buys, or support redesigns where necessary. Our proactive approach keeps production lines moving — even when challenges arise.

Why Our Clients Keep Coming Back

Trust is built over time. Many of our clients have worked with us for years, and we take pride in the relationships we've formed. What keeps them coming back?

Personalised service: No two customers are the same, and we tailor our support accordingly.

Consistent communication: We keep clients informed, from quote to delivery.

Integrity: We never cut corners or compromise on quality.

Responsiveness: We act fast — whether it’s a routine order or an urgent requirement.

Our goal is to be more than a vendor. We strive to be a true partner in every sense of the word.

Part of Your Project Team

Whether you're designing the next generation of electronics, managing a complex supply chain, or simply trying to source a few critical components, we’re here to support you. With a proven track record, extensive network, and technical knowledge, we are ready to help.

We don’t just provide parts. We deliver reliability, accountability, and support — every step of the way.

If you’re looking for a supplier you can count on, one that understands your needs and stands by their service, we’d love to talk. Let’s work together to keep your projects moving forward with confidence.

The Team Behind the Service

Arrival Electronics Limited is a UK-based independent distributor and sourcing partner for high-quality electronic components. With decades of experience, we support clients across multiple industries with supply chain solutions, electronics manufacturing services, technical assistance, and a commitment to dependable service.

Visit us at www.arrivalelectronics.co.uk to learn more or to get in touch with our team.

0 notes

Text

A Guide About Understanding EMS in Electronics Manufacturing

Electronics Manufacturing Services (EMS) play a vital role in the production of electronic components or sub assemblies. EMS providers offer a range of services such as PCB assembly, Box Build, Supply Chain Management, Engineering, Product Management, and after sales support, ensuring that businesses receive high-quality, reliable electronic products without the need for in-house manufacturing capabilities.

At Arrival Electronics Limited, EMS solutions are designed to support businesses in various industries, including automotive, aerospace, medical, industrial, and consumer electronics. By partnering with a reliable EMS provider, companies can focus on innovation and product development while benefiting from expert manufacturing processes.

The Role of EMS in Modern Electronics Production

EMS providers take on various responsibilities to assist businesses in bringing their products to market. These include:

1. Design and Prototyping

EMS providers collaborate with businesses in the early stages of product development. This includes design assistance, prototyping, and testing to ensure functionality and compliance with industry standards.

2. Component Sourcing and Procurement

Finding the right components at competitive prices is essential in electronics manufacturing. EMS providers leverage their supply chain relationships to source components efficiently while ensuring authenticity and quality control.

3. PCB Assembly (PCBA)

Printed Circuit Board Assembly (PCBA) is a core service in EMS. This involves surface-mount technology (SMT) and through-hole assembly, ensuring the electronic components are securely placed and soldered onto circuit boards.

4. Testing and Quality Control

Quality assurance is critical in electronics manufacturing. EMS providers perform rigorous testing, including in-circuit (ICT), functional, and environmental stress testing, to ensure products meet performance standards and reliability expectations.

5. Final Product Assembly and Integration

Beyond assembling circuit boards, EMS providers also manage full product integration, including enclosure assembly, software installation, and final testing.

6. Logistics and Aftermarket Services

Once the product is manufactured, EMS providers handle logistics, warehousing, and distribution. Additionally, they may offer repair and refurbishment services to extend product life cycles.

Comprehensive Turnkey Manufacturing Solutions for Every Stage of Production

Experience full turnkey manufacturing services designed for precision and efficiency. Our expertise includes:

Complex SMT assemblies

High-density PCBs

Rapid-turn prototypes

Serial production

Box build solutions

Complete product assembly & testing

Custom cable assemblies

Aftermarket service support

Our advanced facilities ensure top-tier quality and innovation at every stage of production.

Benefits of Partnering with an EMS Provider

Choosing a trusted EMS provider like Arrival Electronics Limited brings several advantages to businesses looking to produce high-quality electronic products efficiently.

