4G RTU, M2M, IIoT Gateway, LoRa Gateway, PLC Gateway, OPC UA, Gateway, 4G Industrial Routers, IO Modules, , OEM ODM since 2005. Looking for worldwide Distributors. Email: [email protected]

Don't wanna be here? Send us removal request.

Text

ARMxy BL450 Embedded Industrial Computer in Semiconductor Wafer Defect Inspection

Case Details

Based on the hardware and software features of the ARMxy BL450 series embedded industrial computer, it can efficiently meet the high-precision, high-throughput, and reliable requirements of semiconductor wafer defect inspection. Below is a detailed analysis of the solution tailored for this application.

Suitability of ARMxy BL450 for Wafer Defect Inspection

The BL450 series, powered by the Rockchip RK3588J/RK3588 processor, offers the following features that make it suitable for wafer defect inspection:

High-Performance Computing: Equipped with a quad-core ARM Cortex-A76 (up to 2.4GHz) + quad-core Cortex-A55 and a 6TOPS NPU, it supports efficient inference for deep learning models (e.g., CNN, YOLOv8), ideal for defect detection and classification tasks.

Image Processing Capability: Supports dual ISPs (up to 48MP, 8064×6048@15fps), compatible with high-resolution industrial cameras to meet the imaging needs for nanoscale wafer defects.

Rich Interfaces: Provides 2×USB 3.1 (5Gbps), 1–3×RJ-45 Ethernet ports, and HDMI 2.1 (supporting 8K@60fps decoding), facilitating connections to cameras, sensors, and displays.

Wide Temperature Range and Reliability: Operates reliably from -40°C to 85°C, suitable for semiconductor cleanroom environments; passes electromagnetic compatibility (EMC) and environmental adaptability tests (GB/T, IEC standards) for stability in harsh industrial settings.

Flexible Expansion: Supports X/Y-series IO boards with RS485, RS232, DI/DO, AI/AO interfaces, enabling seamless integration with wafer inspection equipment (e.g., probe stations, CMP tools).

Wafer Defect Inspection Solution Architecture

The BL450-based solution covers the entire process of image acquisition, preprocessing, defect detection, data management, and automation control:

(1) Image Acquisition

Hardware Configuration:

Connects high-resolution industrial cameras (e.g., Basler or Hikvision) via USB 3.1 (5Gbps), supporting 48MP (8064×6048@15fps) or 32MP (6528×4898@30fps) image capture.

Optional Mini PCIe supports 4G/5G modules for real-time image data transmission to cloud or local servers.

HDMI 2.1 (8K@60fps) enables real-time wafer image display for debugging and monitoring.

Software Support:

Integrates OpenCV (supported by development examples) for image acquisition and preprocessing, optimizing image quality (e.g., HDR, 3DNR noise reduction).

Runs camera drivers on pre-installed Ubuntu 20.04 or Debian 11, compatible with mainstream industrial camera protocols (e.g., GigE Vision, USB3 Vision).

(2) Image Preprocessing and Defect Detection

Preprocessing:

Leverages the Mali-G610 MP4 GPU for accelerated image preprocessing (e.g., grayscale conversion, edge detection, image enhancement).

Supports ISP hardware acceleration to handle high-resolution images, reducing CPU load.

Defect Detection:

Deep Learning Models: The 6TOPS NPU supports TensorFlow, PyTorch, and other frameworks, running lightweight models (e.g., MobileNet, EfficientNet) for defect classification (scratches, particles, pattern deviations). The NPU supports INT8/FP16 precision for fast inference, ideal for real-time detection.

Development Support: BL450 provides NPU and OpenCV development examples, enabling rapid deployment of pretrained or customized models (e.g., YOLOv8 for object detection).

Example Model Performance: Using YOLOv8n, BL450 achieves over 99% defect detection accuracy with single-frame inference time <50ms (for 32MP images).

Software Tools:

Uses Qt-5.15.10 to develop graphical interfaces for real-time display of detection results.

Node-Red enables rapid development of data processing workflows, facilitating integration of image analysis with downstream processes.

(3) Automation Control and Integration

Hardware Support:

X-series IO boards (e.g., X23: 4×RS485 + 4×DI + 4×DO) enable communication with wafer processing equipment, controlling robotic arms or marking defective wafers.

Y-series IO boards (e.g., Y01: 4×DI + 4×DO) support trigger signal acquisition and control for production line automation.

DIN35 rail mounting simplifies integration into existing wafer inspection systems.

Protocol Conversion:

BLIoTLink software supports Modbus, OPC UA, MQTT, and other protocols, connecting to SCADA systems or cloud platforms (e.g., AWS IoT Core, Alibaba IoT) for real-time data upload and process monitoring.

Remote Maintenance:

BLRAT tool enables remote access for convenient device debugging and maintenance, reducing manual intervention in cleanrooms.

(4) Data Management and Traceability

Local Storage: 32/64/128GB eMMC stores inspection images and results, supporting SQLite or MySQL database management.

Cloud Integration: Uploads data to cloud platforms via 4G/5G or Ethernet (2×10/100/1000M), using Thingsboard or IgnitionSCADA for data analysis and defect traceability.

Docker Support: Deploys data processing and analysis applications in Docker containers, ensuring modularity and scalability.

Recommended Product Configuration

Based on wafer defect inspection requirements, the following BL450 configuration is recommended:

Model: BL452B-SOM452-X23-Y63

Host: BL452B (2×10/100/1000M + 1×10/100M Ethernet ports, 2×USB 3.1, 1×HDMI 2.1, 2×Y-board slots)

SOM Module: SOM452 (RK3588J, 128GB eMMC, 16GB LPDDR4X, -40°C to 85°C)

X Board: X23 (4×RS485 + 4×DI + 4×DO, 20PIN)

Y Board: Y63 (4×RS485/RS232, compatible with equipment communication)

Expansion: BL452BL (adds 4G module and antenna for enhanced data transmission)

Rationale:

High storage and memory (128GB eMMC + 16GB RAM) support large-scale image data processing.

Multiple Ethernet ports and RS485 interfaces meet multi-device connectivity and high-speed communication needs.

Wide temperature range and EMC compliance ensure stability in cleanroom environments.

Advantages and Optimization Suggestions

Advantages:

Efficient Edge Computing: The 6TOPS NPU and GPU enable real-time defect detection, reducing reliance on cloud computing.

Flexible Expansion: X/Y-series IO boards support diverse interfaces, adapting to various inspection equipment and scenarios.

Cost-Effectiveness: Compared to x86 industrial computers, BL450 offers lower power consumption (9-36VDC) and competitive pricing.

Ease of Development: Provides NPU, OpenCV, and Qt development examples, lowering the development barrier.

Optimization Suggestions:

Model Optimization: For high-resolution images, use INT8 quantization or model pruning (e.g., TensorRT optimization) to improve NPU inference speed.

Thermal Management: In high-temperature cleanroom environments, pair with active cooling fans to ensure stable operation of RK3588J in 2.0GHz high-performance mode.

Network Optimization: Utilize 2×10/100/1000M Ethernet ports to separate image data and control signals, enhancing system real-time performance.

Data Augmentation: Deploy generative adversarial networks (GANs) using BL450’s Docker support to generate defect samples, improving model robustness.

Conclusion

The ARMxy BL450 series industrial computer, with its high-performance NPU, robust image processing capabilities, rich interfaces, and industrial-grade reliability, is an ideal choice for semiconductor wafer defect inspection. It supports deep learning, real-time image processing, and automation control, effectively meeting nanoscale defect detection requirements. With flexible IO expansion and a comprehensive software ecosystem (e.g., BLIoTLink, Node-Red), BL450 seamlessly integrates into wafer production lines, enhancing yield and quality.

0 notes

Text

4RS485+8DIN+8DO BL342B ARM Edge Gateway for Photovoltaic Power Station Data Collection and Protocol Conversion

Case Details

Introduction

As the scale of photovoltaic power stations continues to expand and the complexity of equipment access increases, how to efficiently collect equipment data, complete protocol conversion, and support edge computing processing has become a key challenge for field data acquisition systems. The BL342B-SOM341-X23-Y01 industrial embedded controller has become an ideal choice for photovoltaic field station data acquisition systems with its powerful computing performance, rich interface resources and flexible expansion capabilities.

Pain points and needs of photovoltaic power stations

Photovoltaic power stations usually face:

Chaotic equipment protocols: inverters, electricity meters, and weather stations come from different manufacturers (Modbus RTU/TCP, IEC 104 and other protocols coexist);

Data islands: local equipment data cannot be uploaded to the cloud or SCADA system in real time;

Harsh environment: Industrial environment challenges such as high temperature, dust, and electromagnetic interference in power station cabinets.

