Edgetech Industries (ETI) has specialized in providing Rare Earth Elements, Refractory Metals, deposition materials (sputtering target & evaporation materials) and semiconductive materials, permanent magnets for years.

Don't wanna be here? Send us removal request.

Text

Maximizing Industrial Efficiency with Boron Nitride

Efficiency is a crucial factor in any industrial operation. It determines the productivity, profitability, and ultimately the success of a company. Many industries rely on advanced materials to enhance their efficiency and performance, and one such material is boron nitride. This versatile compound has been gaining popularity in various fields due to its exceptional thermal and mechanical properties.

At Edgetech Industries, we are proud to be at the forefront of manufacturing boron nitride ceramics for industrial applications. In this blog post, we will explore how this remarkable material can help maximize industrial efficiency and take your operations to new heights.

Boron Nitride in the manufacturing sector: Uses and benefit

As the manufacturing sector continues to search for ways to improve processes and materials, Boron Nitride has emerged as a key player in this quest for excellence. This versatile material is used in a variety of applications, including high-temperature lubricants, cutting tools, and heat shields. At Edgetech Industries, we specialize in producing Boron Nitride ceramics with exceptional thermal conductivity and high wear resistance. Additionally, Boron Nitride is an excellent electrical insulator, making it an ideal material for applications in the electronics industry. With so many benefits, it's no wonder that Boron Nitride is quickly becoming a go-to material for manufacturers looking to enhance their products and processes. At Edgetech Industries, we are proud to be at the forefront of this exciting trend.

The role of Boron Nitride in improving machinery lifespan

As a manufacturer of Boron Nitride Ceramics, Edgetech Industries has seen first-hand the significant impact Boron Nitride can have on improving machinery lifespan. The use of Boron Nitride coatings and powders as lubricants and thermal management solutions have helped extend the lifespan of machinery across various industries. Its unique characteristics, such as high thermal conductivity, excellent lubrication properties, and chemical inertness, allow it to withstand extreme temperatures and harsh environments. Undoubtedly, the role of Boron Nitride in machinery maintenance and optimization cannot be overlooked. At Edgetech Industries, we are proud to be part of the innovation that is shaping the future of engineering and technology.

Boron Nitride solutions for challenging industrial environments

As the industrial landscape evolves and becomes more complex, it is crucial to find innovative solutions that can withstand challenging environments. That's where Boron Nitride comes in - a material that boasts high thermal conductivity, electrical insulation, and resistance to corrosion. As a manufacturer of Boron Nitride ceramics, Edgetech Industries understands the importance of utilizing advanced technologies to create reliable solutions for industrial applications. Whether you are working in high-temperature environments, highly corrosive conditions, or need superior electrical insulation, our Boron Nitride solutions offer exceptional performance and durability. By partnering with Edgetech Industries, you can rest assured that you are receiving unmatched expertise in Boron Nitride ceramics to help tackle your most challenging industrial applications.

In conclusion, it is clear that Boron Nitride holds a crucial role in the manufacturing sector for its multitude of uses and benefits. Its ability to improve machinery lifespan and provide solutions for challenging industrial environments makes it an invaluable component in many industries. As highlighted throughout this blog post, Boron Nitride has proven to be a versatile material with a wide range of applications, from lubrication to thermal insulation. Its impressive properties such as high thermal stability, chemical inertness, and excellent electrical insulation have made it a popular choice among manufacturers. Moreover, the dedication and expertise of companies like Edgetech Industries in producing high-quality Boron Nitride ceramics have further advanced its utilization in various fields. With ongoing research and advancements in technology, we can only expect to see an increased demand for Boron Nitride and its potential to revolutionize the manufacturing sector. So let us embrace this remarkable material and witness its continuous growth and impact on industries worldwide. Thank you for reading our blog post on Boron Nitride and stay tuned for more insightful content from Edgetech Industries.

0 notes

Text

What is a Nitinol Sheet and Why It’s Revolutionizing Modern Manufacturing

In the world of advanced materials, few innovations have generated as much excitement as Nitinol sheet—a form of shape memory alloy (SMA) known for its exceptional mechanical properties and transformative potential. At Edgetech Industries, we specialize in supplying high-quality Nitinol sheets engineered for demanding industrial applications across aerospace, medical, and robotics fields. But what exactly is a Nitinol sheet, and why is it being adopted at such a rapid pace?

What is a Nitinol Sheet?

Nitinol is a metal alloy primarily composed of approximately 50–51% nickel and the remainder titanium. When processed into sheet form, this superelastic alloy can be fabricated into thin, flexible, and highly durable material capable of returning to a predefined shape after deformation. This unique behavior is the result of a reversible solid-state phase transformation between its martensitic and austenitic structures.

