Don't wanna be here? Send us removal request.

Text

Importance of Industrial Valves

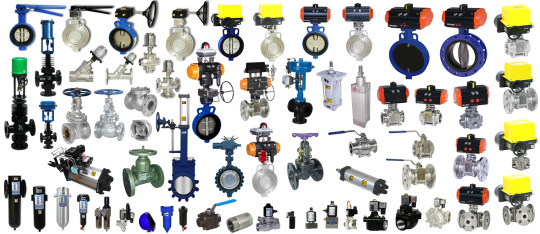

Industrial valves are an essential component of any process industry. They are, nevertheless, the most underappreciated, in part because they are hidden performers whose presence is felt most when they underperform or break down. Valves can be considered to traffic cops who halt, control, or divert traffic. You can only think the havoc that would ensue if there was no traffic cop on the scene. Valves are also necessary for isolating flow, regulating flow, and diverting flow. Depending on the application, various kinds of valves are deployed. Isolating valves such as ball valves and gate valves are employed. Flow control is accomplished by needle and globe valves. Flow is diverted using three-way, four-way, and six-way ball valves. For unidirectional flow, check valves are required. Hydraulic valves are a type of distinct family.

Quality Differences of Industrial Valves

Important industrial equipment like valves should have significantly higher quality and performance ratings. Every time, a valve manufacturer must verify that their product fulfils or meets quality and performance standards. Material analysis, product approvals, product approvals, marketing, product promotion, quality inputs, and other charges are all considered into the final product's price. An unbranded industrial valve manufacturer, on the other hand, skips many or all of the essential testing in order to make a lower-quality but less expensive product. A low-cost valve exposes the purchaser to numerous dangers.

Industrial Valve Manufacturing

Product size, pressure, end connections, port numbers, and construction material are all used to classify valve families. As a result, within a single valve family, such as ball valves, the range of products becomes limitless. As a result, most valve manufacturers can concentrate on a single type of valve in a single site. The larger global corporations have expanded by acquiring specialty valve manufacturing enterprises located throughout the world. Because it is extremely difficult to produce all valves in one site, smaller valve manufacturers collaborate to bid for all types of valves necessary in a project. This arrangement can cause delivery delays, but the buying manager finds it easier to track down a single supplier.

Valve manufacturers with a good reputation find it difficult to quote for project orders when they have to rely on other valve producers whose production quality and delivery promises are uncertain. It's even more problematic in the event of product complaints, which fall under the scope of the supplier that procured the defective goods. Repair assistance can be difficult to get by because projects are often located outside of cities and lack sufficient transportation. When it comes to resolving technical challenges, coordination between the valve supplier, the valve manufacturer, the project advisor, the on-site erection contractor, and the real end user/customer becomes the most difficult task.

Benefit Working with Valve Manufacturer

To minimize disagreement, the end user must make an effort to obtain required types of valves directly from the valve manufacturers. Valves such as Ball Valve, Butterfly valve, Gate valve, Knife Edge Gate Valve, Control Valve and many other valves offers reliable and efficient operation when they are procured with reputed manufacturer. Despite the increased time required to find a reliable manufacturer, negotiate, follow-up, and other tasks, it is ultimately a win-win situation for both sides because products are cheaper and discussion is more direct without a middleman. The product quality is superior, and there is an implied faith that the manufacturer will assist the end user in the event of a rare failure.

0 notes

Text

Importance of Industrial Valves

Industrial valves are an essential component of any process industry. They are, nevertheless, the most underappreciated, in part because they are hidden performers whose presence is felt most when they under perform or break down. Valves can be considered to traffic cops who halt, control, or divert traffic. You can only think the havoc that would ensue if there was no traffic cop on the scene. Valves are also necessary for isolating flow, regulating flow, and diverting flow. Depending on the application, various kinds of valves are deployed. Isolating valves such as ball valves and gate valves are employed. Flow control is accomplished by needle and globe valves. Flow is diverted using three-way, four-way, and six-way ball valves. For unidirectional flow, check valves are required. Hydraulic valves are a type of distinct family.

