Don't wanna be here? Send us removal request.

Text

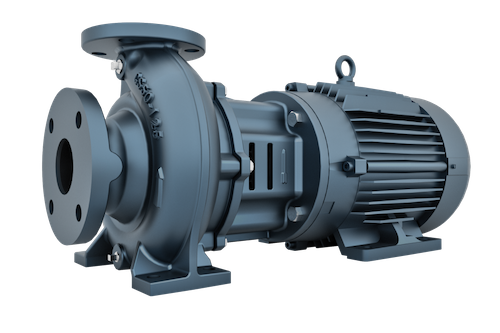

Energy Savings with Ebara End Suction Pumps

Energy efficiency is one of the standout benefits of Ebara End Suction Pumps, contributing to significant long-term savings for businesses across various industries. These pumps are designed to optimize energy consumption, reducing operational costs and making them a highly sustainable choice. By operating efficiently and effectively, Ebara End Suction Pumps help minimize energy usage while maintaining excellent performance.

Key Factors Contributing to Energy Savings:

High-Efficiency Motors:

Ebara End Suction Pumps are equipped with high-efficiency motors that are designed to reduce energy consumption while providing reliable power for continuous operation. These motors are engineered to operate at optimal performance levels, minimizing energy losses and improving the overall efficiency of the system. With low standby power consumption and advanced motor technology, these pumps help businesses save on electricity costs.

Optimized Hydraulic Design:

The hydraulic design of Ebara End Suction Pumps is engineered to ensure that fluid handling is as efficient as possible. By reducing hydraulic losses such as turbulence and friction within the system, the pumps maintain a high flow rate and pressure while using minimal energy. The smooth and efficient fluid handling process reduces the pump’s workload, allowing it to achieve optimal results with less energy input.

Variable Speed Drive (VSD) Compatibility:

Many Ebara End Suction Pumps are compatible with Variable Speed Drives (VSDs). A VSD adjusts the pump’s operating speed based on the demand for fluid flow, allowing the pump to operate only at the speed necessary to meet system requirements. This not only reduces energy consumption during periods of low demand but also ensures that the pump operates at peak efficiency at all times, saving energy without sacrificing performance.

Precise Flow Control:

With variable flow capabilities, Ebara End Suction Pumps allow businesses to precisely control the amount of fluid being pumped at any given time. This means that the pump can adjust its output based on system needs, preventing over-pumping and excessive energy usage. Whether for water treatment, HVAC, or industrial processes, this dynamic flow control reduces energy waste.

Efficient Motor-Pump Matching:

Ebara pumps are designed to ensure that the motor and pump are perfectly matched to optimize performance. By ensuring that the pump operates at the ideal flow rate and pressure, Ebara minimizes the risk of overloading the motor, which can result in energy inefficiency. This careful balance between the motor and pump components helps businesses achieve energy savings while maintaining operational reliability.

Reduced Friction and Wear:

The use of high-quality, wear-resistant components such as stainless steel impellers, bearings, and seals reduces internal friction within the pump. By minimizing friction, the pump requires less energy to move fluids, improving overall efficiency. The use of wear-resistant materials also reduces the frequency of maintenance, ensuring that the pump continues to operate at peak efficiency throughout its lifespan.

Low Vibration and Noise:

Ebara End Suction Pumps are designed to operate with low vibrations and minimal noise. This not only contributes to a more comfortable working environment but also enhances the energy efficiency of the pump. Excessive vibration can cause mechanical stress, leading to energy losses. By reducing vibration, the pump can maintain its optimal operating efficiency and reduce unnecessary energy expenditure.

Reliability and Consistent Performance:

Ebara End Suction Pumps are designed for long-term reliability, which means they deliver consistent performance over time without energy efficiency degradation. Unlike lower-quality pumps that may lose efficiency due to wear and tear, Ebara pumps maintain their energy-efficient operation throughout their lifespan, reducing the need for frequent repairs or replacements that could result in increased energy consumption.

Benefits of Energy Savings:

Lower Operational Costs:

By using less energy to operate, Ebara End Suction Pumps contribute to significant cost savings on electricity bills. Businesses that operate pumps continuously—such as those in water treatment, HVAC systems, and industrial processes—can see substantial reductions in their energy costs over time, leading to improved profitability and budget management.

Improved Return on Investment (ROI):

The energy efficiency of these pumps ensures a faster return on investment. While the initial purchase cost may be higher than less efficient models, the energy savings over the pump’s lifetime far outweigh the upfront cost, resulting in a quicker payback period and more favorable ROI. Lower energy consumption also reduces the overall total cost of ownership.

Sustainability and Environmental Impact:

Reducing energy consumption is not only cost-effective but also contributes to a more sustainable operation. By consuming less electricity, Ebara End Suction Pumps help businesses reduce their carbon footprint, making them an ideal choice for companies looking to meet environmental standards or enhance their corporate sustainability efforts. This is especially important in industries with stringent environmental regulations or sustainability goals.

Compliance with Energy Regulations:

In many regions, businesses are subject to energy efficiency regulations that require them to use equipment that meets certain energy standards. Ebara End Suction Pumps, with their built-in energy-saving features, ensure compliance with these regulations, helping businesses avoid penalties or fines related to energy use.

Enhanced System Efficiency:

Energy-efficient pumps help to optimize the performance of the entire fluid handling system. With lower energy consumption and consistent performance, the system as a whole operates more smoothly, improving overall operational efficiency and reducing the likelihood of system failures or inefficiencies.

Long-Term Sustainability:

With less energy required for operation, Ebara End Suction Pumps offer a long-term sustainable solution for fluid handling. These pumps reduce the need for frequent replacements or repairs, contributing to long-term cost savings and more efficient resource use.

Applications That Benefit from Energy Savings:

Water Treatment Facilities:

In water treatment plants, where pumps often operate continuously, energy-efficient pumps are crucial for managing large-scale water circulation while minimizing energy costs. Ebara End Suction Pumps provide optimal flow rates and pressure levels with minimal energy usage, making them ideal for both municipal and industrial water treatment applications.

HVAC Systems:

For heating, ventilation, and air conditioning (HVAC) systems in large commercial buildings or industrial settings, energy efficiency is essential. Ebara End Suction Pumps ensure that water or fluid circulation within HVAC systems is done at minimal energy consumption, helping businesses reduce energy costs and enhance the sustainability of their heating and cooling operations.

Industrial Manufacturing:

Manufacturing facilities that require pumps to move fluids or chemicals benefit from the energy savings provided by Ebara pumps. By reducing energy consumption during production processes, these pumps help keep operational costs low while improving overall system efficiency.

Fire Protection Systems:

In fire protection systems, where pumps are crucial for providing high-pressure water to sprinklers and fire hoses, energy efficiency is key to minimizing operational costs, especially in large-scale buildings or industrial facilities that require 24/7 system readiness.

Agriculture and Irrigation:

In irrigation systems, energy-efficient pumps help farmers and agricultural businesses reduce energy use while ensuring that water is distributed effectively across large fields, helping increase crop yields without excessive energy costs.

Cooling Systems in Industrial Plants:

In cooling water systems for industrial plants, Ebara End Suction Pumps help optimize the movement of water through cooling systems, reducing energy consumption while maintaining reliable cooling performance for machinery and equipment.

The energy savings provided by Ebara End Suction Pumps make them a highly cost-effective solution for businesses across a range of industries. Their efficient motor technology, optimized hydraulic design, and compatibility with variable speed drives ensure that they operate with minimal energy consumption while delivering optimal performance. By reducing energy use, businesses can lower their operating costs, improve their return on investment, and meet sustainability goals, all while ensuring reliable, high-performance fluid handling. For more info contact Ebara Pump Suppliers in UAE or call us at +971 4 2522966.

