Don't wanna be here? Send us removal request.

Text

Benefits of Robotics in Manufacturing: Efficiency, Precision, and Cost Savings

Robotics used to be something out of a science fiction movie. That was once upon a time. But robotics in manufacturing has actually been around for decades. The automotive sector is among the industries that relies heavily on this technology. In fact, it relies on more than a million robots to manufacture vehicles.

In addition, around 3 million robots are operational in other key industries, such as chemicals, electronics, food, plastics, and machinery. With the rise of artificial intelligence and machine learning, robots have become more sophisticated and capable of contributing greatly to cost savings, productivity, and efficiency in manufacturing.

This article takes a closer look at how robotics benefits manufacturing. Read on to discover the processes and operations that have achieved greater efficiency, precision, and affordability thanks to industrial robots.

Enhanced consistency and accuracy

Compared to humans, robots are more accurate and less prone to making mistakes that could cost manufacturers more down the road. Their accuracy and consistency also help reduce waste.

Better product quality

Robotics in manufacturing has greatly improved repeatability and precision for various operations. They eliminate the problems caused by distraction, exhaustion, and boredom from performing mundane, tedious, and repetitive tasks. This ensures consistent product quality with a high-quality finish every time.

Increased output and efficiency

Manufacturing companies that depend mainly on human labourers must provide constant breaks and set effective work shifts. Robots don’t need those and can be programmed to run continuously, allowing production to continue and boosting productivity. Since 2009, the automotive industry has increased its productivity by 50% by embracing robotics in manufacturing.

In addition, robots allow manufacturers to finish more high-quality products on time, resulting in greater yields. Robotics brings flexibility to manufacturing and production lines, so it helps manufacturers keep up with customer demand and production requirements with minimal effort.

Robotics in a wide range of functions

Industrial robots offer benefits across several processes and operations. The use of robotics in manufacturing continues to grow as they become involved in functions such as pick and place, assembly, and dispensing. With advanced configurations, robots can also be dependable in handling liquids and solids, packing, and palletising. Better control systems, AI, ML, and advanced programming have made robotic automation more reliable in various processing and manufacturing applications.

Introduce efficiency, cost savings, and precision to your manufacturing process.

Cybernetik offers the most advanced robotics solutions for manufacturing. No matter your needs, they will customise a solution for you. Visit their website to learn more about their technologies, and get in touch with their team by calling +91 20 679 09600.

0 notes

Text

The Future of Robotics Automation: Trends Shaping 2024

Robotics has become a global industry that is estimated to be worth $169.8 billion between this year and 2032. Many factors contribute to its success, such as robotic automation, which makes waves in manufacturing and distribution by automating repetitive actions such as sorting, palletisation, and handling of material goods.

Read on to discover the top robotics automation trends in 2024 and how to implement these developments in your business.

AI and ML are increasing the autonomy of robots.

Machine Learning (ML) and Artificial Intelligence (AI) make robots more intelligent and self-sufficient. A recent breakthrough is the development of a generative AI-powered interface that eliminates the need for coding. This interface allows users to program robots using natural language, making autonomous robots that can operate independently easier. Automating tasks that are often time-consuming, error-prone, and expensive when done by humans allows these robots to improve efficiency and reliability across various industries, including healthcare, manufacturing, logistics, and pharmaceuticals.

Using ML and AI in robotic automation can benefit manufacturing businesses by providing efficient algorithms and helping predict maintenance. They simplify data generation to promote continuous optimisation. Additionally, predictive AI reduces downtime by anticipating needs such as maintenance and servicing. Moreover, it improves the performance and adaptability of robots by enabling them to learn from their environment.

New training and education programs to address the automation skill gap

There is a significant skill gap in the robotics industry that is challenging the existing workforce to manage and implement automated robots. This initially caused a labour shortage, but the industry is addressing this by improving access to new technologies and robots. The goal is to equip workers with up-to-date skills through targeted training and education programs so they are ready to handle evolving robotic automation systems.

Collaborative robots

Also known as cobots, collaborative robots are designed to collaborate with humans to complete shared tasks like repetitive motions and heavy lifting. They have advanced vision technologies and sensors to safely interact with people in the workplace without compromising safety in the assembly line.

Are you ready to implement some of these trends in your business?

Cybernetik can help you take a significant leap to improve your manufacturing business with robotics automation. You may email [email protected] to enquire about their solutions.

