Pujiang Changmin Crystal Gifts Co., Ltd. is a Custom Crystal Gifts Manufacturer and Crystal Ornaments Company, Product produces crystal Crafts, Crystal Trophy, Crystal Candlestick, Crystal Office Furnishing Articles, Crystal Animals, Crystal pendants and Crystal Gifts, and Crystal Products.https://www.pjchangmin.com/

Don't wanna be here? Send us removal request.

Text

Crystal Cube Laser 3D Internally Carved Cube

Crystal Cube Laser 3D Internally Carved Cube

Greetings from Crystal Cube Carving, where artistry meets precision to bring you a captivating range of crystal masterpieces. As connoisseurs of timeless beauty, we take pride in presenting our distinguished collection, featuring the enchanting Crystal 3D Carved Rose Cube and the mesmerizing Crystal 3D Internally Carved Cube, among other exquisite creations. In this comprehensive exploration, we invite you to discover the allure and craftsmanship behind each Crystal Cube Carving creation.

0 notes

Text

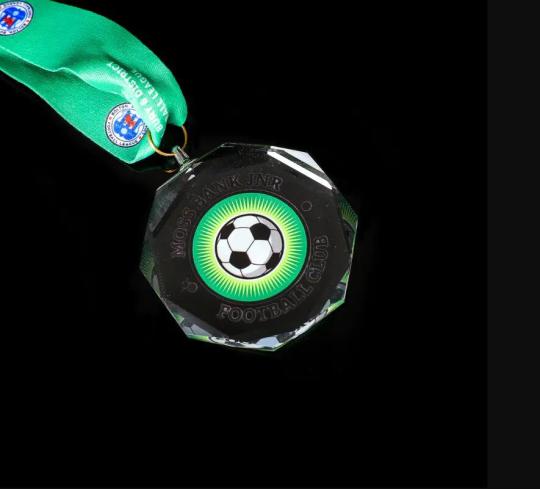

Octagonal UV Football Crystal Glass Medal

Octagonal UV Football Crystal Glass Medal Elevate your recognition to new heights with the Crystal Octagonal Medal—an embodiment of elegance, precision, and enduring achievement.

0 notes

Text

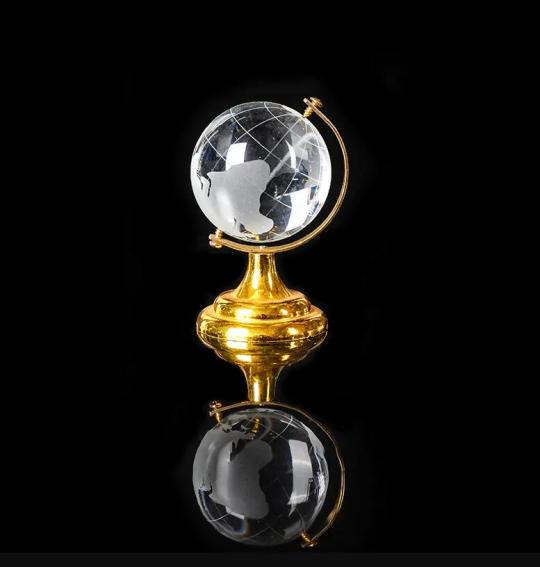

Crystal Earth Ornaments Crystal Laser Ball

Crystal Earth Ornaments Crystal Laser Ball

While the laser engraving technology used in crystal laser balls is a modern breakthrough, the artistry behind crafting crystal animal gifts remains deeply rooted in traditional methods.

0 notes

Text

Golden Crystal Rooster Ornament Crystal Animals Toys

Golden Crystal Rooster Ornament Crystal Animals Toys

Immerse yourself in the graceful beauty of our Crystal Color Pattern Swan. The fusion of crystal and vibrant hues creates a mesmerizing visual spectacle. Whether as a centerpiece or accent, this swan embodies the epitome of elegance and refinement, elevating your space to new heights of sophistication.