0 notes

Text

Reliability and Longevity of Ebara End Suction Pumps

Ebara End Suction Pumps are renowned for their reliability and longevity, making them a trusted solution for fluid handling across various industries. These pumps are designed to provide consistent, long-term performance even in the most demanding environments. Their robust construction, high-quality materials, and precision engineering ensure that they continue to operate efficiently over time, minimizing the risk of failure and reducing the need for frequent repairs or replacements.

Key Aspects of Reliability and Longevity:

High-Quality Materials:

Ebara End Suction Pumps are built using premium-grade materials such as corrosion-resistant stainless steel, cast iron, and bronze. These materials are selected for their ability to withstand the wear and tear of continuous operation in harsh environments. The durability of these materials helps the pump maintain high performance over extended periods, even when exposed to abrasive or corrosive fluids.

Precision Engineering:

The pumps are designed with precision engineering, ensuring that all components fit together perfectly and operate smoothly. This level of detail in the design process helps minimize the risk of mechanical failure, vibration, and wear. The precise alignment of parts ensures optimal operation and reduces the likelihood of issues such as misalignment or component friction that could lead to premature wear.

Wear-Resistant Components:

Wear-resistant impellers, bearings, and seals are integral to the design of Ebara End Suction Pumps. These components are specifically chosen to resist the effects of abrasion, cavitation, and corrosion, ensuring that they perform reliably for long periods without significant degradation. The impellers are particularly important, as they are subject to constant fluid contact, and their durability directly impacts the longevity of the pump.

Efficient Fluid Handling Design:

The hydraulic design of Ebara End Suction Pumps is optimized for efficient fluid handling, ensuring that fluid moves smoothly through the system with minimal turbulence. By reducing the stress on internal components and preventing cavitation (a common cause of damage to pump parts), the pumps are able to operate reliably for extended periods without suffering from operational issues.

Advanced Sealing Technology:

Ebara uses advanced sealing technology to prevent leaks and ensure the integrity of the pump. Mechanical seals and high-quality gaskets are used to prevent the escape of fluids and protect sensitive components. These seals are designed for longevity, requiring minimal maintenance and providing long-term reliability, even in demanding applications.

High-Performance Bearings:

Bearings in Ebara End Suction Pumps are designed to handle heavy loads and reduce friction. The use of high-quality, high-performance bearings ensures smooth operation and reduces wear, contributing to the pump's long service life. The bearings are also lubricated to maintain their performance over time, ensuring that the pump operates without excessive noise, vibration, or failure.

Optimized Motor and Drive Systems:

Ebara End Suction Pumps are equipped with efficient motor and drive systems that are designed for long-term operation. The motors are selected for their reliability and ability to withstand continuous use without overheating or failing prematurely. These drive systems work seamlessly with the pump’s hydraulic components to ensure consistent performance over the long haul.

Built-in Overload and Protection Features:

Many Ebara End Suction Pumps are equipped with overload protection and thermal sensors that automatically shut the pump down in case of operational anomalies. These built-in protection features prevent the pump from running in unfavorable conditions that could lead to damage, contributing to its overall reliability and longevity.

Low-Cost, High-Durability Design:

The design of Ebara End Suction Pumps prioritizes durability without sacrificing cost-efficiency. The long-lasting materials and components, combined with minimal wear and tear, ensure that the pump offers maximum value for its cost, reducing the need for costly replacements and ensuring years of trouble-free operation.

Benefits of Reliability and Longevity:

Reduced Downtime:

Reliable pumps minimize downtime in systems, ensuring that operations run smoothly and without interruption. In industries where continuous fluid handling is critical—such as in water treatment plants, HVAC systems, or industrial processing— minimizing downtime is crucial for maintaining overall system efficiency and meeting production schedules.

Lower Maintenance Costs:

The longevity of Ebara End Suction Pumps translates into lower maintenance costs over the pump's lifespan. Because these pumps are designed to last longer and require less frequent service, businesses spend less on repairs, replacements, and labor. The durability of these pumps also reduces the need for stockpiling spare parts or relying on emergency service calls.

Improved Operational Efficiency:

Pumps that are reliable and long-lasting ensure that the fluid handling system operates at peak efficiency. Optimized performance over time means that the system can operate with minimal disruptions, maintaining the correct flow rates and pressures, which contributes to overall energy efficiency and cost-effectiveness.

Extended Equipment Life:

The durability of Ebara End Suction Pumps contributes to the extended life of the entire system. When the pump operates reliably over many years, it reduces the need for frequent repairs or replacements of associated equipment, such as motors, piping, or seals. This results in fewer system interruptions and a more cost-effective long-term operation.

Enhanced Safety:

The reliability of Ebara End Suction Pumps also enhances safety. In critical applications such as fire protection systems, industrial processes, or water treatment, the consistent performance of the pump ensures that the system operates as intended, reducing the risk of safety failures that could arise from malfunctioning or unreliable equipment.

Maximized ROI (Return on Investment):

The long-lasting nature of Ebara End Suction Pumps ensures that businesses receive maximum value for their investment. The combination of low maintenance costs, energy efficiency, and extended service life means that businesses get a high return on investment, with pumps delivering reliable performance for years without the need for major replacements or repairs.

Sustainability:

The longevity of these pumps contributes to sustainability efforts. Fewer replacements and reduced maintenance requirements mean less waste, fewer materials used, and a smaller environmental footprint. Businesses can achieve long-term operational goals while reducing the environmental impact of their equipment.

Applications Benefiting from Reliability and Longevity:

Water Treatment and Wastewater Facilities:

These facilities rely on pumps that can operate continuously without failure. Ebara End Suction Pumps offer the reliability needed to handle large volumes of water without frequent interruptions, ensuring that the water treatment process remains efficient and effective.

Industrial Manufacturing and Processing:

In manufacturing and industrial applications, equipment downtime can be costly. Ebara’s long-lasting pumps help maintain continuous production, ensuring that the system runs reliably without the need for frequent repairs or replacements, which can disrupt operations.

HVAC Systems in Commercial Buildings:

HVAC systems depend on reliable pumps to circulate water and maintain optimal building temperatures. Ebara End Suction Pumps are designed for long-term operation, reducing the risk of pump failure that could lead to system downtime and discomfort for building occupants.

Fire Protection Systems:

Fire protection systems must be ready to perform in emergencies. Ebara End Suction Pumps ensure that high pressure is always available for fire-fighting systems, providing reliable operation over time, especially in large commercial buildings or industrial plants.

Agriculture and Irrigation:

In agricultural settings, where pumps are often in use continuously for irrigation, Ebara End Suction Pumps offer the reliability and durability needed to ensure a steady water supply for crops, reducing the risk of pump failure during critical irrigation periods.

The reliability and longevity of Ebara End Suction Pumps make them a valuable investment for businesses looking for cost-effective, long-term solutions for fluid handling. Their durable construction, high-quality materials, and precise engineering ensure that they can operate continuously with minimal maintenance and downtime, delivering consistent performance across a variety of industries. By choosing Ebara End Suction Pumps, businesses can achieve maximum efficiency, lower maintenance costs, and extended operational life, ultimately contributing to sustainable and reliable system performance over the long term. For more info contact Ebara Pump Suppliers in UAE or call us at +971 4 2522966.

0 notes

Text

Cost-Effectiveness of Ebara End Suction Pumps

Ebara End Suction Pumps are not only designed to deliver high performance but also to provide a cost-effective solution for businesses across various industries. Their efficient design, durability, and low maintenance requirements make them a highly economical choice, offering significant savings over the lifetime of the pump. From reducing operational costs to minimizing the need for repairs and replacements, these pumps ensure that businesses can achieve high levels of performance without breaking their budgets.

