Text

#silicone gasket suppliers#rubber tubing manufacturer#closed cell sponge rubber gaskets#rubber extruded#rubber seal parts manufacturer

0 notes

Text

Gaskets

Gaskets could be made from a selection of products, so the production procedure of various gaskets differs. As a basic guideline, gaskets are made by just reducing the appropriate form from the product that could be anything from paper, silicone, rubber, steel, fiber glass, plastic polymer and also really felt. Some gaskets could additionally consist of asbestos, when required.

Products typically made use of in gasket production are the following: paper, silicone, fiber glass, steel, rubber, plastic polymer and also really felt. Some gaskets also consist of asbestos needs to their details application requires it. Due to the fact that various type of gaskets could be constructed from various products, the production procedure for every kind additionally varies. Mostly, the procedures entail making an eliminated of the product in its appropriate form (the reducing treatment differs depending upon the product, certainly).

Gaskets have lots of commercial applications, consisting of compression stress of as much as 2,000 extra pounds each square inch (as well as greater). It is typically thought that the more powerful the compressive tons put on a gasket, the longer the gasket will certainly last.

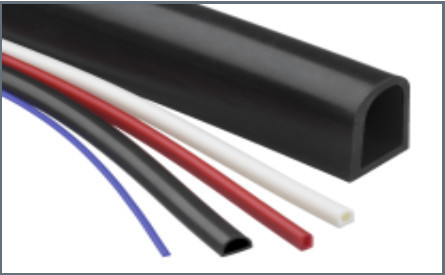

FDA Approved Silicone Gasket are largely made use of to quit liquid or gas leakages. They give some kind of an obstacle in between 2 surface areas. It is very important for the gasket to be able to preserve a seal also under stress or modifications in temperature level. A variety of gaskets are offered today. There is a precut compression that is level as well as squeezes out, and also there are likewise 'created in position' and also 'healed in position' gaskets. Some gaskets and also types of Extruded Rubber Profile could additionally be made use of to secure versus electro-magnetic and also super high frequency disturbance.

When searching for a High Temperature Silicone Rubber, your very first factor to consider needs to be its application. You could inspect the suppliers' web sites as well as item packaging for outcomes of screening, such as the warm compression examination.

Compression is the crucial making gaskets job. The more powerful the compression, the much better the gasket functions. Not having sufficient stress on the seal makes it glide around or open for impurities to go through. This is since gaskets are developed mostly to fit in between mated components of the equipment - it is pressed in between 2 items, filling up the min areas between and also producing a seal that quits fluid, gases and also dust from getting in the device parts.

Makers utilize a warm compression examination to identify if a specific gasket could endure significant stress. This sort of examination uses both to the continuous temperature level as well as temperature level on the gasket. Exactly how does it function? The compression collection of the seal is determined. This identifies the stress and anxiety or creep leisure resistance and also book of the gasket. The supplier will certainly after that understand if the gasket could endure the incredible stress related to it.

Exactly how does a gasket job?

A gasket is made largely to fit in between 2 equipment components. It is pressed in between 2 things to ensure that it loads the tiny areas, producing a seal while doing so. This seal will certainly avoid fluid, dust as well as gas kinds from getting in the area in between parts. The more powerful the compression, the much better the gasket functions. Insufficient stress on the seal will certainly make the gasket slide around and also open for various other impurities to go into. This is why a warm compression examination is made use of to figure out if a specific gasket could endure stress.

By maintaining these units devoid of dust as well as pollutants, the gasket enables the equipment to last much longer, supply a consistent efficiency as well as job quicker as well as extra effectively.

#High Temperature Silicone Rubber#Extruded Rubber Profile#FDA Approved Silicone Gasket#Fluorosilicone Rubber Seals

0 notes

Text

Stepping Into Various Silicone Rubber Gaskets

Silicone gaskets as well as pads are offered in open cell foams, shut cell sponges, different durometer solids, and also is conveniently formed in a wide array of shades. There are high tear stamina silicone, strengthened silicone, electrically conductive silicone, as well as thermally conductive silicone.

Silicone gels are necessary to the electronic devices field, where very specialized applications ask for higher needs on the securing products. Silicone rubber is utilized to shield, seal and also shield circuits, engine gaskets, control device gaskets, digital encapsulation, and also unique aspects for decoupling sound.

