Don't wanna be here? Send us removal request.

Text

Leading Atchutapuram pharma companies

Exploring the Growth of Pharma Companies in Atchutapuram: A Rising Hub for Innovation

Atchutapuram, located in the Visakhapatnam district of Andhra Pradesh, has emerged as one of India's prominent hubs for the pharmaceutical industry. Home to a growing number of companies specializing in pharmaceuticals and chemicals, this region is becoming synonymous with innovation, quality, and operational excellence in the pharma sector. Among the many companies thriving in this area is Connex Pharma, a pioneer in the production of specialty chemicals like Hexamethyldisilazane (HMDS) and Chloromethyl Isopropyl Carbonate (CMIC).

The Rise of Atchutapuram as a Pharma Hub

The strategic location of Atchutapuram near Visakhapatnam, with excellent connectivity via road, rail, and sea, makes it an attractive destination for pharmaceutical companies. Over the past few years, this region has witnessed significant industrial growth, particularly in sectors like chemicals, pharmaceuticals, and biotechnology.

The Pharma City in Atchutapuram, set up by the Andhra Pradesh Industrial Infrastructure Corporation (APIIC), has been a critical driver of this growth. With state-of-the-art infrastructure and a business-friendly environment, the area has attracted several national and international players in the pharmaceutical industry.

Connex Pharma: A Leader in Specialty Chemicals

Among the key players in Atchutapuram, Connex Pharma stands out for its pioneering work in specialty chemicals. Operating from a sprawling 5.4-acre facility, Connex Pharma produces critical chemicals such as HMDS and CMIC, which are widely used in industries like pharmaceuticals, agrochemicals, and electronics. These chemicals are essential for the manufacturing of various medical products, pesticides, and electronic components.

Connex Pharma’s commitment to high-quality standards and safety is evident in its ISO 9001:2015 and ISO 14001:2015 certifications. These certifications highlight the company's dedication to quality management systems and sustainable business practices, both of which are crucial in today’s environmentally conscious world.

Advanced Facilities and Technology

Connex Pharma’s state-of-the-art facility in Atchutapuram is equipped with cutting-edge equipment and technology, allowing the company to consistently deliver high-quality products. The company’s team of seasoned professionals ensures that all operations meet the stringent requirements of their medical and industrial partners.

By adhering to Good Manufacturing Practices (GMP), Connex Pharma guarantees the safety, quality, and efficacy of its products. This adherence to industry best practices is particularly important for the pharmaceutical industry, where precision and reliability are non-negotiable.

The Future of Pharma in Atchutapuram

Atchutapuram is poised for even greater growth as more pharma companies recognize the potential of this region. The combination of government support, excellent infrastructure, and a pool of skilled professionals makes Atchutapuram a prime location for companies looking to expand their operations.

For companies like Connex Pharma, the future looks bright. By continuing to innovate and maintain their high standards of quality, they are well-positioned to be leaders not just in the specialty chemicals sector but in the broader pharmaceutical industry.

Conclusion

Atchutapuram is quickly establishing itself as a powerhouse in the pharmaceutical industry, attracting top companies with its favorable business environment and robust infrastructure. Connex Pharma, with its focus on quality, safety, and sustainability, exemplifies the kind of innovation and excellence that is driving the region's growth. As Atchutapuram continues to evolve, it is likely to play an increasingly important role in India's pharmaceutical landscape, contributing to both national and global health solutions.

0 notes

Text

Introduction: Understanding HMDS (Hexamethyldisilazane)

Introduction: Understanding HMDS (Hexamethyldisilazane)

HMDS, or Hexamethyldisilazane, might not be a household name, but in certain industries, it's nothing short of essential. It’s a versatile chemical compound used extensively in the electronics and semiconductor industries. But what exactly is HMDS? Why is it so crucial in these high-tech fields? And, just as important, what safety precautions should be followed when dealing with it?

In this post, we’ll break down the science behind HMDS, its industrial applications, the reasons for its popularity, and the critical safety protocols for handling it safely.

What is HMDS?

HMDS (chemical formula: [(CH₃)₃Si]₂NH) is an organosilicon compound, meaning it contains silicon atoms bonded to organic groups. This compound is a colorless liquid with an ammonia-like smell. Its molecular structure features two trimethylsilyl groups bonded to a nitrogen atom.

HMDS is known for its water-repellent properties and ability to react with surfaces to modify their characteristics. These properties make it useful in various niche applications, especially where surface treatment or preparation is essential.

Key Properties of HMDS:

Molecular Formula: [(CH₃)₃Si]₂NH

Appearance: Clear, colorless liquid

Odor: Ammonia-like smell

Boiling Point: ~126°C

Water Solubility: Low; it reacts with water, releasing ammonia

Primary Uses of HMDS

HMDS has numerous applications across industries. Let’s take a closer look at some of its most common uses:

1. Semiconductor and Electronics Industry

The semiconductor industry is perhaps the largest consumer of HMDS. It is used as a surface preparation agent in microelectronics manufacturing. Before photolithography—a key process in producing microchips—HMDS is applied to silicon wafers to make the surface more hydrophobic (water-repellent). This allows photoresist to adhere more uniformly, resulting in higher-quality chips.

Why it matters: In the world of electronics, even the tiniest imperfection can cause significant defects in microchips. HMDS helps ensure a smooth surface, improving the overall yield and quality of these intricate components.

2. Adhesion Promoter

HMDS works as an adhesion promoter, not only in semiconductor manufacturing but also in other fields. It is often applied as a primer to improve the bond between surfaces that wouldn’t naturally adhere well. For instance, in certain polymer coatings, HMDS creates a more reactive surface, ensuring better adhesion of other materials.

3. Laboratory Uses

HMDS also has its place in research laboratories. It's used as a siliconizing agent, particularly in organic synthesis. Chemists apply it to glass surfaces in laboratory equipment to render them hydrophobic, minimizing unwanted reactions during experiments. Additionally, HMDS is sometimes used in chemical reactions to protect hydroxyl groups, which are part of many organic molecules.