0 notes

Text

Enhancing Efficiency in Food Production: The Role of IBC Blenders and Chocolate Manufacturing Machines

0 notes

Text

Enhancing Efficiency in Food Production: The Role of IBC Blenders and Chocolate Manufacturing Machines

The key to quality in chocolate manufacturing lies in precisely processed ingredients. And one of the steepest challenges in this regard is blending different granules and powders uniformly. An IBC blenderaddresses this issue effectively.

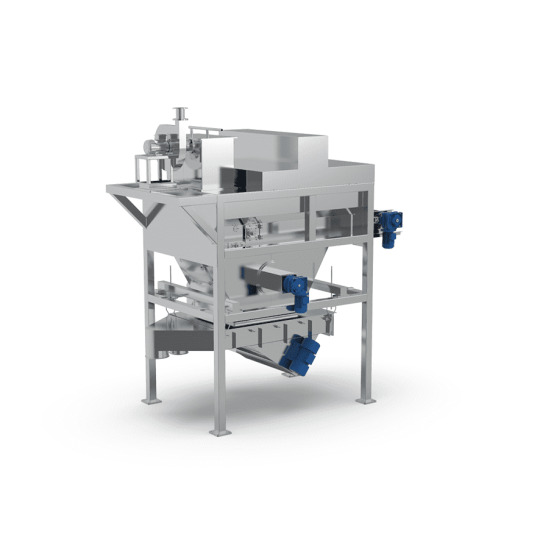

IBC blenders are crucial components of a chocolate manufacturing machine. IBC stands for intermediate bulk container, and it serves as an attachment for storage, blending, and transport of ingredients. Read on to discover how it works and enhances efficiency in food production.

The basics

IBC blenders are industrial machines designed to efficiently mix large quantities of dry ingredients, including those for chocolates. They use a rotating frame to hold and agitate an intermediate bulk container and ensure that all ingredients — such as powders, granules, and other additives — are thoroughly blended.

Using anIBC blendersimplifies handling and ensures a dust-free mixing process. They are also easy to transport and load into the blender, reducing manual labour and the potential for errors.

How it helps chocolate manufacturing

Using advanced mixing techniques such as high-shear, rotation, and 3D mixing, IBC blenders ensure thorough blending and prevent ingredient segregation. This optimized mixing process helps chocolate manufacturers deliver consistently high-quality products.

High-quality IBC blenders are often constructed from durable stainless steel (SS316 or SS304) and are designed to accommodate a wide range of IBC sizes, typically ranging from 300 to 2000 litres. Features such as automated acceleration, deceleration, and fast loading/unloading mechanisms minimize downtime and maximize output. The stainless-steel construction and easy-to-clean design also ensure compliance with stringent food safety standards.

By integrating IBC blenders into their production lines, chocolate manufacturers can streamline operations and deliver high-quality products to consumers.

Ensure high-quality and safe chocolates.

IBC blenders are crucial to the chocolate manufacturing machine to minimize material loss, contamination, and layering. Just be sure they have a hygienic GMP built to improve food safety. Some manufacturers can configure your IBC blender with automation options for downstream and upstream processes. Additionally, they can use an explosion-resistant ATEX construction when you need the blender for a flameproof area.

Complete your chocolate manufacturing machine with the IBC blender by Cybernetik. Leave a message at Cybernetik.com and find out how their cutting-edge equipment can optimize your food production.

0 notes

Text

The Benefits of Technology and Automation for Businesses

The sudden boom of artificial intelligence (AI) and machine learning (ML) encourages manufacturing businesses to embrace the latest automation technologies to remain productive and optimise operations. Part of this effort is implementing new solutions and systems as soon as possible to minimise disruptions. Such efforts can be strategic, especially when they involve advanced IT infrastructure and process automation.

Are you wondering how technology and automation can benefit your manufacturing business? Read on as this article explores their impact on productivity, production rates, service, and material usage.

Boost production capabilities

Robotics is one of the ways to introduce automation in manufacturing. With this solution, you can increase the production capabilities of your business without investing in additional workforce. Over time, it can reduce your operating costs and let your existing staff focus on other activities that require critical thinking and creativity.

Increased safety

Automated material handling and assembly systems eliminate the need for manual labour that could compromise the quality of goods. Additionally, the latest automation technologies and robotics remove workers from potentially hazardous tasks.

Higher productivity

Automation can significantly enhance process control while reducing cycle times, resulting in higher productivity. Furthermore, it eliminates the need to outsource tasks. You can keep processes in-house while saving time and money.

