Don't wanna be here? Send us removal request.

Text

Unlocking Industrial Insights: Visualizing Data with Grafana on ARMxy

Introduction to Grafana

Grafana is an open-source visualization tool widely used for monitoring and analyzing data. It supports multiple data sources like InfluxDB, Prometheus, and MySQL, making it ideal for industrial applications. With customizable dashboards and robust alerting features, Grafana empowers users to track real-time data, visualize trends, and make informed decisions.

Why Use ARMxy with Grafana?

ARMxy Edge IoT Gateway devices are powerful, compact solutions ideal for data collection and processing at the edge. Combining Grafana with ARMxy devices offers a robust system for visualizing industrial data without relying on cloud services. This setup reduces latency, enhances security, and ensures data availability even in offline conditions.

Step 1: Install Grafana on ARMxy

To install Grafana on your ARMxy device, follow these steps:

Update System Packages

Install Grafana Grafana can be installed via official repositories:

Start and Enable Grafana Service

Access Grafana by opening http://:3000 in your browser. Default credentials are admin/admin.

Step 2: Connect Data Sources

For example, to connect an InfluxDB instance:

Navigate to Configuration → Data Sources.

Select InfluxDB and enter the database URL.

Provide authentication credentials and database details.

Click Save & Test to confirm the connection.

Step 3: Build Dashboards

With the data source linked, follow these steps to visualize data:

Go to Create → Dashboard.

Click Add a New Panel.

Select your data source and define the desired metrics.

Customize the graph’s appearance and set alert thresholds if needed.

Save the dashboard for real-time monitoring.

Step 4: Implement Alerts

Grafana’s alerting feature can notify maintenance teams about potential equipment failures or abnormal conditions:

Go to Alerting → Notification Channels.

Add preferred channels like Email, Slack, or Webhooks.

Define alert rules for specific data conditions.

Conclusion

By combining Grafana with ARMxy Edge IoT Gateways, you can create powerful, localized data visualization solutions that enhance monitoring, improve response times, and reduce reliance on cloud platforms. This setup is ideal for industries seeking efficient, real-time insights with flexible deployment options.

0 notes

Text

Enhancing ARMxy Performance with Nginx as a Reverse Proxy

Introduction

Nginx is a high-performance web server that also functions as a reverse proxy, load balancer, and caching server. It is widely used in cloud and edge computing environments due to its lightweight architecture and efficient handling of concurrent connections. By deploying Nginx on ARMxy Edge IoT Gateway, users can optimize data flow, enhance security, and efficiently manage industrial network traffic.

Why Use Nginx on ARMxy?

1. Reverse Proxying – Nginx acts as an intermediary, forwarding client requests to backend services running on ARMxy.

2. Load Balancing – Distributes traffic across multiple devices to prevent overload.

3. Security Hardening – Hides backend services and implements SSL encryption for secure communication.

4. Performance Optimization – Caching frequently accessed data reduces latency.

Setting Up Nginx as a Reverse Proxy on ARMxy

1. Install Nginx

On ARMxy’s Linux-based OS, update the package list and install Nginx:

sudo apt update sudo apt install nginx -y

Start and enable Nginx on boot:

sudo systemctl start nginx sudo systemctl enable nginx

2. Configure Nginx as a Reverse Proxy

Modify the default Nginx configuration to route incoming traffic to an internal service, such as a Node-RED dashboard running on port 1880:

sudo nano /etc/nginx/sites-available/default

Replace the default configuration with the following:

server { listen 80; server_name your_armxy_ip;

location / {

proxy_pass http://localhost:1880/;

proxy_set_header Host $host;

proxy_set_header X-Real-IP $remote_addr;

proxy_set_header X-Forwarded-For $proxy_add_x_forwarded_for;

}

}

Save the file and restart Nginx:

sudo systemctl restart nginx

3. Enable SSL for Secure Communication

To secure the reverse proxy with HTTPS, install Certbot and configure SSL:

sudo apt install certbot python3-certbot-nginx -y sudo certbot --nginx -d your_domain

Follow the prompts to automatically configure SSL for your ARMxy gateway.

Use Case: Secure Edge Data Flow

In an industrial IoT setup, ARMxy collects data from field devices via Modbus, MQTT, or OPC UA, processes it locally using Node-RED or Dockerized applications, and sends it to cloud platforms. With Nginx, you can:

· Secure data transmission with HTTPS encryption.

· Optimize API requests by caching responses.

· Balance traffic when multiple ARMxy devices are used in parallel.

Conclusion

Deploying Nginx as a reverse proxy on ARMxy enhances security, optimizes data handling, and ensures efficient communication between edge devices and cloud platforms. This setup is ideal for industrial automation, smart city applications, and IIoT networks requiring low latency, high availability, and secure remote access.

0 notes

Text

Deploying SQLite for Local Data Storage in Industrial IoT Solutions

Introduction

In Industrial IoT (IIoT) applications, efficient data storage is critical for real-time monitoring, decision-making, and historical analysis. While cloud-based storage solutions offer scalability, local storage is often required for real-time processing, network independence, and data redundancy. SQLite, a lightweight yet powerful database, is an ideal choice for edge computing devices like ARMxy, offering reliability and efficiency in industrial environments.

Why Use SQLite for Industrial IoT?

SQLite is a self-contained, serverless database engine that is widely used in embedded systems. Its advantages include:

Lightweight & Fast: Requires minimal system resources, making it ideal for ARM-based edge gateways.

No Server Dependency: Operates as a standalone database, eliminating the need for complex database management.

Reliable Storage: Supports atomic transactions, ensuring data integrity even in cases of power failures.

