Electric Motor Power stands as a prominent Australian manufacturer specialising in the production of both brushless and brushed electric dc motors.

Don't wanna be here? Send us removal request.

Text

Electric Boat Motors: Navigating the Future of Marine Propulsion

As we sail into the future, the marine industry is experiencing a paradigm shift. The key player in this transformation? Electric boat motors. These motors are not just a trend, they are the future of marine propulsion.

The Rise of Electric Boat Motors

Over the last ten years, there has been a noticeable rise in the popularity of electric boat motors due to a worldwide emphasis on sustainability and effectiveness. Electric boat motors offer a clean, quiet, and efficient alternative to traditional combustion engines. They are free from emissions, making them an ideal choice for the environmentally conscious boater.

EMPPL: Pioneering the Electric Revolution

EMPPL, established in 1989, is a pioneering Australian company at the forefront of the electric motor revolution. Specializing in DC motors, we have played a crucial role in promoting the use of electric boat motors. Our dedication to innovation and sustainability has earned us a prominent position as an industry leader.

Understanding Customer Needs

At EMPPL, we prioritize understanding the unique needs of our customers. We take great pride in building lasting relationships with our clients. Our team of experts works closely with each client to provide them with electric motor solutions that are not just innovative and sustainable, but also deliver on quality and performance.

The EMPPL Advantage

Our electric boat motors are engineered using the most advanced technology to guarantee maximum efficiency and long-lasting durability. They are easy to install, require minimal maintenance, and provide a smooth and silent ride, enhancing the overall boating experience.

Sustainability and Efficiency

One of the key advantages of electric boat motors is their contribution to sustainability. Selecting electric power reduces your carbon footprint and supports a more sustainable environment. Additionally, electric boat motors are highly efficient, resulting in considerable long-term savings on fuel expenses.

A Look into the Future

As we look ahead, the potential for electric boat motors is immense. As battery technology and power management systems continue to advance, we can anticipate increased efficiency and power in these motors. The future holds exciting possibilities for electric marine propulsion, and EMPPL is committed to being at the forefront of this revolution.

Conclusion

The future of marine propulsion is here, and it’s electric. With EMPPL’s electric boat motors, you can navigate the future with confidence, knowing you’re making a sustainable choice that delivers on performance and quality. Join us as we sail into a cleaner, greener future.

0 notes

Text

Exploring Applications and Features of DC Motors with Electric Motor Power

Ever wondered what powers everything from your child's toy car to the electric tools in your garage? The answer is often a DC motor. These nifty gadgets are the unsung heroes of many of our daily devices. Let's dive into the world of DC motors and discover how Electric Motor Power (EMPPL), a proudly Australian-owned company since 1989, is leading the charge in innovative DC motor solutions.

What are DC Motors?

DC motors, or direct current motors, are a type of electric motor that runs on direct current electricity. This means they can transform electrical energy into mechanical energy with high efficiency and reliability. But what makes DC motors so special, and why does Electric Motor Power focus on them?

The Power Behind the Machine

DC motors come packed with features that make them ideal for various applications. They are known for their excellent speed control, high torque, and quick starting and stopping capabilities. Imagine having a motor that not only starts up and stops on a dime but also adjusts its speed according to your needs. That's the kind of precision and flexibility DC motors offer.

Everyday Applications

One of the reasons DC motors are so fascinating is their versatility. From industrial machinery, electric vehicles, and renewable energy systems to household appliances and personal gadgets, DC motors are everywhere. They help in manufacturing processes, power electric cars, and even operate the fans and tools in our homes.

Innovation at Electric Motor Power

At Electric Motor Power (EMPPL), innovation isn't just a buzzword; it's at the heart of everything they do. Since 1989, this Australian gem has been developing sustainable and high-quality electric motor solutions, including DC motors. What sets EMPPL apart is its commitment to understanding each customer's unique needs and its dedication to building long-lasting relationships as your DC electric motor specialist.

Sustainability Meets Performance

In today's world, the push for sustainable solutions is more important than ever. EMPPL rises to the challenge by offering DC motors that not only deliver on performance but also on eco-friendliness. Their motors are designed to reduce energy consumption and increase efficiency, making them a smart choice for businesses and individuals alike.

Looking Ahead

The future of DC motors is bright, with ongoing advancements in technology and design. As we continue to explore their potential, companies like Electric Motor Power play a crucial role in driving innovation forward. By focusing on quality, performance, and sustainability, EMPPL is not just selling motors; they're powering progress.