0 notes

Text

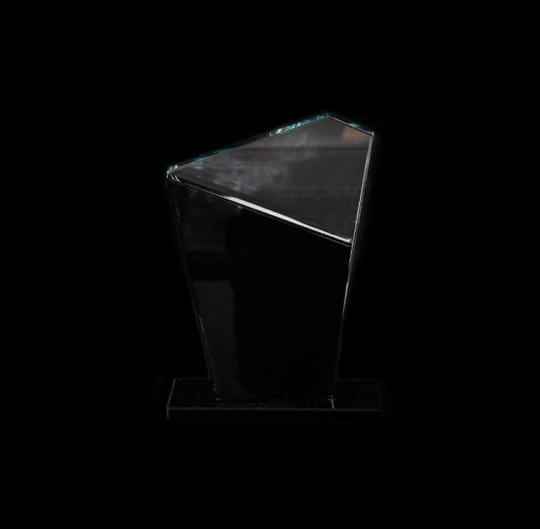

Black And White Two-tone Glass China Crystal Trophy

Black And White Two-tone Glass China Crystal Trophy

Recognizing and celebrating achievements is an art, and the Glass Crystal Trophy is the canvas on which this art comes to life. Its design, craftsmanship, and versatility make it the ideal medium for expressing appreciation and acknowledging the efforts that are ideal for success.

0 notes

Text

Black And White Two-tone China Crystal Trophy Factory

Black And White Two-tone China Crystal Trophy Factory

Customization:

Recognizing that every achievement is unique, the Glass Crystal Trophy offers a platform for customization that elevates it to a level of personal significance. Engraving options allow for the inclusion of names, dates, and specific achievements, ensuring that each trophy tells a personalized story of accomplishment.

0 notes

Text

China Crystal Trophy Blue And White Two-tone Glass Trophy

China Crystal Trophy Blue And White Two-tone Glass Trophy

At the heart of the Glass Crystal Trophy is an unwavering commitment to impeccable craftsmanship. Each trophy is meticulously handcrafted by skilled artisans who bring years of expertise to the table.

0 notes

Text

Wall Mounted Soap Dispenser Factory Crystal Jewish Religious Square Multi-headed Menorah with Butterflies

Wall Mounted Soap Dispenser Factory Crystal Jewish Religious Square Multi-headed Menorah with Butterflies The Crystal Jewish Religious Square Multi-headed Menorah with Butterflies is a beautifully designed and spiritually significant piece, perfect for adding elegance and meaning to any home or place of worship. Crafted with precision, this menorah features a square base adorned with delicate butterfly accents, symbolizing transformation, freedom, and renewal. The multi-headed design allows for the display of all nine branches, each carefully positioned to hold the candles for the celebration of Hanukkah. Made from high-quality crystal, the menorah captures light in a dazzling way, creating a radiant glow that enhances the ambiance of the holiday. Its intricate details and symbolic butterflies make it a meaningful addition to any Jewish tradition, blending artistic beauty with religious reverence. Whether used for ceremonial purposes or as a decorative piece, this menorah brings both spiritual significance and a touch of grace to the celebration of Hanukkah.

0 notes

Text

Crystal Animals Toys Faceted Crystal Butterfly

Crystal Animals Toys Faceted Crystal Butterfly

One of the more appealing aspects of crystal animals toys is their ability to captivate a child's attention. The vibrant colors and intricate designs of these toys spark curiosity, prompting children to explore their surroundings. When children play with crystal animals toys, they often create elaborate stories and scenarios, allowing their imaginations to flourish. This kind of imaginative play is crucial for cognitive development, as it helps children understand the world around them and enhances their problem-solving skills.

0 notes

Text

Glass Ball Trophy Production Process: Technology and Innovation

The world of glass ball trophy production is a fascinating realm where artistry and technology intersect. The glass ball trophy, often used to commemorate achievements or milestones, reflects a unique blend of craftsmanship and innovation. This article delves into the techniques and innovations that define the art of creating glass ball trophies, highlighting the intricate processes involved in their production.

https://www.pjchangmin.com/pjchangmin/2023/11/21/7168.jpg

The process of crafting a glass ball trophy begins with the selection of high-quality glass. The type of glass used significantly impacts the final product's clarity and durability. Manufacturers typically use crystal glass, known for its exceptional clarity and brilliance. The choice of glass is crucial, as it influences the overall appearance and perceived value of the glass ball trophy.

