Don't wanna be here? Send us removal request.

Text

Customizing Blister Pack Inspection Systems for Niche Pharmaceutical Applications

In today’s pharmaceutical landscape, manufacturing is no longer a one-size-fits-all operation. The growing complexity of drug formulations, delivery methods, and regulatory expectations has given rise to specialized or niche pharmaceutical products. These include personalized medicine, biologics, orphan drugs, pediatric formulations, and high-potency medications. Each of these categories presents unique packaging and quality control challenges, especially when it comes to inspection. As a result, the need for customizing blister pack inspection systems to meet these niche requirements is more critical than ever.

Understanding the Diversity of Niche Pharmaceutical Applications

Niche pharmaceutical products differ significantly from conventional drug formats in terms of:

Dosage forms and sizes (e.g., mini tablets, soft gels, powders)

Blister pack geometries (e.g., irregular cavities, non-standard layouts)

Special handling needs (e.g., temperature-sensitive or light-sensitive compounds)

Small batch production for personalized or low-volume drugs

These variations make standard inspection systems less effective, and sometimes incompatible. A customized approach is necessary to maintain both product quality and regulatory compliance.

Key Customization Requirements for Blister Pack Inspection Systems

1. Adaptability to Unique Blister Formats

Standard blister pack inspection systems are calibrated for common cavity sizes and layouts. However, niche applications may use unusual pack configurations to accommodate:

Multi-compartment designs (e.g., drug + diluent)

Circular, oval, or irregular cavity shapes

Custom perforation lines and peelable seals

Customizing the vision system’s field of view, lighting angles, and software mapping tools ensures accurate detection of defects across all cavity types and orientations.

2. Inspection of Unconventional Dosage Forms

In personalized and pediatric medicines, manufacturers often use mini tablets, micro-tablets, granules, or films. These forms differ significantly in appearance and behavior from standard pills or capsules. Customized blister pack inspection systems must be trained to detect subtle variances in:

Color and texture

Uniformity and fill level

Shape and size tolerances

Advanced vision algorithms powered by AI can be tailored to recognize the acceptable range of variation for these niche forms, reducing false positives.

3. Low Volume, High-Mix Production Compatibility

Niche pharmaceuticals often involve short production runs and frequent product changeovers. An inspection system must be flexible enough to:

Reconfigure quickly between different blister formats

Store multiple product profiles in the software interface

Allow operators to make swift adjustments without technical intervention

Custom user interfaces, recipe libraries, and modular hardware design enable the system to support agile, small-batch operations.

4. Support for Sensitive or Hazardous Materials

Certain medications require stringent containment due to their potency or sensitivity. These include cytotoxic drugs, vaccines, and biologics. A customized blister pack inspection system should:

Operate in cleanroom or isolator environments

Incorporate non-intrusive inspection techniques (e.g., contactless vision, sealed camera housings)

Use materials and enclosures compatible with decontamination procedures

Tailoring these aspects ensures the system does not interfere with containment protocols or product integrity.

5. Multilingual and Region-Specific Label Verification

Some niche pharmaceuticals are distributed in multiple regions with unique regulatory labeling standards. Blister pack lidding often contains localized languages, artwork, or compliance marks. Customized OCR (optical character recognition) and pattern-matching capabilities allow inspection systems to:

Validate language-specific batch info and expiry dates

Verify localized regulatory logos and codes

Detect incorrect or missing country-specific labeling

This ensures regulatory alignment and prevents costly recalls due to labeling errors.

The Role of Advanced Technologies in Customization

Artificial Intelligence and Machine Learning

AI-powered inspection systems can be trained on a dataset of acceptable and defective samples, even for rare or novel drug forms. They continually improve accuracy over time, making them ideal for low-volume, high-complexity production.

3D and Hyperspectral Imaging

For inspecting depth variations, fill volumes, and material properties in complex blister formats, 3D vision and hyperspectral imaging offer additional layers of analysis. These can detect inconsistencies not visible to traditional 2D vision.