Easy Integration: Compatible with various programming languages and industrial protocols.

Setting Up SQLite on ARMxy

To deploy SQLite on an ARMxy Edge IoT Gateway, follow these steps:

1. Installing SQLite

Most Linux distributions for ARM-based devices include SQLite in their package manager. Install it with:

sudo apt update

sudo apt install sqlite3

Verify the installation:

sqlite3 --version

2. Creating and Managing a Database

To create a new database:

sqlite3 iiot_data.db

Create a table for sensor data storage:

CREATE TABLE sensor_data (

id INTEGER PRIMARY KEY AUTOINCREMENT,

timestamp DATETIME DEFAULT CURRENT_TIMESTAMP,

sensor_id TEXT,

value REAL

);

Insert sample data:

INSERT INTO sensor_data (sensor_id, value) VALUES ('temperature_01', 25.6);

Retrieve stored data:

SELECT * FROM sensor_data;

3. Integrating SQLite with IIoT Applications

ARMxy devices can use SQLite with programming languages like Python for real-time data collection and processing. For instance, using Python’s sqlite3 module:

import sqlite3

conn = sqlite3.connect('iiot_data.db')

cursor = conn.cursor()

cursor.execute("INSERT INTO sensor_data (sensor_id, value) VALUES (?, ?)", ("pressure_01", 101.3))

conn.commit()

cursor.execute("SELECT * FROM sensor_data")

rows = cursor.fetchall()

for row in rows:

print(row)

conn.close()

Use Cases for SQLite in Industrial IoT

Predictive Maintenance: Store historical machine data to detect anomalies and schedule maintenance.

Energy Monitoring: Log real-time power consumption data to optimize usage and reduce costs.

Production Line Tracking: Maintain local records of manufacturing process data for compliance and quality control.

Remote Sensor Logging: Cache sensor readings when network connectivity is unavailable and sync with the cloud later.

Conclusion

SQLite is a robust, lightweight solution for local data storage in Industrial IoT environments. When deployed on ARMxy Edge IoT Gateways, it enhances real-time processing, improves data reliability, and reduces cloud dependency. By integrating SQLite into IIoT applications, industries can achieve better efficiency and resilience in data-driven operations.

0 notes

Text

Running Docker on ARMxy: Scalable Edge IoT Deployment

Introduction

As Industrial IoT (IIoT) applications continue to evolve, edge computing requires more efficient ways to deploy and manage software. Docker, a lightweight containerization platform, enables modular and scalable application deployment on ARMxy edge gateways. By running Docker on ARMxy, industries can simplify software updates, improve resource utilization, and streamline the integration of different services at the edge.

Why Use Docker on ARMxy?

1. Efficient Resource Utilization

Unlike traditional virtual machines, Docker containers share the same OS kernel, reducing overhead and making better use of ARMxy’s hardware resources.

2. Simplified Application Deployment

With Docker, industrial applications can be packaged as containers, making them easy to deploy, update, and replicate across multiple devices.

3. Seamless Integration with IIoT Systems

Docker allows ARMxy to run various industrial software, including data processing, communication protocols, and cloud connectivity tools, without complex installations.

4. Faster Software Updates

Containers provide a controlled environment where updates can be deployed without affecting the entire system, ensuring minimal downtime.

Practical Applications in Industrial IoT

Protocol Translation: Running Modbus-to-OPC UA converters inside containers.

Data Logging & Processing: Deploying databases and analytics tools at the edge.

Cloud Connectivity: Enabling MQTT or HTTP gateways for seamless cloud integration.

Machine Learning at the Edge: Running AI models for anomaly detection and predictive maintenance.

Conclusion

Running Docker on ARMxy transforms how Industrial IoT applications are deployed and managed. By leveraging containerization, businesses can achieve scalable, flexible, and cost-efficient edge computing solutions. Whether it's protocol conversion, real-time monitoring, or AI inference, Docker provides a robust foundation for industrial automation and IoT innovation.

0 notes

Text

Running Mosquitto MQTT Broker on ARMxy for Secure IoT Communication

Introduction

Mosquitto is a lightweight and open-source MQTT broker designed for low-latency, efficient communication between IoT devices. It is widely used in industrial applications to enable reliable and secure message exchange between edge devices and cloud platforms. In this article, we will guide you through installing and configuring the Mosquitto MQTT broker on the ARMxy RK3568J Edge Gateway, optimizing it for secure and stable IoT communication.

Why Use Mosquitto on ARMxy?

Deploying Mosquitto on ARMxy Edge Gateways enhances industrial IoT (IIoT) solutions by providing:

Lightweight Communication – Suitable for resource-constrained devices.

Secure Data Exchange – Supports SSL/TLS encryption and authentication.

Scalability – Handles thousands of IoT devices efficiently.

Local Processing – Reduces cloud dependency by enabling local message routing.

Installing Mosquitto on ARMxy

To install Mosquitto on an ARMxy running Linux, follow these steps:sudo apt update sudo apt install mosquitto mosquitto-clients -y

Verify the installation:mosquitto -v

This command should display Mosquitto' s version and indicate that the broker is running.

Configuring Secure MQTT Communication

By default, Mosquitto runs without authentication. To enable a secure setup, configure user authentication and TLS encryption:

Create a Mosquitto password file

sudo mosquitto_passwd -c /etc/mosquitto/passwd myuser

You will be prompted to enter a password for the user.