4. Organic Synthesis

In organic chemistry, HMDS is used to convert alcohols into their corresponding trimethylsilyl ethers, which are more stable and less reactive. This allows chemists to temporarily protect these groups during reactions, preventing unwanted side reactions and making complex organic syntheses more manageable.

Handling HMDS: Safety Considerations

Like many industrial chemicals, HMDS must be handled with care. While it’s widely used, improper handling can pose health and safety risks. Here are the key safety measures that should be followed:

1. Personal Protective Equipment (PPE)

When working with HMDS, wearing the right personal protective equipment is critical. This includes:

Gloves (typically nitrile gloves to prevent skin contact)

Safety goggles or face shields (to protect the eyes from splashes)

Lab coats or aprons (to prevent contact with clothing)

Proper ventilation or fume hoods (since HMDS can emit vapors that irritate the respiratory system)

2. Fire Safety

HMDS is flammable, so it should always be stored away from open flames or sources of heat. Ensure fire extinguishers are nearby when working with this chemical, and avoid creating static electricity that might ignite vapors.

3. Chemical Reactivity

HMDS reacts with water, releasing ammonia and sometimes creating hazardous fumes. It's important to store HMDS in airtight containers in dry environments and keep it away from any moisture to prevent this reaction.

4. Disposal of HMDS

Proper disposal of HMDS is a must. It cannot simply be poured down the drain or thrown out with regular trash. Instead, it should be disposed of as hazardous waste, following your local regulations for chemical disposal.

Benefits of Using HMDS

1. Enhanced Performance in Semiconductor Manufacturing

The major benefit of HMDS is its ability to improve the adhesion of photoresist in semiconductor processing. By ensuring a smoother, hydrophobic surface, it significantly enhances the quality and reliability of semiconductor components, which are the backbone of modern technology.

2. Surface Modification Capabilities

HMDS’s ability to alter the surface characteristics of materials makes it invaluable in numerous applications beyond electronics, from biotechnology to materials science.

3. Versatility in Organic Chemistry

In organic synthesis, HMDS’s role as a protecting agent gives chemists more control over complex reactions, allowing for the creation of intricate molecules with precision.

FAQs About HMDS

Q1: Is HMDS safe to use?Yes, but only with proper precautions. As a flammable and reactive chemical, HMDS requires careful handling, appropriate PPE, and adherence to safety protocols to avoid accidents.

Q2: What industries rely on HMDS the most?The semiconductor and electronics industries are the largest users, but it’s also commonly used in organic chemistry and material science research.

Q3: Can HMDS be mixed with water?No, HMDS reacts with water, releasing ammonia. It should be kept dry at all times to prevent unwanted chemical reactions.

Q4: How is HMDS stored?HMDS should be stored in airtight containers, away from moisture and heat sources, in a well-ventilated area.

Wrapping Up: The Importance of HMDS

HMDS is a critical compound in various high-tech industries, especially in semiconductor and microelectronics manufacturing. It’s versatile, offering benefits that range from improving adhesion in chip production to protecting delicate molecules in organic chemistry. However, its usefulness comes with the need for stringent safety measures to avoid accidents and ensure smooth operations.

By understanding what HMDS is, how it’s used, and how to handle it safely, industries and research labs can maximize its benefits while minimizing risks.

0 notes

Text

chloromethyl isopropyl carbonate distributors

Connex Pharma: Your Trusted CMIC Distributor

About Chloromethyl Isopropyl Carbonate (CMIC)

Chloromethyl Isopropyl Carbonate, commonly known as CMIC, is a versatile chemical compound with significant applications in the pharmaceutical industry. As an antiviral agent and crucial intermediate, CMIC plays a vital role in the synthesis of various pharmaceutical drugs, including:

Anti-inflammatory medications

Anti-tumor agents

Antidepressants

Connex Pharma: A Leading CMIC Distributor

Founded in 2016, Connex Pharma has quickly established itself as one of the top chloromethyl isopropyl carbonate distributors in the market. Our success is built on a foundation of:

Hard work

Consistency

Innovation

Our Advantages

State-of-the-Art Facility: Our production facility, spread across 5.4 acres, provides ample space for all operational needs.

GMP Compliance: Our facility adheres to Good Manufacturing Practice (GMP) norms, giving us an edge with international clients.

Client-Centric Approach: We work closely with our clients to deliver tailored solutions of the highest quality and efficacy.

Extensive Portfolio: In addition to CMIC, we offer a wide range of other drug intermediates.

Why Choose Connex Pharma?

As a leading pharmaceutical manufacturer in India, Connex Pharma stands out for its commitment to quality, innovation, and customer satisfaction. Our team, built from the ground up, is dedicated to meeting the diverse demands of our clients according to their specific needs.

For all your CMIC and pharmaceutical intermediate requirements, trust Connex Pharma to deliver excellence.

0 notes

Text

Hexamethyldisilazane (HMDS) Manufacturers in india

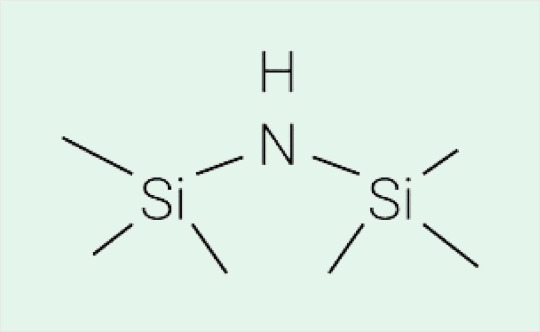

The chemical structure of Hexamethyldisilazane (HMDS) is represented as follows:

H H H H

\ / \ /

Si --- Si

/ \ / \

H H H H

In a more detailed representation, it can be shown as:

Molecular Formula: C6H19N1Si2\text{C}_6\text{H}_{19}\text{N}_1\text{Si}_2C6H19N1Si2

Structural Formula: (CH3)3Si-N(Si(CH3)3)2\text{(CH}_3\text{)}_3\text{Si-N(Si(CH}_3\text{)}_3\text{)}_2(CH3)3Si-N(Si(CH3)3)2

This structure includes two silicon atoms (Si) bonded to a nitrogen atom (N), with each silicon atom connected to three methyl groups (–CH₃). Let me know if you need more information!

