Don't wanna be here? Send us removal request.

Text

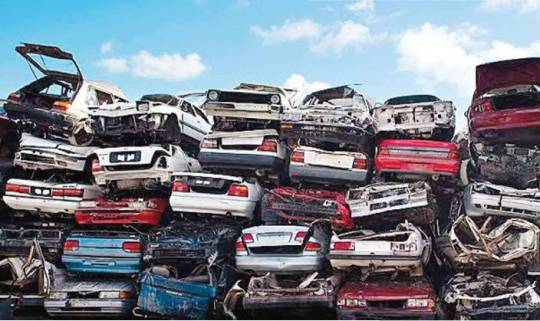

Vehicle Scrappage Policy

The Vehicle Scrappage Policy, launched on August 13, 2021, is a government-funded programme to replace old vehicles with modern & new vehicles on Indian roads. The policy is expected to reduce pollution, create job opportunities and boost demand for new vehicles. Several countries including the US, Germany, Canada and China have introduced vehicle scrappage policies to boost their respective automotive industries and curtail vehicular pollution. Large automakers are onboarding this policy by launching scrappage centres including CERO by Mahindra & Mahindra (2018) and Maruti Suzuki Toyotsu by Maruti Suzuki and Toyota (2019). This policy also supports India’s ‘Green India’ mission, as it creates space for a cleaner fleet of vehicles.

Register Now: https://bit.ly/3RrDnEq

According to the new policy, commercial vehicles aged >15 years and passenger vehicles aged >20 years will have to be mandatorily scrapped if they do not pass the fitness and emission tests. The policy does not treat a vehicle as scrap just because of its age, but considers other factors such as quality of brakes, engine performance and others. The objective is to phase out old cars, reduce urban pollution levels and stimulate automotive sales, which continues to record slowdown amid India’s post-COVID recovery phase. Additionally, the vehicle scrappage policy is also said to be a part of a larger stimulus package majorly requested by original equipment manufacturers (OEMs) to stir their demand.

Under the policy, automated testing stations and scrapping facilities will be set up in phases. Currently, 75 stations are proposed under Phase 1; this count will gradually scale up to 450–500 stations across the country. The government has also welcomed private players to invest in setting up such stations through partnership with the state governments. The government also plans to set up 50–70 facilities for scrapping vehicles in the next 4–5 years. An automobile industry body—the Society of Indian Automobile Manufacturers (SIAM)—has urged the government to allow dealer workshops to function as inspection and certification stations, as establishing new ones may not be commercially viable and delay the policy developments and implementation.

The Vehicle Scrappage Policy extends many obvious benefits, besides pollution control and improved road safety factor. Union Minister Mr. Nitin Gadkari has highlighted that raw materials derived from scrapped vehicles such as copper, rubber, steel, aluminium and plastic can be reused in new vehicles, which can help reduce the price of new vehicles and subsequently, boost sales.

Some incentives for scrapping old vehicles and buying new ones are as follows:

Manufacturers can give up to 5% discount for buying new vehicles

Zero registration fee for new vehicle purchase

Owners can receive scrap value equivalent of 4–6% of ex-showroom price of new vehicles

States can give up to 25% and 15% rebate on road tax for personal and commercial vehicles, respectively

According to the Ministry of Road Transport and Highways (MORTH), India is home to 2.1 crore vehicles that are older than 20 years, with the highest number in Karnataka (39.4 lakh), followed by Delhi (36.1 lakh), Uttar Pradesh (26.2 lakh), Kerala (20.6 lakh), Tamil Nadu (15.9 lakh) and Punjab (15.3 lakh). The policy will likely result in the following projected gains:

30% boost for the Indian automobile industry, from the current Rs. 4.5 lakh crore (US$ 61.46 billion) turnover to Rs. 10 lakh crore (US$ 136.59 billion) over the coming years

Export component of Rs. 1.45 lakh crore (US$ 19.81 billion) in the current turnover is likely to go up to Rs. 3 lakh crore (US$ 40.98 billion)

Decrease India’s huge Rs. 10 lakh crore (US$ 136.59 billion) crude import bill

Attract new investments of ~Rs. 10,000 crore (US$ 1.37 billion) and create as many as 35,000 jobs

The Vehicle Scrappage Policy has been welcomed by most states. Most car dealers in Gujarat have expressed optimism at the new policy enforcements. Mr. Pranav Shah, Chairman, Federation of Automobile Dealers Associations (FADA) in Gujarat, believes that the scrappage policy will boost sales of new vehicles on the back of proposed discounts on new car purchases against vehicle scrappage certificates. Other experts in the industry have stated that the turnaround time of cars will reduce, generating more demand for new cars. The state of Maharashtra is outlining SOPs (that will be soon rolled out) for setting up digitised scrapping centers. The Delhi Government issued a public notice prohibiting plying of over 15-year-old petrol vehicles and over 10-year-old diesel vehicles. The owners of such vehicles have been advised to get their vehicles scrapped through authorized facilities at the earliest, failing which the vehicles can be impounded.