Stay competitive for faster ROI

Modern automation technologies can be tailored to your needs to reduce lead times and operating costs. They boost your output, so they pay for themselves quickly. In addition, your business can benefit from the reduced cost-per-piece and cycle times, giving you a more competitive edge in your industry.

Create a solid business strategy with industrial automation and robotics.

New technologies like industrial automation and robotics are crucial to a well-grounded business strategy. They offer various advantages, from increased productivity and high-quality services to reduced waste and higher production rates. Manufacturing businesses can easily adopt these technologies and adapt their operations quickly to them, and you can have the same experience by partnering with a reputable technology provider like Cybernetik.

Discover the latest automation technologies for your manufacturing business by connecting with Cybernetik. For more info, use our contact form or write to us at [email protected].

0 notes

Text

How Food Packaging Automation Enhances Quality Control in Manufacturing

Efficiency and innovation are crucial in the modern food industry landscape, especially in packaging — a critical aspect of product presentation and preservation. Automation is one of the major developments revolutionising this area. Food packaging automation can help your business meet changing consumer demands while keeping up with industry trends such as faster production and improved sustainability.

Consider automating your packaging processes if you want to improve the cost-efficacy, product quality, and production efficiency in your food manufacturing business. This reduces costs and ensures consistent packaging, minimizes human error, and ultimately increases production speed and throughput — benefits that can elevate your brand's reputation for reliability and innovation.

Why automate food packaging?

Manual food packaging can be expensive because of the intensive labour involved and the risks of human error and contamination. All these issues can be resolved by food packaging automation that involves robotics, machinery, and cutting-edge systems to optimise and streamline packing processes.

Packaging automation enhances overall operations while ensuring your business can adhere to the industry’s quality standards. Plus, it boosts operational efficiency and precision to bring savings.

Automating significant aspects of packaging

Streamlining of several important tasks including filling and bagging, which are extremely labour-intensive when done by hand, is among the foremost benefits of automating the food packaging process. This shift to automation speeds up operations while boosting accuracy.

Automation of packing systems protects product integrity through methods such as nitrogen sealing and stretch wrapping. They also facilitate palletizing and precise volume or mass feeding, ensuring that food products are well-preserved and maintained in excellent condition throughout transport and storage.

Customized automation solutions

It is best to partner with a reliable food packaging automation provider that can tailor a system to meet your specific requirements. A custom system can be designed to help your business overcome the key challenges you currently contend with, whether it’s ensuring the quality of perishable goods or packaging delicate products. Ultimately, the right solution will address your packing complexities to reduce waste and optimize operational costs.

Discover the best automation solutions for food packaging.

Turn to Cybernetik for top-of-the-line food packaging automation tailored to your unique requirements. With a 360-degree approach, they can supply your business with purpose-built systems that use the latest technologies. They can help deploy your new system and provide reliable after-sales support. Visit www.cybernetik.com to learn more about their automated packing solutions.

0 notes

Text

The Importance of Chocolate Packaging & Wrapping

Chocolate packaging and wrapping have gone through many changes over the years. From simple wrappers to those with elaborate designs, they represent different ways of wrapping chocolate. Beyond creating an aesthetically pleasing product, packaging and wrapping are critical for preserving flavours and overall quality.

However, it’s not just about producing high-quality wrappers and packaging. You must ensure the chocolates are wrapped properly, especially with automated packaging solutions.

Read on to understand the importance of chocolate wrapping and packaging and how you can wrap your chocolates well and more effectively with modern packing solutions.

Ensure high-quality and great-tasting chocolates.

Proper packaging prevents the product from being directly exposed to elements such as moisture and air that can impact its taste and texture. Flavours can deteriorate because of oxygen in air, making high-quality and well-sealed packaging and wrapping a necessity. The right wrappers and packaging methods prevent chocolates from absorbing ambient odours, keeping them flavourful and fresh.

Of the many different ways of wrapping chocolate today, the best methods are those that prevent moisture exposure so that your product doesn’t end up dull and grainy. With the right packaging and wrapping, you won't have to worry about moisture ruining the chocolate's flavour and texture.

Additionally, improperly packaged or wrapped chocolates that are exposed to air often end up tasting stale, with off-flavours. This is why it’s important to make sure that your chocolate products are well-sealed to avoid contact with oxygen. This can help preserve its original intended taste.

The best packaging for chocolate

There are many different ways to wrap chocolate, from plastic wraps to foil packaging to cardboard boxes. Foil wrapping is often used to provide a protective and attractive covering for chocolate bars and individual pieces, such as chocolate-covered confections and truffles. Plus, it keeps these products fresh and flavourful.