0 notes

Text

Trimethylsilyl Chloride in India

Trimethylsilyl Chloride in India

Trimethylsilyl Chloride (TMSC) is a versatile chemical compound with significant applications across various industries. Its chemical formula is C3H9ClSi, and it plays a crucial role in chemical synthesis, pharmaceuticals, and electronics. In this article, we will explore the presence, uses, and market trends of Trimethylsilyl Chloride in India, highlighting its importance and relevance.

What is Trimethylsilyl Chloride?

Chemical Composition

Trimethylsilyl Chloride is a silyl chloride with a simple yet impactful molecular structure. It consists of a silicon atom bonded to three methyl groups and one chlorine atom. The chemical formula is C3H9ClSi, indicating its composition.

Properties

Trimethylsilyl Chloride is a colorless liquid with a pungent odor. It is highly reactive and readily hydrolyzes in the presence of water, forming hydrochloric acid and trimethylsilanol. Its volatility and reactivity make it a valuable compound in various chemical processes.

Applications of Trimethylsilyl Chloride

In Chemical Synthesis

Trimethylsilyl Chloride is extensively used in chemical synthesis, especially for the protection of functional groups in organic reactions. For example, it can convert alcohols into trimethylsilyl ethers, which are more stable and less reactive during synthesis.

In Pharmaceuticals

In the pharmaceutical industry, Trimethylsilyl Chloride plays a vital role in drug development. It is used in the synthesis of various pharmaceuticals, including antibiotics and anticancer agents, by facilitating the formation of silyl derivatives.

In the Electronics Industry

The electronics industry benefits from Trimethylsilyl Chloride in the production of silicone-based materials. It is used to create silicone polymers and resins, which are essential for insulating and protecting electronic components.

Trimethylsilyl Chloride in India

Production and Supply

India hosts several manufacturers and suppliers of Trimethylsilyl Chloride. Prominent companies, such as Connex Pharma, are key players in the Indian market, ensuring a steady supply of this critical chemical. Connex Pharma's detailed overview provides insights into the production and supply landscape in India.

Demand and Market Trends

The demand for Trimethylsilyl Chloride in India is on the rise, driven by its applications in various industrial and research sectors. Recent market trends indicate a growing interest in its use in emerging technologies and expanding industries.

Regulatory and Safety Considerations

Regulatory Framework

In India, the use and handling of Trimethylsilyl Chloride are regulated to ensure safety and compliance with national standards. Regulations cover aspects such as storage, transportation, and usage to prevent accidents and environmental harm.

Safety and Handling

Proper safety precautions are essential when working with Trimethylsilyl Chloride. It should be stored in a cool, dry place away from moisture. Personal protective equipment (PPE) such as gloves and goggles should be worn to prevent exposure. Handling procedures must include protocols for dealing with spills and accidental releases.

Challenges and Opportunities

Market Challenges

The Indian market for Trimethylsilyl Chloride faces challenges such as supply chain disruptions and fluctuating costs. These issues can impact availability and pricing, affecting industries reliant on this chemical.

Growth Opportunities

Despite the challenges, there are significant growth opportunities in the Indian market. The expansion of applications in new industries and technological advancements offer potential for market growth. For example, the development of advanced materials and pharmaceuticals could drive increased demand.

Conclusion

Trimethylsilyl Chloride is a vital compound with diverse applications in chemical synthesis, pharmaceuticals, and electronics. Its role in India’s industrial landscape is increasingly important, driven by growing demand and technological advancements. Looking ahead, the market for Trimethylsilyl Chloride in India is poised for expansion, with opportunities for innovation and growth.

References

For more information, visit Connex Pharma’s comprehensive overview of Trimethylsilyl Chloride in India: Connex Pharma Article.

0 notes

Text

Pharma intermediates Manufacturers

Pharma intermediates play a crucial role in the pharmaceutical manufacturing process. They serve as essential building blocks for the production of various drugs and treatments. Choosing a reliable manufacturer for these intermediates is vital to ensure quality, compliance, and efficiency in drug production. This article highlights the top 10 pharma intermediate manufacturers in India, providing insights into their offerings, certifications, and contact details to help you make an informed choice.

What Are Pharma Intermediates?

Pharma intermediates are chemical compounds used in the synthesis of active pharmaceutical ingredients (APIs) and other pharmaceutical products. They act as intermediaries in the manufacturing process, bridging the gap between raw materials and final drug products.

Examples of Commonly Used Intermediates

Cyclohexane: Used in the production of various pharmaceuticals.

2,5-Dichloroaniline: An intermediate in the synthesis of antihistamines and other drugs.

Criteria for Evaluating Pharma Intermediate Manufacturers

When selecting a pharma intermediate manufacturer, several factors should be considered to ensure quality and reliability.

Quality Control Measures

GMP Compliance: Manufacturers should adhere to Good Manufacturing Practices to ensure product safety and consistency.

Example: Connex Pharma is GMP-certified, which underscores its commitment to high-quality production standards.

Manufacturing Capabilities

Production Capacity: Evaluate the manufacturer’s ability to handle large volumes and diverse product requirements.

Example: SRF Limited offers a range of specialty chemicals and intermediates, demonstrating robust production capabilities.

Regulatory Approvals

Certifications: Ensure the manufacturer holds relevant certifications such as FDA or WHO approvals.

Example: Camlin Fine Sciences Ltd. has FDA approvals for its products, ensuring they meet international standards.

Customer Service and Support

After-Sales Service: Good manufacturers offer comprehensive customer support and technical assistance.

Example: Balaji Amines Ltd. provides detailed technical support and customer service to its clients.

Top 10 Pharma Intermediate Manufacturers in India

1. Connex Pharma

Connex Pharma is renowned for its high-quality pharma intermediates. The company focuses on specialty intermediates for various therapeutic areas.

Key Products and Services: Specialty intermediates for pharmaceuticals.

Certifications: GMP, ISO.