DC motors are more than just components; they're the driving force behind countless applications that touch our lives every day. With companies like Electric Motor Power at the forefront of electric motor solutions, the journey of innovation and sustainability is just getting started. Whether you're an industry professional or a curious learner, the world of DC motors is full of possibilities waiting to be explored.

0 notes

Text

Unleash Potential: Exploring Electric Motors and Power Dynamics

In a world that’s constantly moving, the power behind every motion often goes unnoticed. Yet, it’s the heart of our machines, the pulse of our industries, and the silent force that drives innovation. This power comes from an unassuming source: electric motors.

The Essence of Electric Motors

Imagine a world without electric motors; it would be a world devoid of most modern conveniences. Electric motors are everywhere, from the fan that cools you on a hot day to the hard drive in your computer where this blog post was written. They convert electrical energy into mechanical energy, doing so with such efficiency and reliability that they’ve become a cornerstone of our technological society.

Diverse Types for Diverse Needs

Electric motors are not a one-size-fits-all solution. There are numerous types, each tailored for specific tasks. The small, precise motors in your watch contrast starkly with the large, powerful ones that drive subway trains. Each type, from AC and DC to stepper and servo, has its unique characteristics and applications.

Efficiency: The Name of the Game

In our energy-conscious world, efficiency isn’t just a buzzword; it’s a necessity. Electric motors excel in this area, often achieving efficiency ratings of over 90%. This means less energy waste, lower costs, and a smaller environmental footprint. It’s no wonder they’re at the forefront of sustainable technology.

Innovation: The Path Forward

The quest for better, more efficient electric motors is relentless. Engineers and scientists are constantly advancing the limits, creating smaller, more powerful, and energy-efficient motors. These advancements aren’t just academic; they have real-world implications, leading to more sustainable practices across industries.

Power Dynamics: A Delicate Balance

The power dynamics of electric motors involve a complex interplay between voltage, current, resistance, and magnetic fields. Having a grasp of these principles is crucial for those seeking to utilize the complete capabilities of electric motors. It’s a fascinating field, blending physics with practical engineering to create the machines that power our lives.

Empowering Innovation

Electric motors not only power our devices but also empower innovation. They are the silent partners in the dance of progress, enabling us to reach new heights of technological achievement.

A Sustainable Future

By embracing the potential of electric motors, we’re not just investing in technology; we’re investing in a sustainable future. These remarkable machines are key to unlocking a cleaner, more energy-efficient world for generations to come.

Conclusion

Electric motors are the unsung heroes of the modern age, and at EMPPL, we’re passionate about unlocking their potential. Whether you’re a business looking to improve your operations or a consumer seeking more sustainable options, electric motors offer a path to a more efficient, cleaner future. Join us in exploring the exciting world of electric motors and discovering how they can transform your world.

0 notes

Text

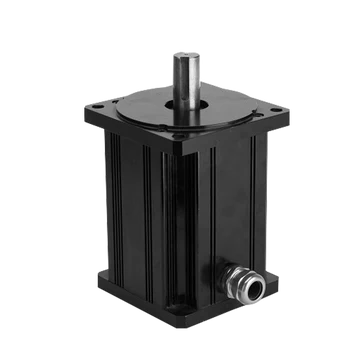

Exploring the Power and Efficiency of Brushless DC Motors: Revolutionizing Industry in Australia

Brushless DC motors, or BLDC motors, are a type of electric motor that uses electronic commutation instead of brushes and commutators. This means they have less friction, noise, maintenance, and higher efficiency than conventional brushed motors. Brushless DC motors are widely used in applications that require high speed, high torque, and precise control, such as robotics, electric vehicles, appliances, and industrial automation systems.

But what makes BLDC motors so powerful and efficient? How do they work, and what are their advantages? In this blog post, we will explore the basics of BLDC motors, their benefits, and their applications in various industries in Australia.

How do BLDC motors work?

BLDC motors consist of two main parts: the rotor and the stator. The rotor is the rotating part that has permanent magnets attached to it. The stator is the stationary part that has coils of wire wound around it.

The coils are connected to an electronic controller that switches the current to the coils based on the position of the rotor. It creates a magnetic field that rotates in space and attracts the rotor magnets, causing the rotor to spin.