Cost Efficiency

By outsourcing electronics manufacturing, businesses can reduce operational costs, including labor, equipment, and infrastructure investments. EMS providers streamline production processes, minimising waste and maximising efficiency.

Access to Advanced Technologies

EMS providers stay current with the latest manufacturing technologies, ensuring that businesses benefit from state-of-the-art production methods without the need for continuous investment in new equipment and training.

Scalability and Flexibility

Whether a business needs low-volume prototyping or high-volume production, EMS providers offer the flexibility to adapt to varying demands. This particularly benefits startups and growing companies that need adaptable manufacturing solutions.

Improved Product Quality

Strict quality control measures in EMS manufacturing ensure that each product meets industry and regulatory standards. This reduces defects, enhances reliability, and leads to greater customer satisfaction.

Faster Time-to-Market

EMS providers help accelerate product development timelines by handling the complexities of manufacturing. With efficient production processes, businesses can bring their products to market faster while maintaining high quality.

Key Industries Benefiting from EMS

Various industries rely on EMS providers to develop and produce electronic products efficiently. Some of the key sectors include:

Automotive Electronics: The automotive industry depends on EMS providers to produce advanced driver-assistance systems (ADAS), infotainment systems, and power management solutions. Precision manufacturing is essential to ensure safety and performance in vehicles.

Medical Devices: Medical electronics, including diagnostic equipment, wearable health monitors, and imaging devices, require strict compliance with regulatory standards. EMS providers ensure medical devices meet these standards while maintaining reliability and accuracy.

Aerospace and Defense: In aerospace and defense applications, reliability is paramount. EMS providers manufacture high-performance electronic components for avionics, radar systems, and communication equipment that withstand extreme conditions.

Industrial Automation: EMS supports the development of industrial control systems, sensors, and automation solutions that optimize manufacturing and operational efficiency in industrial settings.

Consumer Electronics: EMS providers manufacture various consumer electronics, from smartphones to smart home devices, ensuring high-quality production while maintaining cost-effectiveness.

Choosing the Right EMS Provider

When selecting an EMS provider, businesses should consider the following factors:

Industry Experience and Expertise

A provider with extensive experience in a specific industry understands the challenges and requirements unique to that sector. Arrival Electronics Limited has decades of experience delivering quality EMS solutions across multiple industries.

Quality Certifications and Compliance

Certifications such as ISO 9001, ISO 13485 (for medical devices), and AS9120B (for aerospace) indicate a provider’s commitment to quality and compliance with industry standards.

Technological Capabilities

An EMS provider should have access to modern manufacturing technologies, including automated assembly lines, advanced testing equipment, and robust supply chain management systems.

Supply Chain and Component Sourcing

A strong supply chain network ensures access to high-quality components while mitigating risks such as shortages and counterfeit parts.

Customer Support and Communication

Clear communication and reliable customer support are essential for successful collaboration. A responsive EMS provider keeps businesses informed throughout the manufacturing process.

Experience Efficiency & Cost Savings with Our Tailored Manufacturing Solutions

We provide efficient, cost-effective manufacturing services designed to meet your unique needs. By leveraging proven lean manufacturing techniques, we help you maximise value with:

Minimal inventory requirements

Lower overall acquisition costs

Risk mitigation through multiple inventory locations

Enhanced quality assurance

Guaranteed on-time delivery

Why Arrival Electronics Limited?

Arrival Electronics Limited is a trusted partner for businesses seeking comprehensive EMS solutions. With a strong commitment to quality, reliability, and industry expertise, the company provides end-to-end support for electronics manufacturing, from design to final product assembly.

With extensive experience in sourcing, assembling, and testing electronic components, Arrival Electronics Limited ensures businesses receive products that meet performance expectations and regulatory standards. Whether you require small-batch prototyping or large-scale production, their team is ready to assist with your EMS needs.

Conclusion

EMS plays a vital role in modern electronics manufacturing, offering businesses a way to produce high reliability products efficiently and cost-effectively. By working with an experienced EMS provider like Arrival Electronics Limited, companies can streamline their production processes, maintain strict quality control, and confidently bring their electronic products to market.