Solution: Hardware Configuration of BL342B-SOM341-X23-Y01

Purpose-built for PV applications:ModuleConfigurationPV-Specific FunctionalityMain UnitBL342B3× Ethernet ports (local/cloud), 2× Y-slotsSOM BoardSOM341 (16GB eMMC + 2GB DDR4)Edge computing (Quad-core [email protected])X-BoardX23 (4×RS485+4×DI+4×DO)Connects inverters, meters & digital I/OY-Board 1Y01 (4DI+4DO NPN)Monitors breakers/controls cooling fans

Applicable Scenarios

The BL342B-SOM341-X23-Y01 is specifically designed for the following scenarios in photovoltaic power stations:

Data Acquisition:

The X23 board’s 4 × RS485 ports enable seamless communication with PV inverters, smart meters, and other field devices using the Modbus protocol.

The Y01 board’s 4 × DI and 4 × DO (NPN) allow monitoring of equipment status (e.g., on/off signals) and control of auxiliary devices (e.g., relays or actuators).

High-speed data acquisition is supported by the quad-core Cortex-A53 CPU and 2GB DDR4 memory, ensuring real-time processing of large datasets from multiple devices.

Protocol Conversion:

The pre-installed BLIoTLink software supports a wide range of industrial protocols, including Modbus, IEC104, MQTT, OPC UA, and more.

It facilitates seamless integration with IoT cloud platforms (e.g., AWS IoT Core, Alibaba IoT, Huawei IoT) and industrial SCADA systems (e.g., IgnitionSCADA).

The system converts field device data (e.g., Modbus from inverters) into standardized protocols like MQTT for cloud transmission or IEC104 for grid integration.

Edge Computing:

The quad-core CPU and 16GB eMMC storage enable local data processing, reducing latency and dependency on cloud servers.

Support for Node-Red and Qt-5.12.5 allows rapid development of custom IoT applications, such as real-time analytics for PV system performance.

Docker container compatibility enables deployment of lightweight, modular applications for edge computing tasks like data filtering or anomaly detection.

Industrial Environment Adaptability:

The wide operating temperature range (-40°C to 85°C) ensures reliable performance in outdoor PV power stations exposed to extreme weather.

DIN35 rail mounting simplifies installation in control cabinets, and the IP30 rating protects against dust and debris.

Rigorous electromagnetic compatibility (EMC) and environmental testing (e.g., GB/T 9254, IEC 61000-4) ensure stability in electrically noisy industrial settings.

Deployment Case Study (50MW Western China Plant)

ApplicationBL340B ImplementationUser BenefitsInverter Monitoring4×RS485 connects 20 string invertersReal-time anomaly detection → +3% annual yieldCombiner Box ControlY01 DI monitors fuses, DO controls fans60% reduction in thermal failuresWeather IntegrationY23 interfaces third-party RS232 sensors>95% generation forecast accuracyCloud ManagementMQTT data to Alibaba Cloud IoT PlatformPlant-wide monitoring via mobile APP

Conclusion

The BL342B-SOM341-X23-Y01 is an ideal solution for photovoltaic power station data acquisition and protocol conversion. Its robust hardware, flexible I/O configuration, and advanced software capabilities make it well-suited for industrial IoT applications. With support for wide-temperature operation, DIN rail mounting, and comprehensive protocol conversion, this embedded computer ensures reliable performance in demanding PV environments. By leveraging edge computing and seamless cloud integration, it empowers operators to monitor, manage, and optimize PV power stations efficiently.

0 notes

Text

Applications of ARM Industrial Control PCs in Machine Vision

Case Details

ARM Industrial Control Computers (IPCs) serve as the core component in machine vision systems, with key applications spanning the following seven areas:

Image Processing and Analysis

As the central unit of machine vision systems, IPCs acquire and process image data in real time, executing tasks such as target detection, classification, segmentation, and recognition through algorithms. Typical applications include automated defect detection in industrial production lines.

Target Detection and Recognition

Integrated with deep learning and computer vision technologies, IPCs accurately identify objects, faces, vehicles, and other targets in images, enabling applications in intelligent surveillance, security inspection, and facial recognition systems.

Visual Navigation and Positioning

By analyzing visual features in images, IPCs provide robots or autonomous vehicles with precise path planning and location awareness, ensuring high-accuracy motion control.

Industrial Automation and Intelligence

In automation scenarios, IPCs perform workpiece identification, dimensional measurement, defect inspection, and robotic arm positioning. Their stability and reliability ensure continuous operation in harsh industrial environments.

Edge Computing and Real-Time Processing

Supporting edge computing, IPCs process image data locally to minimize transmission latency and enable millisecond-level decision feedback, critical for time-sensitive applications.

Multi-Camera Support and High-Resolution Input

Modern IPCs handle multi-camera inputs and high-resolution image processing, facilitating complex vision tasks such as precision dimensional measurement and surface defect detection in the 3C industry (Computer, Communication, Consumer Electronics).

Industry Applications

Food & Beverage: Product quality and packaging inspection

Pharmaceutical: Drug packaging and label verification

Automotive Manufacturing: Component assembly accuracy testing

Lithium Battery Industry: Battery cell dimension measurement and electrode alignment

Core Value

With robust computing power, real-time performance, stability, and scalability, IPCs drive the advancement of machine vision technology, empowering industrial automation, intelligent monitoring, and quality inspection. ARM IPC BL410 series supports 1TOPS NPU and optional IO board can be applied to machine vision application scenarios such as product appearance quality inspection, precision dimension measurement, AGV visual navigation, photovoltaic panel defect detection, etc. https://armbasedsolutions.com/products/bl410-quad-cortex-a55-rk3568j-arm-embedded-industrial-computers

#ARMxy SBC#ARMxy based SBC#Industrial PC#Machine vision#Image Processing and Analysis#Target Detection and Recognition#Visual Navigation and Positioning

0 notes

Text

ARMxy Embedded PC Applied to Lithium Battery Production Monitoring

Case Details

Application Scenario Overview

Lithium battery production involves multiple process stages (e.g., electrode preparation, battery assembly, formation, and testing), requiring real-time monitoring of equipment status, sensor data collection, production equipment control, and integration with industrial IoT platforms for data analysis and remote management. The BL340 series embedded computer, with its high performance, flexible I/O configuration, and industrial-grade reliability, is well-suited for the following tasks in lithium battery production line monitoring:

Data Acquisition: Real-time collection of temperature, voltage, current, pressure, and other sensor data.

Equipment Control: Controlling production equipment such as relays and actuators via I/O interfaces.

Edge Computing: Performing data preprocessing at the production line to reduce cloud computing load.

Remote Monitoring: Enabling remote access and maintenance through supported 4G/WiFi modules and BLRAT software.

Protocol Conversion and Cloud Integration: Supporting Modbus, MQTT, OPC UA, and other protocols via BLloTLink software for seamless integration with industrial SCADA systems and mainstream IoT cloud platforms.

Core Advantages of the BL340 Series

High-Performance Processor: Equipped with the Allwinner T507-H quad-core ARM Cortex-A53 processor (up to 1.4 GHz), with 8/16GB eMMC storage and 1/2GB DDR4 memory, capable of efficiently handling multi-task data acquisition and real-time computing.

Rich Interfaces:

3×10/100M Ethernet Ports: Support networking for multiple devices, suitable for distributed production line environments.

2×USB 2.0 Ports: Can connect to external sensors or storage devices.

X/Y Series I/O Boards: Support RS485, CAN, RS232, DI/DO, AI/AO, RTD (PT100/PT1000), thermocouples, etc., meeting diverse signal acquisition needs (e.g., temperature, voltage, current) in battery production.

Mini PCIe Interface: Supports 4G, WiFi, and Bluetooth modules for remote communication.

HDMI 2.0a (optional): Can be used for local display of monitoring data or process flows.

Software Support:

Supports operating systems such as Linux-4.9.170, Ubuntu 18.04, and Android 10, compatible with Docker and Node-Red for rapid IoT application development.

BLloTLink protocol conversion software supports Modbus, PLC, BACnet, IEC104, MQTT, OPC UA, and integration with AWS IoT Core, Thingsboard, and other platforms.

BLRAT software enables remote access and maintenance, ideal for remote diagnostics of production line equipment.

Industrial-Grade Reliability:

Wide temperature range (-40~85°C for some models, 0~70°C for others), suitable for high/low-temperature environments in battery production.

Passed electromagnetic compatibility (EMC) tests (ESD, EFT, Surge at Level III) and environmental suitability tests (vibration, drop, IP30 protection), ensuring stability in harsh industrial environments.

Supports DIN35 rail mounting, suitable for compact installation in production line settings.

Specific Applications in Lithium Battery Production Line Monitoring

The following are typical applications of the BL340 series in lithium battery production line monitoring:

(1) Sensor Data Acquisition and Processing

Requirement: The production line needs to monitor battery temperature, voltage, current, internal resistance, and other parameters to ensure production quality.

