Text

Toilet Paper Test in Water Is Your Brand Really Flushable

Toilet Paper Test in Water: Is Your Brand Really Flushable?

Not all toilet papers are created equal. Find out which ones pass the toilet paper test in water and are truly flushable.

Have you ever wondered if your go-to toilet paper brand is really flushable? The toilet paper test in water can help answer that question. Simply drop a few squares of toilet paper into a bucket of water and swirl it around. If the toilet paper disintegrates quickly and completely, it is considered flushable. However, if it stays intact or takes a long time to break down, it could cause clogs in your pipes and harm the environment. Many popular brands claim to be flushable, but fail the toilet paper test. Look for products labeled "septic safe" or "flushable" that have been certified by independent organizations. Don't let a clogged toilet ruin your day - choose a truly flushable toilet paper.

Website link:https://www.hozhong.com/eco-friendly-custom-your-logo-private-label-biodegradable-toilet-paper-wholesale.html

China's Professional Paper Machinery Manufacturer and Supplier- Cailun Mach:https://www.cailunmach.com/

Wholesale OEM & ODM Toilet Paper/Tissue Paper/Napkin Paper Manufacturer/Supplier/Factory/Exporter in China-Baoding Hozhong Hygienic Products Manufacturing Co., Ltd:https://www.hozhong.com/

0 notes

Text

How makes a sheet of tissue paper

Tissue paper is a thin, lightweight and highly absorbent paper that has become an essential item in households, offices, schools, restaurants, and hospitals. It is ideal for wiping and cleaning various surfaces, as well as for personal hygiene purposes such as blowing the nose or wiping sweat from the face.

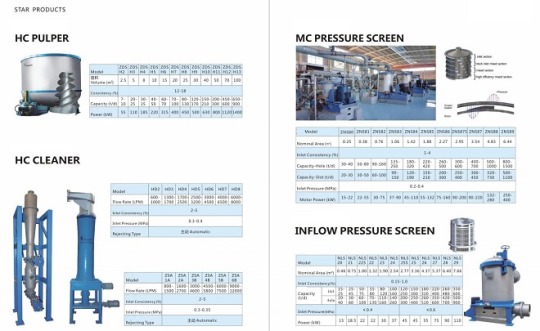

Pulping process(with pulping machinery):

The process of making tissue paper is a complex procedure that involves several stages. The basic raw material used in tissue paper production is wood pulp, which is sourced from hardwood trees such as birch, maple, and oak. The wood chips are first boiled in a large container to remove impurities and break down the cellulose fibers. The resulting pulp is then washed, screened, and bleached to produce high-quality pulp.

Tissue making(with facial tissue making machine):

After that, the pulp is transported to a paper mill, where it is blended with water, chemicals, and other additives to achieve a specific texture and quality. The pulp mixture is then poured onto a moving screen, which helps to evenly distribute the fibers. The screen passes through a series of pressing rollers that squeeze out excess water and create a thin wet sheet of tissue paper.

Rolls cutting(with cutting Machine ):

The wet sheet is then transferred onto a giant felt conveyor belt and passed through a drying cylinder, which dries the paper and gives it its final texture. The tissue paper is then cut into large rolls and shipped to factories for further processing.

Add process(with embossing machine):

At this point, the tissue paper may undergo additional processes such as embossing, where the paper is pressed between engraved metal plates to create a pattern or texture. The paper may also be colored with dyes or printed with patterns or logos.

Packaging(with packing machines):

The final step in tissue paper production is packaging and distribution. The rolls of tissue paper are typically wrapped in plastic or paper and sold to retailers or wholesalers, who in turn distribute them to consumers or end-users.

Eco trend(with recycled paper production machine):

In recent years, there has been a growing trend towards environmentally friendly tissue paper production. Many manufacturers are now using recycled paper as a raw material and incorporating sustainable practices into their operations, such as reducing water and energy usage.

Conclusion:

Overall, the process of making tissue paper is a complex and innovative one that has evolved over the years to meet the growing demand for this ubiquitous household item. From the sourcing of raw materials to the final product packaging, every step in the tissue paper production process is carefully planned and executed to ensure the highest quality and efficiency.

pulping machinery

Website link:

China's Professional Paper Machinery Manufacturer and Supplier- Cailun Mach:https://www.cailunmach.com/

Wholesale OEM & ODM Toilet Paper/Tissue Paper/Napkin Paper Manufacturer/Supplier/Factory/Exporter in China-Baoding Hozhong Hygienic Products Manufacturing Co., Ltd:https://www.hozhong.com/

0 notes

Text

Understanding the Basics of Tissue Paper Machine and Deinking Pulping System

Learn about the basics of tissue paper making and deinking pulping systems to find the best toilet paper making machine for sale.

Tissue paper making is now a profitable business that requires a good understanding of the machines and systems used in the process. Deinking pulping system is a vital part of making tissue paper and involves the process of removing ink, stickies, and other contaminants from recycled paper. The system follows various processes such as pulping, screening, cleaning, and bleaching, which are implemented to recover fiber and create a pulpy mixture for the tissue paper machine. Choosing the right toilet paper making machine for sale requires knowledge of the production capacity, automation, downtime, and maintenance costs. Investing in a tissue paper machine and deinking pulping system is a wise decision that can lead to financial success.

toilet paper making machine for sale

Website link:https://www.cailunmach.com/

0 notes

Text

Cheap v sharp facial tissue box paper product folding making machine with small business

Website link:https://www.cailunmach.com/

0 notes

Text

Why You Should Check out Cailun Automatic Maxi Roll Slitter Rewinder Machine

Discover the benefits of using Cailun's Automatic Maxi Roll Slitter Rewinder Machine.

Looking for an efficient and reliable Maxi Roll slitter rewinder machine? Cailun's Automatic Maxi Roll Slitter Rewinder Machine is exactly what you need! It is designed to handle a wide range of materials, including film, paper, foil, and laminates. With its advanced automation features, it ensures precise and consistent slitting and rewinding, saving you both time and labor costs. Cailun's Automatic Maxi Roll Slitter Rewinder Machine is highly versatile and can handle a wide range of materials with varying thicknesses and widths. Its advanced control system ensures that the machine runs smoothly and efficiently, minimizing downtime and increasing productivity. One of the key benefits of using Cailun's Automatic Maxi Roll Slitter Rewinder Machine is that it is highly automated. This means that you can set it up to run unattended, saving you time and labor costs. The machine's advanced automation features also ensure that it delivers consistent and precise results, every time. In addition to its automation features, the machine is also highly reliable and easy to maintain. Cailun is known for producing reliable equipment that requires minimal downtime and maintenance, ensuring that your production lines run smoothly and efficiently. Overall, if you are looking for an efficient and reliable Maxi Roll slitter rewinder machine that can handle a wide range of materials, Cailun's Automatic Maxi Roll Slitter Rewinder Machine is the perfect choice. With its advanced automation features, precision, and reliability, it is sure to meet all your slitting and rewinding needs.

Website link:https://www.cailunmach.com/maxi-roll-slitting-and-rewinding-machine.html

youtube

Automatic Maxi Roll Slitter Rewinder Machine

1 note

·

View note