In other words, Nitinol sheets can "remember" their original shape. This shape memory effect is complemented by superelasticity, the ability to undergo significant deformation and return to its original form without permanent strain—making it one of the most fascinating materials in the smart metals category.

Key Properties of Nitinol Sheet

At Edgetech Industries, we supply precision-processed Nitinol sheets that retain the alloy’s extraordinary physical and thermal attributes. Some key properties include:

Shape Memory Effect: Upon heating, the sheet returns to its original form after being deformed at lower temperatures.

Superelasticity: At body or ambient temperatures, Nitinol can stretch and return to its original state instantly.

Biocompatibility: Safe for use in medical and implantable devices.

Corrosion Resistance: Resistant to most forms of chemical degradation.

High Fatigue Strength: Ideal for cyclic loading environments.

Excellent Ductility and Strength: Useful in applications that require flexibility and endurance.

These attributes make Nitinol sheet a powerful material for any industry looking to push the boundaries of performance, adaptability, and miniaturization.

0 notes

Text

Edgetech offers forged tungsten alloy, rolled tungsten alloy, die-forged tungsten alloy, without further processing, we call them semi-finished tungsten alloy. https://www.etimaterials.org/tungsten/tungsten-alloy-rod/

0 notes

Text

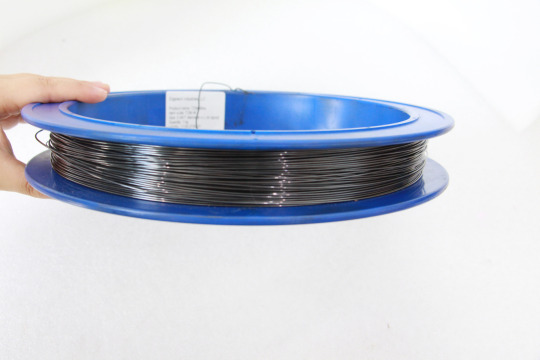

Multi-strand Nitinol wire, also referred to as Nitinol rope, is manufactured by twisting multiple Nitinol wires together into a single, flexible cable. Edgetech provides customized multi-strand Nitinol wire. https://www.etimaterials.org/nitinol/nitinol-rope/

0 notes

Text

Understanding the Unique Properties of Nitinol Wire in Industrial Applications

Wholesale Nitinol wire, a Nickel-Titanium alloy, is transforming various industries with its unique properties of shape memory and superelasticity. Shape memory allows it to return to its original form when heated, while superelasticity lets it endure significant stress without permanent deformation. These qualities make wholesale Nitinol wire ideal for advanced applications in aerospace, robotics, automotive, and especially medical fields, where it’s widely used in stents, guidewires, and surgical instruments.

Table of contents:

What Makes Nitinol Wire a Revolutionary Nickel-Titanium Alloy

Shape Memory and Superelasticity: Core Characteristics of Nitinol

The Role of Nitinol Wire in Aerospace and Robotics

This blog explores why the properties of Nitinol wire give it a competitive edge over traditional materials and how various industries are leveraging its capabilities to push the boundaries of innovation and efficiency.

What Makes Nitinol Wire a Revolutionary Nickel-Titanium Alloy

Nitinol wire is composed of approximately 55% nickel and 45% titanium, forming an alloy that is both tough and flexible. Its name comes from its discovery at the Naval Ordnance Laboratory in the 1960s. One of the core reasons why Nitinol is considered revolutionary is its capacity to return to its original shape when exposed to a specific temperature or stress condition. This phenomenon stems from its molecular structure's ability to shift between two phases, known as the austenite and martensite phases. Nitinol wire's wide-ranging applications are made possible due to this unique phase transformation capability. Edgetech Industries, a trusted manufacturer of advanced material solutions, specializes in wholesale Nitinol Wire production, supplying high-quality materials for cutting-edge applications.As a leading Nitinol Wire manufacturer, Edgetech Industries is recognized for its expertise and commitment to quality. We pride ourselves on our ability to meet specific customer requirements, offering both bulk and custom orders tailored to your unique needs. Our advanced manufacturing capabilities and attention to detail ensure that we deliver reliable, high-performance Nitinol wire for a variety of applications, from medical devices to industrial solutions.

Shape Memory and Superelasticity: Core Characteristics of Nitinol

Shape memory and superelasticity are the pivotal features of Nitinol wire that set it apart from other materials. Shape memory refers to the ability of Nitinol to return to its predetermined shape after deformation, triggered by temperature changes. This makes it indispensable for applications where precision and recovery are critical. Superelasticity, on the other hand, refers to its ability to undergo significant strain and recover instantly without permanent deformation, even under intense mechanical stress. These characteristics are highly advantageous for industries requiring high-performance materials. For example, in the biomedical sector, Nitinol wire is used to create arterial stents that expand precisely when inserted into blocked arteries. Edgetech Industries understands these precise requirements, offering wholesale Nickel-Titanium Alloy Wire for specialized applications that demand top-tier reliability and performance.

