Complete Sourcing Solutions is an industry-leading supplier of aviation, NSN and electronic parts components

Don't wanna be here? Send us removal request.

Text

Clear Skies Ahead: Exclusive Offers on Flight Instruments and Avionics Await You!

0 notes

Text

Innovations in the Aviation Industry: The Rise of Electric Propulsion Systems

In recent years, the aviation industry has been at the forefront of technological innovation, with a notable shift towards sustainable and efficient propulsion systems. One of the most promising developments in this realm is the emergence of electric propulsion systems, which are poised to revolutionize aircraft design and operation. This article explores the advancements and potential impact of electric propulsion in aviation.

Understanding Electric Propulsion Systems

Electric propulsion systems in aviation typically involve the use of electric motors powered by batteries or fuel cells to drive propellers or fans. Unlike traditional combustion engines, electric propulsion offers several advantages, including lower emissions, reduced noise levels, and potentially lower operating costs. These systems leverage advancements in battery technology and electric motor efficiency to deliver comparable performance to conventional engines while minimizing environmental impact.

Types of Electric Propulsion Systems

Hybrid-Electric Systems: Hybrid-electric propulsion systems combine traditional combustion engines with electric motors and batteries. These systems optimize fuel efficiency by allowing the combustion engine to operate at its most efficient RPM while using electric power for additional thrust during takeoff and climb phases. They offer flexibility and redundancy, making them suitable for various aircraft sizes and mission profiles.

All-Electric Systems: All-electric propulsion systems rely entirely on electric motors powered by batteries or fuel cells. These systems eliminate the need for traditional fossil fuels, offering zero-emission flight capabilities. While current battery technology limits the range and endurance of all-electric aircraft, ongoing research and development aim to overcome these challenges, paving the way for sustainable long-haul aviation.

Benefits and Challenges

Environmental Benefits: Electric propulsion systems significantly reduce greenhouse gas emissions and noise pollution compared to conventional jet engines. They contribute to cleaner air quality and support global efforts to mitigate climate change.

Operational Challenges: The adoption of electric propulsion systems in commercial aviation faces challenges such as battery weight, energy density, and infrastructure for charging or hydrogen refueling. Addressing these challenges requires collaborative efforts from industry stakeholders, regulators, and research institutions.

Future Outlook

The future of electric propulsion in aviation looks promising, driven by advancements in battery technology, electric motor efficiency, and renewable energy sources. Manufacturers and airlines are investing in research and development to commercialize electric aircraft for regional and short-haul routes initially, with long-term aspirations for larger, transcontinental flights. Regulatory frameworks and infrastructure developments will play a crucial role in accelerating the adoption of electric propulsion systems and integrating them into global aviation networks.

Conclusion

Electric propulsion systems represent a paradigm shift in the aviation industry, offering sustainable alternatives to conventional jet engines. As technology continues to evolve and barriers are overcome, electric aircraft are poised to redefine air travel, making it cleaner, quieter, and more efficient. The ongoing collaboration between industry leaders, innovators, and policymakers will shape the future of electric aviation and contribute to a more sustainable aviation ecosystem worldwide.

0 notes

Text

Unlocking Efficiency: The Essential Guide to Using a Magneto Timing Tool

In the world of engine maintenance and performance optimization, one tool stands out as a game-changer: the magneto timing tool. In this comprehensive guide, we will delve into everything you need to know about this tool, from its basic functionality to advanced usage tips, helping you unlock maximum efficiency and power for your engine.

Introduction

Ignition timing plays a crucial role in the performance of internal combustion engines. The precise synchronization of spark timing with the engine's piston movement ensures optimal power output and fuel efficiency. This is where a magneto timing tool comes into play, allowing mechanics and enthusiasts to fine-tune ignition timing with accuracy and ease.

What is a Magneto Timing Tool?

A magneto timing tool is a specialized device designed to adjust the timing of a magneto ignition system. It consists of components such as a timing disc, timing light, and various attachments for different engine types. By using a magneto timing tool, you can precisely set the timing of the ignition system to achieve optimal engine performance.

Why Use a Magneto Timing Tool?

The benefits of using a magneto timing tool are manifold. Firstly, it ensures that the spark occurs at the right moment during the engine's cycle, leading to improved combustion efficiency. This, in turn, results in better fuel economy and reduced emissions. Additionally, a properly timed ignition system enhances engine power and overall performance, making it a must-have tool for anyone serious about engine tuning.