Commercial or mass-produced chocolate products are often wrapped in plastic. It’s a cost-effective way to package chocolate bars while protecting against external elements and moisture.

Cardboard boxes are suitable for gift boxes and individual products. These are usually elaborately designed and available in various shapes and sizes. Usually, the chocolates are wrapped in individual foil or plastic before being placed in a box for optimum protection from moisture, odours, and air.

Simplify chocolate wrapping and packaging.

No matter what packaging or wrapping method you use, you can automate the process with Cybernetik. They offer a range of packaging solutions suitable for different ways to wrap chocolate, including bag palletisers and robotic case erectors. They can also customise a carton palletiser or provide a robotic carton packer for pouches. Discover the Cybernetik advantage by sending an enquiry through their website.

0 notes

Text

Boosting Production Quality with Cutting-Edge Sifter Machines for Pharmaceuticals

Sifting is one of the crucial processes in manufacturing pharmaceutical products. The objective is to separate particles of varying sizes to ensure consistency and high-quality medicines. Doing this with manual, outdated tools is not only inefficient, but unhygienic as well, and can result in safety and quality issues. If your business makes medicines, it is better to have a dedicated sifter machine for pharmaceuticals.

You will want the most cutting-edge sifter machine for your business. In that case, the vibratory sifter is a good choice. It is a cutting-edge machine that relies on a vertical component to sift through powders in a linear or circular motion. Of all these options, the vibratory sifter is the most cutting-edge. Also known as a Vibro Sieve, it is an all-around performer for scalping, separating, and grading materials according to particle size. Read on to discover how it can boost production efficiency and why it is the best sifter machine for pharmaceuticals.

Energy-efficient

One of the benefits of the Vibro Sifter is energy efficiency. Automation and robotics reduce the time it takes to sift, grade, or screen pharmaceutical powders. Reputable manufacturers design this machine with a single and double deck, as well as side and central discharge screens. Plus, they provide oversized outlets to discharge rejected particles, eliminating the need to do it manually.

Time-saving

High-quality Vibro Sifters have a vacuum screening feature to cut down processing time. Plus, they have an anti-binding device that can be ultrasonic, electromagnetic, rotary blade, or mechanical. Automation options are also available to support downstream and upstream processes.

Increased safety

Using a sifter machine for pharmaceuticals is not just hygiene based choice. It increases safety on the manufacturing floor. Cutting-edge machines feature ATEX construction for enhanced explosion resistance for flame proof areas.

Quiet performance

If you prefer a noiseless manufacturing environment, a Turbo Sifter can be a good alternative to a Vibro Sifter. It shares the same features as Vibro Sifters, except it works more quietly and has a Variable Frequency Drive for optimum flow rate control.

Get a high-performance sifter for your pharmaceutical company.

Cybernetik specialises in industrial automation and robotics to support your pharmaceutical manufacturing process. Its sifter machine for pharmaceuticals can process powders as fine as 40 µm, ensuring effective sieving and granulation. Plus, it has a hygienic, GMP-built. Get a quote for a state-of-the-art Vibro or Turbo Sifter on their website.

0 notes

Text

Explore the Crucial Function of Sifter Machines in Pharmaceutical Manufacturing

In pharmaceutical manufacturing, sifting means classifying and segregating particles such as active pharmaceutical ingredients and excipients by size, and distributing them efficiently into groups of uniform granularities. Done using a specialisedsifter machine for pharmaceuticals, this process helps prevent contamination, and improves the blend uniformity of the pharmaceutical formulations to ensure the consistency and quality of final products.

Vibro sifters (more commonly called sifter machines for pharmaceuticals) use vibratory or gyratory motions to perform separation, scalping, and grading in pharmaceutical applications as well as in food, chemical, and other industries.

A sifter machine for pharmaceuticals uses a vibratory motor with eccentric weights positioned on both the top and bottom, creating a vibration around the machine's centre of gravity and causing it to move across multiple planes.

The top weight rotates near the machine's centre of mass in a horizontal plane to propel materials across the screen and quickly discharge any oversized particles.

The bottom weight (beneath the centre of mass) rotates and tilts the screen to create additional vertical and tangential plane vibrations. This combined motion helps materials move more efficiently across the screen surface so that finer particles pass through more effectively.

This design makes sifters ideal for single-pass, low-volume processes, providing a cost-effective option for those with minimal capacity needs.