Solution:

Use Y-series I/O boards (e.g., Y51/Y52 for PT100/PT1000 or Y58 for thermocouples) to collect temperature data.

Use Y31/Y33/Y34 boards to collect current/voltage signals (supporting 0/4~20mA or 0~5/10V signals).

Leverage edge computing to process collected data in real-time (e.g., anomaly detection, data filtering), with Node-Red enabling rapid development of data processing workflows.

Advantage: High-precision data acquisition and flexible I/O configuration support various sensor types, meeting the needs of different process stages.

(2) Equipment Control and Automation

Requirement: The production line requires control of robotic arms, conveyors, relays, and other equipment for automated production.

Solution:

Use Y-series I/O boards (e.g., Y01/Y02 for DI/DO or Y24 for relay output) to control production equipment.

Use X-series I/O boards (e.g., X23/X26 for DI/DO) for digital input/output to control equipment start/stop.

Support PWM output and pulse counting (Y95/Y96), suitable for precise control of servo motors or production cycle counting.

Advantage: Flexible I/O board options and hardware watchdog ensure reliable and real-time control.

(3) Data Communication and Cloud Integration

Requirement: Production line data needs to be uploaded to the cloud for analysis, with support for remote monitoring and maintenance.

Solution:

Use Mini PCIe 4G or WiFi modules to upload data to platforms like AWS IoT Core, Alibaba IoT, or Thingsboard via MQTT.

BLloTLink software supports industrial protocols (e.g., Modbus, OPC UA) for seamless integration with PLCs or SCADA systems.

BLRAT software enables remote access, allowing engineers to configure, debug, or upgrade firmware via the cloud.

Advantage: Supports multiple communication modules and protocols, simplifying data upload and remote management.

(4) Local Monitoring and Visualization

Requirement: Production line operators need to view real-time data and equipment status locally.

Solution:

Use the optional HDMI 2.0a interface to connect a display, combined with Qt-5.12.5 to develop graphical interfaces for displaying real-time monitoring data (e.g., temperature curves, voltage changes).

Support for Ubuntu or Android systems facilitates user-friendly interface development.

Advantage: Supports 4K@30fps hardware decoding for smooth display, ideal for production line monitoring dashboards.

(5) Environmental Adaptability

Requirement: Lithium battery production lines may involve high temperatures, vibrations, or humid environments.

Solution:

Select SOM340/SOM341 models (-40~85°C) to adapt to high/low-temperature environments.

IP30 protection and passed vibration/drop tests ensure equipment stability in production settings.

Advantage: Industrial-grade design ensures long-term reliable operation in harsh environments.

Recommended Configuration Example

For a production line requiring temperature and voltage data acquisition, relay control, and data upload via 4G to a cloud platform, the following configuration is recommended:

Model: BL340L-SOM341-X23-Y51-Y24

Host: BL340L (supports 4G module, 1×Ethernet port).

SOM: SOM341 (16GB eMMC, 2GB DDR4, -40~85°C).

X Board: X23 (4×RS232/RS485, 4×DI, 4×DO, 20 PIN).

Y Board 1: Y51 (2×PT100 three-wire, for temperature acquisition).

Y Board 2: Y24 (4×relay output, for equipment control).

Functionality:

Collect battery temperature via Y51 and digital signals/control equipment via X23.

Upload data to a cloud platform (e.g., Thingsboard) via 4G module.

Use Node-Red for data processing logic and BLRAT for remote maintenance.

Implementation Suggestions

Hardware Selection: Choose appropriate SOM models (based on storage, memory, and temperature range) and I/O boards (based on sensor and control device types).

Software Development:

Use Node-Red for rapid development of data acquisition and processing workflows.

Leverage BLloTLink for protocol conversion with existing PLCs or SCADA systems.

Develop local monitoring interfaces using Qt-5.12.5.

Testing and Validation: Conduct high/low-temperature, vibration, and EMC tests before deployment to ensure stability in the production environment.

Technical Support: Utilize the development kits and example code (e.g., Linux, MQTT, Node-Red cases) provided in the datasheet to accelerate application development.

Conclusion

The ARMxy BL340 series embedded computer, with its high-performance processor, flexible I/O configuration, rich communication interfaces, and industrial-grade reliability, is highly suitable for lithium battery production line monitoring. It enables sensor data acquisition, equipment control, edge computing, and cloud platform integration, meeting the needs for automation, intelligence, and remote management in production lines. With proper model selection and software development, the BL340 provides an efficient and reliable solution for monitoring and controlling lithium battery production lines.

0 notes

Text

Industrial ARM Edge Gateway ARMxy Hardware Strength and Software Innovation

Case Details

Amid the wave of Industry 4.0 and digital transformation, edge computing has emerged as a pivotal technology driving advancements in smart manufacturing, smart cities, and beyond. As a hub connecting physical devices to cloud intelligence, the performance, flexibility, and openness of edge gateways directly determine the digital maturity of industrial scenarios. Within this domain, ARM-based edge gateways—with their high performance, low power consumption, multi-interface support, and secondary development capabilities—are becoming the ideal choice for equipment manufacturers, software developers, and system integrators.

ARM Edge Gateway: A Golden Fusion of Hardware and Protocols

The core strength of ARM edge gateways lies in the deep integration of hardware and software ecosystems. Take mainstream products as an example:

Hardware: Multi-core ARM processors (e.g., Cortex-A72/A53), 2GB–8GB RAM, 8GB–128GB storage, and wide-temperature operation support (-40°C to 85°C), meeting industrial demands for stability and durability.

Interfaces:

2× Ethernet ports

4× RS485 serial ports

Wi-Fi

4G cellular module The 4× RS485 ports connect sensors, PLCs, and inverters via Modbus RTU/TCP; dual Ethernet ports enable redundant networking or network segmentation; Wi-Fi/4G ensures flexible remote access.

Value for Equipment Manufacturers: Pre-installed Ubuntu OS supports industrial protocols (OPC UA, MQTT, HTTP/HTTPS), slashing development costs for cloud/local server integration.

Open Ecosystem: Secondary Development Drives Innovation

Ubuntu OS is a key differentiator, offering a full Linux environment compatible with Python, C/C++, Java, and Docker. This enables:

Rapid Expansion: Access 60,000+ software packages (e.g., MySQL, InfluxDB, TensorFlow Lite) for quick integration.

Multi-Role Deployment:

Industrial Controller: CODESYS Runtime for IEC 61131-3 PLC programming.

Soft PLC: Node-RED/OpenPLC for logic control.

AI Edge Box: TensorFlow Lite/PyTorch Mobile for real-time inference.

Cross-Platform Integration: Python/C++ SDKs and RESTful APIs enable seamless SCADA/MES/cloud (AWS/Azure IoT) connectivity. Azure IoT Edge deployment takes <1 hour.

Value for Software Developers: Open environment boosts algorithm migration efficiency by 70%. Example: An auto parts supplier deployed vision QC algorithms in 3 weeks, cutting response time from 2s to 200ms.

Scenario-Based Solutions: From Point Intelligence to System Empowerment

ARM gateways are transforming three key scenarios:

Smart Production Line Control: Connects 12 CNC machines via RS485, runs predictive maintenance, and triggers PLC shutdowns during tool wear. Result: 43% fewer unplanned downtimes.

Smart Campus Energy Management: Manages 32 building subsystems (HVAC/lighting/security) with dual-network isolation (<20ms latency). Result: 18.6% lower annual energy consumption.

Agricultural IoT: Soil sensors + 4G upload + Python-based irrigation control. Result: 60% lower deployment costs per farm.

Value for System Integrators: Replaces "serial server + industrial PC + router" combos, saving space/cabling costs. Example: A water utility tripled device integration density and shortened project cycles by 40%.

Future Outlook

ABI Research forecasts the AI-capable edge gateway market to exceed $24 billion by 2026. With 5G RedCap and TSN adoption, ARM gateways will evolve toward:

Deterministic latency (<1ms)

Containerized app management

Edge-cloud collaborative intelligence

Conclusion

ARM edge gateways transcend being mere bridges—they are core engines for smart algorithms and business innovation. For equipment makers, they offer plug-and-play cloud connectivity; for developers, they unlock algorithmic value; for integrators, they reduce risks and boost margins. Choosing a gateway that balances performance, openness, and adaptability is critical for winning in the smart technology race.

0 notes

Text

ARMxy BL440 Industrial Controller for precision agriculture solutions

Case Details

Core Advantages & Scenario Adaptation

Environmental Adaptability

Wide Temperature Operation (-40°C ~ 85°C): Suitable for extreme field environments (greenhouses/cold regions).

IP30 Protection + Vibration Resistance (2g acceleration tested): Withstands vibrations from agricultural machinery and dust.

EMC Level-3 Protection (EFT±4kV, ESD±8kV): Resists electrical interference in farm environments (e.g., irrigation pump switching).