Key Factors Contributing to Cost-Effectiveness:

Energy Efficiency:

One of the primary ways Ebara End Suction Pumps contribute to cost-effectiveness is through their energy-efficient operation. These pumps are engineered to minimize energy consumption by optimizing their hydraulic design and using high-efficiency motors. By reducing energy costs, businesses can save significantly on their utility bills over time, making the pumps a smart investment for long-term operations.

Variable Speed Drives (VSDs): Many models of Ebara End Suction Pumps are compatible with variable speed drives, allowing operators to adjust the pump speed based on demand. This feature reduces energy consumption by ensuring the pump only uses the necessary power required for the task, further lowering operational costs.

Durable Construction and Longevity:

Ebara End Suction Pumps are built with high-quality materials such as corrosion-resistant stainless steel and cast iron. These materials ensure the pump’s durability even in harsh operating environments. With proper maintenance, these pumps can last for years, reducing the frequency of replacement and repairs. Their extended service life means lower capital expenditure for businesses, which makes them more cost-effective in the long run.

Low Maintenance Costs:

The simple maintenance design of Ebara End Suction Pumps contributes to lower maintenance costs. With easy access to components, minimal need for specialized tools, and fewer service interventions required, these pumps reduce downtime and maintenance expenses. Routine checks and maintenance tasks can be performed with minimal effort, reducing the need for costly professional servicing.

Wear-Resistant Components: The use of wear-resistant materials in key components, such as the impeller and bearings, ensures that the pump operates smoothly for longer periods without requiring frequent parts replacements. This contributes to reducing ongoing operational and maintenance costs.

Reduced Downtime:

Ebara End Suction Pumps are known for their reliability and consistent performance. They are engineered to operate with minimal risk of failure, reducing the likelihood of unexpected breakdowns that lead to costly downtime. By investing in a reliable pump, businesses can avoid the financial losses that often result from system interruptions, repairs, or production delays.

Efficient Fluid Handling:

The efficiency of fluid handling in Ebara End Suction Pumps helps ensure optimal pump performance, even under varying system demands. This reduces the need for over-engineering or large, costly pump systems. Whether handling clean water, chemicals, or viscous liquids, these pumps maintain their efficiency, ensuring that businesses can meet their fluid handling requirements without the need for additional investments in more complex or expensive systems.

Simplified Installation:

The compact and straightforward design of Ebara End Suction Pumps makes installation quick and easy, reducing the costs associated with complex setup procedures. The simplicity of integration into existing systems or new projects helps minimize installation time and labor costs, making the process more economical.

Minimal Spare Parts and Inventory Costs:

Ebara End Suction Pumps require fewer spare parts and specialized components over time due to their durability and design. This translates into lower spare parts costs and easier inventory management. Businesses can rely on the same standard parts for various pump models, streamlining their maintenance and reducing costs associated with stocking a wide range of spare parts.

Scalability and Flexibility:

Ebara End Suction Pumps offer scalability for businesses that may need to expand or adjust their systems in the future. Rather than needing to replace an entire pump system, businesses can scale up by adding additional pumps of the same model, avoiding costly overhauls or system redesigns. The flexibility in their use, whether in water treatment, HVAC, or industrial processing, ensures that businesses get maximum value for their investment.

Reduced Risk of System Failure:

With advanced features that minimize wear and tear, overload protection, and self-priming capabilities, Ebara pumps operate with a lower risk of failure. This reduces the need for emergency repairs or replacements, which can often be costly and disruptive to operations. The pumps' reliability ensures that businesses do not have to invest in constant troubleshooting or unplanned maintenance interventions.

Benefits of Cost-Effectiveness:

Lower Operational Costs:

By using less energy, requiring minimal maintenance, and having long-lasting components, Ebara End Suction Pumps help reduce the overall operational costs of fluid handling systems. These savings can be passed on to the business's bottom line, improving overall profitability.

Faster Return on Investment (ROI):

The low initial investment, combined with long-term energy savings, minimal downtime, and reduced maintenance costs, ensures that businesses can see a faster return on investment when using Ebara End Suction Pumps. The overall cost savings over the lifespan of the pump far exceed the initial purchase cost.

Increased Profit Margins:

By reducing energy bills, maintenance costs, and downtime, businesses can improve their profit margins. Ebara End Suction Pumps help optimize the efficiency of the system while keeping costs low, allowing companies to allocate resources to other areas of the business or improve financial performance.

Improved Budget Planning:

The predictability of maintenance schedules and the reliability of these pumps make it easier for businesses to budget for ongoing operating costs. With fewer surprises and predictable maintenance intervals, businesses can better plan for long-term operational expenses.

Sustainable Cost Management:

Ebara pumps are designed with sustainability in mind, not only helping businesses reduce their environmental footprint but also managing costs efficiently. Reduced energy consumption, fewer replacement parts, and longer pump lifespans contribute to sustainable cost management, ensuring businesses can grow without overspending on maintenance or energy use.

Applications Benefiting from Cost-Effectiveness:

Water Treatment Plants:

In water treatment facilities, where efficiency and cost control are essential, Ebara End Suction Pumps provide a cost-effective solution by reducing both energy consumption and maintenance costs, ensuring long-term operational efficiency.

HVAC Systems:

Commercial and residential HVAC systems benefit from the pumps' low energy use and easy maintenance, which translates to lower operating costs and improved cost-effectiveness in climate control systems.

Industrial Manufacturing:

Ebara End Suction Pumps are ideal for industrial processes, where reliability and durability reduce the need for frequent repairs or replacements. Their energy-efficient performance ensures that manufacturing systems can operate at optimal levels while keeping overhead costs low.

Agriculture and Irrigation:

In agricultural applications, where water management is critical, these pumps help optimize water usage and reduce operational costs. Their durability ensures that they can withstand the demands of continuous operation, while their low maintenance requirements help reduce downtime and repair expenses.

Fire Protection Systems:

In fire-fighting systems, where high pressure and reliable performance are needed, Ebara End Suction Pumps provide an affordable, long-lasting solution that keeps both installation and maintenance costs in check.

Ebara End Suction Pumps offer exceptional cost-effectiveness across various industries by delivering energy-efficient performance, low maintenance requirements, and long-term durability. The reduced operational costs, minimized downtime, and predictable maintenance schedules make these pumps an economical choice that delivers value over the lifetime of the equipment. Whether in water treatment, HVAC, industrial manufacturing, or agriculture, businesses can rely on Ebara End Suction Pumps to achieve significant savings while maintaining high levels of performance and reliability. For more info contact Ebara Pump Suppliers in UAE or call us at +971 4 2522966.

0 notes

Text

Low Noise and Vibration of Ebara End Suction Pumps

One of the key features that sets Ebara End Suction Pumps apart is their low noise and vibration performance. These pumps are engineered to operate smoothly, minimizing noise levels and vibrations that could otherwise interfere with system performance or cause discomfort in commercial and industrial environments. The design and technology behind Ebara pumps ensure that they deliver effective fluid handling without creating disruptive operational noise or excessive vibrations.

Key Aspects of Low Noise and Vibration Performance:

Precision-Crafted Components:

Ebara End Suction Pumps are built with precision-machined components that ensure all parts fit together smoothly. The impeller, motor, and shaft are carefully designed to reduce imbalances and eliminate unnecessary friction, which helps minimize the source of vibrations and noise during operation.

Balanced Impeller Design:

The impeller is a critical component in determining the smoothness of pump operation. Ebara’s hydraulic design focuses on achieving perfect balance in the impeller, reducing the risk of vibration caused by uneven flow or pressure distribution. A well-balanced impeller results in quieter operation and more efficient performance.