2. Modify the Mosquitto configuration file (/etc/mosquitto/mosquitto.conf):allow_anonymous false password_file /etc/mosquitto/passwd listener 1883

Restart the Mosquitto service for changes to take effect:sudo systemctl restart mosquitto

Testing MQTT Communication

You can test the broker by publishing and subscribing to messages locally:

Open one terminal and run:

mosquitto_sub -h localhost -t test/topic -u myuser -P mypassword

Open another terminal and send a message:

mosquitto_pub -h localhost -t test/topic -m "Hello, ARMxy!" -u myuser -P mypassword

If everything is set up correctly, you should see the message appear in the subscriber terminal.

Conclusion

Deploying Mosquitto MQTT on ARMxy Edge Gateways enables secure, low-latency communication for IIoT applications. By leveraging MQTT’s lightweight protocol, you can optimize industrial automation, smart infrastructure, and real-time monitoring solutions with reliable data exchange.

Would you like to integrate MQTT with other services like Node-RED or InfluxDB? Stay tuned for more tutorials!

0 notes

Text

Managing Industrial Data with PostgreSQL on ARMxy SBC

Introduction

In modern industrial environments, handling large volumes of data efficiently is crucial for monitoring, analysis, and decision-making. PostgreSQL, an advanced open-source relational database, offers powerful features for managing structured industrial data. When deployed on ARMxy edge computing devices, PostgreSQL enables local storage, real-time processing, and seamless integration with industrial control systems.

Why PostgreSQL for Industrial Data?

PostgreSQL is widely used in industrial applications due to its:

Reliability – ACID compliance ensures data integrity.

Scalability – Handles growing data loads efficiently.

Extensibility – Supports JSON, time-series, and spatial data.

Advanced Query Capabilities – Optimized for analytics and reporting.

Industrial Use Cases

When combined with ARMxy, PostgreSQL becomes a powerful solution for:

Real-time Data Logging: Storing sensor data from PLCs, RTUs, and SCADA systems.

Predictive Maintenance: Analyzing historical trends to detect failures before they occur.

Batch Process Monitoring: Tracking production metrics in industrial workflows.

Edge Analytics: Performing on-device queries before transmitting relevant insights to the cloud.

Deploying PostgreSQL on ARMxy

ARMxy devices provide an optimized platform for running PostgreSQL with efficient resource utilization. Key deployment considerations include:

Storage Optimization – Using SSDs or SD cards for improved read/write performance.

Connection Pooling – Enhancing query efficiency using tools like PgBouncer.

Backup Strategies – Implementing periodic backups using pg_dump or streaming replication.

Security Hardening – Enabling SSL, user authentication, and firewall configurations.

Conclusion

Leveraging PostgreSQL on ARMxy enables industrial systems to process and store data locally, reducing cloud dependency and improving real-time decision-making. Its robust feature set makes it an ideal choice for managing industrial data efficiently in edge computing environments.

Would you consider PostgreSQL for your industrial IoT applications? Let’s discuss!

0 notes

Text

Integrating ARMxy SBC with InfluxDB for Time-Series Monitoring

In the world of Industrial IoT (IIoT), the ability to efficiently monitor, store, and analyze large volumes of time-stamped data is essential. From environmental sensors in smart factories to energy meters in power systems, time-series data forms the backbone of real-time insight and historical analysis.

InfluxDB, an open-source time-series database, is designed specifically for these use cases. Combined with the industrial-grade ARMxy Edge Gateway, it creates a robust edge solution for reliable data acquisition, storage, and visualization—all without depending on cloud availability.

🧠 Why InfluxDB on ARMxy?

InfluxDB is lightweight, high-performance, and optimized for time-series workloads. It supports powerful query languages, retention policies, and integrations with monitoring tools such as Grafana. When deployed directly on an ARMxy (RK3568J/RK3568B2) gateway, it becomes a local data engine with key advantages:

Minimal latency: Store and query data at the edge

Offline reliability: Operate without cloud or internet connection

Flexible integration: Compatible with Modbus, OPC UA, MQTT, and more

🏭 Real-World Use Case Example

Imagine a factory floor with multiple PLCs controlling machinery. Each PLC sends temperature, vibration, and power consumption data every few seconds. Instead of sending that data to a remote server, it can be ingested directly into InfluxDB running on the ARMxy device.

You can then use:

Telegraf for parsing and collecting metrics

Grafana for local visualization dashboards

Node-RED to add logic and alarms

The result? A self-contained edge monitoring system capable of showing trends, detecting anomalies, and buffering data even during connectivity drops.

🔗 Integration Workflow Overview

Install InfluxDB on ARMxy via Docker or native ARM64 package

Connect data sources: Modbus devices, MQTT brokers, etc.

Configure retention policies to manage local storage

Use Grafana (also installable on ARMxy) to build dashboards

(Optional) Forward selected metrics to cloud or central server for backup

✅ Benefits of Edge Time-Series Monitoring

Faster Insights: No need to wait for data to hit the cloud

Bandwidth Optimization: Only send essential data upstream

Improved System Resilience: Data remains accessible during downtime

Security & Compliance: Sensitive data can stay on-premises

🔚 Conclusion

Deploying InfluxDB on ARMxy Edge Gateways transforms traditional data loggers into intelligent local data hubs. With flexible integration options, support for real-time applications, and a compact industrial design, ARMxy with InfluxDB is a perfect fit for smart manufacturing, energy monitoring, and any IIoT scenario that demands fast, local decision-making.

Let the data stay close—and smart.

0 notes

Text

Launched New ARM Embedded Industrial Computer with RK3562J for ARMxy Series

The BL370 series is powered by the industrial-grade Rockchip RK3562/RK3562J processor, featuring a multi-core heterogeneous architecture with a quad-core ARM Cortex-A53 and a single-core ARM Cortex-M0, clocked at up to 1.8GHz/2.0GHz. It offers a robust solution with 4GB LPDDR4X RAM and 32GB eMMC storage, along with a rich set of I/O interfaces. The built-in 1 TOPS NPU supports deep learning capabilities, making it ideal for AI-driven applications.