The Role of Nitinol Wire in Aerospace and Robotics

Nitinol wire has found significant applications in the aerospace and robotics industries due to its ability to withstand extreme conditions and its exceptional durability. For aerospace, Nitinol's high strength-to-weight ratio makes it ideal for high-performance aircraft mechanisms, where weight savings can significantly enhance efficiency. It is commonly utilized in actuators and sensors that need to function reliably under fluctuating temperature and atmospheric conditions. Similarly, robotics harnesses the flexibility and shape-retention characteristics of Nitinol for creating smart components. Nitinol wire is employed in robotic arms, providing the exact movement control required in advanced manufacturing processes. Being strongly positioned as a top supplier, Edgetech Industries not only offers Nitinol Wire but also supplies a range of titanium and nickel-based alloys. Renowned as Edgetech Industries' TITANIUM manufacturer division, they provide unparalleled expertise in premium-grade material customizations.

With its fascinating properties and widespread applicability, Nitinol wire has truly become a material of choice across multiple industries. Whether it’s healthcare, aerospace, robotics, or other advanced manufacturing spaces, the ability of Nitinol to deliver consistent performance under demanding conditions makes it invaluable. For organizations and professionals seeking wholesale solutions, Edgetech Industries' Nitinol Wire products serve as a benchmark for quality and innovation, bridging the gap between theoretical potential and practical application. Explore their offerings via their website to source top-tier wholesale Nitinol Wire with tailored specifications.

0 notes

Text

Marker Bands in Medical Imaging and Interventional Procedures

Marker bands serve a critical function in medical imaging and interventional procedures, offering Marker bands are essential for precise visualization during medical treatments. Designed for visibility under fluoroscopic imaging, these radiopaque bands, made from materials like platinum-iridium alloy, gold, and tantalum, play a critical role in healthcare applications. They enhance accuracy in diagnostic and therapeutic procedures, ensuring better outcomes and reduced risks for patients. As a leading Marker Band manufacturer, Edgetech Industries specializes in producing high-quality marker bands used in cardiology, vascular interventions, and neurovascular procedures. This blog delves into their significance in medical imaging and specialized treatments.

Table of contents:

Why Radiopaque Marker Bands Are Vital in Fluoroscopic Imaging

The Use of Marker Bands in Cardiology and Vascular Procedures

Marker Bands for Neurovascular Applications: Challenges and Solutions

Why Radiopaque Marker Bands Are Vital in Fluoroscopic Imaging

Radiopaque marker bands are crucial in fluoroscopic imaging because they provide enhanced visibility under X-rays, enabling medical professionals to track and position devices with precision. During procedures such as stent placement or catheter navigation, visualization is key to ensuring accuracy and avoiding complications. Marker bands, offered by manufacturers like Edgetech Industries, are typically made from dense metals that block X-rays, making them distinctly visible on imaging. Their integration allows for real-time monitoring and adjustments, playing a pivotal role in ensuring alignment and placement. Wholesale radiopaque marker bands from trusted suppliers help in maintaining the consistency and precision needed in medical settings. Edgetech Industries stands out as a radiopaque marker band manufacturer, offering high-precision products tailored to specific procedural requirements.

The Use of Marker Bands in Cardiology and Vascular Procedures

Cardiology and vascular procedures have witnessed significant advancements, thanks to the application of radiopaque marker bands. These bands are used to guide and position catheters, stents, and guidewires during interventional procedures, such as angioplasty and coronary artery stent placement. By providing clear visibility under imaging, marker bands help medical professionals to accurately deploy devices in areas such as arteries or veins, ensuring successful outcomes. Manufacturers like Edgetech Industries specialize in wholesale marker bands designed for this purpose, enabling healthcare providers to source reliable components for their devices. Additionally, the customization options offered by manufacturers, such as alloy composition and sizes, cater to the diverse requirements of cardiology and vascular interventions. The ability to work with a trusted manufacturer ensures that these marker bands perform flawlessly under high-pressure environments, reducing the margin for error.