Quality Differences of Industrial Valves

Important industrial equipment like valves should have significantly higher quality and performance ratings. Every time, a valve manufacturer must verify that their product fulfils or meets quality and performance standards. Material analysis, product approvals, product approvals, marketing, product promotion, quality inputs, and other charges are all considered into the final product's price. An unbranded industrial valve manufacturer, on the other hand, skips many or all of the essential testing in order to make a lower-quality but less expensive product. A low-cost valve exposes the purchaser to numerous dangers.

Industrial Valve Manufacturing

Product size, pressure, end connections, port numbers, and construction material are all used to classify valve families. As a result, within a single valve family, such as ball valves, the range of products becomes limitless. As a result, most valve manufacturers can concentrate on a single type of valve in a single site. The larger global corporations have expanded by acquiring specialty valve manufacturing enterprises located throughout the world. Because it is extremely difficult to produce all valves in one site, smaller valve manufacturers collaborate to bid for all types of valves necessary in a project. This arrangement can cause delivery delays, but the buying manager finds it easier to track down a single supplier.

Valve manufacturers with a good reputation find it difficult to quote for project orders when they have to rely on other valve producers whose production quality and delivery promises are uncertain. It's even more problematic in the event of product complaints, which fall under the scope of the supplier that procured the defective goods. Repair assistance can be difficult to get by because projects are often located outside of cities and lack sufficient transportation. When it comes to resolving technical challenges, coordination between the valve supplier, the valve manufacturer, the project advisor, the on-site erection contractor, and the real end user/customer becomes the most difficult task.

Benefit Working with Valve Manufacturer

To minimize disagreement, the end user must make an effort to obtain required types of valves directly from the valve manufacturers. Valves such as Ball Valve, Butterfly valve, Gate valve, Knife Edge Gate Valve, Control Valve and many other valves offers reliable and efficient operation when they are procured with reputed manufacturer. Despite the increased time required to find a reliable manufacturer, negotiate, follow-up, and other tasks, it is ultimately a win-win situation for both sides because products are cheaper and discussion is more direct without a middleman. The product quality is superior, and there is an implied faith that the manufacturer will assist the end user in the event of a rare failure.

1 note

·

View note

Text

Engimek Automation is a leading Pneumatic Butterfly Valve supplier, manufacturer and exporter in the valve industry. These valves are highly preferable because of their durability and extended life. Valves of various pressure classes are available with us. We also provide Single-acting and double-acting pneumatically operated butterfly valves. These valves are classified as quarter turn valves. Our durable butterfly valves are easy to use, need minimum maintenance and provide quick operation with great safety. They are ideal to control combustible liquids such as oil, petrochemical and gas. They are also useful in high pressure and high temperature applications. We offer custom made Pneumatic Butterfly Valve as per customer requirements.

#Pneumatic Butterfly Valve#Pneumatic Butterfly Valve Supplier#industrial valve#industrial valve manufacturer

1 note

·

View note

Text

Our Pneumatic Diaphragm Control Valve is designed to work in a variety of challenging environments. that have been precisely treated are designed to perform simple movements and work continually. Our quality control professionals inspect and test these high-grade valves at various stages of production to ensure their flawlessness. Our valves are designed to endure a long time, are leak-proof, and require little maintenance. We offer our products in numerous technical specifications at the most discounted rate to customers as a leading Pneumatic Diaphragm Control Valve supplier.

#Pneumatic Diaphragm Control Valve#Pneumatic Diaphragm Control Valve Supplier#industrial valve#industrial valve manufacturer

1 note

·

View note

Text

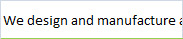

We design and manufacture a range of high-reliability instrumentation Pneumatic Ball valves for global applications, and we do it according to customer specifications and drawings.So, if you're seeking for a good Pneumatic Ball Valve Manufacturer in India, you've come to the right place. Simply submit your request to receive complete information and pricing on a pneumatic ball valve. They are used in various industrial and commercial applications. It is made up of pneumatic actuator for saving time and energy. Contact us for best quotes.

1 note

·

View note

Text

Use of Valves in Water Industry

Industrial valves are widely used in engineering, manufacturing, commercial and scientific communities. The valve's primary function is to regulate water flow and pressure while also releasing air from the system. In the water segment, valves play a significant role. Many aspects of everyday mechanical systems, such as the HVAC and water system in an office, require water valves.