Once the glass is selected, the production process involves several key steps. The one step is melting the glass at extremely high temperatures. This molten glass is then shaped into a rough sphere, which forms the base of the glass ball trophy. Shaping the sphere requires precision and skill, as any imidealions at this stage can affect the outcome. Skilled artisans carefully monitor the glass to ensure it achieves the desired shape and smoothness.

After shaping, the glass ball trophy undergoes a cooling process known as annealing. Annealing involves slowly cooling the glass to relieve internal stresses and prevent cracking. This step is vital in ensuring the glass ball trophy retains its integrity and durability over time. The cooling process must be meticulously controlled to achieve the ideal results.

Once the glass ball trophy has cooled, it is ready for further refinement. This stage involves polishing and engraving. Polishing is done to enhance the clarity and shine of the glass. Artisans use specialized tools to remove any surface blemishes and ensure a smooth, reflective finish. The polishing process is delicate, as it requires careful attention to detail to avoid damaging the glass.

Engraving is another critical aspect of the craftsmanship involved in creating a glass ball trophy. Engraving can be done using various techniques, including sandblasting and laser engraving. Sandblasting involves using abrasive materials to etch designs onto the surface of the glass. Laser engraving, on the other hand, uses a laser to create precise and intricate patterns. Both methods offer unique advantages, and the choice of technique often depends on the complexity of the design and the desired effect.

The design of the glass ball trophy can range from simple to elaborate. Customization plays a significant role in this process, as many trophies are personalized to reflect specific achievements or events. Custom designs often include logos, text, or unique patterns that hold special significance. The ability to personalize a glass ball trophy adds a layer of uniqueness and value, making each piece a meaningful and memorable award.

Innovation continues to drive advancements in glass ball trophy production. Modern techniques and technologies have introduced new possibilities for enhancing the design and production process. For example, advancements in 3D printing technology allow for the creation of intricate and complex designs that were previously challenging to achieve. Additionally, the use of advanced coatings and finishes can further enhance the visual appeal and durability of the glass ball trophy.

Sustainability is also becoming an important consideration in glass ball trophy production. Manufacturers are increasingly adopting eco-friendly practices, such as using recycled glass and reducing energy consumption during production. These efforts not only contribute to environmental conservation but also reflect a commitment to responsible manufacturing practices.

In summary, the craftsmanship involved in glass ball trophy production encompasses a range of techniques and innovations. From selecting high-quality glass to shaping, polishing, and engraving, each step requires skill and precision. Advances in technology and a focus on sustainability are shaping the future of glass ball trophy manufacturing, offering new opportunities for creativity and environmental responsibility. The art of creating glass ball trophies continues to evolve, blending tradition with innovation to produce awards that celebrate achievements in a truly unique and elegant manner.

0 notes

Text

The Art of Surface Finishing on Glass Heart Trophy Techniques and Significance

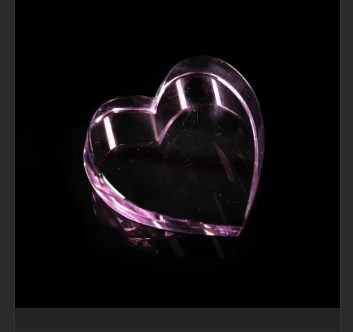

The Glass Heart Trophy, a beacon of well and a symbol of heartfelt recognition is a cherished award in various domains, from sports to academia and from corporate achievements to artistic endeavors. The allure of these trophies lies not only in their form but also in the meticulous surface treatment that enhances their visual appeal and durability. This article explores the intricate world of surface finishing techniques applied to Glass Heart Trophies, examining the processes that transform a piece of glass into a gleaming symbol of honor.

The journey of a Glass Heart Trophy begins with the selection of high-quality glass, which is the foundation of its beauty and strength. The raw material is carefully chosen for its clarity, purity, and resistance to wear. Once the glass is cut and shaped into the iconic heart form, the focus shifts to the surface treatment processes that will give the trophy its lustrous finish.