Advanced Bearing Technology:

Bearings play an essential role in reducing vibration and noise. Ebara End Suction Pumps use high-quality bearings designed to provide smooth and quiet operation. These bearings help absorb mechanical stress and prevent unwanted movement, contributing to the overall stability and smoothness of the pump.

Optimized Shaft and Motor Alignment:

Ebara ensures that the shaft and motor are perfectly aligned to avoid mechanical misalignment, which can lead to both vibrations and noise. Proper alignment ensures that the pump operates in a stable manner, with less friction between moving parts, resulting in smoother performance.

Vibration-Damping Features:

Ebara pumps are designed with vibration-damping features, including the use of rubber mounts, shock absorbers, and isolating materials that help absorb and dissipate vibrations. These features reduce the transfer of vibrations to the surrounding environment, ensuring that the system operates with minimal impact on nearby equipment or structures.

Low-Vibration Pumping Technology:

Ebara’s pumping technology incorporates elements that reduce cavitation, a phenomenon that can generate significant noise and vibration in pumps. By reducing cavitation through efficient fluid handling, the pumps operate with lower levels of turbulence, which helps reduce both noise and vibration.

Efficient Fluid Handling:

The smooth, efficient handling of fluid within the pump contributes to lower noise levels. Ebara’s End Suction Pumps are designed to manage fluid flow with minimal turbulence, ensuring that the liquid moves through the system quietly and smoothly, rather than causing erratic movements or noise.

Benefits of Low Noise and Vibration:

Improved Comfort in Commercial and Residential Environments:

Pumps operating with low noise levels are especially beneficial in commercial and residential environments where the reduction of noise pollution is a priority. In buildings with HVAC systems, water treatment facilities, or fire protection systems, the noise generated by pumps can be disruptive to occupants or employees. Ebara End Suction Pumps provide a quieter solution, ensuring that systems operate unobtrusively.

Enhanced Worker Health and Safety:

Excessive noise and vibration can have detrimental effects on worker health over time, including hearing loss and physical strain. By minimizing noise and vibration, Ebara End Suction Pumps contribute to a healthier working environment and reduce the potential for long-term damage caused by constant exposure to loud, vibrating equipment.

Protection of Sensitive Equipment:

Excessive vibration can cause damage to sensitive machinery, leading to increased wear, mechanical failure, or the need for premature replacement. The low vibration performance of Ebara pumps helps protect surrounding equipment from unnecessary stress, reducing maintenance and repair costs for other components within the system.

Improved System Longevity:

Lower vibrations mean less mechanical stress on both the pump and its associated components. As a result, the system experiences less wear and tear, leading to extended equipment life. This reduces the frequency of repairs and part replacements, making the pump more cost-effective over time.

Energy Efficiency:

When a pump operates with minimal vibrations and noise, it’s typically running more efficiently. Energy losses due to vibrations are minimized, and the system functions more smoothly. By reducing unnecessary movement and friction, energy consumption is optimized, contributing to overall system efficiency.

Regulatory Compliance:

In certain industries or regions, there are strict noise regulations that mandate the operation of equipment within specific decibel levels. Ebara End Suction Pumps meet these noise standards, helping businesses comply with local regulations and avoid penalties associated with excessive noise emissions.

Smoother Operation of Systems:

Low vibration levels contribute to the smooth operation of the entire system. When pumps generate minimal vibrations, the fluid handling system operates more efficiently, and there are fewer disruptions to the overall functioning of interconnected components. This leads to more reliable performance and fewer maintenance interventions.

Applications Benefiting from Low Noise and Vibration:

Residential Buildings:

In apartments, hotels, or residential complexes, Ebara End Suction Pumps are ideal for HVAC systems, water supply systems, and hot water circulation due to their quiet operation, ensuring minimal disturbance to residents.

Office and Commercial Buildings:

Commercial spaces that require HVAC systems or water management systems benefit from low noise pumps to create a more comfortable work environment. These pumps contribute to a quieter atmosphere, improving employee satisfaction and productivity.

Laboratories and Hospitals:

Sensitive environments like laboratories and hospitals require extremely low noise levels. Ebara End Suction Pumps are well-suited for these applications, where even minor noise can interfere with operations or patient care.

Manufacturing Facilities:

In factories or processing plants, where machinery is already running, the reduction of additional noise and vibration from pumps contributes to an overall better working environment. It helps maintain worker safety and reduces mechanical stress on other machinery.

Water Treatment Plants:

In water treatment facilities, where pumps are running continuously, low noise and vibration levels help ensure that the system runs quietly and efficiently. This is especially beneficial in urban areas where sound levels need to be controlled.

The low noise and vibration performance of Ebara End Suction Pumps provides multiple benefits, including improved comfort, worker safety, and system efficiency. The precision design, high-quality components, and advanced technology used in these pumps ensure that they operate quietly and smoothly, without causing disruptive noise or vibrations. Whether in commercial, industrial, or residential applications, Ebara pumps contribute to a more comfortable, reliable, and efficient system, enhancing both operational performance and the longevity of the equipment. For more info contact Ebara Pump Suppliers in UAE or call us at +971 4 2522966.

0 notes

Text

Versatility in Applications of Ebara End Suction Pumps

Ebara End Suction Pumps are highly versatile, making them suitable for a wide range of applications across different industries. Their robust design, combined with their ability to handle a variety of fluids, pressures, and flow rates, ensures they can adapt to the unique requirements of multiple sectors. Whether you're in water treatment, HVAC, industrial processing, or fire protection, these pumps offer reliable performance, contributing to optimized systems and efficient fluid handling.

Key Applications for Ebara End Suction Pumps:

HVAC Systems:

Application: Ebara End Suction Pumps are widely used in heating, ventilation, and air conditioning (HVAC) systems, where reliable water or fluid circulation is essential. They help in circulating chilled or heated water through the building, ensuring efficient temperature regulation in large commercial or residential structures.

Benefits: These pumps help maintain consistent water pressure in heating and cooling systems, improving the energy efficiency of HVAC units and ensuring optimal comfort in commercial and industrial environments.

Water Treatment Plants:

Application: Ebara End Suction Pumps play a crucial role in water treatment plants, ensuring the efficient circulation of water through filtration, purification, and distribution systems. They are used for transferring clean or treated water, managing flow rates, and maintaining pressure levels throughout the plant.

Benefits: These pumps help improve the efficiency of water treatment processes by ensuring consistent flow and pressure. Their corrosion-resistant design ensures long-term durability in the presence of chemicals used in water purification processes.

Fire Protection Systems:

Application: In fire protection systems, Ebara End Suction Pumps are used to boost water pressure, ensuring that fire suppression systems, including sprinklers and hydrants, have an adequate water supply in emergency situations.

Benefits: Their ability to deliver high pressure at a relatively low flow rate makes them ideal for fire-fighting applications. They provide the necessary pressure for the quick and efficient activation of fire suppression systems, ensuring safety in commercial, industrial, and residential buildings.

Industrial Processing:

Application: Ebara End Suction Pumps are widely used in various industrial processes, including chemical processing, oil and gas, and food and beverage production. They are used to handle a variety of fluids, such as chemicals, oils, water, and slurries, in manufacturing and production environments.

Benefits: The ability to handle a wide range of liquids, including chemicals and viscous fluids, makes these pumps versatile for industrial applications. Their durability and wear-resistant components ensure long-lasting performance even in harsh industrial environments.

Agriculture and Irrigation Systems:

Application: In agriculture and irrigation, Ebara End Suction Pumps are used for irrigating crops, supplying water to livestock, and supporting drainage systems in agricultural facilities.

Benefits: Their reliability in moving large volumes of water makes them ideal for irrigation applications. These pumps help optimize water usage in farming, ensuring that crops receive adequate water for growth while maintaining efficiency in water distribution systems.

