Don't wanna be here? Send us removal request.

Text

The impact of concrete printing on an organization

Since there is no need for a mold the company can reduces costs on material and manpower making the molds. This means waste is reduced, which contributes to environmental awareness. Components can be made offsite at lower costs, while building onsite can be done to create more freedom of design at the exterior of a building.

The houses that are build using this method have lower operation costs, since less employees and less resources are needed in the process.

A possible impact on a company is the opportunity of creating a new product portfolio and increasing the service level by making spare parts and/or renting out the 3D printer.

0 notes

Text

A flowchart about how to print a concrete house

3D concrete printing brings lots of benefits, including the fact that it becomes easier to build a liveable house. The entire proces is about placing layers upon layers of concrete until you have reach the planned height of the walls. If necessary, isolation could be added after the walls have been constructed. When these things are done you start with finishing all the different components of the house, like the window and door frames, electricity outlets, heating and everything a house needs.

0 notes

Text

A Succes!

The market was a succes. Our stand had videos and posters of the methods and materials of 3D concrete printing. There were other project groups and teachers that had to assess our stand and the presentation that we gave. They were very interested and enthousiastic! We talked about different compositions of concrete, the opportunities of 3D printing and the obstacles in this proces. It was a fun and interactive meeting and we would like to thank our teachers and fellow students for this.

0 notes

Text

Different subjects on the market

During the market we were asked to take a look at the subjects of the other groups. We first noticed that multiple groups had a technology regarding 3D printing. Unlike us, these subjects were about metal and plastic printing. It wasn’t a surprise that 3D printing was such a common topic, because it is part of the technological innovations which are currently most spoken about. There was also a group that spoke about industry 4.0 and how it could affect their respective industry. The conclusion however was that not every company would have a use for industry 4.0 because of the huge investment costs. The last group we talked to spoke about 5-axel milling. The biggest difference between 5-axel milling and regular milling work is that the object and the machine are both moving. This way you can mill cleaner lines and more complicated shapes.

0 notes

Text

Concrete printing on the market

Today you can visit our stand on the Technology Market of Fontys Hogescholen at Eindhoven. We’re looking forward to see you at our stand!

0 notes

Text

Company visit

Last Friday our research group went to Weber Beamix, later on called Beamix, to interview the head of R&D about the exciting developments on 3D concrete printing.

‘Current building methods are still the same as hundred years ago, we stack the bricks the same way as we did back then’. The most recent innovation was the usage of prefab components. Beamix makes many kinds of concrete mortars, with different specifications.

Developments in concrete printing where Beamix was involved:

- 2005: within 1.5 hours a wall of 2 metres was printed.

- 2017: A project where a cycling bridge was printed and implemented in Gemert.

- 2018: An independent printing site of Beamix and Bam was formed, where both experiments and real usage are combined. The companies can use the printer for making parts or do some more research. The printer at Beamix uses an arm and the printer of the TU/e is a gantry printer.

- During 2019 the first houses will be printed by Bam and Beamix in Meerveldhoven.

The technique can horizontally reinforce the concrete, by laying wires on top of a layer. But because of the need to create layers, the vertical reinforcement still needs development. When looking at building houses with 3D printing, the isolation will be done by having another output at the printer.

The concrete mortar itself:

The exact components were already mentioned at a previous post but during the interview the difference in mortars became clear. There are two types of printing, each with its own strengths and weaknesses.

The first type of mortar is used by Beamix. It is a mortar based on reology of the mortar. This means the concrete has certain specifications which create a mixture that is soft, but when energy is put into the mixture gets hard, so whenever a new layer of concrete is put on the previous layer, it is able to hold that weight. Because the concrete is still wet during a longer period of time the layers will attach very well to each other, which creates a strong product. The mortar will start to gain its strength after 1.5/2 hours. In the end this mortar will have a strength of 60 newton/ cm2.