Polishing is the one step in the surface treatment of a Glass Heart Trophy. This process involves the use of abrasive materials to smooth the edges and surfaces of the glass, removing any roughness or imperfections. The polishing process can be manual or automated, with the latter offering a more consistent and precise finish. The goal is to achieve a smooth, mirror-like surface that reflects light beautifully, enhancing the trophy's visual impact.

Following polishing, the Glass Heart Trophy may undergo a process known as sandblasting. This technique uses high-pressure air to propel fine sand particles against the glass surface, creating a frosted or etched effect. Sandblasting can be used to add texture, depth, or even intricate designs to the trophy, making each piece unique and personalized.

Another important aspect of surface treatment is the application of protective coatings. These coatings can be applied to the Glass Heart Trophy to protect it from scratches, UV damage, and other environmental factors that could degrade its appearance over time. The coatings are carefully selected to ensure they do not interfere with the trophy's transparency or brilliance.

In some cases, the Glass Heart Trophy may be adorned with metallic or colored finishes. These finishes can be applied through various methods, including electroplating, which involves the deposition of a thin layer of metal onto the glass surface. Alternatively, a process known as glass painting can be used to add vibrant colors or intricate patterns to the trophy, further enhancing its visual appeal.

The final stage of surface treatment for a Glass Heart Trophy is the application of a protective sealant. This sealant not only protects the trophy from damage but also provides a barrier against moisture and other environmental factors that could affect the integrity of the glass. The sealant is carefully chosen to ensure it is durable, clear, and does not detract from the trophy's appearance.

Throughout the surface treatment process, quality control is of paramount importance. Each Glass Heart Trophy is inspected at various stages to ensure it meets high standards of craftsmanship and beauty. Any imperfections or deviations from the design are addressed immediately, ensuring that each trophy is a testament to well.

In conclusion, the surface treatment of a Glass Heart Trophy is a complex and meticulous process that involves a series of specialized techniques. From polishing to sandblasting, from protective coatings to metallic finishes, each step is carefully executed to create a trophy that is not only a symbol of achievement but also a work of art. The Glass Heart Trophy, with its carefully treated surfaces, stands as a shining example of the marriage between form and function, beauty and durability.

0 notes

Text

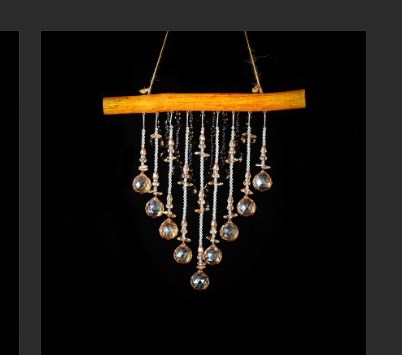

Maintaining Long-lasting Beauty and Luster of Crystal Glass Pendants

Crystal glass pendant is prized for its dazzling brilliance and timeless elegance, making them a popular choice for jewelry enthusiasts and fashion aficionados alike. To ensure these exquisite pieces retain their allure and shine over time, proper care and maintenance are essential.

The key to preserving the long-lasting beauty of crystal glass pendants lies in understanding their unique characteristics and employing appropriate cleaning and storage practices. Unlike traditional glass or other materials, crystal glass is renowned for its clarity and light-refracting properties, which contribute to its stunning visual appeal.

Regular cleaning is paramount in maintaining the pristine appearance of crystal glass pendants. Dust, oils from the skin, and environmental pollutants can accumulate on the surface over time, dulling its sparkle. To clean your pendant, start by gently wiping it with a soft, lint-free cloth to remove any surface dust or particles. Avoid abrasive materials or harsh chemicals that may scratch or damage the glass.

For more cleaning, use a mild soap solution and lukewarm water. Dip a soft-bristled toothbrush or a jewelry cleaning brush into the solution and gently scrub the pendant to remove stubborn residues. Rinse it under running water to ensure all soap residue is removed. Pat dry with a clean cloth or let it air dry naturally.