Fire Fighting Systems:

Application: Ebara End Suction Pumps are used in fire fighting applications, where they provide high-pressure water supply to fire hoses, sprinklers, and other firefighting equipment in both industrial and commercial settings.

Benefits: Their high-pressure capabilities make them essential in delivering sufficient water pressure to extinguish fires effectively. These pumps are integral to fire protection systems, especially in high-risk environments like factories, high-rise buildings, and industrial complexes.

Municipal Water Systems:

Application: These pumps are often deployed in municipal water distribution systems, where they help maintain steady water flow and pressure across cities, towns, or residential areas.

Benefits: Ebara End Suction Pumps are capable of delivering consistent and reliable flow, which is crucial for large-scale water distribution networks that supply residential and industrial customers.

Cooling Water Circulation Systems:

Application: In industrial settings like power plants, refineries, and manufacturing facilities, these pumps are used to circulate cooling water through systems to regulate temperature and prevent overheating of machinery and equipment.

Benefits: Their ability to move large volumes of water at a stable flow rate makes them effective in managing cooling water systems, preventing overheating, and ensuring the proper functioning of industrial machinery.

Desalination Plants:

Application: Ebara End Suction Pumps are employed in desalination plants to help transfer seawater, treat it, and convert it into fresh, potable water for use in coastal areas or regions where fresh water is scarce.

Benefits: These pumps are capable of handling highly corrosive seawater and are designed to withstand the demands of desalination processes, ensuring reliable and efficient water treatment.

Cooling and Heat Exchange Systems:

Application: In systems that require heat exchange processes, such as refrigeration, power generation, and chemical production, Ebara End Suction Pumps circulate water or other cooling fluids to manage temperatures and prevent system malfunctions.

Benefits: They ensure that cooling systems operate effectively by maintaining consistent flow and pressure, which is crucial for keeping equipment and systems within operational temperature limits.

Benefits of Versatility in Applications:

Cost-Effectiveness:

The ability to use one type of pump across multiple applications reduces the need to purchase and maintain various pumps for different tasks. This helps save on capital expenditures, spare parts inventory, and maintenance costs.

Simplified Inventory Management:

Having a versatile pump that can handle multiple tasks means businesses can maintain a smaller inventory of parts and systems. This simplifies spare parts management and reduces downtime due to part shortages or incompatibility between different pumps.

Flexibility and Scalability:

Ebara End Suction Pumps are adaptable to changing demands. If a facility needs to expand or alter its operations, the same pump model can often be used with minor adjustments, ensuring scalability without having to completely overhaul the system.

Ease of Integration:

Their ability to be integrated seamlessly into various systems means that these pumps are often the preferred choice for upgrades or retrofits in existing infrastructure. They are compatible with a wide range of piping configurations and system layouts, simplifying installation in both new projects and system renovations.

Reliability Across Industries:

Across various industries, from water treatment to chemical processing, the proven reliability of Ebara End Suction Pumps ensures minimal disruptions to operations. Their versatility in handling different types of fluids, flow rates, and pressure requirements means that they can be trusted to perform consistently in a variety of settings.

Improved Operational Efficiency:

The reliability and efficiency of Ebara End Suction Pumps across different applications contribute to the overall performance of the system. In each industry, these pumps help optimize fluid handling, improve flow regulation, and reduce energy consumption, leading to improved operational efficiency.

The versatility of Ebara End Suction Pumps makes them a valuable asset in many industries. Whether used in water treatment, HVAC systems, industrial processing, or fire protection, these pumps offer reliable, efficient, and cost-effective solutions. Their ability to handle a variety of fluids, pressures, and flow rates ensures that they meet the specific needs of each application while contributing to operational efficiency and long-term system reliability. For more info contact Ebara Pump Suppliers in UAE or call us at +971 4 2522966.

0 notes

Text

Simple Maintenance of Ebara End Suction Pumps

Ebara End Suction Pumps are designed with simplicity and ease of maintenance in mind, helping to minimize downtime, reduce maintenance costs, and ensure long-term operational efficiency. Their user-friendly design makes it easier for operators and technicians to carry out regular checks, troubleshoot issues, and replace components when needed. This feature is particularly valuable for industries and facilities that rely on continuous operation and cannot afford extended periods of pump downtime.

Key Aspects of Simple Maintenance:

Accessible Components:

Ebara End Suction Pumps are engineered to allow easy access to key components such as the impeller, seals, and bearings. This design simplifies routine maintenance tasks, allowing technicians to inspect and service the pump without having to dismantle complex parts or systems. The straightforward configuration ensures that each component is easily reachable for inspections and replacements.

Easy-to-Remove Parts:

Many of the parts in the pump, such as the impeller, seals, and bearings, can be quickly removed for inspection, cleaning, or replacement. This makes it easy to carry out preventive maintenance or repair procedures without requiring significant downtime or specialist tools.

No Complex Alignment or Calibration:

Ebara End Suction Pumps are designed to operate with minimal need for realignment or recalibration during routine maintenance. Once installed, the pump runs efficiently without requiring frequent adjustments to keep it running optimally. This eliminates the need for continuous monitoring or realignment that is common in more complex pump systems.

Durable Seals and Bearings:

The mechanical seals and bearings used in Ebara End Suction Pumps are designed for long-lasting performance, requiring minimal attention under normal operating conditions. These parts are built to withstand the rigors of continuous operation, reducing the frequency of seal or bearing replacements and ensuring that the pump maintains high performance with fewer service interruptions.

Simple Lubrication Procedures:

The lubrication system for Ebara End Suction Pumps is designed to be straightforward. Many models feature grease-lubricated bearings or oil-lubricated systems that require periodic checks and top-ups. The simplicity of this process ensures that users can maintain the pump’s performance with minimal effort.

Wear-Resistant Components:

Ebara incorporates wear-resistant materials such as stainless steel and bronze in critical parts like the impeller, casing, and shaft. These materials are designed to withstand abrasive wear, which helps extend the intervals between maintenance tasks and reduces the frequency of part replacements.

Self-Priming Capabilities:

Many Ebara End Suction Pumps are designed with self-priming capabilities, meaning that they can operate with minimal intervention after initial setup. This reduces the need for frequent priming or complex setup procedures and ensures that the pump continues to function properly without additional steps being taken during maintenance.

Clear Maintenance Guidelines:

Ebara provides clear, easy-to-follow maintenance manuals and guidelines for its pumps, making it easier for maintenance staff to perform checks, cleaning, and troubleshooting. These documents are designed to minimize the time spent on maintenance by providing step-by-step instructions and addressing common issues with simple solutions.

Built-in Protection Features:

Ebara End Suction Pumps come equipped with built-in protection features, such as overload protection and thermal sensors, which help prevent damage to the pump and its components in case of irregular operation. These features alert users to potential problems before they cause significant damage, allowing for prompt intervention and reducing the need for extensive repairs.

Benefits of Simple Maintenance:

Reduced Downtime:

The simplicity of Ebara End Suction Pump maintenance ensures that routine tasks can be completed quickly and efficiently. This reduces the amount of time the pump is offline, allowing systems to continue running without significant interruptions. For businesses relying on continuous operation, minimizing downtime is a crucial benefit.

Lower Maintenance Costs:

With fewer parts requiring regular attention and easy access to key components, the overall cost of maintenance is reduced. The pump’s durability and easy serviceability mean that you won’t need to rely on expensive external technicians or undergo lengthy service procedures. Operators can perform many tasks in-house, saving time and money.

Extended Equipment Life:

Regular, simple maintenance tasks help keep the pump running at peak efficiency, extending its overall service life. By reducing wear and tear, performing routine inspections, and replacing worn components promptly, you ensure that the pump continues to operate smoothly for years.