The second type of mortar is used by Cybe, another company which researches 3D concrete printing. Cybe solved the basic problem of collapsing layers by using a mortar which dries very fast. The problem with this technique is the mortar dries fast and when a problem occurs, the pipes and pumps are likely to become obstructed. After this it is cheaper to replace the parts than try to clean the pump and/or pipes. The mortar almost instantly reaches its strength. In the end this mortar will have a strength of 10 to 12 newton/ cm2.

Advantage of 3D printing:

Positive sides of the development are:

A high level of digitalization, since it is no longer necessary to have sketches on paper because everything can be found in digital sketches. This aspect has potential to grow when all sketches are made into a parametric model, this way people can customize their home by adjusting the parameters and the model calculates every sketch automatically.

Freedom of design is also an advantage of the technique, since it is easier to make organic shapes.

Also the material usage can be reduced. You can think of metal beams which have an I-shape, which is also possible with concrete. The ability to choose in mortars gives an opportunity to make a certain part of the wall stronger. While walls in the current building way consist of the same material. The new building way can reduce building costs

0 notes

Text

5W2H and research question

Research question:

Which developments does 3D concrete printing have to make to become a method that will be used within the construction industry?

What:

· What technology? The chosen technology is 3D concrete printing for building houses.

· What are the relevant technical issues/specifications for this technology?

How many compositions of concrete can be printed with?

Can the current 3D concrete printers build large (multi story) houses?

Can people already live in these houses?

How many operators are needed for operating the 3D concrete printer?

What are the design options for the printer?

How long does it take to print the houses?

· What do you already know?

In test fases, only a few operators were needed, and the costs were low in comparison with the building process of a house in the ‘normal’ way.

The latest house built took 24 hours to print.

They have only built smaller houses up to 350 feet squared.

The houses need to conform to certain standards, which haven’t all been met yet.

· What do you not know and want to find out?

How many companies?

How much money invested?

How far in development?

Looking at concrete mixes?

Looking at private use?

Effect on jobs?

Effect on housing market?

Effect on companies? (like electric cars for manufacturers?)

Why?

· Why choose this question?

At the moment there is a shortage of houses in the Netherlands. The 3D printing of houses could solve this problem. The possibilities of 3D printing in itself are endless, this would be a huge step in its development.

· Which result do you expect?

The development concrete printing will have the coming years. What the influence of this development is on the construction industry.

· Who is your target audience?

Students who, just like us, started in their fourth year of industrial engineering.

Our teachers.

The construction industry.

Where?

There are multiple sites which provide information about the subject, with a few listed below. On Friday 15th of February we have an interview with a person from Weber Beamix.

· https://www.fundainbusiness.nl/meer/artikel-fib/3d-betonprinten-innoveert-bouw/

· https://www.deingenieur.nl/artikel/betonrobot-print-compleet-woonhuis

· https://cybe.eu/

· https://www.deingenieur.nl/artikel/eerste-industriele-betonprinter-in-gebruik

· https://www.rohaco.com/tu-eindhovengangtry-robot

· http://betonhuis-betonmortel.nl/beton-kenniscentrum/kennis-delen/dossiers/3d-betonprinten

· https://www.youtube.com/watch?v=f0HUHXE9mU4

· https://3dprintmagazine.eu/3d-betonprinten-verandert-bouwwerf-high-tech-productieomgeving/

· www.iconbuild.com

· http://www.arconiko.nl/onderwijs-2/3d-beton-printen/

When and who?:

Research is done for a few different subjects. These subjects are devided among the project group:

· Daan: Strengths and weaknesses of the product and the different applications;

· Rolf: The needed material;

· Udin: Other developments;

· Thomas: Machine parts.

Besides this, some interviews will be taken by the whole group.

Research is done in spare moments of time throughout the day. The interview(s) will take place on workdays after the scheduled hours.

How?:

Some of the gathered information is published on the blog.

The moment where all the information will be presented is at the market.

How much?:

This project will not cost any money.

The time we think it will cost is somewhere along the lines of 2 hours per group member per workday, not including the time spent at things like interviews.