Key Features:

High Reliability and Cost-Effectiveness: The BL370 series is widely used in industrial control, edge computing, AIoT, artificial intelligence, communication management, AGV robots, machine vision, robotics, industrial IoT gateways, energy storage systems, automation control, and rail transportation.

Versatile Connectivity:

Data Acquisition and Control: Supports communication, PWM output, pulse counting, and more.

Video Processing: Capable of 1080P@60fps H.264 encoding and 4K@30fps H.265 decoding.

Wireless Communication: Built-in Mini PCIe interface supports Bluetooth, WiFi, 4G, and 5G modules.

Software and Development Support:

Operating Systems: Linux-5.10.198, Linux-RT-5.10.198, Ubuntu 20.04, Debian 11 (planned), Android 13 (planned).

Development Tools: Docker containers, Node-RED, and Qt-5.15.2 for GUI development.

Industrial Software:

Robust Design for Harsh Environments:

The BL370 series has undergone professional electrical performance design and high/low-temperature testing, ensuring stable operation in extreme conditions with temperatures ranging from -40°C to 85°C and resistance to electromagnetic interference. Its DIN35 rail mounting makes it suitable for various industrial applications.

Typical Application Areas:

Industrial Control

Energy Storage Systems (EMS/BMS)

AIoT and Artificial Intelligence

Smart Manufacturing

Communication Management

AGV Robots

Machine Vision

Edge Computing

Motion Control

Robotics

Rail Transportation

Smart Devices

The BL370 series combines high performance, reliability, and versatility, making it an ideal solution for demanding industrial and IoT applications.

0 notes

Text

ARM architecture

The ARM architecture refers to a family of RISC (Reduced Instruction Set Computing) based processor designs developed by ARM Holdings. Due to its high performance, low power consumption and scalability , it is widely used in various applications including mobile devices, embedded systems and IoT (Internet of Things) devices.

The main features of the ARM architecture are:

RISC design : ARM processors use a simplified instruction set, resulting in faster execution and lower power consumption.

Load-store architecture : Operations are performed only on data stored in registers, thus improving efficiency.

Thumb instruction set : A compact 16-bit instruction set that reduces code size and improves performance in memory-constrained environments.

Multiprocessor series :

Scalability : The ARM architecture supports 32-bit (ARMv7) and 64-bit (ARMv8, ARMv9) designs to meet a wide range of performance requirements.

Advanced Technology :

application:

Mobile devices : ARM processors power most smartphones and tablets.

Embedded Systems : Used in IoT devices, industrial automation, and consumer electronics.

Automotive : Applied in advanced driver assistance systems (ADAS) and infotainment systems.

Network : Present in routers, switches, and other network devices.

Artificial Intelligence and Machine Learning : ARM-based processors are increasingly used for edge AI applications.

In summary, the ARM architecture is a versatile, efficient processor design that has become a cornerstone of modern computing, especially in power-sensitive and performance-critical applications.

0 notes

Text

Thumb Instruction Set and Their Differences

1.nbsp;ARM Instruction Set

Bit Width: 32-bit

Purpose: Designed for high performance and full functionality.

Features:

Rich set of instructions for complex operations.

Optimized for performance in applications requiring high computational power.

Use Cases:

Early ARM processors (e.g., ARM7, ARM9).

Applications where performance is critical.

2. Thumb Instruction Set

Bit Width: 16-bit

Purpose: Designed for improved code density and lower power consumption.

Features:

Smaller instruction size reduces memory usage.

Limited functionality compared to the ARM instruction set.

Use Cases:

Embedded systems with limited memory (e.g., Cortex-M series).

Applications where power efficiency and code size are critical.

3. Thumb-2 Instruction Set

Bit Width: Mixed 16-bit and 32-bit

Purpose: Combines the advantages of ARM and Thumb instruction sets.

Features:

Provides high code density (like Thumb) and high performance (like ARM).

Allows 16-bit and 32-bit instructions to be used interchangeably.

Use Cases:

Modern ARM processors (e.g., Cortex-M, Cortex-R, and some Cortex-A).

Applications requiring a balance of performance and efficiency.

4. A64 Instruction Set

Bit Width: 64-bit

Purpose: Designed for 64-bit ARM architectures (ARMv8 and ARMv9).

Features:

Supports larger address space and enhanced performance.

Introduces new instructions for advanced computing tasks (e.g., cryptography, AI).

Use Cases:

High-performance applications (e.g., smartphones, servers, data centers).

Modern ARM processors (e.g., Cortex-A53, Cortex-A72, Apple M1/M2).

Key Differences Between ARM Instruction Sets

Summary

ARM (32-bit): High performance, used in early ARM processors.

Thumb (16-bit): High code density, used in memory-constrained systems.

Thumb-2 (16/32-bit): Balances performance and code density, used in modern embedded systems.

A64 (64-bit): Designed for 64-bit architectures, used in high-performance applications.

These instruction sets enable ARM processors to cater to a wide range of applications, from low-power embedded systems to high-performance computing platforms.