Inning accordance with the various layouts based upon commercial use, budget plan, chemical call and also physical criteria, there are some various sort of gaskets. Currently, some significant kinds are presented right here.

Intro To Silicone As Well As Silicone Products Silicone (officially described as polymerized siloxane or polysiloxane) describes any one of a variety of polymers consisting of alternating silicon and also oxygen atoms, whose homes are identified by the natural teams connected to the silicon atoms. Silicone is liquid, resinous, rubbery, incredibly steady in heats, as well as water-repellent, making them perfect for usage as adhesives, lubes, hydraulic oils and also insulation in a wide range of areas.

Gaskets are frequently generated by reducing from sheet products, such as paper, rubber, silicone, steel, cork, really felt, neoprene, fiberglass, or a plastic polymer. If some particular needs are required, gaskets are made consisting of asbestos. In some cases, sealer is used straight to the gasket surface area to work correctly.

A sheet gasket is typically an extremely unrefined, quick and also affordable gasket. The product for this kind is just a sheet of product which utilized to be pressed asbestos, today normally a coarse product such as graphite. The drawback of this kind in the commercial procedure is the limitations of the forgiving temperature level as well as stress.

There are silicone foams that are UL94-V0 ranked which is typically needed in the transportation and also digital fields. It does well in compression collection examinations, as well as silicone is likewise normally UV immune makings it suitable for many outside applications.

Severe temperature level resistance, security with severe ecological as well as chemical tension, and also sturdiness are a few of the factors silicone advantages air travel and also aerospace. Silicone rubber sealers are presently made use of to secure exterior and interior doors, home windows and also paneling. Liquid resistance makes silicone suitable for gas control diaphragms, hydraulic lines as well as wire clamp obstructs. Silicone rubber keypads are also utilized in computer systems in the world as well as precede.

After that one more inexpensive kind is a strong product gasket. It utilizes steels which could not be punched from sheet. Unlike the previous kind, this kind has the ability to birth a lot heat as well as stress with a much greater degree of quality assurance. However it holds it abandons. One is that it ought to obtain fantastic compress to attain the feature for avoiding leak. And also the compress needs to not terrific adequate to ruin the various other affixed items. Hence, the steel made use of have to be softer. As well as the various other one is that the resource as well as option for the steel are restricted.

Silicone is usually incorrectly described as "silicon". Although silicones include silicon atoms, they are not comprised solely of silicon, as well as have totally various physical attributes from the aspect silicon.

Silicone sealers are generally utilized to secure voids, joints, and also gaps in structures being created or remodelled. Both expert and also retail quality silicones are generously offered for this function. These one-part silicone sealers heal by soaking up climatic wetness, which assists in the specialist installment. A moistened finger or damp towel is all that is should use, and also several do-it-yourselfers commonly utilize this technique to use silicone caulking. Comparable techniques help urethane caulking, the biggest rival of silicone caulking.

A continuous seats tension Rubber Extrusion & Seals is a cutting edge innovation in gasket style, particularly in 2005. it is generally includes a strong provider ring of an appropriate product and also 2 securing components of some compressible product mounted within 2 opposing networks. It is called a change for the service provider ring could be adapted to make it possible for the gasket seating anxiety to be consistent throughout the whole securing location. The creep leisure, high system resonance, or system thermal cycles make this kind be impressive.

Whatever, the generating or style for gasket requires some renovations, if the gasket sector is anticipated to play a beneficial duty in contemporary market. Hope the production would certainly take effort to enhance the production treatment with appropriate products and also establishing modern technologies.

Among the crucial elements of silicone is its capacity to preserve it's mechanical buildings over a variety of temperature levels, -80 ° F - 400 ° F( 60 ° C -205 ° C)and also in many cases normality could be endured in an also more comprehensive variety of temperature levels.

Describing the basic mechanical parts, individuals would certainly think about shafts, flanges and also moldings and more. Really, a gasket is additionally a typical kind. It is extensively made use of to load the room in between 2 mating surface areas, typically to stop leak from or right into the signed up with things while under compression. For instance, the Reinforced Silicone Tubing is placed in both securing faces of flanges. Besides, it is additionally considered an excellent product to fill up abnormalities of mating surface areas on maker components. It is preferred in commercial applications for the factor with the capability to stand up to high compressive tons. Usually, commercial gasket applications entail screws putting in compression well right into the 14 MPa (2000 psi) variety or greater.