Cloud Integration and Remote Monitoring

For companies managing niche drug production across multiple facilities or CMOs (Contract Manufacturing Organizations), customized systems can include:

Cloud-based inspection data storage

Real-time monitoring dashboards

Remote troubleshooting capabilities

This ensures centralized quality oversight across decentralized production environments.

Benefits of Customizing Blister Pack Inspection Systems

Increased accuracy and lower false rejection rates

Compliance with niche product regulations (e.g., FDA, EMA, PMDA)

Reduced downtime during changeovers

Enhanced operator usability and training

Improved patient safety and brand reputation

Ultimately, customized systems reduce operational risks and improve ROI by aligning quality control with the unique requirements of specialized pharmaceutical lines.

Collaborating with the Right Inspection Partner

When customizing a blister pack inspection system, manufacturers should seek partners with:

Experience in niche pharmaceutical applications

Engineering flexibility to adapt hardware and software

In-depth understanding of industry-specific compliance

Strong after-sales support for maintenance and upgrades

Close collaboration between the packaging line team, quality assurance, and system providers ensures that the final solution meets operational, regulatory, and technical needs.

Conclusion

As the pharmaceutical industry continues to diversify, the demand for tailored quality assurance solutions grows in parallel. Customizing a blister pack inspection system for niche pharmaceutical applications is no longer optional—it is essential to maintaining integrity, compliance, and competitive edge in a specialized market.

With the right technology and a partner-focused approach, manufacturers can deploy inspection systems that are as specialized as the products they protect, ensuring every blister pack meets the highest standards of safety and accuracy.

0 notes

Text

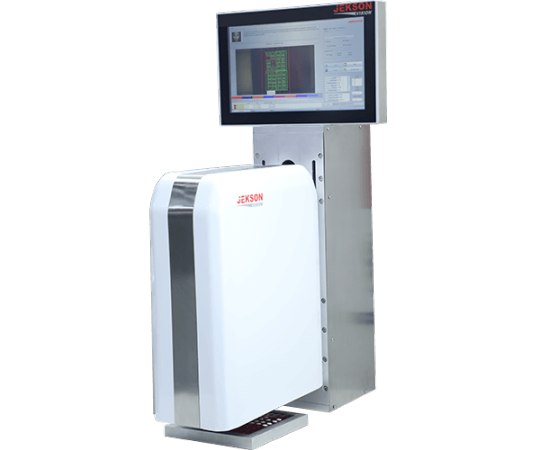

In the pharmaceutical industry, product integrity and patient safety are paramount. Jekson Vision's advanced blister inspection systems are designed to meticulously examine blister packs, ensuring that only defect-free products reach the market.

0 notes

Text

Choosing the Right Blister Inspection System for Your Pharmaceutical Manufacturing Needs

In the pharmaceutical industry, precision, safety, and compliance are non-negotiable. As global demand for high-quality medications continues to rise, so does the pressure on pharmaceutical manufacturers to deliver defect-free products. One critical step in ensuring product quality and packaging integrity is the use of a blister inspection system. These systems help manufacturers detect defects in blister packs, improve production efficiency, and maintain compliance with stringent regulatory requirements.

However, not all blister inspection systems are created equal. Choosing the right solution involves a thorough understanding of your production needs, regulatory obligations, and technological requirements.

Why a Blister Inspection System Is Essential

A blister inspection system is a vision-based quality control technology that inspects each blister pack on the production line. These systems detect a variety of issues, including:

Missing or misaligned tablets or capsules

Color or shape mismatches

Cracked or broken tablets

Foreign objects or contamination

Seal integrity or printing defects

By identifying and rejecting defective products in real time, blister inspection systems reduce waste, prevent recalls, and ensure only compliant products reach consumers. This not only improves quality assurance but also supports compliance with Good Manufacturing Practices (GMP) and regulations from agencies like the FDA and EMA.