The Tamil Nadu govt. has reported mixed responses towards the scrappage policy, raising concerns of owners of second-hand or third-hand cars as they may have a tough time finding potential buyers. Additionally, some stakeholders from the state also believe that a well-maintained car fetches a good price irrespective of its age. Mr. Wilson Joseph of BRK Automobiles, who owns a used cars business in Chennai, expressed doubts over how the policy will cater to the second-hand cars market. The policy has received a similar response from lorry/truck owners in the state.

However, at a broader level, the policy has a good mix of incentives for new vehicle buyers and automotive dealers and hence, is anticipated to generate positive results in the near future. This will also pave the way for a whole new business segment—‘Scrappage Facility’—which will flourish in a well-organised manner. Additionally, the policy addresses the intent of all stakeholders from exporters, importers, car dealers, micro, small & medium enterprises (MSMEs), original equipment manufacturers (OEMs) and end consumers. Prime Minister Mr. Narendra Modi, while introducing the policy stated, “The policy is an important link to achieve the circular economy of waste to wealth. It will also energise India's auto sector and metal sector under the principles of reuse, recycle and recover.” The Vehicle Scrappage Policy is expected to truly touch every aspect of the automobile industry in India, the result of which is expected to churn in the years to come.

0 notes

Text

India's Auto Components Industry

Introduction In recent years, India's auto component industry has experienced immense growth. The industry can be broadly classified into various organised and unorganised sectors. The organised sector contains high-value precision instruments and services OEMs, while the unorganised sector primarily caters to the aftermarket and consists of low-value goods. The industry has been a major driver of macroeconomic growth and employment. India's auto component industry has contributed 2.3% of the Gross Domestic Production (GDP) and employed around 3 million people directly and indirectly. Rising incomes and a fast-growing economy aided the growth of India's auto component industry. India has also experienced a rise in the demand for automobiles. India has the fourth-largest automobile industry, and the country dominates in the two-wheeler and the three-wheeler segment. This rising demand for automobiles has greatly supported the demand for auto components.

Register Now: https://bit.ly/3RrDnEq

Significance of India's auto component industry India's auto components are well-known worldwide for their quality and their precision. India's auto component industry's turnover stood at Rs. 4.20 lakh crore (US$ 56.5 billion) as of FY22. The industry's turnover has grown significantly from US$ 39.05 billion in FY16 to US$ 56.50 billion in FY22, recording a CAGR growth of 6.35%. Demand from domestic OEMs has significantly contributed to the auto component industry at 81.1%. This demonstrates the correlation between India's automobile and auto component industries. This increase in turnover in FY22 can be largely attributed to shifting trends in market preferences towards larger and more powerful vehicles.

India's auto component exports stood at US$ 19 billion in FY22. The exports of auto components have increased from US$ 10.83 billion in FY16 to US$ 19 billion in FY22. North America dominates these auto component exports at 32%, Europe at 31% and Asia at 25%. India has also seen growing traction for two-wheeler auto components in Africa. This is due to rising incomes in Africa and the expertise of well-established OEMs in India with auto components suitable to the African market.

India's auto components aftermarket stood at US$ 10 billion in FY22. The industry grew at a CAGR of 8.02%, from US$ 6.80 billion in FY16 to US$ 10 billion in FY22. The auto component industry's aftermarket growth can be majorly attributed to engine components contributing a 24% share of the total aftermarket turnover, followed by Suspension and breaking at 15% and Drive emission at 14%.

Importance of Electric Vehicles in Auto components India has experienced a growth in demand for electric vehicles. According to the Ministry of Heavy Industries, India has sold approximately 0.56 million electric vehicles in recent years. Most of India's electric vehicle markets are dominated by two-wheelers and three-wheelers. India's growing auto component industry aids this rise in demand for electric vehicles. India's electric vehicle auto component industry is divided into various component segments.

These components include various segments; these segments are:

Powertrain & Power Electronics: India's powertrain and power electronics are critical components for electric vehicle manufacturing. The share of these components is almost 20-30% of the cost for manufacturers. India's electric power and electronics will be valued at more than US$ 2.5 billion by 2030.