The electronic controller also adjusts the motor's speed and torque by varying the current pulses' frequency and amplitude. The controller can also receive feedback from sensors that monitor the speed and position of the rotor, allowing for more precise and responsive control.

What are the benefits of BLDC motors?

Brushless DC motors have many advantages over brushed motors, such as:

Higher efficiency: BLDC motors can convert up to 90% of the electrical energy into mechanical energy, compared to 75% for brushed motors. It means they consume less power and generate less heat, reducing operating costs and extending the motor's lifespan.

Higher power-to-weight ratio: BLDC motors can deliver more power with less weight and size, thanks to their compact design and high-performance magnets. This makes them ideal for applications that require high power density and low inertia, such as drones, electric bikes, and medical devices.

Higher speed and torque: BLDC motors can operate up to 100,000 rpm and produce high torque even at low speeds. This enables them to accelerate and decelerate quickly and to handle variable loads and sudden changes in demand, such as in CNC machines, pumps, and fans.

Lower noise and vibration: BLDC motors have no brushes or commutators that can cause sparks, wear, and noise. They also have less cogging torque, which is the resistance to rotation caused by the interaction of the magnets and the coils. This results in smoother and quieter operation, which improves the comfort and safety of the users and the environment.

Lower maintenance: BLDC motors have fewer moving parts and less friction, which reduces the need for lubrication, cleaning, and replacement. They also have better thermal stability and corrosion, dust, and moisture resistance, enhancing their reliability and durability.

How are BLDC motors revolutionizing the industry in Australia?

Brushless DC motors are widely used in various industries in Australia, such as:

Agriculture: BLDC motors are used to power irrigation systems, sprayers, harvesters, and other agricultural equipment. They offer high efficiency, low noise, and long life, which help farmers save energy, water, and money and increase their productivity and profitability.

Mining: BLDC motors are used to drive conveyors, crushers, drills, and other mining equipment. They offer high torque, high speed, and high reliability, which help miners cope with the harsh and demanding conditions of the mining industry and improve their safety and performance.

Manufacturing: BLDC motors control CNC machines, robots, printers, and other manufacturing equipment. They offer high precision, high responsiveness, and high flexibility, which help manufacturers produce high-quality products, reduce waste, and optimize their processes.

Renewable energy: BLDC motors are used to generate electricity from wind, solar, and hydro sources. They offer high efficiency, high power, and low maintenance, which help renewable energy providers reduce their carbon footprint, lower operating costs, and increase their energy output.

Brushless DC motors are the future of electric motors, transforming the industry in Australia. They offer superior performance, efficiency, and reliability, and they can meet various applications' diverse and demanding needs.

If you are looking for high-quality BLDC motors, you can check out the collection of EMPPL, a leading supplier of electric motors and power transmission products in Australia. EMPPL offers a wide range of BLDC motors, from 12V to 48V and 30W to 3000W, with various speed, torque, and size options.

EMPPL also provides custom solutions and technical support to help you find the best BLDC motor for your specific needs. Visit their website or contact them today to learn more.

0 notes

Text

An Introduction to Electric Vehicle Motors: Advances and Applications

The transportation sector is currently undergoing a significant change as electric vehicles gain widespread popularity. At the heart of this transformation lies the electric vehicle motor, which is integral to these vehicles.

Understanding Electric Vehicle Motors

The electric motor in a vehicle plays a crucial role in converting the stored electrical energy from a battery into mechanical power. The selection of an appropriate electric motor for an electric vehicle (EV) system is a crucial decision. There are multiple options for electric vehicles on the market, each equipped with different motors designed for specific functions.

Types of Electric Vehicle Motors

Electric vehicles may activate AC or DC motors, depending on their configuration or intended purpose. The most frequently utilized electric vehicle motors include the DC Series Motor, Brushless DC Motor, Permanent Magnet Synchronous Motor (PMSM), Three Phase AC Induction Motors, and Switched Reluctance Motors (SRM).

Advances in Electric Vehicle Motors

Electric Motor Power, a top manufacturer of electric vehicle motors in Australia, produces high-performance and efficient Permanent Magnet Synchronous Motors (PMSMs). These AC synchronous motors use permanent magnets for field excitation and have a sinusoidal back EMF waveform. PMSMs combine the qualities of induction and brushless DC motors, making them a popular choice for their reliability, efficiency, and ability to reduce energy consumption while increasing range and environmental sustainability.