Key Considerations for Choosing the Right Blister Inspection System

Selecting the ideal blister inspection system requires a comprehensive evaluation of your current and future production needs. Below are the key factors to consider:

1. Product and Packaging Specifications

Start by analyzing your product’s characteristics and the types of blister packs used. Important considerations include:

Tablet or capsule size, shape, and color

Material and design of blister packs (e.g., PVC, aluminum, thermoformed)

Number of cavities per pack

Size and speed of your production line

Ensure the system can accurately inspect the range of products you manufacture, including future product variations.

2. Inspection Capabilities

Modern blister inspection systems offer a variety of inspection features. Look for systems that can perform:

Presence/absence checks

Color and shape verification

Foreign object detection

3D inspection for depth analysis

Foil seal and print quality verification

Some systems even use artificial intelligence (AI) or machine learning algorithms to adapt to product variations and improve defect detection over time.

3. Camera and Illumination Technology

Image quality is crucial for accurate inspection. Choose a system with:

High-resolution cameras

Multiple camera angles (top, bottom, side) if needed

Proper lighting configurations (e.g., backlighting, coaxial, dome lighting)

Infrared or UV lighting for specialized needs

These components ensure consistent performance under different environmental and product conditions.

4. Speed and Throughput Requirements

The inspection system must keep pace with your production line. High-speed lines require systems with fast processing capabilities and real-time rejection mechanisms. Make sure the system’s speed matches your output without compromising accuracy.

5. Ease of Integration

Your chosen blister inspection system should integrate smoothly with existing production lines. Consider:

Footprint and physical compatibility with your equipment

Compatibility with Programmable Logic Controllers (PLCs)

Ability to interface with Manufacturing Execution Systems (MES)

Support for Industry 4.0 and digital traceability standards

Modular and customizable systems can offer more flexibility during integration.

6. User Interface and Usability

A user-friendly interface is important for line operators and quality control personnel. Look for systems with:

Intuitive touchscreens and dashboards

Recipe management for different products

Real-time alerts and visual defect indicators

Easy access to data logs and inspection reports

Ease of use reduces training time and increases productivity.

7. Compliance and Validation Support

Your blister inspection system must help you meet regulatory standards, including:

FDA 21 CFR Part 11 for electronic records

GMP requirements for automated inspections

Full audit trails and time-stamped images of defects

Validation documentation (IQ/OQ/PQ protocols)

Work with vendors that provide validation assistance and ensure the system meets industry-specific guidelines.

8. Service, Support, and Training

Post-installation support is just as important as the system itself. Choose a vendor that offers:

Prompt technical support and remote diagnostics

Spare parts availability

Operator training and refresher courses

Preventive maintenance programs

Good vendor support reduces downtime and extends the system’s lifecycle.

Cost Considerations

While cost is always a factor, it should be evaluated in the context of value. A cheaper system may lack critical features or fail to meet regulatory needs, resulting in long-term losses. Conversely, a high-quality system with robust capabilities can deliver substantial ROI through defect reduction, compliance, and improved efficiency.

When budgeting, consider:

Initial investment and installation costs

Licensing or software fees

Maintenance and calibration expenses

Upgrade potential and scalability

Case in Point: Making the Right Choice

A mid-sized pharmaceutical manufacturer recently expanded production of a new pediatric medication in chewable form. The company needed a blister inspection system capable of:

Inspecting multi-color tablets

Detecting minor cracks and defects

Logging images for traceability

Seamlessly integrating with an older production line

After evaluating several options, they selected a system with dual cameras, AI-enhanced detection, and a compact frame. Integration was completed in two weeks, resulting in:

A 40% reduction in defective packs

Streamlined compliance audits

Improved operator confidence with the user-friendly interface

Conclusion

Selecting the right blister inspection system is a critical decision for pharmaceutical manufacturers committed to product quality, compliance, and operational excellence. By considering your production needs, regulatory requirements, and system capabilities, you can ensure a solution that not only fits your current processes but also supports your future growth.

Whether you’re updating a legacy line or building a new facility, investing in the right inspection technology today lays the foundation for reliable, efficient, and compliant operations tomorrow.

1 note

·

View note