It’s easy to operate a well-designed sifter machine for pharmaceuticals. Before starting, ensure everything is secure. Tighten the clamp rings on the dust cover, mesh screens, sieve decks, and bottom deck. Load your materials into the feed inlet located on the dust cover. Turn on the power and let the machine do its work.

Where can you order a sifter machine for pharmaceuticals?

Cybernetik’s range of single and double-deck sifters are capable of handling powders as fine as 40 µm. Suitable for the pharmaceuticals as well as the chemical, manufacturing, and food industries, these sifters come with various features such as side and central discharge screens, hygienic GMP construction, options for vacuum screening, anti-binding devices, and automation for integrated process efficiency.

Cybernetik’ssifter machines for pharmaceuticalsare designed to meet stringent industry standards. They offer oversized outlets for ejecting larger rejected particles, and come with additional options such as explosion-resistant construction and various anti-binding devices, ensuring versatility and safety in demanding environments.

0 notes

Text

Automation in Food Packaging: How It Eliminates Waste?

Did you know that one of the biggest contributors to food waste is improper packaging? If food products aren't packaged correctly, they can spoil during production or at any point along the supply chain. This can lead to issues such as a physically damaged produce and/or contamination from bacteria, mould, and pests. Fortunately, modern technologies such as food packaging automation are available to help prevent these problems.

And the challenge is steep by the way, for recalls are the worst profitability killers in the food industry. Automation in food packaging eliminates waste by ensuring proper packing that preserves the quality and extends the shelf life of food products. In addition, automated equipment helps get rid of unnecessary processes and materials that could contribute to waste throughout the food life cycle.

How does it eliminate waste?

Traditional food packaging relies on manual processes that are time-consuming and prone to human error. Mistakes during packaging can compromise the quality, safety, and longevity of food products, leading to costly waste. However, automation eliminates those extra steps to reduce manufacturing costs and save time.

In addition, food packaging automation improves quality control measures by ensuring that every product meets health and safety standards. It can:

Minimise spoilage caused by temperature fluctuations.

Ensure quality control throughout a multi-stage production process that requires intermediate packaging.

Control the moisture content of food inside the packaging to avoid drying out or sogginess over time.

Ensure the food products are safe and intact when they reach customers.

Better quality control with automation and smart packaging

Every manufacturing process needs stringent quality control measures to avoid producing defective and potentially harmful products. Poorly packaged food can compromise the health and safety of consumers. Plus, it results in low-quality goods that will be rejected by distributors and retailers.

Food packaging automation helps maintain the integrity of food products via solutions such as nitrogen sealing, accurate volume or mass feeding, stretch wrapping, and palletising. Moreover, it helps improve the customer’s confidence in the food they buy from your business. Just be sure to get the right packing automation solutions from a reputable provider such as Cybernetik.

Cybernetik offers advanced and reliable food packaging automation systems, from automated bagging machines to valve bag packers and stretch wrappers. Learn more about their equipment and get a quote at Cybernetik.com.

0 notes

Text

The Advancements and Impact of Robotics and Automation

Robotics has been used in manufacturing for almost seven decades now — starting when the first industrial robot (which was designed to autonomously lift heavy objects and weld car parts) was developed and deployed for vehicle assembly lines. These days, robotics and automation are almost inseparable in manufacturing. Manufacturers that use them experience several benefits, including increased productivity, safety, and reduced human error. The positive impact of these solutions is undeniable, especially as they continue to advance and become widely accessible to more businesses across different industries.

Discover the advancements in robotics.

Robotics and automation are rapidly growing fields that have experienced significant improvements and developments in the past few years. With AI, robots have greater perception to interpret and sense their environment, allowing them to recognise and track objects more effectively and navigate new, unstructured spaces. This resulted in robots that can perform precise tasks in manufacturing, such as pick and place, packing, and palletising.

In addition, robots are now capable of interacting physically with their environment, and they do it with precision through arms and grippers. With automation, they can handle fragile and sensitive ingredients or objects, and assemble parts.

New developments in automation

Automation is the technology that allows robots and machinery to perform tasks without human involvement at the operational level. Recently, significant advancements have been seen in areas such as control systems and machine learning.

Machine learning optimises automated systems by allowing them to learn from data to improve performance. This resulted in solutions that can do things intuitively, such as predictive maintenance and image recognition. Modern pick-and-place systems are now data-driven and support decisions related to manufacturing processes. In addition, the latest control systems feature robotics and automation to coordinate, manage, and perform tasks with precision.

