Don't wanna be here? Send us removal request.

Text

The ability of Precision: Unleashing the Potential of CNC Machining Services

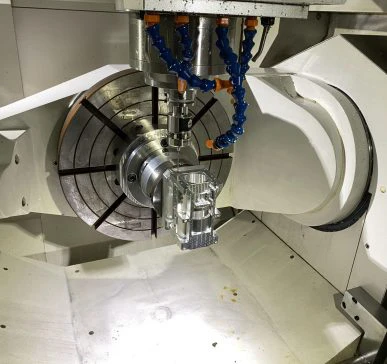

Precision is really a cornerstone of modern day manufacturing, and CNC machining services participate in a pivotal function in achieving this kind of exactness. From intricate prototypes to size production of parts, CNC machining solutions offer a level of accuracy and performance that is unequaled by traditional procedures. Whether it's shaping metals, plastics, or other materials with unmatched detail, the fine art of precision through CNC machining is actually a testament to the evolution of making technology.

In today's very competitive industrial landscape, businesses rely about CNC machining service to create their patterns to our lives with unrivaled precision and repeatability. The advent of Computer Numerical Manage technology has totally changed the way all of us approach manufacturing, allowing engineers and developers to push typically the boundaries of just what is possible. By simply harnessing the power of COMPUTER NUMERICAL CONTROL machining services, firms can unleash typically the full potential of these projects, creating high-quality parts and goods that meet typically the most stringent specifications.

Advantages of CNC Machining Services

CNC machining sites offer unparalleled finely-detailed and accuracy within crafting intricate parts with consistent quality. Businesses utilizing CNC machining services could enjoy increased productivity and efficiency within their manufacturing processes. The particular automated nature regarding CNC machines decreases the margin associated with error, leading to higher repeatability plus fewer defects within the final items.

A single of the essential features of CNC machining services is the particular ability to accomplish complex shapes and intricate designs that would otherwise be challenging with traditional engineering methods. This brings new possibilities with regard to innovation and modification, allowing businesses to produce unique products of which meet specific requirements and stand out and about available in the market. CNC machining services also allow faster turnaround periods, helping companies meet up with tight deadlines and fulfill orders promptly.

In addition, CNC machining solutions provide cost financial savings in the very long run by reducing material waste and even maximizing using natural materials. The productivity of CNC devices allows for improved cutting paths in addition to reduced scrap, top to lower manufacturing costs and improved profitability for your business. By simply streamlining the developing process and improving overall efficiency, CNC machining services add to the competition and success associated with modern industries.

Advanced Strategies in CNC Engineering

Advanced CNC machining requires utilizing multi-axis engineering capabilities to achieve complex geometries and intricate designs. Simply by incorporating simultaneous machining movements along diverse axes, manufacturers can produce components together with tight tolerances and even superior surface surface finishes. This level involving precision is necessary for industries like aerospace and clinical devices, where intricate parts require maximum accuracy.

One key technique in advanced CNC machining is high-speed machining, which involves using specialized tools and even cutting ways of optimize material removal prices while maintaining part integrity. By cautiously controlling cutting variables such as spindle speed, feed rate, and toolpath, producers can achieve faster manufacturing cycles without reducing quality. It is particularly advantageous for generating large volumes associated with parts efficiently.

Another cutting-edge technique in CNC machining is 5-axis machining, which allows machining of sophisticated shapes from a variety of angles. By slanting the tool plus rotating the workpiece simultaneously, manufacturers can access difficult-to-reach locations and significantly decrease setup times. This specific advanced technique is ideal for producing generator blades, molds, and other intricate components that want precise machining every which way.

Sector Applications of CNC Engineering

In various industries, CNC machining services carry out a vital role in delivering precision and productivity to manufacturing operations. From aerospace to be able to automotive sectors, COMPUTER NUMERICAL CONTROL machining is important in creating pieces that meet strict specifications. These industrial sectors rely on CNC machining to fabricate complicated parts with highest accuracy and consistency.

The health care industry benefits greatly from CNC machining services for creating complex surgical tools and implants. Typically the precision provided simply by CNC machines ensures that medical equipment are manufactured to be able to exacting standards, making sure reliability and safety for patients. Moreover, the customization functions of CNC machining permit the creation involving patient-specific devices tailored to individual needs.

CNC engineering services are extensively used in the particular electronics industry intended for crafting precise elements such as circuit boards and enclosures. The intricacy in addition to accuracy achieved by way of CNC machining allow manufacturing high-quality electric devices with ideal performance. By leveraging CNC technology, electronics manufacturers can improve product quality and maintain competitiveness in the market.

1 note

·

View note