Marker Bands for Neurovascular Applications: Challenges and Solutions

The neurovascular field presents unique challenges for medical device design due to the complexity of the brain’s vascular system and the high level of precision required. Marker bands in this context must be smaller, lighter, and even more precise to avoid adverse effects while maintaining high visibility during imaging. Edgetech Industries, a leading marker band manufacturer, addresses these challenges by leveraging advanced manufacturing techniques to create products tailored explicitly for neurovascular applications. From aneurysm treatments to stroke interventions, the use of radiopaque marker bands ensures precise device navigation and placement within the intricate blood vessels of the brain. The innovation in materials, such as platinum-iridium alloys, enhances both visibility and biocompatibility, making these bands indispensable tools in modern neurovascular treatments.

Radiopaque marker bands are vital components in medical imaging and interventional procedures, offering unmatched precision and visibility. From cardiology to challenging neurovascular applications, their importance cannot be overstated. Edgetech Industries stands at the forefront of wholesale radiopaque marker band manufacturing, specializing in high-quality, customizable options to meet diverse medical demands. By choosing Edgetech Industries as your supplier, you’re investing in reliability, precision, and cutting-edge solutions tailored to your needs. Our commitment to quality ensures that every product we deliver meets the highest standards of performance and durability. Partner with us to enhance your procedural accuracy and improve patient outcomes through our exceptional range of radiopaque marker bands, designed for precision and optimized to seamlessly integrate with advanced medical devices. With Edgetech Industries, you’re not just choosing a supplier—you’re gaining a trusted partner dedicated to supporting your success and innovation in the medical field.

0 notes

Text

Edgetech Industries LLC provides titanium mesh basket for titanium mesh anode, and it can also be coated with mixed metal oxides to make MMO titanium mesh anode. Titanium mesh basket can be made by titanium wire mesh and titanium expanded mesh.

0 notes

Text

Molybdenum screws and custom fasteners, by Edgetech Industries. We provide a variety of molybdenum, TZM molybdenum, and molybdenum lanthanum alloy machined parts according to needs.

0 notes

Text

At Edgetech Industries LLC, we produce high-performance Nitinol (NiTi) wire drawn from premium rod stock, serving a wide array of industries and uses—including orthodontic braces, dental brackets, eyeglass frames, fishing lines, springs, drive wires, and more.

0 notes

Text

Nitinol in Orthopedic Implants: Revolutionizing Modern Surgical Solutions

The Evolution of Orthopedic Implants with Nitinol Technology

Orthopedic surgery has undergone remarkable advancements, particularly in spine, foot, and ankle procedures. Traditional rigid implants are being replaced by innovative materials that enhance patient outcomes—and Nitinol, a shape-memory alloy, is leading this transformation.

At EdgeTech, we recognize the potential of Nitinol in orthopedic applications. Its unique properties—shape memory, superelasticity, and biocompatibility—make it a superior choice for implants that adapt to the body’s natural movements while promoting faster, more stable healing.

Why Nitinol is Transforming Orthopedic Surgery

1. Shape Memory for Dynamic Compression

Nitinol’s ability to return to a pre-set shape ensures continuous, adaptive compression across fracture or fusion sites. Unlike static implants, Nitinol staples and plates maintain optimal pressure even as bones shift during healing, reducing complications like non-union.

2. Superelasticity for Enhanced Durability

Where traditional metals may fail under stress, Nitinol flexes and rebounds without permanent deformation. This makes it ideal for high-movement areas like the foot, ankle, and spine, where repetitive loading demands long-lasting performance.

3. Biocompatibility & Corrosion Resistance

Nitinol is highly compatible with human tissue, minimizing inflammatory responses. Its corrosion-resistant nature ensures implants remain stable over time, reducing the risk of long-term complications.

4. Minimally Invasive Applications

Nitinol’s flexibility allows for smaller incisions and faster surgical placement, reducing operating time and improving recovery. Compression staples, for example, offer simpler insertion compared to screws, making them a preferred choice in minimally invasive procedures.

Key Applications of Nitinol in Orthopedics

1. Compression Staples (Foot & Ankle Surgery)

Maintain consistent compression even as bone settles

Faster placement than screws, reducing surgical time

Promotes stable fusion in foot and ankle procedures

2. Bone Plates & Patellar Fixation

Mimics cortical bone stiffness, reducing stress shielding

Flexes naturally with movement, improving long-term outcomes

3. Spinal Implants

Self-expanding properties minimize insertion trauma

Fatigue-resistant, making it ideal for high-load spinal applications

The Future of Nitinol in Orthopedics

Ongoing research is expanding Nitinol’s potential, including:

Smart implants that adapt to physiological changes

3D-printed Nitinol structures for patient-specific solutions

Enhanced coatings to further improve biocompatibility

At EdgeTech, we’re committed to advancing orthopedic innovation with high-performance Nitinol implants. By leveraging its unique properties, we help surgeons achieve better outcomes, faster recoveries, and longer-lasting results.