Silicone Rubber O-Rings need in the United States will certainly expand 4.7 percent every year via 2010, driven by efficiency and also ecological benefits over acrylic, polyurethane, and also rubber. Silicone liquids have, as well as will certainly remain to have the greatest need. Need for silicone gels will certainly expand quicker based upon restored development in the electronic devices market.

#FDA Approved Silicone Gasket#Custom Silicone Gaskets#Fluorosilicone Rubber Tubing#Rubber Bulb Seals

0 notes

Text

Benefits and also Limitations of Spliced & Vulcanized O-Rings

vulconizing oringsVulcanized o-rings are an excellent option for fixed securing applications, or ones where the o-ring does not be available in call with relocating components. They are not advised in vibrant applications, where the o-ring goes through the stress and anxiety of relocating components. Vulcanized o-rings additionally might not be an excellent option for those that require large amounts of o-rings. In this instance, maybe extra affordable to produce tooling as well as get customized shaped o-rings.

Cold Bonding and also EMI O-Rings Cold bonding is a signing up with strategy that's taken into consideration to be "cool" due to the fact that, unlike vulcanization, there's no warm entailed. With chilly splicing, a non-conductive adhesive is related to the cable finishes. The lack of compression molding implies much shorter preparation for your clients, yet the benefits do not finish there. Since a proficient employee could cold-bond as numerous as 200 to 400 EMI O-rings in an eight-hour change, cool splicing assists to restrict your per-part expenses.

To transform EMI cable supply, gasket producers could merely gauge and also reduce with a razor blade. After the sizes are reduced, completions are collaborated using chilly bonding or vulcanization. Specialized Silicone Products (SSP) products EMI cable supply to producers and also gasket producers, yet our dedication to your success does not finish there. Due to the fact that we recognize your application, we could share our expertise regarding the advantages and disadvantages of each signing up with technique.

o-ring cable To earn a vulcanized o-ring, continual size cable is reduced to size and afterwards collaborated. A bonding representative is related to completions which are after that collaborated in a mold and mildew at a heat for a given amount of time. This procedure develops the molecular bond essential to develop a solid joint.

Vulcanization and also EMI O-Rings Vulcanization is a signing up with procedure that utilizes warmth as well as stress to sign up with completions of cut sizes. Unlike cool bonding, vulcanization utilizes conductive adhesives. These heat-activated adhesives are related to the cut finishes, which are after that compressed in a warm mold and mildew or vulcanizing press Extruded Rubber Seals. Designers like the dependability that vulcanized EMI O-rings give as well as contrast them to pass away cut EMI gaskets. And also, vulcanized bonds usually satisfy or surpass the toughness of the product itself.

Just what's the most effective Method to Bond EMI O-Rings? EMI O-rings incorporate ecological securing with defense versus electro-magnetic disturbance (EMI). They're made from silicone substances that are full of steel or metal-coated fragments such as silver, silver-aluminum, or nickel-graphite. Gasket producers create EMI O-rings by reducing EMI cable supply and afterwards bonding completions of cut sizes with each other. Applications for these donut-shaped seals consist of vehicle, aerospace, commercial, clinical, as well as army electronic devices.

Vulcanized EMI O-rings have some negative aspects, nevertheless. As compared to cool bonding, the preparations are much longer as well as the tooling prices are greater. Since compression molding is needed, the per-part expense of a vulcanized EMI Spliced Rubber O-Rings is extra costly. Several component illustrations define vulcanized O-Rings, nevertheless, so designers have to stabilize every one of a job's demands in order to pick one of the most ideal signing up with technique for their application.

Cold bonding has some negative aspects, nevertheless. If an employee mates an EMI O-ring inaccurately, the non-conductive adhesive could allow the flow of specific regularities where completions are collaborated. With EMI fluorosilicones, cool bonding could be tough due to the chemical resistance of the base product. Cold entwined EMI O-rings supply trusted protecting for the majority of applications, however gasket makers have to make sure that workers understand the best ways to cold-bond EMI O-rings with rate as well as accuracy.