0 notes

Text

OPC UA Field eXchange (UAFX)

OPC UA Field eXchange (UAFX) is a new generation of field layer communication standard launched by the OPC Foundation, which aims to solve the core pain points of the long-standing coexistence of multiple protocols and poor device interoperability in the field of industrial automation. As an extension of the OPC UA standard, UAFX realizes end-to-end standardized data interaction from the control layer to field devices through a unified information model and communication framework, providing key infrastructure for Industry 4.0 and smart manufacturing. Its core value lies in breaking the technical barriers of traditional fieldbuses, enabling devices from different manufacturers to achieve plug-and-play interconnection without relying on dedicated gateways, while meeting the stringent requirements of modern industry for real-time, security and flexibility.

Core Functions and Applications of OPC UAFX

I. Key Features

1. Cross-vendor Interoperability

Enables seamless communication between controllers/devices from different brands through standardized OPC UA information models

Supports three-tier communication architectures: Controller-to-Controller (C2C), Controller-to-Device (C2D), and Device-to-Device (D2D)

2. Real-time Data Exchange

Delivers deterministic communication via Ethernet TSN and 5G networks

Achieves microsecond-level synchronization using UDP/IP (IEEE 802.1AS)

3. Unified Engineering Configuration

Built-in Connection Manager for automatic secure link establishment

Supports integration with standard engineering tools (e.g., FDT/DTM, AML)

4. Advanced Diagnostics

Real-time monitoring of device health (network latency, packet loss, etc.)

Asset Information Model (AIM) for full lifecycle data tracking

5. Secure Communication

Inherits OPC UA's native X.509 certificate authentication and AES-256 encryption

Complies with both functional safety (IEC 61508) and cybersecurity (IEC 62443) standards

II. Industrial Applications

1. Smart Factories

Plug-and-play configuration for PLCs, robots, AGVs, etc.

Use case: Multi-brand robot collaboration in automotive welding lines

2. Process Automation

Eliminates protocol conversion between DCS and field instruments (flow meters/temperature transmitters)

Application: Direct data transmission from smart instruments to MES in petrochemical plants

3. Motion Control

Enables precision synchronization (<1μs jitter) for servo drives and CNC equipment

Typical scenario: Multi-axis synchronization in packaging machinery

4. Energy Management

Standardized monitoring for PV inverters, energy storage PCS, etc.

Implementation: Gateway-free data acquisition for wind farm SCADA systems

III. Technical Advantages

IV. Implementation Benefits

Lower TCO: 30+% reduction in protocol conversion hardware costs

Faster Deployment: 50% shorter engineering configuration time

Higher OEE: Predictive maintenance reduces unplanned downtime

Currently supported by leading automation vendors like ABB and Siemens, UAFX is expected to achieve widespread adoption in discrete manufacturing by 2025. This standard is particularly suited for Industry 4.0 scenarios demanding high real-time performance and multi-vendor device integration.

0 notes

Text

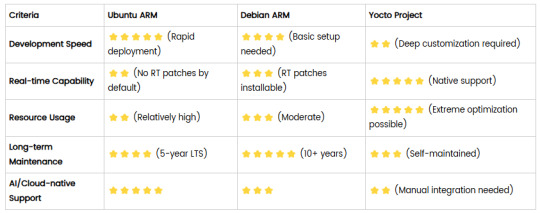

Comparison of Ubuntu, Debian, and Yocto for IIoT and Edge Computing

In industrial IoT (IIoT) and edge computing scenarios, Ubuntu, Debian, and Yocto Project each have unique advantages. Below is a detailed comparison and recommendations for these three systems:

1. Ubuntu (ARM)

Advantages

Ready-to-use: Provides official ARM images (e.g., Ubuntu Server 22.04 LTS) supporting hardware like Raspberry Pi and NVIDIA Jetson, requiring no complex configuration.

Cloud-native support: Built-in tools like MicroK8s, Docker, and Kubernetes, ideal for edge-cloud collaboration.

Long-term support (LTS): 5 years of security updates, meeting industrial stability requirements.

Rich software ecosystem: Access to AI/ML tools (e.g., TensorFlow Lite) and databases (e.g., PostgreSQL ARM-optimized) via APT and Snap Store.

Use Cases

Rapid prototyping: Quick deployment of Python/Node.js applications on edge gateways.

AI edge inference: Running computer vision models (e.g., ROS 2 + Ubuntu) on Jetson devices.

Lightweight K8s clusters: Edge nodes managed by MicroK8s.

Limitations

Higher resource usage (minimum ~512MB RAM), unsuitable for ultra-low-power devices.

2. Debian (ARM)

Advantages

Exceptional stability: Packages undergo rigorous testing, ideal for 24/7 industrial operation.

Lightweight: Minimal installation requires only 128MB RAM; GUI-free versions available.

Long-term support: Up to 10+ years of security updates via Debian LTS (with commercial support).

Hardware compatibility: Supports older or niche ARM chips (e.g., TI Sitara series).

Use Cases

Industrial controllers: PLCs, HMIs, and other devices requiring deterministic responses.

Network edge devices: Firewalls, protocol gateways (e.g., Modbus-to-MQTT).

Critical systems (medical/transport): Compliance with IEC 62304/DO-178C certifications.

Limitations

Older software versions (e.g., default GCC version); newer features require backports.

3. Yocto Project

Advantages

Full customization: Tailor everything from kernel to user space, generating minimal images (<50MB possible).

Real-time extensions: Supports Xenomai/Preempt-RT patches for μs-level latency.

Cross-platform portability: Single recipe set adapts to multiple hardware platforms (e.g., NXP i.MX6 → i.MX8).

Security design: Built-in industrial-grade features like SELinux and dm-verity.

Use Cases

Custom industrial devices: Requires specific kernel configurations or proprietary drivers (e.g., CAN-FD bus support).

High real-time systems: Robotic motion control, CNC machines.

Resource-constrained terminals: Sensor nodes running lightweight stacks (e.g., Zephyr+FreeRTOS hybrid deployment).