Flexible I/O Expansion

Sensor Integration:

Soil temperature/humidity, light intensity → Y33/Y34 (4AI single-ended/differential 0~10V).

pH/EC monitoring → Y36 (differential ±10V high-precision acquisition).

Weather station data (wind/rainfall) → Y13 (dry contact DI) or Y95 (pulse counting).

Actuator Control:

Irrigation solenoid valves → Y24 (relay output) or Y22 (NPN DO).

Fertilizer spreader speed control → Y95/Y96 (PWM output for motor speed).

Edge AI & Data Processing

6TOPS NPU enables real-time field analysis:

Crop disease/pest identification (TensorFlow model deployment).

Drone image processing (4K@60fps H.265 decoding + OpenCV).

Multi-core Architecture (A72+A53+M0):

A72 runs AI algorithms; M0 core handles real-time control (e.g., precision irrigation timing).

Communication & Cloud Connectivity

4G/5G Module (Mini PCIe slot) → Remote data transmission in network-limited areas.

Dual Gigabit Ethernet → Connects to local LoRa gateways or machinery CAN bus.

BLIoTLink Protocol Software:

Direct integration with agricultural cloud platforms (e.g., Alibaba Cloud IoT, ThingsBoard), supporting Modbus-to-MQTT soil data uploads.

Recommended Configuration

ComponentModel SelectionAgricultural Use CaseHostBL442B (3 ETH ports + HDMI)Multi-device networking + field debuggingSOM Core BoardSOM442 (8GB RAM + 64GB eMMC)Edge AI model storage/executionX-Series BoardX26 (8DI + 4DO)Machinery status monitoring/valve controlY-Series Board 1Y33 (4AI 0~10V)Soil sensor analog acquisitionY-Series Board 2Y95 (PWM + high-speed pulse count)Irrigation motor control/flow monitoringWireless Module4G module (NANO-SIM slot)Remote cloud data reporting

Software Deployment Recommendations

OS Selection:

Ubuntu 22.04 + Docker → Rapid deployment of agricultural AI containers (e.g., crop growth models).

Linux-RT kernel → Guarantees real-time irrigation control (<100μs response).

Development Tools:

Node-RED: Drag-and-drop automation logic (e.g., humidity <30% → trigger irrigation).

Qt Examples: Custom HMI interfaces for machinery, displaying field maps/sensor heatmaps.

Cloud Integration:

BLIoTLink pushes sensor data to cloud platforms to generate fertilization/irrigation optimization strategies.

BLRAT Remote Tool: Online debugging reduces field maintenance costs.

Risk Mitigation

Power Stability: Use wide-voltage input (9-36V DC) with overcurrent protection for volatile farm grids.

Moisture Protection: Despite passing humidity tests, seal interface ports (e.g., RS485 terminals).

Expandability: Reserve Y-slots for future sensors (e.g., Y58 for CO₂ monitoring).

Note: For large farms, deploy multiple BL440 units networked via HDMI2.1 multi-screen monitoring. Integrate with ROS for coordinated agricultural robotics.

ARMxy BL440 industrial controlle delivers high computing power + flexible I/O + industrial reliability, enabling efficient edge control for smart agriculture while enhancing farming decision-making and resource utilization rates.

0 notes

Text

Why ARM Edge Gateways Must Feature Independent Hardware Watchdog?

Case Details

Core Necessity: Why ARM Edge Gateways Must Feature Independent Hardware Watchdog

System-Level Reliability Guarantee:

Independent Operation: Functions independently of the main processor (ARM CPU).

Ultimate Protection: Can reliably trigger a system reset even if the main CPU completely locks up, the OS crashes, or applications fail.

Software Independence: Its functionality is unaffected by the status of upper-layer software (OS/Applications).

Capability to Handle Harsh Industrial Environments:

Limitations of Software Watchdogs: Common industrial site issues like voltage fluctuations and strong electromagnetic interference (EMI) can cause software-dependent watchdogs to fail.

Advantage of Hardware: Independent hardware circuitry offers greater immunity to such disturbances, ensuring watchdog functionality remains effective under demanding conditions.

Unique Hardware Watchdog Advantages of BLIIoT ARMxy Edge Gateway

BLIIoT ARMxy Edge Gateway provides superior, multi-layered protection through its dedicated hardware watchdog design:

Dual-Layer Protection Mechanism:

Utilizes an independent hardware watchdog chip + MCU's built-in watchdog.

These work complementarily to form a more comprehensive and reliable fault protection system.

Millisecond-Level Fast Response:

Responds 10-100 times faster than software watchdogs.

Allows flexible configuration of timeout thresholds ranging from hundreds of milliseconds to several minutes.

Stringent Industrial-Grade Protection Standards:

Passes IEC 61000-4-2 Level 4 Electrostatic Discharge (ESD) immunity test (Contact Discharge: 8kV).

Complies with IEC 61000-4-3 Radiated Radio-Frequency Electromagnetic Field Immunity requirements.

Zero Resource Consumption:

The independent hardware watchdog consumes no main CPU computational resources.

Ensures the real-time performance of edge computing tasks remains unaffected.

Industry Application Value

The hardware watchdog design of the BLIIoT ARMxy Gateway is particularly well-suited for scenarios demanding extremely high system reliability:

Unattended Remote Industrial Sites (e.g., oil/gas fields, substations, environmental monitoring stations)

Smart Manufacturing in Harsh Environments (e.g., production lines with high EMI, significant temperature/humidity fluctuations)

Mission-Critical Infrastructure (e.g., traffic control, energy supply, public safety systems)

Conclusion: The design philosophy of incorporating an independent hardware watchdog is a core reliability differentiator for the Bliiot ARMxy Edge Gateway compared to similar products. It provides a robust foundation at the hardware level, ensuring 7x24 uninterrupted stable operation��of Industrial IoT (IIoT) systems, meeting the stringent demands for high reliability and robustness in industrial settings.

0 notes

Text

How to install FUXA Web-based Visualization SCADA on ARMxy SBC BL410?

Step 1: Download Node.js 18

Visit the official Node.js website.

Click Download in the navigation bar.

In the selection box behind Get Node.js®, choose version v18.20.8 (LTS).

Select the Linux version for the binary package. Since the BL410 uses an ARM64 architecture, download the Standalone Binary (.xz) for node-v18.20.8-linux-arm64.

Step 2: Unzip and Install Node.js 18

Copy the downloaded node-v18.20.8-linux-arm64.tar.xz to the BL410 using a USB flash drive. The BL410 has a script that automatically mounts the USB drive. Use the command ls to verify the installation package is visible on the USB drive.

Create a directory named Node in the root directory: mkdir /Node.

Copy the Node.js installation package to the Node folder:cp node-v18.20.8-linux-arm64.tar.xz /Node/

Decompress the package:tar -xvJf /Node/node-v18.20.8-linux-arm64.tar.xzThis creates a folder named node-v18.20.8-linux-arm64 in the /Node directory.

Navigate to the bin folder:cd /Node/node-v18.20.8-linux-arm64/binYou should see four files: corepack, node, npm, and npx.

Create symbolic links to make Node.js and its tools accessible system-wide:ln -sf /Node/node-v18.20.8-linux-arm64/bin/node /usr/bin/ ln -sf /Node/node-v18.20.8-linux-arm64/bin/npm /usr/bin/ ln -sf /Node/node-v18.20.8-linux-arm64/bin/npx /usr/bin/

Step 3: Download the FUXA Installation Package

Visit the official FUXA website.

Click Download to navigate to the download page and locate the Star FUXA repo button, which redirects to the FUXA GitHub repository.

On the GitHub page, scroll to the Install from source section.

Click Download the latest release and select the latest FUXA version (e.g., FUXA-1.2.5.tar.gz).

Copy the downloaded FUXA-1.2.5.tar.gz to the BL410 using a USB drive:cp FUXA-1.2.5.tar.gz /FUXA/

Step 4: Unzip the FUXA Installation Package

Decompress the FUXA package:tar -zxvf /FUXA/FUXA-1.2.5.tar.gz

Verify the decompressed files:ls

Step 5: Modify the Configuration File

Navigate to the server folder:cd server

Open the package.json file using the vi editor:vi package.json

Locate and delete the line referencing odbc.

Save and exit the file::wq!

Install the dependencies, which may take some time:npm install

Step 6: Start FUXA

Start the FUXA application:npm start

Step 7: Access FUXA

Open a web browser on a device connected to the same network as the BL410.

Enter the BL410’s IP address followed by port Device IP+1881

Press Enter to access the FUXA Web SCADA interface.

Notes

Ensure the BL410 is connected to a network and has a valid IP address before attempting to access FUXA.

The npm install step may take a while depending on the device’s performance and network conditions.