Contact Information and Website URL: Connex Pharma

2. Aarti Industries Ltd.

Aarti Industries Ltd. is a leading manufacturer of custom intermediates, known for its innovation and quality control.

Key Products and Services: Custom synthesis of intermediates.

Certifications: ISO 9001.

Contact Information and Website URL: Aarti Industries

3. SRF Limited

SRF Limited offers a wide range of specialty chemicals and intermediates, supported by advanced manufacturing facilities.

Key Products and Services: Specialty chemicals and intermediates.

Certifications: GMP compliance.

Contact Information and Website URL: SRF Limited

4. Balaji Amines Ltd.

Balaji Amines Ltd. specializes in the production of aliphatic amines and related intermediates.

Key Products and Services: Aliphatic amines and intermediates.

Certifications: ISO 14001.

Contact Information and Website URL: Balaji Amines

5. Camlin Fine Sciences Ltd.

Camlin Fine Sciences Ltd. is known for its production of antioxidants and specialty intermediates, with a strong focus on quality and regulatory compliance.

Key Products and Services: Antioxidants and specialty intermediates.

Certifications: FDA approval.

Contact Information and Website URL: Camlin Fine Sciences

6. Meghmani Organics Ltd.

Meghmani Organics Ltd. provides organic intermediates primarily for dyes and pigments, with an emphasis on environmental compliance.

Key Products and Services: Organic intermediates for dyes and pigments.

Certifications: ISO certifications.

Contact Information and Website URL: Meghmani Organics

7. Fine Organics Industries Ltd.

Fine Organics Industries Ltd. offers specialty additives and intermediates, focusing on high-quality production processes.

Key Products and Services: Specialty additives and intermediates.

Certifications: GMP, ISO.

Contact Information and Website URL: Fine Organics

8. Tanfac Industries Ltd.

Tanfac Industries Ltd. specializes in fluoride-based intermediates, supported by a robust manufacturing infrastructure.

Key Products and Services: Fluoride-based intermediates.

Certifications: ISO 9001.

Contact Information and Website URL: Tanfac Industries

9. Navin Fluorine International Ltd.

Navin Fluorine International Ltd. is a key player in the production of fluorinated intermediates, known for its technological expertise.

Key Products and Services: Fluorinated intermediates.

Certifications: GMP, ISO.

Contact Information and Website URL: Navin Fluorine

10. Vinati Organics Ltd.

Vinati Organics Ltd. manufactures a range of specialty chemicals and intermediates, with a focus on quality and regulatory compliance.

Key Products and Services: Specialty chemicals and intermediates.

Certifications: FDA, ISO.

Contact Information and Website URL: Vinati Organics

Conclusion

Choosing the right pharma intermediate manufacturer is essential for ensuring the quality and efficacy of pharmaceutical products. The top 10 manufacturers listed in this article represent some of the best options available in India, each offering a range of high-quality intermediates and strong regulatory compliance. Evaluate these manufacturers based on your specific needs, and don’t hesitate to reach out for more detailed information or inquiries.

0 notes

Text

Pharma Intermediates Manufacturers

Definition of Pharmaceutical Intermediates

Pharmaceutical intermediates are chemical substances used as raw materials or building blocks in the synthesis of active pharmaceutical ingredients (APIs) and finished drugs. These intermediates play a critical role in the drug manufacturing process, bridging the gap between basic chemicals and complex pharmaceuticals.

Importance of Suppliers in the Pharmaceutical Industry

Suppliers of pharmaceutical intermediates are essential to the pharmaceutical supply chain. They provide the necessary chemicals and compounds that pharmaceutical companies use to create medications. The reliability, quality, and cost-effectiveness of these suppliers can significantly impact drug production efficiency and quality.

Types of Pharmaceutical Intermediates

Primary Intermediates

Primary intermediates are the initial chemicals transformed into more complex substances during drug synthesis.

Examples:

Benzyl Chloride: Used in the production of various APIs and chemical compounds.

Acetic Anhydride: Commonly used in the manufacture of aspirin and other pharmaceutical products.

Usage: These intermediates are crucial in the early stages of drug development, providing the foundational chemical structures needed for more complex synthesis.

Secondary Intermediates

Secondary intermediates are chemicals used in subsequent stages of pharmaceutical manufacturing, often for refining or modifying primary intermediates.

Examples:

1,3-Butadiene: Utilized in creating synthetic rubbers and polymers used in drug delivery systems.

Ethyl Acetate: Employed as a solvent in various pharmaceutical formulations.

Role: These intermediates help in fine-tuning the properties of APIs and improving the efficiency of the production process.

Key Considerations When Choosing Pharmaceutical Intermediates Suppliers

Quality Assurance

When selecting a supplier, ensuring high-quality standards is paramount. Suppliers must adhere to rigorous quality control measures.

Compliance: Suppliers should comply with Good Manufacturing Practices (GMP) to ensure the safety and efficacy of intermediates.

Examples of Certifications: ISO 9001 for quality management systems, cGMP for current good manufacturing practices.

Supply Chain Reliability

A reliable supply chain is crucial for maintaining consistent production schedules and avoiding disruptions.

Factors: Look for suppliers with a proven track record of timely delivery and robust logistical capabilities.

Example: Geopolitical issues, such as trade restrictions, can impact the stability of supply chains, making it important to choose suppliers with diversified sources and contingency plans.

Cost Efficiency

Balancing cost with quality is vital for maintaining profitability while ensuring the efficacy of pharmaceutical products.

Balancing Act: Evaluate the total cost of ownership, including potential cost savings from bulk purchases versus the flexibility of single orders.

Example: Bulk purchases may offer lower per-unit costs but require higher upfront investment, while single orders offer flexibility but might be more expensive per unit.

Leading Pharmaceutical Intermediates Suppliers

Connex Pharma

Connex Pharma is a pioneer in the production of speciality chemicals like Hexamethyldisilazane (HMDS) and Chloromethyl Isopropyl Carbonate (CMIC). These chemicals are used in various industries, including pharmaceuticals, agrochemicals, and electronics.