Limitations

Steep learning curve (BitBake syntax required); longer development cycles.

4. Comparison Summary

5. Selection Recommendations

Choose Ubuntu ARM: For rapid deployment of edge AI applications (e.g., vision detection on Jetson) or deep integration with public clouds (e.g., AWS IoT Greengrass).

Choose Debian ARM: For mission-critical industrial equipment (e.g., substation monitoring) where stability outweighs feature novelty.

Choose Yocto Project: For custom hardware development (e.g., proprietary industrial boards) or strict real-time/safety certification (e.g., ISO 13849) requirements.

6. Hybrid Architecture Example

Smart factory edge node:

Real-time control layer: RTOS built with Yocto (controlling robotic arms)

Data processing layer: Debian running OPC UA servers

Cloud connectivity layer: Ubuntu Server managing K8s edge clusters

Combining these systems based on specific needs can maximize the efficiency of IIoT edge computing.

0 notes

Text

Features and Applications of Debian/Arch Linux ARM OS

1. Core Features of Debian ARM

(1) Stable and Reliable Foundation

Community-maintained: Developed by global contributors without commercial influence

Extended support cycle: 5-year security updates for each stable release (extendable to 10 years via LTS project)

Rigorous quality control: Packages undergo strict stability testing before entering stable repos

(2) Broad Hardware Compatibility

Supports full ARMv7/ARMv8 architectures from Cortex-A7 to A78

Officially maintains ports for over 20 single-board computers (including all Raspberry Pi models)

(3) Lightweight Design

Minimal installation requires only ~128MB RAM

Offers systemd-free Devuan branch alternative

(4) Software Ecosystem

Includes over 59,000 precompiled packages

Provides newer software versions via backports repository

2. Typical Applications of Debian ARM

(1) Server Domain

Low-power ARM servers (e.g. AWS Graviton instances)

Network infrastructure (routers, firewalls)

(2) Embedded Systems

Industrial control equipment (requiring long-term stable operation)

Medical devices (compliant with IEC 62304 standard)

(3) Education & Research

Computer architecture teaching platforms

Scientific computing cluster nodes

3. Core Features of Arch Linux ARM

(1) Rolling Release Model

Provides latest software versions (kernel/toolchain etc.)

Daily synchronization with upstream Arch Linux updates

(2) Ultimate Customization

Build from base system according to needs

Supports custom kernel compilation (e.g. enabling specific CPU features)

(3) Community Support

Active AUR (Arch User Repository)

Detailed Wiki documentation

(4) Performance Optimization

Default ARM-specific compilation optimizations

NEON instruction set acceleration support

4. Typical Applications of Arch Linux ARM

(1) Development Platform

Embedded development testing environment

Kernel/driver development platform

(2) Enthusiast Devices

Customized smart home hubs

Portable development workstations

(3) Cutting-edge Technology Testing

New architecture validation (e.g. ARMv9)

Machine learning framework experimentation

5. Comparative Summary

6. Usage Recommendations

Choose Debian ARM: For mission-critical systems, industrial control requiring long-term stability

Choose Arch Linux ARM: For latest software features, hardware R&D or deep customization

0 notes

Text

BL335 + Node-Red = The Ultimate Industrial IoT Combo!

BL335: The Industrial-Grade ARM Computer Built for Node-Red - Perfect Balance of Performance and Cost!

In the fields of industrial automation and IoT, Node-Red has become the go-to tool for rapid development of data acquisition, protocol conversion, and edge computing, thanks to its visual programming and low-code features. However, not all hardware is perfectly suited for Node-Red—some are over-spec’d and wasteful, while others lack the necessary resources for smooth operation.

Beilai Technology' s ARMxy BL335 Industrial Computer, with its Node-Red-optimized hardware design, is the ideal choice for industrial users! It delivers smooth performance, rock-solid reliability, and competitive pricing to meet diverse industrial needs.

Why is the BL335 the Best Industrial Computer for Node-Red?

1. Dual-Core A7 Processor – Just the Right Performance

2× ARM Cortex-A7 @1.2GHz, optimized for lightweight applications—Node-Red runs smoothly without lag.

Unlike overpowered quad/octa-core processors, the dual-core A7 design avoids wasted resources, balancing performance and cost efficiency.

2. RAM & ROM Perfectly Matched for Node-Red

512MB/1GB DDR3 RAM, fully meeting Node-Red’s long-term stability requirements (recommended ≥512MB).

4GB/8GB eMMC storage, ensuring ample space for the OS, Node-Red, and data storage without bottlenecks.

3. Pre-Installed Node-Red, Ready Out of the Box

Comes with Ubuntu/Linux + Node-Red pre-installed—power it up and start developing immediately.

Pre-configured system images enable rapid deployment, significantly shortening project timelines.

4. Dedicated Node-Red Technical Support Team

Bairen Technology provides Node-Red application examples, development guides, and customized support to help users get started quickly.

Stuck with protocol conversion or data collection? Our expert team offers real-time remote assistance!

5. Rich Serial & Network Ports for Easy Data Acquisition

Optional 4-8x RS485/RS232 ports, supporting Modbus RTU, DL/T645, and other industrial protocols.

Dual Ethernet (Gigabit + Fast Ethernet), compatible with TCP/IP, MQTT, OPC UA, and more for flexible device integration.

6. Industrial-Grade Stability for 24/7 Reliability

Fully isolated serial ports & independent hardware watchdog prevent crashes, ensuring long-term stable operation.

Wide-temperature design (-40℃~85℃), built to withstand harsh industrial environments.