Improved System Reliability:

With regular maintenance being simple and accessible, operators can quickly detect any emerging issues, such as leaks or mechanical wear, before they develop into more serious problems. This proactive approach enhances the overall reliability of the system and ensures that the pump remains operational when needed most.

Minimal Training Required:

Because the maintenance process is intuitive and requires minimal specialized training, staff can quickly become proficient in performing essential upkeep. This allows for smoother operations, especially in environments with high staff turnover or where external specialists may not be readily available.

Enhanced Operational Efficiency:

A well-maintained Ebara End Suction Pump operates at optimal efficiency, ensuring that energy consumption remains low, fluid transfer remains consistent, and system performance remains high. Regular maintenance helps preserve the pump's energy-efficient performance, ensuring that it contributes to overall operational efficiency.

Common Maintenance Tasks:

Inspecting and Replacing the Impeller:

The impeller is the heart of the pump. Periodically inspecting and replacing the impeller if necessary is crucial to maintain pump performance.

Lubrication of Bearings:

Keeping bearings properly lubricated ensures smooth operation and prevents excessive wear. This is typically done on a set schedule based on the manufacturer's recommendations.

Seal Inspection and Replacement:

Regular checks of the mechanical seals prevent leaks and ensure that the pump remains efficient. Seals should be replaced when signs of wear or leaks are detected.

Cleaning the Pump Casing:

Over time, debris, dirt, or other particles may accumulate in the pump casing. Cleaning the casing ensures that the fluid flows without obstruction and prevents clogging.

Checking Pump Alignment:

Ensuring that the pump is properly aligned prevents unnecessary strain on the motor and other components, reducing the risk of failure.

System Performance Check:

Regularly testing the pump’s output, flow rate, and pressure ensures that it continues to perform as expected. Any discrepancies can be addressed before they become serious issues.

The simple maintenance of Ebara End Suction Pumps is one of their key advantages, making them a practical choice for businesses seeking reliable and cost-effective solutions. With easy access to components, straightforward maintenance procedures, and durable parts that require minimal attention, these pumps ensure that operators can keep systems running smoothly without the need for extensive downtime or costly repairs. By following basic maintenance practices, businesses can extend the life of their pumps, reduce operational costs, and enhance the overall efficiency of their fluid handling systems. For more info contact Ebara Pump Suppliers in UAE or call us at +971 4 2522966.

0 notes

Text

Compact and Space-Saving Design of Ebara End Suction Pumps

One of the standout advantages of Ebara End Suction Pumps is their compact and space-saving design, making them an ideal choice for installations where space is limited or where maximizing available space is a priority. Whether in industrial settings, commercial buildings, or municipal facilities, the design of these pumps ensures they can be efficiently integrated into existing systems without requiring significant alterations or extensive floor space.

Key Aspects of the Compact and Space-Saving Design:

End-Suction Configuration:

The end-suction design is one of the main contributors to the compactness of these pumps. Unlike traditional pump configurations, where the suction and discharge ports may be located on opposite sides, the end-suction pump has both ports located on the same side. This design allows the pump to be shorter in length and more compact, reducing its footprint and making it easier to fit into confined spaces.

Smaller Footprint:

Ebara End Suction Pumps are designed with a smaller overall footprint, allowing them to be installed in areas where space is a premium. Their compact nature makes them ideal for retrofit installations or tight spaces where larger pumps or systems might not be feasible.

Lightweight Construction:

The use of high-strength but lightweight materials, such as cast iron and stainless steel, contributes to the pump's reduced weight. This makes the pumps easier to handle during installation, especially in spaces where heavy equipment might be difficult to maneuver. It also simplifies transportation, reducing installation costs and time.

Compact Motor Options:

Ebara End Suction Pumps can be paired with compact, high-efficiency motors that are designed to deliver powerful performance while occupying minimal space. These motors are specifically chosen to ensure that the pump delivers optimal performance without requiring large motor sizes, which further enhances the space-saving nature of the system.

Efficient Pump Casing Design:

The pump casing is carefully engineered to minimize its size without sacrificing strength or durability. The streamlined design of the casing helps reduce the overall bulk of the pump, ensuring it fits into smaller enclosures or tight installations. This makes it ideal for applications where the pump must be installed within existing systems or in retrofit projects.

Vertical or Horizontal Mounting Options:

The flexibility in mounting options, whether vertical or horizontal, provides additional versatility for installation. This allows for better utilization of available space and enables users to choose the most space-efficient setup based on their system requirements. In some cases, the ability to mount the pump vertically can further save space, especially in systems with limited floor area.

Minimized Piping Connections:

Due to the end-suction configuration and efficient design, Ebara End Suction Pumps require fewer and simpler piping connections. This reduces the need for complex piping setups, saving both space and installation time. The straightforward design also minimizes the overall space needed for surrounding infrastructure and reduces the overall system footprint.

Benefits of a Compact and Space-Saving Design:

Ideal for Confined Spaces:

Many industries and applications, such as HVAC systems, water treatment plants, and industrial processes, face challenges when working in tight spaces. The compact design of Ebara End Suction Pumps allows them to be installed in these smaller areas without compromising system performance or functionality. This is especially important for facilities that have limited floor space or when retrofitting existing equipment.

Flexibility in Installation Locations:

The smaller size and lightweight construction give greater flexibility in installation location. Whether the pump needs to be placed in a basement, roof-mounted system, or modular system, Ebara End Suction Pumps can be easily integrated without requiring significant space or costly modifications to the building or system.

Reduced Installation Costs:

With their compact design and ability to fit into smaller spaces, installation becomes quicker and more cost-effective. The need for extra space or expansion work is minimized, reducing both installation time and the associated costs.

Improved System Efficiency:

By taking up less space, these pumps allow for more efficient use of the available area. This means that other critical equipment can be placed in the same space, or more efficient layouts can be designed to improve overall system efficiency. In systems where real estate or floor space is valuable, this helps businesses optimize their setups for both performance and space utilization.

Easier Maintenance and Access:

Due to the more compact size, it is often easier to provide access for maintenance tasks. In installations where space is limited, having smaller equipment means it’s easier to navigate around the pump for inspections, servicing, or repairs. This can reduce the complexity and duration of maintenance activities, leading to less downtime and more efficient operations.

Better Use of Floor Space:

For commercial and industrial applications, floor space is a valuable resource. The compact design of Ebara End Suction Pumps ensures that it doesn’t occupy unnecessary space, freeing up room for other equipment, storage, or operational needs. This helps businesses maximize the utility of the area available.

Scalability in Systems:

The smaller size of these pumps makes them ideal for modular or scalable systems, where additional pumps can be added without requiring extensive changes to the existing setup. As businesses grow or as systems need to be expanded, Ebara End Suction Pumps can be added or reconfigured to meet increased demand without taking up excessive space.

Applications Benefiting from Compact Design:

HVAC Systems:

In commercial buildings, offices, and residential complexes, space is often limited. Ebara End Suction Pumps are ideal for circulating water or other fluids in HVAC systems where floor space and mechanical room sizes are constrained.

Water Treatment Plants:

Many water treatment plants, particularly in urban environments, operate in confined spaces. The compact design of these pumps ensures that they can be easily integrated into existing systems without requiring extensive reconfiguration or additional space for installation.

Fire Protection Systems:

Fire-fighting systems often require pumps to be installed in limited spaces within buildings or other structures. The compact and efficient design of Ebara End Suction Pumps makes them suitable for these applications where reliable performance is crucial but space is at a premium.

Industrial and Commercial Applications:

Whether for pumping fluids in manufacturing, chemical processing, or food and beverage production, Ebara End Suction Pumps offer the flexibility to fit into industrial systems with space limitations. Their compact nature makes them perfect for retrofitting or upgrading existing systems without the need for major facility changes.