Characteristics of the Most Common Valves Used in the Water Industry

There are many type of industrial valves can be used in water industry but some most helpful valves are given as below.

Gate Valves- The most important valves in the distribution system are gate valves. The on/off control of gate valves is the most common use and also known as isolating valves. Gate valves stop liquid from flowing in both directions. Manual gate valves are most utilised in the pipe line system for their effective flow regulations. They're simple to set up and keep up with. Gate valves are low-cost and widely employed in the water, petroleum and many other industries due to their ability to cut through liquids.

Butterfly Valve- Butterfly valves can control, regulate or isolate large fluid flow effectively. Because it provides a 90-degree rotating motion for stoppage, the butterfly valve is also known as a quarter turn valve. They were frequently huge in size but short in length and light in weight. They only require a small amount of torque and space in comparison with any other valves.

Ball Valve- Ball valves are priority valves for fluid control. A ball rotates between two circular seats consisting of a kind of PTFE and co-polymer in ball valves. They are available in a tiny size range of 1/2" to 12". These valves are utilised in situations that require a higher level of pressure. Ball valves require less force to operate than gate valves, have a smaller size, and are lighter than gate valves. Ball valve manufacturers offer them in various type and specifications, most preferable Manual, Pneumatic and Electric Ball Valves.

Plug Valves- By rotating the conically tapered plugs inside the valve body, plug valves may control the flow. They have a very simple design with few parts, and they are very easy to maintain and repair. They have a cheap cost per head and a drip-tight seal.

Regulating Valves- Regulating valves are designed to provide for direct control of flow rate as well as significant control of process quantities, i.e. flow/pressure reduction. Regulating valves can sustain a large head loss and come with different control scenarios. These valves consist of a regulating unit that changes the flow cross-section and are used on trunk or industrial pipelines.

Vacuum Release Valves- These sorts of valves, as the name implies, release air during the filling and testing of pipes, as well as air that naturally accumulates in pipes. It enables air into the pipe when draining and ensures the pipeline's carrying capacity.

An Engipro solution is a leading provider of industrial valves including Gate Valves, Globe Valves, Ball Valves, Check Valves, Non-return Valves, Pressure Reducing Valves, and Shutoff Valves. If you need any type of valve or want to learn more about our company, we are always willing to help you with our heart and soul.

1 note

·

View note

Text

Engimek Controls is one of the leading Manual Gate Valve supplier, manufacturer and exporter in India. We have capabilities to offer customized gate valve solutions to suit your varying application requirement. Our manual gate valves are mostly utilised in pipeline systems for on-off and flow regulation, but they can also be used as isolating valves. The valve is operated by rotating it clockwise to open or clockwise to close it, while the operative gate slides up or down depending on the use.

1 note

·

View note

Text

Use of Valves in Water Industry

Industrial valves are widely used in engineering, manufacturing, commercial and scientific communities. The valve's primary function is to regulate water flow and pressure while also releasing air from the system. In the water segment, valves play a significant role. Many aspects of everyday mechanical systems, such as the HVAC and water system in an office, require water valves.

Characteristics of the Most Common Valves Used in the Water Industry

There are many type of industrial valves can be used in water industry but some most helpful valves are given as below.

Gate Valves- The most important valves in the distribution system are gate valves. The on/off control of gate valves is the most common use and also known as isolating valves. Gate valves stop liquid from flowing in both directions. Manual gate valvesare most utilised in the pipe line system for their effective flow regulations. They're simple to set up and keep up with. Gate valves are low-cost and widely employed in the water, petroleum and many other industries due to their ability to cut through liquids.

Butterfly Valve- Butterfly valves can control, regulate or isolate large fluid flow effectively. Because it provides a 90-degree rotating motion for stoppage, the butterfly valve is also known as a quarter turn valve. They were frequently huge in size but short in length and light in weight. They only require a small amount of torque and space in comparison with any other valves.