To maintain the pendant's luster, consider using a specialized crystal cleaner or polishing cloth designed specifically for glass jewelry. These products are formulated to safely remove fingerprints, smudges, and light tarnishes without causing damage to the delicate surface of the crystal glass.

Storage also plays a crucial role in preserving the beauty of crystal glass pendants. When not being worn, store your pendant in a jewelry box or pouch that is lined with soft fabric to prevent scratches and minimize exposure to dust and humidity. Avoid storing crystal glass jewelry alongside other pieces that could potentially scratch its surface, such as metal jewelry with sharp edges.

Furthermore, be mindful of how you wear and handle your crystal glass pendant. Avoid exposing it to harsh chemicals, including perfumes, cosmetics, and household cleaners, which can corrode or discolor the metal components and diminish the brilliance of the glass. Remove your pendant before engaging in activities such as swimming or exercising to prevent accidental damage.

Inspect your crystal glass pendant regularly for any signs of damage or loosening of settings. If you notice any issues, such as loose stones or scratches, consult a professional jeweler for repair and maintenance. Prompt attention to these matters can prevent further damage and ensure the pendant retains its beauty and integrity for years to come.

In addition to individual care practices, consider the environment in which you display or wear your crystal glass pendant. Direct sunlight and extreme temperatures can affect the clarity and color of the glass over time. Store your pendant in a cool, dry place away from sunlight when not in use, and avoid prolonged exposure to heat or UV rays.

For heirloom or particularly valuable crystal glass pendants, periodic professional cleaning and inspection may be beneficial. Professional jewelers have the expertise and tools to safely clean and restore the brilliance of crystal glass jewelry, ensuring it continues to be a cherished piece for future generations.

In conclusion, the enduring beauty of crystal glass pendants is a testament to their quality craftsmanship and exquisite design. By adopting proper care and maintenance practices, such as regular cleaning, safe storage, and cautious handling, you can prolong the luster and elegance of these timeless pieces. Whether worn as a personal adornment or gifted as a cherished token, a well-maintained crystal glass pendant remains a captivating symbol of beauty and refinement.

0 notes

Text

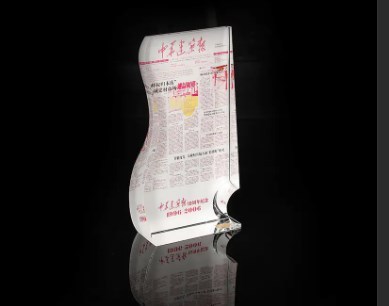

Sustainable Practices in the Production of Glass Crystal Trophies

Glass crystal trophies are not only symbols of achievement and recognition but also embodiments of craftsmanship and artistry. As demand for these prestigious awards continues to rise, so too does the importance of ensuring that their production processes align with principles of sustainability. In this article, we delve into the various ways in which manufacturers can implement sustainable practices throughout the production of glass crystal trophies, from material sourcing to manufacturing and beyond.

At the heart of sustainable trophy production lies the responsible sourcing of raw materials. Glass crystal trophies, the primary component of crystal trophies, are traditionally derived from silica sand, soda ash, and limestone—a process that can be resource-intensive and environmentally impactful. However, manufacturers are increasingly turning to recycled glass crystal trophies as a sustainable alternative. Recycled glass not only conserves natural resources but also reduces energy consumption and greenhouse gas emissions associated with glass production. By partnering with glass crystal trophies

recycling facilities and incorporating recycled glass cullet into their manufacturing processes, trophy manufacturers can significantly reduce their environmental footprint while maintaining the quality and integrity of their products.

In addition to recycled glass, manufacturers are exploring other eco-friendly materials and alternatives to traditional trophy components. For instance, sustainable bases made from responsibly sourced wood or bamboo provide a natural and biodegradable alternative to traditional plastic or metal bases. Furthermore, eco-friendly adhesives and finishes, free from harmful chemicals and volatile organic compounds (VOCs), ensure that the production process remains environmentally conscious from start to finish.