Overview: The company offers a wide range of intermediates used in various pharmaceutical applications.

Specializations: Known for their advanced intermediate manufacturing processes and adherence to stringent quality standards\

Visit the website now to knowmore !

Conclusion

Summary of Key Points

Choosing the right supplier for pharmaceutical intermediates is crucial for ensuring drug quality and production efficiency. Key factors include quality assurance, supply chain reliability, and cost efficiency.

0 notes

Text

CAS No. 999-97-3 Manufacturers

Introduction to CAS No. 999-97-3

Overview of CAS Numbers

Chemical Abstracts Service (CAS) Numbers are unique identifiers assigned to every chemical substance described in the scientific literature. They facilitate the precise identification and differentiation of chemicals, crucial for researchers, manufacturers, and regulatory bodies alike. CAS numbers are used globally to avoid confusion between chemicals with similar names or structures.

Introduction to CAS No. 999-97-3

CAS No. 999-97-3 corresponds to Hexamethyldisilazane (HMDS), a chemical compound frequently used in various industrial and research applications. Known for its distinctive chemical properties, Hexamethyldisilazane plays a vital role in the synthesis and modification of chemicals.

Medical and Laboratory Uses

In laboratory settings, Hexamethyldisilazane is used as a derivatizing agent, particularly in gas chromatography. This application allows for the analysis of non-volatile compounds by converting them into more volatile forms. Its role in research and quality control is pivotal for accurate and efficient analysis.

Medical Oxygen Generators

While Hexamethyldisilazane itself is not directly involved in medical oxygen generation, it may play a role in the production and purification processes by assisting in the maintenance and calibration of equipment used in oxygen generation. For insights into how medical oxygen generators work, visit Connex Pharma.

Safety and Handling

Safety Guidelines

Handling Hexamethyldisilazane requires careful attention to safety protocols due to its chemical reactivity. Key safety measures include:

Personal Protective Equipment (PPE): Use gloves, safety goggles, and lab coats to avoid skin and eye contact.

Ventilation: Work in a well-ventilated area or under a fume hood to prevent inhalation of fumes.

Storage and Disposal

Storage: Store Hexamethyldisilazane in a cool, dry place, away from moisture and incompatible substances.

Disposal: Follow local regulations for chemical waste disposal. Avoid direct discharge into the environment and consult safety data sheets (SDS) for specific disposal instructions.

Emergency Measures

In case of exposure or spills:

First Aid: In case of skin contact, wash thoroughly with soap and water. If inhaled, move to fresh air immediately.

Spill Response: Contain spills using inert materials like sand or vermiculite. Dispose of residues according to local regulations.

Regulatory and Environmental Considerations

Regulatory Status

Hexamethyldisilazane must comply with various chemical safety regulations. It is essential to review labeling and safety data sheets (SDS) for detailed regulatory information and safety instructions.

Environmental Impact

Environmental Risks: Potential risks include chemical runoff or accidental spills, which could impact water sources or soil quality.

Waste Management: Implement strategies to minimize waste, such as recycling or neutralizing chemicals before disposal.

Conclusion

Summary of Key Points

Hexamethyldisilazane (CAS No. 999-97-3) is a versatile chemical compound used in various industrial and laboratory applications. Its unique properties make it valuable in chemical synthesis, surface modification, and analytical chemistry. Proper handling and disposal are crucial to ensuring safety and minimizing environmental impact.

Future Outlook

Ongoing research may reveal new applications for Hexamethyldisilazane and improvements in safety and efficiency. Advances in chemical technologies and environmental regulations will likely shape the future use and management of this compound.

0 notes

Text

Pharmaceutical intermediates suppliers

Introduction

Overview of Pharmaceutical Intermediates

Pharmaceutical intermediates are crucial compounds used in the synthesis of active pharmaceutical ingredients (APIs) and finished drug products. They act as building blocks in the production process, ensuring the efficacy, safety, and quality of medications. These intermediates are typically produced through chemical reactions and play a vital role in the pharmaceutical supply chain.

What Are Pharmaceutical Intermediates?

Definition and Characteristics

Pharmaceutical intermediates are chemical substances used during the manufacturing process of APIs. They are not directly used as drugs but are essential for the synthesis of the final pharmaceutical product. For example, benzyl alcohol and ethyl acetate are common intermediates used in the production of various medications.

Types of Pharmaceutical Intermediates

Active Pharmaceutical Ingredients (APIs)

These are the active components in a drug that produce the desired effect.

Example: Penicillin used in antibiotics.

Auxiliary Intermediates

These support the API in achieving the final drug formulation.

Example: Solvents and reagents.

Fine Chemicals

These are high-purity chemicals used in small quantities for specific pharmaceutical applications.

Example: Specialty reagents for research and development.

Why Are Pharmaceutical Intermediates Important?

Critical Role in Drug Development

Pharmaceutical intermediates ensure the quality and efficacy of the final pharmaceutical product. They are involved in critical stages of drug synthesis, impacting the purity and effectiveness of the medication. For instance, intermediates used in the synthesis of antibiotics must meet stringent quality standards to ensure the drug’s therapeutic efficacy.

Impact on Cost and Efficiency

The choice of intermediates affects the overall cost and efficiency of drug production. Cost-effective intermediates can lower production costs, while high-quality intermediates can enhance the drug's performance. For example, using a more efficient solvent can reduce both material costs and processing time.

How to Choose a Pharmaceutical Intermediates Supplier

Key Criteria for Selection

Quality Assurance and Compliance

Ensure the supplier adheres to certification standards such as Good Manufacturing Practice (GMP) and ISO certifications.

Example: A supplier with GMP certification ensures that the intermediates are produced under strict quality control measures.

Reputation and Experience

Assess the supplier’s track record and experience in the industry. Look for testimonials and case studies that demonstrate successful collaborations.

Example: A supplier with a long-standing reputation in the pharmaceutical industry is more likely to offer reliable products and services.

Cost and Supply Chain Efficiency

Evaluate the supplier’s pricing models and delivery capabilities. Consider the total cost of ownership, including logistics and potential delays.