Discover how EdgeTech is shaping the future of Nitinol—contact us today.

0 notes

Text

Platinum Iridium Marker Bands: Unleashing Innovation in Interventional Procedure

When it comes to interventional procedures, the ability to accurately and precisely target tissue structures has always been a challenge. However, in today's ever-evolving medical landscape, innovation is on the rise – one of which is platinum-iridium, marker bands. Built with advanced technology and customizable features, platinum-iridium marker bands are revolutionizing how physicians operate by creating a new level of accuracy for targeted intervention. Furthermore, they provide access to a whole host of other benefits through their unique alloy composition that can help make complex procedures simpler than ever before! Ready to explore what this incredible new tool can do for your practice? Read on as we dive into the details and uncover why platinum iridium marker bands offer such unprecedented advantages in interventional medicine!

Radiopaque Marker Bands: Facilitating Accurate and Reliable Imaging in Diagnostic Procedures

Radiopaque marker bands are an essential tool in diagnostic imaging procedures, ensuring that images are both accurate and reliable. By providing a clear marker, radiopaque bands help technicians and physicians position equipment and instruments with precision, guaranteeing a successful outcome. Without this technology, diagnostic procedures would be fraught with potential errors and uncertainty, leading to misdiagnosis and ineffective treatments. With radiopaque marker bands, patients can trust that their imaging is as thorough and accurate as possible, resulting in better health outcomes and peace of mind during the diagnostic process.

Minimally Invasive Techniques: Enabling Precision and Safety with Platinum Iridium Marker Bands

Minimally invasive techniques have been a game-changer in medicine, allowing for more precision and safety in various procedures. One innovative tool that has been gaining popularity is platinum-iridium, marker bands. These tiny markers provide clear identification of the exact location where the treatment needs to be performed, allowing surgeons to access the area with greater accuracy. The best part is that these bands require only a minimally invasive procedure to apply and can stay in place for months or even years. This technology is particularly useful in the treatment of cancer, where it is vital to deliver radiation accurately and minimize the damage to surrounding healthy tissues. By enabling such precision, platinum-iridium marker bands are proving to be invaluable in the fight against cancer.

High-Temperature Resistance: The Advantages of Platinum Iridium Marker Bands in Thermal Ablation

When it comes to thermal ablation procedures, having the right tools and materials is essential for success. One material that stands out above the rest in terms of high-temperature resistance is platinum-iridium. By using platinum-iridium marker bands in thermal ablation, medical professionals can benefit from superior durability and accuracy. These marker bands are able to withstand extreme temperatures without degrading or losing their shape, ensuring that they remain in the correct location throughout the entire ablation procedure. Additionally, the use of platinum-iridium marker bands allows for precise placement within the target area, resulting in better outcomes for patients. Overall, the advantages of platinum-iridium in thermal ablation make it an invaluable tool for medical professionals seeking the best possible results.

Radiopaque marker bands can play a significant role in contemporary healthcare. Providing accuracy and reliability to diagnostic imaging, these advancements are continuing to evolve the field of healthcare component technology. The ability of platinum-iridium marker bands to withstand extreme heat temperatures is making them increasingly popular as a way to enable safe and precise thermal ablation systems. Their flexibility offers unique customization capabilities, allowing radiologists and physicians alike to make the most of their specialized medical components with the precision that only radiopaque marker bands can provide. With new innovations continuing to transform this field of care, there’s no doubt that radiopaque marker bands will continue playing an important part in today's healthcare.

0 notes

Text

Maximizing Efficiency with Silicon Nitride in High-Temperature Applications

Welcome to our latest blog post, where we delve into the world of high-temperature applications and how to maximize efficiency with silicon nitride. Whether you are an engineer or a business owner in the aerospace, automotive, or energy industries, understanding the importance of choosing the right materials for high-temperature environments is crucial. Enter silicon nitride – a versatile ceramic material that has gained popularity for its exceptional thermal and mechanical properties. In this post, we will explore why silicon nitride is becoming increasingly prominent in high-temperature applications and how it can help businesses improve their performance, reduce costs, and stay ahead of their competition. So buckle up as we take a deep dive into this powerful material that is revolutionizing industries all over the world!

Unveiling the Secrets of Silicon Nitride's Thermal Stability

Silicon nitride ceramics have long been renowned for their exceptional thermal stability. By carefully uncovering the secrets of this unique material, scientists have gained valuable insight into how silicon nitride ceramics maintain their impressive durability even under extreme conditions. From its unique crystal structure to its ability to resist oxidation and corrosion, silicon nitride ceramics have proven to be a standout material in the world of engineering. By continuing to explore the mysteries of silicon nitride ceramics, researchers are paving the way for even greater advancements in fields such as aerospace, energy, and electronics.