Ball Valve- Ball valves are priority valves for fluid control. A ball rotates between two circular seats consisting of a kind of PTFE and co-polymer in ball valves. They are available in a tiny size range of 1/2" to 12". These valves are utilised in situations that require a higher level of pressure. Ball valves require less force to operate than gate valves, have a smaller size, and are lighter than gate valves. Ball valve manufacturers offer them in various type and specifications, most preferable Manual, Pneumatic and Electric Ball Valves.

Plug Valves- By rotating the conically tapered plugs inside the valve body, plug valves may control the flow. They have a very simple design with few parts, and they are very easy to maintain and repair. They have a cheap cost per head and a drip-tight seal.

Regulating Valves- Regulating valves are designed to provide for direct control of flow rate as well as significant control of process quantities, i.e. flow/pressure reduction. Regulating valves can sustain a large head loss and come with different control scenarios. These valves consist of a regulating unit that changes the flow cross-section and are used on trunk or industrial pipelines.

Vacuum Release Valves- These sorts of valves, as the name implies, release air during the filling and testing of pipes, as well as air that naturally accumulates in pipes. It enables air into the pipe when draining and ensures the pipeline's carrying capacity.

An Engipro solution is a leading provider of industrial valves including Gate Valves, Globe Valves, Ball Valves, Check Valves, Non-return Valves, Pressure Reducing Valves, and Shutoff Valves. If you need any type of valve or want to learn more about our company, we are always willing to help you with our heart and soul.

0 notes

Text

We are leading Industrial Valve Supplier, Manufacturer & Exporter, offering quality valves for various industrial as well as commercial applications at best price. Further our valves are highly appreciated among customers for their quality and durability.

0 notes

Text

Counted as leading Knife Edge Gate Valve Supplier, These valves has ability to cut solid media flow such as heavy oils, grease, waste water, pulp hence allow to flow thick media more freely. They are used in sludge and slurry applications in many industries. Knife Edge Gate Valve offers smooth and consistent operation and need minimum maintenance. Contact us for best quality valves.

#Knife Edge Gate Valve#Knife Edge Gate Valve Supplier#industrial valve#Industrial valve manufacturing

1 note

·

View note

Text

Best Quality Globe Valve at market leading price

Known as Globe Valve manufacturer and supplier, we offer best quality Globe Valves to control various type of fluid flow. It can regulate fluid flow very effectively and also used to handle high pressure steam. It is used in water treatment plant, chemical industries, oil industries, food industries, air industry and many other industrial and commercial applications.

0 notes

Text

Premium Quality Triple Offset Butterfly Valve at Best Price

We are offering premium quality Triple Offset Butterfly Valve, our offered valves are widely used in various industrial and commercial application where tight shut off is required. They need low maintenance and offer best performance with zero leakage. Contact Us for best quotes.

#triple offset butterfly valve supplier#triple offset butterfly valve manufacturers#industrial valve

1 note

·

View note

Text

Best Quality Gate Valve Manufacturer

We are one of the leading Gate Valve manufacturer, supplier and exporter. Our unique quality gate valve can effectively regulate the movement of unwanted liquid, oils, slurry, gases and other impurities. That is why they are widely used in various industrial, commercial and even domestic applications. Clients can also request for customized set of gate valve to meet special requirements or increase efficiency.

1 note

·

View note

Text

Supreme quality Ball valve with affordable prices

Known as a reputed Ball Valve supplier and manufacturer, our ball valves are used to control the pressure of fluids, gases, slurry and other media. They can handle high pressure and used in variety of applications. Get quality ball valves at best prices.

1 note

·

View note

Text

Premium Quality Butterfly Valve at Best Price

Known as leading Butterfly valve supplier and manufacturer, we offer butterfly valve to suit different pressure usage and applications. Our valves are simple and provide quick response. They are used to regulate large flow of gas, liquid, chemicals and slurry. They are also used to regulate high pressure and temperature services. Contact us to get best offers.

0 notes

Text

Industrial Valve Supplier, Manufacturer & Exporter in India

We are leading Industrial Valve Supplier, Manufacturer and Exporter in India. We are offering custom valve solutions as per customer requirements at best prices. Contact Us Now.

0 notes

Photo

Best Quality Gate Valve Manufacture

1 note

·

View note