What Are Spliced & Vulcanized O-Rings? Mated and also vulcanized o-rings are made from extruded cable supply that has actually been reduced as well as adhered with each other, in contrast to shaped o-rings; those that have actually been compression or shot built as one item. Vulcanized o-rings are a superb option for fixed securing applications when shaped o-rings could not be made use of because of huge or non-standard measurements, when just a couple of items are required, or when you require an o-ring immediately and also could not wait the typical preparation for shaped manufacturing. Vulcanized o-rings could be made from a variety of elastomers and also in essentially any type of dimension and High Temperature Silicone Tubing.

Various Choices for Spliced & Vulcanized O-Rings splicing o-ringsThere are a number of vital qualities that specify any type of vulcanized o-ring:

Product-- kind of rubber, shade, durometer Sample (CS)-- density of the cable Cut Size (CL)-- computed based upon the wanted size of the o-ring. See listed below. Cut Angle: Butt Cut (default)-- 90 level cut where the cable is reduced directly inside out. Skive Cut (added fee)-- 45 level angle cut, likewise called a bevel cut. This cut is utilized in order to have even more of the product's area in call at the joint to earn it more powerful

0 notes

Text

Commonly Asked Questions Concerning Rubber Extrusions

A firm creating rubber extrusions in CA will certainly approve a large range of customers. They could make rubber parts for organisations connected with the vehicle sector, air travel, the armed forces, aerospace, pipes, computer systems and also electronic devices, and so on. If a client requires a rubber component, extrusion experts will possibly have the ability to make it.

1. What tools is utilized throughout the production procedure?

A well-known manufacturer in CA will certainly make use of first-rate 2", 2 1/2" as well as 3 1/2" Davis Criterion extrusion devices. For the treating, he will count on a 12', 2 area warm air stove for silicone application, along with a 14' steam-heated autoclave maker for Neoprene, Nitrile, EPDM, as well as various other sorts of rubber. To end up the item, his trim division will certainly use high quality drill presses, exceptional sanders, and also excellent rubbing devices. Furthermore, he will certainly ensure that every information of the item is each consumer specs, also if this implies that employees need to hand cut the things to excellence. Educated examiners will certainly supervise the production procedure to make certain that the ended up item will certainly constantly be specifically the means the customer requested it.

2. What sort of items can be created?

It is difficult to state all feasible Platinum Cured Silicone Gaskets, as a result of the variety of markets that are utilizing them. Rubber extrusion items could be anything from rubber gaskets, exhaust collars, pump discharge tubes as well as cupboard seals, to drain pipes tubes, stress button tubes, ports and also bumpers. A maker of Spliced Rubber O-Rings extrusions in CA could tailor each item to match his customers' requirements.

3. Just how much will my order expense?

The rate of an item will certainly rely on the complexity of the product, in addition to the quantity of the order. The even more you order, the less costly the device rate will certainly be. Talk with a business agent for specifics.

0 notes

Text

Out there For Rubber Molding?

FDA Approved Silicone O-RingsIf you remain in the marketplace for an expert in the rubber molding market, after that there are a couple of variables to think about. The initial would certainly be to identify the marketplaces that the business solutions. Whether it is health care or automobile, they ought to have the ability to offer you with a detailed listing of where their items wind up, in addition to the quantity of repeat company that they have.

Quality handiwork ought to take priority over whatever else when it concerns rubber molding. If that washing machine in your water line is malfunctioning, there is a respectable opportunity that it is mosting likely to leakage and also if it does after that you remain in for a very large repair work costs when you should change drywall and also floorboards in addition to the resource of the leakage itself.

Repeat organisation is essential due to the fact that it represents consumer complete satisfaction. Usually talking, a business that remains in business of rubber molding will not stay in business for long if the only customers that they have do not linger for long. While this might be for a wide range of factors, it is typically since the customer located far better worth or top quality somewhere else. Most of the times, it is as an outcome of top quality, where their customers have actually had an issue and also they relocated their service in other places because of this.

You must constantly have the capability to send your custom-made rubber items layout into the firm of your deciding on so as to get a quote. Be cautious business that has you acquire prior to you attempt. Modification needs to be a provided and also need to constantly be readily available. Greater accuracy items along with wonderful worth are something to maintain your eyes out for as both will certainly conserve you money and time.