Pioneering Uses of Silicon Nitride in Extreme Environments

Silicon Nitride Ceramics has opened up new frontiers in materials science, creating a revolutionary class of high-performance materials with unparalleled strength, durability, and corrosion resistance. Their unique properties make them ideal for use in extreme environments, where conventional materials like steel, aluminum, and other metals fall short. Pioneering uses for Silicon Nitride Ceramics include everything from bearings and cutting tools to aerospace components, where they offer superior performance and longevity compared to traditional materials. With their potential to unlock new possibilities in a wide range of industries, Silicon Nitride Ceramics are poised to transform the world of materials science.

Comparing Silicon Nitride with Other High-Temperature Materials

Silicon Nitride ceramics are known to have exceptional properties that make them one of the most reliable and high-performing high-temperature materials in the market. Compared to other materials, this ceramic exhibits a unique blend of strength, toughness, and resistance to wear and thermal shock. Silicon Nitride ceramics stand out as a versatile and cost-effective solution for many applications in diverse industries such as power generation, aerospace, and automotive. Other high-temperature materials such as ceramics, metals, and alloys may have certain merits, but Silicon Nitride ceramics continue to dominate in terms of high-temperature performance, offering a reliable and efficient solution for challenging environments.

In conclusion, it is evident that silicon nitride ceramics have proven to be an invaluable material in multiple industries due to its exceptional thermal stability. From its pioneering uses in extreme environments such as aerospace and automotive engines, to its continued success in various high-temperature applications, it is clear that silicon nitride ceramics are here to stay. As we continue to explore the secrets of this remarkable material, the possibilities for its use seem endless. So why not join us on this exciting journey and see where silicon nitride can take us next? Whether you are an engineer looking for a solution to your extreme environmental problems or simply have a curiosity about advanced materials, the potential for silicon nitride is undeniable. Let's push the boundaries together and discover even more revolutionary uses for this versatile ceramic. Don't wait, start exploring the world of silicon nitride today!

0 notes

Text

Innovations and Trends in Radiopaque Marker Bands for the Medical Industry

The medical industry is embracing a technological revolution, transforming the way healthcare providers deliver treatment. Among these advancements, wholesale radiopaque marker bands are critical in medical imaging and device guidance during procedures like stent placement, catheter navigation, and endovascular therapy. These marker bands ensure fluoroscopic visibility, enhance precision, and contribute to successful therapeutic outcomes.

This blog explores the innovations and trends in radiopaque marker bands, including the booming demand for specific materials such as tantalum and platinum-iridium, and highlights why leveraging a trusted supplier, like Edgetech Industries LLC, is paramount for medical equipment manufacturers.

How Advanced Materials Are Transforming the Marker Band Industry

Advancements in materials science have significantly impacted the marker band manufacturing industry. Today, manufacturers focus on creating radiopaque marker bands with superior visibility under fluoroscopy while ensuring durability and biocompatibility. Materials such as tantalum and platinum-iridium alloys have quickly become the industry's gold standard due to their high density and remarkable radiopacity. These materials improve the precision of medical procedures, particularly in critical interventions like cardiovascular surgeries. Edgetech Industries LLC, an established tantalum marker bands manufacturer, exemplifies innovation in this space by employing advanced processing techniques such as CNC cutting and polishing to produce high-precision marker bands that meet stringent medical standards. Their expertise ensures reliable products that match the demands of modern healthcare technology.

Key Features of Radiopaque Marker Bands for Fluoroscopic Visibility in Medical Imaging

Radiopaque marker bands are indispensable in the medical sector due to their unique features that enable superior fluoroscopic visibility. These bands markedly improve imaging precision by defining device boundaries within a patient’s body under X-ray guidance. High-density metals like tantalum, platinum-iridium, and gold are commonly chosen for their unparalleled X-ray absorption and contrast. An increasing number of manufacturers, including Edgetech Industries LLC, incorporate customizable designs tailored for various medical devices, from guidewires to catheters. These customizations may include diverse sizes, shapes, and alloys to accommodate industry-specific requirements while ensuring structural integrity and safety during procedures. Medical professionals rely on these critical features to minimize error and improve patient outcomes.

The Growing Demand for Tantalum and Platinum Iridium Marker Bands

One of the most notable trends in the radiopaque marker band industry is the surging demand for tantalum and platinum-iridium bands. Tantalum, renowned for its corrosion resistance, biocompatibility, and high density, has solidified its position as a preferred material in medical applications. Similarly, the platinum-iridium alloy (Pt90/Ir10) continues to gain traction due to its combination of radiopacity, strength, and compatibility with medical-grade equipment. Wholesale marker bands made of these materials are increasingly sought after by medical device companies looking to streamline production while maintaining premium quality standards. Suppliers like Edgetech Industries offer bespoke manufacturing services that cater to these demands, producing marker bands tailored to match detailed specifications. Their ability to deliver reliable products with consistent precision reinforces their reputation as a trusted marker bands manufacturer.