Moreover, sustainable trophy production extends beyond material sourcing to encompass energy-efficient manufacturing processes. Glass manufacturing is inherently energy-intensive, requiring high temperatures to melt raw materials and shape molten glass crystal trophies into desired forms. However, manufacturers can mitigate energy consumption and reduce emissions by investing in energy-efficient furnaces, kilns, and equipment. Additionally, optimizing production workflows, decreasing idle time, and implementing lean manufacturing principles help to improve efficiency and reduce waste throughout the manufacturing process.

Furthermore, manufacturers are exploring innovative glass-forming techniques and technologies to reduce material waste and improve production yields. Advanced molding and casting methods, such as precision molding and computer-aided design (CAD) modeling, allow for greater precision and control over the shaping and finishing of glass crystal trophies. By decreasing the need for manual intervention and reducing errors in the production process, these technologies help to conserve materials and optimize resource utilization.

Additionally, manufacturers are implementing closed-loop recycling systems to manage and recycle waste generated during the production process. Glass scraps, trimmings, and defective pieces are collected and recycled back into the production process, reducing the need for virgin materials and decreasing waste sent to landfills. Furthermore, water used in glass crystal trophies manufacturing processes is treated and recycled wherever possible, decreasing water consumption and reducing the environmental impact of production.

In terms of packaging and transportation, manufacturers are adopting sustainable practices to reduce their carbon footprint and reduce environmental impact. Eco-friendly packaging materials, such as recycled cardboard, biodegradable plastics, and compostable packaging alternatives, help to reduce waste and promote a circular economy. Additionally, manufacturers are optimizing logistics networks, consolidating shipments, and utilizing fuel-efficient vehicles to reduce emissions and reduce transportation-related environmental impact.

In conclusion, sustainable trophy production requires a holistic approach that encompasses responsible material sourcing, energy-efficient manufacturing processes, waste reduction, and eco-friendly packaging and distribution practices. By prioritizing recycled materials, decreasing energy consumption, optimizing production workflows, and promoting transparency and accountability throughout the supply chain, manufacturers can produce glass crystal trophies that not only celebrate achievement and well but also embody principles of environmental stewardship and sustainability.

0 notes

Text

The Art of Selection Crafting a Memorable Glass Trophy with Engraving

The process of choosing the perfect design for a glass trophy with engraving is akin to composing a symphony; it requires a delicate balance of aesthetics, meaning, and functionality. A well-designed glass trophy not only serves as a symbol of achievement but also as a piece of art that can be cherished for years to come. Herein lies the challenge: how to create a design that is both visually stunning and deeply personal, reflecting the essence of the honor it bestows. This article will explore the intricacies of selecting a design for a glass trophy with engraving that will resonate with the recipient and stand the test of time.

When embarking on the journey to find the ideal glass trophy with engraving, one must first consider the purpose of the award. Is it for a sports championship, a corporate milestone, academic excellence, or artistic achievement? The nature of the accomplishment should be the guiding star in the design process. For instance, a trophy for a golf tournament might incorporate elements of the sport, such as a miniature golfer or a golf club, within the engraving.

The material of the glass trophy with engraving is also of paramount importance. High-quality glass ensures that the trophy will have a professional and luxurious appearance. It also allows for more intricate and detailed engravings, which can add depth and dimension to the design. The choice between clear, colored, or even frosted glass can set the tone for the overall look of the trophy.

The shape of the glass trophy with engraving is another critical decision. Traditional shapes like the classic obelisk or the more modern, angular designs each convey a different message. The shape should be chosen to complement the design elements and to provide a canvas that allows the engraving to stand out.

Speaking of engraving, the content and style of the inscription on the glass trophy with engraving are where personalization truly comes to life. The text should be concise, meaningful, and reflective of the recipient's achievement. The font style, size, and placement must be carefully considered to ensure readability and visual harmony. Some glass trophies with engraving also offer the option of including logos or symbols, which can add a layer of recognition and prestige.