Superior top quality rubber molding is likewise unbelievably crucial in a commercial setup, where the grasp on your brake pedal could indicate the distinction in between life and also fatality for customers. Not all rubber molding is developed equivalent as well as a various business indicates not just a various item however additionally a differing level of top quality.

Whether you understand it or otherwise, rubber belongs of our day-to-day lives. When you switch on the faucet, there's rubber in the tap washing machine, protecting against leak in the pipelines as well as maintaining scents out of your residence. Rubber could be discovered in ordinary view when you continue the gas pedal in your auto as an example, however, for one of the most component rubber does the substantial bulk of its job behind shut doors.

Elastostar is a leading provider of Dairy Hose & Tubing , FDA Approved Silicone O-Rings , Reinforced Silicone Hose Tubing at best price online.

#Custom Silicone Hose#Platinum Cured Silicone Tubing#Medical Grade Silicone Tubing#FDA Approved Silicone O-Rings#T-Shaped Rubber Seal#Rubber P-Seal

0 notes

Text

Now You Too Can Print With Silicone Ink on Wrist Bands, Swim Caps, Cellular phone Owners

From time to time you find a technology that is straightforward and well-timed. Printing into a silicone part seems to perplex a lot of. Today; shade filled silicone wrist bands are regularly printed via a warm procedure using silicone ink. Numerous inks will cure and also provide the look of bond yet they abrade rather rapidly. Some make use of silicone ink without the warm procedure producing comparable outcomes; the ink will certainly heal yet attachment is never developed. Absolutely nothing adheres to silicone but silicone. Today UNITED STATE made silicone ink is the finest worldwide and offered in a simple 10:1 mix ratio formula. All you require are a gram scale, some mix mugs a stick and a remedy oven (400F for 2-6 mins).

Although silicone wrist bands came to be preferred with Lance Armstrong and his support of cancer sufferers; they are immensely popular now as company free gifts and advertising free gifts. Silicone wristbands are economical, unforgettable and also trendy! There are many various other parts being constructed from silicone also which implies the usages for silicone ink are unlimited. Silicone keypads and also silicone control switches should be published on with silicone ink. Silicone swim caps are very preferred as well as have to be printed with logos and such. More products consist of cell phone owners, device takes care of, wire as well as cable, clinical as well as various other tooling. Everybody as well as their sibling wants to capitalize on the characteristics of silicone which indicates silicone components. Messages could be printed, identifying for silicone rubber sheet, wire and wire, logo's on swim caps and any product can be printed. The ink can be pad printed or silk evaluated as well as splashed or dipped. United States silicone ink will certainly being in an ink mug for 24 hours yet cure in 2 to 6 minutes when subjected to warm. The fact is it has never been simpler to utilize and also a lot more commonly required. silicone rubber strips can be found in dazzling primaries plus clear. With the clear silicone ink you can add your personal colorant to obtain the pan-tone color you could call for. Colors include silver, black, white, eco-friendly, blue, red, yellow, gold. Shades can be blended to create custom blends. New is a Glow In The Dark additive!

You'll be in a very choose group if you are a silk screen printer or if you are a pad printer that will specialize this area early on; lots of individuals are aiming to resolve to exact same trouble over as well as over once again - "Why cannot I print on my components?" If there are electronic devices to be embedded in the component do everything feasible to publish prior to the electronics are put; they often could not stand the Platinum Cured Silicone Tubing warm.

0 notes

Text

Elastostar Rubber Profiles, Consisting of Sponge Rubber

Elastostar Proxy focuses on the layout and custom-made fabrication of rubber profiles for industries such as auto, defense, mobile specialized automobiles, food and medical tools, electronic devices, environment-friendly power, and also public transportation. We have the application knowledge as well as technical proficiency to reinforce your supply chain with on-time shipments of high-value, low-to-medium quantity rubber products.

Today, Elastostar Proxy supplies over 700 extruded rubber and shaped rubber profiles made from compounds such as CR, EPDM, NBR, NR, as well as SBR materials. So whether you require standard, specialty, or sponge rubber accounts, our technical services team can suggest rubber molding and rubber extrusions with the right characteristics, including product buildings and chemical resistance.