Example: A supplier offering competitive pricing and reliable delivery schedules can significantly impact your production timelines and cost efficiency.

Top Pharmaceutical Intermediates Suppliers

Connex Pharma

Connex Pharma is renowned for its extensive range of pharmaceutical intermediates and its commitment to quality and compliance.

Product Range and Specializations

Specializes in intermediates for various therapeutic categories, including antibiotics and antivirals.

Key Strengths and Market Presence

Known for high-quality standards and a robust supply chain.

URL: https://www.connexpharma.in/

Conclusion

Summary of Key Points

Pharmaceutical intermediates are essential in drug manufacturing and significantly impact the final product's quality and cost.

Choosing the right supplier involves evaluating their quality assurance practices, reputation, and supply chain efficiency.

0 notes

Text

TMCS Manufacturers

Introduction to TMCS Manufacturers

Trimethylchlorosilane (TMCS) plays a crucial role in various industries, serving as a versatile precursor in the production of silicones, pharmaceuticals, and specialty chemicals. Reliable TMCS manufacturers are essential for ensuring consistent supply chains and maintaining product quality.

Key Characteristics of Trusted TMCS Manufacturers

Quality Standards and Certifications

TMCS manufacturers adhere to stringent quality standards such as ISO 9001:2015.

Compliance with regulatory requirements (e.g., REACH, FDA) ensures product safety and reliability.

Manufacturing Capacity and Capability

Advanced production facilities equipped with state-of-the-art technology.

Ability to scale production to meet varying market demands.

Factors Influencing Choice of TMCS Manufacturers

Reputation and Market Standing

Established manufacturers with a proven track record of reliability.

Positive customer feedback and testimonials reinforce trustworthiness.

Geographic Reach and Distribution Network

Global manufacturers offer extensive logistics and distribution networks.

Regional manufacturers provide localized support and quicker delivery times.

Prominent TMCS Manufacturers in the Market

Example:Connex Pharma

Overview of Connex Pharma

Operating out of our 5.4-acre facility in Visakhapatnam, Andhra Pradesh, we place a strong emphasis on maintaining high-quality standards, safety, and reliability of all our undertakings. We hold certifications for ISO 9001:2015 and 14001:2015, cementing our commitment towards solid quality management systems and sustainable business practices

Product Offerings and Specialization

Connex Pharma offers high-purity TMCS with customizable packaging options.

Applications span across industries including electronics and pharmaceuticals.

Choosing the Right TMCS Manufacturer: Considerations and Tips

Assessing Product Quality and Purity

Manufacturers provide detailed Certificates of Analysis (CoA) to verify product specifications.

Rigorous testing methods ensure consistency and purity.

Evaluating Supplier Reliability

Effective supply chain management practices ensure timely deliveries.

Responsive customer support and contingency planning for emergencies.

Future Trends in TMCS Manufacturing

Innovations in Production Techniques

Adoption of green chemistry initiatives to minimize environmental impact.

Improved process efficiencies through technological advancements.

Market Outlook and Growth Projections

Anticipated growth in demand from emerging markets.

Opportunities in niche applications driving innovation in TMCS manufacturing.

0 notes

Text

A Comprehensive Guide to Pharma Intermediate Manufacturers

A Comprehensive Guide to Pharma Intermediate Manufacturers

Introduction to Pharmaceutical Intermediates

Pharmaceutical intermediates are pivotal components in drug manufacturing, serving as precursor chemicals that undergo further modification to form active pharmaceutical ingredients (APIs). These substances play a crucial role in bridging the gap between raw materials and final drug products.

Importance of High-Quality Intermediates for Drug Efficacy and Safety

Ensuring Drug Efficacy: High-quality intermediates contribute directly to the efficacy and therapeutic effects of pharmaceutical products.

Enhancing Safety: Quality intermediates minimize the presence of impurities and ensure that drugs meet safety standards.

Regulatory Compliance: Meeting regulatory requirements, such as those set by the FDA and EMA, ensures that intermediates and final drugs are safe and effective for patient use.

Link to Final Drug Production and Regulatory Compliance

Critical Role: Intermediates serve as building blocks for APIs, influencing the final drug's characteristics and performance.

Regulatory Standards: Compliance with regulatory frameworks guarantees that manufacturing processes and products adhere to strict quality and safety guidelines.

Understanding Pharma Intermediate Manufacturing

Key Processes Involved

Synthesis Methods and Techniques

Chemical Synthesis: Involves chemical reactions to create intermediates, often using precise conditions and catalysts.

Biochemical Synthesis: Utilizes biological agents like enzymes to facilitate reactions, particularly in biopharmaceutical production.

Quality Control Measures and Standards

Stringent Testing: Rigorous quality control ensures intermediates meet purity, potency, and safety specifications.

Regulatory Adherence: Compliance with FDA, EMA, and other regulatory bodies' standards ensures consistent product quality and safety.

Market Insights and Trends

Global Market Overview

Growing Demand: The pharmaceutical intermediate Manufacturers (Connexpharma )market experiences significant growth due to increasing drug production globally.

Regional Focus - India: India emerges as a key player in pharmaceutical manufacturing, leveraging cost-effective production capabilities.

Impact of Emerging Markets: Emerging economies contribute substantially to global supply chains and market expansion.

Technological Innovations

Automation and AI in Manufacturing

Automated systems streamline production processes, reducing costs and improving efficiency.

AI applications optimize operations through predictive analytics and process automation.

Sustainability Initiatives and Green Chemistry

Adoption of green chemistry principles minimizes environmental impact during manufacturing.

Companies like Actylis Pharmaceuticals lead sustainability efforts with innovative production practices.

Challenges and Solutions in Pharma Intermediate Manufacturing

Common Challenges

Raw Material Sourcing and Supply Chain Management

Ensuring a stable supply of high-quality raw materials is essential for uninterrupted production.

Managing global supply chains effectively to mitigate risks and ensure regulatory compliance.

Regulatory Hurdles and Compliance Issues

Navigating complex regulatory landscapes requires expertise and adherence to evolving standards.