For productivity and efficient performance

Combining robotics and automation results in intelligent systems that allow manufacturers to harness data-based models and their full potential to reduce waste and optimise performance. Using automation, they can maximise emerging possibilities born from technological developments.

Invest in the best systems.

Are you looking to include robotics and automation in your business? Check with the experts at Cybernetik Technologies for the latest solutions. The company offers a wide range of solutions that feature these advancements to boost your productivity and save time. Visit Cybernetik to learn more about its turnkey integrated solutions, material handling systems, and process automation.

0 notes

Text

Why is Secondary Packaging Automation an Asset in the Manufacturing Industry?

In the manufacturing industry, secondary packaging automation refers to the automated process of enclosing already packaged products (such as bags, boxes, or bottles) in additional packaging materials—such as cases, totes, trays, or cartons—primarily for shipping, storage, or display. This technology replaces slower and more labour-intensive manual methods, significantly improving efficiency, accuracy, and productivity while reducing costs.

Manufacturers can reap many benefits from incorporating secondary packaging automation into their production lines.

Cost-savings - It significantly reduces the high material and labour costs associated with manual packaging—a crucial advantage when dealing with large product volumes. Automation also diminishes the need for extensive manual labour, leading to savings in wages, training, recruitment, and other staffing expenses. Moreover, secondary packaging automation reduces manual product handling, which can, in turn, reduce material loss and further cut labour requirements.

Consistency and quality - Automated packaging machinery ensures consistent packaging size, weight, and shape. This consistency minimises material usage and manual labour, maintaining high product quality, which in turn increases customer satisfaction and reduces the likelihood of returns, complaints, and revenue loss.

Enhanced line flexibility - For manufacturers dealing with a diverse range of products, manual secondary packaging can be inefficient due to varying requirements for different items. Secondary packaging automation provides the needed flexibility by intelligently accommodating various packaging materials and product types.

Meeting production demands - Manufacturers are automating their secondary packaging processes to keep up with rising production demands. Automated machinery operates faster and more accurately than manual methods, leading to increased output and fewer errors. This capability allows manufacturers to produce and package more goods and bring them to market more quickly.

Regulatory compliance and safety - Manual packaging, especially for products requiring sterile conditions, may fall short of strict regulatory and safety standards. Secondary packaging automation addresses these concerns by reducing risks such as contamination and mislabelling. Additionally, many automated solutions can collect data and analytics, aiding manufacturers in quality control and production optimisation.

Integrating secondary packaging automation into your business

To learn more about secondary packaging automation, consider exploring solutions from companies such as Cybernetik. They offer innovative products such as automatic bagging machines suitable for industries like pharmaceuticals, food, and chemicals. Contact Cybernetik for more information and quotes on automating your secondary packaging processes.

0 notes

Text

Impact of Robots in the Manufacturing Industry

As automation gains momentum among manufacturers, the prominence of robotics in the manufacturing sector becomes increasingly apparent. Its profound influence on enhancing operational efficiency and accelerating processes, as well as reshaping job roles, cannot be overstated. The integration of automated solutions with robotics has been demonstrated to significantly enhance productivity, streamline operations, and mitigate or even eliminate expensive errors.

Keep reading to explore the impact of industrial automation and robotics in the manufacturing industry. This will also help you understand how to implement these innovations in your business.

Quality control

Robotics can improve the precision of manufacturing processes by ensuring consistent quality for each product. As a result, it helps improve customer satisfaction and product safety and quality.

Increasing efficiencies, precision, and productivity

Robotics in manufacturing used to be limited to programmable mechanical arms. Now, it includes autonomous mobile robots that optimise efficiency and minimise production costs. Modern robots can consistently perform complex tasks with accuracy, as demonstrated by pick-and-place automation systems, among others. These systems are known for their intelligent automation that brings data-driven monitoring, decision-making, and control to manufacturers. Additionally, they help reduce waste and are versatile enough for various applications, such as food and pharmaceutical manufacturing.

Advancements in automation and robotics have also resulted in equipment that can perform diverse operations, such as pick and place, palletising, and stretch-wrapping. These solutions maximise state-of-the-art automation technology for efficient and precise product handling, making them helpful in optimising production processes in various applications.

Impact on jobs

Robotics has become a standard in modern production lines, taking over tasks previously performed by humans. This might sound like a negative development that results in job displacement, but that doesn’t necessarily have to be the case. When used correctly and strategically, robots can undertake risky, mundane, or laborious activities so human workers can focus on other tasks that require their intellect and decision-making.