For more information about EMS solutions, visit www.arrivalelectronics.co.uk.

0 notes

Text

Reliable PCB Assembly & Component Distribution Partner

In the fast-moving world of electronics, sourcing high-quality components is critical for manufacturers and engineers. Arrival Electronics Limited stands out as a reliable distributor, offering a broad range of electronic components, technical expertise, and dedicated customer support. With years of experience in the industry, the company has built a reputation for providing top-tier products and services, including PCB assembly, to meet the needs of businesses across various sectors..

A Comprehensive Range of Electronic Components for PCB Assembly

Whether designing new products or maintaining existing systems, having access to a diverse inventory of components is essential. A vast selection of semiconductors, passive components, electromechanical parts, and embedded solutions is available to meet diverse industry needs. These products cater to industries such as automotive, medical, industrial, aerospace, and telecommunications, ensuring that businesses find the right components for their applications.

The company collaborates with leading manufacturers, ensuring that all components are genuine, high-quality, and sourced through authorized channels. This commitment to quality reduces the risks associated with counterfeit or substandard parts, giving businesses peace of mind when integrating components into their designs.

Your Trusted Partner for UK Electronic Manufacturing Solutions

Arrival Electronics provides comprehensive, full-turnkey electronic manufacturing services—all from a single, reliable source. From design to PCB assembly, component kitting, and distribution, we streamline your supply chain with value-added solutions customized to your needs.

Seamless Contract Manufacturing: End-to-end electronic manufacturing services, including PCB assembly, box build, and rigorous testing to ensure quality and reliability.

Expert Electronic Design: Comprehensive PCB design and electronic engineering services, covering layout, component selection, and optimization for performance.

Efficient Component Kitting: Strategic procurement services, including inventory management, kitting, and obsolescence monitoring, to keep your production running smoothly.

Industry-Leading Products: Authorized distributor for Silicon Motion (SSD solutions) and CMedia (Audio/USB control solutions), providing cutting-edge components for your designs.

Expertise in Design and Engineering Support

Beyond supplying components, we provide engineering support to help clients optimize their designs. Their team of experienced professionals assists in selecting the right components, offering design recommendations and technical insights. This collaborative approach helps businesses streamline development processes, improve product performance, and reduce time to market.

The company also offers value-added services such as custom programming, kitting, and component modifications. These services ensure that manufacturers receive ready-to-use solutions, minimizing additional work and enhancing efficiency in production.

A Commitment to Quality and Reliability

In the electronics industry, reliability is a top priority. Strict quality control measures are followed to maintain the highest standards. Every component undergoes thorough inspections and testing processes to meet industry regulations and customer specifications.

With a strong focus on traceability, the company ensures that all products come from reputable sources. This level of accountability is vital in critical applications, such as medical devices and aerospace systems, where component integrity directly impacts safety and performance.

Supplying Components for Various Industries

Different industries require specialized components to meet unique operational demands. Providing components designed to meet the specific requirements of various industries:

Automotive: Modern vehicles rely on advanced electronics for safety, performance, and connectivity. We supply components for automotive control units, sensors, infotainment systems, and electric vehicle applications, supporting innovation in the automotive industry.

Industrial: Industrial automation and control systems demand durable and efficient components. The company offers microcontrollers, power management solutions, and sensors that enable precise monitoring and control in manufacturing environments.

Medical: Medical devices require highly reliable and certified electronic components. These components are used in imaging systems, diagnostic equipment, patient monitoring devices, and wearable health technologies.

Aerospace and Defense: In mission-critical aerospace and defense applications, quality and reliability are paramount. The company delivers high-performance components that meet stringent military and aviation standards, ensuring optimal performance in extreme conditions.

Telecommunications: With the growing demand for high-speed connectivity, telecommunications companies rely on quality electronic components. We supply parts for networking equipment, base stations, fiber optics, and wireless communication systems.

Partnering with Leading Manufacturers

Strong partnerships with reputable manufacturers set this company apart from other distributors. These collaborations ensure customers have access to cutting-edge components, backed by manufacturer warranties and support. By working closely with global suppliers, the company stays ahead of industry trends, providing customers with the latest innovations in electronic components.