Rubber Molding, Thermal as well as Acoustic Insulation, and Windows and door Seals

As a long-time distributor of rubber as well as plastic components to the automobile sector, Elastostar Proxy recognizes that stock-outs are not an alternative. That's why we add value to the automobile supply chain by supplying on high quality, supply, and also rate for shaped stoppers, pads, and also end-pieces. We could additionally cut rubber floor mats and supply door and window seals for automobiles, trucks, as well as buses.

Elastostar Proxy additionally provides high temperature silicone rubber parts to the defense industry and to manufacturers of mobile specialized lorries. From door seals and also window seals to thermal as well as acoustic insulation, Elasto Proxy understands the demands of the army industry. Our application experience also suggests that our securing items appropriate for the rollover defense constructs (ROPS) discovered on combines and also forestry equipment.

Rubber Extrusions, Sanitary Seals, and also Weatherstripping

With our large range of rubber products, Elasto Proxy provides hygienic seals for food devices as well as medical tools. In commercial kitchen areas, instances include rubber gaskets for refrigerators, EPDM networks for mixers, and also custom-made door seals for dining establishment ovens. Clinical tools such as X-ray makers as well as medical aid tools such as mattress overlays as well as client lifts also require medical seals.

Securing outdoor electronics rubber extrusion profiles, eco-friendly nuclear power plant, as well as public transportation systems (including rail) against the elements requires industrial rubber products that could withstand wind, water, and also temperature level extremes. So whether you require door and window seals for railcars, gasketing for outdoor signs, or rubber accounts for PV panels and also windmill nacelles, Elasto Proxy has the rubber components that you require silicone rubber strips.

0 notes

Text

Entering Numerous Gaskets

Referring to the basic mechanical components, people would certainly think about shafts, flanges as well as moldings and more. Actually, a gasket is additionally an usual kind. It is commonly made use of to complete the area between 2 mating surface areas, generally to avoid leak from or right into the joined items while under compression. For example, the gasket is placed in both sealing faces of flanges. Besides, it is also considered a great material to complete abnormalities of mating surfaces on equipment parts. It is popular in commercial applications for the reason with the capacity to stand up to high compressive lots. Normally, industrial gasket applications involve screws applying compression well right into the 14 MPa (2000 psi) range or greater.

Gaskets are typically generated by reducing from sheet products, such as paper, FDA Silicone O-Rings, silicone, metal, cork, really felt, neoprene, fiberglass, or a plastic polymer. If some particular demands are required, gaskets are made consisting of asbestos. Occasionally, sealer is employed directly to the gasket surface to function correctly.

According to the different layouts based upon industrial use, budget plan, chemical call and also physical criteria, there are some various sort of gaskets. Now, some significant types are presented below.

A sheet gasket is commonly an extremely unrefined, rapid and also low-cost gasket. The material for this kind is just a sheet of material which used to be pressed asbestos, today typically a coarse material such as graphite. The downside of this kind in the commercial process is the constraints of the forgiving temperature level as well as pressure.

Then another cheap kind is a strong material Silicone Rubber O-Rings. It utilizes metals which can not be punched from sheet. Unlike the previous kind, this type is able to bear a lot heat and stress with a much greater degree of quality assurance. But it holds it abandons. One is that it should get terrific compress to achieve the feature for preventing leak. And the compress ought to not great sufficient to ruin the various other affixed things. Thus, the steel utilized must be softer. And also the various other one is that the resource as well as option for the steel are limited.

A constant seating stress Platinum Cured Silicone Tubing is an innovative advancement in gasket style, especially in 2005. it is frequently includes a strong service provider ring of an appropriate material and 2 securing components of some compressible material set up within 2 opposing networks. It is called a transformation for the carrier ring could be adjusted to enable the gasket seating anxiety to be uniform throughout the entire securing area. The creep relaxation, high system resonance, or system thermal cycles make this kind be exceptional.

#NSF Approved rubber Gaskets#FDA Silicone O-Rings#high temperature silicone rubber#silicone rubber gaskets high temperature rubber tubing silicone door gaskets fda silicone gasket fda silicone o-rings

0 notes

Text

Why Is Silicone Rubber Valuable?