Applications of Electric Vehicle Motors

The world of electric vehicle motor is an ever-expanding universe, bursting with endless possibilities and potential. These powerful motors have found their way into many applications, from sleek electric cars to nimble scooters and even life-changing wheelchairs. With their impressive power-to-weight ratio, lightning-fast speed, and precise control over torque and rpm, it's no wonder they've become the go-to choice for such a diverse range of uses.

But the true beauty of these motors lies not only in their versatility but also in their unparalleled efficiency and low maintenance requirements. They are the perfect marriage of form and function, seamlessly integrating into our daily lives while silently propelling us toward a more sustainable future.

As we continue to push the boundaries of electric vehicle motor technology, we unlock new levels of innovation and usher in a brighter tomorrow. Whether you're a seasoned industry expert or simply fascinated by the wonders of technology, the journey of exploring these remarkable motors promises thrills and enlightenment.

0 notes

Text

Exploring Brushed DC Motors: Operations, Applications, and Innovations

The world of electric motors is vast and diverse, with the Brushed DC motor being one of its most significant members. A Brushed DC motor is an electric motor that is internally commutated and specifically designed to operate using a direct current power source.

Understanding the Operations of Brushed DC Motors

A Brushed DC motor operates by utilizing the interaction between two magnetic fields. One is created by the current passing through the armature (rotor), while the other is produced by the stator as a static field. Current is supplied to the rotor through carbon or graphite brushes, which are connected to a mechanical rotary switch called the commutator. As the rotor rotates, the brushes remain stationary while the commutator segments move beneath them. This mechanism ensures that the rotor continues to rotate in one direction.

Applications of Brushed DC Motors

Brushed DC motors are widely used in a variety of applications due to their versatility and functionality. Some notable examples include:

Electric Vehicles: The high starting torque of Brushed DC motors makes them ideal for use in electric vehicles.

Industrial Machinery: With excellent speed control and high torque, these motors are a popular choice for various industrial machinery such as lathes and drills.

Home Appliances: Smaller Brushed DC motors are commonly used in household appliances such as fans, mixers, and toys.

Computer Systems: These motors play an integral role in computer hardware, specifically in spinning the hard drive disk.

Innovations in Brushed DC Motors

Electric Motor Power (EMPPL) is a highly reputable and established manufacturer of Brushed DC motors in Australia. With a focus on excellence and innovation, they pride themselves on offering top-of-the-line, high-performance, and efficient Brushed DC motors that are unmatched in the industry.

At EMPPL, they understand that every motor has unique requirements, which is why they offer a diverse range of options to cater to the specific needs of their customers. Their product line includes 3 different sizes of Permanent Magnet Brushed DC motors, each designed to deliver exceptional performance. These motor sizes cover a wide range between 30 W to 540 W for continuous-duty applications, while also capable of handling intermittent use up to 1 kW. Additionally, their motors are available in various voltage ranges from 12V to 250V DC.

Conclusion

The field of Brushed DC motors is expansive and varied, with numerous applications and benefits that make them essential in various industries. As we continue to innovate and improve upon these technologies, we move closer to a future where Brushed DC motors continue to play a significant role in various applications. The advancements in Brushed DC motor technology are not just enhancing our present but are also paving the way for a more sustainable and efficient future. So, whether you’re an industry professional or a technology enthusiast, the journey of exploring Brushed DC motors promises to be an exciting and enlightening one.

0 notes

Text

The Rise of Electric Boat Motors in Sustainable Marine Propulsion

The marine industry is witnessing a significant shift towards sustainability, with the rise of electric boat motors playing a pivotal role. As we strive to reduce our carbon footprint and embrace greener alternatives, the adoption of electric boat motors is gaining momentum.

Electric boat motors, such as those offered by Electric Motor Power, are revolutionizing the marine industry. They offer a sustainable solution for marine propulsion, providing a host of benefits that traditional combustion engines simply can’t match.

Why Choose an Electric Boat Motor?

Electric boat motors are known for their quiet operation and lack of harmful emissions, making them an environmentally friendly option. By using an electric boat, you can navigate the waters without leaving a carbon footprint. Although the initial cost may be higher, electric boats can lead to long-term savings by eliminating the need for expensive fuel used in traditional gasoline engines.