Robotics in manufacturing can increase productivity and efficiency, especially for tasks that require round-the-clock work. Robots can keep functioning without downtime or breaks and perform at consistent precision and speed for increased and predictable production output.

In addition, robots can take over potentially hazardous tasks, such as handling sharp objects, dealing with hot-running machines, and heavy equipment operations to significantly increase workplace safety and prevent unnecessary injuries.

Cost savings

Industrial robots are known to increase productivity and reduce production lead times, cutting manufacturing costs by 20% to 60%. In addition, using robotics in manufacturing could help reduce energy and operating costs, leading to a higher ROI.

Experience the positive impact of robotics on your business by engaging the experts at Cybernetik. The industrial automation company has years of experience designing, building, and installing end-to-end custom solutions for manufacturing companies. Visit Cybernetik.com today to get in touch.

0 notes

Text

Learn More About Vibro Sifter

Separating, grading, and scalping materials can be time-consuming and labor-intensive with traditional methods. This is where a vibro sifter comes in, offering automation for these tasks. Specifically designed for various industries such as chemical, pharmaceutical, and food processing, this equipment uses an automated vibrational sifting system. It efficiently sorts, grades, and scales ingredients or materials, relying on an advanced vibrational mechanism for the process.

Why vibro sifters are essential in pharmaceuticals and food industries

Vibro sifters are indispensable tools in the production of pharmaceutical and food products. Operating on the principle of gyratory motion, these sifters place the mixture in the center of a screen. The mixture then travels down a spiral path to the periphery while being sifted. This action separates the screened material into finer particles. A significant advantage of using a vibro sifter is that it maintains the quality and integrity of the ingredients by sieving them with minimal abrasion. Moreover, this equipment is versatile enough for both moist and dry granulation applications.

Versatile applications of a vibro sifter

Apart from sifting, vibro sifters are also valuable for several other functions:

Scalping: Vibro sifters efficiently remove unwanted foreign objects and lumps, producing a finer end product.

Grading, scoring, or screening: This machine makes it easier to differentiate ingredients or materials based on their sizes.

Proof sifting: In pharmaceutical applications, proof sifting serves as a quality assurance step, ensuring drug consistency.

Features of a high-quality vibro sifter

Some vibro sifters stand out for their advanced technology, longevity, easy maintenance, and reliable features. Characteristics of a top-notch vibro sifter include:

Single and double-deck configurations

cGMP-compliant and hygienic design

Central and side discharge screen options

Oversized outlets for larger, rejected particles

Vacuum screening capabilities

Centralized discharge screen, either supported or suspended

Various anti-binding devices such as ultrasonic, electromagnetic, mechanical, or rotary blades

Explosion-resistant builds conforming to ATEX standards

Automation options to integrate with downstream and upstream processes

Tailoring to your manufacturing needs

Renowned manufacturers offer vibro sifters in various capacities, ensuring that companies can select the equipment best suited to their specific needs. Customizable features such as mesh size and overall capacity make these sifters even more versatile.

In need of a vibro sifter? Consider the innovative solutions from Cybernetik, a leader in automation and material processing. Contact us at Cybernetik.com for a personalized quote.

About the author:

Cybernetik is a leading global automation solutions provider based in India. With over 25 years of experience, the company offers innovative automation solutions for various industries, including food, pharmaceuticals, chemicals, automotive, and more. Their services include process design, equipment supply, integration, and after-sales support. They specialize in delivering customized solutions to meet clients' specific requirements, resulting in higher efficiency, improved product quality, and reduced costs. Cybernetik's expertise in advanced technologies such as robotics, artificial intelligence, and machine vision enables them to provide cutting-edge automation solutions to clients worldwide.

0 notes

Text

Trending Now: Automation and Robotics in 2023

In today's hypercompetitive market, leaders face the challenge of maximising results with finite investment resources. Balancing economic unpredictability, workforce concerns, and the rapidly evolving landscape of automation and AI has complicated their decision-making processes. Could robotic automation be the solution? Let’s look at the current landscape of robotics and automation for answers.

Changing definitions

Since the inauguration of the first industrial robot in 1961, robots have been primarily recognised as devices for material handling or tool manipulation. But today's definition of robotics has broadened to include physical and business process automation. Autonomous mobile robots (AMRs) have joined the family of four, five, and six-axis machines prevalent in factories worldwide. These AMRs navigate warehouses and distribution centres, transporting materials and kits between storage, kitting, and packing areas.