Silicone rubber is very valued product - because it has numerous physical homes that are not discovered other polymers. Its natural materials could melt or decay.

The material is unsusceptible weather, aging, heat, sunlight, wetness, chilly, and some chemical assaults. It sticks, bond, or couples things with each other.

One-of-a-kind surface area homes even more distinguish silicone rubber from various other products. Along with rubber, silicone could additionally be fluids. It is excellent for applications like paper launch representatives, fiber lubricating substances, mould launch representatives, antifouling materials, and water repellents.

As a matter of fact, silicone, as a result of its special surface area buildings, has actually been used in foam control and as anticaking helps, rust inhibitors, emulsifiers, lubes, conditioners, and gloss boosters.

silicone rubber tubing is an important part of your daily life. It makes garments really feel softer, aid hair to radiate as well as skin to feel smooth. Silicon-based materials are made use of in food and to regulate foam. Safeguarding surface areas is one more. They lube and protect vital surface areas. Silicone can be found in automobiles, buildings, and also houses. This enables the building of high-rises, aquariums as well as bath tubs.

On a daily basis, people enter into call with several products that have silicone in them - owing to its unique buildings.

There are hundreds of uses for the product - being among the most versatile available. It is found in an incredibly vast array of applications. After being mixed as well as coloured, it could be extruded right into tubes, strips, strong cable or bespoke shapes of any layout.

Cable could be signed up with making O-rings and also silicone extrusions could be joined making seals.

It is a residential material. Products that include this exceptionally functional product are currently discovered in every residence throughout the nation. Along with cooking, food storage, clothes, electronic devices, and also equipment it is discovered in many hidden devices.

Also solar heating utilizes custom rubber gaskets, where the elasticity of the materials assists panels stand up to above ground or low temperature levels. Silicone rubber is also chemically durable - which quits waterborne microorganisms, such as Legionella, from freezing.

Silicone rubber tape - combined with iron oxide - is utilized extensively is aeronautics since it is non-flammable.

Owing to that iron oxide includes the thermal conductivity, without transforming the insulation of the silicone rubber, it is used in circuitry. Silicone rubber tape can self-fuse or integrate without any included adhesive.

0 notes

Text

Just how Do You Style a Silicone Rubber Keypad?

Silicone rubber keypads are one of the most widely used kind of switching modern technology today. They supply integrity, long life as well as design flexibility. There are some basic policies and standard layout components to consider when developing a silicone rubber keypad.

Secret style will differ with the functional and visual needs of the application. It is possible to mold a type in nearly any form as well as to fit practically any type of setup. It is important to consider that the vital shape will influence the feeling of the key. While a round designed typical secret will have a constant feel across the entire surface a half-moon designed key will react various relying on where the secret is pushed.

As soon as you have decided upon an essential shape as well as layout; the next thing to consider is the method for noting the rubber as well as developing tales. There are three common approaches for noting keypads; printing, laser etching, as well as plastic essential caps.

Printing

Printing is the most usual approach of noting rubber The rubber is fixtured to flatten the vital top then screen printed. There is no limit to the variety of colors offered. The arc of the key leading figures out exactly how far publishing need to be set back from the side of the secret.

There are presently numerous choices readily available for boosting legend life with printed rubber.

Plastic Key Caps - custom molded clear plastic is adhered over the tale or formed right into the rubber. Oil or Epoxy Layer - finish is deposited on the leading surface area of the trick over printing, available in matte, semi-gloss, or gloss finish Drip Layer - drip finish could be difficult or flexible. It includes a glossy layer over the essential top. It can not be utilized on some keys with sharp angles. Hard coatings are subject to cracking if the key has large surface areas. Parylene Covering - offers the highest level of defense for a non-plastic finishing. Parylene bonds to the rubber at the molecular level. Laser Etching

Laser etching is particularly well fit for applications where the keypad is backlit. Etching generally includes three production actions.

1) Transparent rubber (any different colors) is sprayed with a transparent base coat ink which will certainly be the legend shade that shows up to the individual.

2) Rubber is splashed with a nontransparent leading coat ink which will be the overall shade of the keypad.

3) The top coat of ink is laser etched away utilizing broadband etchers to disclose the base coat.