Choose Edgetech Industries LLC for Precision Manufacturing

Edgetech Industries LLC has emerged as a leader in the production of high-quality radiopaque marker bands. Leveraging cutting-edge technology, they produce tantalum and platinum-iridium bands supported by unparalleled precision and customizability. Whether clients require small-batch orders or wholesale marker bands, Edgetech Industries LLC demonstrates a commitment to quality and client satisfaction. Furthermore, their strict quality control processes ensure every product manufactured adheres to rigorous international medical standards. For enterprises seeking a reliable partner to meet their marker band needs, Edgetech Industries is more than a manufacturer—they’re a trusted partner in advancing healthcare innovation.

The innovations and trends emerging in the radiopaque marker band industry underline its critical role in enhancing medical imaging accuracy. From the adoption of advanced materials like tantalum to the application of cutting-edge processing techniques, the industry is on a path of remarkable growth and transformation. Businesses seeking trusted partners for cutting-edge marker bands must prioritize quality and expertise—qualities exemplified by Edgetech Industries LLC.

Exploring wholesale and customized solutions with leading manufacturers ensures healthcare providers have access to the best medical products available, improving patient care outcomes worldwide. To learn more about Edgetech Industries' product range and services, explore their offerings today and experience the benchmark in marker band manufacturing.

0 notes

Text

Edgetech Industries manufactures high-performance Boron Nitride Washer and Precision Part solutions, offering customized designs in premium BN ceramics. Our washers provide exceptional thermal conductivity and electrical insulation for demanding applications. Trust Edgetech for reliable, custom-engineered ceramic components that meet your exact requirements.

0 notes

Text

Marker Bands: Advancing Medical Technologies with Platinum Iridium Marker Bands

Doctors and nurses have long relied on tried-and-true medical technologies to care for their patients, but the ever-increasing focus on patient safety has made innovation in this field a priority. One growing technology is the use of marker bands, which are platform agnostic data capture tools (e.g., barcodes or RFID) used to monitor patient conditions accurately and efficiently. Through its innovative application of this modern technology, Platinum Iridium Marker Bands not only serve as precision instruments that help physicians identify at-risk patients faster than traditional methods allow, but also vastly supplement documentation processes while streamlining treatment protocols in areas such as surgery, cardiac care wards, neonatal units and more.

Precision and Accuracy: The Role of Platinum Iridium Marker Bands in Medical Procedures"

Precision and accuracy are crucial aspects in medical procedures such as radiation therapy. To ensure that the targeted area is treated without damaging surrounding tissues, marker bands are used to accurately pinpoint the location of the treatment site. Platinum iridium marker bands are often preferred over other types due to their high density and radiopacity, making them more visible under imaging equipment. This results in a more precise treatment with reduced risk of complications. The use of these bands not only improves the efficacy of the procedure, but also provides a higher level of patient safety and satisfaction.

Enhancing Visibility: How Marker Bands Improve Imaging and Localization in Medical Devices

Medical devices have come a long way in the past few decades, and enhanced visibility and localization are critical components of their advancement. Marker bands, a simple but effective solution, are now commonly used to improve imaging and localization, resulting in more accurate and effective medical diagnoses and treatments. These small metal bands are inserted in the body, often via catheter, and provide an easy-to-see reference point for medical professionals. With their help, doctors can better track the location of medical devices in real-time, giving them greater insight into the patient's health and progress. Overall, marker bands have proven to be an indispensable tool in enhancing visibility during medical procedures, allowing medical professionals to help patients with greater confidence and accuracy than ever before.

Customized Solutions: Ensuring Safety and Quality in Medical Implantation

As medical implantation continues to advance, customized solutions have become increasingly important in ensuring the safety and quality of the procedures. This is where Edgetech supplier comes in. Edgetech Industries is a worldwide reliable provider of imaging rings and also provide multi-material capillaries which are very useful in medical applications.

Precision and accuracy in medical procedures is a critical component when it comes to patients’ wellbeing and the quality of care they receive. Using precision, gold standard materials such as Platinum Iridium Marker Bands ensure these measures are met. Non-invasive imaging and laser technology are able to employ safety protocols with exact localization of implants, leading to outcomes that benefit patient health and improve satisfaction for all parties involved. Moreover, by offering customized marker bands that can be adapted for specific applications and determined circumstances—designed for deep implantation into difficult tissue or dermal sites—the surgical experience continues without interruption or difficulty. Edgetech invites you to see how our solutions are emerging as the gold standard in the medical industry today.