Robotics and automation are presently at the forefront of Industry 4.0. Intelligent sensors, communication technologies, analytics tools, machine learning, and artificial intelligence are facilitating data-driven decision-making. Simultaneously, the European Union is promoting the concept of Industry 5.0—a vision of interconnected smart manufacturing that prioritises humans over machinery.

Progress in artificial intelligence and machine learning

AI and ML have an expanding roster of applications in robotics and automation. They aid in optimising route planning, decision support, safety enhancement, material yield optimisation, and factory efficiency enhancement.

Developments in smart manufacturing

Research group Forrester suggests manufacturers adopt an "Automation Triangle," blending the abilities of hardware and software automation with the adaptability, creativity, and resilience of human workers.

In this model, hardware automation handles repetitive tasks while software automation undertakes repetitive data processing and analytical functions. This strategy liberates human workers to oversee automation and address issues such as sustainability.

This approach provides numerous benefits for human workers. By being relieved from unpredictable manufacturing tasks, they experience reduced stress and uncertainty while having more opportunities to use their creative skills and exert greater autonomy over their work. For employers, this translates to a more motivated and engaged workforce.

The way forward

While robotics and automation technology are drivers of growth, manufacturers must be prepared to adapt to a rapidly evolving environment.

If you need a partner to deliver stunning, ergonomic, and fully integrated robotics and automation solutions from inception to implementation, consider Cybernetik. Beyond robotic automation, Cybernetik also delivers process automation, designed to enhance the beauty of engineering from an aesthetic, productivity, safety, ergonomics, and efficiency standpoint. Schedule a consultation to start.

About the author:

Cybernetik is a leading global automation solution provider based in India. With over 25 years of experience, the company offers innovative automation solutions for various industries, including food, pharmaceuticals, chemicals, automotive, and more. Their services include process design, equipment supply, integration, and after-sales support. They specialise in delivering customised solutions to meet clients' specific requirements, resulting in higher efficiency, improved product quality, and reduced costs. Cybernetik's expertise in advanced technologies such as robotics, artificial intelligence, and machine vision enables them to provide cutting-edge automation solutions to clients worldwide.

0 notes

Text

Why Is Robotics and Automation Considered a Revolution in 2022?

Technology has become a vital part of our lives in the modern age, and each year it seems as if something new is being discovered or perfected. It could be anything from the latest smartphones to decentralised digital currencies. Robotics and automation are the two main technologies revolutionising the manufacturing industry.

The importance of robotic automation - How it can change the manufacturing industry

Industrial robotics and automation involve using computers and control systems to control and manage industrial processes and machinery. These technologies are used everywhere, from food processing facilities to chemical and extraction plants.

But why are they considered revolutionary? Overall, robotic automation is valuable for businesses because they offer the following benefits:

· Improved productivity

Robots and computers can work 24 hours a day, seven days a week, with little to no downtime. All it takes is some code, and you can program your equipment to perform precise and repetitive tasks.

As a result, these technologies help boost your overall productivity and efficiency, allowing human workers to focus on higher-value tasks that require expertise and can’t be automated.

· Enhanced workplace safety

Tasks that require repetitive movements, such as lifting heavy weights or handling sharp objects, can lead to costly, irreversible injuries. Dealing with the medical and legal aspects of such injuries usually costs hours and hours of time. Not to mention, some workplaces constantly expose human labourers to hazardous materials, such as chemicals, fire, and lasers.

Investing in robotics and automation is investing in the health and well-being of your employees. This is because, unlike humans, machines are made to withstand large amounts of stress or handle toxic chemicals without breaking.

· Increased savings

Fewer injuries and better productivity lead to more cost savings. Consider an automatic bagging machine, for example. This machine can perform automatic bagging at a rate of 6,000 kilograms per hour, allowing your organisation to produce more products in less time.

In fact, according to experts, industrial robots can reduce total manufacturing costs by up to 60%. Moreover, these technologies are becoming more affordable as more innovations are made.

Robotics and automation processes can also help reduce material waste thanks to their precision.

The future of your manufacturing organisation begins with robotic automation. If you’re looking for a solution that is tailored to your needs and industry, consider working with an experienced and knowledgeable industrial automation company.

About The Company:

Cybernetik is an Indian industrial automation company that blends experience with innovation to design, build, and install end-to-end, customized automation solutions for the Food, Pharmaceutical, Chemical, and Manufacturing industries across the world. With 30+ years of experience and counting, we deliver value through customized, turnkey automation solutions with best-in-class productivity, safety, sustainability, efficiency, and ergonomics.

0 notes