If you encounter issues, verify that all symbolic links for Node.js are correctly set and that the FUXA package is properly decompressed.

https://armbasedsolutions.com/blog-detail/how-to-install-fuxa-web-based-visualization-scada-on-armxy-sbc-bl410

0 notes

Text

Building Cost-Effective Industrial Automation with Open Source SCADA Solutions

Introduction

Supervisory Control and Data Acquisition (SCADA) systems are the backbone of modern industrial automation, enabling real-time monitoring and control of complex processes in industries like manufacturing, energy, and water management. Traditionally, proprietary SCADA systems have dominated the market, but their high costs and vendor lock-in have driven industries to explore open source alternatives. Open source SCADA solutions offer a cost-effective, flexible, and customizable approach to industrial automation, making them an attractive choice for businesses of all sizes. This article explores how open source SCADA systems can reduce costs, enhance scalability, and empower industries to build robust automation solutions.

Why Choose Open Source SCADA?

Cost Efficiency

Proprietary SCADA systems often come with hefty licensing fees, maintenance costs, and expensive hardware requirements. Open source SCADA solutions, such as Scada-LTS, Rapid SCADA, and OpenSCADA, eliminate licensing costs, allowing businesses to allocate budgets to hardware, integration, or customization. For small and medium-sized enterprises (SMEs), this cost reduction can be a game-changer, enabling them to adopt advanced automation without breaking the bank.

Flexibility and Customization

Unlike proprietary systems, open source SCADA platforms provide access to their source code, allowing developers to tailor the system to specific industrial needs. Whether it’s integrating with existing IoT devices, customizing dashboards, or adding new protocols, open source solutions offer unparalleled flexibility. For example, PyScada, built on Django, allows developers to create web-based interfaces with minimal coding, adapting to unique workflows.

Community Support and Innovation

Open source SCADA systems benefit from vibrant communities of developers who contribute to continuous improvement, bug fixes, and security updates. Platforms like Scada-LTS and Rapid SCADA have active forums and documentation, ensuring users have access to resources and support. This collaborative environment fosters innovation, with new features and integrations often available faster than in proprietary systems.

Key Open Source SCADA Solutions

Scada-LTS

Scada-LTS is a web-based, open source SCADA platform designed for scalability and cross-platform compatibility. It supports a wide range of protocols, including Modbus and OPC UA, making it suitable for diverse industrial applications. Its modular architecture allows users to build custom dashboards and integrate with databases like MySQL or PostgreSQL, reducing deployment costs.

Rapid SCADA

Rapid SCADA is a lightweight, open source solution ideal for small to medium-scale automation projects. It offers real-time data visualization, alarm management, and reporting features. Its low hardware requirements make it a cost-effective choice for industries like water treatment or renewable energy, where budget constraints are common.

PyScada

PyScada leverages Python and Django to provide a flexible, web-based SCADA framework. It’s particularly suited for industries requiring custom data processing or integration with IoT devices. Its open source nature allows developers to extend functionality, such as adding support for new sensors or creating tailored analytics.

Emoncms

Emoncms is an open source SCADA platform focused on energy monitoring, particularly for solar and renewable energy systems. Its low-cost deployment and integration with low-power hardware like Raspberry Pi make it an excellent choice for cost-conscious projects. Emoncms also supports data logging and visualization, enabling real-time insights into energy consumption.

Implementing Open Source SCADA: A Step-by-Step Guide

1. Define Requirements

Start by identifying the specific needs of your industrial process. Consider factors like the number of data points, required protocols (e.g., Modbus, MQTT), and visualization needs. For example, a manufacturing plant may need real-time machine status updates, while a water treatment facility may prioritize historical data logging.

2. Select the Right Platform

Choose an open source SCADA system that aligns with your requirements. For instance, Scada-LTS is ideal for large-scale, multi-protocol systems, while Rapid SCADA suits smaller projects with simpler needs. Evaluate hardware compatibility, as many open source solutions run on low-cost devices like Raspberry Pi or Linux servers.

3. Install and Configure

Most open source SCADA systems provide detailed installation guides. For example, Rapid SCADA can be set up on a Windows or Linux server in under an hour. Configure communication protocols to connect with your PLCs, sensors, or IoT devices. Ensure network security by implementing firewalls and secure protocols like HTTPS.

4. Customize and Integrate

Leverage the open source nature of the platform to customize dashboards, alarms, or data processing logic. For instance, PyScada’s Python-based framework allows developers to add custom scripts for advanced analytics. Integrate with existing systems, such as ERP or MES, to streamline operations.

5. Test and Deploy

Conduct thorough testing to ensure data accuracy, system reliability, and responsiveness. Simulate real-world scenarios, such as sensor failures or network interruptions, to validate system performance. Once tested, deploy the system and monitor its performance using built-in diagnostic tools.

Case Study: Solar Plant Monitoring with Emoncms

A small solar energy company needed a cost-effective SCADA system to monitor its photovoltaic (PV) plant. Proprietary solutions were too expensive, so they turned to Emoncms. Using a ARMxy SBC BL410 series as the server, they integrated Emoncms with their PV inverters via Modbus. The system provided real-time power output data, historical trends, and alerts for underperforming panels. Total implementation costs were under $500, compared to $10,000 for a proprietary system, demonstrating the cost-effectiveness of open source SCADA.

Challenges and Considerations

While open source SCADA systems offer significant benefits, they come with challenges. Lack of formal vendor support may require in-house expertise or reliance on community forums. Security is another concern; since the source code is public, regular updates and robust cybersecurity practices are essential. Additionally, integrating open source SCADA with legacy systems may require custom development, which could increase initial setup time.

Conclusion

Open source SCADA solutions like Scada-LTS, Rapid SCADA, PyScada, and Emoncms provide a cost-effective alternative to proprietary systems, enabling businesses to achieve industrial automation without prohibitive costs. Their flexibility, community support, and compatibility with modern technologies make them ideal for a wide range of applications, from energy monitoring to manufacturing. By carefully selecting and implementing an open source SCADA platform, industries can build scalable, efficient, and budget-friendly automation systems that meet their unique needs.

References

Scada-LTS Official Documentation: https://scada-lts.org/

Rapid SCADA User Guide: https://rapidscada.org/

PyScada GitHub Repository: https://github.com/pyscada/PyScada

Emoncms Documentation: https://emoncms.org/

0 notes

Text

How to install N3uron Visualization Software Platform on ARM Edge Gateway?

Step 1: Download the N3uron Installation Package

Visit the official N3uron website.

Locate and click Download N3uron in the upper right corner to access the download page.

Select the Linux ARM32 version (or ARM64 if applicable).

Click DOWNLOAD SOFTWARE to download the installation package.

Step 2: Unzip and Install N3uron

Once the package is downloaded, transfer it to your BL330 device and follow these steps to install N3uron:

Copy the downloaded installation package to the BL330 device.

Open a terminal and decompress the package by entering:tar -zxvf n3uron-setup-linux-arm32-1.21.12-250219.1123.tar.gzThis extracts the files into the system.

Navigate to the extracted folder by entering:cd /n3uron/bin

Run the installation command:./n3uron install

Start the N3uron service with:systemctl start n3uron

Step 3: Run N3uron

After installation, access the N3uron interface through a web browser:

Open a browser and enter the device’s IP address followed by the appropriate port:

For HTTP, use port 8003 (e.g., http://:8003).

For HTTPS, use port 8443 (e.g., https://:8443).

Log in using the default credentials:

Username: admin

Password: n3uron

Once logged in, the installation is complete, and you can begin using N3uron.

Conclusion

By following these steps, you should have N3uron installed and running on your BL330 device. Ensure you use the correct version (ARM32 or ARM64) for your system and verify the IP address and port when accessing the platform. For further configuration or troubleshooting, refer to N3uron’s official documentation.

0 notes

Text

Core Principles and Architecture of Soft Programmable Logic Controller

Introduction

A Soft PLC (Programmable Logic Controller) emulates the functionality of traditional hardware PLCs through software, enabling industrial automation control on general-purpose computers or embedded devices. By leveraging universal hardware and flexible software architectures, Soft PLCs reduce costs and enhance scalability, making them widely adopted in modern industrial applications. This article elaborates on the core principles, common software, system architecture, workflow, advantages, and challenges of Soft PLCs.

Core Principles

Soft PLCs achieve industrial control through the following key components:

1. Virtualized Control Logic

Soft PLCs simulate the control logic of hardware PLCs via software, adhering to the IEC 61131-3 standard and supporting multiple programming languages such as Ladder Diagram (LD), Function Block Diagram (FBD), and Structured Text (ST). User-written control programs are compiled into executable code, running in a logic execution engine to process input signals, perform logical operations, and control outputs.