Compliance with stringent regulatory requirements ensures product safety and market approval.

Quality Assurance Throughout the Production Cycle

Implementing robust QA/QC protocols guarantees consistent product quality and compliance with regulatory standards.

Continuous monitoring and improvement are critical to maintaining high-quality standards.

Strategies for Overcoming Challenges

Collaboration with Research Institutions

Partnering with research institutions fosters innovation and accelerates the development of new intermediates and technologies.

Joint initiatives lead to advancements in manufacturing processes and product innovation.

Adoption of Advanced Analytical Techniques

Utilizing state-of-the-art analytical tools enhances product testing and quality assurance capabilities.

Advanced techniques enable precise monitoring of processes, ensuring compliance and product integrity.

Continuous Improvement and Lean Manufacturing Principles

Implementing lean practices optimizes production efficiency, reduces waste, and enhances operational excellence.

Continuous improvement fosters innovation, responsiveness to market demands, and sustainable growth.

Future Outlook and Opportunities

Market Projections

Growth Forecast: The pharmaceutical intermediate market is poised for significant expansion, driven by global healthcare needs.

Geopolitical Factors: Changes in trade policies and geopolitical landscapes influence market dynamics and supply chain strategies.

Opportunities for Innovation

Investment in R&D

Increasing R&D investments stimulate innovation in intermediate development and manufacturing processes.

Focus on developing specialized intermediates for niche markets and therapeutic applications.

Expansion into Niche Markets and Therapeutic Areas

Diversifying product portfolios into specialized markets enhances competitiveness and market penetration.

Targeting therapeutic areas with unmet medical needs presents opportunities for growth and differentiation.

Conclusion

Summary of Key Points

Pharmaceutical intermediates are critical for drug manufacturing, ensuring efficacy, safety, and regulatory compliance.

Addressing challenges through innovation, collaboration, and adherence to quality standards is crucial for industry advancement.

Choosing Reliable Manufacturers

Selecting manufacturers with robust quality control systems and regulatory compliance ensures reliable supply and product consistency.

Future Directions and Implications

Continued innovation, sustainability, and adaptation to regulatory changes are key to shaping the future of pharmaceutical intermediate manufacturing.

—----------------------------------------------------------------------------------------------------------------------------

0 notes

Text

HMDS Manufacturers In India

In the realm of modern chemistry and industrial applications, there exists a silent yet indispensable hero: Hexamethyldisilazane (HMDS). This compound, with its diverse range of applications, plays a crucial role in various industries, from electronics to pharmaceuticals. Behind its widespread usage lies the diligent work of HMDS manufacturers, who continually innovate to meet the evolving demands of the market.

Hexamethyldisilazane (HMDS) is a colorless, clear liquid with a chemical formula of (CH3)3SiNHSi(CH3)3. Its molecular structure, featuring silicon and nitrogen atoms, renders it uniquely versatile in chemical processes. One of the primary functions of HMDS is its role as a silylation agent, which involves the introduction of silicon-containing groups to a substrate surface. This process finds extensive use in semiconductor manufacturing, where HMDS is employed to enhance the adhesion of photoresist materials during photolithography.

Moreover, HMDS serves as a critical component in the synthesis of various silicon-based compounds and polymers. Its ability to modify surface properties, improve wetting, and enhance film formation makes it invaluable in the production of coatings, adhesives, and sealants. Additionally, HMDS plays a vital role in organic chemistry as a reagent for the protection of functional groups, facilitating complex synthetic pathways in pharmaceutical and agrochemical research.

The landscape of HMDS manufacturing is characterized by a commitment to innovation and sustainability. Manufacturers continually strive to improve production processes, enhance product purity, and minimize environmental impact. Advanced purification techniques and quality control measures ensure that HMDS meets stringent industry standards, guaranteeing reliability and consistency in its performance across diverse applications.

In recent years, HMDS manufacturers have embraced technological advancements to streamline production and optimize resource utilization. Automation and digitalization have revolutionized manufacturing processes, enabling greater precision, efficiency, and scalability. Furthermore, manufacturers have implemented eco-friendly initiatives, such as solvent recovery systems and waste minimization strategies, to reduce their carbon footprint and promote sustainability.

Collaboration and partnerships play a pivotal role in driving innovation within the HMDS manufacturing sector. By fostering synergies with research institutions, universities, and industry stakeholders, manufacturers gain access to cutting-edge technologies and scientific expertise. This collaborative approach fosters the development of novel applications and expands the potential utility of HMDS across diverse sectors, from advanced materials to biotechnology.

Looking ahead, the future of HMDS manufacturing holds exciting possibilities. As industries continue to evolve and demand for high-performance chemicals grows, manufacturers are poised to respond with innovative solutions. From tailored formulations to novel synthesis routes, HMDS manufacturers remain at the forefront of technological advancement, driving progress and propelling innovation in the global chemical industry.

In conclusion, Hexamethyldisilazane (HMDS) manufacturers play a crucial role in enabling progress across various industries through their commitment to innovation, quality, and sustainability. As the demand for high-performance chemicals continues to rise, these manufacturers will continue to spearhead advancements in HMDS synthesis, paving the way for enhanced efficiency, reliability, and versatility in its applications.

0 notes

Text

Hexamethyldisilazane Manufacturers (HMDS)

HMDS, or Hexamethyldisilazane, is a versatile compound derived from organosilicon compound. It has a wide range of applications which makes it a valuable base precursor and reagent.

HMDS is primarily used in the pharmaceutical manufacturing for silylating processes, which is used in the production of antibiotics such as Cefprozil, Cefadroxil, along with antiretroviral drugs like Sofosbuvir, Lamivudine, and Emtricitabine. In addition, it also finds utility in the semiconductor industry that aids in enhancing the tearing strength of vinyl silicone rubber.

0 notes

Text

Chloromethyl Isopropyl Carbonate 35180-01-9 Manufacturers

Chloromethyl isopropyl carbonate (CAS No. 35180-01-9), also known as CMIC, is used primarily as an intermediate in the synthesis of pharmaceutical compounds. Some of its applications include:

Protecting Group: CMIC is often utilized as a protecting group for amines in the synthesis of pharmaceuticals. It can be selectively removed under mild conditions, allowing for the selective manipulation of functional groups in complex molecules.