0 notes

Text

Opinions from field experts

Coming friday the student group will interview experts at Weber Beamix about their opinion and experience on the developments and role in the 3D concrete printing field.

0 notes

Text

ICON

In March 2018, the non-profit ‘ICON’ unveiled their first 3D-printed house.

This house is an example of what is possible with 3D concrete printing. This single story, 600 square foot home was printed in less than 24 hours and the total cost for the house was no higher than $4.000,-. Another advantage is the low number of skilled workers that are needed for the construction.

Their goal is to begin printing homes on a greater scale in the U.S. beginning in 2019. The benefits mentioned above make 3D concrete printing very useful to tackle a great problem mankind is facing now. That problem is more than 1 billion people not having access to adequate housing. And ICON wants to be one of the leading parties in this front.

However, there may be some downfalls. Because this technique is relatively new and the house was only built in March 2018, there is no information about the durability of these houses.

Also because the house was built in Austin, Texas, it will not be exposed to every type of environment.

For now there are a lot of benefits to be named, but it has to be seen if they hold up for different areas and longer periods of time.

ICON is already working on a newer version of their 3D concrete printer, although it is not known when they will be able to release it.

0 notes

Text

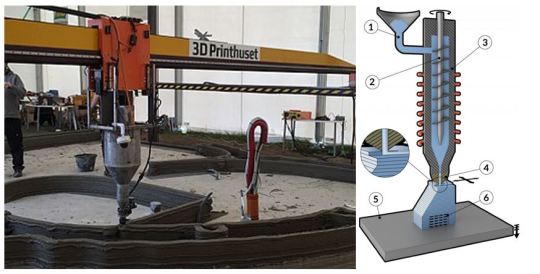

Components of a 3D concrete printer

In the image above a 3D concrete printer is shown and also a schematic view how the inside of a 3D printer looks like. In the following piece the different components are described, first of all there is a tube with the concrete mixtures, which has the purpose of supplying the printer with fresh material. The mixture has to be exactly right, otherwise the layers will not support each other or will not stick to each other (for more information on the mixture see my previous posts). Secondly there is a mixer inside the hopper which pushes the concrete to the nozzle, component number three is the hopper where a small amount of concrete is contained to ensure a consistent flow of concrete to the nozzle. The fourth component is the nozzle, which is set to a certain amount of concrete per minute. It is possible to adjust the nozzle when it is required to make smaller or larger layers. the fifth piece is the surface which the product is printed on. The sixth component is the product itself. In the first few hours the layers are not dry yet. After it has dried the structure get it’s intended strength.

0 notes

Text

Innovations with regards towards concrete printing

The usage of concrete within a 3D-printing proces has a wide range of possibilities. What started in the Netherlands with a bridge of 9 meters long has been surpassed with a bridge in Shanghai, China Which is over 26 meters long.

youtube

This bridge contains 44, hollow, 3D-printed blocks which were printed offsite and reconstructed on the planned location. The printing was done by two 3D-printers and together with the assembly it took just over 19 days to construct.

0 notes

Text

What is the subject?

The chosen subject is about 3D-printing of concrete in the contructionsector and the developments of this Technology. In the last twenty years 3D-printing of houses has been an upcoming trend, with one of the first houses build in China.

youtube

In 2018 the 3d printed houses are still not livable and only have a ground floor. The houses are still in the testphase. The concrete is brittle and not strong enough to be safe because the concrete isn’t reinforced with steel.

2019

The Technical University of Eindhoven is building 3D-printed houses in the region of Eindhoven. They will start with a house that only has a ground floor. After that one is finished they will try to build houses with a first and a second floor. The image below gives an illustration of the plan. The first house will be finished in May 2019.

0 notes

Text

Introduction

We are a group of four students who study Industrial Engineering and Management at Fontys university of applied sciences, currently participating in our fourth year in which we have to do research on a self chosen subject. The chosen subject is about 3D Concrete printing in the construction industry.

Who are we?

Daan van de Ven

Udin Wodak

Thomas Meurs

Rolf Reyntjes

0 notes