The compact and space-saving design of Ebara End Suction Pumps is a significant advantage for industries and applications that need to optimize their space usage. Their ability to fit into tight spaces without compromising on performance, reliability, or efficiency makes them an excellent choice for both new installations and retrofits. Whether in HVAC systems, water treatment, fire protection, or industrial processes, these pumps provide a reliable, space-efficient solution that meets the demanding needs of modern applications. For more info contact Ebara Pump Suppliers in UAE or call us at +971 4 2522966.

0 notes

Text

Durable Construction of Ebara End Suction Pumps

The durable construction of Ebara End Suction Pumps is a key factor in their ability to deliver reliable and long-lasting performance in demanding applications. Built to withstand harsh operating environments and continuous use, these pumps are designed with high-quality materials and engineering techniques that ensure they can handle tough conditions without compromising their efficiency or reliability.

Key Aspects of Durable Construction:

High-Quality Materials:

Ebara End Suction Pumps are constructed using premium materials that are chosen for their strength, corrosion resistance, and longevity. Common materials used include cast iron, stainless steel, and bronze, depending on the application and the type of fluid being pumped. These materials ensure that the pump can withstand corrosion from chemicals, rust from water exposure, and wear and tear from continuous operation.

Corrosion-Resistant Components:

For applications where the pump is exposed to corrosive liquids, such as chemicals or seawater, Ebara uses corrosion-resistant materials like stainless steel for the pump casing, impeller, and shaft. The use of these materials protects the pump from degradation and extends its operational life, reducing the need for frequent repairs or replacements.

Heavy-Duty Bearings and Shaft Design:

The pump's shaft and bearings are designed to handle high loads and pressures. Ebara End Suction Pumps feature heavy-duty bearings that reduce friction and prevent overheating. The shaft is carefully engineered for maximum strength to endure the mechanical stresses encountered during operation, ensuring that the pump runs smoothly for extended periods without failure.

Robust Pump Casing:

The pump casing is designed to be strong and resistant to physical damage. Ebara uses cast iron and other durable materials to create casings that can withstand the pressures and stresses typical in demanding applications. The casings are also designed to prevent leaks and ensure that the fluid handling process remains uninterrupted and secure.

Seals and Gaskets for Protection:

Seals and gaskets are essential to preventing leakage, maintaining efficiency, and ensuring that the pump operates safely. Ebara End Suction Pumps are equipped with high-quality mechanical seals and gaskets that prevent leaks and protect sensitive components from exposure to the pumped fluid. These seals are designed to maintain performance even under high pressure or when exposed to aggressive fluids.

Wear-Resistant Impeller:

The impeller, which is responsible for transferring energy to the fluid, is constructed from materials that are both wear-resistant and efficient. Stainless steel and bronze impellers are often used, depending on the application. The wear-resistant design ensures that the impeller maintains its shape and function even when handling abrasive materials or fluids, reducing the need for frequent maintenance or part replacement.

Vibration and Noise Reduction Features:

Ebara End Suction Pumps are designed with features that reduce vibration and noise, which not only improve operational comfort but also protect the pump components from unnecessary stress. By minimizing vibrations, the pump's mechanical parts are less likely to experience wear and tear, resulting in a longer service life.

Temperature Resistance:

Ebara End Suction Pumps are engineered to operate under a range of temperature conditions, from cold water to hot fluids. Whether dealing with high-temperature fluids in industrial processes or extreme environmental conditions, these pumps are designed to maintain optimal performance without compromising their structural integrity. The materials used are resistant to thermal expansion and contraction, which helps prevent damage over time.

Benefits of Durable Construction:

Extended Service Life:

The durable construction of Ebara End Suction Pumps ensures that they can handle the demands of continuous operation over long periods. This results in lower downtime and a longer service life, which ultimately leads to reduced operational costs and a more reliable pumping solution for businesses.

Reduced Maintenance Costs:

Durable construction reduces the frequency of repairs and the need for part replacements, leading to significant savings in maintenance costs. Since the pump’s components are designed to withstand wear and corrosion, the need for frequent inspections and servicing is minimized, making the pump more cost-effective in the long term.

Reliability in Harsh Environments:

Whether used in high-pressure industrial applications, corrosive chemical processing, or high-temperature systems, the robust materials and design of Ebara End Suction Pumps ensure reliable operation in harsh environments. This reliability is critical for industries that cannot afford downtime due to equipment failure, such as in water treatment plants, HVAC systems, and fire-fighting systems.

Increased Operational Efficiency:

The durable design helps to maintain the pump's performance efficiency over time. With fewer breakdowns and the ability to handle demanding conditions, the pump remains an efficient part of the system throughout its life cycle, maintaining consistent flow rates, pressures, and energy consumption.

Safety and Reduced Risk of Failure:

With high-quality seals, gaskets, and protective components, the risk of leaks, failures, or system malfunctions is greatly reduced. This makes Ebara End Suction Pumps safer to use in critical applications like fire protection, chemical processing, and water treatment, where reliability is paramount for safety.

Environmental Protection:

The durable construction of these pumps also ensures that they are less likely to cause environmental damage. The reliable seals and corrosion-resistant components help prevent spills or leaks of hazardous fluids, ensuring that the surrounding environment remains protected from contamination.

Lower Total Cost of Ownership:

Due to their long life, reduced need for maintenance, and ability to perform consistently in tough conditions, Ebara End Suction Pumps offer a lower total cost of ownership. Their durability ensures that businesses won’t have to replace pumps frequently, helping them manage their budgets more effectively and minimizing operational interruptions.

The durable construction of Ebara End Suction Pumps ensures they can withstand the rigors of demanding industrial and commercial applications. Built with high-quality materials, corrosion-resistant components, and precision engineering, these pumps offer unmatched reliability, longevity, and efficiency. By choosing Ebara End Suction Pumps, businesses can enjoy extended service life, lower maintenance costs, and high performance in even the harshest operating conditions. For more info contact Ebara Pump Suppliers in UAE or call us at +971 4 2522966.

0 notes

Text

Versatile Performance of Ebara End Suction Pumps

Ebara End Suction Pumps are celebrated for their versatile performance, making them a reliable choice across a broad range of industries and applications. From water treatment facilities to industrial processes, these pumps offer flexible, high-performance solutions to meet varied fluid handling needs.

Key Factors Contributing to Versatile Performance:

Wide Range of Fluid Compatibility:

Ebara End Suction Pumps are engineered to handle a variety of fluids, including clean water, chemicals, oils, and even some slurries. This versatility in fluid compatibility makes these pumps suitable for multiple sectors, such as water treatment, HVAC, fire-fighting systems, industrial processing, and irrigation. Their ability to manage diverse fluids ensures their broad application across commercial, industrial, and municipal systems.

Adaptability to Different Flow Rates and Pressures:

Ebara End Suction Pumps come in various models designed to cater to different flow rates and pressure requirements. Whether the need is for a low-flow, high-pressure application or a high-flow, low-pressure system, Ebara’s pump range has a solution. This adaptability ensures that businesses can choose the right pump for their specific needs, whether it's boosting water pressure or circulating large volumes of fluid.

Ease of Integration with Existing Systems:

The design of Ebara End Suction Pumps allows them to be easily integrated into both new and existing systems. Their compact design and end-suction configuration mean they can fit into tight spaces, making them ideal for retrofit installations or upgrades to older systems. Whether it's in a building’s HVAC system or an industrial manufacturing facility, the pumps can be easily incorporated to enhance system performance.

Customization for Specific Applications:

Ebara offers customizable options for their end suction pumps to suit the unique demands of various industries. Different materials (such as stainless steel for corrosive environments), pump sizes, and configurations can be tailored to meet application-specific requirements. For instance, pumps can be adapted for chemical processing, hot water circulation, or high-pressure water supply, making them highly versatile in terms of customization.