7. Flexible Expansion for Diverse Needs

Optional DI/DO, CAN, GPIO, AI/AO modules for seamless connectivity with PLCs, sensors, actuators, and more.

4,000+ I/O combinations—customize your setup without overspending.

8. Optimized Hardware, Unbeatable Value

A refined hardware design that perfectly balances performance, stability, and cost.

Priced at just 60%~70% of comparable solutions, making industrial IoT more accessible than ever!

BL335 + Node-Red = The Ultimate Industrial IoT Combo!

✅ Data Acquisition: Easily connect PLCs, meters, and sensors with support for Modbus, CAN, MQTT, and more.

✅ Edge Computing: Local data processing reduces cloud dependency and network costs.

✅ Protocol Conversion: Use BLIoTLink software to quickly integrate with SCADA, Alibaba Cloud, Huawei Cloud, and other platforms.

✅ Remote Maintenance: BLRAT tool enables remote debugging, cutting on-site service costs.

Experience the Power of BL335 for Node-Red Today!

Website: www.BLIIoT.com

Free technical evaluations & industry solutions available!

Let BL335 be your ultimate Node-Red partner—low cost, high efficiency, and the perfect engine for industrial IoT! 🚀

0 notes

Text

ARMxy Industrial Computer BL410 in Electric Vehicle Charging Stations

Introduction

As the electric vehicle (EV) market continues to grow, the demand for efficient, reliable, and intelligent charging infrastructure is surging. With its flexible I/O configuration, high-performance processing capabilities, and industrial-grade reliability, the BL410 is well suited to meet the complex demands of EV charging systems. This case study explores the application of the BL410 in EV charging stations and highlights its key features and benefits.

Application Scenario

EV charging stations require real-time data acquisition, communication with cloud platforms, and precise control of charging processes. These stations must operate reliably in diverse environmental conditions, support multiple communication protocols, and enable remote monitoring and maintenance. The ARMxy BL410 series addresses these needs through its advanced hardware and software capabilities, making it an excellent choice for both AC and DC charging stations.

Solution Implementation

The BL410 industrial computer is deployed as the central controller in EV charging stations, managing critical functions such as data acquisition, protocol conversion, and cloud integration. Below is an overview of how the BL410 is utilized in this application:

1. Hardware Configuration

The BL410 is customized to meet the specific needs of EV charging stations:

Processor and Memory: Equipped with a Rockchip RK3568J/RK3568B2 quad-core ARM Cortex-A55 processor (up to 2.0 GHz) and 4GB LPDDR4X RAM, the BL410 ensures efficient processing of real-time data and multitasking for charging operations.

Storage: A 32GB eMMC storage configuration provides ample space for firmware, logs, and application data.

I/O Interfaces:

X Series I/O Board (e.g., X23): Configured with 4 RS485 ports for communication with charging modules and meters, and 4 digital inputs/outputs (DI/DO) for controlling relays and monitoring status signals.

Y Series I/O Board (e.g., Y31): Includes 4 analog inputs (0/4-20mA) for monitoring current and voltage during charging.

Communication:

Ethernet Ports: 3x 10/100M Ethernet ports enable robust connectivity to local networks and cloud platforms.

4G Module: A Mini PCIe slot with a 4G module (e.g., BL410L) ensures reliable cellular connectivity for remote access and data transmission.

WiFi Module: Optional WiFi support for local wireless communication.

Power and Protection: Supports a wide voltage range (9-36V DC) with reverse polarity and overcurrent protection, ensuring stable operation in fluctuating power conditions.

Mounting: DIN35 rail mounting facilitates easy installation within charging station enclosures.

2. Software Integration

The BL410’s software ecosystem enhances its suitability for EV charging applications:

Operating System: Runs Ubuntu 20.04, providing a stable and developer-friendly environment for application development.

Protocol Conversion: The pre-installed BLIoTLink software supports protocols such as Modbus, MQTT, and OPC UA, enabling seamless communication with charging modules, energy meters, and IoT cloud platforms like AWS IoT Core and Alibaba IoT.

Remote Access: BLRAT (Beilai Remote Access Tool) allows operators to monitor and maintain charging stations remotely, reducing downtime and service costs.

Node-RED: Facilitates rapid development of IoT applications, such as real-time monitoring dashboards and automated fault detection workflows.

Docker Support: Enables containerized deployment of applications, ensuring scalability and ease of updates.

3. Key Functions

The BL410 performs the following critical functions in EV charging stations:

Data Acquisition: Collects real-time data from energy meters (voltage, current, power) and environmental sensors (temperature, humidity) via analog and digital inputs.

Charging Control: Manages charging sessions by controlling relays and communicating with charging modules to regulate power delivery.

Cloud Integration: Transmits operational data (e.g., charging status, energy consumption) to IoT cloud platforms for analytics and billing.

Fault Detection: Monitors system health and triggers alerts for anomalies, such as overcurrent or communication failures, using Node-RED workflows.

User Interface: Supports optional HDMI output for local display of charging status or integration with touchscreen HMIs using Qt-5.15.2.

4. Environmental Reliability

The BL410 is designed to withstand the harsh conditions often encountered in outdoor charging stations:

Temperature Range: Operates reliably from -40°C to +85°C (with RK3568J SOM), suitable for extreme climates.

IP30 Protection: Prevents dust ingress, ensuring durability in dusty environments.

EMC Compliance: Passes rigorous electromagnetic compatibility tests (e.g., ESD Level III, EFT Level III), minimizing interference and ensuring stable operation.

Vibration and Shock Resistance: Complies with sinusoidal vibration and free-fall tests, making it robust for transportation and installation.