According to market predictions, the electric boat sector is expected to experience significant growth in the coming years, estimated to increase from $3.3 billion to $19 billion between 2023 and 2032. This trend reflects a growing consumer preference for eco-friendly alternatives that not only benefit the planet but also offer financial advantages.

Advantages of Electric Boat Motors

Electric boat motors are gaining popularity in the maritime industry due to their numerous advantages over traditional boats. One of the key advantages of these motors is their positive influence on water ecosystems. Due to their lack of pollutants, they are essential in maintaining the delicate equilibrium of aquatic environments and preventing harm to marine life.

Additionally, using electric boats allows for a more enjoyable boating experience with no compromise on air quality. These boats emit zero emissions, providing a cleaner and more refreshing atmosphere without the unpleasant smell of fuel. This not only adds a touch of luxury to boating but also contributes to promoting cleaner practices on the water.

Boaters are now recognizing the importance of sustainable practices and are increasingly choosing electric boat motors. The silent operation allows for a more enjoyable experience on the water, enhancing the connection with nature.

Moreover, the maintenance of electric boat motors is significantly less demanding compared to their gasoline counterparts. The absence of oil changes and tune-ups, coupled with the longevity of electric motors, further adds to their appeal.

The rise of electric boat motors is a testament to our collective effort towards a sustainable future. As we continue to advance and enhance these technologies, we are getting closer to a future where our enjoyment of the world's waterways will have no negative impact.

Bottom Line

The increasing adoption of electric boat motors is not merely a fad, but a significant step towards promoting environmentally-friendly marine propulsion. This transition benefits both the ecosystem and boaters globally, making it a win-win situation. The future of boating is undeniably electric and will continue to be so.

0 notes

Text

Brushless DC Motors Working Principle and Applications

Brushless DC motors (BLDC) are a type of electric motor that operate on direct current (DC) power and use electronic commutation to switch the current direction in the armature windings. They have many advantages over traditional brushed DC motors, such as higher efficiency, longer lifespan, and lower maintenance requirements. They are widely used in various applications, such as electric vehicles, industrial automation, robotics, and power generation. This blog post will explain the basic structure, working principle, and applications of BLDC motors.

Structure of Brushless DC Motors

A Brushless DC motors consists of two main parts: the stator and the rotor. The stator is the stationary part of the motor that contains the armature windings. The armature windings are arranged in a sequence of coils that produce a uniform magnetic field when energized. The rotor is the rotating part of the motor that contains permanent magnets. The permanent magnets are attached to the rotor in a specific pattern that determines the number of poles of the motor. The rotor rotates around the stator due to the interaction of the magnetic fields.

The BLDC motor also requires a controller and a sensor to control the commutation of the armature current. The controller is an electronic circuit that switches the current in the armature windings according to the position of the rotor. The sensor is a device that detects the position of the rotor and sends a signal to the controller. The sensor can be either a Hall sensor or a rotary encoder. The Hall sensor is a magnetic sensor that detects the change of the magnetic field due to the rotation of the permanent magnets. The rotary encoder is an optical or mechanical sensor that detects the angular position of the rotor.

Working Principle of Brushless DC Motors

The working principle of a Brushless DC motors is based on the Lorentz force law, which states that a current-carrying conductor placed in a magnetic field experiences a force. The direction of the force is perpendicular to both the current and the magnetic field. In a BLDC motor, the current-carrying conductors are the armature windings, and the permanent magnets produce the magnetic field. The force acting on the armature windings causes them to rotate around the stator.

The commutation of the armature current is done electronically by the controller and the sensor. The controller switches the current in the armature windings in a specific sequence that ensures that the magnetic field of the stator is always perpendicular to the magnetic field of the rotor. This creates a maximum torque and a smooth rotation. The sensor provides feedback to the controller about the position of the rotor, so that the controller can switch the current at the right time.

Applications of Brushless DC Motors

BLDC motors are suitable for applications that require high efficiency, precision, and reliability. Some of the common applications of BLDC motors are:

Electric vehicles: BLDC motors are used to power electric vehicles, such as electric bikes, scooters, cars, and buses. They offer high performance, low noise, and long battery life.

Industrial automation: BLDC motors are used to drive various machines and equipment in industrial automation, such as conveyor belts, pumps, fans, and robots. They offer high speed, accuracy, and durability.