Reliability Across Diverse Operating Conditions:

Ebara End Suction Pumps are built to operate reliably in a wide range of environmental conditions. From extreme temperatures and varying fluid viscosities to challenging operational settings like heavy industrial plants or offshore platforms, these pumps maintain their performance without compromising durability. They can also handle occasional system fluctuations, ensuring consistent performance in dynamic environments.

Multi-Industry Applications:

The versatility of Ebara End Suction Pumps is reflected in their widespread use across multiple industries:

HVAC Systems: Ensuring efficient fluid circulation and pressure regulation for heating and cooling systems in large commercial and residential buildings.

Water Treatment Plants: Handling clean or treated water, ensuring proper distribution and circulation for filtration and purification processes.

Industrial Processing: Moving chemicals, oils, and other liquids in manufacturing processes, where precision and reliability are crucial.

Fire Protection Systems: Providing the necessary water pressure to fire suppression systems, ensuring rapid and effective response in emergencies.

Agriculture and Irrigation: Ensuring consistent water flow for irrigation systems, promoting efficient crop production.

Durability in Harsh Environments:

Designed to withstand demanding conditions, Ebara End Suction Pumps are highly durable in harsh environments. Whether it’s handling corrosive chemicals, high-temperature fluids, or abrasive materials, these pumps are built to last. Their corrosion-resistant materials and robust construction make them suitable for environments where reliability and long-term operation are essential.

Variable Speed and Flow Control:

Many Ebara End Suction Pumps support variable speed drives (VSDs), allowing users to adjust the pump’s operating speed to match system demand. This feature provides precise control over fluid flow and pressure, enhancing performance across a range of applications. It also leads to energy savings and more efficient operation by ensuring the pump runs only as fast as necessary for the task at hand.

Benefits of Versatile Performance:

Cost Savings through Efficiency:

The flexibility to handle a wide variety of applications and fluid types reduces the need for multiple specialized pumps, cutting down on initial capital investment, maintenance costs, and system complexity. One Ebara End Suction Pump can be used for multiple purposes, offering significant cost savings in terms of both purchase and operational costs.

Maximized System Efficiency:

Ebara End Suction Pumps help optimize system efficiency by ensuring that the right pump is selected for the right task, whether it's high pressure, high flow, or handling specific fluids. This results in fewer system failures, lower energy consumption, and overall improved operational efficiency.

Improved System Reliability:

By offering multi-industry applications and operating under various environmental conditions, Ebara End Suction Pumps ensure that businesses experience minimal downtime and long-term, reliable performance. The versatility of the pumps ensures that systems remain functional and effective for extended periods, reducing the need for frequent repairs or replacements.

Future-Proof Performance:

With the ability to adapt to changing system requirements or new technological advancements, Ebara End Suction Pumps are an investment that can grow with your business. Their flexibility means they can accommodate future needs, such as expansions, system upgrades, or new fluid handling tasks, ensuring continued optimal performance.

Simplified Maintenance and Service:

The ability to handle various tasks with one pump reduces the complexity of maintenance. Instead of dealing with multiple pump types, technicians can focus on servicing one model, making maintenance tasks simpler and reducing operational disruption.

The versatile performance of Ebara End Suction Pumps is one of the key factors that makes them a valuable asset across a variety of industries. From their adaptability to different fluids and operating conditions to their ease of integration and durability, these pumps offer a level of flexibility that enhances system efficiency and reduces costs. Whether for industrial, commercial, or municipal applications, Ebara End Suction Pumps deliver the reliable, high-performance solution needed to optimize fluid handling across diverse systems. For more info contact Ebara Pump Suppliers in UAE or call us at +971 4 2522966.

0 notes

Text

High Efficiency of Ebara End Suction Pumps

One of the standout features of Ebara End Suction Pumps is their high efficiency, which makes them a preferred choice for a wide range of applications. These pumps are designed to optimize energy use while maintaining consistent and reliable performance, offering both cost savings and sustainability for businesses and industries.

Key Elements Contributing to High Efficiency:

Optimized Impeller Design:

The impeller is one of the most critical components in any centrifugal pump. Ebara’s end suction pumps feature advanced impeller designs that are carefully engineered to provide the maximum possible flow rate with minimal energy consumption. The hydraulic design minimizes turbulence and friction, which means the pump requires less energy to move the same volume of fluid compared to less efficient pumps.

Precision-Machined Components:

Ebara pumps are built using precision-machined parts that reduce internal friction and energy loss. The smooth surfaces inside the pump casing and around the impeller ensure that the fluid flows smoothly, reducing resistance and increasing the pump's overall efficiency.

High-Performance Motors:

Ebara End Suction Pumps are paired with high-efficiency motors that ensure the pump runs at optimal speeds with minimal energy consumption. These motors are designed to deliver reliable performance while reducing operational costs by consuming less electricity.

Variable Speed Drives (VSD) Compatibility:

Many Ebara End Suction Pumps are compatible with variable speed drives, which allow the pump’s operating speed to be adjusted based on the system’s demand. This means the pump can operate at lower speeds when the full capacity is not required, saving energy when the system is running at partial loads.

Efficient Sealing and Bearing Systems:

Ebara uses high-quality seals and bearings that minimize friction and heat generation, further reducing the energy loss in the system. This contributes to both improved pump efficiency and extended service life.

Hydraulic Performance Optimization:

Ebara carefully designs the hydraulic system of their pumps to maximize flow efficiency. This ensures that the pump operates at its best performance level while using the least amount of energy. The optimization of hydraulic efficiency helps in maintaining high system pressure without wasting energy.

Energy Recovery:

In some configurations, Ebara’s end suction pumps are designed to recover and redistribute energy in the system. This approach helps minimize overall energy usage, making the pump even more energy-efficient in applications like HVAC systems or water treatment plants, where energy recovery is crucial.

Benefits of High Efficiency:

Cost Savings:

The most immediate benefit of using high-efficiency pumps is the reduction in energy costs. By consuming less electricity to perform the same tasks, businesses can significantly lower their utility bills, making the Ebara End Suction Pump a cost-effective solution in the long run.

Reduced Carbon Footprint:

High-efficiency pumps contribute to sustainability efforts by reducing overall energy consumption. Less energy usage means fewer greenhouse gas emissions, making these pumps a good choice for businesses aiming to reduce their environmental impact.

Long-Term Reliability:

Ebara's focus on high efficiency means that the pumps experience less wear and tear over time, improving their longevity and reducing the frequency of maintenance and repairs. This leads to reduced downtime and lower maintenance costs.

Better System Performance:

A high-efficiency pump operates optimally under varying loads, ensuring that the entire system performs smoothly. Whether it’s maintaining water circulation, boosting pressure, or moving liquids in industrial processes, Ebara pumps maintain consistent performance without overtaxing the system.

Compliance with Energy Regulations:

Many regions have strict regulations regarding energy consumption and carbon emissions. By selecting high-efficiency pumps like Ebara’s end suction models, businesses can stay compliant with energy efficiency standards and avoid penalties.

The high efficiency of Ebara End Suction Pumps is a key factor that sets them apart from competitors. With innovations in pump design, impeller technology, and energy-saving motor systems, Ebara ensures that their pumps not only meet but exceed the energy performance needs of various industries. This efficiency translates into direct financial benefits, a reduced environmental footprint, and enhanced system performance—making these pumps an excellent choice for anyone looking to optimize their fluid handling systems. For more info contact Ebara Pump Suppliers in UAE or call us at +971 4 2522966.

0 notes

Text

Understanding the Range: Ebara Centrifugal vs. Jet vs. Self-Priming Surface Pumps