Benefits

The deployment of the ARMxy BL410 in EV charging stations offers several advantages:

Flexibility: Customizable I/O boards and SOM configurations allow tailored solutions for different charging station designs.

Reliability: Industrial-grade design with extensive environmental and EMC testing ensures long-term stability.

Scalability: Support for Docker and cloud integration enables easy expansion as the charging network grows.

Cost-Effectiveness: Remote access and maintenance via BLRAT reduce on-site service costs.

Rapid Development: Node-RED and Qt tools accelerate application development, shortening time-to-market.

Conclusion

The ARMxy BL410 series industrial computer is a powerful and versatile solution for managing EV charging stations. Its high-performance hardware, flexible I/O options, and robust software ecosystem enable efficient data acquisition, reliable communication, and seamless cloud integration. With its proven reliability in harsh industrial environments, the BL410 is helping to power the future of electric vehicle infrastructure, ensuring efficient and scalable charging solutions for a growing market.

0 notes

Text

ARM Cortex-A55 Embedded Controller BL410 in Photovoltaic Energy Storage System

0 notes

Text

ARMxy Cortex-A53 based Computers BL340 for Wind Farm Monitoring

Hardware Support for Wind Farm Monitoring Needs

High-Performance Processor: The BL340 is equipped with the Allwinner T507-H quad-core ARM Cortex-A53 processor (up to 1.4GHz), supporting real-time data processing for monitoring wind turbine operational status and data analysis.

Flexible I/O Configuration:

(1)X and Y Series IO Boards support interfaces such as RS485, RS232, DI/DO, AI/AO, enabling connections to wind turbine sensors (e.g., vibration, temperature, rotational speed) and actuators (e.g., braking systems).

(2)For example, Y51/Y53 (PT100/PT1000) can be used for precise temperature monitoring, while Y95/Y96 (PWM output and pulse counting) are suitable for wind speed and rotor speed measurement.

Communication Interfaces:

(1)Provides 1-3 10/100M Ethernet ports, supporting networked device communication within the wind farm for centralized data management.

(2)The Mini PCIe interface supports 4G/WiFi modules, ensuring remote data transmission to cloud platforms, ideal for remote wind farms.

Environmental Durability: Certified for operation from -40°C to 85°C and with IP30 protection, it is well-suited for the harsh environments of wind farms.

Software Support for Energy Production Optimization

BLloTLink Protocol Conversion Software: Supports protocols like Modbus, MQTT, and OPC UA, enabling seamless integration with wind farm equipment, mainstream industrial SCADA systems, or cloud platforms (e.g., AWS IoT, Thingsboard) for data collection, analysis, and optimization.

BLRAT Remote Access: Facilitates remote monitoring and maintenance, reducing on-site maintenance costs and improving wind farm operational efficiency.

Real-Time Operating System: Supports Linux-RT-4.9.170, ensuring low-latency data processing for real-time turbine status monitoring.

Qt-5.12.5 GUI Tool: Enables the development of intuitive user interfaces for on-site personnel to monitor and operate the system.

Docker and Node-Red Support: Simplifies the rapid development of IoT applications for wind farm monitoring.

Typical Application Scenarios

Condition Monitoring: Collects data from sensors on vibration, temperature, and hydraulic pressure to analyze equipment health, predict maintenance needs, and extend equipment lifespan.

Energy Optimization: Leverages edge computing to analyze wind speed and power output, dynamically adjusting turbine angles or loads to maximize energy production efficiency.

Fault Diagnosis: Uses AI modules (e.g., Y31 AIN Modules) to detect abnormal vibrations or mechanical faults, providing early warnings to minimize downtime.

Cloud Integration: Uploads operational data to the cloud via 4G/WiFi for long-term trend analysis, optimizing the energy management strategy of the entire wind farm.

Customization and Scalability

Modular Design: Users can select different SOMs (e.g., SOM341: 16GB eMMC + 2GB DDR4) and IO boards (e.g., X23: 4 RS485 + 4 DI/DO) to meet specific monitoring requirements.

Development Support: Offers extensive development examples (e.g., Node-Red, MQTT, CAN) to accelerate the creation of customized monitoring applications.

Long-Term Support: Shenzhen Beilai provides customized R&D and long-term after-sales support to ensure continuous system optimization.

Practical Benefits

Enhanced Reliability: Real-time monitoring and predictive maintenance reduce wind turbine failure rates.

Optimized Energy Output: Data-driven adjustments to operational parameters improve power generation efficiency.

Reduced Operating Costs: Remote management and automated monitoring minimize manual intervention and maintenance costs.

Strong Environmental Adaptability: DIN35 rail mounting and rugged aluminum alloy casing suit the complex environments of wind farms.

Example Configuration

For wind farm monitoring, a recommended configuration is:

Model: BL342B-SOM341-X23-Y51-Y95

(1)Hardware: 3 Ethernet ports, 16GB eMMC, 2GB DDR4, 4 RS485, 4 DI/DO, 2 PT100 temperature sensors, 4 PWM outputs + pulse counters.

(2)Functions: Supports multi-device networking, temperature monitoring, wind speed measurement, and remote data transmission.

Software: Ubuntu 20.04 + BLloTLink + Node-Red for data collection, protocol conversion, and IoT application development.

Conclusion

The ARMxy BL340 series embedded industrial computer, with its high-performance hardware, flexible I/O configuration, robust software support, and industrial-grade reliability, provides an ideal solution for wind farm monitoring. It not only enables real-time management of wind turbines but also optimizes energy production through data analysis and remote maintenance, reducing operational costs. It is a core component for the intelligent operation of wind farms.

0 notes