2. Real-Time Task Scheduling

Real-time performance is critical for Soft PLCs. They rely on Real-Time Operating Systems (RTOS) or real-time extensions (e.g., RTX for Windows, PREEMPT_RT for Linux) to ensure deterministic task execution. A real-time scheduler manages periodic scanning of inputs, execution of control logic, and updating of outputs, meeting the stringent timing requirements of industrial control.

3. Input/Output (I/O) Processing

Soft PLCs interface with external devices through hardware interfaces (e.g., industrial I/O modules, communication buses, or standard PC interfaces) to collect sensor signals and drive actuators. I/O data is mapped to the Soft PLC’s memory via drivers or communication protocols (e.g., Modbus, OPC UA, EtherCAT) for processing by the control logic.

4. Runtime Engine

The runtime engine is the core component of a Soft PLC, responsible for parsing and executing user programs, managing I/O data, handling communications, and performing diagnostics. It includes a task manager, data storage area (for variables and states), and error-handling mechanisms to ensure stable operation.

5. Communication and Integration

Soft PLCs support various industrial communication protocols (e.g., Modbus TCP, PROFINET, Ethernet/IP), facilitating integration with HMIs, SCADA systems, or other control systems. Their open software architecture enables interaction with enterprise-level systems (e.g., MES, ERP) for data collection and remote monitoring.

Common Soft PLC Software

Soft PLCs rely on specialized software platforms. Below are several mainstream Soft PLC software solutions and their features:

CODESYS: A powerful Soft PLC development platform supporting the full range of IEC 61131-3 programming languages, offering extensive industrial protocol support and visualization tools, widely used in industrial automation projects.

OpenPLC: An open-source Soft PLC solution compatible with various hardware platforms (e.g., Raspberry Pi, Arduino), ideal for education, research, and small-scale industrial applications.

PLCnext: Developed by Phoenix Contact, it combines Soft PLC functionality with an open Linux platform, supporting hybrid development with high-level languages (e.g., C++, Python) and traditional PLC programming, suitable for complex applications. These software platforms provide development environments and runtime engines, enabling users to efficiently build and deploy control logic for diverse industrial needs.

System Architecture

The system architecture of a Soft PLC consists of three main components:

Development Environment: Provides programming and debugging tools, allowing users to design control logic and simulate operations.

Runtime Environment: The runtime software is deployed on target hardware, integrating with the operating system and I/O interfaces to execute real-time control tasks.

Hardware Platform: Typically an industrial PC, embedded device, or server, which must meet performance and environmental adaptability requirements.

Workflow

The operation of a Soft PLC follows these steps:

Initialization: Upon startup, the Soft PLC loads the user program and initializes I/O interfaces and communication modules.

Cyclic Scanning: At preset intervals (scan cycles), the Soft PLC reads input data, executes control logic, and updates output data.

Communication Processing: Handles communication requests from external devices, uploading status data or receiving control commands.

Exception Management: Monitors system status and manages errors or faults (e.g., I/O disconnections, program anomalies).

Advantages and Challenges

Advantages

Cost Efficiency: Utilizing general-purpose hardware significantly reduces costs.

Flexibility: Supports integration of complex algorithms (e.g., AI, data analytics) and easy scalability.

Rapid Iteration: Software-based architecture facilitates development and upgrades, adapting to modern industrial demands.

Benefits of Running Soft PLC on ARM-Based Industrial PCs ARMxy series

Deploying Soft PLCs on ARM-based industrial PCs ARMxy series offers the following advantages:

Low Power Consumption: ARM processors are known for high energy efficiency, ideal for long-term operation in industrial settings, reducing energy costs.

High Integration: ARM industrial PCs ARMxy series typically feature rich peripheral interfaces (e.g., GPIO, CAN, Ethernet, RS485/RS232), simplifying connections with industrial devices.

Cost Efficiency: ARM hardware is cost-competitive, and when paired with Soft PLC software, it significantly lowers overall system costs.

Compact Design: The small form factor of ARM industrial PCs ARMxy series suits space-constrained industrial environments.

Open-Source Ecosystem: ARM platforms are compatible with various open-source Soft PLC software (e.g., OpenPLC), facilitating customization and development. These characteristics make ARM-based industrial PCs ARMxy series an excellent choice for small to medium-scale industrial automation projects.

Recommended Models:ARMxy Series RS3568J 4*A55 Architecture BL410 series, RK3576 4*A72 Architecture BL440 series and RK3588 4*A76 Architecture BL450 series

Challenges

Real-Time Performance: General-purpose hardware and operating systems require optimization to meet industrial control’s deterministic requirements.

Reliability: General-purpose hardware may lack the robustness of dedicated PLCs, necessitating redundancy or protective measures.

Security: Soft PLCs operating in networked environments must defend against cyberattacks and data breaches.

Conclusion

Soft PLCs replicate the functionality of traditional PLCs through software, leveraging general-purpose wortware and flexible architectures to provide cost-effective, scalable solutions for industrial automation. Mainstream Soft PLC software, such as CODESYS and OpenPLC, simplifies development and deployment. Running Soft PLCs on ARM-based industrial PCs capitalizes on low power consumption, high integration, and cost efficiency, making them ideal for modern industrial applications. However, challenges in real-time performance, reliability, and security require ongoing optimization. As Industry 4.0 advances, Soft PLCs will play an increasingly vital role in smart manufacturing.

0 notes

Text

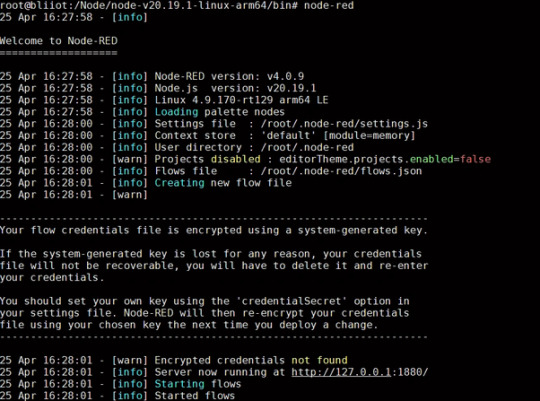

How to install Node-Red on Linux ARM based SBC ARMxy?

Download the environment from Node.js

Enter the node.js official website

Click Download in the navigation bar to download the node.js version we need.

Click the selection box behind Get Node.js® and select the version we need to download. Here we choose v20.19.1 (LTS)

We install it through the binary package. We select the Linux version below the instruction installation box. Because BL410 is the ARM64 version, we select the corresponding version and click Standalone Binary (.xz) to download the binary package.

Unzip the environment package

Use a USB flash drive to copy the installation package to the device. There is a script in BL410 that automatically mounts the USB flash drive. We use ls to view the installation package in the USB flash drive.

create a Node folder in the root directory in advance, and use cp node-v20.19.1-linux-arm64.tar.xz /Node/ to copy the node.js installation package to the Node folder

Enter tar -xvJf node-v20.19.1-linux-arm64.tar.xz to decompress the installation package.

Link operating environment

The unzipped installation package will generate a node-v20.19.1-linux-arm64 folder in the /Node folder

Enter cd node-v20.19.1-linux-arm64/bin to enter the bin folder. At this time, we can see four files, namely corepack node npm npx

Use ln -sf to create link files ln -sf /Node/node-v20.19.1-linux-arm64/bin/node /usr/bin/ and ln -sf /Node/node-v20.19.1-linux-arm64/bin/npx /usr/bin/ and ln -sf /Node/node-v20.19.1-linux-arm64/bin/npx /usr/bin/

Enter node -v and npm -v to verify whether the node.js and npm package management tools are installed successfully. The version number indicates that the installation is complete.

Install Node-Red

Use the command npm install -g --unsafe-perm node-red to install node-red.

Run Node-Red

After node-red is installed, enter ls and we can view the node-red file

Use ln -sf /Node/node-v20.19.1-linux-arm64/bin/node-red /usr/bin/ to create a link

Enter node-red to verify the software installation environment.

Using node-red

Open the browser and enter the device IP + 1880 in the browser address bar to access

When the browser now opens Node-red, the installation is complete.

0 notes

Text

Six Technology Trends Shaping Industrial Automation

Industrial automation is entering its most transformative phase since the introduction of PLCs and SCADA in the 1970s. Driven by advancements in connectivity, artificial intelligence, and digital engineering, automation is evolving from programmed control to predictive, adaptive, and autonomous systems. Over the next five years (2025–2030), six core technology trends will reshape the operations, scale, and adaptability of factories, warehouses, utilities, and processing plants. This article explores these trends and their implications for OEMs, system integrators, and industrial product developers, with a focus on the role of ARM-based industrial PCs in enabling these advancements.

Edge AI and Machine Learning for Predictive Control

What’s Happening: Artificial Intelligence (AI) has shifted from cloud-based systems to edge devices, enabling real-time processing of sensor data on embedded platforms like ARM-based industrial PCs.

Key Benefits:

Reduced latency for time-critical decisions.

Predictive maintenance using behavioral models.