The use of color in a glass trophy with engraving can be a powerful tool in enhancing the design. While traditional engraving relies on the contrast of the etched glass against the surrounding surface, modern techniques allow for the incorporation of colored fill to add vibrancy and depth. This can be particularly effective in highlighting specific elements of the design or in creating a more dynamic visual effect.

Moreover, the base of the glass trophy with engraving is often overlooked but is a crucial element in the overall presentation. A well-crafted base not only provides stability but can also be an opportunity to add additional engraved information or decorative elements. The choice of materials for the base, such as wood or marble, can also contribute to the overall aesthetic and perceived value of the trophy.

In conclusion, the selection of a design for a glass trophy with engraving is a multifaceted endeavor that requires attention to detail, creativity, and a keen understanding of the recipient's achievements. By considering the purpose, material, shape, content, style, color, and base of the trophy, one can create a glass trophy with engraving that is not only a testament to success but also a beautiful piece of art to be treasured.

0 notes

Text

The Crafting Artistry Behind The Crystal Glass Awards

Crystal glass award stands as timeless symbols of recognition and achievement, coveted by recipients for their elegance and prestige. Behind their exquisite beauty lies a meticulous crafting process that combines traditional techniques with modern innovation. In this article, we delve into the artistry behind the creation of crystal glass awards, exploring the intricate craftsmanship and attention to detail that elevates them to objects of admiration.

The journey of crafting a crystal glass award begins with the careful selection of raw materials. High-quality optical crystal, renowned for its clarity and brilliance, serves as the foundation for creating stunning awards. Manufacturers source premium crystal glass, free from impurities or blemishes, to ensure a high level of transparency and light refraction.

The selected raw materials undergo a precise melting process in specialized furnaces, reaching temperatures exceeding 2,000 degrees Celsius. Once molten, the crystal glass is carefully poured into molds or shaped by skilled artisans using techniques such as blowing or pressing. This initial forming stage determines the basic shape and structure of the award.

After shaping, the crystal glass awards undergo a controlled cooling process known as annealing. This gradual cooling period helps relieve internal stresses within the glass, preventing structural flaws or fractures. Proper annealing is critical to ensure the durability and stability of the finished awards, allowing them to withstand handling and display without compromising integrity.

The next stage involves precision cutting and polishing to refine the shape and enhance the optical properties of the crystal glass. Master craftsmen use diamond-tipped tools and abrasive compounds to meticulously sculpt the glass, creating intricate facets, bevels, and contours. Each cut reflects light in unique ways, imparting a mesmerizing brilliance to the awards.

Engraving adds a personal touch to crystal glass awards, transforming them into bespoke tributes tailored to individual recipients. Advanced laser engraving technology allows for precise customization of text, logos, and artwork directly onto the surface of the glass. This meticulous process ensures crisp, permanent markings that withstand the test of time, preserving the significance of the award for generations to come.

Once the engraving is complete, the various components of the crystal glass awards are meticulously assembled by skilled artisans. Metal accents, such as bases or mounting hardware, are carefully attached to complement the elegance of the glass. Final inspections are conducted to verify quality and consistency, ensuring that each award meets high standards of craftsmanship.

The presentation of crystal glass awards is as important as their craftsmanship, conveying a sense of reverence and admiration for the recipients' achievements. Awards are delicately packaged in premium gift boxes or display cases, complete with protective padding and elegant finishes. Attention to detail in packaging enhances the overall presentation and reinforces the significance of the award ceremony.

Throughout the manufacturing process, stringent quality control measures are implemented to uphold the reputation of Crystal Glass awards for well. Manufacturers adhere to industry standards and certifications, verifying the purity, clarity, and durability of the glass. Quality assurance protocols encompass every stage of production, from material sourcing to final inspection, ensuring that each award meets or exceeds expectations.

The crafting of crystal glass awards is a labor of love, blending artistry, technology, and tradition to create timeless symbols of recognition and achievement. From the selection of raw materials to the final presentation, every step in the manufacturing process reflects a commitment to well and craftsmanship. As recipients proudly display their awards, they not only celebrate their accomplishments but also honor the dedication and skill of the artisans who brought these exquisite creations to life.

1 note

·

View note