A Customer-Centric Approach

Customer satisfaction is at the core of the company's business philosophy. The knowledgeable team works closely with clients to understand their specific needs, offering customized solutions and responsive support. Whether a business requires standard components or customized solutions, the company is committed to delivering the best possible service.

With a user-friendly online platform, customers can browse product listings, access detailed specifications, and request quotes effortlessly. Additionally, the company maintains strong communication channels to address inquiries, provide order updates, and ensure seamless transactions.

Keeping Up with Industry Trends

The electronics industry is constantly evolving, driven by advancements in technology and changing market demands. Staying informed about industry trends enables them to offer innovative solutions that meet emerging challenges.

Some key trends shaping the industry include:

Miniaturization of Components – As electronic devices become smaller and more powerful, the demand for compact and efficient components continues to rise.

Sustainability in Electronics – Companies are increasingly focusing on eco-friendly components and sustainable manufacturing practices.

IoT and Smart Devices – The expansion of the Internet of Things (IoT) has increased the demand for sensors, wireless connectivity modules, and energy-efficient components.

Advanced Semiconductor Technologies – With ongoing advancements in semiconductor fabrication, new generations of processors and memory components are enhancing device performance and efficiency.

By staying ahead of these trends, customers have access to the most relevant and high-quality components, customized to meet their specific needs.

Why Arrival Electronics is Your Ideal Manufacturing Partner

Quality You Can Trust: AS9120B certified for aerospace and defense markets, with the capability to manufacture to ISO13485, TS16949, and AS9100 standards—ensuring precision and reliability in every project.

Decades of Industry Expertise: With 40 years of experience, we have a proven track record of delivering high-quality solutions across aerospace, medical, automotive, and other demanding sectors.

End-to-End Electronic Solutions: As a single-source partner, we offer seamless integration from design and manufacturing to kitting and component distribution—streamlining your supply chain for maximum efficiency.

Your Trusted Partner for Electronic Manufacturing & Component Solutions

Over 40 Years of Excellence in EMS

A privately owned company based in Arundel, UK, we have been delivering high-quality Electronic Manufacturing Solutions for over four decades. Our services cover design, manufacturing, component kitting, and aftermarket support, ensuring a seamless supply chain for our customers.

Comprehensive Electronic Manufacturing Services

As an AS9120B-approved specialist, we offer expert electronic design support, including PCB layout, assembly, box build, EOL testing, and EMS supply chain management. Our electronic component services encompass high-integrity procurement, verification, testing, obsolescence management, counterfeit detection, kitting, and vendor-managed inventory (VMI).

Flexible Supply Chain & Distribution

We provide complete PCB assemblies and component kits tailored to your needs through scheduled orders, consolidated shipments, JIT delivery, and consignment stock options. As a franchised distributor for Silicon Motion and CMedia, we also offer cutting-edge components for memory, storage, graphics, USB controllers, and audio codec solutions.

Customer-Centric Approach with Guaranteed Quality

At the heart of our business is a commitment to exceptional service, long-term partnerships, and customer satisfaction. Our AS9120B accreditation ensures full traceability throughout the supply chain, with a strong focus on quality, cost efficiency, and on-time delivery performance.

Final Thoughts

In a rapidly evolving electronics industry, having a reliable partner is essential for success. Arrival Electronics Limited stands out as a trusted provider of high-quality components, expert design support, and comprehensive manufacturing solutions. With a strong commitment to quality, innovation, and customer satisfaction, we help businesses across various industries achieve seamless production and superior performance.

Whether you need cutting-edge components, efficient supply chain solutions, or expert engineering support, Arrival Electronics is your go-to partner. Let us help you bring your designs to life with precision, reliability, and efficiency. Get in touch today to discover how we can support your electronic manufacturing needs.

Visit www.arrivalelectronics.co.uk to explore their extensive product offerings and learn more about how they can support your electronic component needs.

1 note

·

View note