0 notes

Text

Comparing Titanium Mesh to Other Materials in Industrial Applications

Industries worldwide continually seek cutting-edge materials to strengthen operations and ensure long-term efficiencies. Among these materials, titanium mesh has emerged as a standout option thanks to its unique properties. This blog will explore how titanium mesh compares to other materials frequently used in industrial applications, emphasizing factors such as corrosion resistance, performance against other non-ferrous metals, and cost-effectiveness. Whether you're looking to source wholesale titanium mesh or assess its compatibility for your industrial needs, this guide will help clarify its advantageous features.

Table of contents:

Corrosion Resistance: Benefits in Harsh Environmental Conditions

Performance Against Other Non-Ferrous Metals

Cost-Benefit Analysis: Initial Investment vs. Long-Term Gains

Corrosion Resistance: Benefits in Harsh Environmental Conditions

Titanium mesh is renowned for its exceptional corrosion resistance, making it an ideal choice for demanding industrial environments. Unlike materials susceptible to rust or degradation, such as untreated steel or certain non-ferrous metals, titanium develops a natural oxide layer that protects it from chemical reactions. This characteristic is particularly beneficial for industries like chemical processing, marine engineering, and aerospace, where exposure to harsh chemicals or saltwater is common. For example, suppliers like Edgetech Industries, a recognized refractory & non-ferrous metals manufacturer, often recommend titanium for applications requiring consistent durability in challenging environments. This resistance not only reduces maintenance costs but also significantly extends the lifespan of components, making it a more durable and cost-effective choice in the long run. Unlike aluminum or copper, which are prone to faster corrosion when exposed to harsh environmental conditions such as moisture, chemicals, or extreme temperatures, these materials maintain their integrity and performance over time, ensuring reliability and less frequent replacements.

Performance Against Other Non-Ferrous Metals

When evaluating titanium mesh against other common non-ferrous metals, such as aluminum, copper, and nickel, its superior strength-to-weight ratio becomes apparent. For example, aluminum is lightweight and widely used, but it cannot match the rigidity and durability of titanium in structurally demanding applications. Copper, on the other hand, is an excellent conductor and ideal for electrical applications but lacks the strength and corrosion resistance required for other industrial uses. Nickel alloys are often deployed in high-strength applications but are heavier and generally more expensive per unit weight than titanium. Additionally, titanium's compatibility with advanced manufacturing techniques like laser cutting and CNC machining, as offered by Edgetech Industries, makes it an incredibly versatile option for customized solutions. Across industries ranging from healthcare to automotive, titanium mesh demonstrates a balanced performance, offering both resilience and adaptability that other non-ferrous metals struggle to match.

Cost-Benefit Analysis: Initial Investment vs. Long-Term Gains

One of the most frequently asked questions about titanium mesh is whether its higher upfront cost is worth it. While titanium typically has a higher initial cost compared to aluminum or conventional steels, the long-term cost benefits make it a superior investment for many industrial applications. Titanium's durability reduces the need for frequent replacements, while its low maintenance reduces operational downtime. Furthermore, its exceptional corrosion resistance minimizes the likelihood of failures due to material degradation, resulting in fewer repair costs. Wholesale titanium mesh suppliers, such as Edgetech Industries, can often tailor solutions to meet specific industrial requirements, ensuring businesses get exactly what they need without overspending on unnecessary materials. Considering factors like reduced maintenance, extended service life, and enhanced performance in harsh conditions, titanium mesh often offers better economic value than alternatives such as copper or aluminum.

When it comes to industrial applications, the material choice can greatly influence operational efficiencies, costs, and longevity. Titanium mesh checks all the key boxes, offering superior corrosion resistance, competitive performance against other non-ferrous metals, and undeniable long-term economic benefits. If you're considering sourcing wholesale titanium mesh, Edgetech Industries, a trusted titanium mesh manufacturer, is an excellent place to start. As a leader in refractory and non-ferrous metals, Edgetech Industries provides not only high-quality titanium products but also customization options to meet specific industrial needs. Their expertise ensures that businesses receive materials optimized for their unique applications, reducing waste and maximizing productivity. Don't miss your chance to leverage the benefits of titanium in your operations.

0 notes

Text

Edgetech Industries provides premium Nitinol Tube and Nitinol Hypotube solutions, offering customized designs for medical and industrial applications. Our precision-engineered nitinol components deliver superior flexibility, kink resistance, and shape memory performance. Trust Edgetech for high-quality, tailor-made nitinol tubing that meets your exact specifications.

0 notes