Types of Magneto Timing Tools

There are several types of magneto timing tools available, each catering to specific engine configurations and requirements. These include handheld timing lights, digital timing tools, and specialized kits for vintage or high-performance engines. Choosing the right type of tool depends on factors such as engine model, ignition system design, and personal preferences.

How to Use a Magneto Timing Tool

Using a magneto timing tool may seem daunting at first, but it's a straightforward process with the right guidance. Here's a step-by-step guide to help you get started:

Prepare Your Engine: Ensure the engine is turned off and cool before beginning the timing adjustment process.

Locate the Magneto: Identify the magneto ignition system on your engine, usually near the flywheel or crankshaft.

Connect the Timing Light: Attach the timing light to the spark plug wire of the cylinder you're timing.

Set the Timing Disc: Place the timing disc on the engine's crankshaft or designated timing mark.

Start the Engine: Start the engine and aim the timing light at the timing marks on the timing disc.

Adjust the Timing: Use the magneto timing tool to adjust the timing until the timing marks align as per specifications.

Verify and Fine-Tune: Double-check the timing marks and make any necessary fine-tuning adjustments for perfect timing.

Common Mistakes to Avoid

While using a magneto timing tool, certain common mistakes can lead to inaccurate timing and subpar engine performance. Avoid these pitfalls by:

Ensuring the engine is at operating temperature before timing adjustments.

Using the correct timing specifications for your engine model and type.

Checking for any mechanical issues that could affect timing accuracy, such as worn components or loose connections.

Following the manufacturer's instructions and guidelines for your specific magneto timing tool.

Maintenance and Care

Proper maintenance and care of your magneto timing tool are essential to ensure its longevity and accuracy. Regularly clean the tool, inspect for any wear or damage, and store it in a dry, secure place when not in use. Additionally, calibrate the tool as needed to maintain precise timing adjustments.

FAQs About Magneto Timing Tools

Can a magneto timing tool be used on all engine types?

Magneto timing tools are designed to work with a wide range of engine configurations. However, it's crucial to ensure compatibility with your specific engine model and ignition system.

How often should I check and adjust ignition timing?

It's recommended to check and adjust ignition timing as part of regular engine maintenance or whenever you notice changes in performance or fuel consumption.

Can I use a magneto timing tool without prior experience?

While basic mechanical knowledge is helpful, many magneto timing tools come with user-friendly instructions and guides to assist beginners in the timing adjustment process.

Conclusion

In conclusion, a magneto timing tool is a must-have tool for anyone looking to optimize engine performance and efficiency. Whether you're a professional mechanic or a DIY enthusiast, investing in a quality magneto timing tool can lead to significant improvements in your engine's operation.

At Complete Sourcing Solutions, we understand the importance of having the right tools for the job. As an ASAP Semiconductor-owned and operated purchasing platform, we provide access to a vast inventory of new, used, and hard-to-find products from leading manufacturers. Explore our selection today and experience the difference that precision timing can make in your engine's performance. Get started with our online RFQ service for quick and tailored solutions to your part fulfillment needs.

#MagnetoTimingTool#EnginePerformance#IgnitionTiming#MechanicTips#AutomotiveTools#ToolMaintenance#EngineTuning

0 notes

Photo

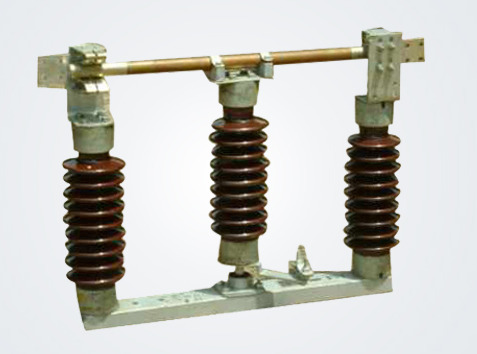

Purchase isolators parts Now Online

Visit Complete Sourcing Solution and get your parts within 24 hrs after order

For Purchase:https://buff.ly/2Ek2LrV

0 notes

Text

Purches at one click best quality #currentsensors from #CompleteSourcingSolutions For Purchase: https://www.completesourcingsolutions.com/electronic/part-types/current-sensors/

0 notes