Enhanced resilience by minimizing reliance on cloud infrastructure.

Real-World Applications:

Anomaly detection in rotating equipment using vibration sensors and machine learning (ML) models.

Predictive quality control on production lines with computer vision.

Adaptive process optimization in chemical and food manufacturing.

Technology Enablers:

ARM-based industrial PCs (e.g., those powered by NXP i.MX 9, Rockchip RK3588J, or NVIDIA Jetson) provide energy-efficient, high-performance platforms for edge AI.

Frameworks like Edge Impulse and TensorFlow Lite for microcontrollers.

Integration of Real-Time Operating Systems (RTOS) with model inference pipelines.

Outlook (2025–2030): Factory equipment will increasingly become AI-native, leveraging ARM industrial PCs for on-device model retr -- ARMxy BL450 series Rockchip RK3588J supports 6Tops NPU to promote the development of Edge AI

System: aining via federated learning or MLOps practices, enabling continuous improvement and adaptation at the edge.

Interoperability Through Unified Industrial Protocols

The Challenge: Traditional systems rely on proprietary fieldbuses, vendor-specific integrations, and siloed architectures, limiting scalability.

Trend: Open, vendor-neutral communication protocols are gaining traction:

OPC UA over TSN for deterministic communication.

MQTT + Sparkplug B for lightweight messaging.

EtherCAT + Ethernet-APL for real-time, deterministic Ethernet.

Benefits:

Plug-and-play device integration.

Cross-vendor communication in brownfield and greenfield environments.

Simplified migration to Industry 4.0 and digital twin ecosystems.

Key Development: Adoption of IEC 61499 for event-driven automation logic, interoperating with cloud APIs for remote control and monitoring.

Role of ARM Industrial PCs: ARM-based industrial PCs, with their support for modern networking stacks and low-power, high-throughput processing, serve as gateways or controllers to bridge legacy and modern protocols, enabling seamless interoperability. BLIoTLink supports multiple industrial protocols, such as Modbus, MQTT, OPC UA, etc., and can be adapted to ARMxy series industrial computers and other ARM architecture hardware devices for data acquisition and protocol conversion.

Digital Twins and Model-Based Engineering

Concept: Digital twins are real-time virtual representations of physical systems, used for simulation, monitoring, and optimization.

Why It’s Growing:

Enables remote debugging and system tuning.

Supports predictive diagnostics and process optimization.

Simplifies training, testing, and certification.

Enabling Technologies:

3D CAD and simulation tools (e.g., ANSYS Twin Builder, Siemens NX).

IoT platforms for real-time data synchronization.

Open standards like Functional Mock-up Interface (FMI).

Trends to Watch:

Integration of PLC code and physics-based models in unified runtimes.

Digital twin ecosystems across OEMs, integrators, and end-users.

Coupling digital twins with AI models for next-generation control systems.

Role of ARM Industrial PCs: ARM-based industrial PCs provide the computational power and connectivity needed to host digital twin runtimes locally, ensuring low-latency synchronization with physical systems.

Challenges: Ensuring data quality, sensor integration, real-time synchronization, and model maintenance as systems evolve.

Collaborative Robots (Cobots) and Autonomous Systems

Shift: Unlike traditional caged industrial robots, collaborative robots (cobots) and Autonomous Mobile Robots (AMRs) operate in shared spaces with human workers.

Key Advancements:

Safety path planning using 3D sensors and AI.

Flexible reprogramming for dynamic tasks.

Real-time integration with Manufacturing Execution Systems (MES) and Warehouse Management Systems (WMS).

Applications:

Bin picking and assembly on hybrid production lines.

Autonomous material transport in smart warehouses.

Inspection and maintenance in hazardous areas.

Technology Drivers:

ROS 2 and MoveIt for motion planning and control.

EtherCAT-based motion control systems.

AI-enhanced vision and grasping libraries.

Role of ARMxy Industrial PCs: ARM-based industrial PCs power the control and AI processing for cobots and AMRs, offering compact, energy-efficient platforms for real-time decision-making and sensor integration.

Outlook: Cobots will evolve to learn and adapt through reinforcement learning and shared datasets, with ARM industrial PCs enabling scalable, on-device intelligence.

Cybersecurity and Regulatory Compliance in Industrial Environments

Why It Matters: The growing connectivity of industrial systems increases vulnerability to cyberattacks, as seen in incidents targeting water utilities, pipelines, and factories.

Key Regulatory Frameworks:

IEC 62443 (Industrial Cybersecurity).

NIST 800-82.

ISO/SAE 21434 (for automotive applications).

EU Cyber Resilience Act (effective 2025+).

Emerging Strategies:

Security-by-design at the chip and firmware levels.

Zero-trust architectures with identity-based access.

Secure boot, over-the-air (OTA) updates, and encrypted logging.

Role of ARM Industrial PCs: ARM-based industrial PCs, with built-in security features like TrustZone and secure boot, provide robust platforms for implementing cybersecurity measures at the edge, ensuring compliance and protection.

Outlook: Cybersecurity will become an embedded product feature, integrated into PLCs, drives, HMIs, and sensor nodes, with ARM industrial PCs serving as secure hubs.

Edge-to-Cloud Integration for Closed-Loop Industrial Intelligence

Trend: As edge devices like ARM-based industrial PCs become smarter, seamless, secure, and real-time data flow between edge and cloud is critical, representing the convergence of Operational Technology (OT) and Information Technology (IT).

Key Developments:

Data preprocessing at the edge to reduce cloud payloads and costs.

Cloud-native microservices for SCADA/PLC integration.

Real-time feedback loops between factory sensors and cloud-based AI engines.

Use Cases:

Cloud-to-edge synchronization for production planning and quality control.

Dynamic model deployment from cloud AI platforms to edge accelerators.

Visualization dashboards powered by Azure IoT, AWS Greengrass, or private Kubernetes clusters.

Benefits:

Agile production systems.

Unified data lakes for analytics.

Reduced latency for mission-critical control.

Role of ARM Industrial PCs: ARM-based industrial PCs act as edge gateways, performing preprocessing, local analytics, and secure communication with cloud platforms, enabling efficient closed-loop systems.

Adoption Challenges: Managing latency, ensuring cybersecurity, and addressing data model fragmentation.

Final Thoughts: From Automation to Autonomy

The next five years will redefine industrial automation by integrating real-time control with AI, connectivity with cybersecurity, and physical systems with digital twins. ARM-based industrial PCs will play a pivotal role as versatile, power-efficient platforms that enable edge computing, interoperability, and secure, scalable automation.

OEMs, system designers, and technology providers that embrace these trends early will build more adaptive, scalable, and future-ready platforms. Let’s shape the future of automation together.

0 notes

Text

From Traditional PLC to ARM Industrial PC: An Intelligent Leap in Industrial Control Systems

The transition from traditional PLCs (Programmable Logic Controllers) to ARM-based industrial PCs represents an intelligent leap in industrial control systems, reflecting the evolution of industrial automation from specialized hardware to universal, flexible, and high-performance computing platforms. Below is a concise analysis of this transformation, covering its background, characteristics, advantages, and challenges:

Background: The Evolving Needs of Industrial Control Systems

Limitations of Traditional PLCs: PLCs have long dominated industrial control due to their high reliability, real-time performance, and specialization. However, their complex programming, limited scalability, and inability to handle complex algorithms or big data make them less suited for the flexibility and intelligence demands of Industry 4.0 and smart manufacturing.

Rise of ARM Industrial PCs: The ARM architecture, known for low power consumption, high performance, versatility, and a rich ecosystem, is increasingly penetrating the industrial control sector. ARM industrial PCs, combining embedded systems with industrial-grade design, offer higher computing power, more flexible software ecosystems, and lower costs.

Core Characteristics of ARM Industrial PC vs. PLC

FeatureTraditional PLCARM Industrial PCHardware ArchitectureSpecialized hardware, fixed-function modulesUniversal ARM architecture, highly customizableComputing PowerSuitable for simple logic control, limited for complex algorithmsSupports complex algorithms, AI, and data processingProgrammingLadder logic, structured text, etc.Supports general-purpose languages like C/C++, PythonScalabilityModular expansion, high costRich interfaces (USB, Ethernet, GPIO, etc.)Real-Time PerformanceHard real-time, high determinismSoft/hard real-time, requires optimized RTOSCostHigh, due to specialized hardware and software licensesLower, with general-purpose hardware and open-source softwareNetworkingLimited, requires gateways for IoTNative support for IoT and edge computing

Core Advantages of the Intelligent Leap

High Performance and Intelligence: ARM industrial PCs support AI algorithms (e.g., machine vision, predictive maintenance), enabling edge computing, reducing cloud dependency, and enhancing real-time decision-making.

Flexibility and Openness: They support Linux, RTOS, and other operating systems, allowing developers to leverage rich open-source tools and frameworks for rapid, customized application development.