Conversely, you can make a decision to make use of a single translucent or nontransparent Rubber P Gaskets ink as well as laser etch the legends exposing the shade of the rubber that is utilized.

Plastic Trick Caps

The lengthiest enduring legend kind is customized molded plastic. Plastic tales will certainly not wear out. Numerous cellular phone keypads are created with plastic secrets over Fire Retardant Silicone Tubing.

Practical Design Factors to consider

Snap Proportion & Tactile Feeling

The snap proportion of a keypad determines the tactile feel experienced by the customer. The advised snap ratio for designers to keep is 40%-60%; if dropped below 40% the secrets will shed responsive feel however have actually a boosted life. Loss of responsive feel implies the individual will certainly not get a 'click' responses during actuation.

0 notes

Text

Production Refine of Silicone Hose pipes

Silicone tubes are used in a host of applications varying from auto, food handling, clinical, commercial and so on. The convenience of silicone rubber makes it ideal for use in countless areas. Hoses are typically made use of in consumption systems, air coolers, and so on. They are available in a number of diameters from large to small and also can be ordered in numerous cuts and also bents.

An order of silicone pipes does not take also lengthy to make considering that the production procedure has actually been personalized by their producers. The production process calls for the ideal abilities, devices, products and also the appropriate time. Here is an in-depth take a look at the manufacturing procedure of silicone pipes:

Stage 1: Making a Mandrel Device A mandrel device is a shaping tool that is made of steel and is hollow. It is made use of to bend silicone rubber in the shape as well as size of the wanted silicone hose. It is commonly used in lots of other applications like blowing glass.

The initial stage is to make mandrel tool( s) in the form of the silicone tube( s). This is done by manipulating steel in the desired form of the pipe. These devices are usually kept by manufacturers in countless shapes and sizes. The measurements are readily available on their website or item catalogue.

Phase 2: Picking the Raw Materials The raw materials are picked especially for making silicone hose pipes. These consist of silicone rubber, different colors pigments and support textiles. Hoses are multi-layered and also reinforcement fabrics are made use of to provide them strength.

Stage 3: Milling & Calendering The silicone rubber substance and the different colors pigments are mixed with each other in a mill. This procedure is called 'milling'. It takes about half an hour in the mill to create a shade pigmented silicone rubber compound.

The tinted silicone rubber substance is put into a calendaring machine. The equipment presses the compound between rollers making it right into slim sheets. The calendaring machine then presses the flattened compound on to the support material. Currently the material prepares to hand construct the hose pipes.

Stage 4: Reducing & Rolling The slim silicone rubber sheet are reduced and stacked to roll. The home builders roll the slim sheets in tubes. It is necessary to maintain the proper thickness of televisions. A finished tube have to have the proper variety of support plies. Currently these tubes are ready to be made use of for developing hoses.

The silicone tubes are carefully advanced the mandrel devices to offer the preferred shape. Any air bubbles or joints are smoothed out. Silicone tubes that have additional joints or bends have to have added care to press the tubes right into form.

Stage 5: Stove Treating, Air conditioning & Stripping The reinforced silicone hose pipes are after that treated in the oven then cooled down. This gives them the intended form. To remove them, they are removed from the mold and mildew in one swift motion and also place in the laundry tube for cleansing. The pipes are then sent out for trimming and evaluation.

#silicone rubber sheet#extruded rubber seals#silicone rubber strips#silicone rubber cord#reinforced silicone hose

0 notes

Link

Elastostar Rubber Corporation is recognized for manufacturing of high quality custom silicone rubber extrusion, gaskets, seals, and custom silicone O-ring products.

0 notes

Link

Elastoster provides gaskets NSF/FDA at most affordable price. Rubber Gaskets include NSF 61 rubber gasket, W 270 rubber gasket, rubber gasket, FDA gaskets.

0 notes

Link

Conductive silicone rubber tubing from Elastostar rubber corporation. We provide custom and standard size of conductive rubber tubing and custom extruded conductive rubber profile.

0 notes

Link

Silicone P seal rubber extrusions are available in various profiles to suit your individual requirements. Elastoster is a leading provider of silicone rubber P-Shape, P-Seal, Gaskets extrusions.

0 notes

Link

Extruded D Shape, Custom Rubber D Seal, Rubber Gaskets by Elastostar

0 notes