Synthetic Intermediate: It serves as a key intermediate in the synthesis of various pharmaceutical compounds, including antiviral drugs and inhibitors.

Functionalization Reagent: CMIC can be used as a reagent for introducing specific functional groups into organic molecules. Its reactivity allows for the modification of molecular structures to achieve desired properties or activities.

Overall, chloromethyl isopropyl carbonate plays a crucial role in the synthesis and modification of pharmaceutical compounds, contributing to the development of new drugs and drug delivery systems.

Visit : Top Quality Chloromethyl Isopropyl Carbonate to knowmore !

0 notes

Text

Chloromethyl Isopropyl Carbonate Manufacturers

Chloromethyl Isopropyl Carbonate

Chemistry, the language of matter, unveils a fascinating realm of compounds, each with its unique properties and applications. One such compound that merits exploration is Chloromethyl Isopropyl Carbonate (CMIC). This chemical marvel holds significance in various industrial processes, and understanding its fundamentals opens the door to a deeper comprehension of organic chemistry.

What is Chloromethyl Isopropyl Carbonate?

At its core, Chloromethyl Isopropyl Carbonate is an organic compound with the chemical formula C₅H₉ClO₃. Breaking down its name provides insights into its structure: 'Chloromethyl' indicates the presence of a chloromethyl group (–CH₂Cl), 'Isopropyl' signifies an isopropyl group (–C₃H₇), and 'Carbonate' refers to the carbonate ester functional group (–OCO₂). This compound is known for its versatile applications in the realm of organic synthesis.

Chemical Structure and Formula:

Understanding the structural makeup of Chloromethyl Isopropyl Carbonate enhances our appreciation for its properties and behavior in chemical reactions. The compound's structure features a chloromethyl group attached to an isopropyl group, forming a distinctive molecular arrangement. The chemical formula, C₅H₉ClO₃, succinctly represents the number and types of atoms present in a single molecule.

Synthesis Methods:

Scientists and chemists have devised various methods for synthesizing Chloromethyl Isopropyl Carbonate, each with its unique set of advantages and challenges. One common approach involves the reaction between chloroform and isopropyl carbonate in the presence of a catalyst. This synthesis method highlights the importance of carefully controlled conditions to achieve optimal yields.

Applications in Industry:

The applications of Chloromethyl Isopropyl Carbonate extend across diverse industrial sectors. It serves as a key intermediate in the synthesis of pharmaceuticals, agrochemicals, and specialty chemicals. Its role in creating essential building blocks for these industries underscores its significance in the production of a wide array of products that impact our daily lives.

Safety and Handling:

While Chloromethyl Isopropyl Carbonate is a valuable compound, it is essential to approach its handling with caution. Understanding safety protocols, proper storage conditions, and potential hazards associated with its use are paramount. This ensures a secure working environment and minimizes the risks associated with its manipulation.

0 notes

Text

CAS No. 999-97-3 Manufacturer in India

Your Go-To CAS No. 999-97-3 Manufacturer in India

Are you in search of a distinguished CAS No. 999-97-3 manufacturer in India? Your quest ends here!

Established in 2016 with the vision to emerge as a premier drug intermediate manufacturer, Connex Pharma has swiftly risen to prominence as one of the leading CAS No. 999-97-3 manufacturers in India. This unique code identifies Hexamethyldisilazane, a colorless liquid renowned for its potent odor, and versatile applications across diverse industries.

Unveiling Hexamethyldisilazane's Versatility

Primarily recognized as a hydrophobic agent, Hexamethyldisilazane boasts the remarkable ability to repel water. This attribute proves invaluable in crafting pharmaceutical adhesives and coatings, exemplifying its pivotal role in the industry.

Our Journey: A Testament to Excellence

Despite being a relative newcomer, Connex Pharma has swiftly solidified its position as one of the most sought-after manufacturers of drug intermediates. Our success extends beyond domestic borders, making us a reputable name in international markets. Anchored by a team of seasoned experts, our collective mission is to deliver high-quality drugs at a competitive cost.

Pride in Precision: Our State-of-the-Art Facility

At the heart of our operations lies a sprawling production facility spanning 5.4 acres, meticulously designed to adhere to Good Manufacturing Practices (GMP). Housing cutting-edge equipment and machinery, our facility positions us to consistently produce high-efficacy drugs. This commitment to excellence ensures that every product leaving our premises meets the highest standards of quality.

Connect with Excellence: Contact Us Today!

For more in-depth insights into why Connex Pharma stands as the best CAS No. 999-97-3 manufacturer in India, we invite you to get in touch with us today. Your journey toward superior drug intermediates begins here!

0 notes

Text

Applications and Uses of CAS NO. 999-97-3 in Industry

Introduction:

CAS NO. 999-97-3 is a chemical compound with diverse applications across various industries. This article aims to provide a detailed exploration of the uses and significance of CAS NO. 999-97-3 in different industrial sectors.

1. Pharmaceutical Industry:

CAS NO. 999-97-3 finds extensive use in the pharmaceutical industry as a key component in the synthesis of specific medications. Discuss its role in drug development, highlighting notable examples and the impact on the pharmaceutical landscape.

2. Chemical Manufacturing:

Explore the applications of CAS NO. 999-97-3 in chemical manufacturing processes. Detail its role in the production of intermediates and final products, showcasing its versatility in creating a range of chemical compounds.

3. Plastics and Polymers:

Delve into how CAS NO. 999-97-3 contributes to the plastics and polymers industry. Discuss its role in enhancing the properties of polymers, such as improving durability, flexibility, or heat resistance.

4. Agrochemicals and Pesticides:

Investigate the significance of CAS NO. 999-97-3 in the development of agrochemicals and pesticides. Highlight its role in formulating effective solutions for pest control and crop protection.

Visit : Superior Quality Hexamethyldisilazan to knowmore !

0 notes