Low Power and Compact Design: ARM’s low-power architecture is ideal for long-term operation and compact industrial settings, reducing energy and space costs.

IoT and Interconnectivity: ARM industrial PCs are naturally suited for Industrial IoT (IIoT), supporting protocols like MQTT and OPC UA, and easily integrating with cloud platforms and other devices.

Cost Efficiency: Compared to PLCs, ARM industrial PCs have lower hardware costs, and software development benefits from open-source ecosystems, reducing licensing fees.

Challenges and Solutions

Real-Time Performance and Reliability: PLCs excel in hard real-time and industrial-grade reliability. ARM industrial PCs need real-time operating systems (RTOS, e.g., FreeRTOS, Zephyr) and redundant designs to bridge this gap.

Development Complexity: The versatility of ARM industrial PCs increases development freedom but also programming and debugging complexity, requiring more skilled development teams.

Industrial Environment Adaptability: Harsh industrial environments (e.g., high temperatures, vibrations) demand ruggedized hardware designs and certifications (e.g., IP65, EMC) for ARM industrial PCs.

Ecosystem Compatibility: PLCs benefit from mature industrial standards and vendor ecosystems. ARM industrial PCs need to enhance compatibility with traditional industrial protocols and devices.

Applications and Future Trends

Typical Applications:

Smart Manufacturing: Data acquisition, analysis, and optimization on production lines.

Edge Computing: Running AI models at the device level to reduce latency.

Robot Control: Supporting complex motion control and sensor fusion.

Energy Management: Real-time monitoring and optimization of energy consumption.

Future Trends:

AIoT Integration: ARM industrial PCs will deeply integrate AI and IoT, promoting “device-edge-cloud” collaboration.

Modularity and Standardization: They will adopt PLC-like modular designs, offering more standardized industrial solutions.

Enhanced Security: As connectivity grows, ARM industrial PCs will need stronger cybersecurity and data protection (e.g., hardware encryption, OTA updates).

RISC-V Competition: The open-source RISC-V architecture may challenge ARM’s dominance in the industrial sector.

ARMxy industrial PC is an ARM-based SBC with flexible ARM SoM and I/O ports. It has more than 1,000 application options, supports Python and C language programming, can install soft PLC software for programming, and supports the installation of protocol conversion software and edge computing functions. It is very suitable for industrial automation and other application solutions.

Conclusion

The transition from PLC to ARM industrial PC is not only a change in hardware architecture, but also a step for industrial control systems to move towards higher intelligence, openness and flexibility. With high performance, low cost and an open ecosystem, ARM industrial PC is reshaping industrial automation. However, to fully replace PLCs, they must continue to improve real-time performance, reliability, and compatibility with industrial standards. Looking ahead, as Industry 4.0 and AIoT advance, ARM industrial PCs are poised to become the core platform for intelligent industrial control.

0 notes

Text

ARMxy-based SBC BL450 and Thingsboard: Edge Computing for Industry 4.0

Case Details

The ARMxy-based SBC BL450 series, an industrial-grade embedded computer powered by the Rockchip RK3588J/RK3588 processor, integrates seamlessly with the Thingsboard IoT platform to deliver a robust "device-edge-cloud" solution. This architecture supports industrial control, smart manufacturing, and IoT applications with low-latency processing (<20ms), local AI inference, and multi-protocol compatibility. Designed for harsh environments (-40°C to 85°C), the BL450 series ensures reliability, security, and scalability for Industrial 4.0 transformation.

Hardware and System Architecture

ARMxy-based SBC BL450 Hardware Specifications

Processor: Rockchip RK3588J/RK3588, featuring 4×ARM Cortex-A76 (up to 2.4GHz), 4×ARM Cortex-A55, and 3×Cortex-M0, with a 6TOPS NPU for AI tasks.

Memory/Storage: 4/8/16GB LPDDR4X RAM, 32/64/128GB eMMC storage.

Interfaces: 1–3 RJ-45 Ethernet ports (2×10/100/1000M, 1×10/100M), 2×USB 3.1, optional HDMI 2.1, Mini PCIe for WiFi/4G/5G, and flexible X/Y-series I/O boards (RS485, RS232, DI/DO, etc.).

Durability: Aluminum alloy casing, IP30 protection, DIN35 rail/wall mounting, and wide voltage range (9–36VDC) with reverse polarity and overcurrent protection.

System Architecture

Edge Layer: Runs Ubuntu 20.04 LTS or Linux-5.10.209 with Docker-hosted Thingsboard Edge for real-time data collection, rule-based processing, and local visualization.

Cloud Layer: Thingsboard cloud instance (AWS/Azure) for data aggregation, long-term storage, and multi-tenant analytics.

Collaboration: MQTT/HTTP protocols enable edge-cloud synchronization, with critical commands issued locally and non-real-time data uploaded in batches.

Core Functionalities

Data Acquisition and Processing

Multi-Protocol Support: Integrates with PLCs and sensors via RS485 (Modbus RTU/TCP) and wireless devices via WiFi/4G/5G. X/Y-series I/O boards support diverse inputs (e.g., PT100, 4–20mA).

Thingsboard Edge Rules: Configurable for data filtering, threshold-based alerts (e.g., temperature anomalies), and local actions (e.g., valve control) or notifications to mobile apps.

Edge AI and Computing

AI Inference: The 6TOPS NPU accelerates TensorFlow/PyTorch models for tasks like image classification (e.g., defect detection) and predictive maintenance (e.g., LSTM-based fault prediction).

Task Optimization: Cortex-A76/A55 handles lightweight tasks, while the NPU processes complex models, improving energy efficiency by 50%.

Cloud Integration and Visualization

Data Sync: Key metrics (e.g., energy usage, production rates) are uploaded to the cloud for cross-site analysis.

Dashboards: Thingsboard’s customizable dashboards provide real-time device status, historical trends, and integration with tools like Grafana, accessible on PC/mobile.

Security and Scalability

Security Features

Hardware Security: TrustZone isolates sensitive data, with robust electromagnetic compatibility (EMC) passing GB/T 9254 and IEC 61000 standards.

Data Protection: MQTT over TLS/SSL ensures secure transmission, with anonymized data uploads compliant with GDPR.

Scalability

Flexible Configuration: Modular X/Y-series I/O boards and SOM options (e.g., SOM450–SOM454) support diverse application needs.

Software Ecosystem: Supports Python, C++, Node-RED, and Docker for rapid development, with BLIoTLink enabling integration with AWS IoT, Thingsboard, and OPC UA.

Use Cases

Smart Manufacturing: Vibration data analysis via LSTM models predicts equipment failure, reducing downtime by 43% through MES integration.

Smart Agriculture: Soil sensor data triggers precision irrigation, with 4G-enabled reports cutting deployment costs by 60%.

Smart Buildings: ISP-processed camera feeds optimize HVAC based on occupancy, reducing energy use by 18.6% with dual Ethernet for network isolation.

Implementation and Benefits

Deployment Steps

Hardware Setup: Install BL450, configure network/interfaces, and deploy Ubuntu/Docker.

Software Configuration: Install Thingsboard Edge, set up device rules, and enable cloud sync.

AI Integration: Deploy pre-trained models to the NPU using optimized frameworks.

Benefits

Cost Efficiency: Replaces multiple devices, saving 40% on wiring and space.

Performance: Reduces AI inference latency from 2s to 200ms, boosting responsiveness by 10x.

Reliability: Operates in extreme temperatures (-40°C to 85°C) and passes vibration/free-fall tests.

Conclusion

The ARMxy-based SBC BL450 series, combined with Thingsboard, delivers a high-performance, secure, and scalable edge computing solution. Its robust hardware, flexible I/O, and seamless cloud integration empower enterprises to achieve real-time intelligence and cost-effective digital transformation in Industrial 4.0 and beyond.

0 notes

Text

ARM Embedded Industrial Computer in Smart Vending and Automated Retail

Case Details

With the rapid development of smart retail, devices such as unmanned vending machines, cold chain cabinets, and smart delivery lockers have gained widespread adoption in the retail industry. These devices require efficient and reliable monitoring systems to ensure real-time data collection, remote management, and intelligent interaction. The ARMxy BL410 series industrial computer, with its high performance, low power consumption, and flexible expansion capabilities, is an ideal choice for Smart vending machine. This article explores the application scenarios, technical advantages, and implementation strategies of the BL410 series in smart vending machine.

Core Features of the BL410 Series Industrial Computer

The ARMxy BL410 series is an industrial-grade embedded computer based on the Rockchip RK3568J/RK3568B2 quad-core Cortex-A55 processor (up to 2.0GHz), offering the following key features:

High-Performance Computing: Equipped with a 1TOPS Neural Processing Unit (NPU) to support edge AI tasks such as facial recognition and image analysis.