Robotics: BLDC motors are used to control the movement and operation of robots, such as humanoid robots, service robots, and drones. They offer high torque, responsiveness, and flexibility.

Power generation: BLDC motors are used to generate electricity from renewable sources, such as wind, solar, and hydro. They offer high efficiency, low maintenance, and environmental friendliness.

EMPPL is a company that specializes in providing high-quality Brushless DC motors for various applications. EMPPL offers a wide range of BLDC motors, such as brushless motors, brushless outrunner motors, brushless inrunner motors, and brushless hub motors. EMPPL also offers custom-made BLDC motors according to the customer’s specifications and requirements. EMPPL is your trusted partner for all your BLDC motor needs. You can visit their website here to learn more about their products and services.

0 notes

Text

DC Motors: The Power Behind Precision Motion

DC motors are widely used in various industries and applications that require precise and reliable motion control. From small tools and appliances to large lifts and hoists, DC motors offer many advantages over other types of motors, such as easy installation, high starting torque, and speed regulation over a wide range.

However, not all DC motors are created equal. If you are looking for high-quality DC motors that can meet your specific needs and standards, you need to choose a reputable manufacturer, supplier, and exporter from Australia.

Electric Motor Power (EMP) is one of the leading companies in the field of DC motors in Australia. Since 1974, EMP has been involved in the design and production of DC motors, earning recognition for their commitment to quality and creativity. Their product line includes DC motors ranging from 10 to 120 mm in diameter, with power capabilities spanning from 30 W to 540 W for continuous use (or over 1 kW for intermittent use). These motors are available in a voltage range of 12V to 250V DC and are manufactured in accordance with IEC standards by EMP themselves. Additionally, NEMA frame sizes are also offered.

EMP's DC motors are suitable for various applications, such as medical equipment, robotics, automation, aerospace, defense, and more. EMP's DC motors can be customized to fit your specific requirements, such as shaft size, length, voltage, speed, torque, and feedback options. EMP also provides complementary products and services, such as gearboxes, controllers, encoders, brakes, and motor installation, maintenance, and repairs.

EMP is not only a manufacturer, but also a supplier and exporter of DC motors. EMP has a global network of distributors and agents who can provide you with fast and reliable delivery of DC motors anywhere in the world. EMP also offers technical support and after-sales service to ensure your satisfaction and peace of mind.

If you are looking for DC motors that can deliver superior performance, durability, and efficiency, look no further than EMP. EMP is your trusted partner for all your DC motor needs. Contact EMP today and discover how they can help you achieve your motion goals with their DC motors.

0 notes

Text

Discover Emppl's Innovative Brushless Motor Solutions for Australian Industries

Emppl, a trailblazer in the realm of advanced engineering solutions, invites you to explore our cutting-edge collection of Brushless Motors tailored to meet the diverse needs of Australian industries. As a front runner in the field, we are committed to delivering unparalleled performance, efficiency, and reliability through our innovative brushless motor technologies.

Our extensive range of brushless motors is meticulously designed to cater to the unique requirements of various industrial applications. Whether you're in manufacturing, automation, robotics, or any other sector, Emppl's brushless motors are engineered to elevate your operations to new heights. By harnessing the power of advanced electromagnetic principles, our motors offer a host of advantages over traditional brushed counterparts.

One key advantage of brushless motors is their enhanced efficiency and longevity. The absence of brushes eliminates friction, reducing wear and tear and, consequently, increasing the overall lifespan of the motor. This not only translates to cost savings but also ensures a more sustainable and eco-friendly solution for your industrial needs.

Emppl's brushless motors are known for their precision and reliability. With state-of-the-art sensor technology and intelligent control systems, our motors deliver precise and consistent performance under varying conditions. This level of control is crucial for applications that demand accuracy and stability, ensuring optimal results in every operation.

At Emppl, we understand the importance of customization. Our brushless motor solutions can be tailored to meet the specific requirements of your application, providing a versatile and adaptable solution for your unique industrial challenges. Whether you need high torque, rapid acceleration, or precise control, Emppl has the expertise to deliver a motor that aligns seamlessly with your needs.

Explore Emppl's comprehensive collection of brushless motors, meticulously curated to empower Australian industries with the latest in engineering excellence. Elevate your operations with our innovative solutions that prioritize efficiency, reliability, and safety. Contact us today to discuss how Emppl's brushless motors can revolutionize your industrial processes.

1 note

·

View note