Battery And Battery-Related Components: Batteries contribute almost 40% share of the cost for electric vehicle manufacturers; it is one of the most expensive electrical components and has gained much traction in recent years. The government of India has introduced various policies to boost India's battery markets. These policies include the 'National Program on Advanced Chemistry Cell (ACC) Battery Storage (DHI) and the Battery swapping policy. India's EV battery market is expected to reach US$ 2 billion by 2026 and surpass US$ 3 billion by 2031.

Connectivity And Control Systems: These are the systems responsible for the electric vehicle intelligence, efficiency and safety while the vehicles are in motion or on charge. These systems are essential and will play an important role for electric auto components manufacturers. To improve vehicle characteristics, several 2W players have joined with technology providers; for instance, Ather partnered with Google Cloud for cloud solutions, and Okinawa partnered with Aeris to connect and control the system of electric vehicles.

Electric vehicles are expected to play a major role in the auto component industries. According to ICRA, India's auto ancillaries' revenue is expected to grow by 8-10% in FY23. This will be due to favourable auto component manufacturing policies and rising demand for electric vehicles.

Government Initiatives for the Auto component Industry The Government of India has introduced various policies to boost the auto component manufacturing industry. These policies have aided the auto component industry significantly. Few of these policies include:

Production Linked Incentives (PLI) for the Automobile and Auto Component industry: In September 2021, India introduced the PLI scheme to boost automobile and auto component manufacturing. The scheme proposed financial incentives to boost domestic manufacturing of Advanced Automotive Technology (AAT) products and attract investments in the automotive manufacturing value chain. A total of 115 companies had filed applications under this PLI scheme, and it was able to attract proposed investments of Rs. 74,850 crores (US$ 9.38 billion) against the target of Rs. 42,500 crores (US$ 5.32 billion).

PLI Scheme for National Programme on Advanced Chemistry Cell (ACC) Battery Storage: The scheme was notified in June 2022. The main aim of this scheme was to reduce the cost of battery manufacturing in India and make India globally competitive. The scheme will help the country transition from a fossil fuel-based automobile transportation system to electric vehicle-based transport. The government of India is expected to provide manufacturing incentives worth Rs. 18,100 crores (US$ 2.26 billion) to auto components manufacturers. In July 2022, the scheme received three bidders: Reliance New Energy Limited, Ola Electric Mobility Private Limited and Rajesh Exports Limited.

FAME INDIA II Scheme: Faster Adoption and Manufacturing of Electric and Hybrid Vehicles (FAME) was introduced in India to promote India's transition from a fossil fuel-based automobile transportation system to electric vehicles. Phase II of this scheme had a total budget outlay of Rs. 10,000 crores (US$ 1.25 billion) from April 1, 2019 till the next three years. By supporting 7000 e-Buses, 5 lakh e-3 Wheelers, 55000 e-4 Wheeler Passenger Cars (including Strong Hybrid), and 10 lakh e-2 Wheelers, this phase attempts to create demand for electric vehicles.

Conclusion The rapidly globalising world is opening up new prospects for the transportation business, particularly as the industry shifts toward electric, electronic, and hybrid vehicles, which are more efficient, safe, and dependable. This will increase verticals and possibilities for auto component producers during the next decade. The government of India has already granted several manufacturing incentives to assist businesses in adapting to the sector's changing dynamics. India is also aggressively investing in electric vehicle infrastructure. These investments, alongside rising incomes and growing demand for sustainable transportation, will significantly aid the auto component industry and help achieve new heights in the upcoming years.

0 notes

Text

Bharat Mobility Global Expo 2024

India has been among the global leaders in manufacturing and exports of high quality auto components over the past two decades, while, the vehicle manufacturing also witnessed significant growth. The forward and the backward linkages of the mobility sector has also contributes significantly to the growth of allied sectors such as steel, rubber, plastics, and electronics sector.

With the plethora of emerging global challenges such as depletion of fossil fuels sources, climate change and rapid urbanization, we are extremely proud of the able and visionary leadership of our Honorable PM Mr Narendra Modi, Bharat is setting a strong foundations for New age mobility solutions. And with supportive Government policies towards development alternative fuel vehicles such as Hydrogen, EVs, besides existing skillsets in advanced IT, electronics and growing startup enthusiasm, Bharat is all set to emerge as global leader in entire Automotive and mobility value chain in the near future.

EEPC India is honored to be the Coordinating Agency of the landmark event Bharat Mobility Global Expo 2024

Mr. Arun Kumar Garodia, Chairman, Advisory Committee of Bharat Mobility Global Expo and EEPC India

To know more: Log on to www.bharat-mobility.com

1 note

·

View note